Patents

Literature

74results about How to "Low use value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel high-efficiency biological fish manure

InactiveCN102047857AImprove water qualityPromote rapid growth and reproductionClimate change adaptationAnimal feeding stuffEcological environmentPhosphate

The invention relates to aquaculture biological fish manure, in particular to novel high-efficiency biological fish manure for various aquacultures. The fish manure is prepared from the following raw materials in parts by weight: 17.5 to 70 parts of ammonium chloride, 10 to 40 parts of monoammonium phosphate, 7.5 to 30 parts of calcium superphosphate, 12 to 48 parts of organic matters, 0.5 to 2 parts of bacillus, and 2.5 to 10 parts of humic acid. The fish manure is prepared by selecting more than twenty types of major and trace element inorganic fertilizers with comprehensive nutrition and organic fertilizers which can be easily absorbed, is rich in more than twenty types of major and trace elements and various amino acids, vitamins, polysaccharide, nucleic acids, humic acid and the like, and is fermented by 81 beneficial microorganisms in five major groups of microorganisms existing in the whole ecosystem. The fermented free-state nutritional substances are advantageous to absorption and utilization, so that the nutrition balance of a water body is ensured. By application, a small ecological environment is formed, so the biological fish manure is particularly suitable for growing and breeding of plankton which facilitates aquaculture.

Owner:YUEYANG SHENLI BIOTECH

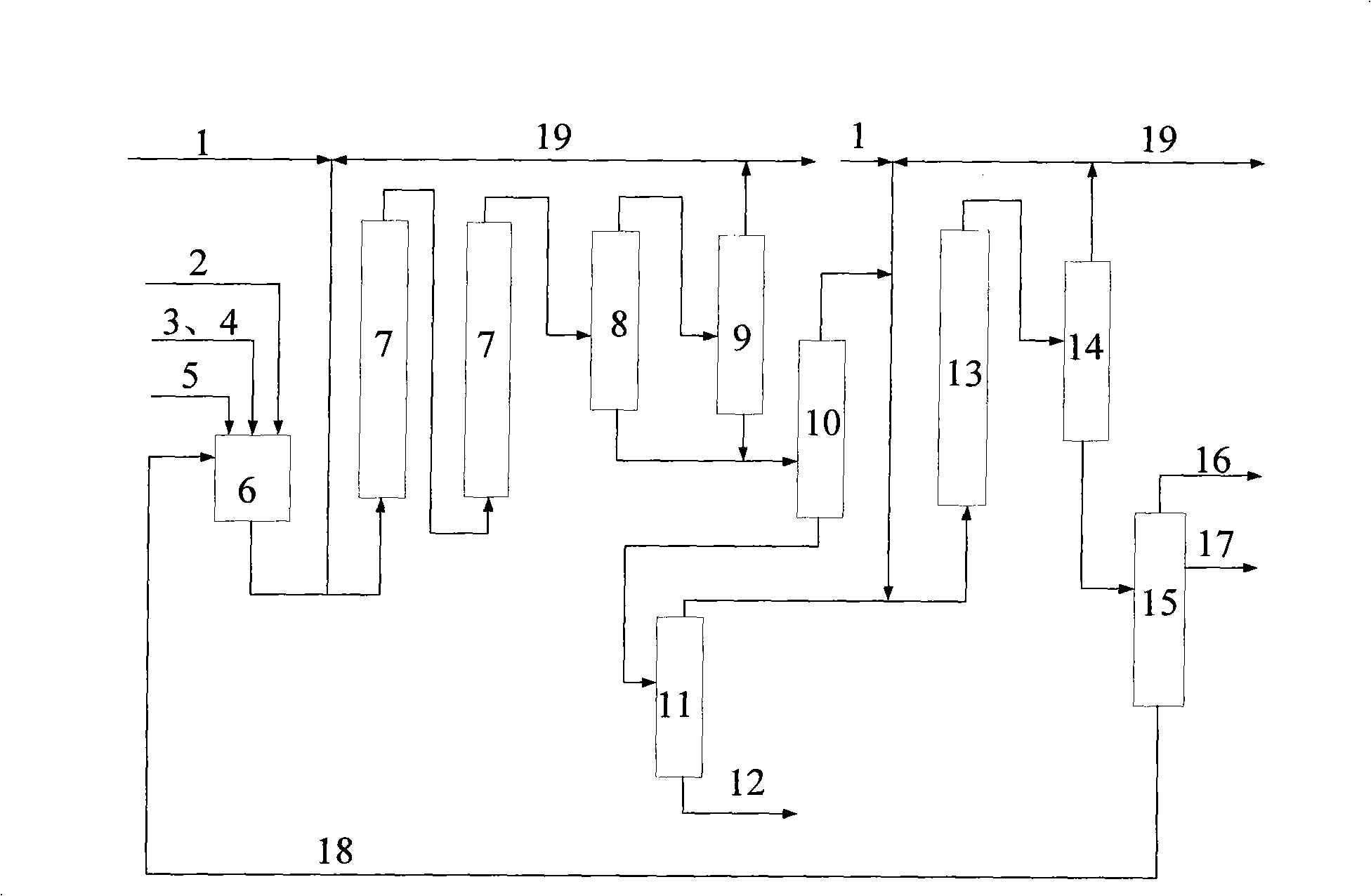

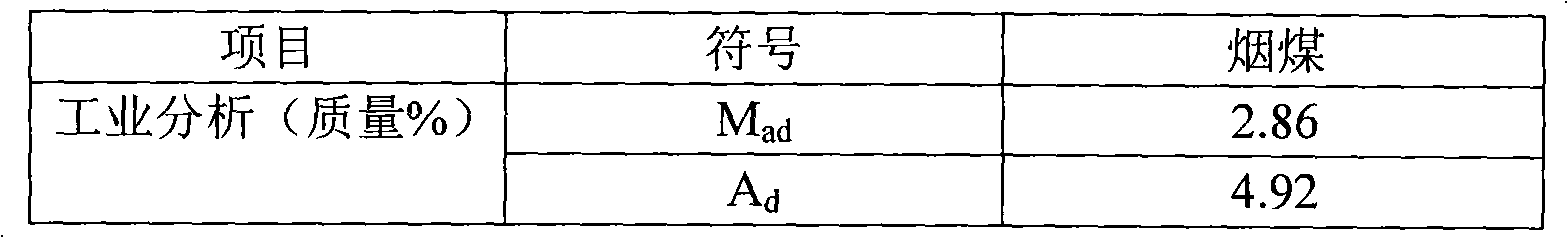

Direct liquefaction process of coal by replacing circling solvent with petroleum or petroleum refining byproduct

ActiveCN101333448AWide range of sources and cheapLow use valueLiquid hydrocarbon mixture productionCoal conversionSolvent

The invention relates to a coal direct liquefaction method using petroleum or petroleum refining byproducts to replace a cycling solvent, which comprises processes of: replacing or partially replacing the traditional coal liquefied cycling solvent by low quality petroleum with high metal and asphaltene content and heavy oil, as well as petroleum refining byproducts such as catalytic cracking heavy recycle stock, clarified oil and outside throwing slurry oil, preparing coal slurry by co-catalyst sulfur and high-activity Gamma-hydrated iron oxide type liquefaction catalyst, then implementing the coal direct liquefaction and hydrogenation, finally obtaining light and medium distillate oil, the coal conversion is increased by 1 percent to 5 percent, the yield of generated oil products is increased by 5 percent to 40 percent, the sedimentation and coking in a reactor are reduced, also the utilization value of low value-added petroleum and petroleum refining byproducts is greatly increased, and economic benefits of coal direct liquefaction are increased. The method can be widely used for coal direct liquefaction.

Owner:CCTEG CHINA COAL RES INST

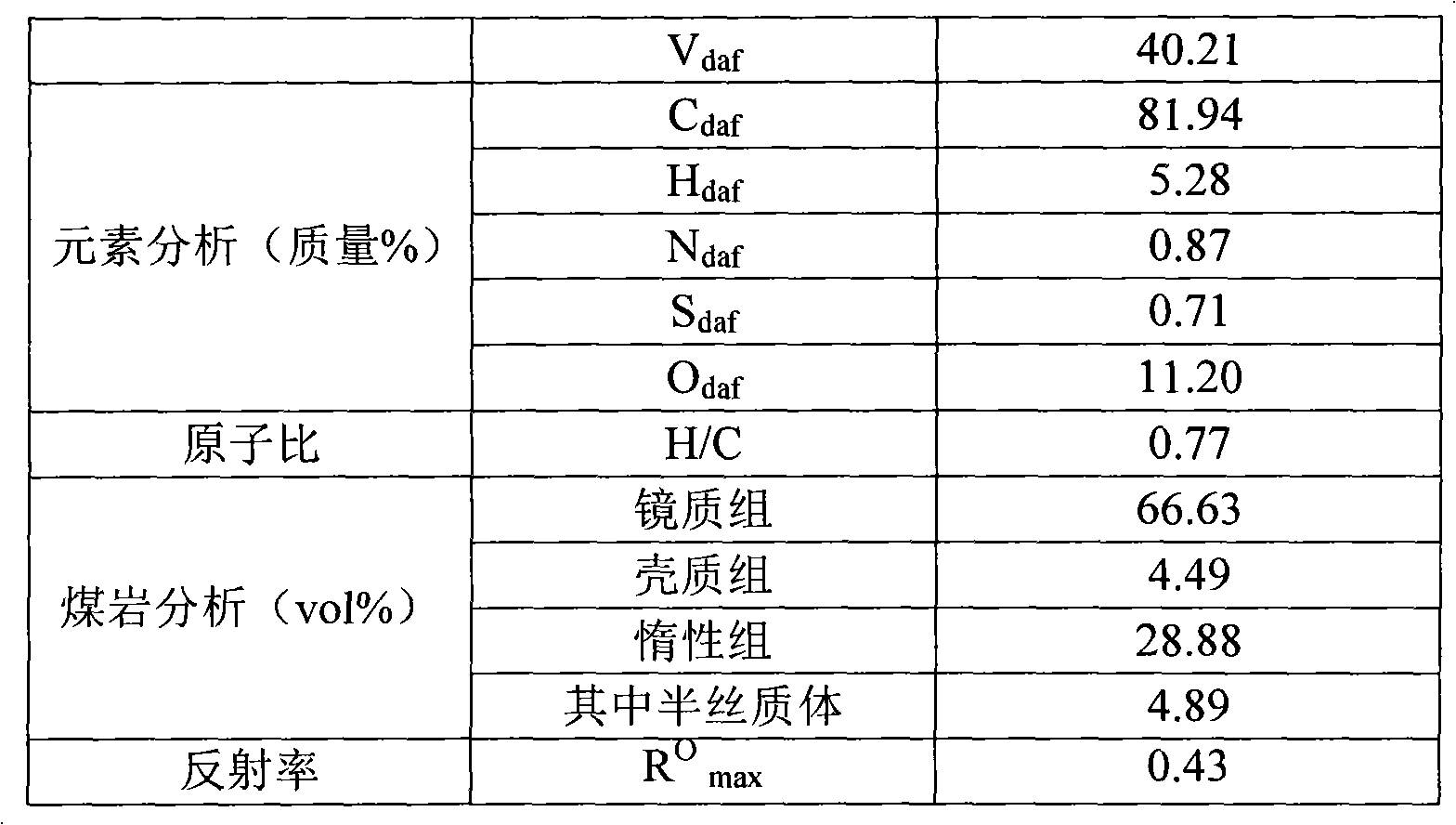

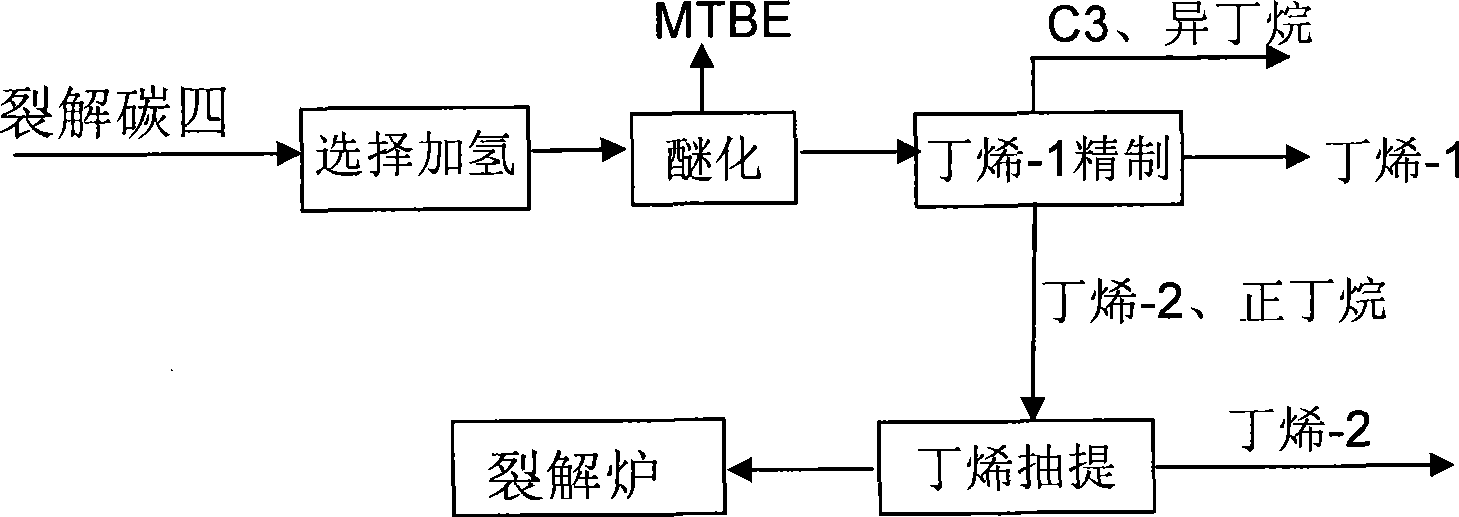

Method for comprehensive utilization of cracking C4

ActiveCN101475429ATake advantage ofIncrease productionHydrocarbon by hydrogenationDistillation purification/separationHydrogenation reactionEconomic benefits

The invention discloses a method for comprehensively utilizing cracking carbon four. The method comprises: firstly, the cracking carbon four is subjected to selective hydrogenation reaction so that acetylene hydrocarbon and diene in the cracking carbon four are subjected to selective hydrogenation to generate mono-olefine; secondly, isobutene in the cracking carbon four reacts to generate methyl tertiary butyl ether by an etherification device; a methyl tertiary butyl ether product and a material mainly comprising butylene-1, butylene-2 and butane are obtained through separation; the materialcomprising the butylene-1, butylene-2 and butane is introduced to a butylene-1 refining system to obtain a butylene-1 product, a material containing carbon three and isobutene and a material mainly containing butylene-2 and n-butane through separation; the material mainly containing the butylene-2 and n-butane is treated to remove the butylene-2 so as to obtain a material containing the n-butane;and the material containing the n-butane is returned to a cracking furnace and is used as raw material. The method adopts selective hydrogenation, full hydrogenation, etherification, rectification, extraction and other combined technologies to fully utilize each component of the cracking carbon four, thereby obtaining largest economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid-liquid enrichment separation method for tobacco sheet wastewater in paper-making method

InactiveCN101731736ATargetedRapid phase separationTobacco preparationSludge treatment by de-watering/drying/thickeningSolid phasesPesticide

The invention relates to a solid-liquid enrichment separation method for tobacco sheet wastewater in a paper-making method. Nicotine and other components in the wastewater are enriched to a solid phase for separation, wherein the COD removal rate in single-stage separation can reach 70-80 percent; and then a biomedical forced aerobic method or anaerobic / aerobic method are adopted to treat, reuse or discharge the treated water, and the sludge solid can be reused. The solid-liquid enrichment separation method comprises the following steps: blocking slag by grilling; performing coagulation and enrichment reaction; settling; performing subsequent treatment clear water on an upper layer; concentrating sludge solid, and other steps. The solid-liquid enrichment separation method has the advantages that: the prepared calcium-magnesium compound coagulants are easily prepared and can be prepared into quality-grading formulations aiming at fluctuation of the wastewater; the obtained sludge solidobtained by separation is rich in nicotine and other components which can be subsequently extracted as active ingredients of biogenic pesticides; the extracted dry soil powder can be totally used as loading agents of powder pesticides; and special treatment facilities and equipment are unnecessarily used, and the investment and operating cost of biochemical facilities can be reduced simultaneously.

