Patents

Literature

88 results about "Ferric oxide hydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron(II) oxide or ferrous oxide is the inorganic compound with the formula FeO. Its mineral form is known as wüstite . One of several iron oxides , it is a black-colored powder that is sometimes confused with rust , which consists of hydrated iron(III) oxide (ferric oxide).

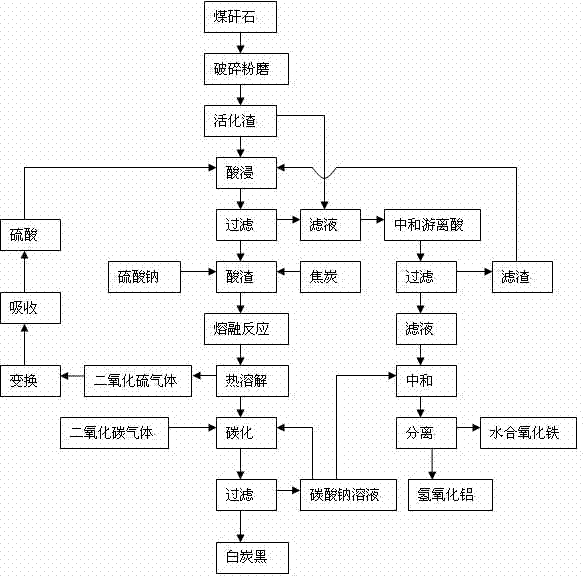

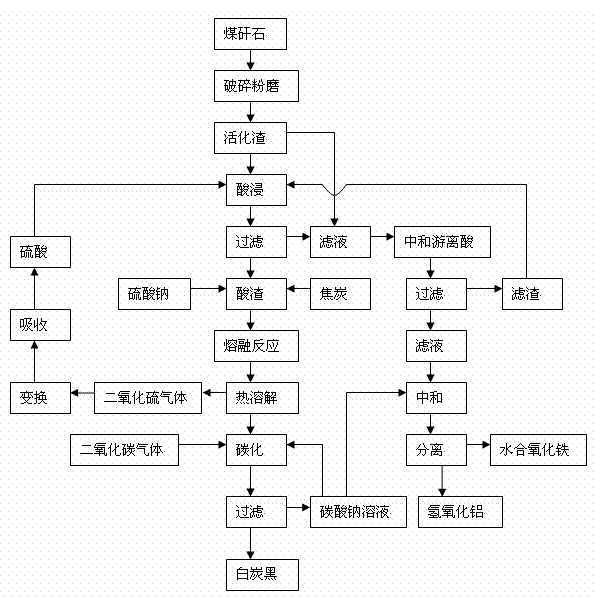

Comprehensive extraction method of ferro-silico-aluminum in gangue

ActiveCN102515279AGood slag activityMeet operating conditionsSilicaIron oxides/hydroxidesAluminium hydroxideSlag

The invention discloses a comprehensive extraction method of ferro-silico-aluminum in gangue, comprising the following steps of: using gangue as a raw material, crushing, grinding, activating, carrying out acid leaching, filtering, neutralizing free acid in the acid leaching filtered solution by the use of active slag, filtering to obtain a neutralized acid leaching solution, adding a sodium carbonate solution into the neutralized acid leaching solution, adjusting pH value, separating iron and aluminium to obtain hydrous iron oxide, aluminium hydroxide and a by-product sodium sulphate, adding sodium sulphate and coke into the acid leaching slag which has undergone acid leaching and filtration, carrying out a high-temperature melt reaction to recover silicon so as to prepare soluble glass, simultaneously recovering sulfur dioxide to prepare sulfuric acid, reusing sulfuric acid for the acid leaching treatment, diluting the soluble glass by the use of a sodium carbonate solution, carrying out carborization to obtain white carbon black, and reusing the carbonating solution for iron-aluminium separation. The method provided by the invention has characteristics of wide application range of the raw material gangue, high comprehensive recovery rate, no output of by-products, less residue amount and the like, provides a novel technological process for high-efficiency recovery of ferro-silico-aluminum from gangue, and expands the ways of gangue application.

Owner:KUNMING UNIV OF SCI & TECH +1

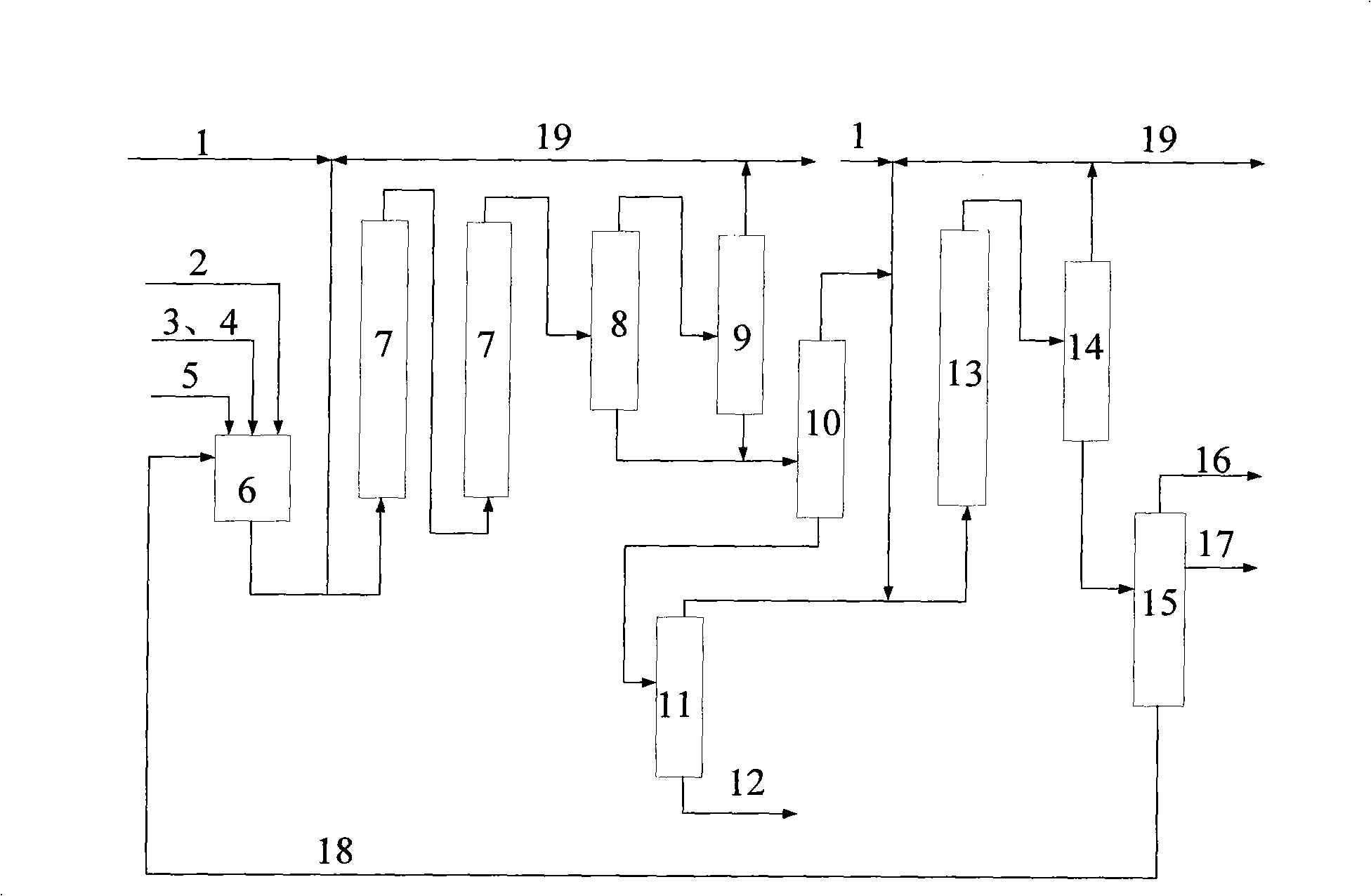

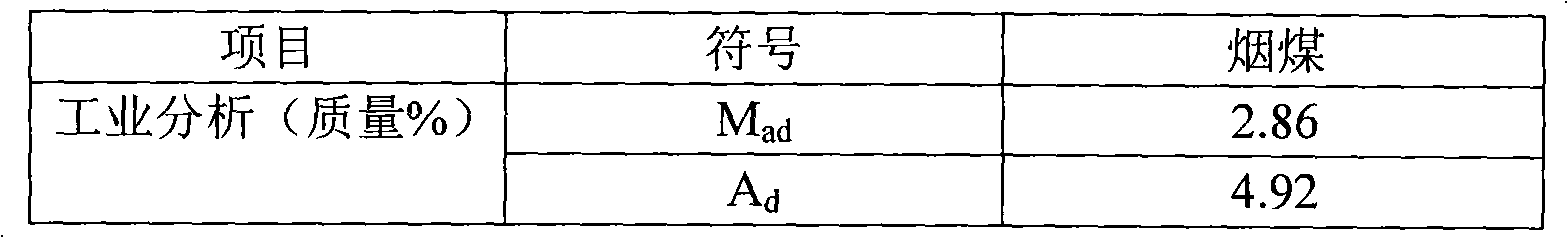

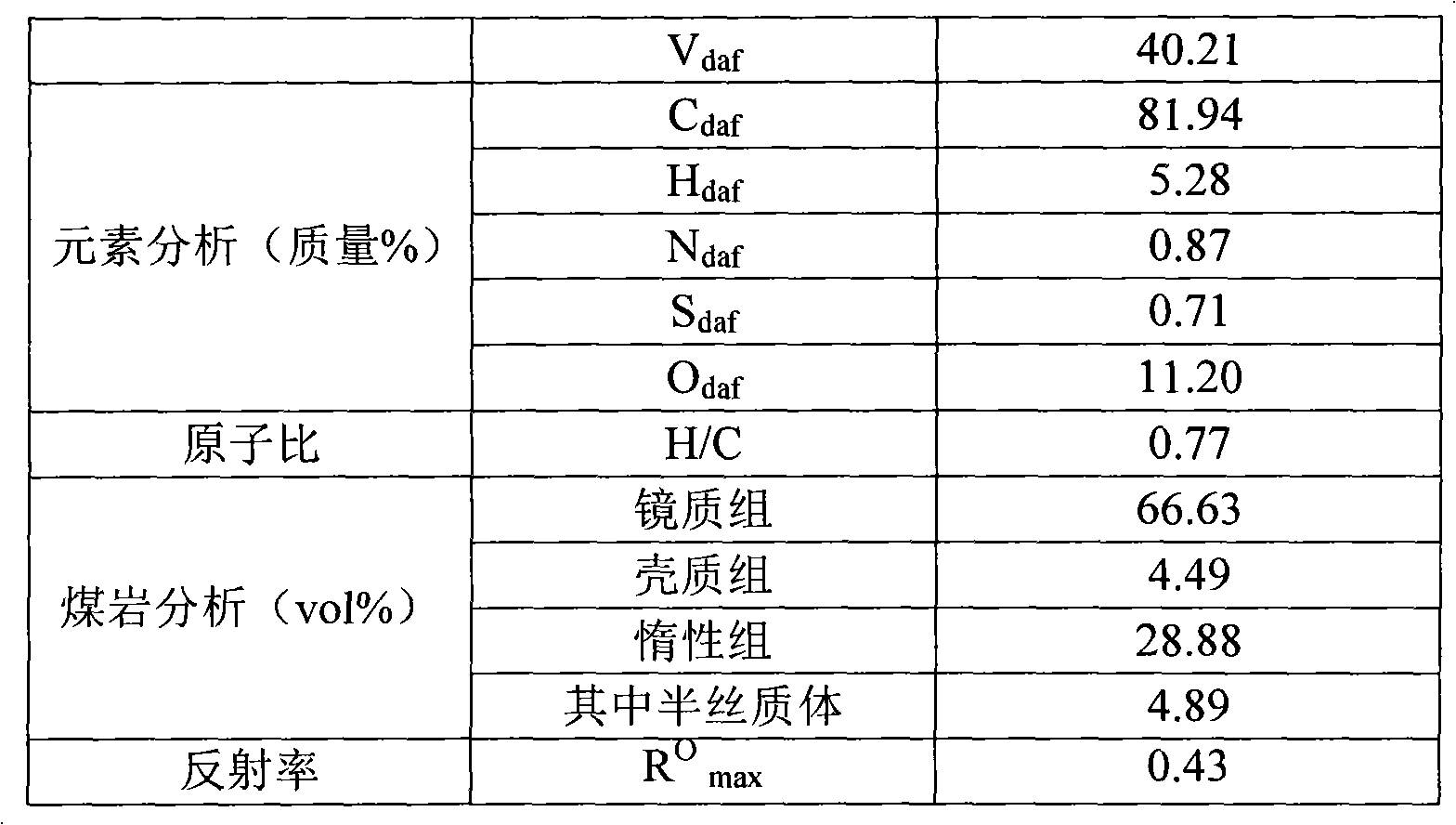

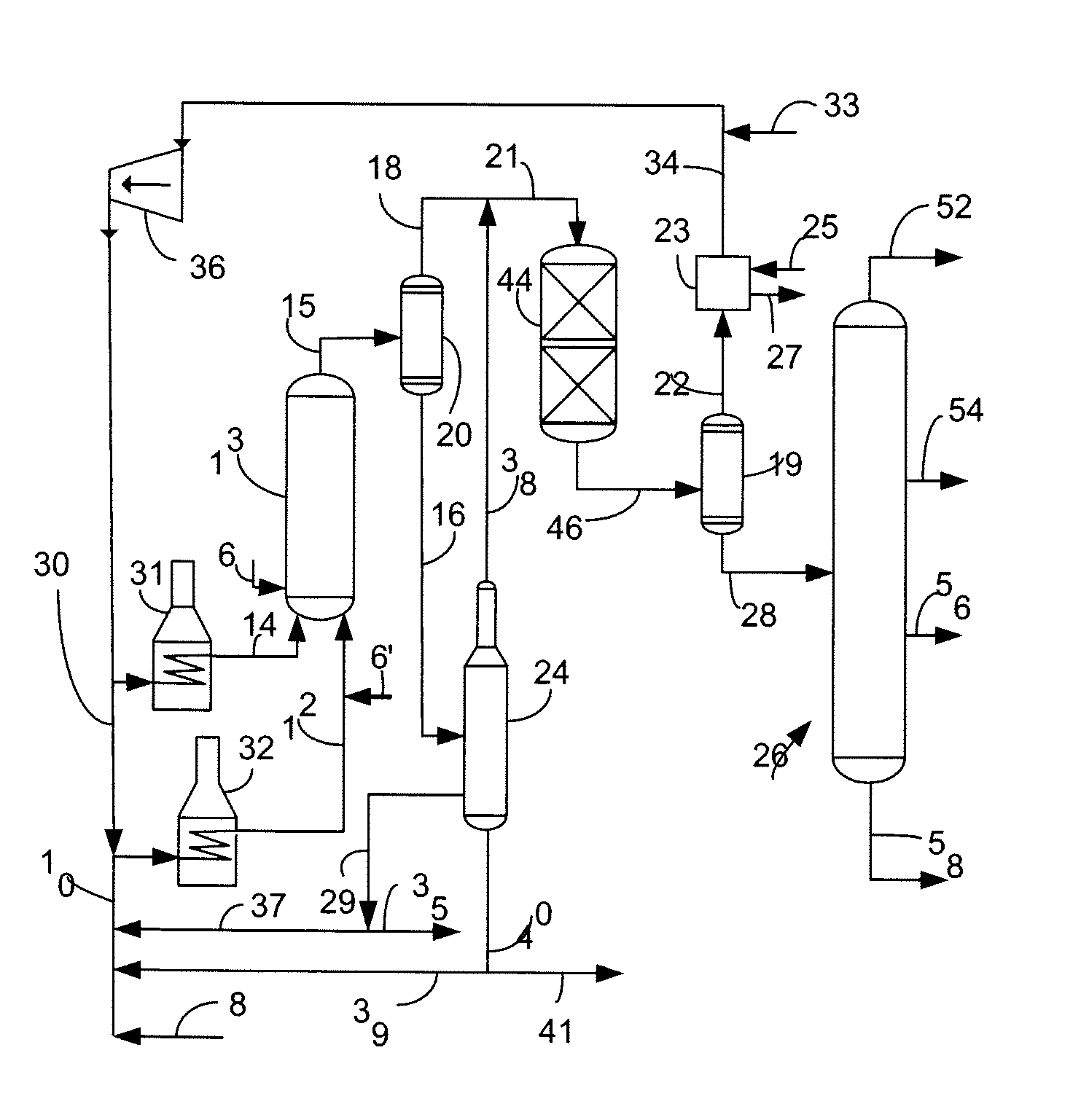

Direct liquefaction process of coal by replacing circling solvent with petroleum or petroleum refining byproduct

ActiveCN101333448AWide range of sources and cheapLow use valueLiquid hydrocarbon mixture productionCoal conversionSolvent

The invention relates to a coal direct liquefaction method using petroleum or petroleum refining byproducts to replace a cycling solvent, which comprises processes of: replacing or partially replacing the traditional coal liquefied cycling solvent by low quality petroleum with high metal and asphaltene content and heavy oil, as well as petroleum refining byproducts such as catalytic cracking heavy recycle stock, clarified oil and outside throwing slurry oil, preparing coal slurry by co-catalyst sulfur and high-activity Gamma-hydrated iron oxide type liquefaction catalyst, then implementing the coal direct liquefaction and hydrogenation, finally obtaining light and medium distillate oil, the coal conversion is increased by 1 percent to 5 percent, the yield of generated oil products is increased by 5 percent to 40 percent, the sedimentation and coking in a reactor are reduced, also the utilization value of low value-added petroleum and petroleum refining byproducts is greatly increased, and economic benefits of coal direct liquefaction are increased. The method can be widely used for coal direct liquefaction.

