Patents

Literature

433 results about "Methyl tertiary butyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methyl tertiary butyl ether (methyl tert-butyl ether, methyl t-butyl ether, or MTBE) is a chemical compound once commonly used in the United States as a fuel additive in gasoline. While the use of MTBE as a fuel additive in gasoline helped to reduce harmful air emissions, accidental releases and spills have contaminated surface and groundwaters.

Aqueous emulsion polymerization in the presence of ethers as chain transfer agents to produce fluoropolymers

The present invention provides a method of making a fluoropolymer comprising repeating units derived from one or more gaseous fluorinated monomers. The method comprises an aqueous emulsion polymerization of gaseous fluorinated monomers in the presence of an ether selected from the group consisting of dimethyl ether (DME), methyl tertiary butyl ether (MTBE) and mixtures thereof.

Owner:3M INNOVATIVE PROPERTIES CO

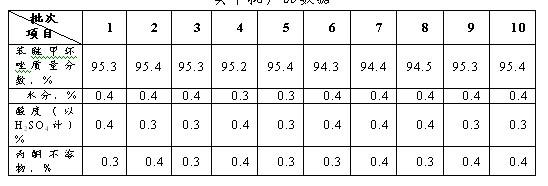

Method for producing low-sulfur methyl tertiary butyl ether

ActiveCN102491882ASatisfy to reconcileFulfil requirementsEther separation/purificationSulfur contentRaw material

The invention provides a method for producing low-sulfur methyl tertiary butyl ether (MTBE), which is used for producing low-sulfur MTBE products by re-rectifying MTBE containing sulfur. The method can use the MTBE with 10-150 ppm of sulfur content as a raw material to produce the MTBE products with containing sulfur content less than 10 ppm or even less than 5 ppm, and can use the MTBE with sulfur content more than150 ppm to produce the MTBE products with sulfur content less than 150 ppm. Especially, produced MTBE with the sulfur content less than 10 ppm or even less than 5 ppm can not only meet blend requirements of state V clean gasoline, but also requirements of industrial chemical raw materials can be met.

Owner:HEBEI REFINING TECH CO LTD

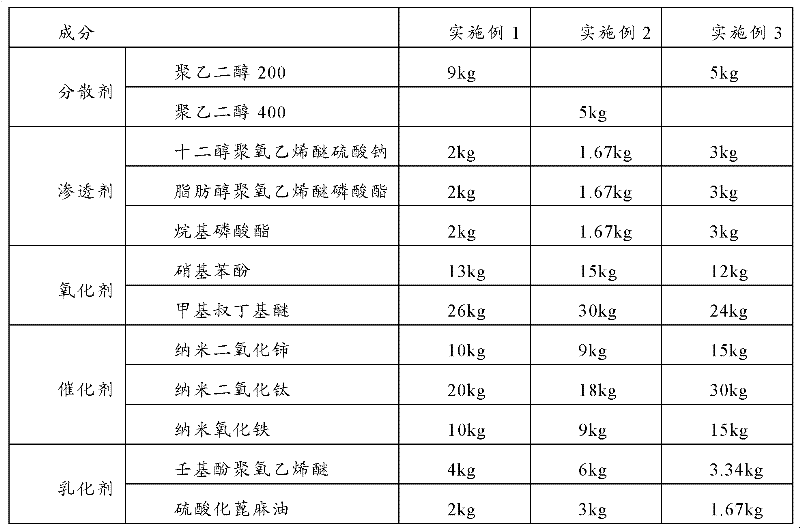

A kind of coal combustion accelerant

The invention provides a coal combustion improver which comprises 5 to 10 percent of dispersing agent, 5 to 10 percent of penetrant, 35 to 50 percent of oxidizing agent, 35 to 50 percent of catalyst and 5 to 10 percent of emulsifying agent, wherein the oxidizing agent is a mixture of nitrophenol and methyl tertiary butyl ether; and the catalyst is nano-scale metallic oxide. The coal combustion improver provided by the invention has high combustion improving efficiency and is safe and environmental-friendly. The invention also provides a method for preparing the coal combustion improver.