Owner:WUHAN TEXTILE UNIV

Method for preparing sea cucumber glycoprotein by using sea cucumber blanching solution

ActiveCN102406048AOvercome costsImprove use valueProtein composition from fishUltrafiltrationCentrifugation

The present invention relates to a method for preparing sea cucumber glycoprotein by using a sea cucumber blanching solution. The method comprises that: a sea cucumber blanching solution is adopted as a raw material, and is subjected to treatments of reduced pressure condense, alcohol precipitation, drying to prepare into powder; the powder is subjected to treatments of alcohol leaching and desalination, and then is redissolved in purified water; the resulting solution is subjected to treatments of enzymolysis and centrifugation; the resulting supernatant is subjected to treatments of tube ultrafiltration, ultrafiltration and drying to obtain the sea cucumber glycoprotein product. The preparation method of the present invention has characteristics of low equipment investment, simple operation, short production period, high yield and low product cost. The prepared sea cucumber glycoprotein has good biological activity.

Owner:SHANDONG HOMEY AQUATIC DEV +1

Novel chain-throwing blowing and cleaning device for anode scrap electrolyte

InactiveCN103831273ALow costImprove efficiencyCleaning using gasesEngineeringUltimate tensile strength

The invention provides a novel chain-throwing blowing and cleaning device for anode scrap electrolyte. The device comprises a roller type chain-throwing cleaning part, a fixed rack and a blowing part, wherein the roller type chain-throwing cleaning part is fixedly connected with the fixed rack; the blowing part is fixedly connected with the fixed rack. Due to the novel chain-throwing blowing and cleaning device for anode scrap electrolyte, the anode scrap electrolyte will be cleaned up, manual residue cleaning through an air pick in the later stage or manual surface blowing operation can be replaced, not only is labor intensity reduced, but also harm to the health of the body of a worker is reduced, running cost of the equipment is low, and production efficiency is greatly improved.

Owner:洛阳宇航重工科技股份有限公司

Low-sulfur heavy bunker fuel oil and preparation method of same

Low-sulfur heavy bunker fuel oil and a preparation method of same. The invention belongs to the technical field of heavy fuel oil. The low-sulfur heavy bunker fuel oil comprises, by weight, 40-65 parts of residual oil, 5-15 parts of catalytic oil slurry, 5-20 parts of styrene tar, 5-20 parts of ethylene tar, 5-20 parts of diesel oil, 0.2-1 part of an additive OP-10, and 0.1-0.5 parts of an additive AES. The preparation method includes: successively adding the styrene tar and diesel, the additive OP-10, the additive AES, the residual oil, and the catalytic oil slurry, and stirring the mixture at medium speed, and adding the ethylene tar and performing high-speed stirring to obtain the fuel oil. The invention solves the problems that the product is liable to generate flocs and to coke duringuse since the styrene tar cannot be uniformly blended with other oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

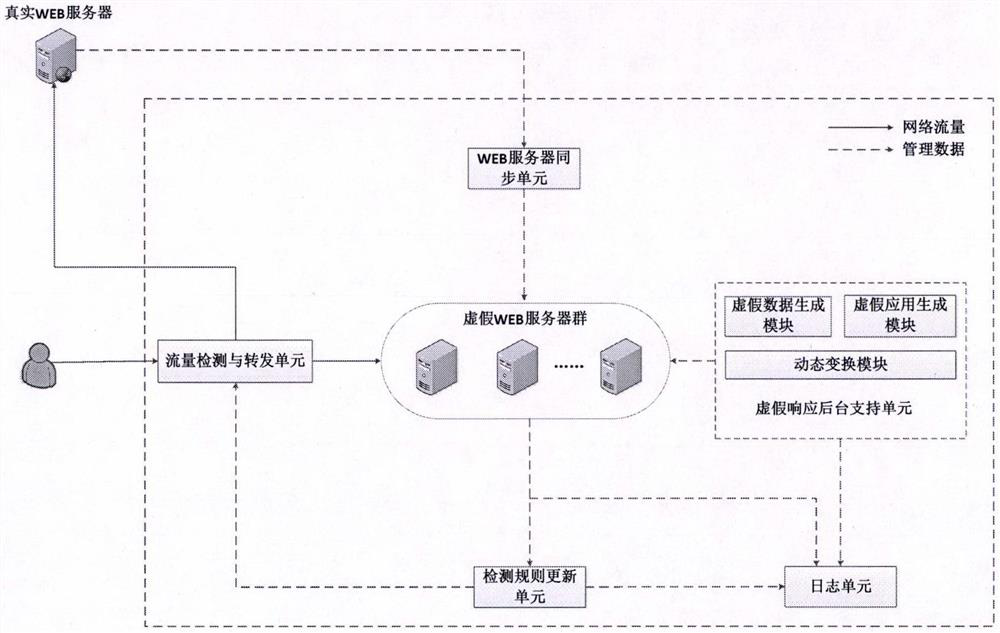

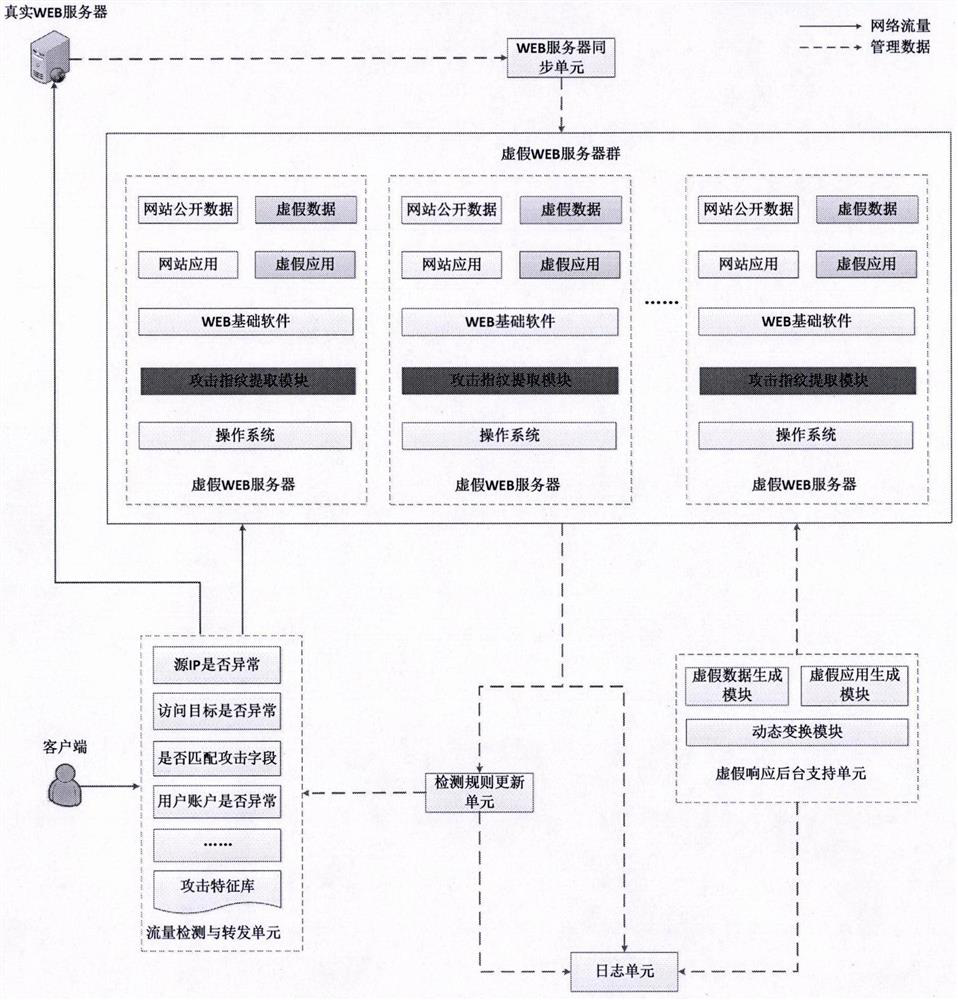

WEB dynamic adaptive defense system and defense method based on false response

The invention provides a WEB dynamic adaptive defense system and defense method based on false response. Based on the concept of moving target defense, a plurality of false WEB servers capable of being dynamically transformed is constructed around a protected WEB server, false sensitive data, false applications, false vulnerabilities and the like are constructed on the false WEB servers, and cheating hackers attack the false WEB servers. When a known attack or a suspicious behavior is identified, the known attack or the suspicious behavior is introduced into the false WEB server, and an attacker enters the false environment and then executes a subsequent attack action in the false environment until the attack is finished, so that multiple attempt attacks of the attacker are effectively defended, and meanwhile, the method has a relatively good defending capability on an unknown WEB attack. Besides, by continuously observing attack behaviors in a false environment, WEB attack features can be automatically extracted, attack detection rules are dynamically and adaptively adjusted, and the dynamic adaptive capacity of a defense system is improved.

Owner:张长河

Method of making mixed oil using cotton seed puffing impregnation process

InactiveCN1869181AImprove qualityIncrease the refining rateFatty-oils/fats productionResidual oilPre treatment

The invention relates to a cotton seed oil mixture manufacturing method by straight leaching. It adopts parts of soybean preprocessing line to make cotton kernel soften, expanding after flaking, and process straight leaching without pre-squeezing and dust removal systems. It has the advantages of little investment and good effect. The phenol content of the post-leaching liberation cotton is less than 0.12%. And the residual oil of the cake is less than 0.5%.

Owner:白长军

Polymethyl methacrylate simulated redwood composite material and preparation method thereof

InactiveCN101791815AHigh strengthHigh hardnessWood treatment detailsCork treatment detailsEconomic benefitsPolymethyl methacrylate

The invention relates to a polymethyl methacrylate simulated redwood composite material and a preparation method thereof. The material is a composite material prepared by using softwood as a substrate and introducing a methyl methacrylate monomer to be soaked into the softwood. The preparation method comprises the following steps of: (1) soaking the softwood in an alkali liquor to perform reflux degreasing; (2) taking out the softwood after the degreasing, refluxing the softwood to remove the alkali liquor, and drying the softwood; (3) in a vacuum state at the normal temperature, soaking the softwood in solution of the methyl methacrylate monomer dissolved with a dye for 0.5 to 10 hours; and (4) putting the softwood into a drying apparatus, and performing polymerization to obtain the polymethyl methacrylate simulated redwood composite material. The polymethyl methacrylate simulated redwood composite material prepared by the method improves the density of woods, reduces the water absorption, the swell-shrink characteristics and the sensitivity to climates of the woods, and improves the dimensional stability and the balance of mechanical properties; besides, the preparation method is simple to operate and has a low cost and high economic benefits.

Owner:DONGHUA UNIV

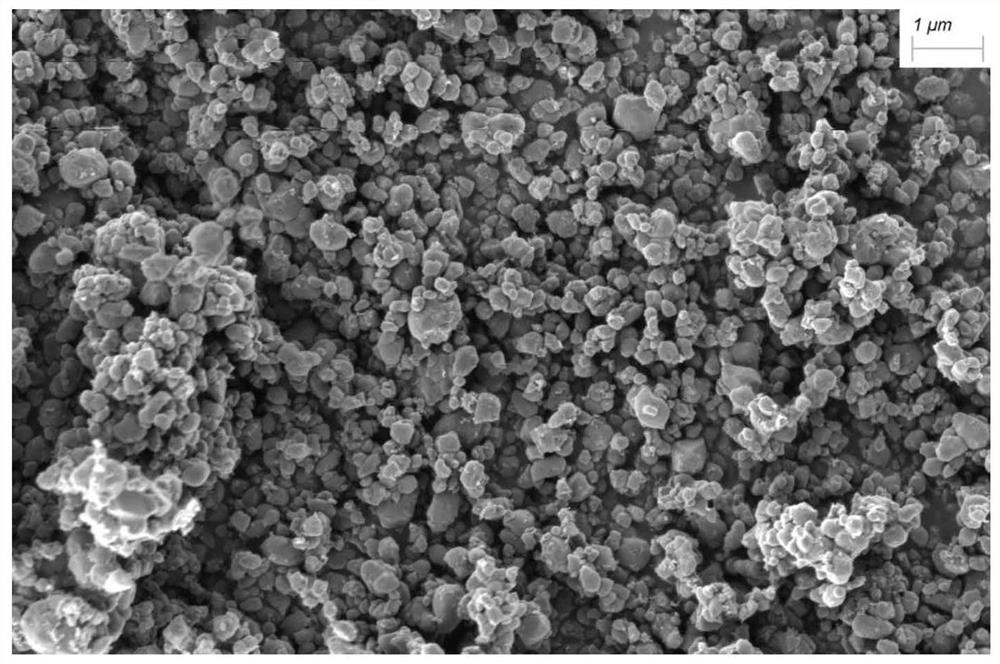

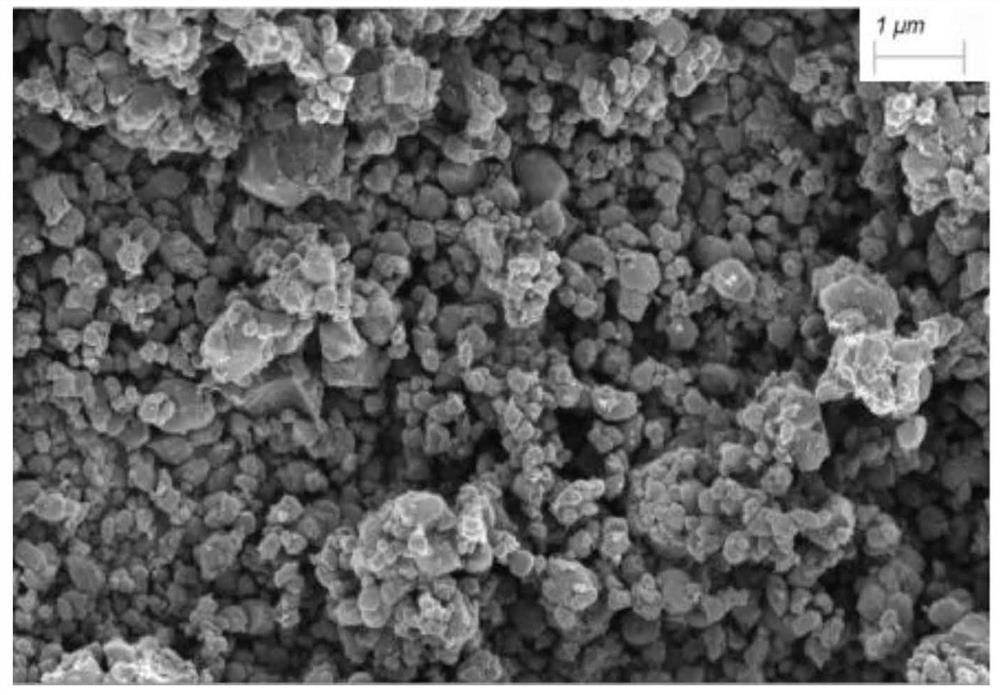

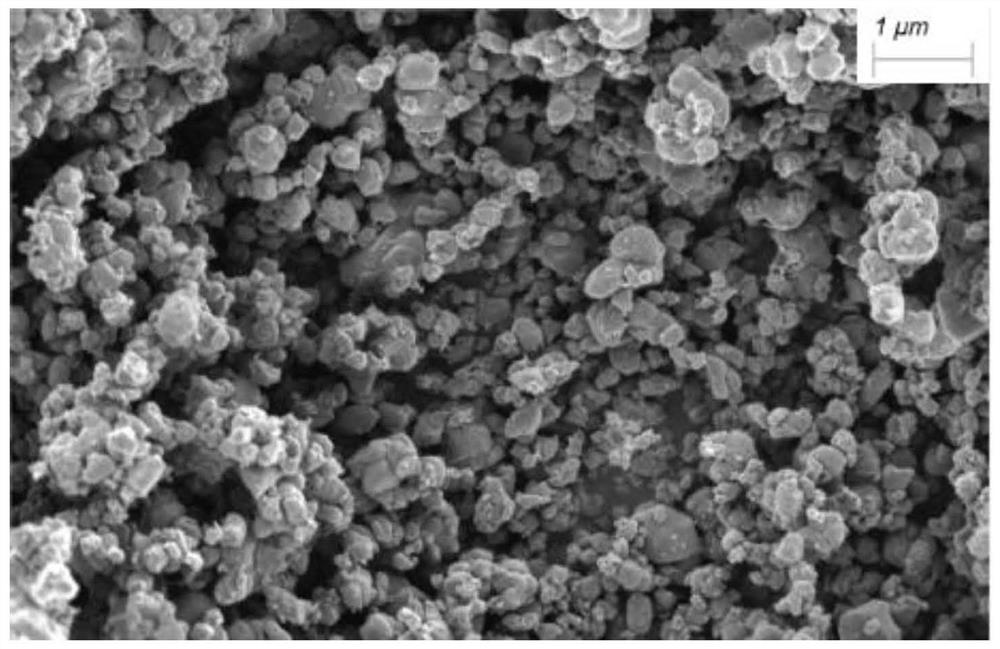

Preparation method of lithium iron phosphate and application thereof

ActiveCN113772650AGood dispersionUniform particle size distributionSecondary cellsPositive electrodesPhosphateElectrical battery

The invention relates to the technical field of preparation of lithium ion battery positive electrode materials, in particular to a preparation method of lithium iron phosphate and an application thereof. The preparation method comprises the following steps: mixing a ferrous sulfate solution and a phosphate solution, carrying out a synthetic reaction, aging the solution after the synthetic reaction, carrying out solid-liquid separation on the aged solution, washing a filter cake, drying, calcining, crushing, screening, and removing iron to obtain a mixture of anhydrous iron phosphate and ferric oxide; sequentially adding the mixture, Li3PO4 and H3PO4 into a glucose solution to obtain mixed slurry, grinding the mixed slurry to obtain nanoscale mixed slurry, and drying the nanoscale mixed slurry to obtain a mixed powder material; and roasting the mixed powder material at the temperature of 700-800 DEG C in a heat preservation manner, and crushing to obtain the lithium iron phosphate. According to the method, one-step synthesis of anhydrous iron phosphate in an inorganic system is realized, the obtained anhydrous iron phosphate is good in dispersity and uniform in particle size distribution, and back-end lithium iron phosphate process control and performance parameter optimization are facilitated.