Owner:CCTEG CHINA COAL RES INST

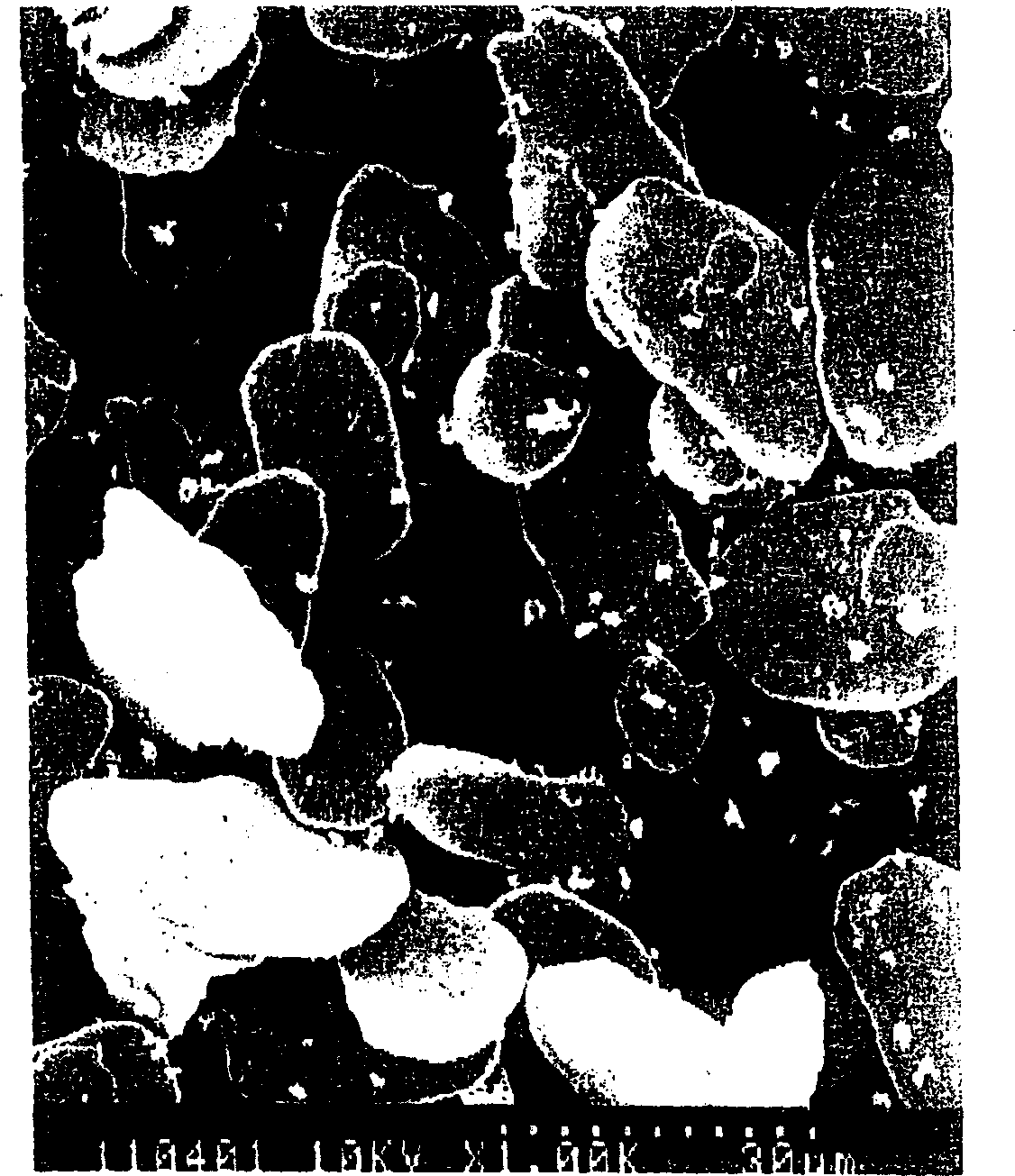

Colored interference pigments having metallic luster, preparing method and use of same

InactiveCN1673284AHigh glossSimple processInorganic pigment treatmentInksFerric oxide hydrateMetal substrate

Colored interference pigments having metallic luster comprising, on the surface of a thin platelet-like metal substrate a layer of an anti-corrosive treatment in a non-aqueous system, and, thereon (1) an intermediate binder layer comprising hydrated tin oxide (first layer); and, thereon, (2) a hydrated iron oxide layer (second layer), exhibiting a reddish color and improved adhesion and denseness of the hydrated iron oxide layer, a process for producing same and their use.

Owner:MERCK PATENT GMBH

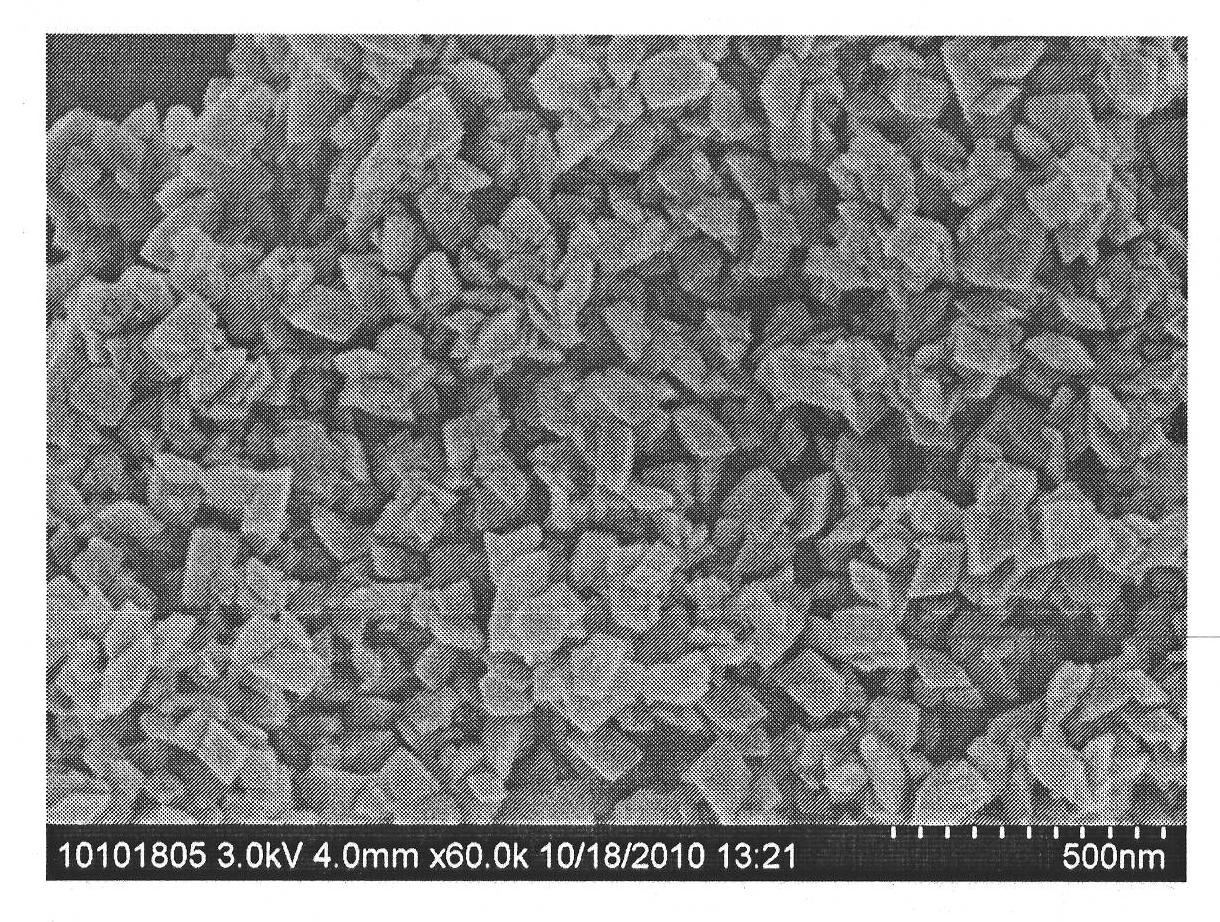

Method for deep purifying heavy metal micro-polluted water by resin-base nano hydrated ferric oxide

ActiveCN101186357AReduce concentrationSolving High Fluid Resistance ProblemsWater/sewage treatment by ion-exchangeAbsorption columnPhysical chemistry

The invention discloses a method of deeply purifying heavy metal micro-polluted water body through resin-based nano hydrated ferric oxide, which pertains to the technical field of water environmental treatment. The steps are: nano hydrated ferric oxide granules are supported on cation exchange resin so as to generate the resin-based nano hydrated ferric oxide materials; the water micro-polluted by the heavy metal passes through an absorption column which is filled with the resin-based nano hydrated ferric oxide or the heavy metal micro-polluted water and the resin-based nano hydrated ferric oxide are mixed in a container and then are vibrated before being centrifugally dried; the absorbed resin-based nano hydrated ferric oxide can be desorbed by acid fluid such as HC1or HNO3 solution etc. or can be desorbed and regenerated by EDTA solution. When a great number of cations such as Na<+>, k<+>, Ca<2+>, Mg<2+>, etc. exist in the polluted water, the invention still can reduce and lead the effluent heavy metal concentration to meet safety control standard; when a great number of competitive cations coexist in the heavy metal micro-polluted water, the effluent heavy metal concentration can be reduced to meet the safety control standard with very large treatment capacity.

Owner:NANJING UNIV

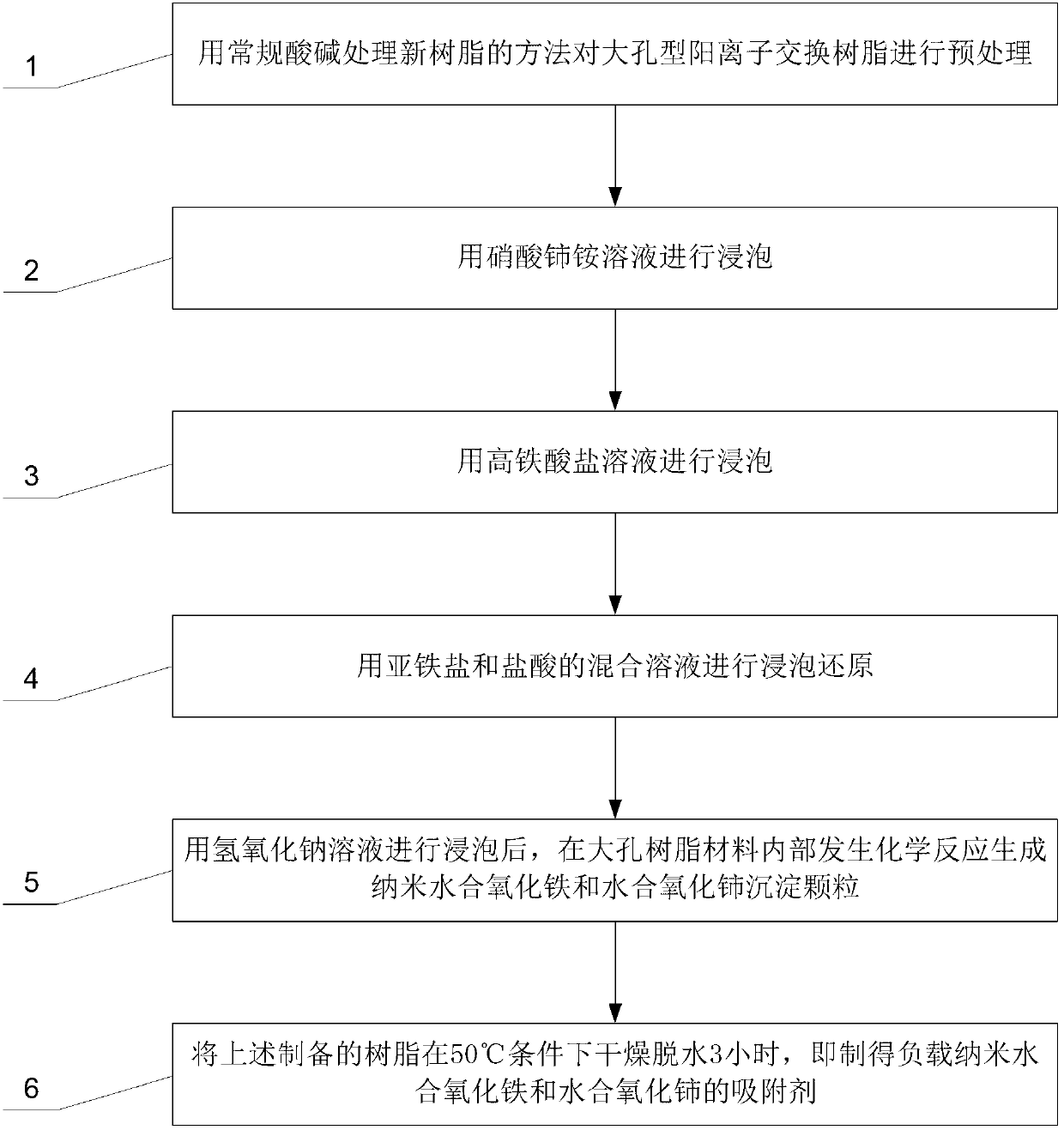

Nano adsorbent for removing arsenic, stibium and fluorin in wastewater as well as preparation method and regeneration method of nano adsorbent

ActiveCN103341353AGood choiceOther chemical processesCombustible gas purificationChemical reactionSorbent

The invention discloses a nano adsorbent for removing arsenic, stibium and fluorin in wastewater as well as a preparation method and regeneration method of the nano adsorbent, belonging to the technical field of wastewater treatment. The nano adsorbent is prepared by pretreating macroporous cation exchange resin with a conventional method for acid and alkali treatment on new resin at first, and then sequentially carrying out the following processes of: soaking by using ammonium ceric nitrate and a ferrate solution; performing soaking restoration by using a mixed solution containing ferrite and hydrochloric acid; soaking by using a sodium hydroxide solution, and then performing chemical reaction inside a macroporous resin material to generate nano ferric oxide hydrate and ceric oxide hydrate precipitate particles; and drying and dehydrating for 3 hours at 50 DEG C to obtain an adsorbent loaded with nano ferric oxide hydrate and ceric oxide hydrate. The adsorbent disclosed by the invention can be used for eliminating ions including arsenic, stibium, fluorin and the like in heavy metal wastewater and has good selectivity, and the adsorbent loaded with the nano ferric oxide hydrate and ceric oxide hydrate can be regenerated for use after adsorption saturation.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Compound biosorbent capable of greatly improving capability of adsorbing heavy metal by waste biomasses and preparation method thereof

InactiveCN104138748AImplement security controlsReduce concentrationOther chemical processesWater/sewage treatment by sorptionSorbentSolid particle

The invention discloses a compound biosorbent capable of greatly improving the capability of adsorbing heavy metal by waste biomasses and a preparation method thereof. The biosorbent comprises following components: particles made of crops or wood wastes and nano ferric oxide hydrate which is loaded on the surfaces of the particles and is 10-100mg / g based on iron. The preparation method of the sorbent comprises the following preparation steps: enabling a Fe (III) solution with a certain mass concentration to slowly pass through an adsorption column filled with particle-form agricultural wastes and sufficiently contacting the Fe (III) solution with solid particles; then drying the solid particles at the temperature of 40-60 DEG C for 2 hours; adding the solid particles into a Na-NaCl mixed solution to be vibrated for 12-24 hours; filtering solid substances and repeatedly washing by using 0.001M HCl solution and distilled water until the pH value is 6-8; and finally, drying the treated agricultural waste particles at the temperature of 40-60 DEG C for 12-24 hours to obtain a needed material. According to the compound biosorbent, the adsorption capacity can be increased by 2-6 times, the adsorption speed can be increased by 2-5 times and the distribution coefficient of representation adsorption selectivity is increased by 10-50 times.

Owner:HUANGSHAN UNIV

Method for stabilizing fly ash from refuse incineration by combination of complementary type medicaments

InactiveCN101690934AReduce usageReduce processing costsSolid waste disposalFerric hydroxidePrecipitation types

The invention belongs to the technical field of the harmless treatment of dangerous solid waste and particularly relates to a method for stabilizing fly ash from refuse incineration by the combination of complementary type medicaments. The stabilizing method combines a reducing inorganic medicament (I type medicament) capable of precipitating and absorbing Pb, Zn, Cd, Hg, Cr, Cu and other heavy metals and an heavy metal ion precipitation type organic chelating agent (II type medicament). The method comprises the following steps: firstly mixing the I type medicament with the fly ash first in aqueous solution or in the presence of water for reaction to generate ferric hydroxide for absorbing and precipitating heavy metals or generating sulfides of the heavy metals to precipitate the heavy metals; and then adding the II type medicament in the system to allow the II type medicament to further generate precipitate type chelates with the residual heavy metals, particularly Pb, Cd, Hg and the like. The first step of the method is characterized in that reducing atmosphere still remains after the reaction. As a major part of heavy metals are stabilized by chalybeate or the chalybeate, so the dosage of the II type medicament is reduced considerably.

