Method for comprehensive utilization of cracking C4

A technology for cracking carbon and materials, which is applied in the fields of dehydration of hydroxyl-containing compounds to prepare ethers, organic chemistry, and hydrogenation to hydrocarbons, etc. Great economic benefits and low utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

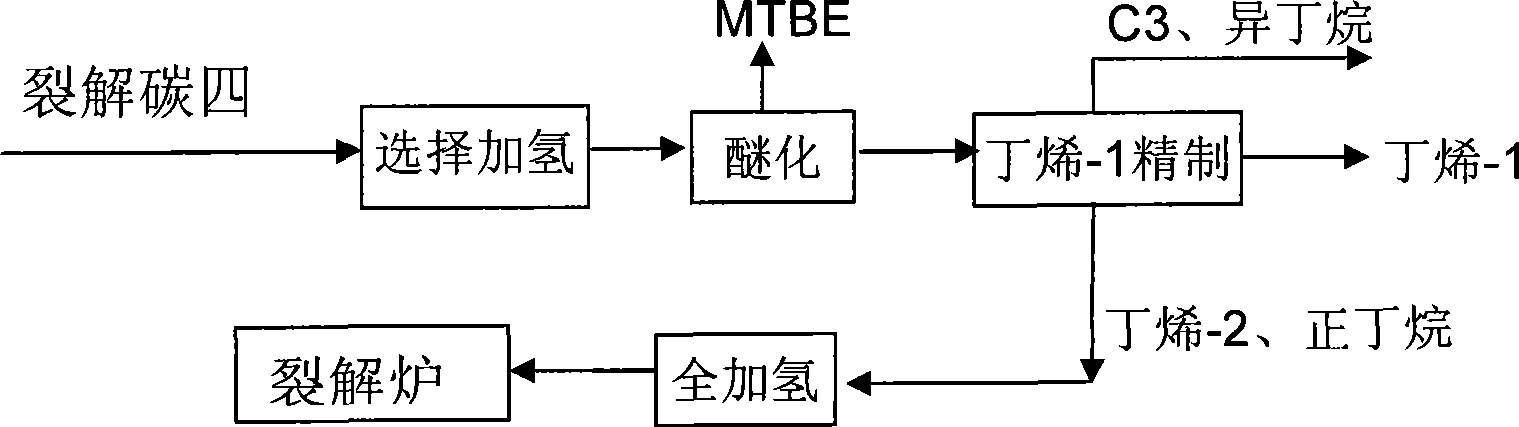

[0040] Reference attached figure 1 Describe the process.

[0041] The mixed C4 component from the ethylene plant, the temperature is 40°C, the pressure is 0.3MPa, the main composition and its mass percentage content are: 50% of 1,3-butadiene, 0.5% of isobutane, 2.3% of n-butane, trans -2-butene 7.3%, cis-2-butene 5.1%, isobutene 22.8%, 1-butene 10%. The cracked mixed C4 enters the selective hydrogenation reactor to remove the diolefins and alkynes therein. The reactor is a fixed-bed reactor, and the catalyst is a Group VIII metal catalyst added with rare earth elements, such as the catalyst for the selective hydrogenation of alkynes and dienes disclosed in the patent CN99112545.2. The reaction conditions are temperature 40°C, pressure 1.0MPa, liquid space velocity 20h -1 . Select the hydrogenation product to enter the etherification unit, use QRE type macroporous cation exchange resin (produced by Qilu Petrochemical Research Institute) as the catalyst, and the reaction con...

Embodiment 2

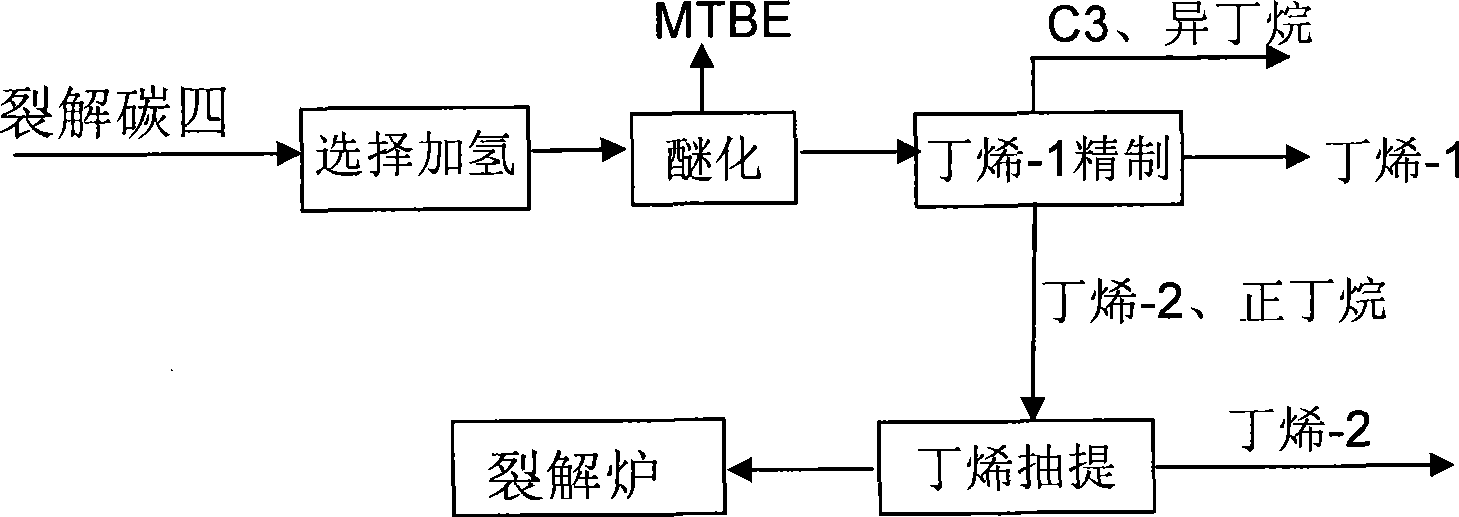

[0043] Reference attached figure 2 Describe the process.

[0044] The material mainly containing butene-2 and n-butane in Example 1 is sent to the butene extraction unit, which includes an extractive distillation column and a desorption column. The extractive distillation tower uses acetonitrile as a solvent, extracts a raffinate containing 93.4% of n-butane and 6.6% of butene from the top of the extractive distillation tower, and is sent to the cracking furnace for recycling; The acetonitrile solvent of ene-2 is sent to the desorption tower; the butene-2 product with a purity of more than 93% obtained from the top of the desorption tower is sent out of the boundary area, and the acetonitrile solvent is obtained in the tower reactor, and returned to the extraction and rectification tower recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com