Owner:河南佰利新能源材料有限公司

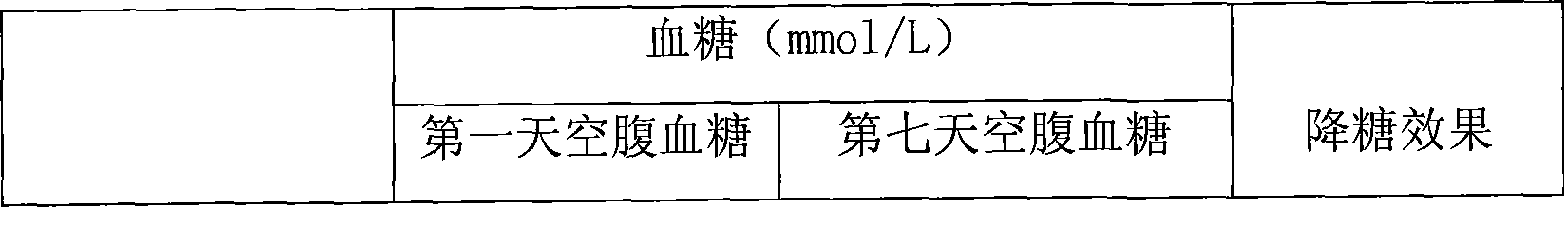

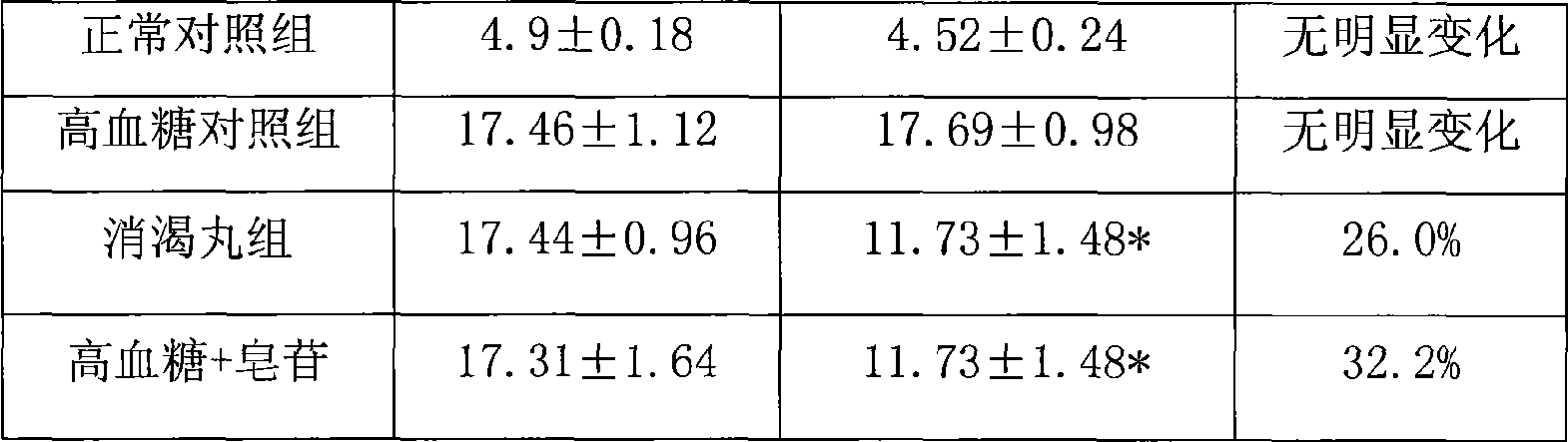

Application of franchet groundcherry calyx or fruit saponin in preparing medicament and health product for treating diabetes

ActiveCN101474291AImprove immunitySignificant hypoglycemic effectMetabolism disorderPlant ingredientsReflux extractionMedicine

The invention belongs to an application in the pharmaceutical field, in particular to the application of wintercherry fruit or calyx persistent calyx saponin in preparing medicines and health products for curing diabetes. In the invention, dry wintercherry fruit or calyx goes through the processes of reflux extraction, concentration, extraction, washing, drying and the like, thus obtaining a crude product of saponin. Through a D-101 type macroporous absorbent resin column, distilled water is adopted for elution, then ethanol solution is adopted for elution, finally the wintercherry fruit or calyx persistent calyx saponin is obtained after the processes of rotary evaporation and lyophilization, etc. The extraction process is simple and the cost is low, the source of materials is wide, adaptability thereof is strong and the materials are extremely easy to be planted manually in a large scale. The product of the invention has the functions of markedly lowering blood sugar level and strengthening immunity, therefore, the product can be applied as the medicine for curing patients suffering from diabetes and as health products for preventing diabetes and improving organism immunity.