Owner:TONGJI UNIV +1

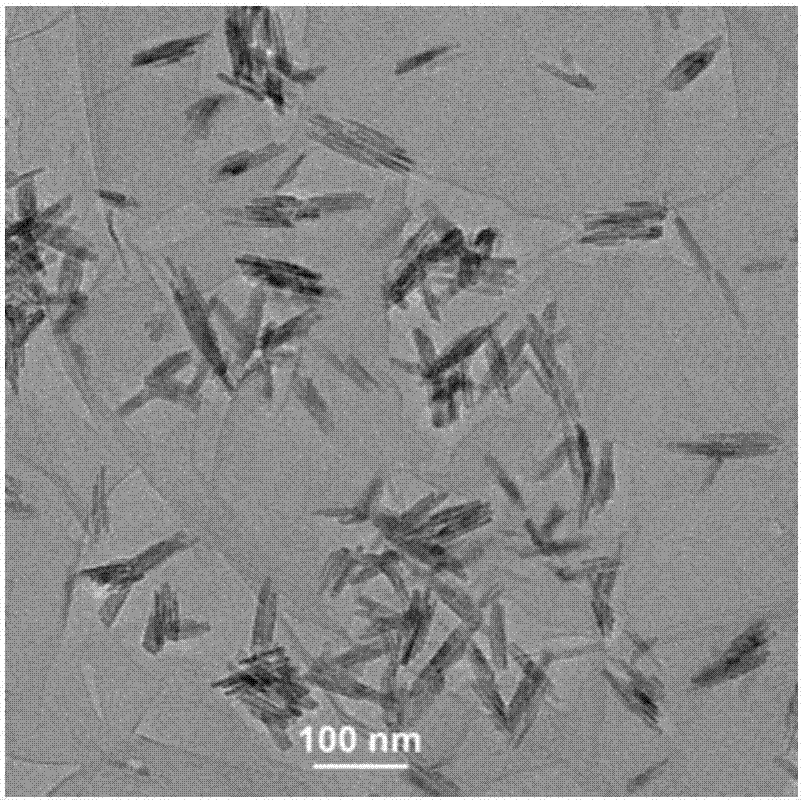

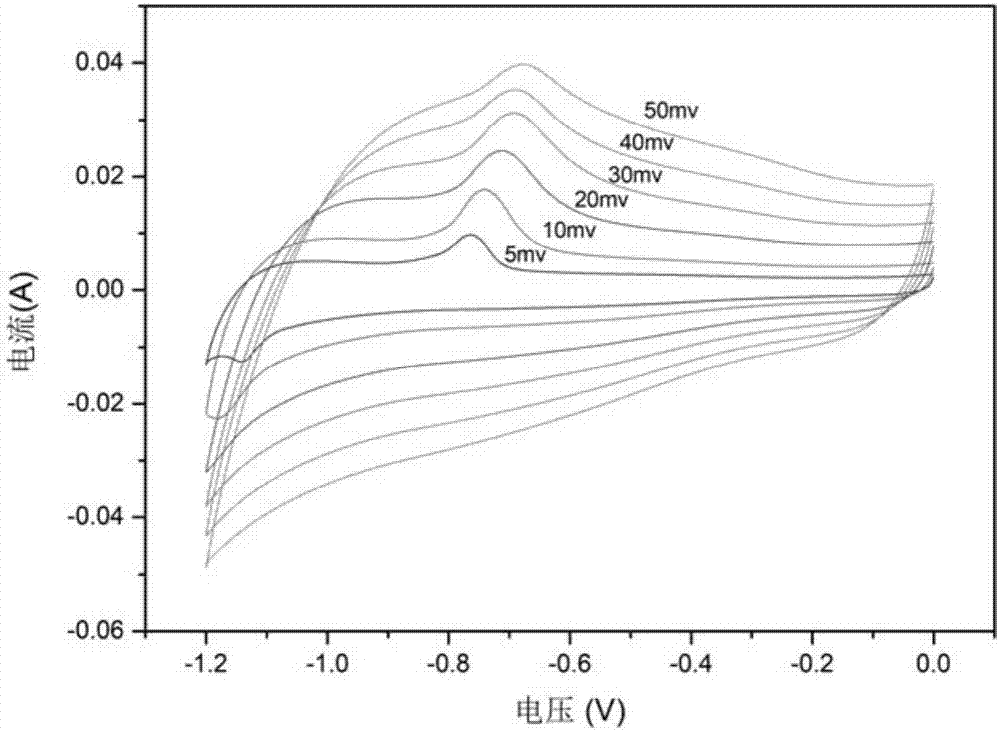

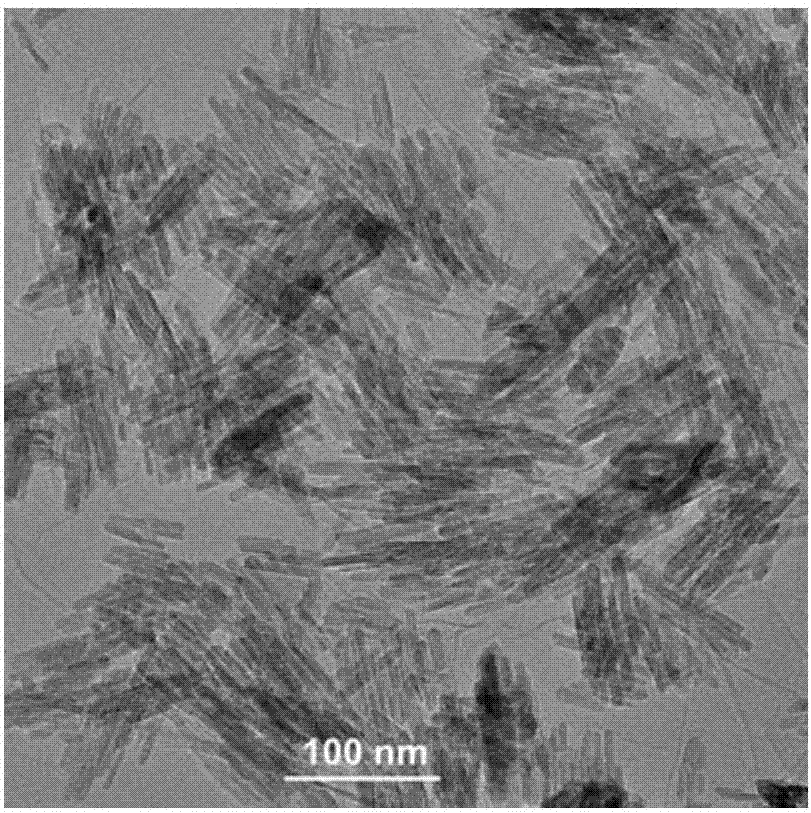

Iron oxide/graphene oxide nanocomposite, its preparation method, and its application in supercapacitor

InactiveCN107256810AEvenly distributedNo agglomerationMaterial nanotechnologyHybrid capacitor electrodesCapacitanceCalcination

The invention discloses an iron oxide / graphene oxide nanocomposite, its preparation method, and its application in a supercapacitor. The iron oxide / graphene oxide nanocomposite is prepared in the following ways: preparing an inorganic iron salt solution; adding the inorganic iron salt solution to the hydrogel of the graphene oxide to obtain a fluid suspension; and obtaining a complex of the hydrated iron oxide nanoparticles and the graphene oxide by subjecting the fluid suspension to hydrothermal reaction, and obtaining by drying and calcination in order. The graphene oxide loaded nanorods have a diameter ranging from 3-6nm, and the average length of 55nm; and the nanorods are uniformly distributed on the surface of the graphene oxide and is free of agglomeration phenomenon. The graphene oxide loaded iron oxide nanorods can be applied to the supercapacitor. The prepared material effectively combines the characteristics of a double electric layer capacitor and a pseudocapacitor, and shows high specific capacitance (680F / g) and good cycle life (after 2000 cycles, 85% specific capacitance is maintained).

Owner:SYNFUELS CHINA TECH CO LTD

Method for treating arsenic-containing wastewater

InactiveCN102476836AHigh removal rateRaw materials are easy to getWater/sewage treatment by sorptionHydration reactionMagnetite

The invention discloses a method for treating arsenic-containing wastewater, belonging to the technical field of sewage treatment in environmental protection. The method provided by the invention sequentially comprises the following steps of: (1) immersing crushed magnetite powder of 40-100 meshes or magnetite grains with the grain diameter of 5-7 mm in water with the pH value of 7.5-9.5 at a constant temperature of 50-80 DEG C for 5-7 days, and then separating, and drying and activating the immersed magnetite powder or magnetite grains at a temperature of 110 DEG C for 1.5 hours to obtain activated magnetite; (2) acidifying the activated magnetite by using a hydrochloric acid solution with the concentration of 0.1 mol / L and carrying out alkaline washing on the acidified activated magnetite by using sodium hydroxide with the concentration of 2.0 mol / L, and then immersing the alkaline-washed magnetite into an organic amine solution for 12-24 hours; (3) adding 50-100 mg of the activated and modified magnetite powder into 30-800 mL of the arsenic-containing wastewater and stirring for 2.5-3.5 hours; and (4) depositing the stirred mixed liquid and then separating. According to the method disclosed by the invention, amorphous ferric oxide hydrate is generated by hydrolyzing mineral substances including the magnetite and the like, and the amorphous ferric oxide hydrate is aminated in the organic amine solution to form active sites for adsorbing the arsenic after the acidification and the alkaline washing of the amorphous ferric oxide hydrate; the arsenic is easy to combine with an amino so as to be firmly adsorbed on the surface of the magnetite, and the removing rate of the arsenic in the wastewater reaches up to more than 99.9%; and the adsorbed magnetite can be repeatedly utilized after being acidified.

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

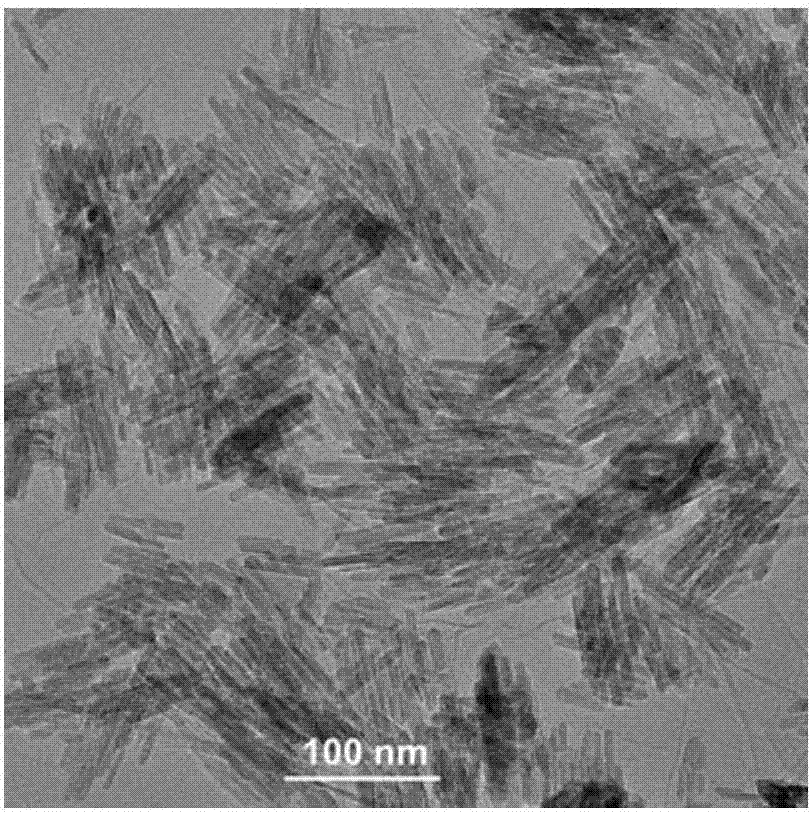

Application of porous ferric oxide/graphene oxide nano-composite material to catalysis of Fischer-Tropsch synthesis

ActiveCN107570155AUniform sizeHigh surface areaMaterial nanotechnologyCatalyst activation/preparationIron saltsNano composites

The invention discloses application of a porous ferric oxide / graphene oxide nano-composite material to catalysis of Fischer-Tropsch synthesis. The porous ferric oxide / graphene oxide nano-composite material can be applied to catalysis of Fischer-Tropsch synthesis. The porous ferric oxide / graphene oxide nano-composite material is prepared according to the following steps: (1) preparing a solution ofinorganic iron salt; (2) adding the solution of the inorganic iron salt into hydrosol of graphene oxide to obtain suspension liquid; and (3) performing hydrothermal reaction on the suspension liquidto obtain a ferric oxide hydrate nano-particle and graphene oxide compound, and drying and calcining sequentially. The porous ferric oxide / graphene oxide nano-composite material can be applied to catalysis of Fischer-Tropsch synthesis. The prepared catalyst has high wear capacity (the wear rate is lower than 2%.h<-1>), high CO conversion rate (90 percent), high heavy hydrocarbon C5+ selectivity (50 percent) and high stability.

Owner:SYNFUELS CHINA TECH CO LTD

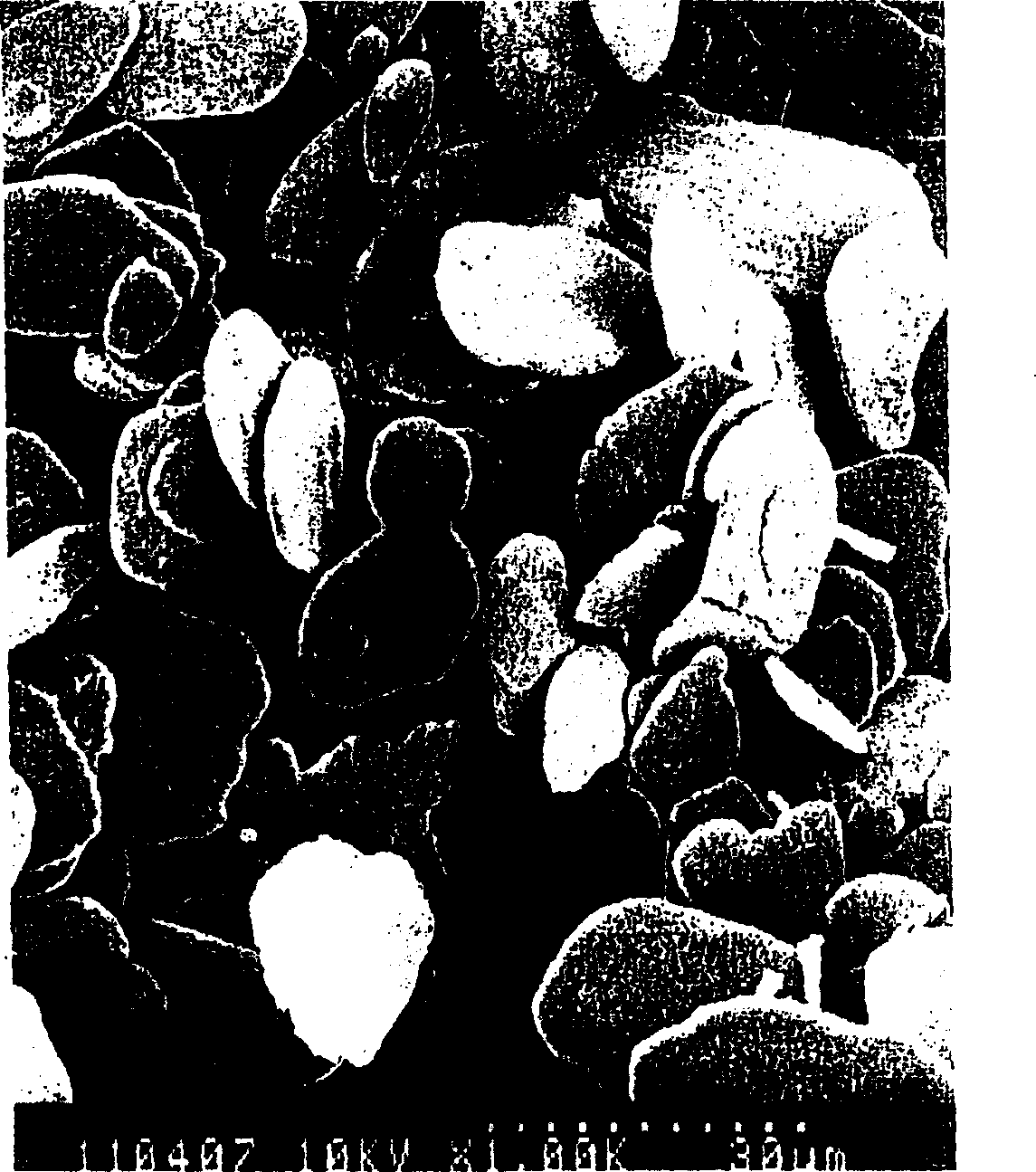

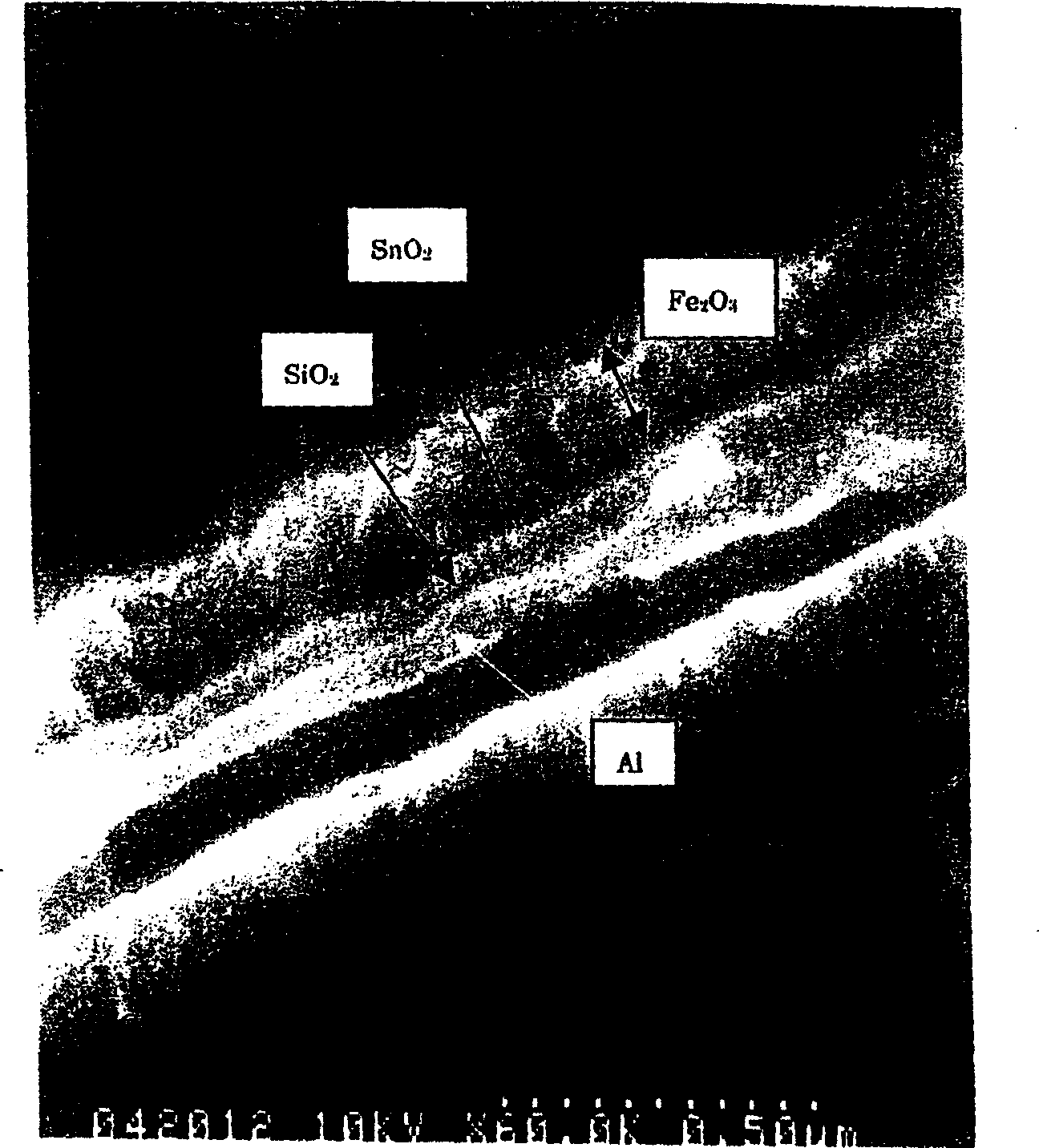

Low infrared emittance sheet-like pigment and method for preparing same

InactiveCN1884395ASolve Oxidation ProblemsLow emissivityInorganic pigment treatmentEmissivityFerric oxide hydrate

The invention discloses the aluminum dust dye and preparing method. The dye has emissing ability, and is covered with ferrite yellow. The particle mean size of aluminum dust is 1-100 mum, and the aluminum dust is lack-lustre, golden ocher, and good oxidation resistance. The average emissing ability of infrared band is 0.50-0.60.

