Bamboo and wood double-layer floor

A double-layer, floor technology, applied in the direction of floor, building, building structure, etc., can solve the problems of low production efficiency, uncomfortable foot feeling, poor elasticity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

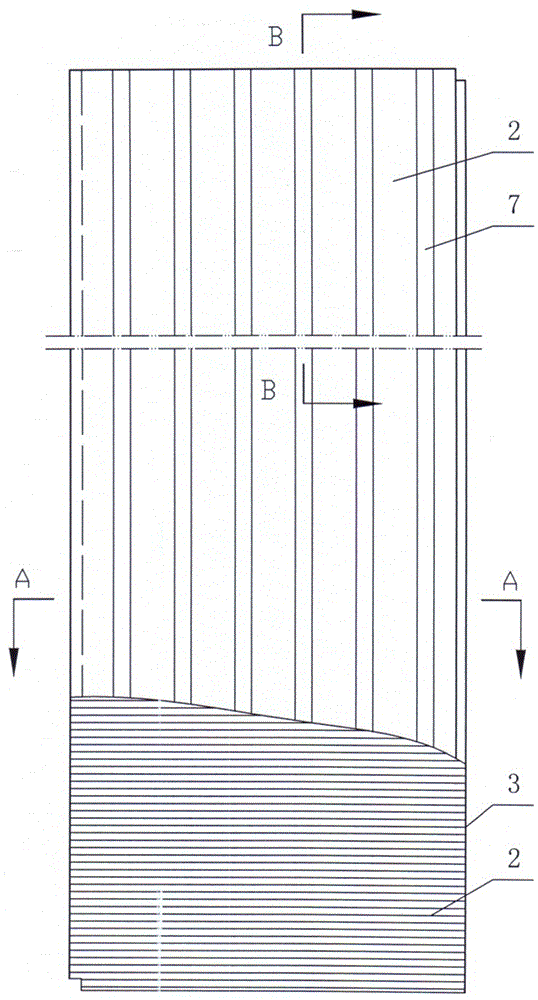

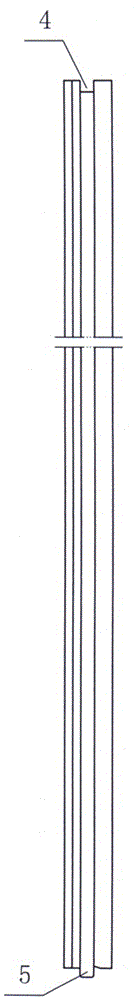

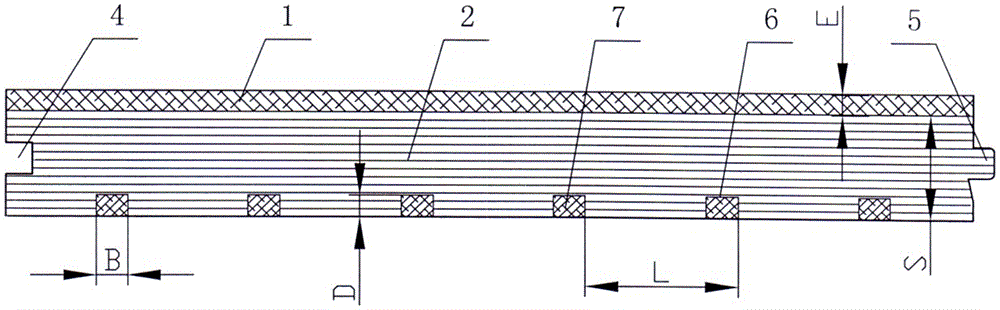

[0031] Example 1: figure 1 , figure 2 , image 3 , Figure 4 It is a schematic diagram of the structure of a bamboo-wood double-layer floor whose floor wood fibers are perpendicular to the long side of the floor. It can be seen from the figure that it includes a long strip-shaped panel 1 made of a whole piece of log and a whole piece of log under panel 1. The finished bottom plate 2, wherein the thickness of the panel 1 is E, and the bottom plate 2 is made of a whole piece of pine wood with a thickness of S. The wood fiber direction of the panel 1 is parallel to the long side 3 of the floor, the wood fiber direction of the bottom plate 2 is perpendicular to the long side 3, the panel 1 and the bottom plate 2 are bonded by adhesive, and a female groove is formed around the bottom plate 2 4 and male tenon 5, as the opening of mutual splicing. On the lower surface of base plate 2, be shaped on the groove 6 in a row perpendicular to the wood fiber direction of base plate 2, d...

Embodiment 2

[0032] Example 2: Figure 4 , Figure 5 , Figure 7 , Figure 8 It is a schematic diagram of the structure of bamboo-wood double-layer flooring with the wood fiber of the bottom board parallel to the long side of the floor. It can be seen from the figure that it includes a long strip-shaped panel 1 made of a whole piece of log and a whole piece of log under panel 1. The finished bottom plate 2, wherein the thickness of the panel 1 is E, and the bottom plate 2 is made of a whole piece of pine wood with a thickness of S. The wood fiber direction of the panel 1 is parallel to the long side 3 of the floor, the wood fiber direction of the bottom plate 2 is parallel to the long side 3, the panel 1 and the bottom plate 2 are bonded by adhesive, and a female groove is formed around the bottom plate 2 4 and male tenon 5, as the opening of mutual splicing. On the lower surface of base plate 2, be shaped on the groove 6 in a row perpendicular to the wood fiber direction of base plate...

Embodiment 3

[0033] Example 3: Figure 9 , Figure 10 , Figure 11 , Figure 12 It is a schematic diagram of the structure of the built-in double-layer bamboo flooring in which the wood fiber of the bottom plate is perpendicular to the long side of the floor. It can be seen from the figure that it includes a long panel 1 made of a whole piece of log and a whole piece of wood under the panel 1. A base plate 2 made of logs, wherein the thickness of the panel 1 is E, and the base plate 2 is made of a whole piece of pine with a thickness of S. The wood fiber direction of the panel 1 is parallel to the long side 3 of the floor, the wood fiber direction of the bottom plate 2 is perpendicular to the long side 3, the panel 1 and the bottom plate 2 are bonded by adhesive, and a female groove is formed around the bottom plate 2 4 and male tenon 5, as the opening of mutual splicing. Rows of grooves 6 perpendicular to the wood fiber direction of the bottom plate 2 are formed on the upper surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com