Owner:NORTHEAST NORMAL UNIVERSITY

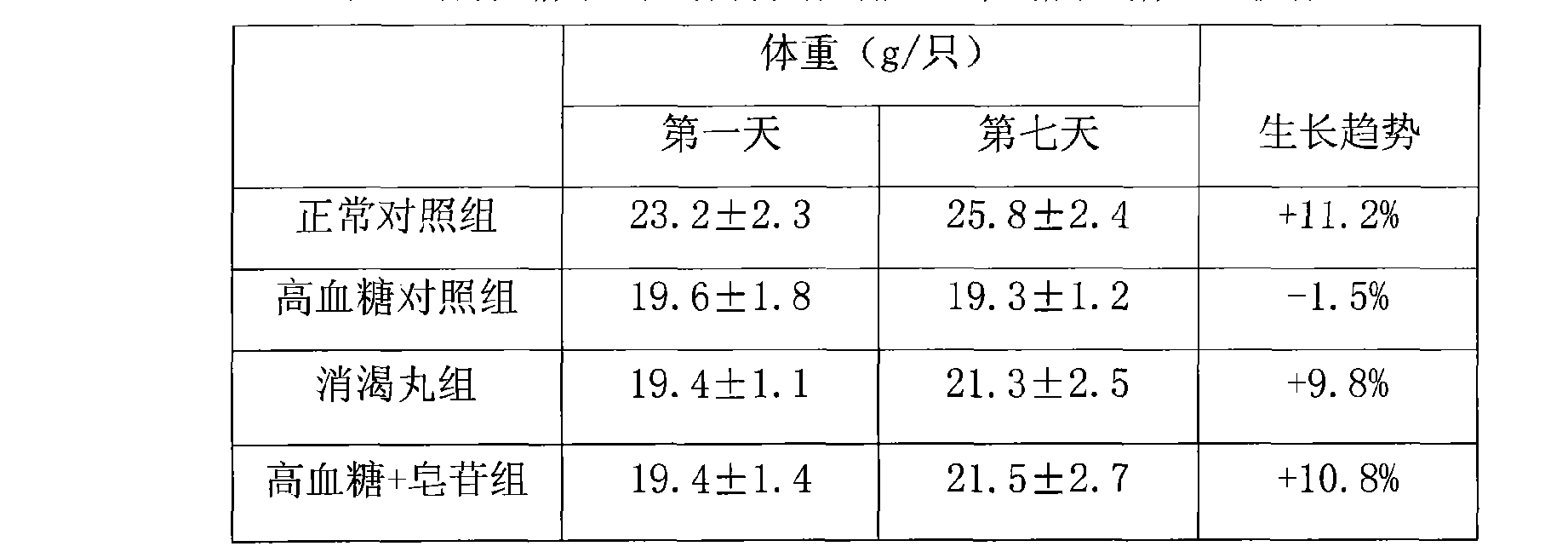

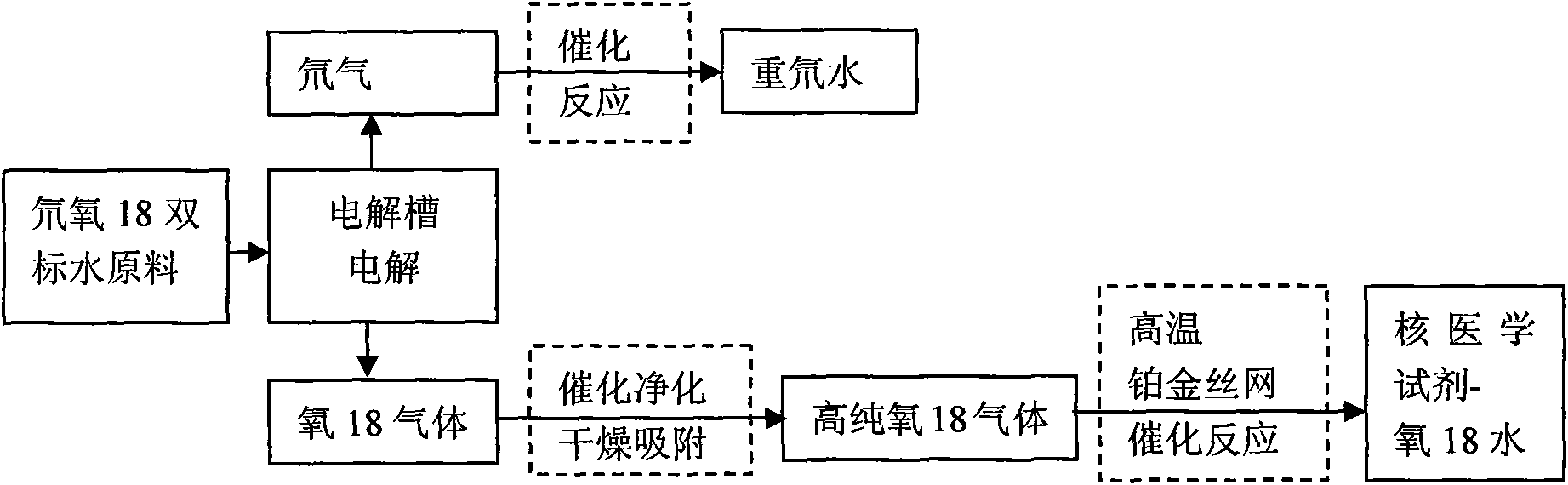

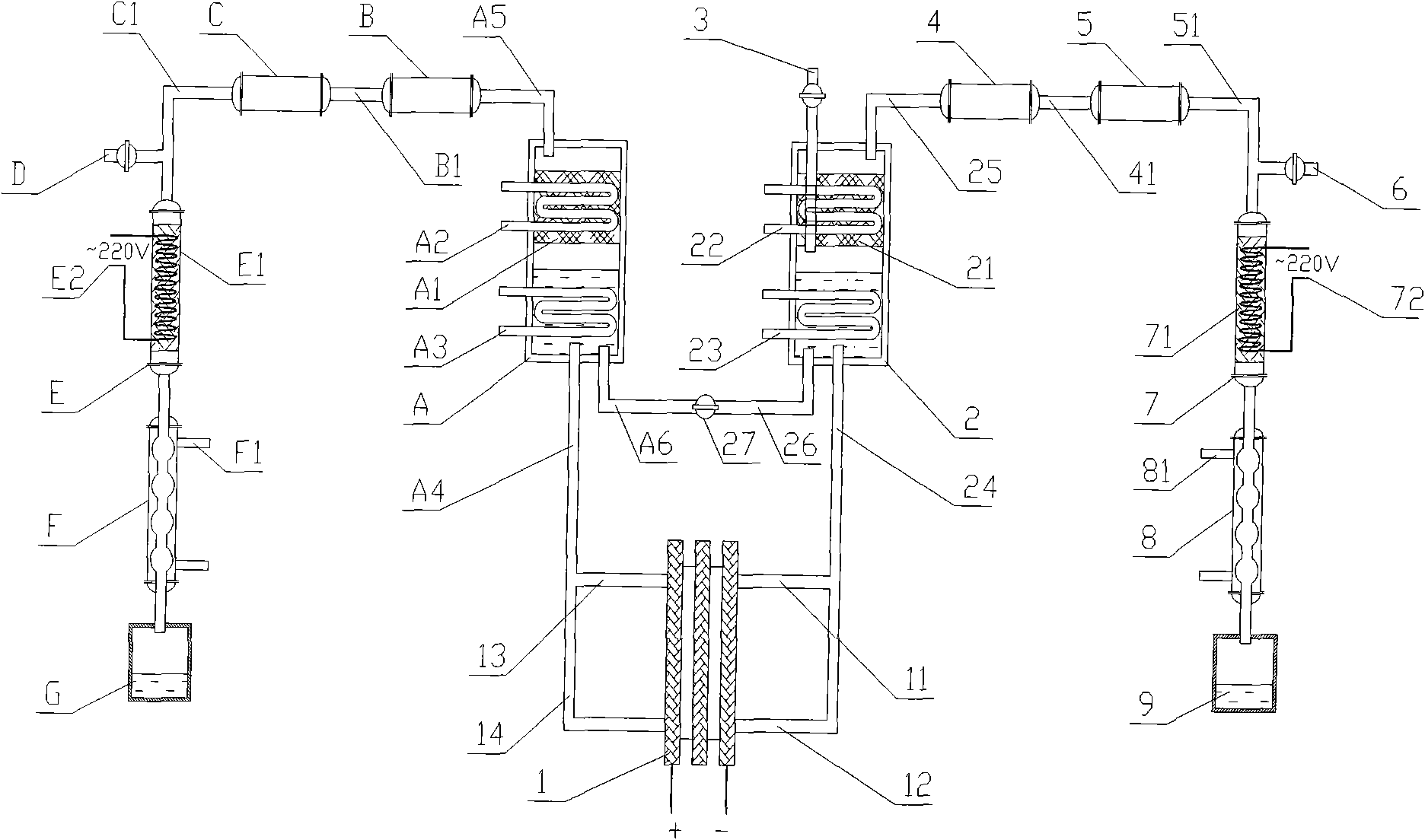

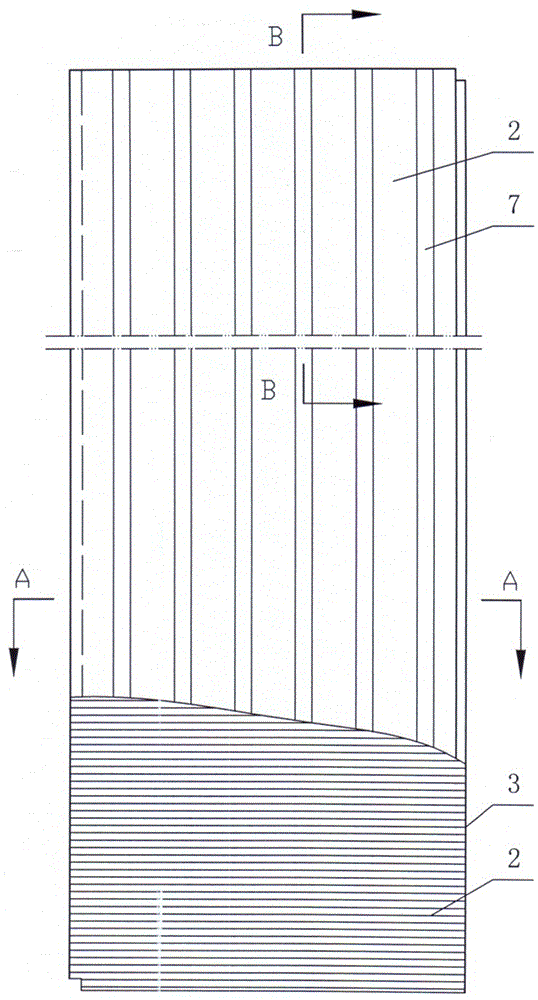

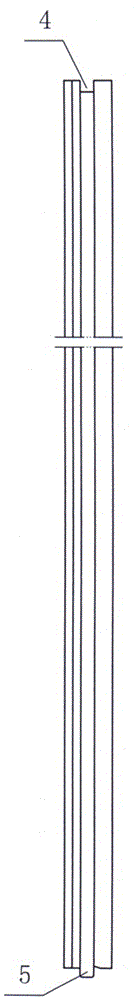

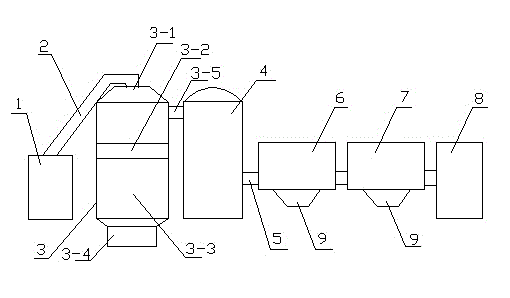

Method for preparing nuclear medicine diagnostic reagent oxygen-18 water and device thereof

ActiveCN101575086AImprove gas purityReduce running lossElectrolysis componentsWaterProduct gasRadiochemistry

The invention relates to a method for preparing nuclear medicine diagnostic reagent oxygen-18 water and a device thereof. The method comprises the steps of: utilizing an oxygen isotope water industrial rectifying separation device to obtain deuterium oxygen 18 doubly-labelled water as material; carrying out steps of electrolysis, purification and filtering to obtain high-purity deuterium and high-purity oxygen-18 gas; adopting a high-temperature platinum mesh to carry out catalyzing so as to lead the high-purity deuterium to react with the high-purity oxygen-18 gas at high temperature to generate deuterium water; and adopting the high-temperature platinum mesh to carry out catalyzing to lead the high-purity oxygen-18 gas to directly react with high-purity hydrogen to obtain the highly-purified oxygen-18 water adopted as the diagnostic reagent of nuclear medicine. Compared with the prior art, the invention which not only can make full use of the deuterium oxygen 18 doubly-labelled water to prepare the nuclear medicine diagnostic reagent oxygen-18 water and utilize by-product deuterium to prepare deuterium water but also can reduce process steps, enhance quality and yielding of oxygen-18 water of nuclear medicine and reduce product cost really has simple process and better effect.

Owner:SHANGHAI RES INST OF CHEM IND +1

Method for preparing sea cucumber glycoprotein by using sea cucumber blanching solution

ActiveCN102406048BImprove use valueLow use valueProtein composition from fishUltrafiltrationCentrifugation

The present invention relates to a method for preparing sea cucumber glycoprotein by using a sea cucumber blanching solution. The method comprises that: a sea cucumber blanching solution is adopted as a raw material, and is subjected to treatments of reduced pressure condense, alcohol precipitation, drying to prepare into powder; the powder is subjected to treatments of alcohol leaching and desalination, and then is redissolved in purified water; the resulting solution is subjected to treatments of enzymolysis and centrifugation; the resulting supernatant is subjected to treatments of tube ultrafiltration, ultrafiltration and drying to obtain the sea cucumber glycoprotein product. The preparation method of the present invention has characteristics of low equipment investment, simple operation, short production period, high yield and low product cost. The prepared sea cucumber glycoprotein has good biological activity.

Owner:SHANDONG HOMEY AQUATIC DEV +1

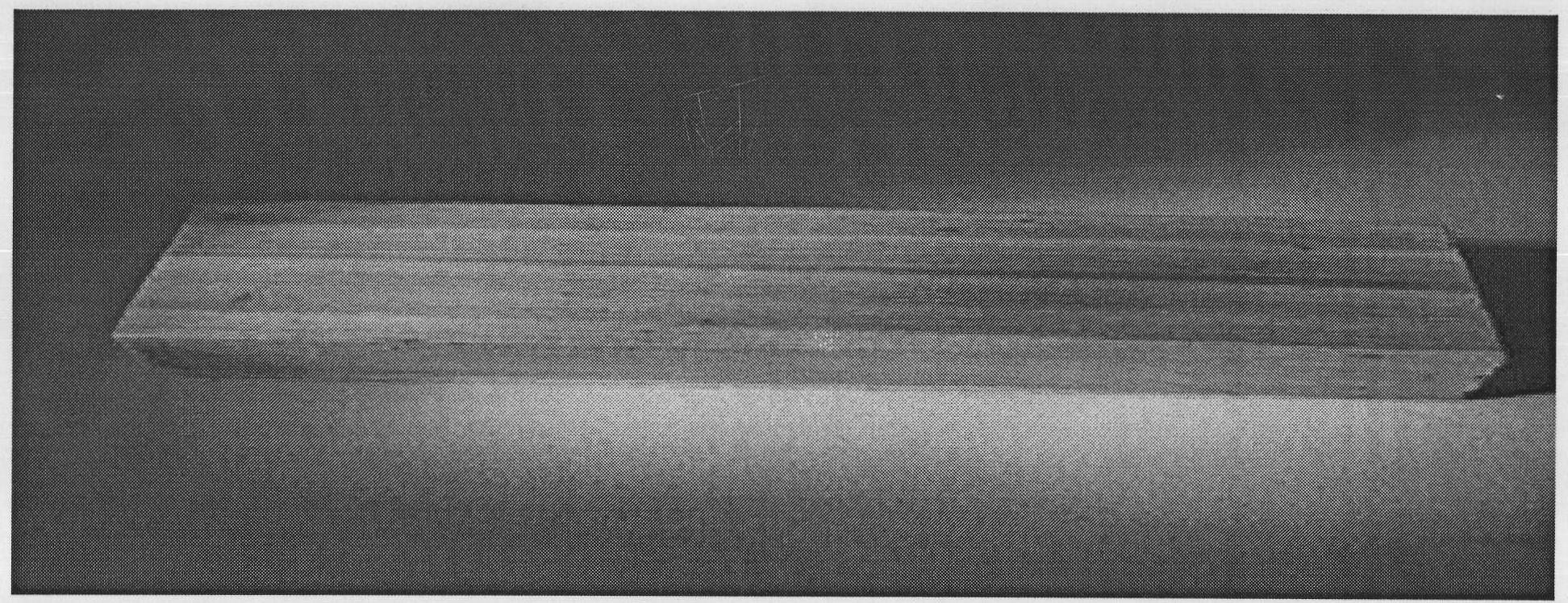

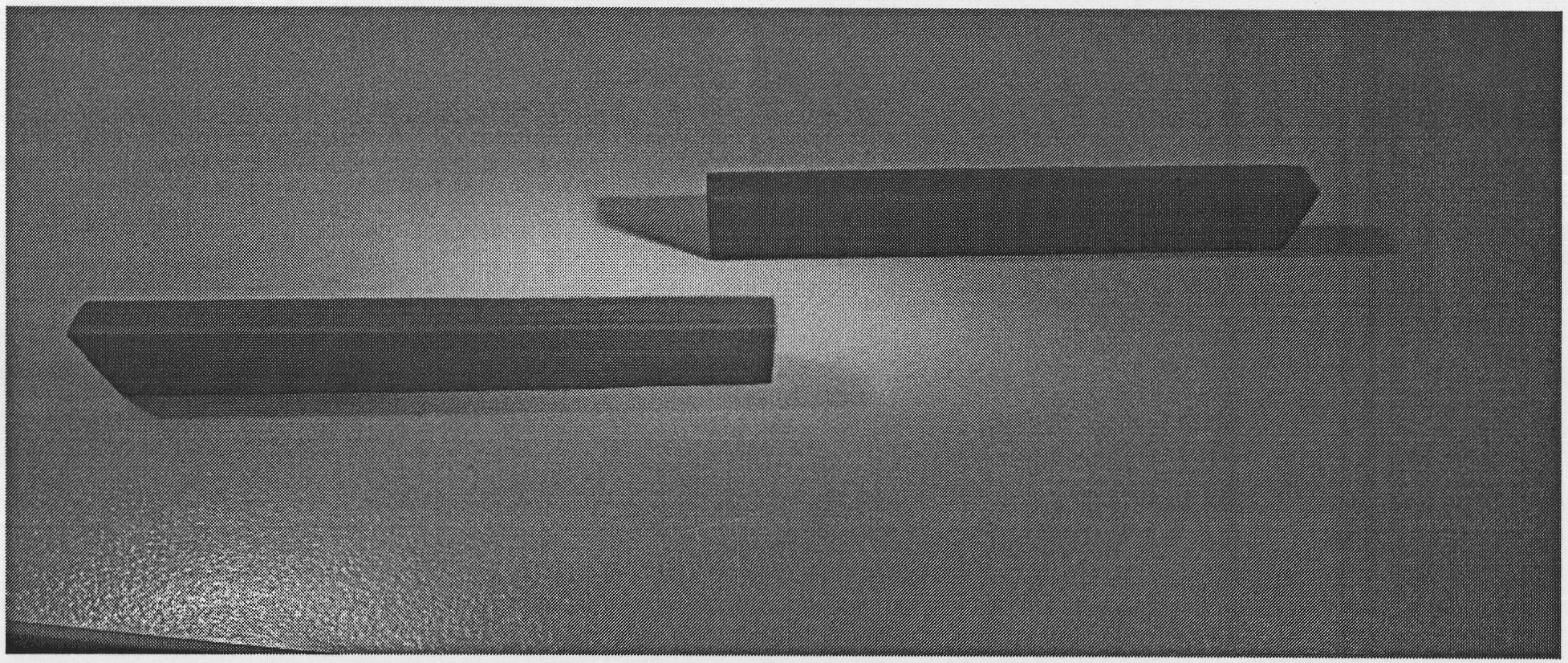

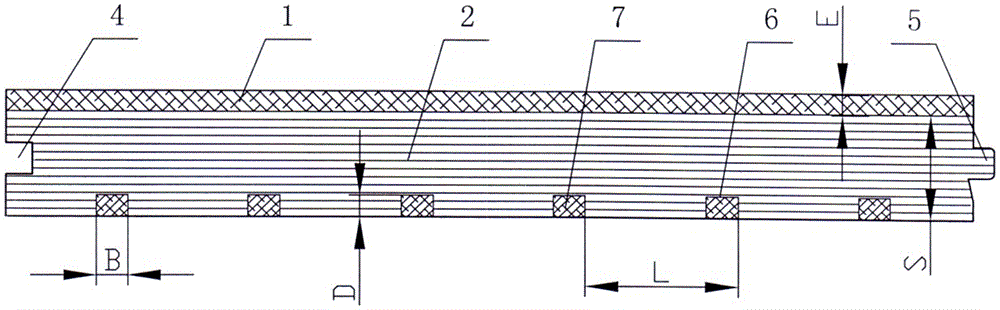

Bamboo and wood double-layer floor

The invention discloses a bamboo and wood double-layer floor. The bamboo and wood double-layer floor is simple in structure and convenient to manufacture, and consumption of adhesive can be reduced to a great extent. The bamboo and wood double-layer floor comprises an elongated face plate and a bottom plate. The elongated face plate is made of integral log, the bottom plate below the face plate is made of integral log, wood fibers of the face plate are parallel to long edges of the floor, wood fibers of the bottom plate are perpendicular or parallel to the long edges of the floor, the face plate and the bottom plate are adhered with each other by adhesive, and rabbets which are spliced with one another are arranged on the periphery of the bottom plate. The bamboo and wood double-layer floor is characterized in that grooves in rows are formed in the lower surface of the bottom plate or the upper surface of a bottom plate and face plate joint surface of the bottom plate and are perpendicular to the wood fibers of the bottom plate, elongated bamboo materials which are matched with the grooves are inlaid and adhered in the grooves, and the directions fibers of the bamboo materials are consistent with the length directions of the bamboo materials. The bamboo and wood double-layer floor has the advantages that the bamboo and wood double-layer floor is simple in manufacturing process, high in production efficiency, low in material and production cost and good in environmental friendliness and service performance, and laying and service requirements of places with diversified special requirements can be met.

Owner:JIASHAN HUIJIALE DECORATION MATERIALS CO LTD

Polystyrene imitating padauk composite material and preparation method thereof

InactiveCN101602215ALow use valueHigh densityPolymerisation impregnationWood impregnation detailsPolystyreneVolumetric Mass Density

The invention relates to a polystyrene imitating padauk composite material and a preparation method thereof. The material is a composite material prepared by using soft wood as a substrate and introducing styrene monomer into the wood to polymerize. The preparation method comprises the following steps: (1) soaking the soft wood in lye, reflowing for derosination; (2) reflowing the wood with water at 30 to 100 DEG C to wash away the lye, drying the wood; (3) introducing styrene monomer and dye into the soft wood under vacuum condition; (4) placing the soft wood soaked with the styrene monomer and dye in a drier to polymerize to produce the polystyrene for 10 to 20 hours. The composite material of the invention increases the density of the wood, reduces the water absorption rate, swell-shrink characteristic and sensitivity to weather of the wood, improves the stability of size and balance of mechanical property, and has simple operation of preparation method, low cost and high economic effect.

Owner:DONGHUA UNIV

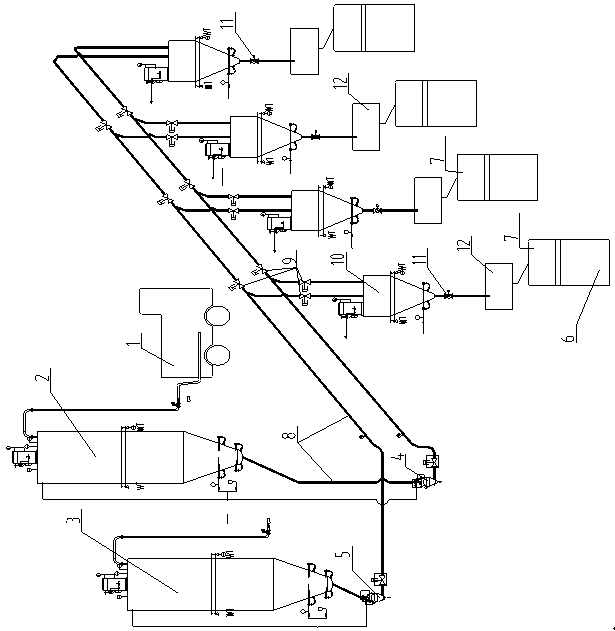

Coking fly ash/coke powder blast furnace blowing synergy utilizing system and technology

PendingCN108300824AAvoid pollutionDoes not affect milling abilityBlast furnace detailsFrequency conversionTank truck

The invention discloses a coking fly ash / coke powder blast furnace blowing synergy utilizing system and technology. A full-sealed suction discharging tank truck transports coke powder to inlets of powder collecting bins, outlets of the powder collecting bins communicate with one ends of bin pumps through conveying pipelines correspondingly, and the other ends of the bin pumps communicate with theconveying pipelines correspondingly; the conveying pipelines of the bin pumps are connected with the top of a buffer bin or the tops of multiple buffer bins through switching valves; outlets of the buffer bins communicate with one ends of feeders through frequency conversion type soft seal cinder valves correspondingly, and the other ends of the feeders communicate with mills; and the mills communicate with a blast furnace. The technology comprises the steps that fly ash / coke powder is transported into the powder collecting bins through the full-sealed suction discharging tank truck, the cokepowder is transported into the buffer bins form the bottoms of the powder collecting bins through the bin pumps, then is discharged into the feeders by the rotation cinder valves adjustable in speed,enters the mills to be reformed and then enters the blast furnace together with coal powder, and the coke powder transferring process is completed. The energy saving and environment protection effectis achieved.