Owner:安徽海螺材料科技股份有限公司

Aqueous emulsion polymerization in the presence of ethers as chain transfer agents to produce fluoropolymers

The present invention provides a method of making a fluoropolymer comprising repeating units derived from one or more gaseous fluorinated monomers. The method comprises an aqueous emulsion polymerization of gaseous fluorinated monomers in the presence of an ether selected from the group consisting of dimethyl ether (DME), methyl tertiary butyl ether (MTBE) and mixtures thereof.

Owner:3M INNOVATIVE PROPERTIES CO

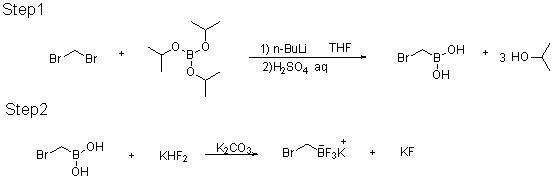

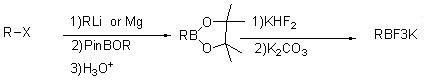

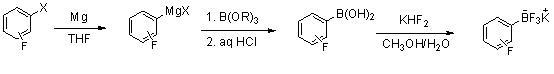

Method for preparing potassium trifluoroborate series compounds

InactiveCN102060867ASolve corrosiveAvoid affecting yieldGroup 3/13 element organic compoundsOrganic baseBoronic acid

The invention relates to synthesis of organic compounds, and provides a method for preparing potassium trifluoroborate series compounds. The method comprises the following steps of: adding organic boric acid or organic borate and solvent (THF (tetrahydrofuran), or MTBE (Methyl Tertiary Butyl Ether), or ethyl acetate, or methanol) into a reaction kettle lined with tetrafluoroethylene plastic at room temperature; adding potassium bifluoride and water at normal temperature, stirring for 1 to 12 hours, and reacting to prepare a solid-liquid mixture; adding solid potassium ion containing inorganic or organic alkali into the solid-liquid mixture after the reaction is completed, neutralizing until the pH is between 7 and 9, and continuously stirring for 1 to 5 hours; directly filtering to obtain a solid coarse product after stirring is completed; dissolving the coarse product with solvent, filtering and concentrating, adding nonpolar solvent, and pulping to obtain high-quality RBF3K series compounds. The method is easy to operate, has mild reaction conditions, and can realize scale-up production; and the product prepared by the method has high yield and excellent purity, and the cost is greatly reduced.