Owner:SHANGHAI HUAMING HI TECH GRP

Environment-friendly sewage nitrogen and phosphorus removal cleaning agent and preparation method thereof

InactiveCN103145210ALarge specific surface areaLow costOther chemical processesWater/sewage treatment by sorptionHydration reactionCleansing Agents

The invention relates to an environment-friendly sewage nitrogen and phosphorus removal cleaning agent and a preparation method thereof. The environment-friendly sewage nitrogen and phosphorus removal cleaning agent is characterized in that the cleaning agent contains 40-80 percentage by weight of biological black wood charcoal, 0-20 percentage by weight of hydrated iron oxide, 0-20 percentage by weight of attapulgite and 0-20 percentage by weight of cement on the basis of the total weigh of the cleaning agent. The cleaning agent preparation method comprises the following steps of: (1) uniformly mixing the powdery iological black wood charcoal, the hydrated iron oxide, the attapulgite, the cement and the like by weight percent; and (2) processing the mixture obtained in step (1) into granulates. The cleaning agent provided by the invention has the advantages of large specific surface, suitability for purification of multiple water bodies, reliable purification effect of sewage, low construction cost, convenience for use, environmental friendliness, wide source of raw materials, stable property of basic component materials and contribution to construction of a circular economy pattern.

Owner:苏州绿世界园林发展有限公司

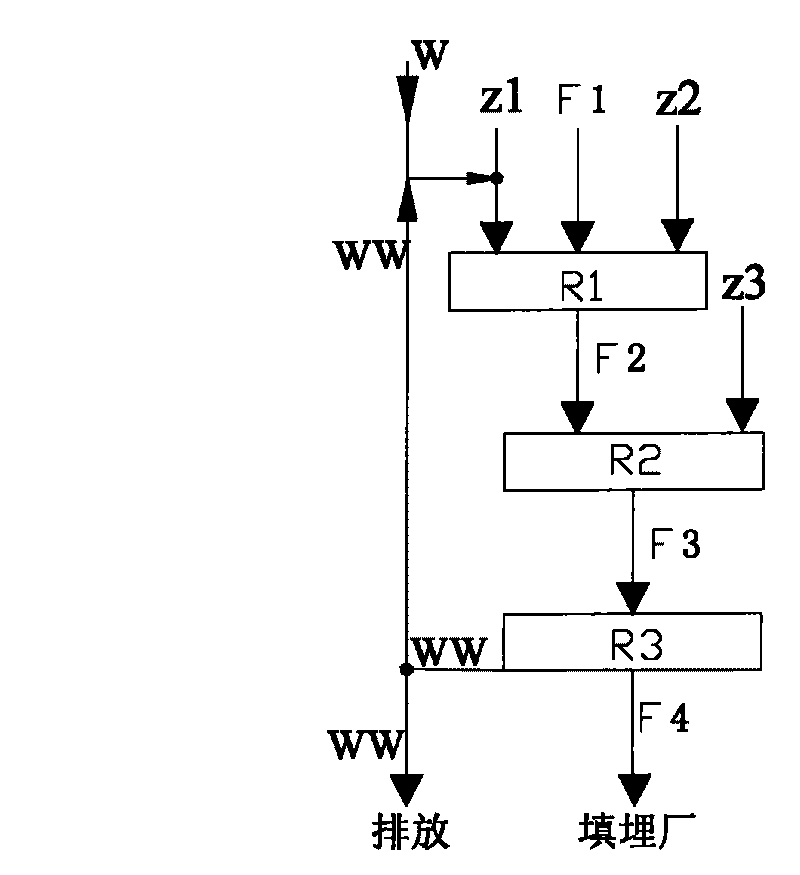

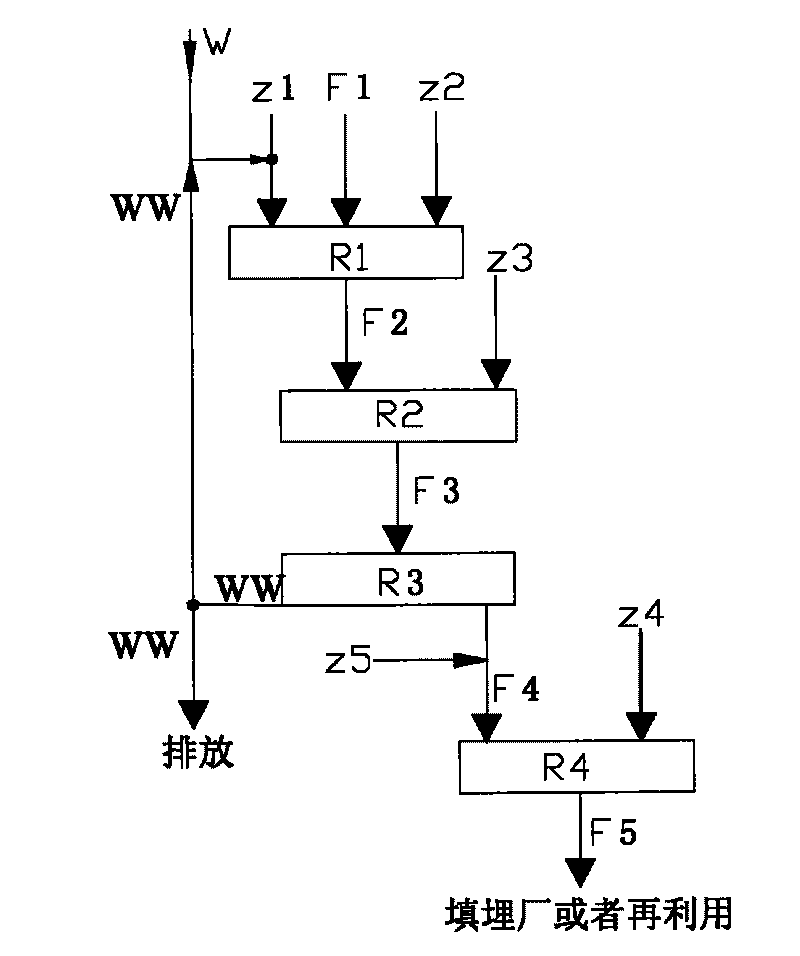

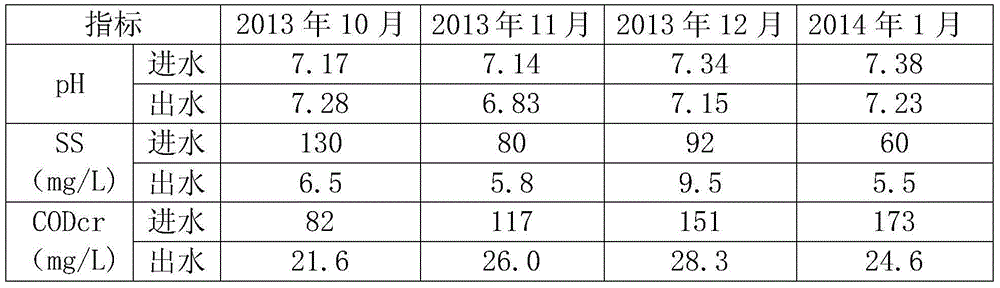

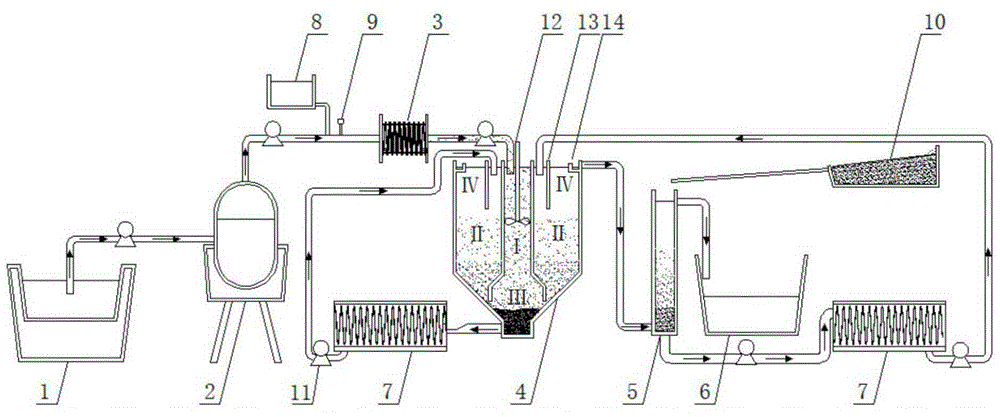

Method for synchronously removing organic matter and phosphorus in sewage biochemical tail water

ActiveCN103936206AExcellent synchronous removal effectHigh energy consumptionMultistage water/sewage treatmentWater/sewage treatment by sorptionParticulatesDesorption

The invention discloses a method for synchronously removing organic matters and phosphorus in sewage biochemical tail water, belonging to the field of advanced treatment and recovery of wastewater. The method comprises the steps of (a) enabling effluent of a secondary sedimentation tank of a sewage biochemical treatment system to pass through a shallow-layer sand filter, and removing suspended particulate matters in water; (b) enabling filtrate to pass through an adsorption tower filled with a composite material HFO-802; (c) stopping adsorption when the effluent COD or total phosphorus concentration reaches a breakthrough point, performing desorption and regeneration on a nano composite material in the adsorption tower by using a NaOH-NaCl mixed solution, and recycling after regeneration. The method adopts a special adsorption material, and organically combines the adsorption property of a polymer carrier to the organic matters in wastewater and the selective phosphorus removal performance of nano ferric oxide hydrate so as to realize synchronous removal of the organic matters and phosphorus in the biochemical tail water. The method disclosed by the invention is simple in operation process and low in cost, and can be used for providing important guarantees for the advanced treatment and comprehensive utilization of the sewage biochemical tail water.

Owner:NANJING UNIV

Sewage disposal agent

ActiveCN104478056AImprove processing efficiencyInhibit swellingSpecific water treatment objectivesWater/sewage treatment using germicide/oligodynamic-processSludgePolyvinyl chloride

The invention provides a sewage disposal agent. A preparation method of the sewage disposal agent comprise the following steps: at first, preparing a solution through hybrid heating of FeSO4.7H2O and a polyvinyl chloride hollow sphere, hydrolysis of ferric salt and adding of deionized water, adding strong base in the solution, regulating the pH value to be 7-9, loading on the polyvinyl chloride hollow sphere to form a ferric oxide hydrate, and drying to obtain the sewage disposal agent. The sewage disposal agent can be preferentially combined with filamentous bacteria in sewage and coat the filamentous bacteria to form a reticular structure floc which is not easy to break; rising water flow during the precipitation process has a filtering effect to adsorb small particles and free bacteria which are intercepted in sewage to make sewage clear. Since the sewage disposal agent can preferentially coat the filamentous bacteria, zoogloea is always at an advantage in the substrate competition, which can improve the sewage disposal efficiency and effectively prevent filamentous bacteria sludge bulking.