Owner:南通东来冶金装备有限公司

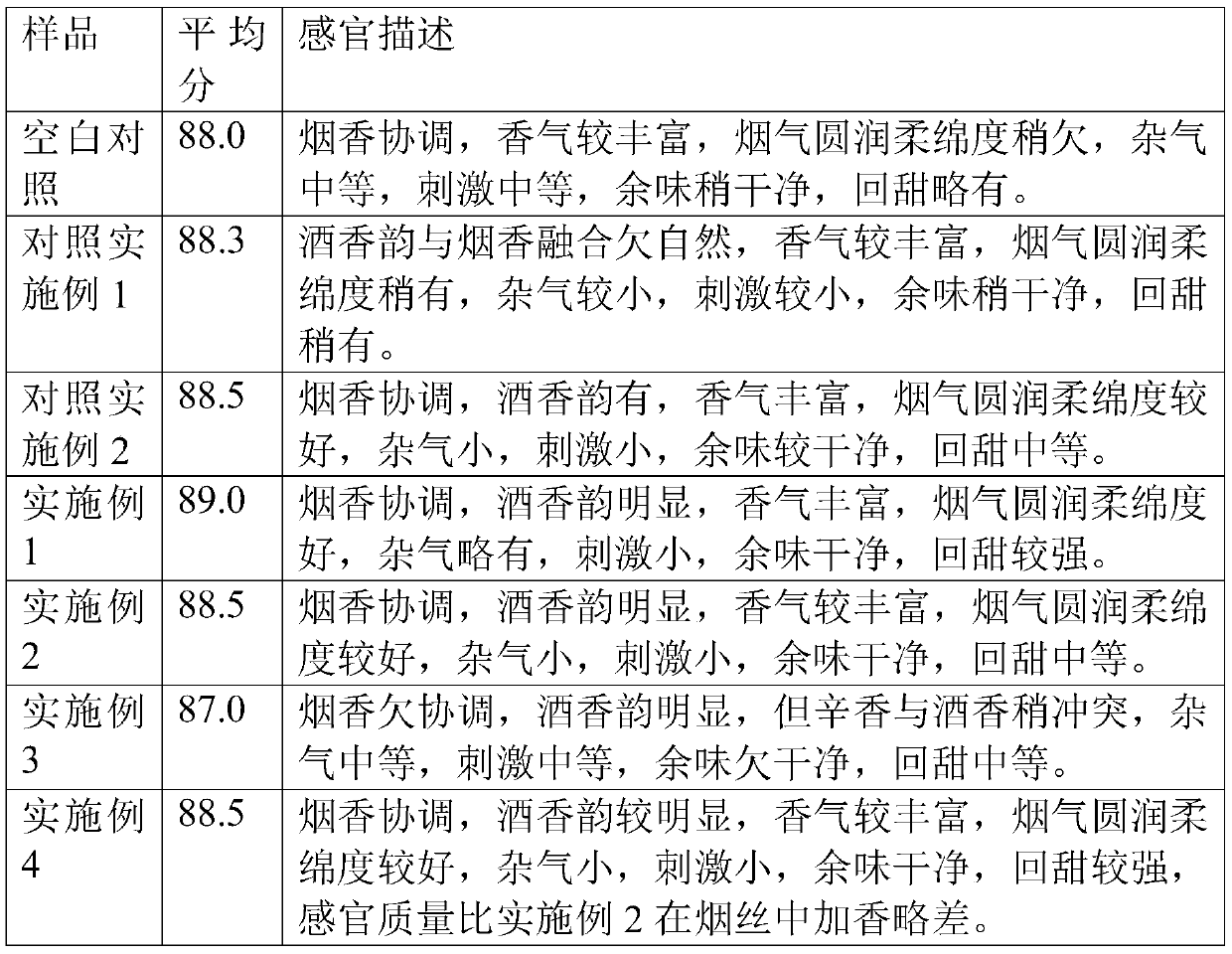

Vinasse extract based wine aroma base for cigarettes

InactiveCN111362434AImprove aroma qualityIncrease sweetnessTobacco preparationMultistage water/sewage treatmentBiotechnologyFennel extract

The invention discloses a vinasse extract based wine aroma base for cigarettes. The vinasse extract based wine aroma base comprises the following components in parts by weight: 2-4 parts of a Zimbabwetobacco extract, 2-4 parts of 1% dihydrocoumarin, 5-7 parts of a vinasse extract and 1-3 parts of a caraway extract. The utilization value of vinasse is improved, the vinasse extract can increase thewine aroma, the wine aroma well coordinates with the spicy and sweet aroma of the caraway extract, and two extract are used together to improve the aroma quality, soften and plump smoke and increasethe sweetness. The Zimbabwe tobacco leaf extract can enhance the natural scorch sweetness of cigarettes and improve the smoke concentration and the tobacco aroma concentration. Dihydrocoumarin has cream-like fragrance, coconut fragrance and cinnamon fragrance. The four spices have good compatibility, after compatibility, the cigarettes can be endowed with elegant bouquet characteristics, the aromaquality of the cigarettes is improved, the aroma is enriched, smoke is soft, the aftertaste is improved, and the sweet aftertaste of the cigarettes is improved.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

Method for preparing sucralose-6-ester by utilizing bis(trichloromethyl)carbonate

InactiveCN105111250AColor transparentImprove use valueEsterified saccharide compoundsSugar derivativesWater bathsSucrose

The invention relates to a method for preparing sucralose-6-ester by utilizing bis(trichloromethyl)carbonate. The method comprises the following steps: 1) reacting sucrose to obtain an esterification liquid; 2) adding bis(trichloromethyl)carbonate and trichloroethane to a reaction kettle, stirring the materials to dissolve the materials until the liquid is clear, and reducing the temperature with an ice brine bath; 3) slowly dropwise adding a dimethylformamide solution of sucrose-6-ester to the reaction kettle; 4) maintaining the temperature below 5 DEG C for 2 hours after dropwise adding is completed; 5) carrying out programmed temperature raising and maintaining; 6) reducing the temperature, adjusting the pH value to 10, stirring the solution and adjusting the pH value to 7; 7) removing the trichloroethane solvent, adding water, carrying out suction filtration, weighing the filter residues and computing the yield. The method has the beneficial effects that 1) the tail gases are absorbed only with water, so that the method has the advantages that the cost input is reduced, the byproduct hydrochloric acid is purer, the color is transparent and the value in use is higher compared with existing water absorption and sodium hydroxide absorption methods; and 2) liquid chromatographic analysis verifies that the yield of a bis(trichloromethyl)carbonate method is 60%, and the yield of a thionyl chloride method is 55%.

Owner:SHANDONG KANBO BIOCHEM TECH

Ion-exchange recovery method for synergistic matter in Bt fermentation

ActiveCN101508656BHigh recovery rateIncrease concentrationBiocideCarboxylic acid amide separation/purificationOXALIC ACID DIHYDRATEPotassium ferricyanide

The invention discloses an ion exchange recycling method for synergistic material in fermentation of Bt, comprising steps: (1) pre-treating Bt supernatant fluid, carrying out precipitation reaction by adding protein flocculating agent zinc sulfate, yellow potassium ferrocyanide and metallic ion complexing agent oxalic acid under condition of pH value, filtering and removing precipitate by a plateframe, and adjusting the pH value to pH6 before filtrate enters a column; (2) choosing polymeric adsorbent ZJ-16 with high adsorption capacity, good selectivity, high mechanical strength and long service life to adsorb synergistic material of Bt; and (3) collecting the obtained precipitated liquid and processing as follows according to needs: A, processing and producing Bt water suspension preparation with high valence, adding thinner assistants such as sodium chloride, sodium benzoate and xanthan gum into the precipitated liquid collected through ion exchange to produce Bt water aqua; B, processing Bt raw powder with high valence; and C, processing synergistic material powder for scientific research with high purity and high content. The method is simple and practical, improves the valence yield of a product, reduces production cost and improves the quality of the product.

Owner:WUHAN KERNEL BIO-TECH CO LTD

Cultivation technology for straw mushrooms

The invention discloses a cultivation technology for straw mushrooms. The technology successively comprises the steps of mushroom room building, mushroom variety selection, pre-processing of cultivation raw materials, selection of the cultivation raw materials, material mixing, basket loading, normal-pressure sterilization, cooling and sowing, mycelium culture, inversion for inducement to primordium, mushroom fruiting management and harvesting. In this way, finished products of the straw mushrooms can be obtained. According to the invention, a new formula and supporting production technologies are adopted, so that the cost is reduced and raw material sources are added in comparison with traditional cultivation technologies; and a high and stable biological conversion rate reaching 20%-30% is obtained. The basket cultivation technology disclosed by the invention has the advantages that labor strength is greatly reduced in comparison with a traditional bed cultivation technology; mechanical operations can be achieved easily; occurrence of pest and disease damage is reduced; and the technology is applicable to industrial large-scale cultivation.

Owner:江西省鲜禾生态农业发展有限公司

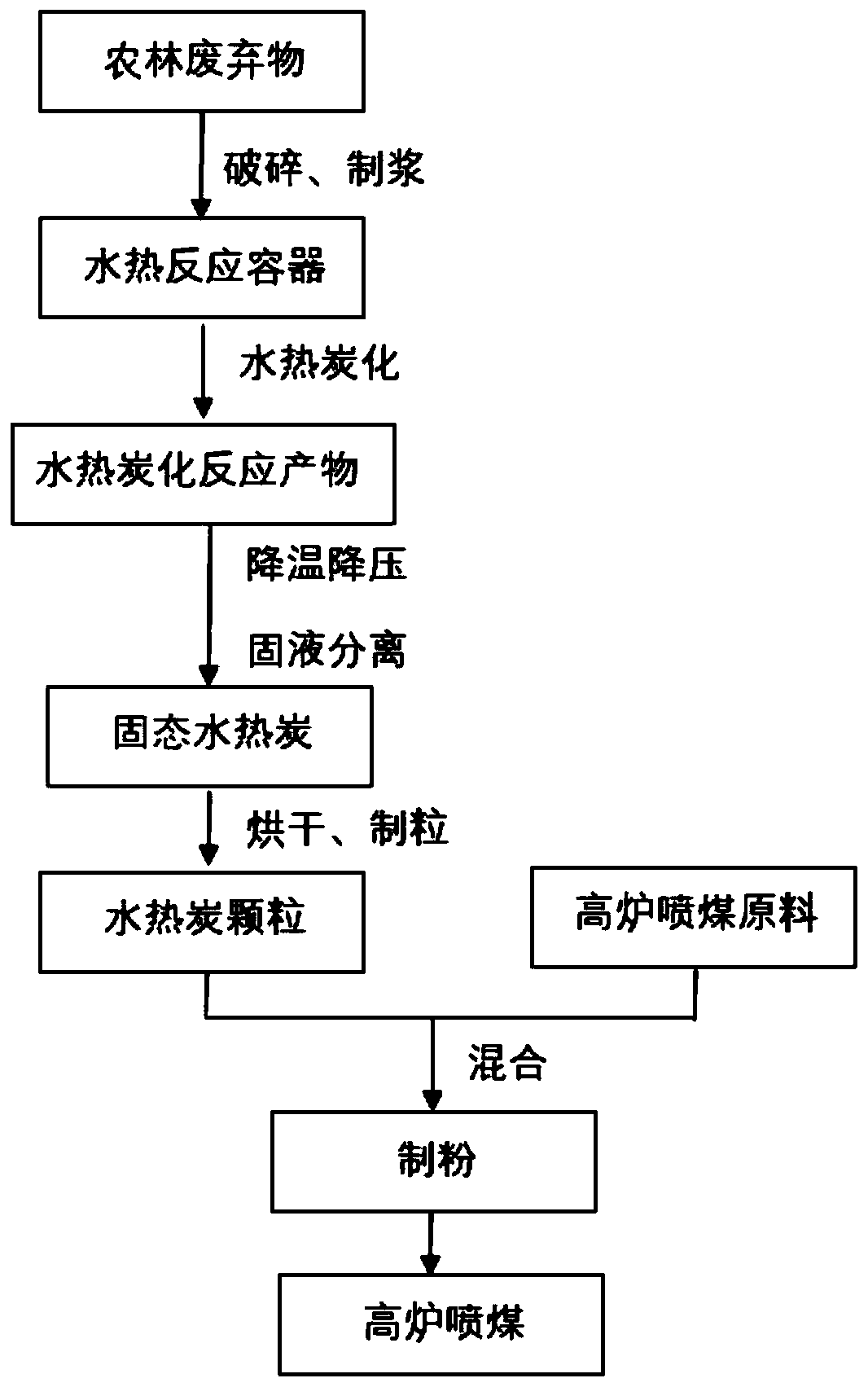

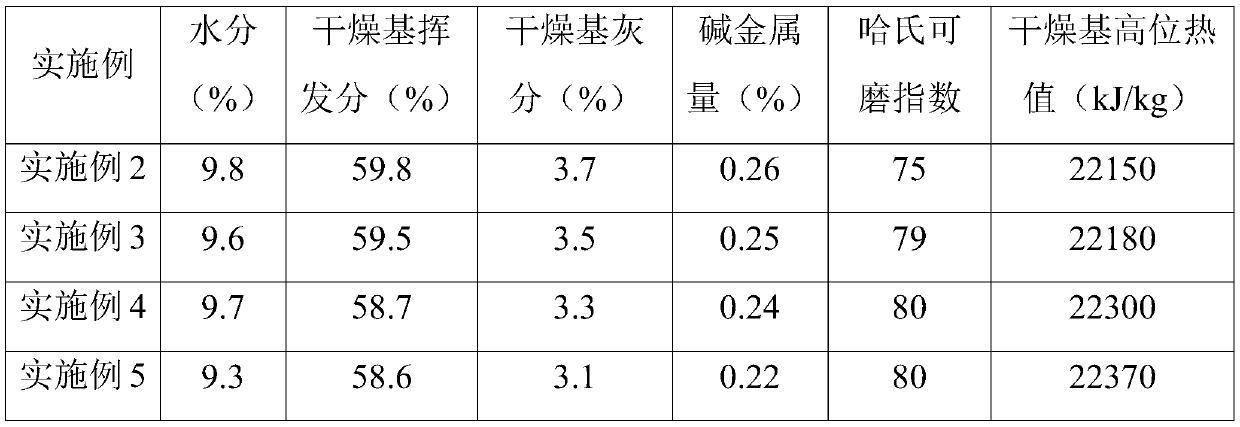

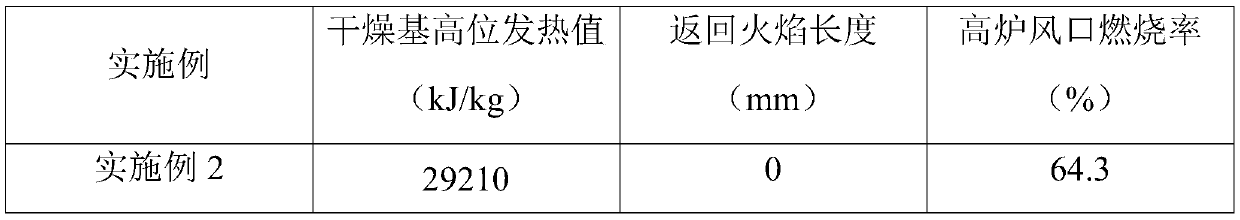

A process based on hydrothermal reaction treatment of agricultural and forestry wastes to prepare carbonized products for blast furnace coal injection

ActiveCN110257575BHigh volatile contentLow calorific valueBiofuelsSolid fuelsCarbideProcess engineering

The invention discloses a hydrothermal-reaction-based process for treating agricultural and forest residues to prepare carbide used for blast furnace coal injection. Hydrothermal reaction technology is utilized for converting the agricultural and forest residues high in volatile content, low in calorific value and low in use value into high-quality hydrothermal carbide low in volatile content, low in ash content and high in calorific value, and the hydrothermal carbide and blast furnace coal injection pulverized coal are mixed to be used so as to achieve application of the agricultural and forest residues to blast furnace coal injection. In this way, the prepared hydrothermal carbide can meet performance index requirements for fuel of blast furnace coal injection and can serve as clean and renewable fuel to partially replace blast furnace coal injection pulverized coal to be used, utilization efficiency of the residues can be improved, emission of carbon dioxide in ironmaking production can also be lowered, and significant economic, social and ecological benefits are achieved.

