Precipitation iron-based Fischer-Tropsch synthesis catalyst and preparation method thereof

A technology for synthesis of catalysts and tropes, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, heterogeneous catalyst chemical elements, etc., can solve the problem of low selectivity of long-chain hydrocarbon products, low wear resistance, easy wear, etc. problems, to achieve the effect of reducing overall operating costs, good physical wear performance, and avoiding structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The present invention also provides a slurry-bed Fischer-Tropsch synthesis method, which comprises: performing Fischer-Tropsch synthesis reaction on synthesis gas containing CO and hydrogen in the presence of the above-mentioned precipitated iron-based Fischer-Tropsch synthesis catalyst.

[0070] The Fischer-Tropsch synthesis reaction can be implemented in a conventional slurry bed reactor. The conditions of the Fischer-Tropsch synthesis reaction can adopt conventional Fischer-Tropsch synthesis reaction conditions.

[0071] Technical effect of the present invention is as follows:

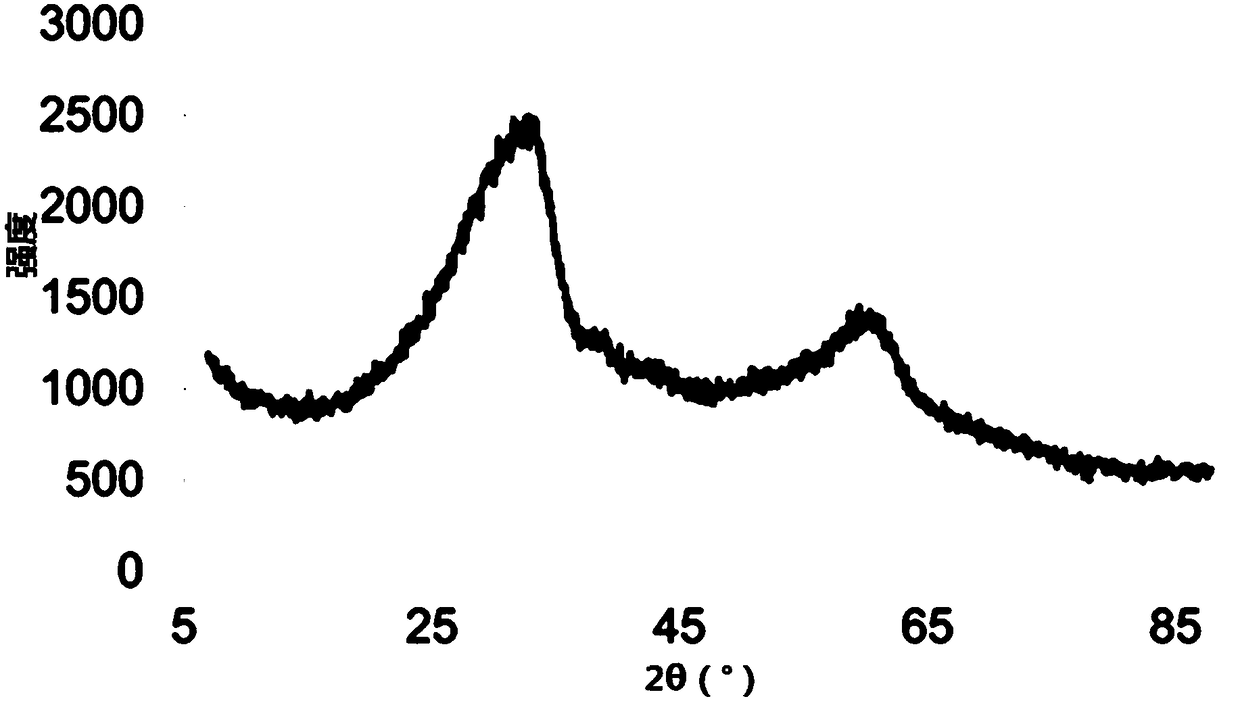

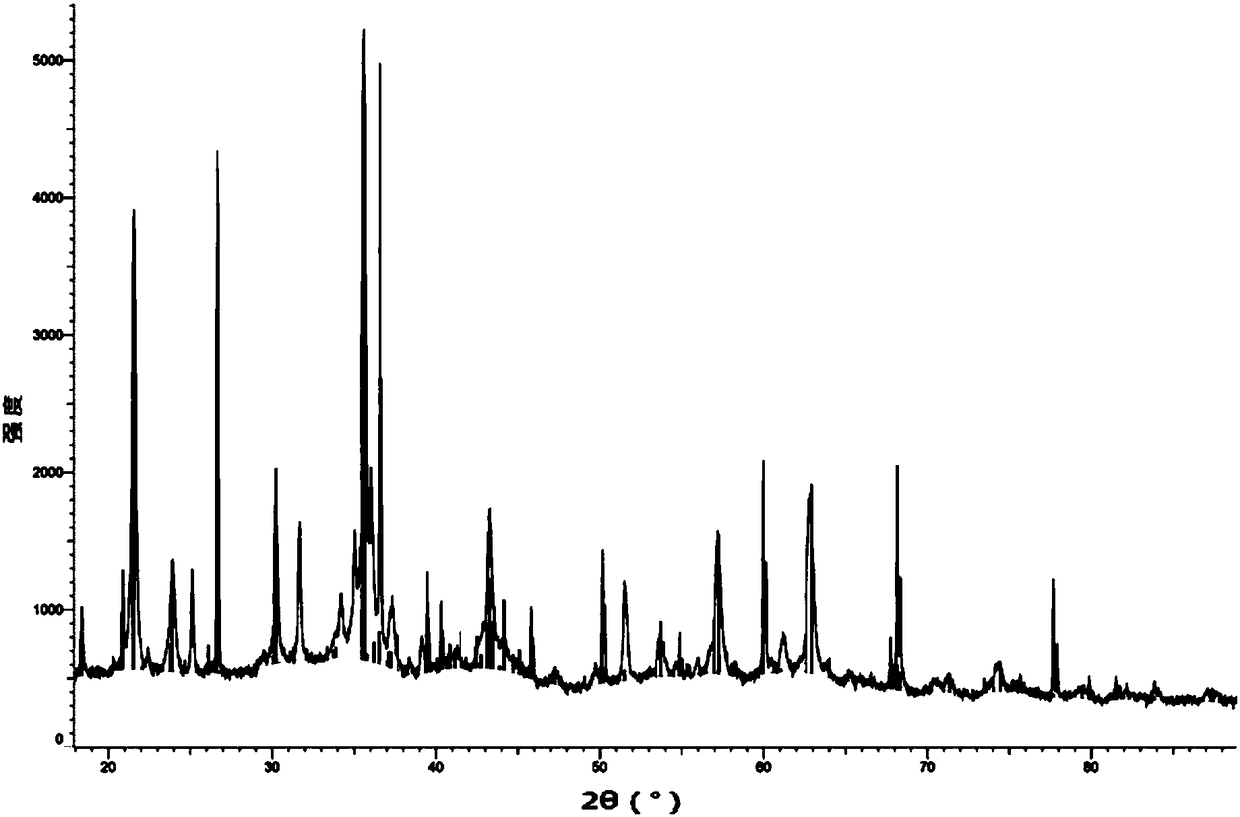

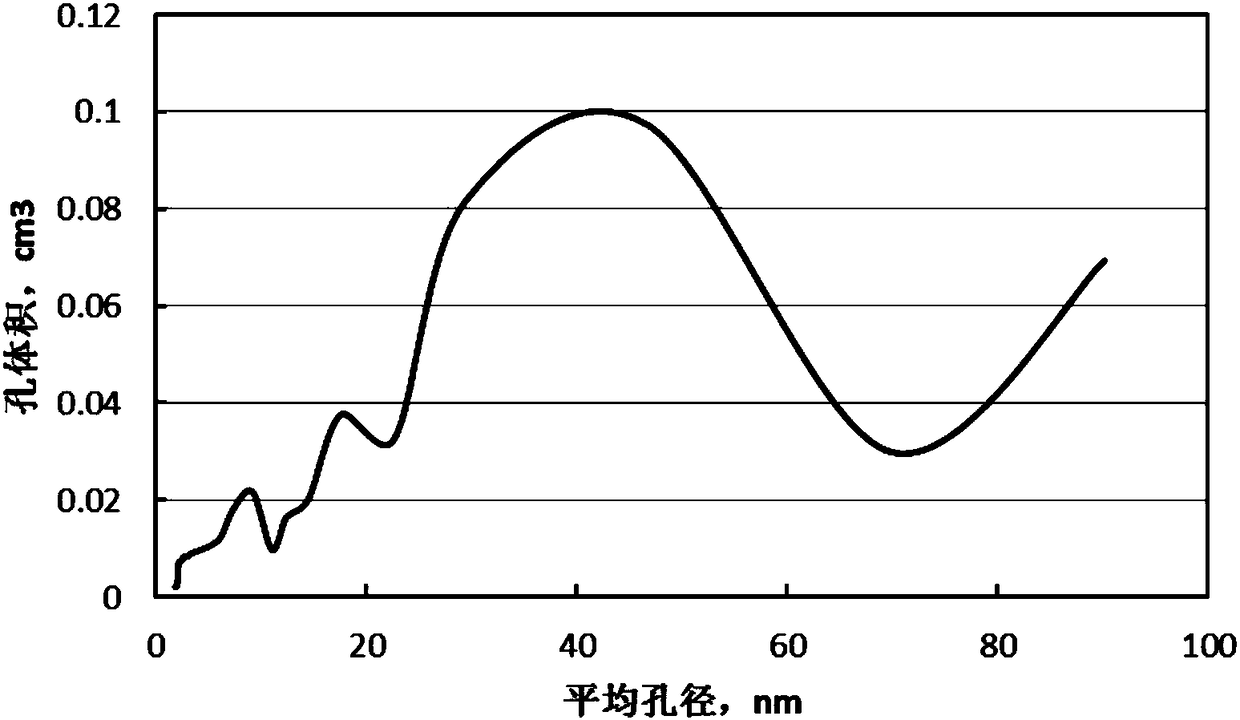