Owner:广州岸碧化工科技有限公司

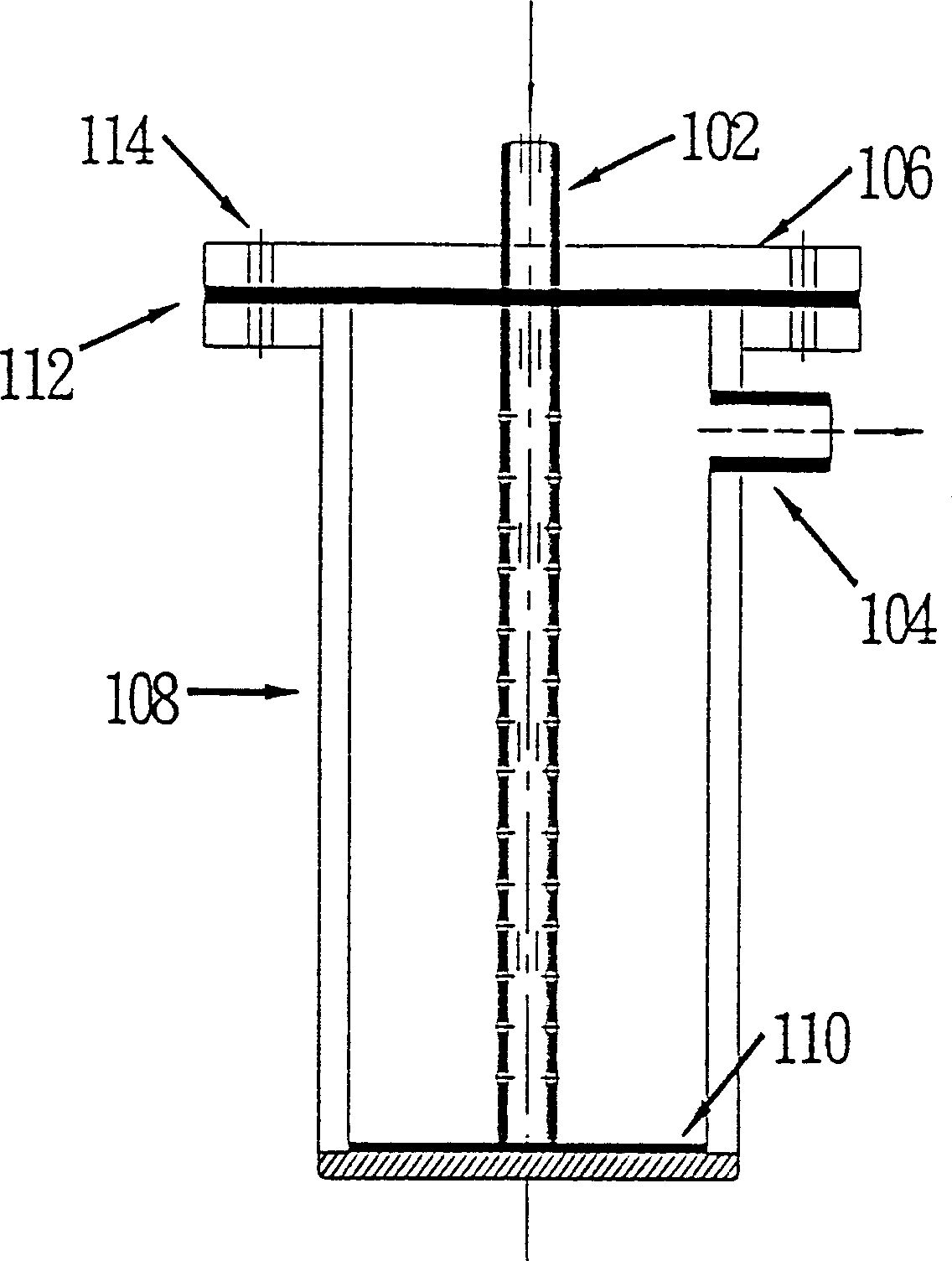

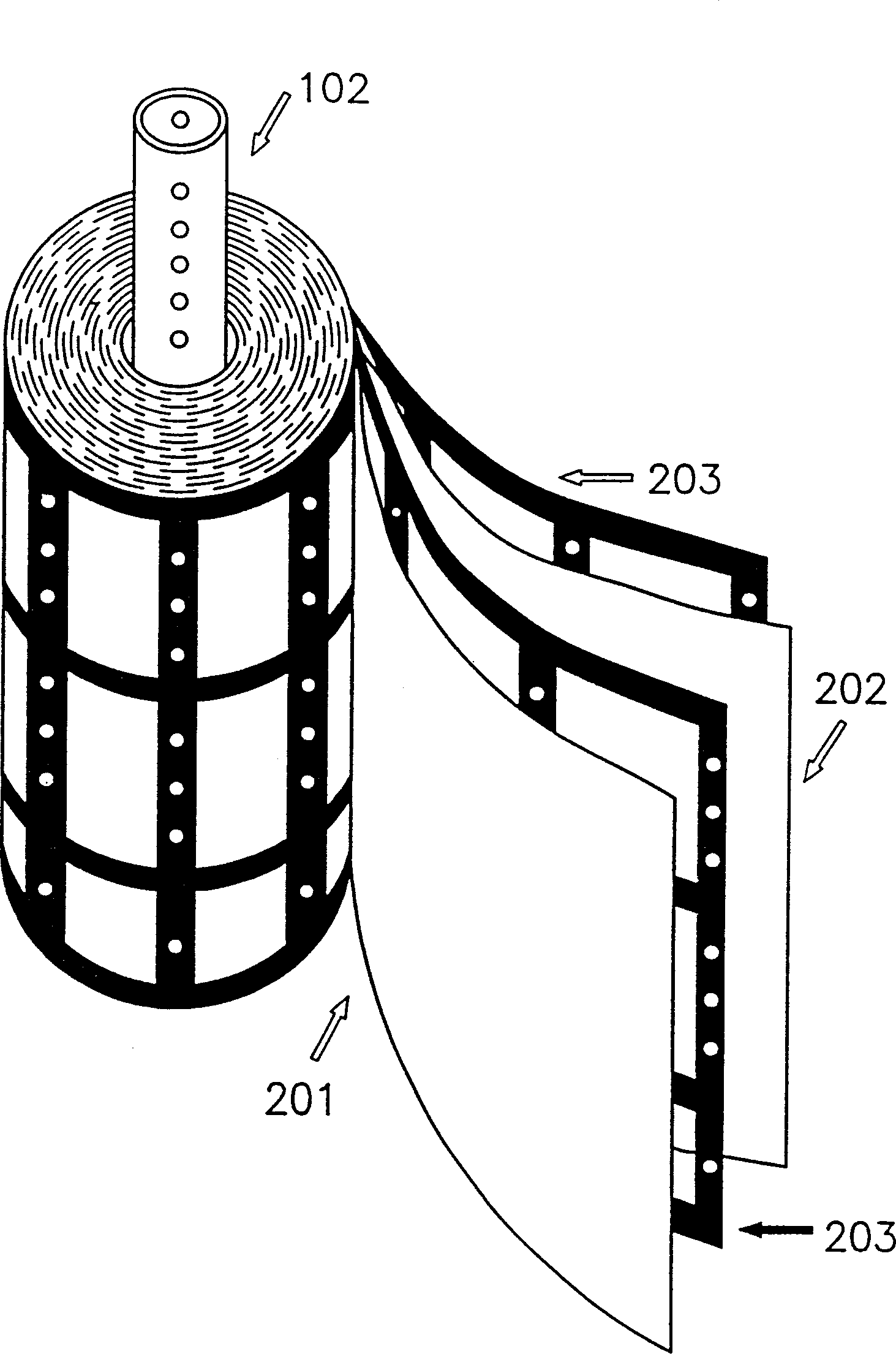

Independent flow-thru capacitor

InactiveCN1417816AReduce dosageImprove automationAnti-noise capacitorsFeed-through capacitorsCapacitanceFerric oxide hydrate

The independent flow-thru capacitor (FTC) consists of two coaxial wound electrodes and two coaxial wound film layers to constitute one reel, and the center of the reel is one central hole for liquid feeding pipe to insert in to convey fluid to FTC. The active electrode material is nanometer hydrated ferric oxide particle or powder with Fe3O4 as main component. When fluid flows in, the fluid will pass through the channel of the film layers and to whole electrode length. When one DC voltage lower than 1 v is applied, charged matter will be adsorbed, contacted with electrodes and eliminated by the fluid. When water solution of NaCl or CuSO4 or sea water is made to pass through FTC, ion eliminating rate up to 19% may be reached. The FTC of the present invention may be used for reducing waste liquid, purity water and elimiante salt in low cost and simple operation.

Owner:LUXON ENERGY DEVICES CORP

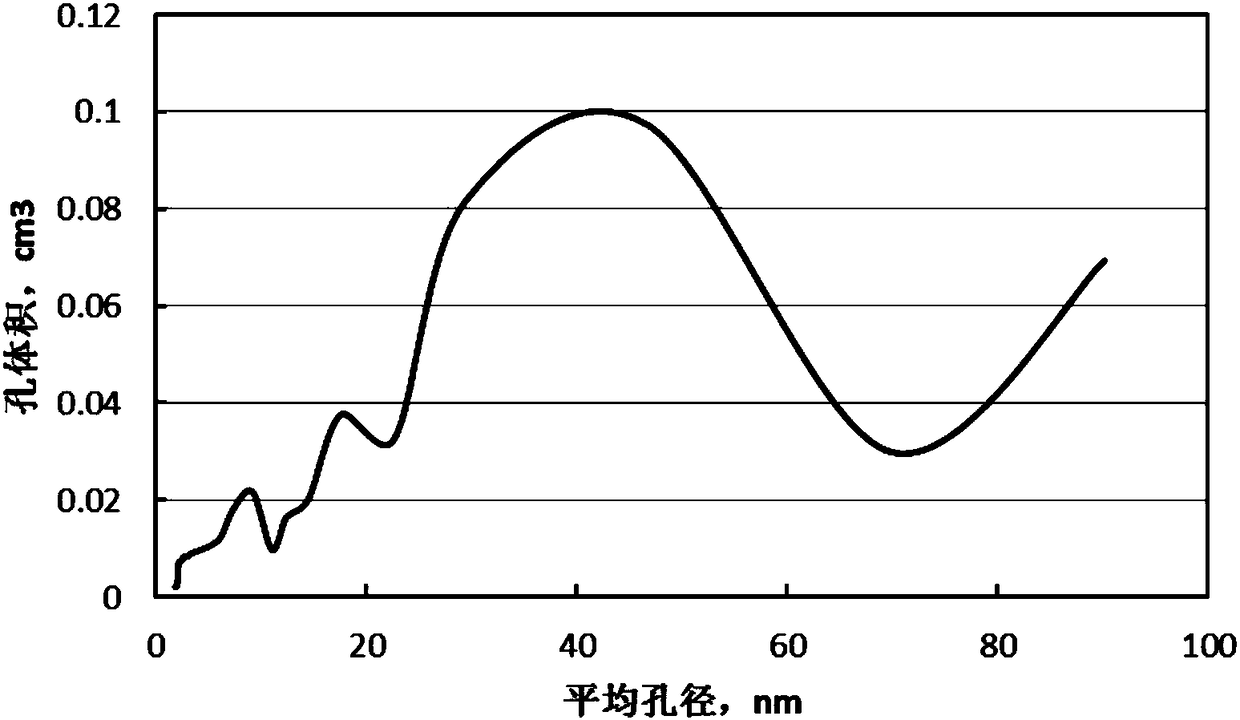

Hydrated ferric oxide loaded nano-composite semi-coke and preparation method thereof

InactiveCN103769049AEfficient removalEfficient adsorption and removal characteristicsOther chemical processesWater/sewage treatment by sorptionPore distributionIon exchange

The invention provides a hydrated ferric oxide loaded nano-composite semi-coke and a preparation method of the hydrated ferric oxide loaded nano-composite semi-coke. The method comprises the following steps: taking biomass pyrolysis semi-coke with good pore distribution and electronic constraint feature as a carrier, introducing FeCl<4-> ion into inside and outside surfaces of the biomass pyrolysis semi-coke through ion exchange effect, and then reducing the FeCl<4-> ion introduced into the inside and outside surfaces of the biomass pyrolysis semi-coke as nano hydrated ferric oxide, washing and drying to obtain the hydrated ferric oxide loaded nano-composite semi-coke. The Donnan pre-concentration effect of the biomass pyrolysis semi-coke for inorganic anions pollutant in the water body and the function of the nano hydrated ferric oxide for effectively removing phosphorus in waste water are combined, the defects that the nano hydrated ferric oxide particles are easy to agglomerate, the chemical property is unstable and the particle small pressure head is large in damage are overcome, and the phosphorus in the waste water can be fast, effectively and inexpensively adsorbed.

Owner:SOUTHWEST UNIV

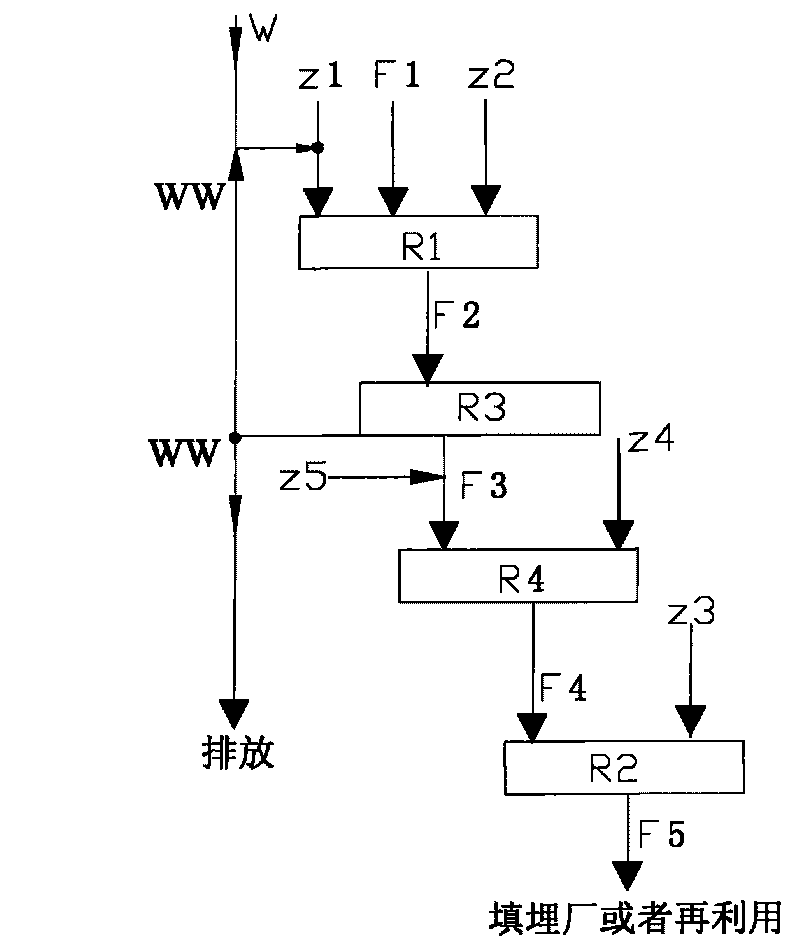

Method for removing phosphorus in water by using resin-loaded ferric oxide hydrate

InactiveCN110560012AThe synthesis process is simpleImprove stabilityOther chemical processesWater contaminantsFerric oxide hydrateWastewater

The invention relates to a method for removing phosphorus in water by using resin-loaded ferric oxide hydrate, which comprises the following steps: preparing a ferric oxide hydrate-resin (HFO-301) composite resin, adding the prepared HFO-301 resin into mixed wastewater containing inorganic phosphorus, HETP and TPhP, regulating the pH value, and carrying out oscillation reaction. The prepared HFO-301 composite resin can synchronously adsorb inorganic phosphorus and organic phosphorus, and the purpose of removing phosphorus-containing pollutants in water is achieved. The prepared HFO-301 can absorb inorganic phosphorus on one hand and can remove organophosphorus such as triphenyl phosphate (TPhP) and Hydroxyethylidene-1,1-diphosphonic acid (HEDP) on the other hand through non-specific electrostatic adsorption, ligand exchange and inner-layer complexing action. It is shown by researches that the prepared nano resin composite material has the advantages of low resin preparation cost, simple process, high treatment efficiency, wide pH application range, high stability and the like, and has great potential in the aspect of phosphorus-containing wastewater treatment.

Owner:NANJING UNIV OF TECH

DGT probe and sediment/water interface micro-area detection method using same

InactiveCN104155215AAccurate Test ToolAccurate evaluation systemSurface/boundary effectDiffusionEutrophication

A DGT probe and sediment / water interface micro-area detection method using same. A three-layer fixed-glue DGT probe is provided in the invention. The probe includes sliver iodine-Chelex 100 fixed glue composed of sliver iodine glue and Chelex 100 fixed glue, wherein the sliver iodine glue and the Chelex 100 fixed glue are attached tightly to each other. The probe also includes hydrated ferric oxide fixed glue. Internal sides of both the sliver iodine-Chelex 100 fixed glue and the hydrated ferric oxide fixed glue are at least provided with substrates. External side of both the sliver iodine-Chelex 100 fixed glue and the hydrated ferric oxide fixed glue are at least provided with diffusion glue. The hydrated ferric oxide fixed glue is not arranged on the external side of the sliver iodine-Chelex 100 fixed glue. With the fixed glue DGT probe, a detection tool and an evaluation system which are more accurate in deep identification and determination of characteristics of lake phosphorus internal loading are provided and an important scientific basis for lake eutrophication control and water ecological restoration.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Method for resource recycling of phosphorus in breeding waste

The invention provides a method for resource recycling of phosphorus in breeding waste. The method comprises the following steps that (1) pulse ultrasonic treatment is conducted on the breeding waste; (2) the breeding waste treated in the step (1) is introduced into a wet type chemical oxygenizer and oxidized under the action of an oxidizing agent; (3) a magnesium solution and a pH value regulating agent are added into supernate of the breeding waste treated in the step (2), and pulse microwaves are applied to the mixed solution; (4) the mixed solution treated in the step (3) is introduced into a crystallizing bed, bird dung crystal mud and supernate are obtained after the mixed solution is crystallized, and the bird dung crystal mud is collected; and (5) the supernate obtained in the step (4) is introduced into an adsorption column, and ferric oxide hydrate-carried charcoal after adsorption is collected with ferric oxide hydrate-carried charcoal as an adsorbent. According to the method, the pulse ultrasonic and advanced oxidation coupling technique is adopted, and the phosphorus release rate and the organophosphorus conversion rate are high; the bird dung crystal and ferric oxide hydrate-carried charcoal adsorption coupling technique is adopted, and thus phosphorus loss rate is low.