Owner:UNIV OF SCI & TECH BEIJING

Application of physalis alkekengi polysaccharide in preparation of medicine and health care product for treating diabetes

InactiveCN1823811AGood hypoglycemic effectActive ingredients are not clearOrganic active ingredientsMetabolism disorderMedicineDiabetic patient

An application of the Calyx Seu Fructus Physalis' polyose in preparing the medicine and hypoglycemic health-care food for treating diabetes is disclosed. Its preparing process includes such steps as adding the fruits of Calyx Seu Fructus Physalis in deionized water, heating, filtering, concentrating, stirring, depositing, centrifugal separation and vacuum drying.

Owner:NORTHEAST NORMAL UNIVERSITY

Method for extracting zinc oxide from iron-smelting blast furnace fly ash

The invention discloses a method for extracting zinc oxide from iron-smelting blast furnace fly ash. Compared with the commonly used rotary furnace process at present, the method has the following advantages that 1, the used fly ash index is wide: the iron content required by the fly ash used by the rotary furnace process is below 20% and the zinc content is above 20%, and iron content required by the fly ash used by the method is not limited and the zinc content is above 6%; 2, fuel addition is not required: 0.45 ton of anthracite or 0.35 ton of coke powder is required to be added in each ton of fly ash in the rotary furnace, and the method does not require fuel addition; 3, the operation cycle is long: the operation cycle of the rotary furnace is 60 days and the operation period of the enclosed furnace in the method is longer than one year; 4, the fireproof material in the furnace is low in cost: the high-temperature wear-resistant fireproof brick used by the rotary furnace costs ** yuan per ton, and the common fireproof brick used in the enclosed furnace costs ** yuan per ton; and 5, the tailing recycle is convenient: the tailings of the rotary furnace process flow out in a liquid state and need to be continuously cooled by water, and contain less iron so that the value in use is low, and the tailings in the method are discharged in a solid state, the tailings with iron content higher than 50% can be directly used in ironworks and the tailings with iron content lower than 50% can be used in cement plants.

Owner:王全生

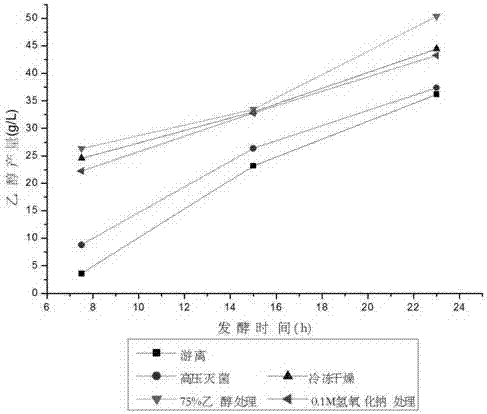

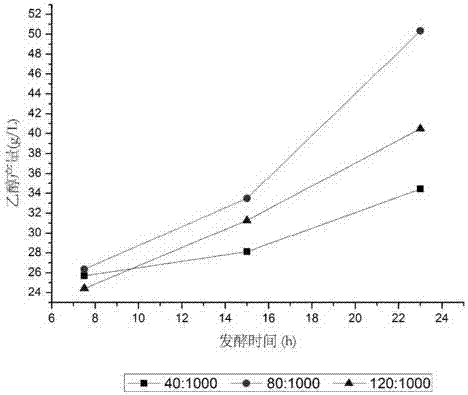

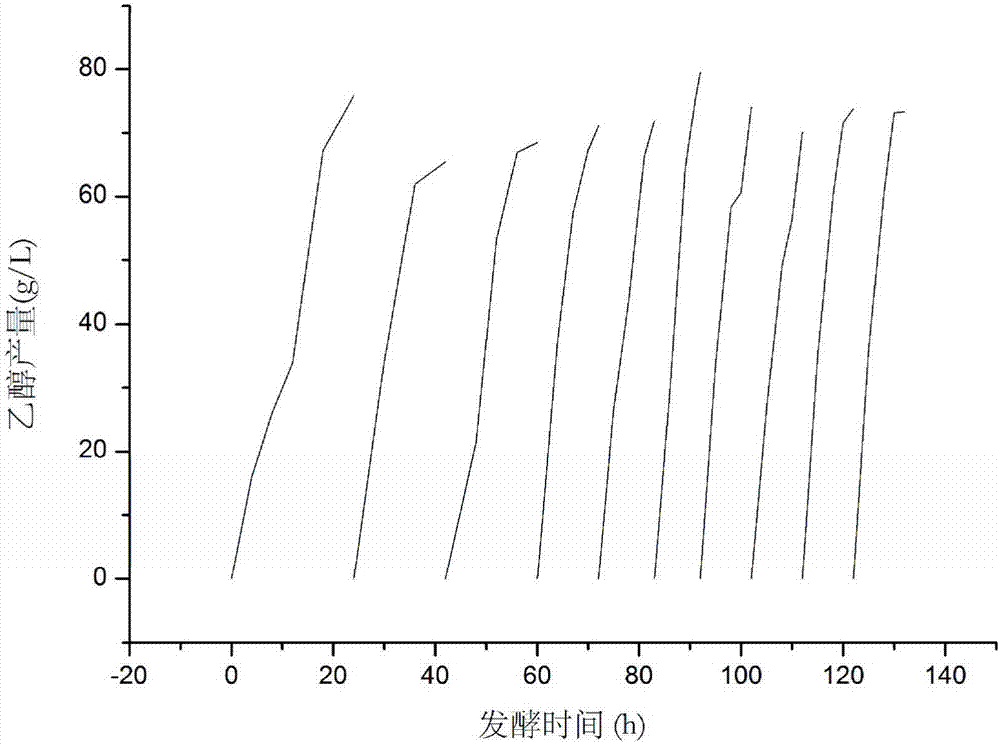

Method for continuously fermenting to produce ethyl alcohol by using immobilized wine brewing yeast cells

InactiveCN106868056AAvoid churnImprove toleranceBiofuelsMicroorganism based processesYeastContinuous fermentation

The invention discloses a method for continuously fermenting to produce ethyl alcohol by using immobilized wine brewing yeast cells. The method is characterized in that small intestines of pigs are used as an immobilized carrier, and the immobilized wine brewing yeast cells are continuously fermented to produce the ethyl alcohol. The method has the advantages that the small intestines of the pigs are used as the immobilized material, so that the toxicity is avoided, the adsorbing effect is good, the continuous fermenting effect is realized, the fermenting time is shortened, and the fermenting rate is improved; the output of the ethyl alcohol is increased, and solid and liquid of a product are favorably separated.

