Method for treating sodium oxalate solid waste residues produced in aluminum oxide production process

A technology of sodium oxalate and solid waste residue, which is applied in the removal of solid waste, chemical instruments and methods, preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., to achieve high utilization value, simple process and good economy and the effect of environmental value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

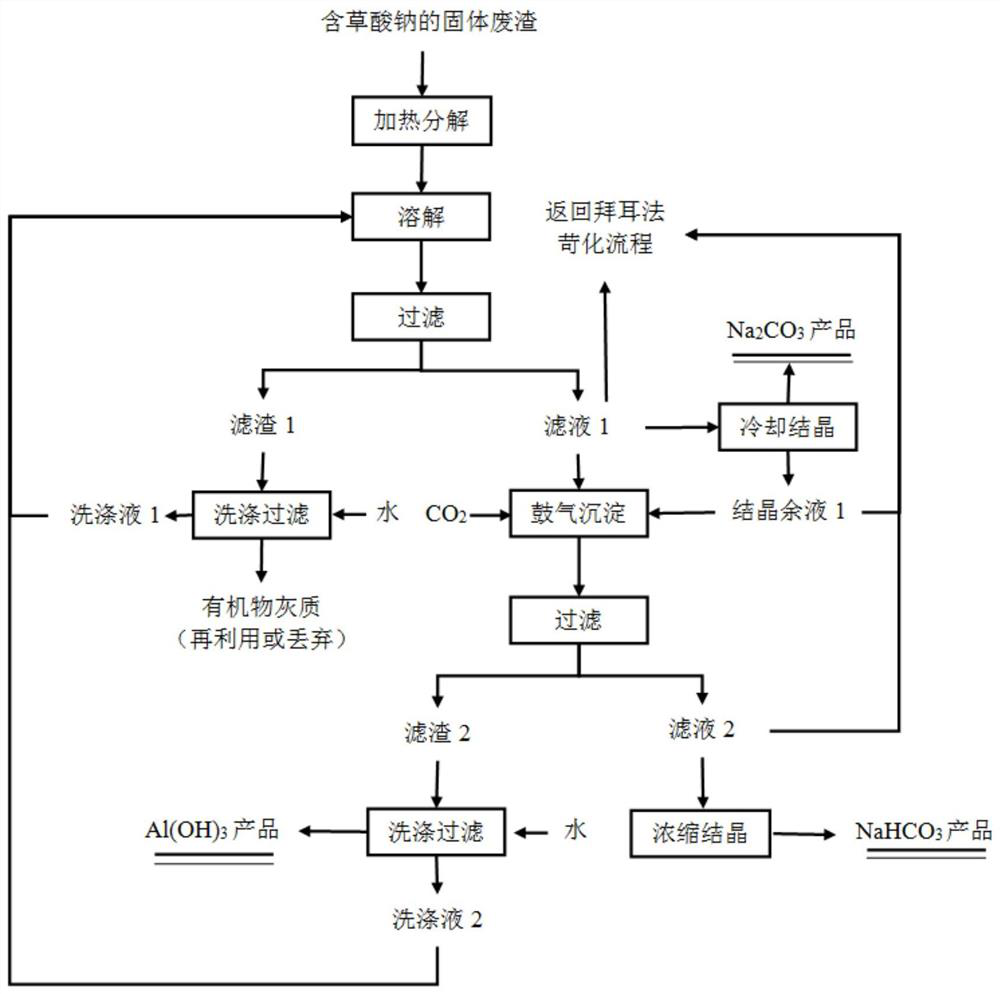

[0036] A kind of treatment method of sodium oxalate solid waste residue in alumina production process, such as figure 1 As shown, the steps of its technological process are:

[0037] (1) the sodium oxalate solid waste residue separated out by removing sodium oxalate from the mother liquor of Bayer process alumina production is heated and decomposed for 1h under the condition that the temperature is 750°C to obtain a decomposed product, and the sodium oxalate solid waste residue contains sodium oxalate The mass percentage of sodium aluminate is 75%, the mass percentage of sodium aluminate is 1%, and the mass percentage of water is 8%;

[0038] (2) the decomposition product is dissolved under the condition of 45 ℃, the dissolving amount of the decomposition product is the decomposition product that every liter of water adds 380g, obtains filter residue 1 and filtrate 1 (containing sodium carbonate, sodium aluminate and sodium hydroxide after filtration) mixed solution);

[003...

Embodiment 2

[0042] A kind of treatment method of sodium oxalate solid waste residue in alumina production process, such asfigure 1 As shown, the steps of its technological process are:

[0043] (1) The sodium oxalate solid waste residue separated out by removing sodium oxalate from the mother liquor of Bayer process alumina production is heated and decomposed for 2.5h under the condition that the temperature is 500° C. to obtain a decomposed product, and the sodium oxalate solid waste residue contains oxalic acid The mass percentage of sodium is 80%, the mass percentage of sodium aluminate is 6%, and the mass percentage of water is 4%;

[0044] (2) the decomposition product is dissolved under the condition of 40 ℃, the dissolving amount of the decomposition product is the decomposition product that every liter of water adds 500g, obtains filter residue 1 and filtrate 1 (containing sodium carbonate, sodium aluminate and sodium hydroxide after filtration) mixed solution);

[0045] (3) filt...

Embodiment 3

[0049] A kind of treatment method of sodium oxalate solid waste residue in alumina production process, such as figure 1 As shown, the steps of its technological process are:

[0050] (1) the sodium oxalate solid waste residue separated out by removing sodium oxalate from the mother liquor of the alumina production by the Bayer process is heated and decomposed for 1.5h under the condition that the temperature is 650° C. to obtain a decomposed product, and the sodium oxalate solid waste residue contains oxalic acid The mass percentage of sodium is 76%, the mass percentage of sodium aluminate is 4%, and the mass percentage of water is 10%;

[0051] (2) the decomposition product is dissolved under the condition of 35 ℃, the dissolving amount of the decomposition product is the decomposition product that every liter of water adds 450g, obtains filter residue 1 and filtrate 1 (containing sodium carbonate, sodium aluminate and sodium hydroxide after filtration) mixed solution);

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com