Owner:CHINA AGRI UNIV

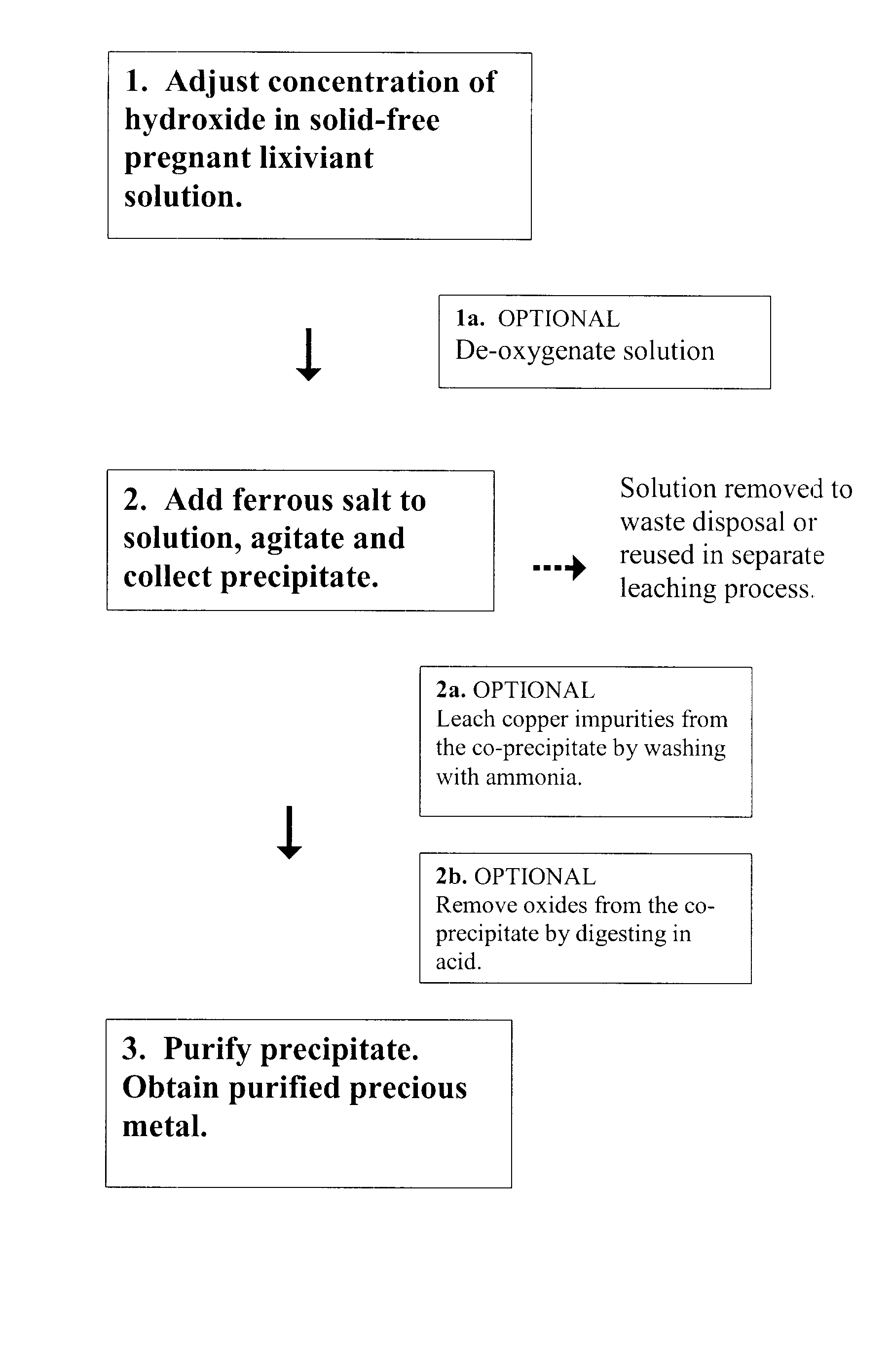

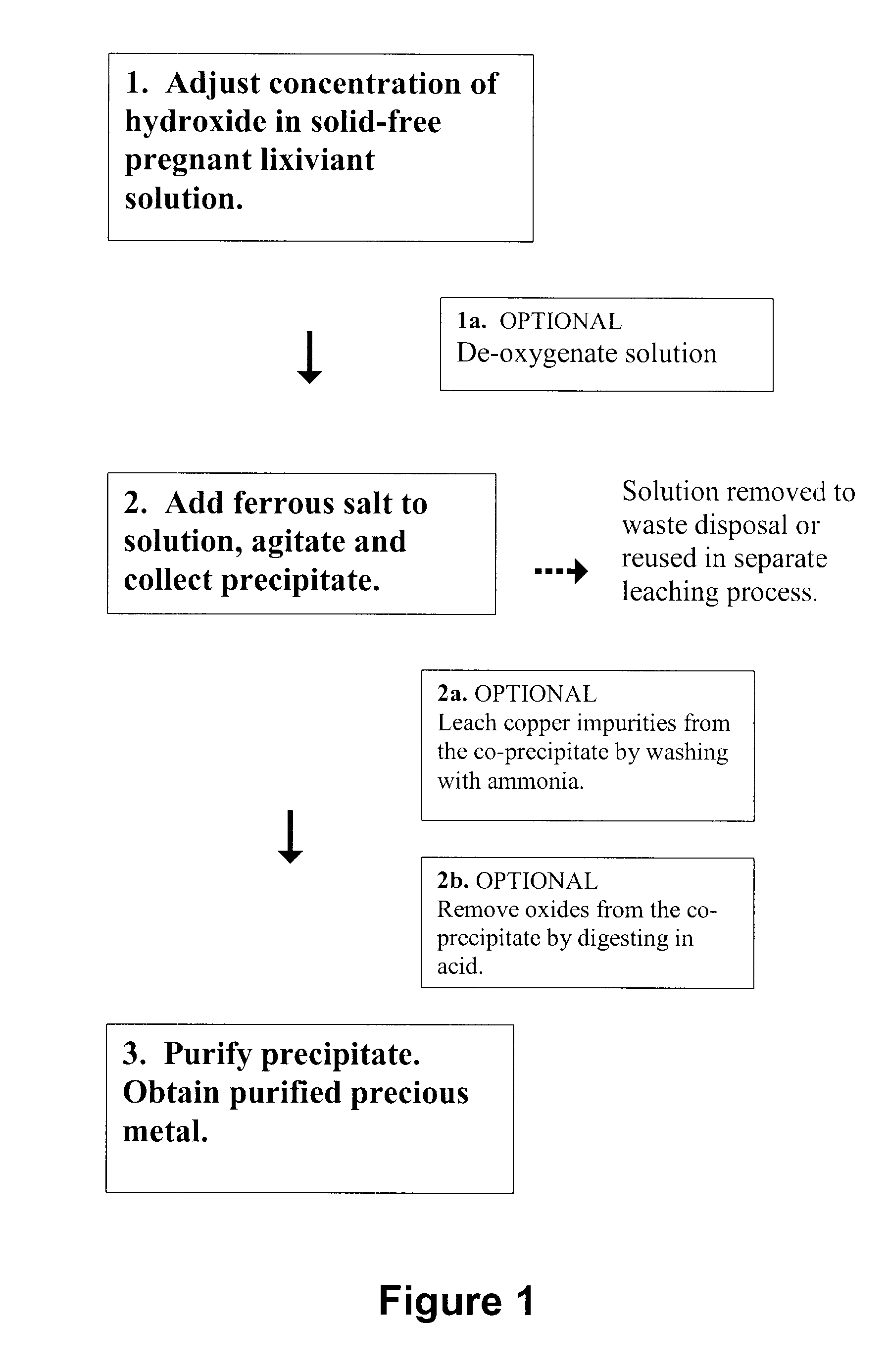

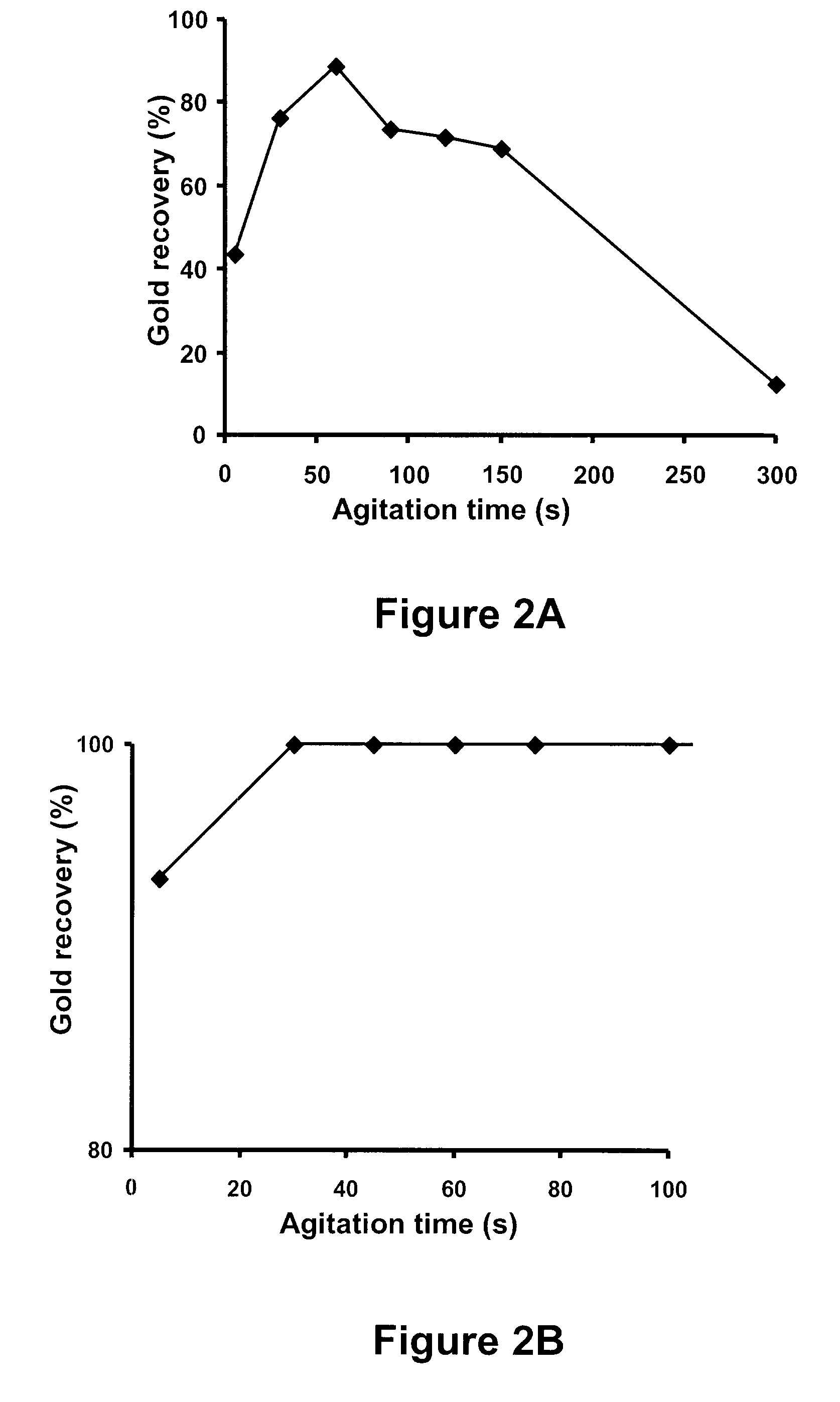

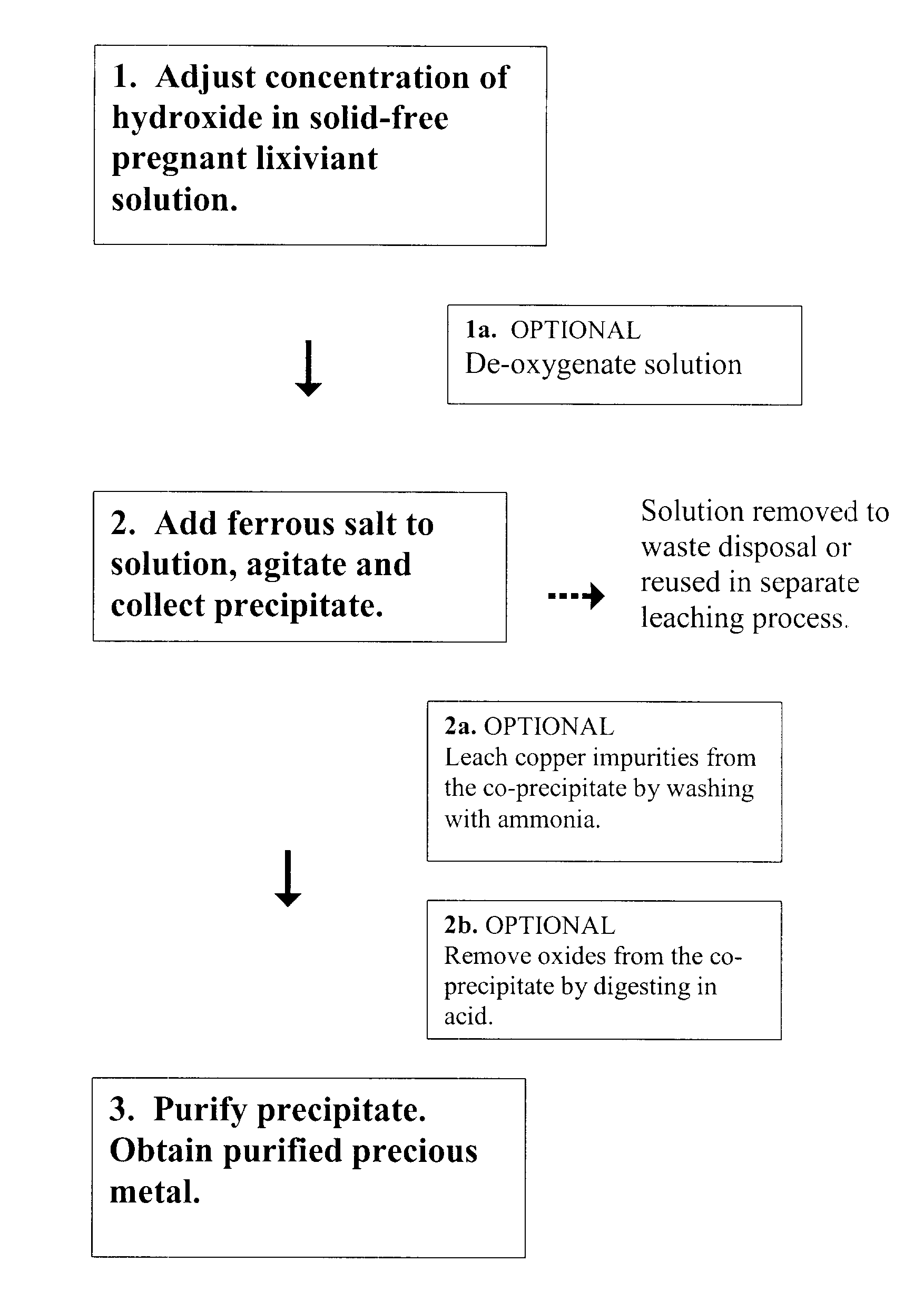

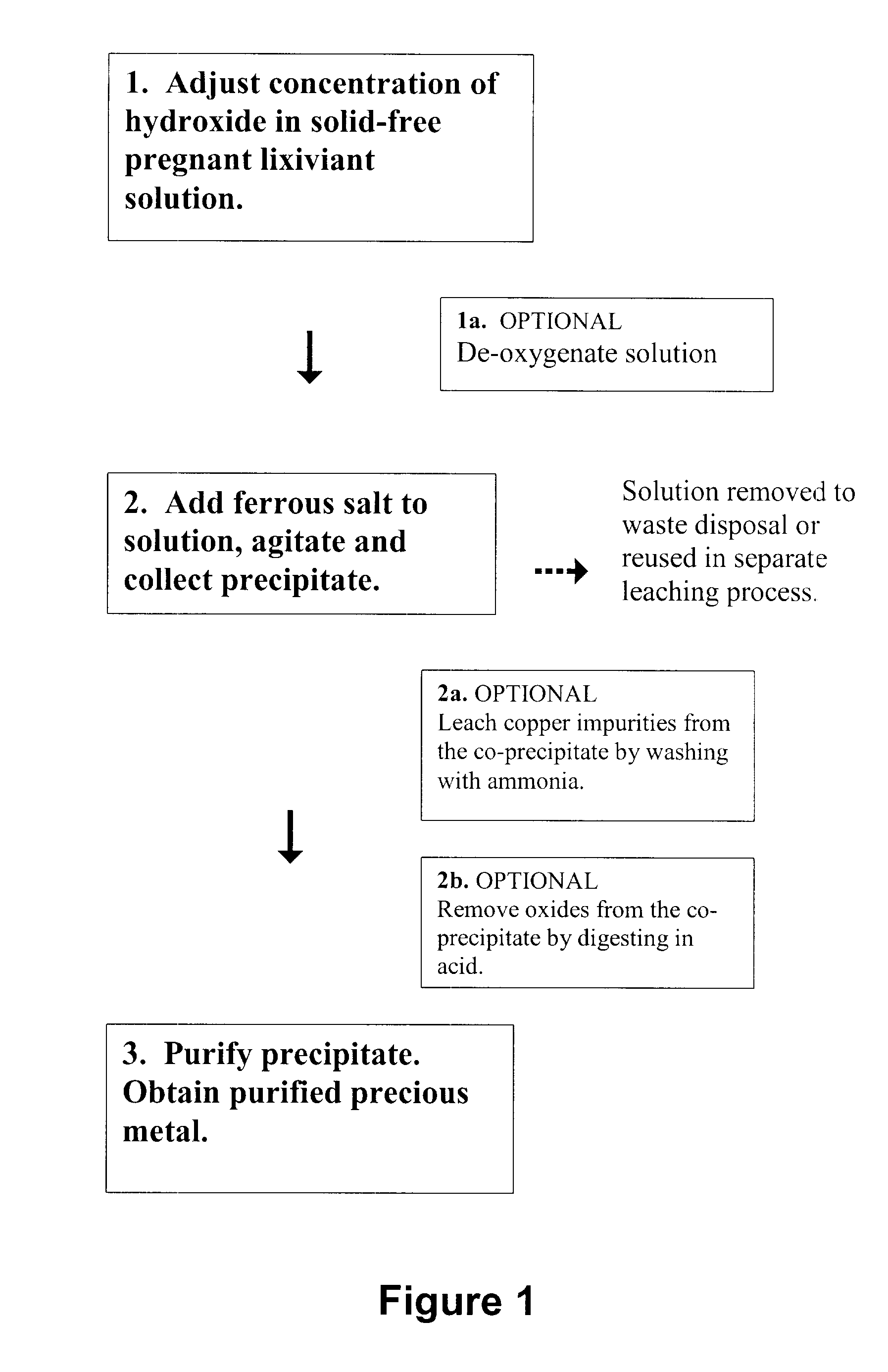

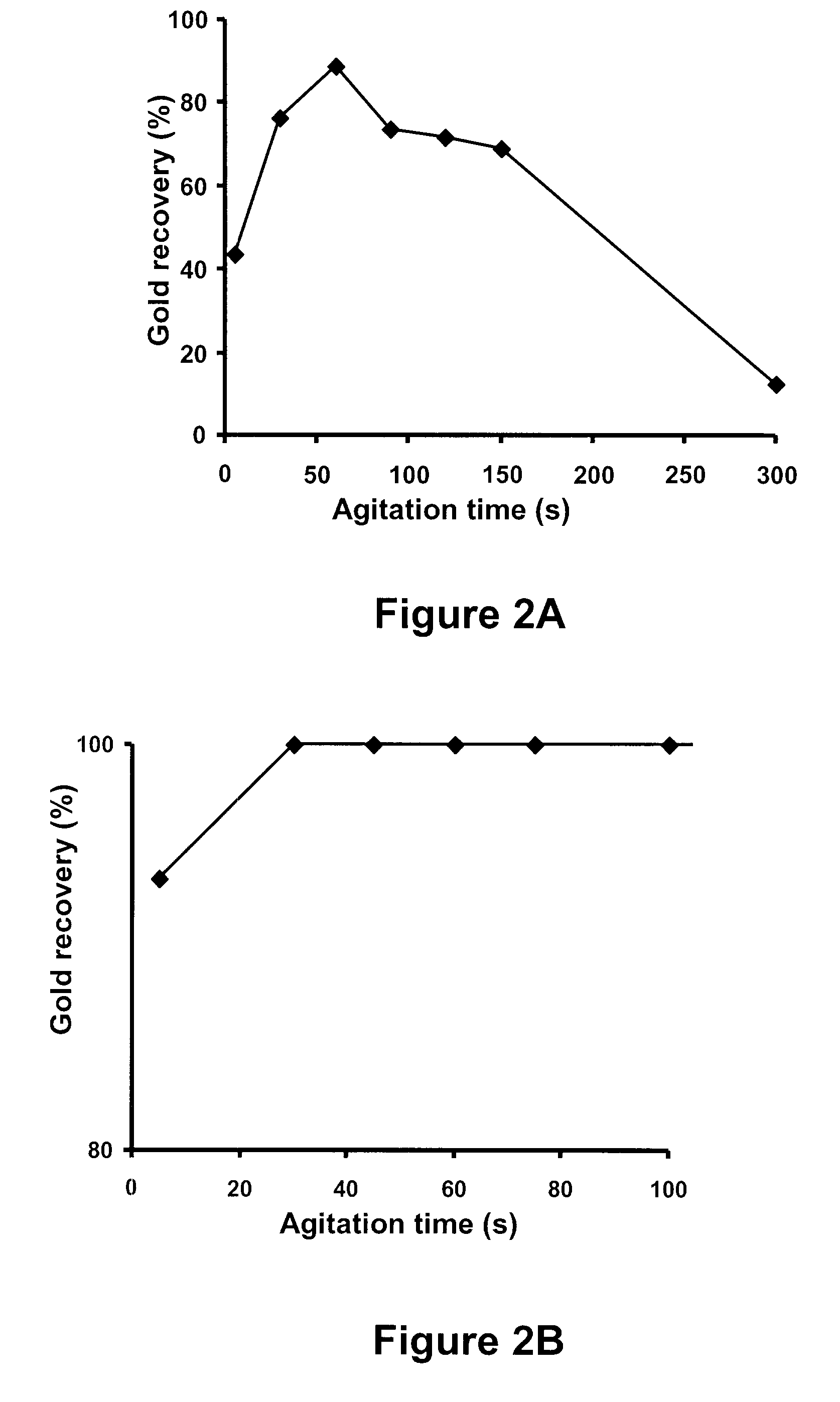

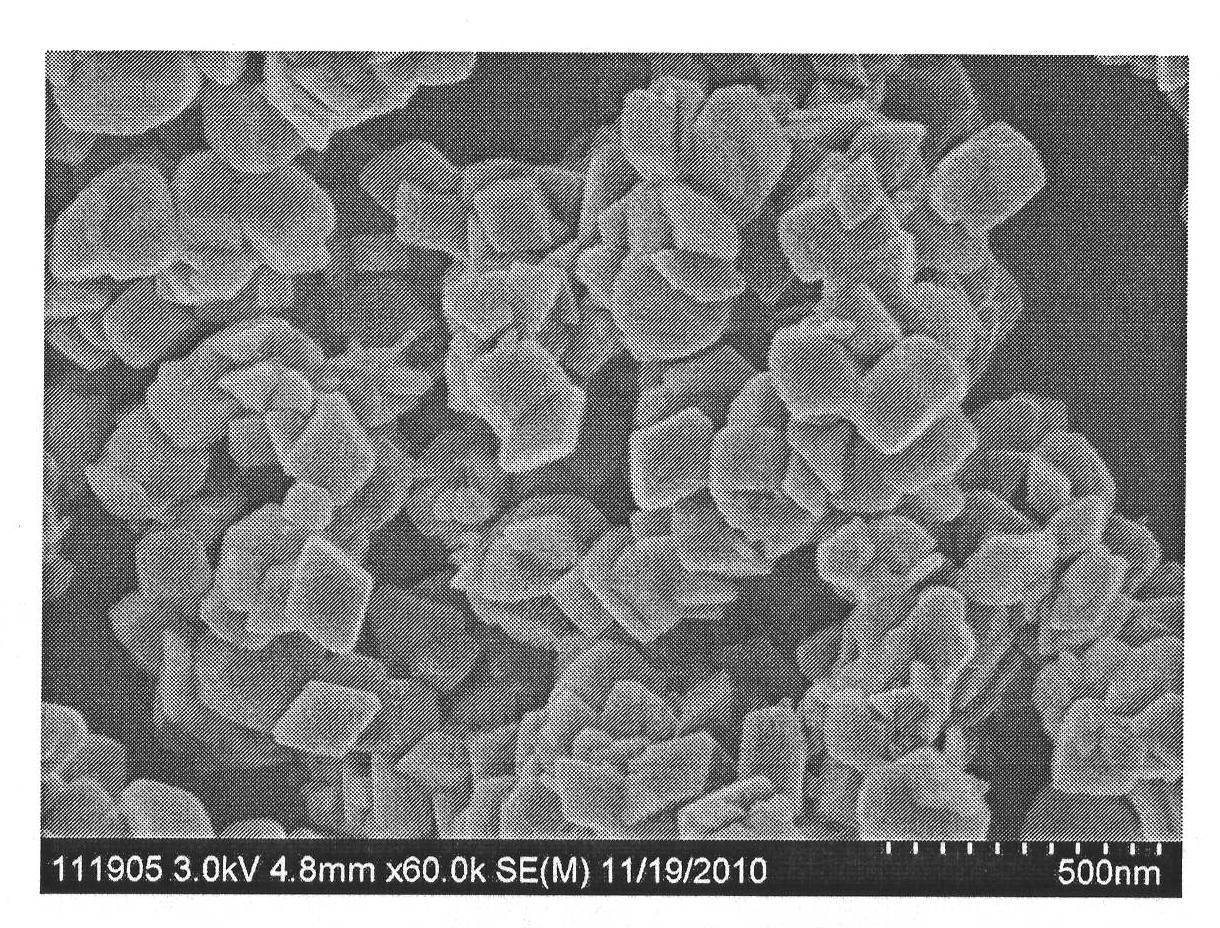

Precious metal recovery from solution

InactiveUS7972413B2Easy to separateLow cost of reagentsPhotography auxillary processesProcess efficiency improvementFerric oxide hydrateAqueous solution

A method for recovering precious metals such as gold and silver from aqueous solution as solid is described The method includes mixing an aqueous solution (e.g, thiosulfate or thiocyanate lixiviant) containing precious metals with ferrous ions in the presence of an effective amount of hydroxide ions. The precious metal ions are reduced and co-precipitate with iron hydroxides and / or hydrated iron oxides The co-precipitate is collected and purified. De-oxygenation of the reaction solution is optional. The recover / method is fast, complete and clean.

Owner:METAL ASIA INT

Method and Composition for Sorbing Toxic Substances

InactiveUS20090294368A1Waste water treatment from quariesUsing liquid separation agentSorbentRed mud

Toxic substances such as heavy metals are extracted from a medium using a sorbent composition. The sorbent composition is derived by sulfidation of red mud, which contains hydrated ferric oxides derived from the Bayer processing of bauxite ores. Exemplary sulfidizing compounds are H2S, Na2S, K2S, (NH4)2S, and CaSx. The sulfur content typically is from about 0.2 to about 10% above the residual sulfur in the red mud. Sulfidized red mud is an improved sorbent compared to red mud for most of the heavy metals tested (Hg, Cr, Pb, Cu, Zn, Cd, Se, Th, and U). Unlike red mud, sulfidized red mud does not leach naturally contained metals. Sulfidized red mud also prevents leaching of metals when mixed with red mud. Mixtures of sulfidized red mud and red mud are more effective for sorbing other ions, such as As, Co, Mn, and Sr, than sulfidized red mud alone.

Owner:J I ENTERPRISES

Preparation method of active carbon fiber phosphorous removal agent loaded with ferric oxide hydrate

InactiveCN102600817ALow costImprove adsorption capacityOther chemical processesFiberActivated carbon

The invention relates to a preparation method of an active carbon fiber phosphorous removal agent loaded with ferric oxide hydrate, belonging to the technical field of preparation process of phosphorous adsorption removal agents. The preparation method in the invention has the characteristics of being short in preparation time, simple in steps, simple and practicable in operation and the like; and the obtained composite adsorbent has the advantages of being uniform in fiber surface load, large in load capability, excellent in adsorption performance, low in preparation cost and the like.