Owner:南京外国语学校

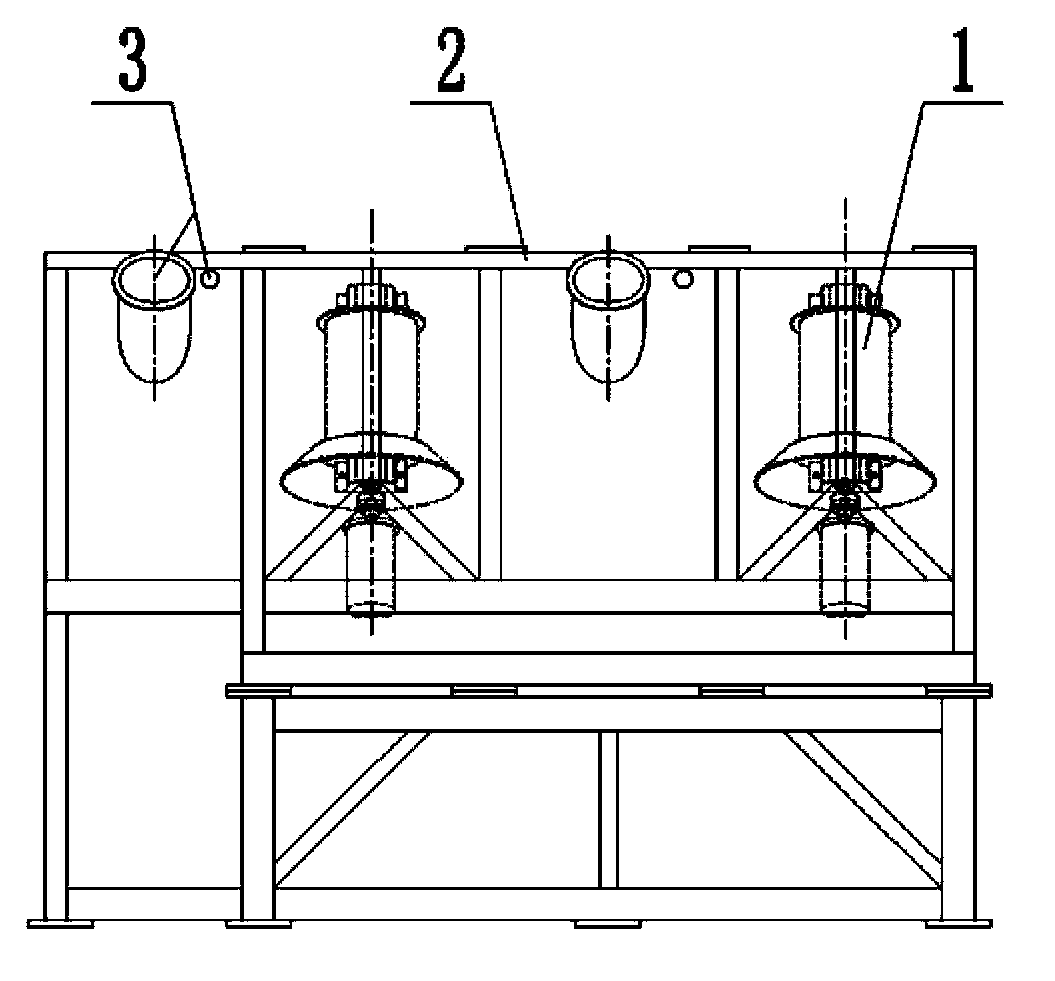

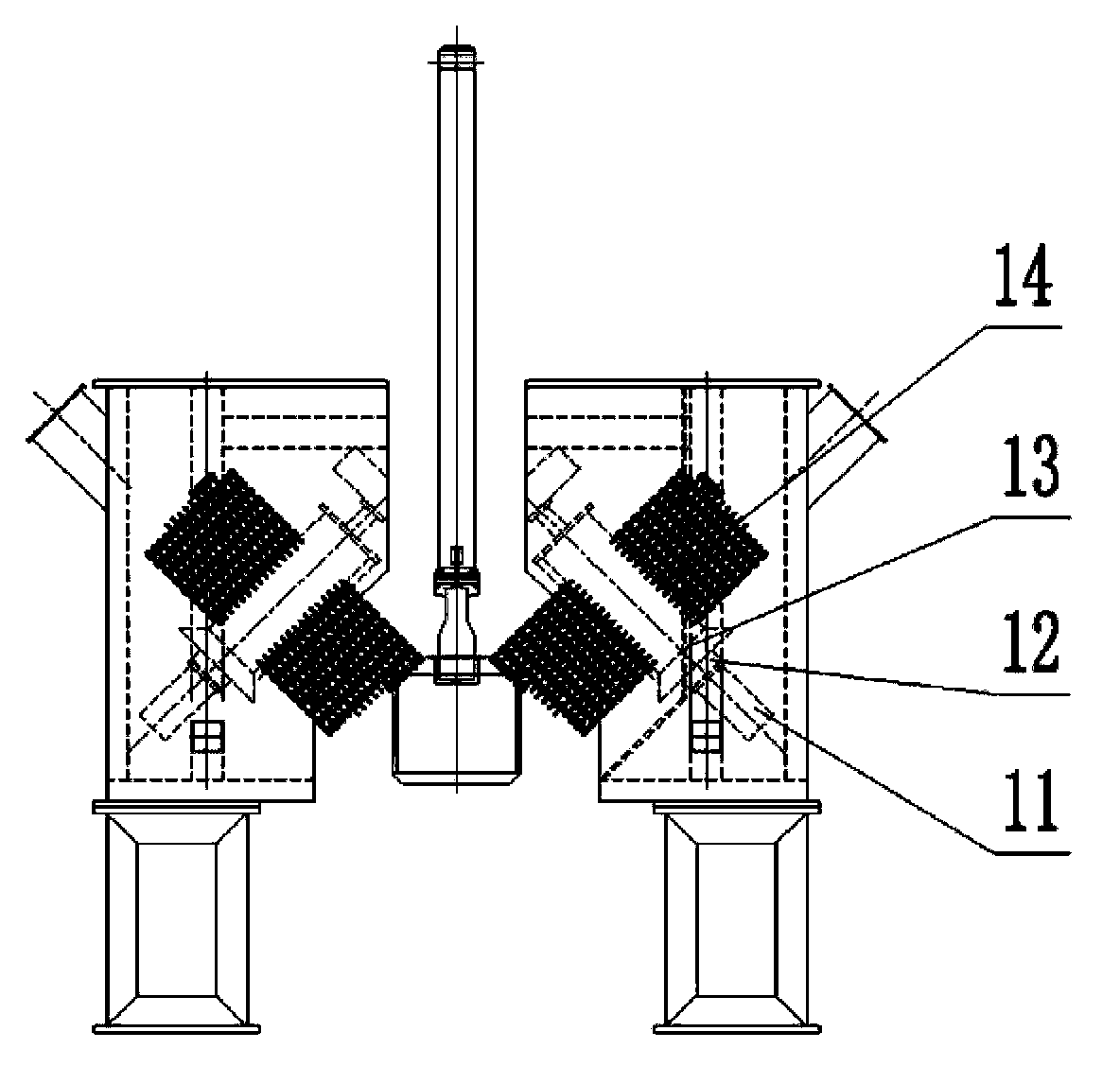

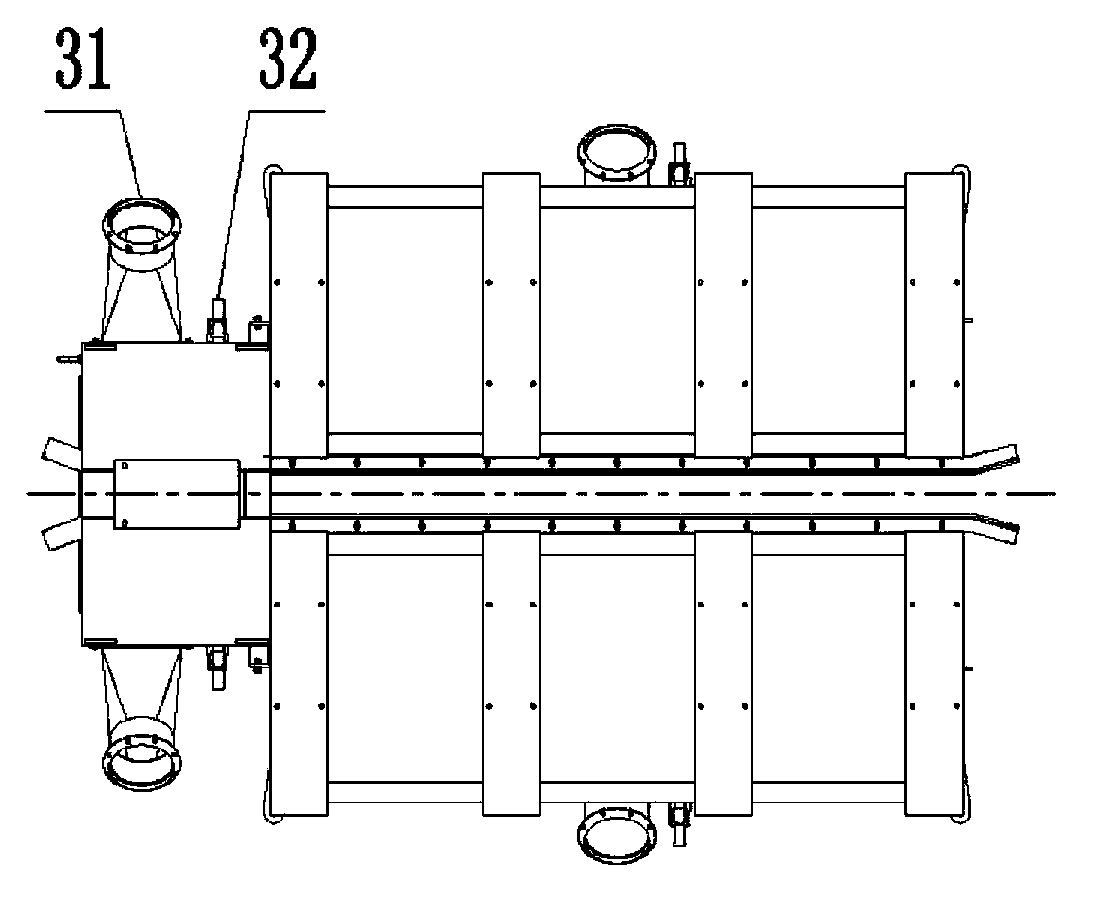

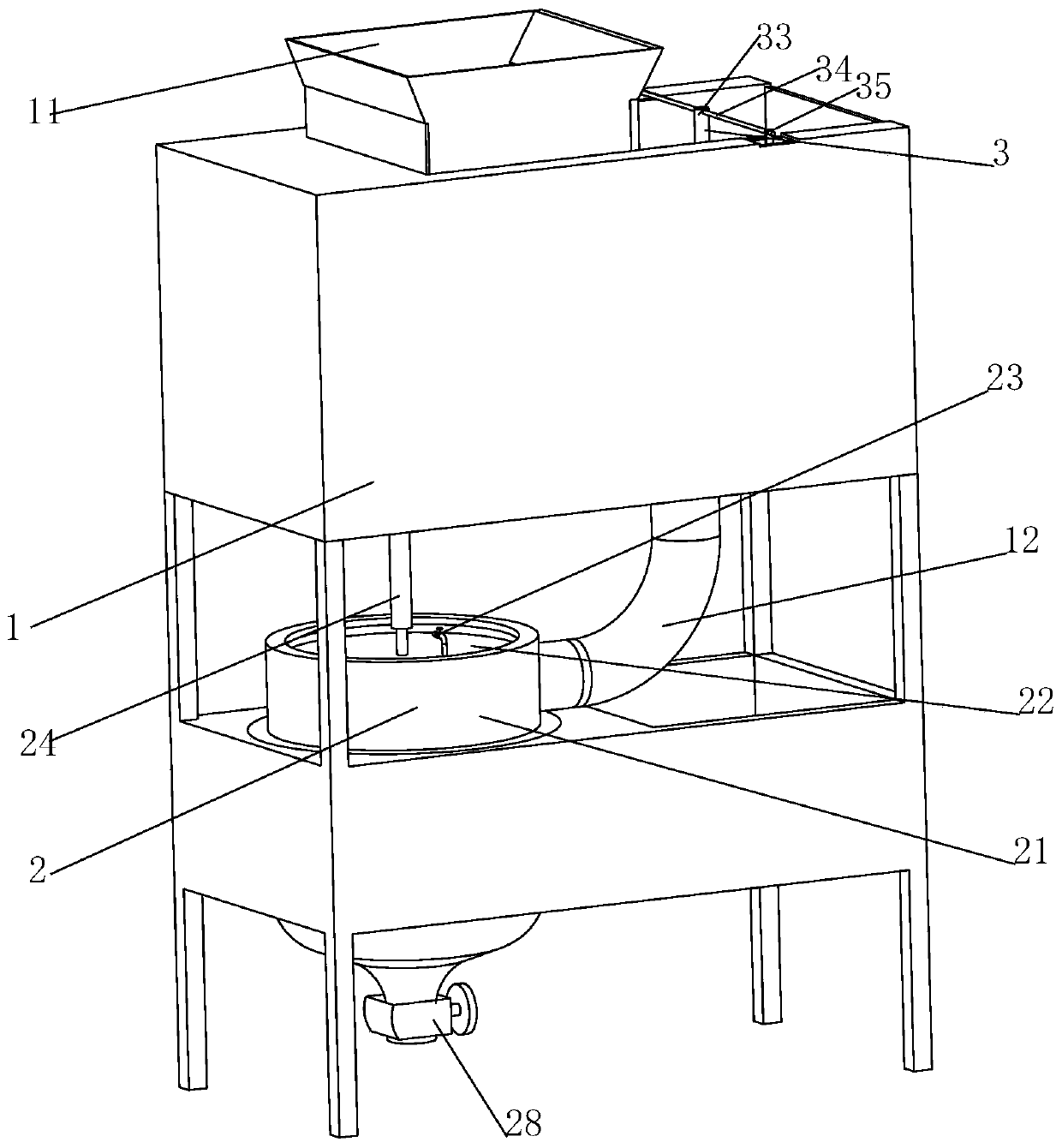

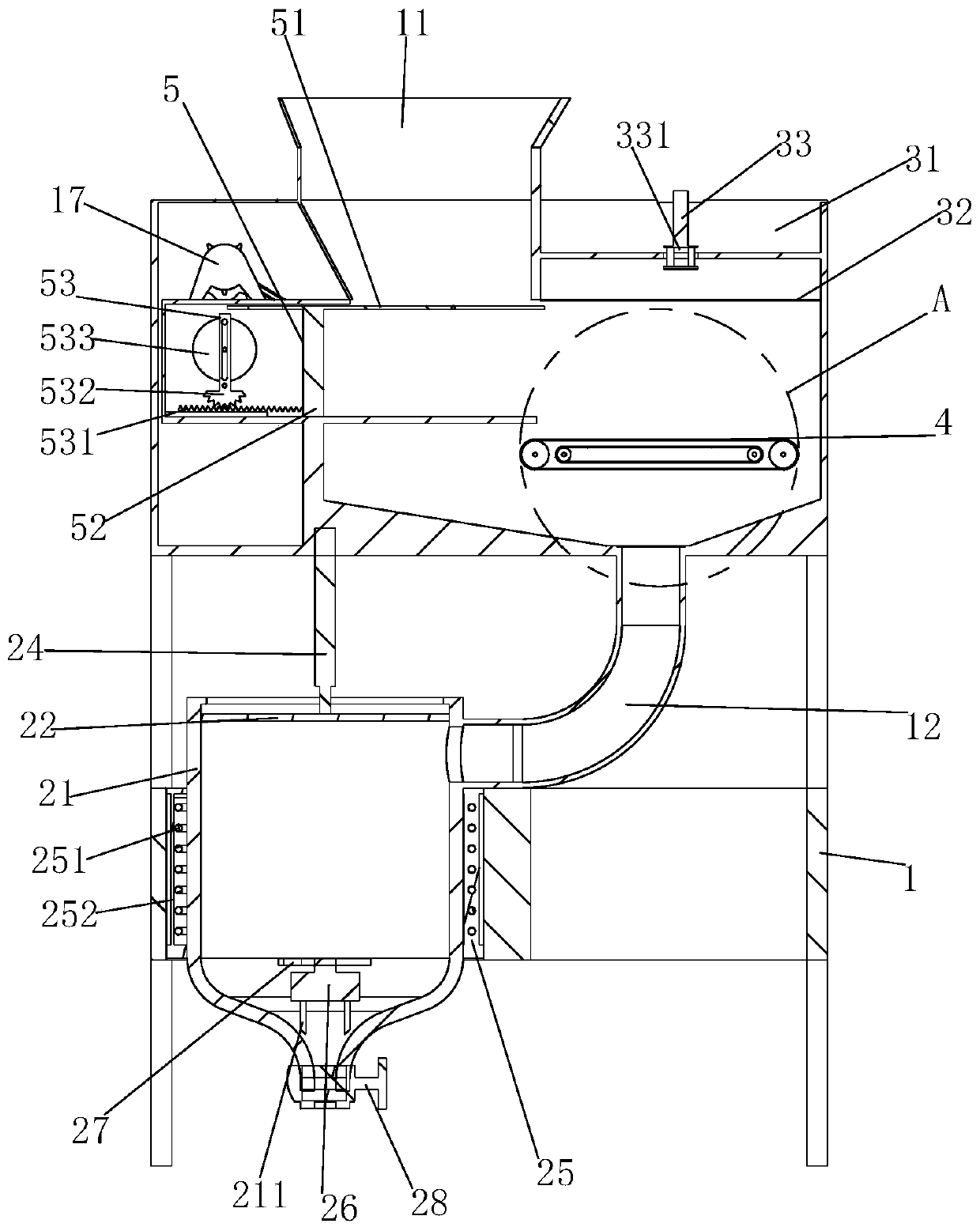

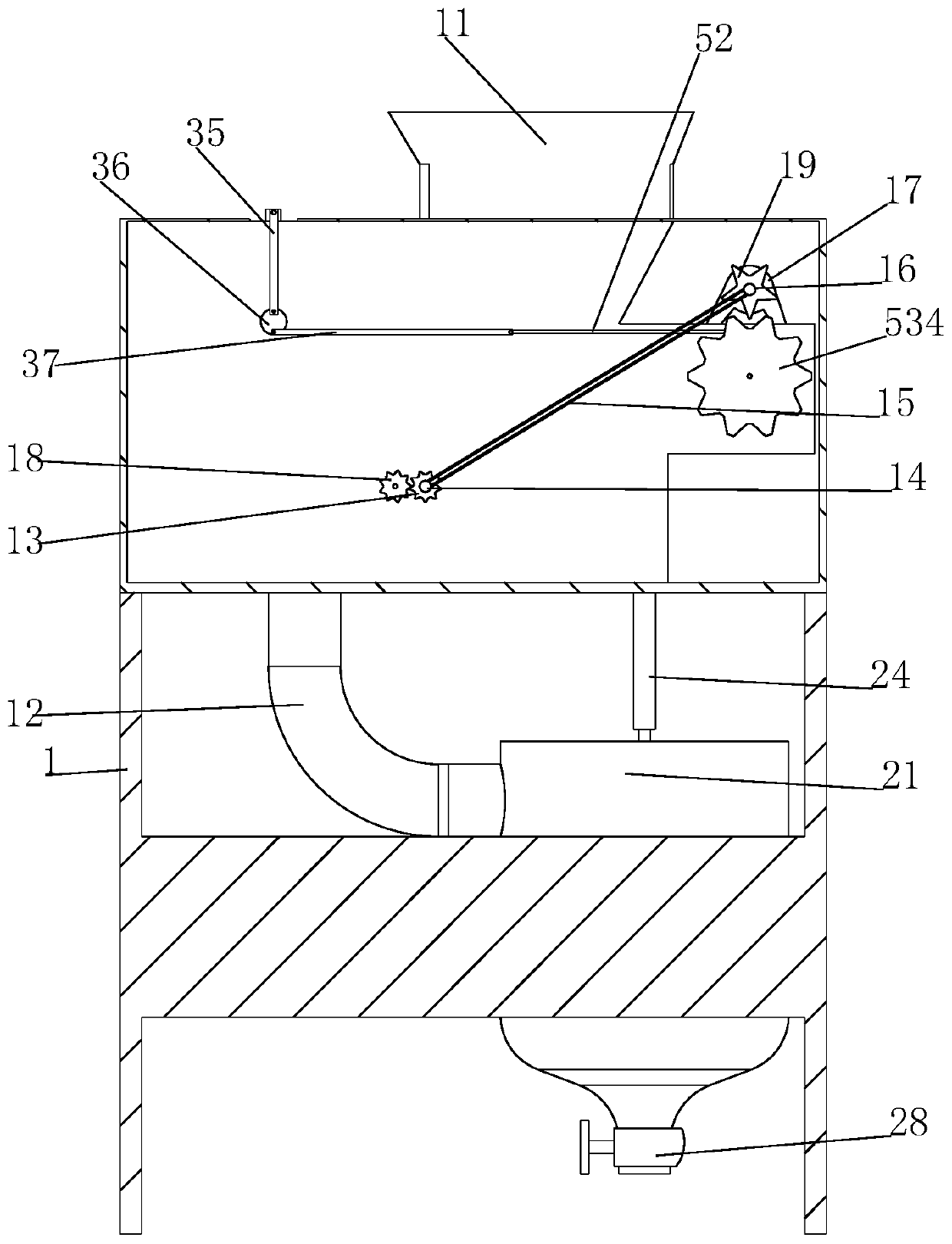

Pulping system for producing paper products by recycling waste paper

ActiveCN111005249ALow use valueEasy to crushPaper recyclingRaw material divisionProcess engineeringCellulose

The invention relates to a pulping system for producing paper products by recycling waste paper. The system comprises a mounting frame, a pulping device, a spraying device, a crushing device and a pushing mechanism, wherein the pulping device is installed at the bottom of the mounting frame, the spraying device is installed on the right side of the top of the mounting frame, a material inlet is formed in the left side of the top of the mounting frame, the pushing mechanism is arranged below the material inlet, the crushing device is installed on the right side of the middle of the mounting frame, a discharging pipe is connected between the pulping device and the crushing device, and the spraying device is located just above the crushing device. The pulping system of the invention can solvethe problems in the treatment after waste paper recovery in the prior art that in a waste paper pulping process, paper pulp is prepared after waste paper is not fully crushed, and the cellulose contained in the paper pulp in the pulping process cannot be fully decomposed when being decomposed again, so that the surface roughness of the produced recycled paper is overlarge, the recycled paper is easy to tear and difficult to form when meeting water so as to reduce the utilization value of the recycled paper..

