A kind of method for preparing organic amine from synthesis gas

An organic amine and synthesis gas technology, applied in the preparation of amino compounds, organic compounds, organic chemistry, etc., can solve the problems of many side reactions, low conversion rate, and limited product types, etc., to reduce chemical wear and increase selectivity , to avoid the effect of phase transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

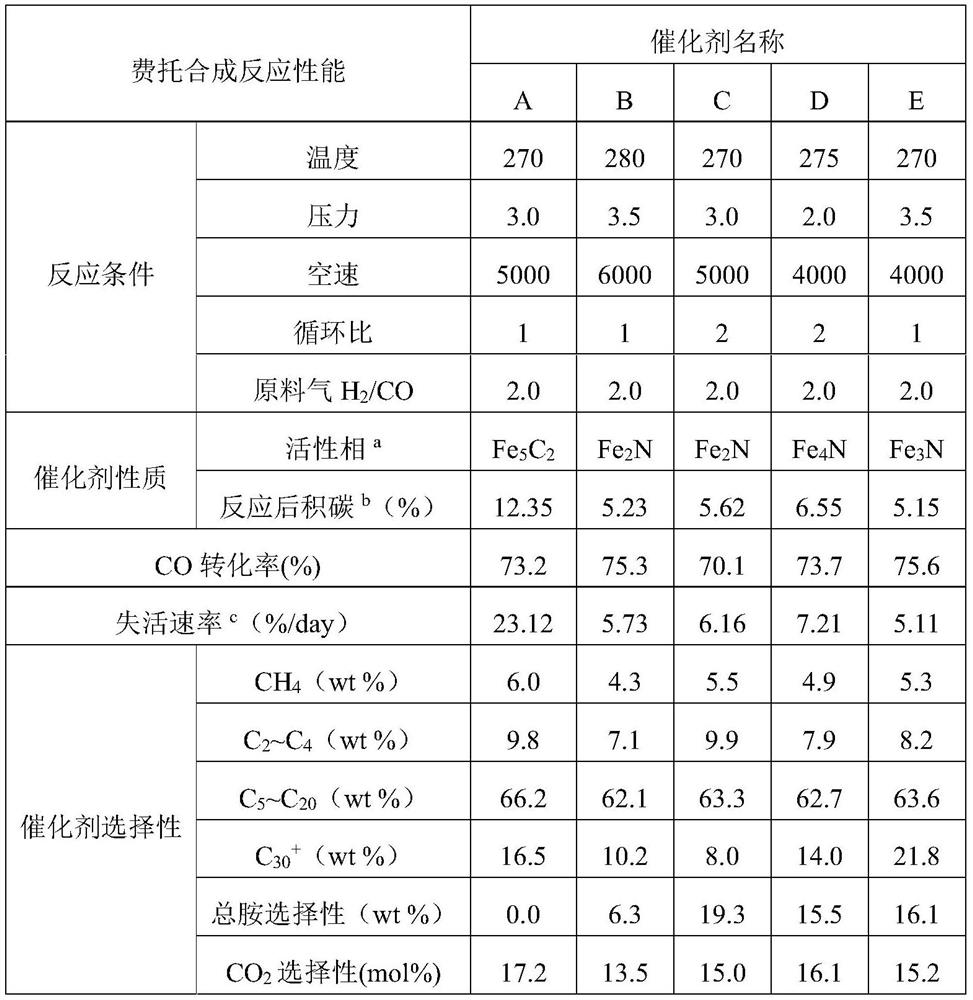

Examples

Embodiment 1

[0071] (1) prepare iron-based catalyst filter cake;

[0072] Weighing 10.0 kilograms of iron nuggets, 0.30 kilograms of electrolytic copper and dissolving with nitric acid to obtain a mixed nitrate solution with a concentration of 10.00wt% for subsequent use, it consists of: Fe:Cu=100:3.00 (mass ratio); 3.33 kg of 30wt% silica sol and 5.72 kg of boric acid were added to the above mixed nitrate solution, fully stirred; and the temperature was raised to 80°C; a certain amount of ammonia solution with a concentration of 5.5wt% was taken, preheated to 70°C, and in a state of stirring co-precipitate continuously at 80°C and pH 6.0; age for 5 minutes after precipitation, wash with deionized water, and filter to obtain a filter cake with a solid content of 16.5%; the content of Fe and ammonium nitrate in the filter cake meets The following relationship: Fe:NH 4 NO 3 =100:21 (mass ratio);

[0073] (2) in the filter cake prepared by step (1), add deionized water to adjust solid cont...

Embodiment 2

[0078] (1) prepare iron-based catalyst filter cake;

[0079]Weighing 10.0 kilograms of iron nuggets, 0.30 kilograms of electrolytic copper and dissolving with nitric acid to obtain a mixed nitrate solution with a concentration of 10.00wt% is for subsequent use, and its composition is: Fe:Cu=100:3.00 (mass ratio); 3.33 kg of 30wt% silica sol, 4.58 kg of boric acid, and 0.92 kg of ammonium molybdate tetrahydrate were added to the above mixed nitrate solution, fully stirred; Heat to 70°C, co-precipitate continuously at 80°C and pH 6.0 under stirring; age for 5 minutes after precipitation, wash with deionized water, and filter to obtain a filter cake with a solid content of 16.5%; filter cake The content of Fe and ammonium nitrate satisfies the following relationship: Fe:NH 4 NO 3 =100:21 (mass ratio);

[0080] (2) in the filter cake prepared by step (1), add deionized water to adjust solid content to 13.5%, then add 1.79 kilograms of potassium bicarbonate, 38.0 kilograms of me...

Embodiment 3

[0085] (1) prepare iron-based catalyst filter cake;

[0086] Weighing 10.0 kilograms of iron nuggets, 0.20 kilograms of electrolytic copper and dissolving with nitric acid to obtain a mixed nitrate solution with a concentration of 10.00wt% is for subsequent use, and its composition is: Fe:Cu=100:2.00 (mass ratio); 3.33 kg of 30 wt % silica sol and 2.02 kg of ammonium metatungstate hydrate were added to the above mixed nitrate solution, fully stirred; and heated to 80 ° C; a certain amount of ammonia solution with a concentration of 5.5 wt % was taken and preheated to 70 ℃, continuous co-precipitation at 80 ℃ and pH value of 6.0 under stirring; aging for 5 minutes after precipitation, washing with deionized water, and filtration to obtain a filter cake with a solid content of 16.5%; Fe and Fe in the filter cake The content of ammonium nitrate satisfies the following relationship: Fe:NH 4 NO 3 =100:21 (mass ratio);

[0087] (2) in the filter cake prepared by step (1), add dei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com