Owner:SHANGHAI UNIV

Precious Metal Recovery from Solution

InactiveUS20100025259A1Easy to separateLow cost of reagentsPhotography auxillary processesProcess efficiency improvementFerric oxide hydrateFerric hydroxide oxide

A method for recovering precious metals such as gold and silver from aqueous solution as solid is described The method includes mixing an aqueous solution (e.g, thiosulfate or thiocyanate lixiviant) containing precious metals with ferrous ions in the presence of an effective amount of hydroxide ions. The precious metal ions are reduced and co-precipitate with iron hydroxides and / or hydrated iron oxides The co-precipitate is collected and purified. De-oxygenation of the reaction solution is optional. The recover / method is fast, complete and clean.

Owner:METAL ASIA INT

Environment-friendly synthesis method of pigment-grade iron oxide red

The invention discloses an environment-friendly synthesis method of pigment-grade iron oxide red. The method comprises the following steps: by taking ferric salt or ferrous salt as a raw material, respectively regulating the pH to 7 and 9 so as to respectively prepare amorphous hydrated ferric oxide seed crystal and delta-FeOOH seed crystal; respectively adding the seed crystals in a reaction kettle, so that the concentrations of the seed crystals are 0.0125mol / L and 0.07mol / L respectively; respectively controlling the temperature to 90-95 DEG C and 90-100 DEG C; adding a Fe<2+> ion catalyst (a ferrous chloride solution or a ferrous sulfate solution) to react for 0.5 hour; adding 30g of excess waste scrap iron, introducing air, supplementing a ferrite solution in a reaction process, maintaining the concentration of ferrous ion in the reaction system to 0.16-0.20 mol / L, and reacting for 48-82 hours; and filtering, washing and drying the product so as to obtain the pigment-grade iron oxide red powder with a good pigment property. The environment-friendly synthesis method has no environment pollution and low raw material cost, and process condition is easy to control, thus an effective, practicable and environment-friendly novel method is provided for the industrial production of the pigment-grade iron oxide red.

Owner:HEBEI NORMAL UNIV

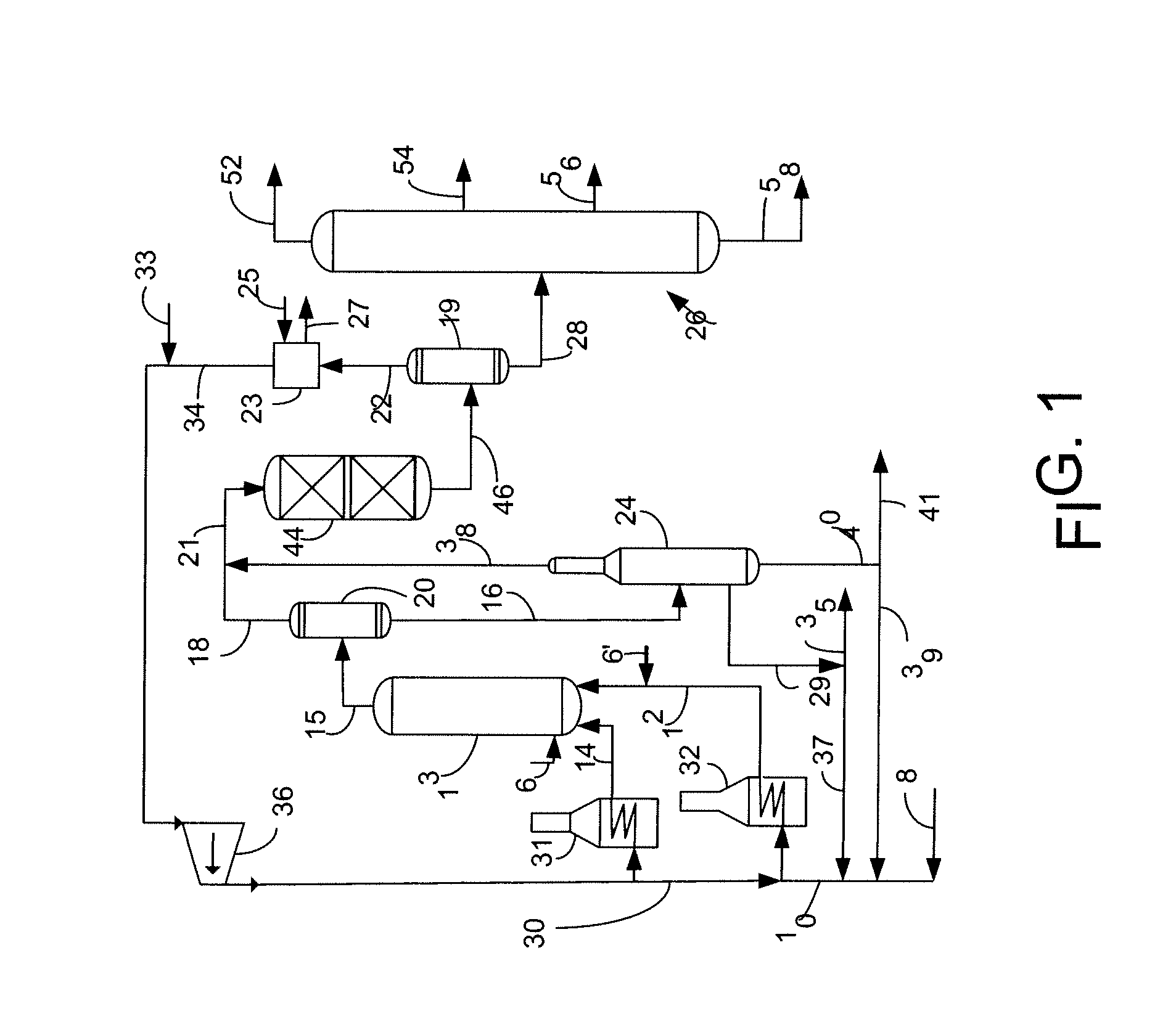

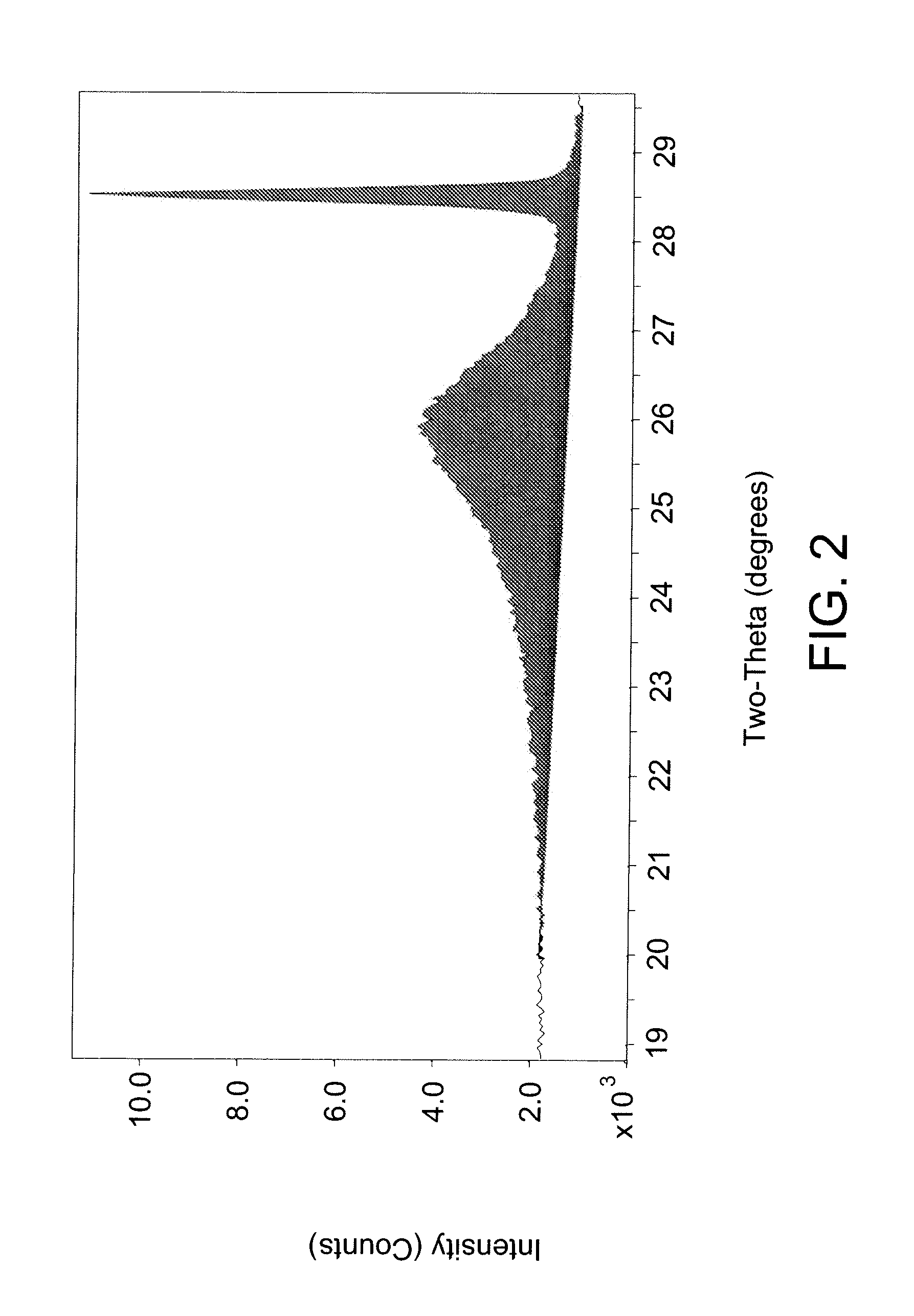

Process for Using Hydrated Iron Oxide and Alumina Catalyst for Slurry Hydrocracking

A process and apparatus is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a catalyst comprising iron oxide and alumina to form a heavy hydrocarbon slurry and hydrocracked to produce lighter hydrocarbons. Performance of the iron oxide and alumina catalyst is not substantially affected by significant quantities of water on the catalyst.