Owner:张亚勤

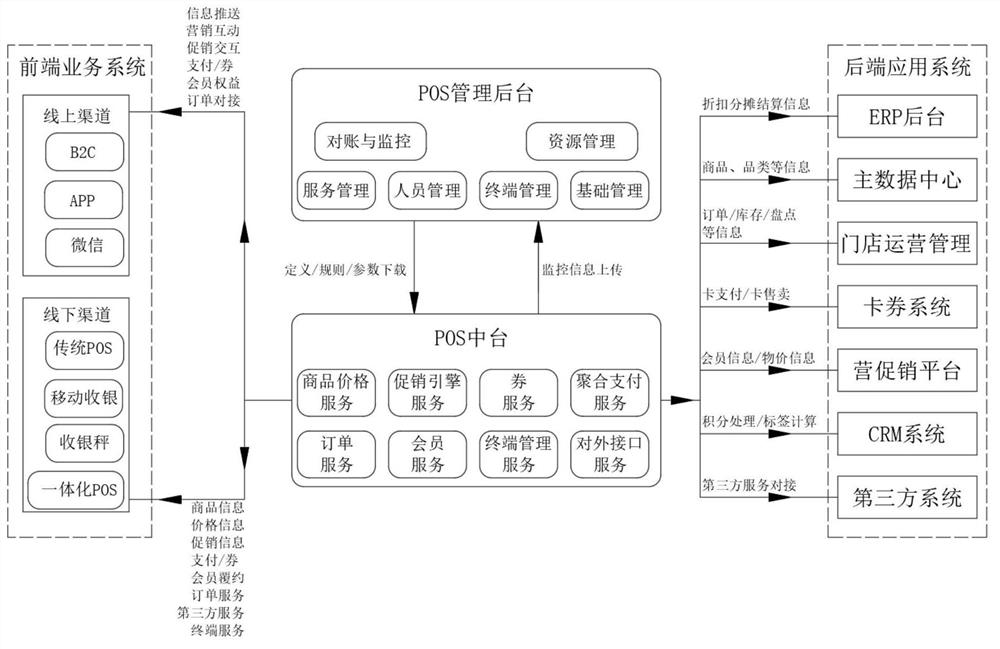

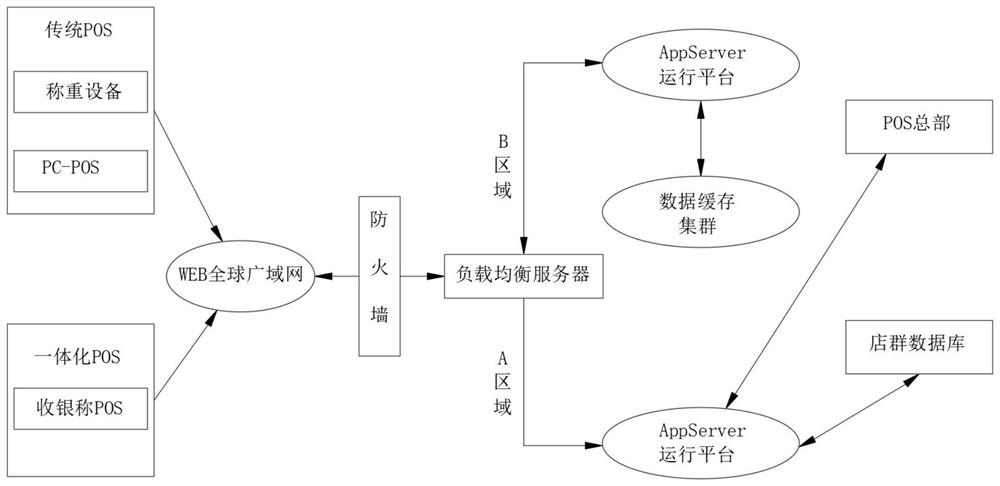

Chain retail POS system

PendingCN113222581AImprove use valueReduce the risk of lossDatabase distribution/replicationCash registersComputer performanceComputer science

The invention relates to the technical field of POS systems, and particularly discloses a chain retail POS system which comprises a POS management background, a POS middle platform, a front-end service system and a rear-end application system, the front-end service system and the rear-end application system both operate based on the POS middle platform, the POS middle platform is used for monitoring information and uploading the information to the POS management background, and the POS management background can download definitions, rules and parameters of the POS middle platform; and business logic is processed in a centralized mode through the POS middle platform, the terminals and channels are opened in a service arrangement mode, the capacity of sharing, adapting and rapidly responding to market requirements of core business is improved, meanwhile, the requirement of a front end is lowered, rapid adapting of multiple types of terminals is facilitated, and after a new offline file is generated every day through POS background service, old files are directly replaced, so that the problem that a large number of off-line files occupy disk space is effectively avoided, the requirement for computer performance is not high, the use cost is low, and the concurrency requirement for a headquarter server is reduced.

Owner:深圳市昂捷信息技术股份有限公司

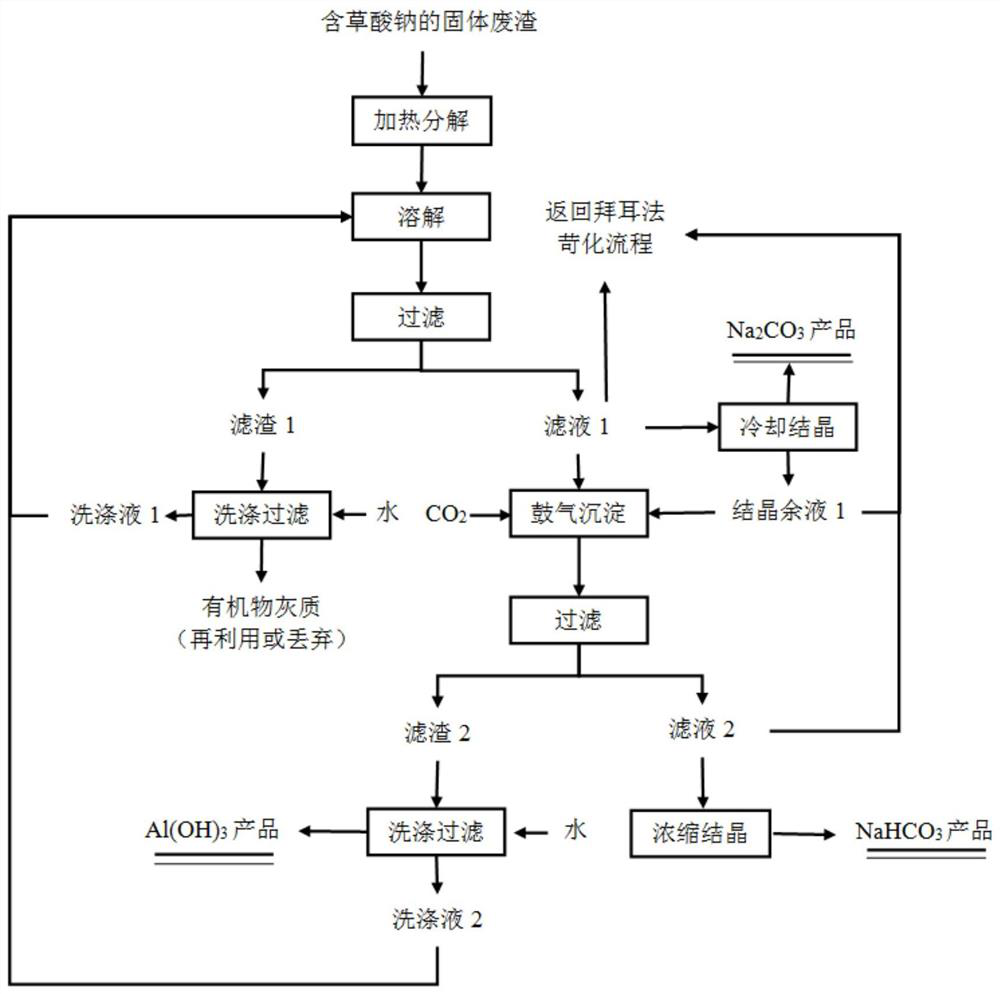

Method for treating sodium oxalate solid waste residues produced in aluminum oxide production process

ActiveCN113149048ALow use valueIndustrial application value is not highBicarbonate preparationTransportation and packagingSodium bicarbonateAluminium hydroxide

The invention provides a method for treating sodium oxalate solid waste residues produced in an aluminum oxide production process, belonging to the technical field of treatment of solid waste residues. The method comprises the following steps: (1) heating and decomposing the sodium oxalate solid waste residues to obtain a decomposition product; (2) dissolving and filtering the decomposition product to obtain filter residues and a filtrate; (3) washing and filtering the filter residues to obtain a washing solution and organic matter ash; and (4) processing and recycling the filtrate. According to the method, the sodium oxalate solid waste residues co-crystallized and separated from sodium aluminate mother liquor are converted and recycled, and obtained materials can be returned to the Bayer causticization process and can also be recycled to obtain sodium carbonate, aluminum hydroxide and sodium bicarbonate products. According to the method, various recovery combinations can be carried out according to actual requirements. According to the method, the sodium oxalate solid waste residues are recycled to the maximum extent, a technological process is simple, and the method has good economic and environmental protection values and has good industrial application prospects.

Owner:马朝扬

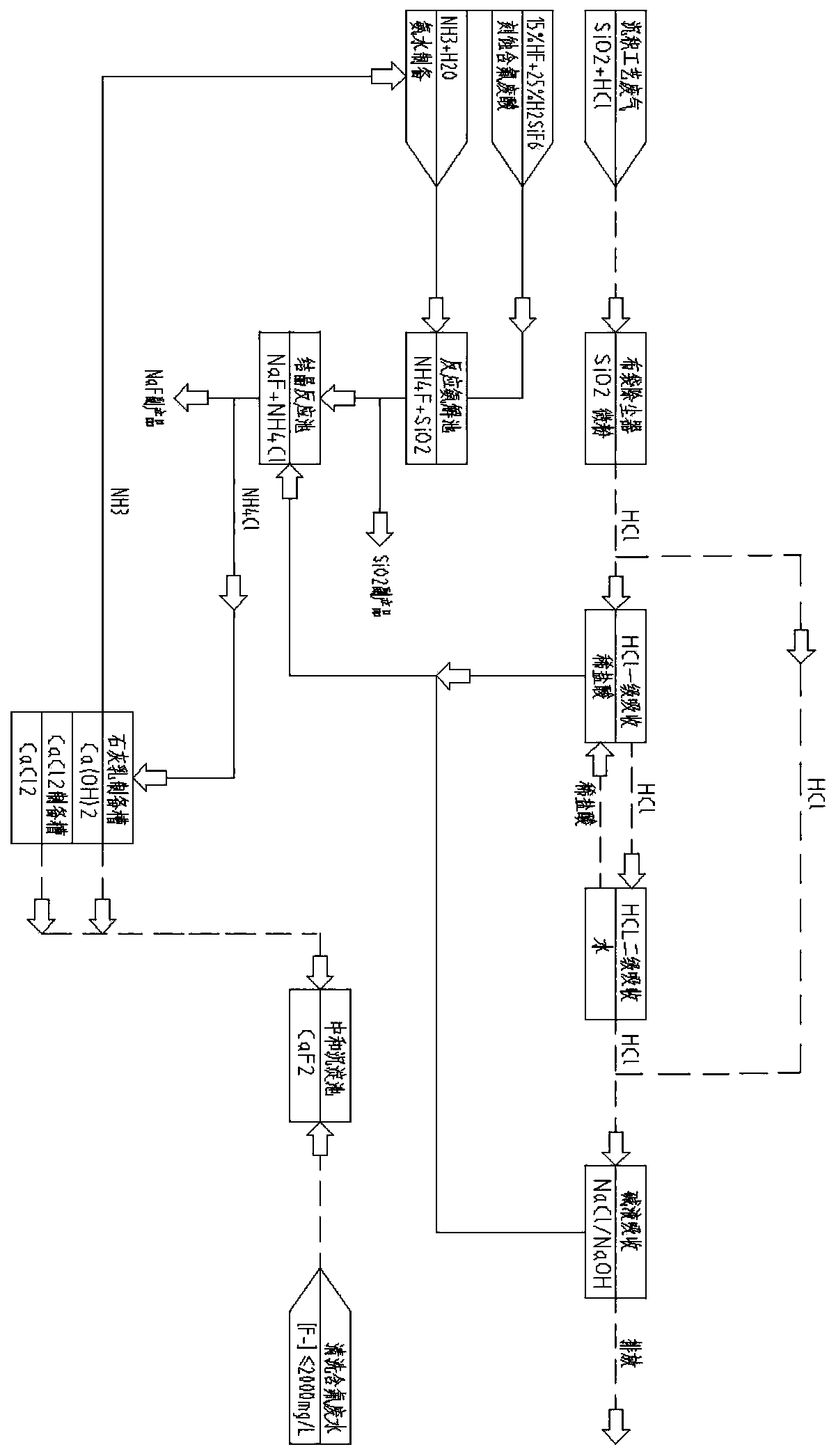

Method for recycling waste liquid generated by absorbing HCl and application of method

InactiveCN111252785AEasy to separateLow use valueSilicaCalcium/strontium/barium chloridesWastewaterAmmonia

The invention discloses a method for recycling waste liquid generated by absorbing HCl and an application of the method. The recycling method of the waste liquid generated by absorbing HCl comprises the following steps: (1) adding excessive ammonia water, HF, H2SiF6 and NH3.H2O into the waste liquid generated by quartz etching treatment, and reacting to generate NH4F and SiO2; and (2) filtering the reaction product obtained in the step (1) to obtain a filtrate, mixing the filtrate with a waste liquid generated by absorbing HCl, and reacting NH4F with NaCl to generate NaF and NH4Cl. The invention discloses the method for recycling waste liquid generated by absorbing HCl. The waste alkali liquor, waste acid liquor, cleaning wastewater and diluted hydrochloric acid which are low in utilization value are comprehensively treated and recycled, a solution generated in the whole treatment process basically does not need to be discharged outwards, required chemicals can be circularly prepared,additional auxiliary chemicals do not need to be added, and byproducts with market utilization value can be generated.

Owner:HAWK SHANGHAI ENVIRONMENTAL TECH

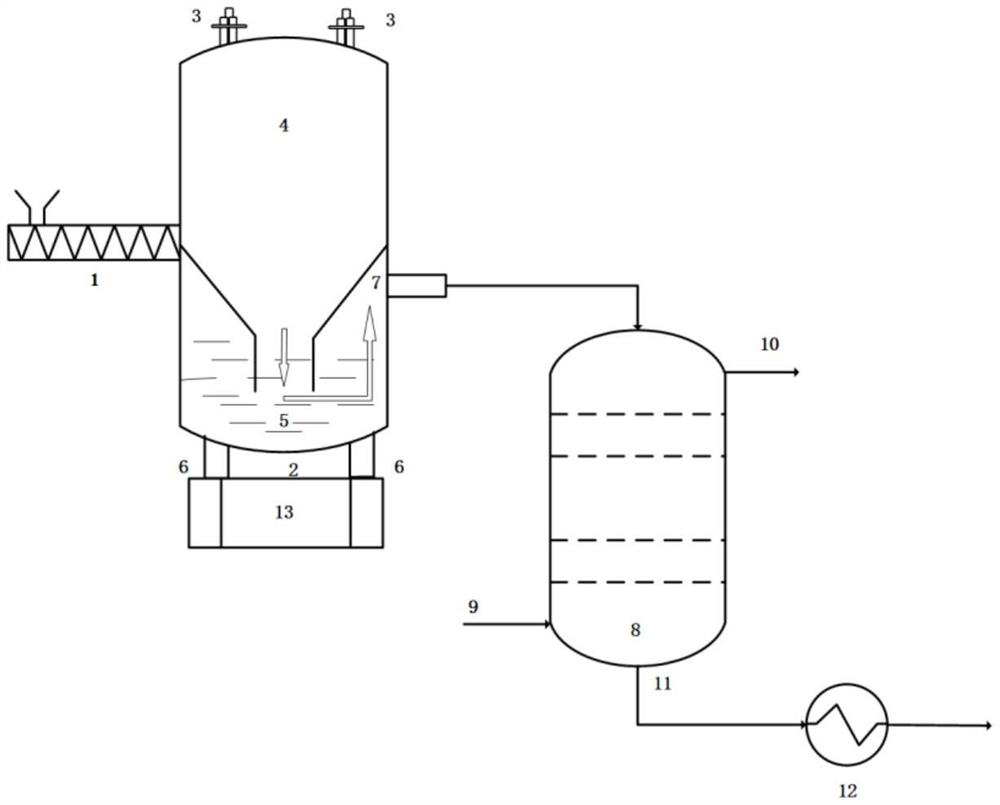

Yellow phosphorus preparation process based on oxygen thermal method

PendingCN112624069AReduce manufacturing costEconomic advantageEnergy inputPhosphorus compoundsPhosphateChemical engineering

The invention aims to overcome the defects of high production cost, low byproduct gas yield and the like in the prior art, and provides a yellow phosphorus preparation process based on an oxygen thermal method. A feeding nozzle 3 is arranged at the top of an entrained-flow bed reactor, a phosphate ore feeder 1 is arranged at the middle-lower part of the furnace, a synthesis gas outlet 7 is formed in the middle-lower part of the furnace, a slag discharge port 6 is formed in the bottom of the furnace, and the interior of a hearth is divided into a gasification reaction zone 10 and a molten pool reaction zone 11 from top to bottom. The synthesis gas outlet 7 is connected with a cylinder body 8 with a water cooling wall; and the cylinder body is simultaneously provided with a water supply inlet 9 and a steam outlet 10. And a synthesis gas outlet 11 of the water-cooled wall cylinder is connected with a phosphate ore / silica preheater 12. Excessive coal and oxygen are subjected to partial gasification reaction to generate a large amount of heat and coke, the heat and the coke are used for reduction of phosphate ore, the generated yellow phosphorus sublimates into the synthesis gas, then the yellow phosphorus in the synthesis gas is separated and purified, and the byproduct high-quality synthesis gas can be used as a chemical raw material.

Owner:车建青

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com