Pulping system for producing paper products by recycling waste paper

A technology of recycling and paper products, which is applied in the field of waste paper recycling and processing, can solve the problems of reduced value of recycled paper, difficulty in forming, loss of meaning of recycled waste paper and reuse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

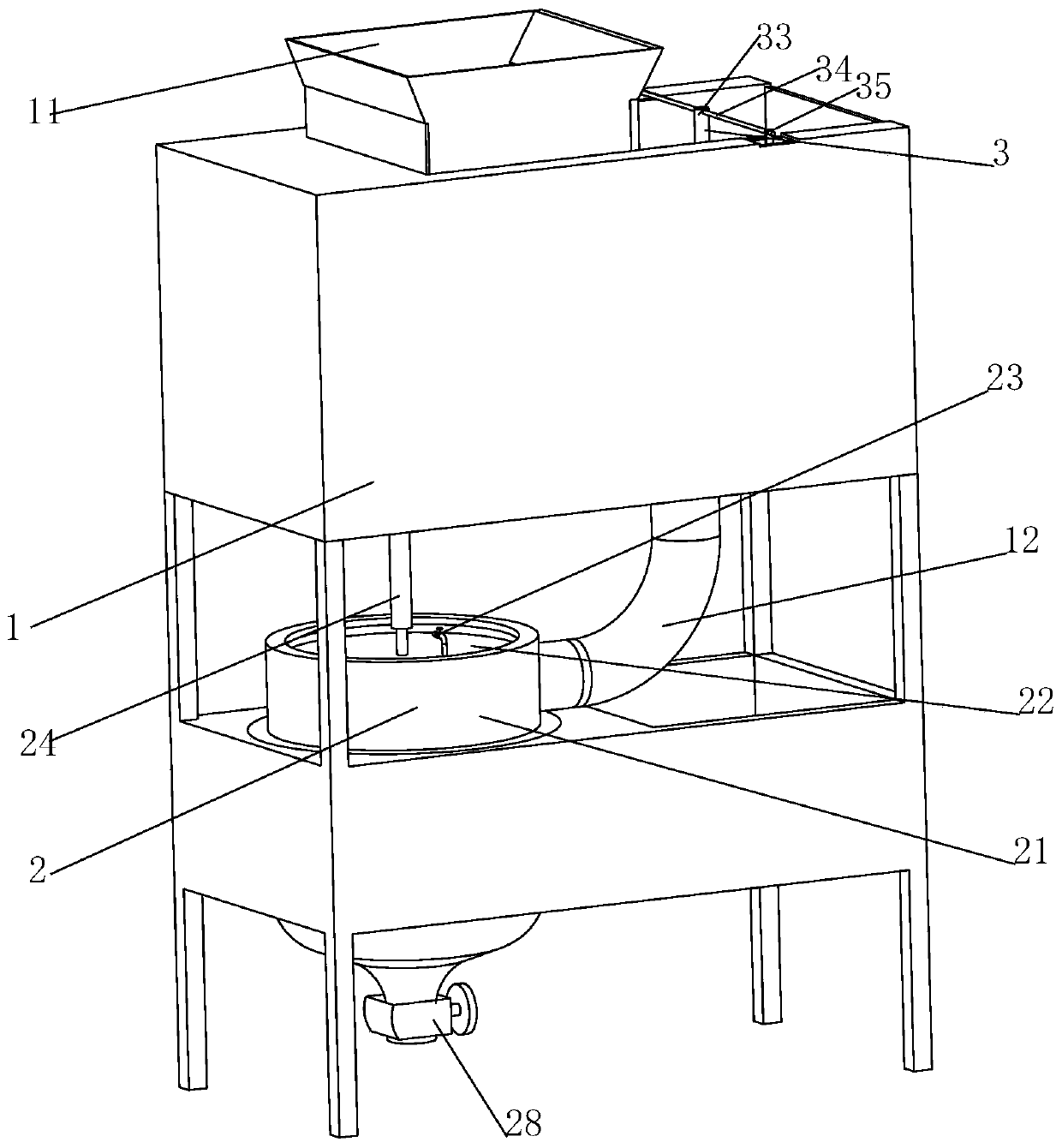

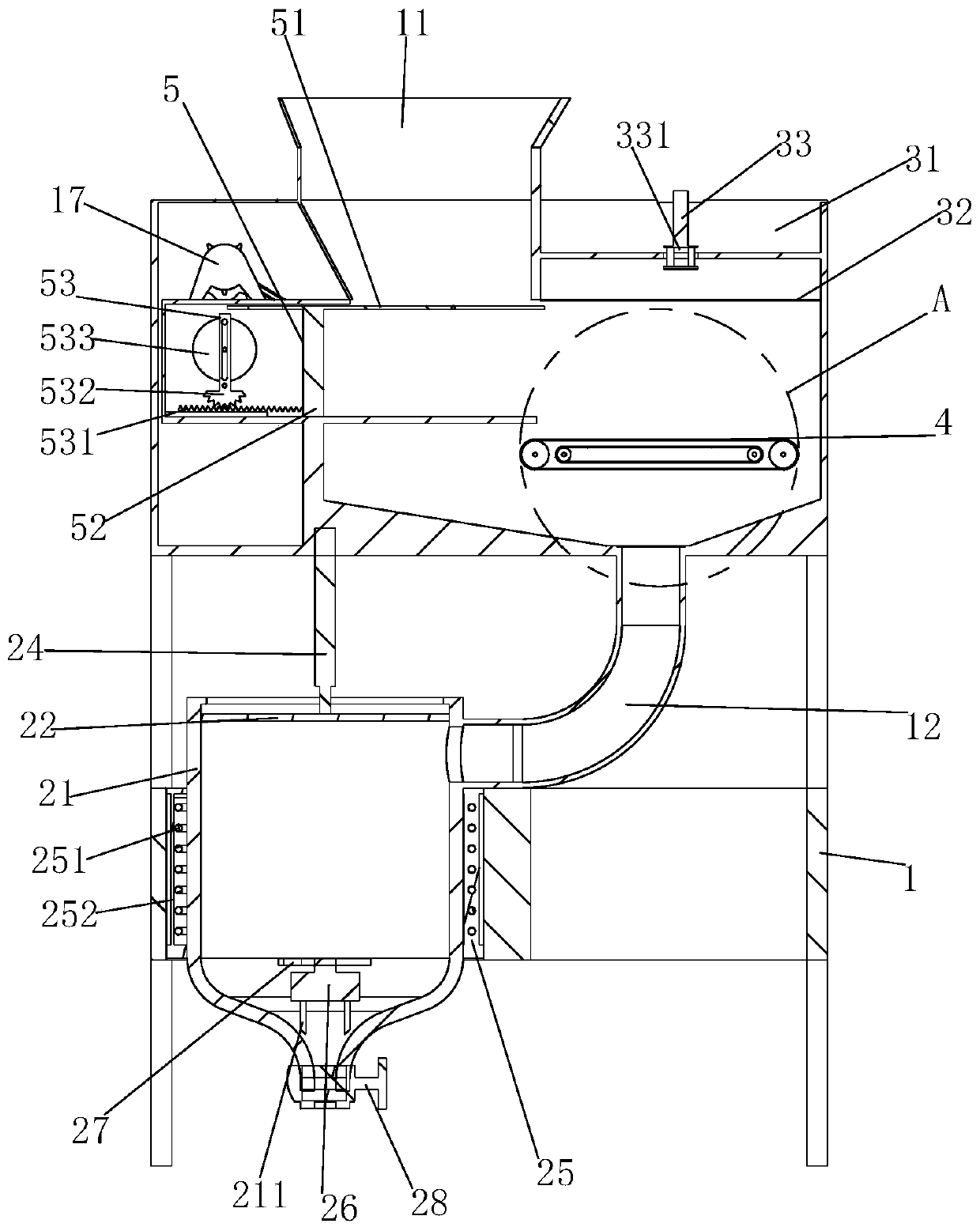

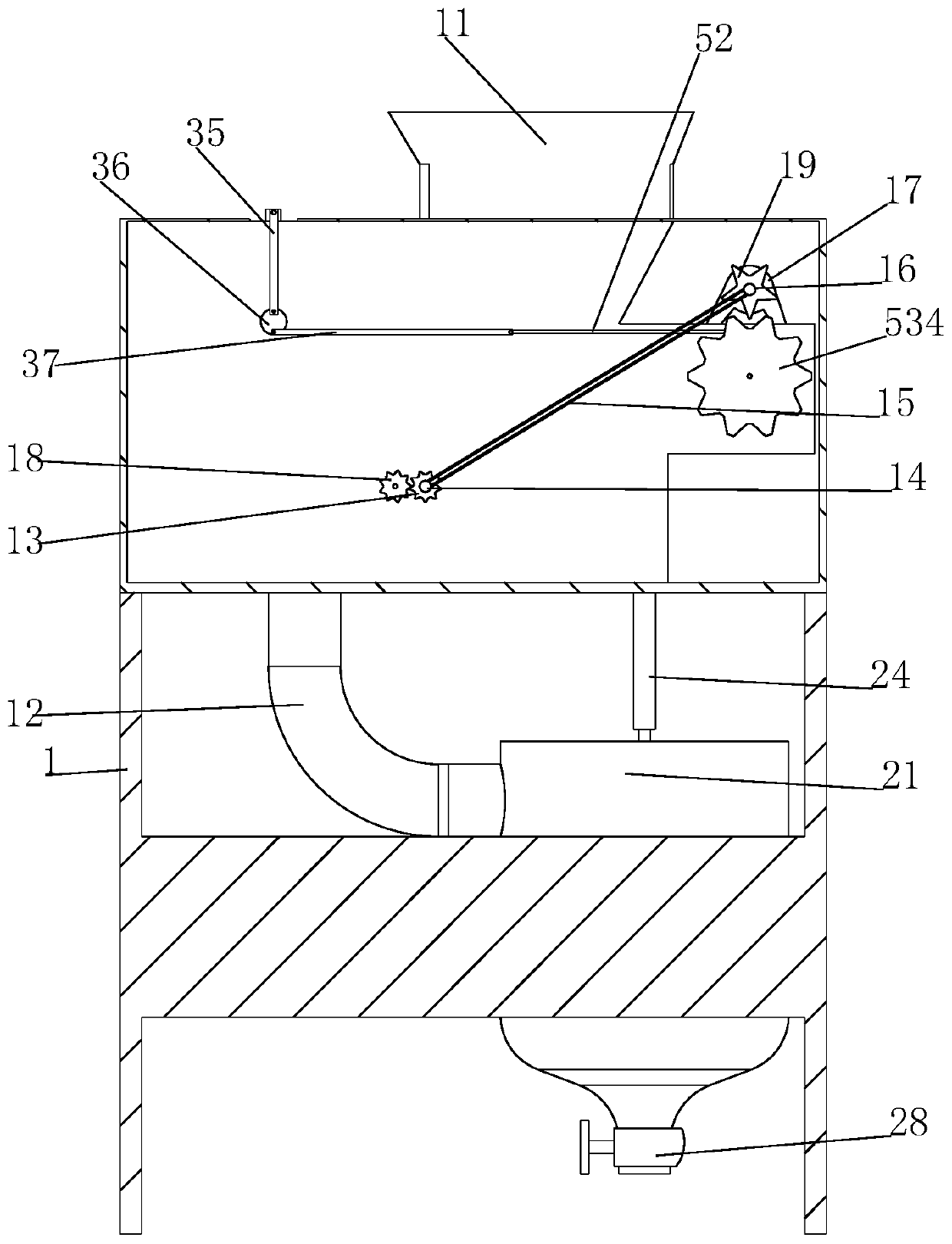

[0021] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, below in conjunction with Fig. 1 to Figure 4 , to further elaborate the present invention.

[0022] A pulping system for recycling and reusing waste paper to produce paper products, comprising a mounting frame 1, a pulping device 2, a spraying device 3, a crushing device 4 and a pushing device 5, characterized in that: a pulping device is installed at the bottom of the mounting frame 1 Device 2, a spraying device 3 is installed on the right side of the top of the mounting frame 1, a material inlet 11 is provided on the left side of the top of the mounting frame 1, a pushing device 5 is arranged below the material inlet 11, and a crushing device is installed on the right side of the middle part of the mounting frame 1 4. A feeding pipe 12 is connected between the pulping device 2 and the crushing device 4, and the spraying device 3 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com