Owner:大连联化医药技术有限公司

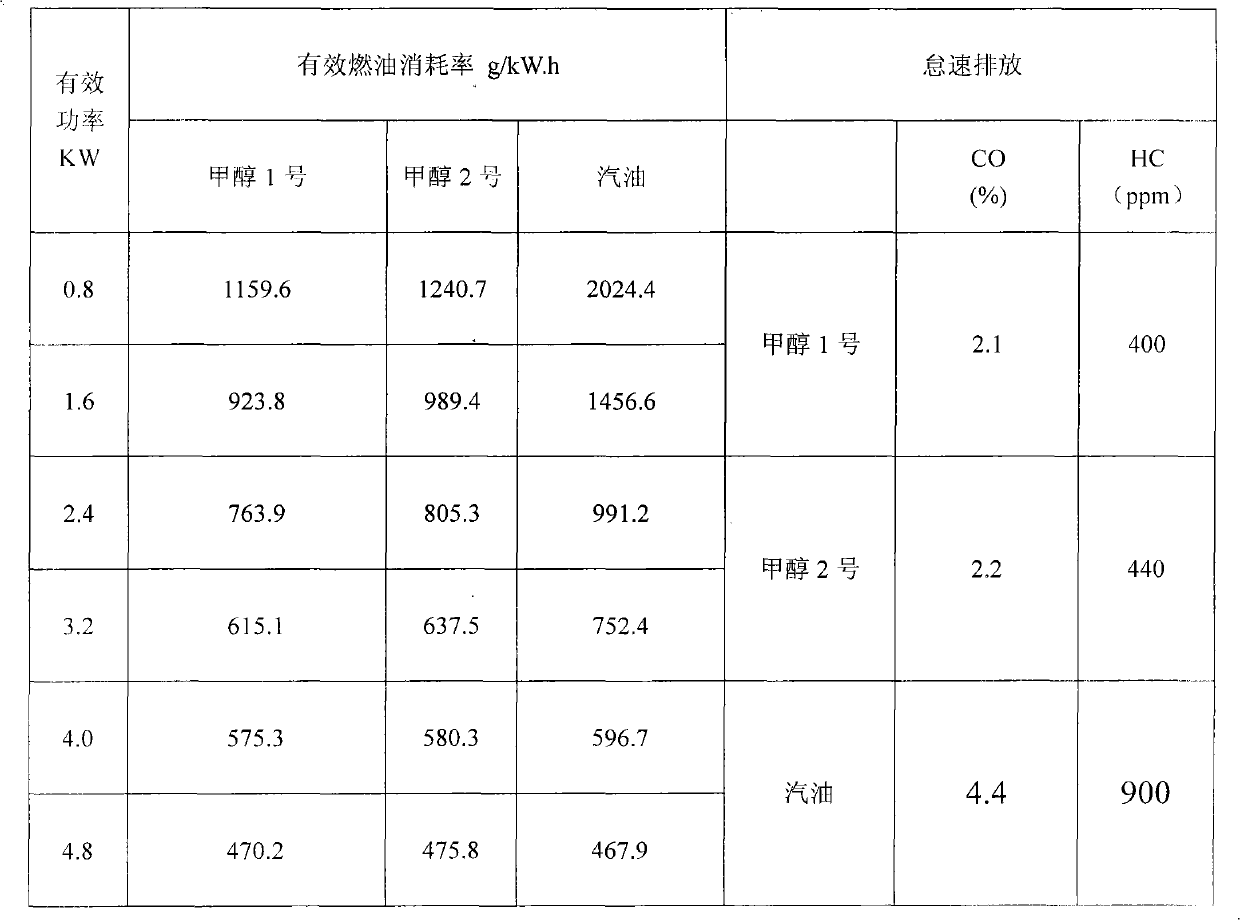