Owner:UOP LLC

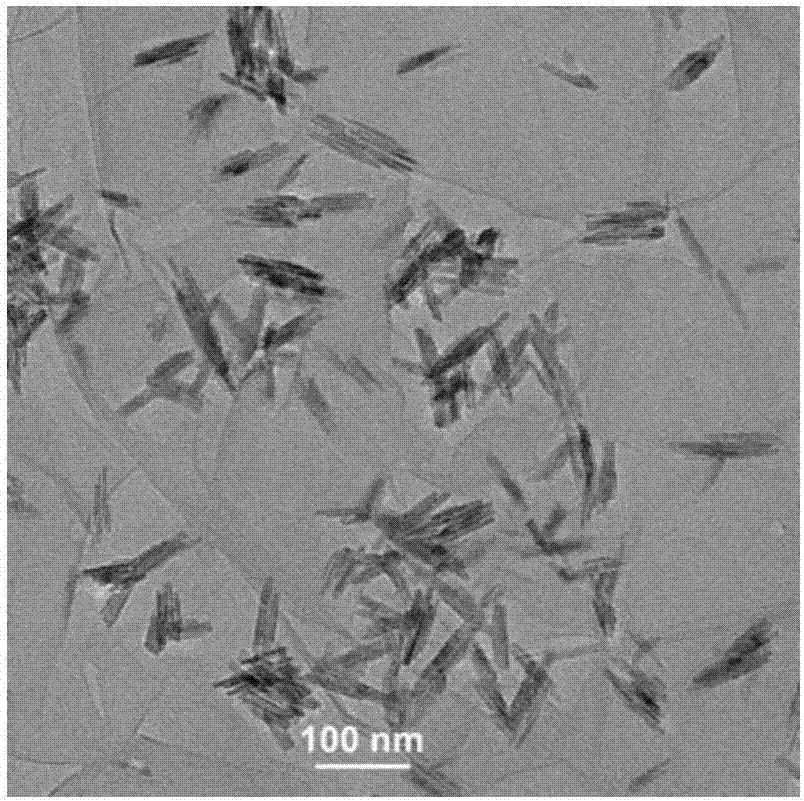

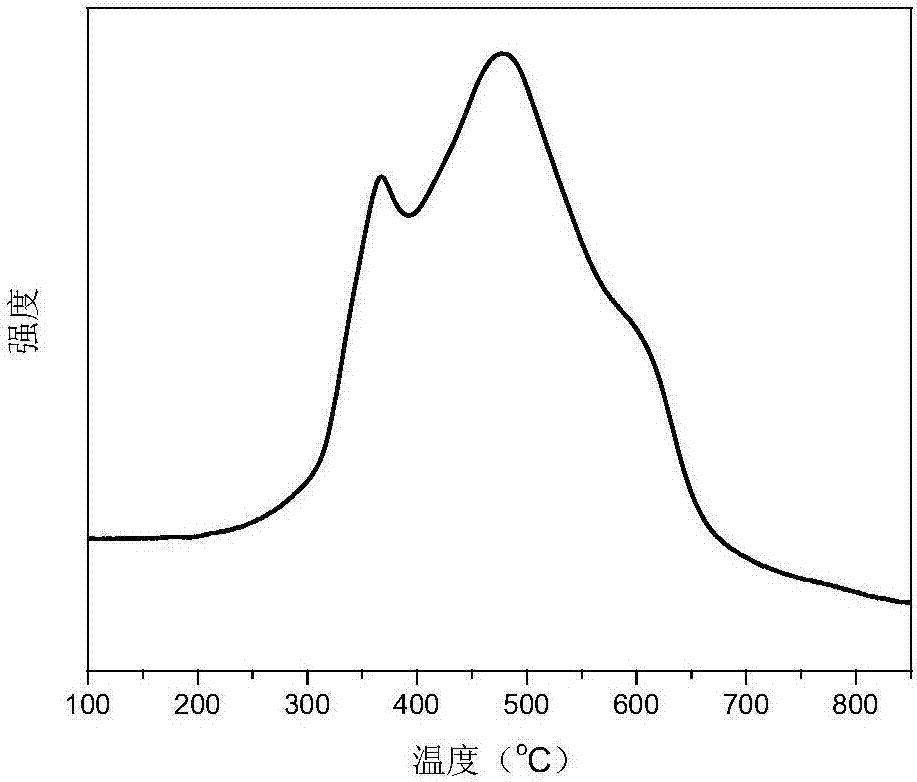

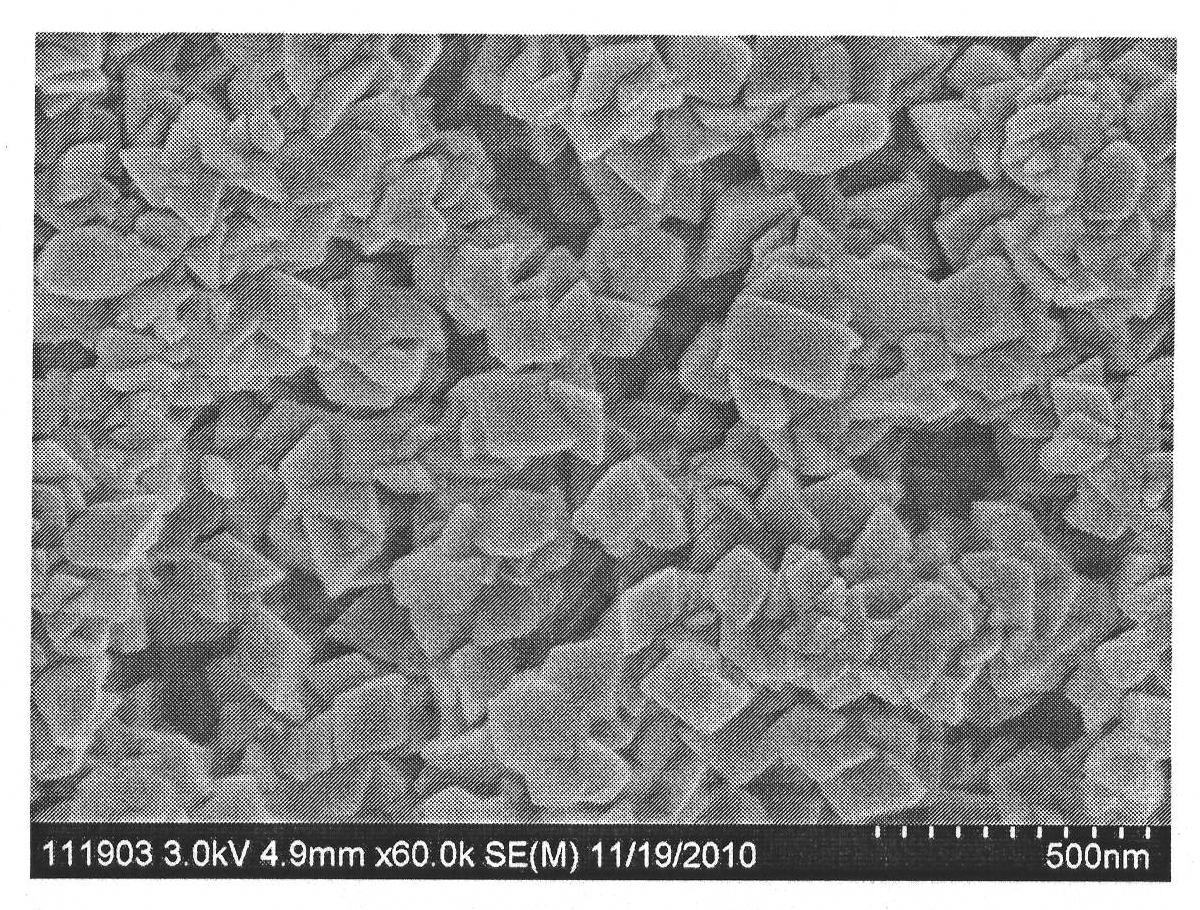

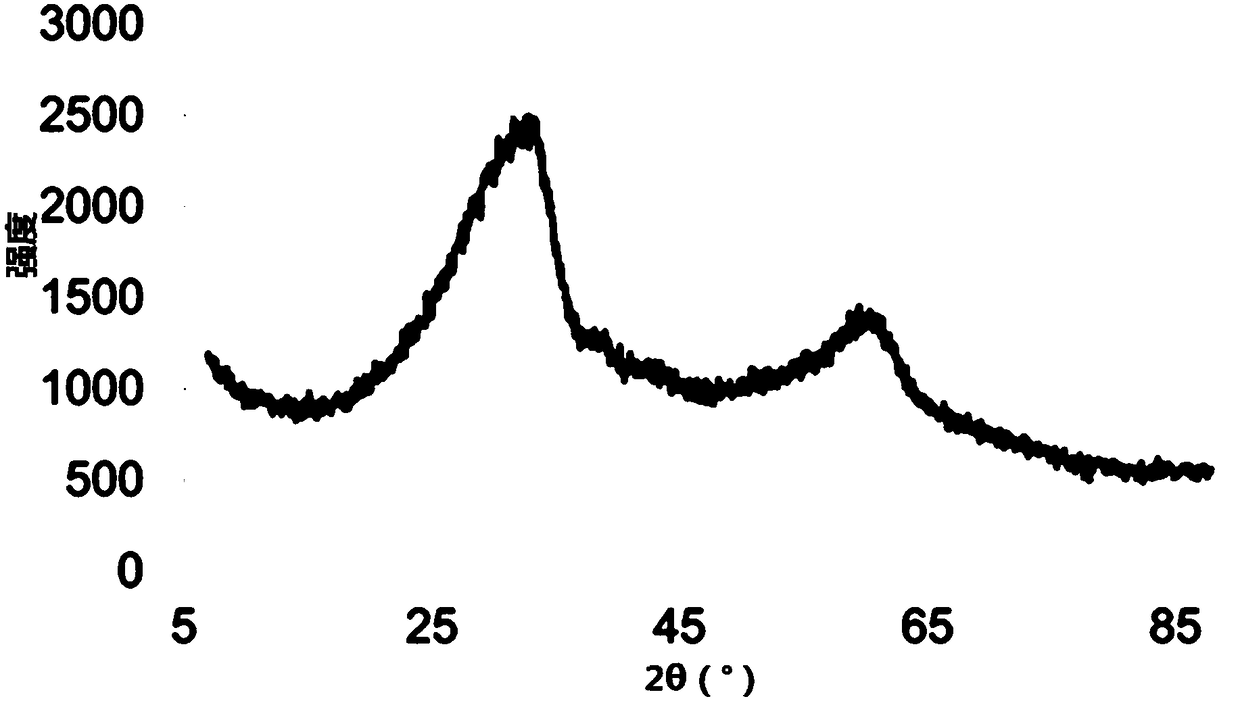

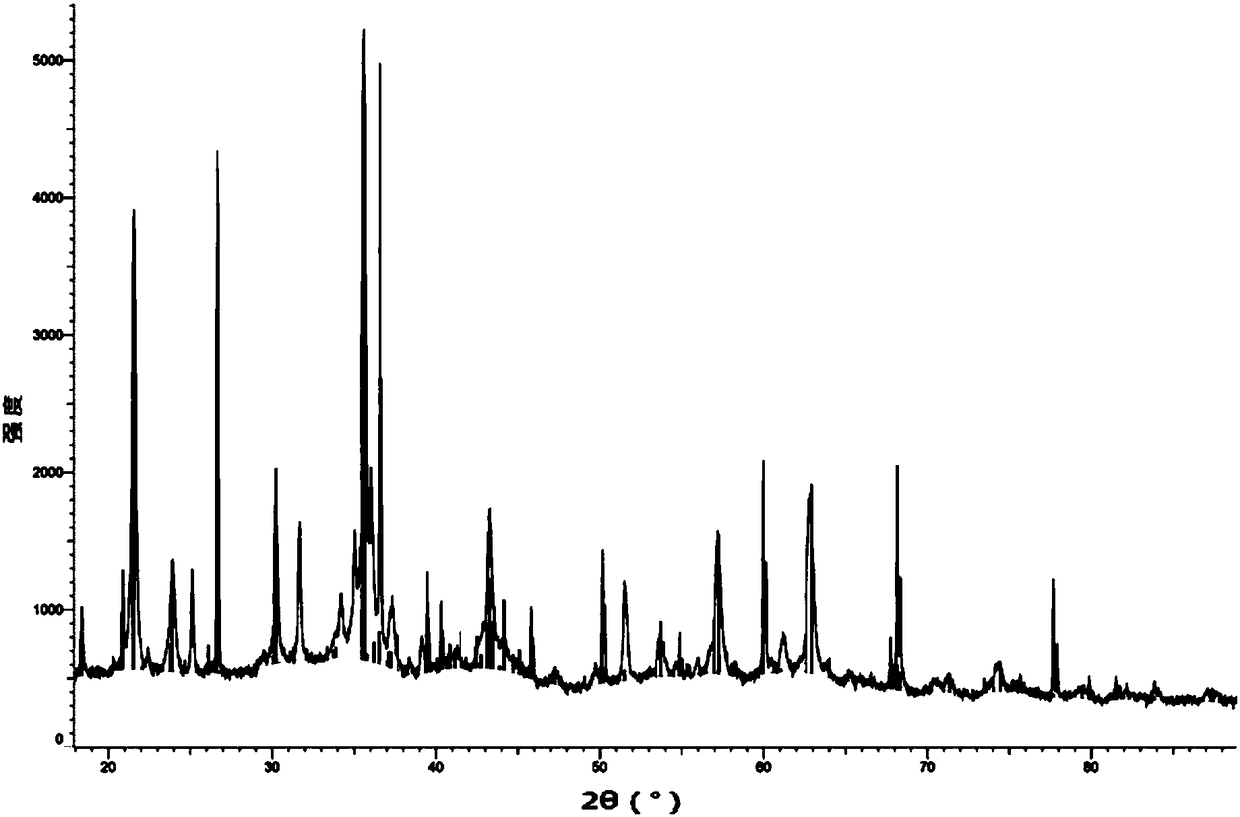

Precipitation iron-based Fischer-Tropsch synthesis catalyst and preparation method thereof

ActiveCN108067234AReduce chemical wearImprove running stabilityHeterogenous catalyst chemical elementsLiquid hydrocarbon mixture productionFerric oxide hydrateSlurry

The invention relates to the field of Fischer-Tropsch synthesis reaction, and discloses a precipitation iron-based Fischer-Tropsch synthesis catalyst and a preparation method thereof. The precipitation iron-based Fischer-Tropsch synthesis catalyst is prepared from Fe, Cu, K, Na and SiO2 according to a weight ratio of 100:(0.1 to 6):(0.6 to 6):(0 to 1):(5 to 24), wherein the Fe mainly exists in thetwo-line hydrated iron oxide phase and is mixed with material phases of alpha-Fe2O3 and gamma-Fe2O3; the Cu, K and Na respectively exist in an oxide form; chemical bond combination Fe-O-Si bridging feature peaks exist between infrared adsorption spectrums 960 to 980 cm<-1>. The precipitation iron-based Fischer-Tropsch synthesis catalyst provided by the invention has higher anti-chemical-abrasionintensity and anti-physical-abrasion intensity. When the catalyst is used for slurry state bed Fischer-Tropsch synthesis reaction, the service life is longer; the selectivity on the long-chain hydrocarbon heavy-weight products (such as C5+ products) is obviously and greatly enhanced; the methane selectivity and the C2 to C4 lighter hydrocarbon product selectivity can be reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Methods for using sulfidized red mud

InactiveUS8236185B2More facile recyclingEffective sorbentDifferential sedimentationLoose filtering material filtersRed mudSorbent

Owner:J I ENTERPRISES

Microbial preparation method of strontium carbonate

InactiveCN104313055AEasy to trainCultivate continuous expansionMicroorganism based processesFermentationSodium bicarbonateSodium lactate

The invention discloses a microbial preparation method of strontium carbonate. The method comprises the following steps: adjusting pH value of a FeCl3 solution to 10-12 by the use of a NaOH aqueous solution at normal temperature by a titration method so as to carry out a precipitation reaction, centrifuging a mixed liquor, removing a supernatant, washing a precipitate with deionized water, and centrifuging to obtain hydrated iron oxide; preparing a reaction liquid containing strontium nitrate, sodium bicarbonate, sodium lactate and hydrated iron oxide by using water as a solvent, inoculating a culture solution which undergoes enlarge culture and contains iron-reducing bacteria to the above reaction liquid, and carrying out an anaerobic reaction at 20-50 DEG C for 2-5d to obtain a solution containing a strontium carbonate precipitate; standing for 1h, filtering, removing a supernatant, washing a white precipitate successively by using distilled water and absolute ethyl alcohol in turns, and drying to prepare a high-purity strontium carbonate powder. By wet-process one-step synthesis, the strontium carbonate powder in different granular sizes and shapes can be prepared, satisfying different purposes.

Owner:NANJING UNIV OF TECH

Method of Sorbing Discolored Organic Compounds from Water

InactiveUS20100243568A1Easy to operateLow costWaste water treatment from quariesSolvent extractionWater useFiltration

Discolored organic compounds (DOC) may be extracted from a medium using a sorbent composition derived by sulfidation of red mud, which contains hydrated ferric oxides derived from the Bayer processing of bauxitic ores. In some aspects, the sorbent composition is slurried with the medium. In other aspects, the sorbent composition is formed into pellets or the like, which are contacted with the medium. The red mud (along with adsorbed contaminants) is then separated from the water using any suitable technique, such as filtration, sedimentation, or centrifugation.

Owner:J I ENTERPRISES

Supported ortho-parahydrogen conversion catalyst and preparation method thereof

ActiveCN112044457AHigh activitySolve easy pulverizationHydrogenCatalyst activation/preparationPtru catalystPhysical chemistry

The invention relates to an ortho-parahydrogen conversion catalyst used for a liquid hydrogen production and storage device and a preparation method thereof, in particular to a preparation method of asupported ortho-parahydrogen conversion catalyst in which a metal active substance is supported on the surface of a non-metal modified porous carrier. The preparation method of the supported catalystis simple in process, the prepared supported catalyst is high in strength and uniform in particle, catalyst bed flow resistance is effectively reduced, and the acidity of the surface of the porous carrier can be adjusted after the surface of the porous carrier is modified by non-metal ions. The subsequent metal oxide can be more uniformly attached to the surface of the catalyst, so that the activity of the catalyst is remarkably improved compared with that of a traditional ferric oxide hydrate catalyst.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com