[0072] (1) The phase structure of the precipitated iron-based Fischer-Tropsch synthesis catalyst is mainly two-line hydrated iron oxide, mixed with a maghemite phase, and has between 960-980 / cm-1 in the infrared absorption spectrum The Fe-O-Si bridging characteristic peaks combined with chemical bonds greatly enhanced the dispersion of Fe species grains in the fresh catalyst samples.

[007...

Embodiment 1

[0088] This example is used to illustrate the precipitated iron-based Fischer-Tropsch synthesis catalyst provided by the present invention and its preparation method.

[0089] Weigh 22kg Fe(NO 3 ) 3 9H 2 O and 0.34kg Cu(NO 3 ) 2 ·3H 2 O, add 75L of deionized water and stir to dissolve, fully stir to obtain a mixed solution of iron salt and copper salt. Weigh 11kg Na 2 CO 3 (sodium source and precipitation agent) and 0.34kg potassium-containing silica sol (silicon content is 25.3% by weight, the first potassium source and the first silicon source), add 50L deionized water stirring and dissolving to obtain sodium source, the first potassium source, the second A mixed solution of silicon source and precipitant. The above two mixed solutions are respectively heated to above 65°C by means of jacket heating, and are respectively fed into the vigorously stirred precipitation reactor in parallel by using a transfer pump, and coprecipitate is formed through reaction. The volum...

Embodiment 2

[0099] This example is used to illustrate the precipitated iron-based Fischer-Tropsch synthesis catalyst provided by the present invention and its preparation method.

[0100] Weigh 22kg Fe(NO 3 ) 3 9H 2 O and 0.44kg copper nitrate, add 78L deionized water and stir to dissolve, fully stir, obtain the mixed solution of iron salt and copper salt. Weigh 2.2kg Na 2 CO 3 (sodium source and precipitation agent), 8.6kg potassium carbonate (a part of the first potassium source), 2.0kg potassium bicarbonate (another part of the first potassium source) and 0.28kg silica sol (the first silicon source), add 50L to The ionized water is stirred and dissolved to obtain a mixed solution of the sodium source, the first potassium source, the first silicon source and the precipitating agent. The above two mixed solutions were heated to above 55°C by means of jacket heating, respectively, and fed into the vigorously stirred precipitation reactor in parallel by using transfer pumps, and copre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com