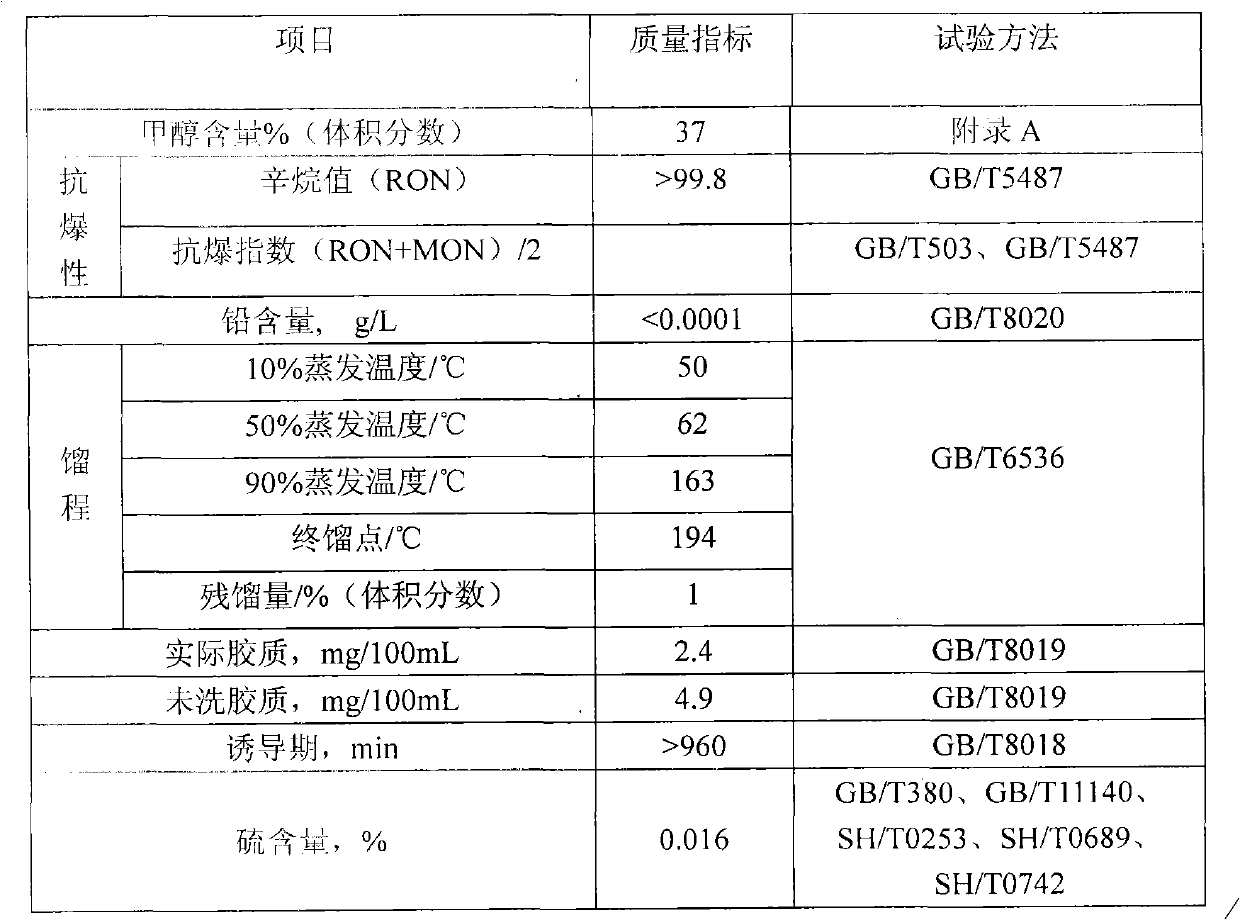

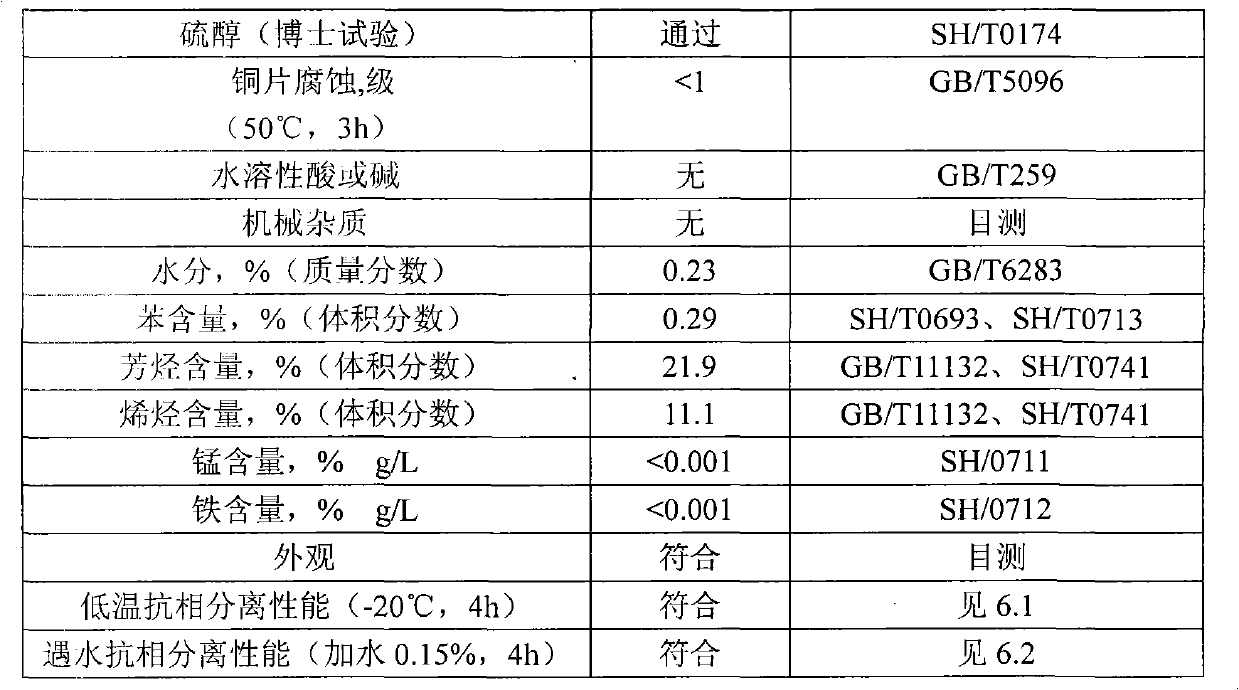

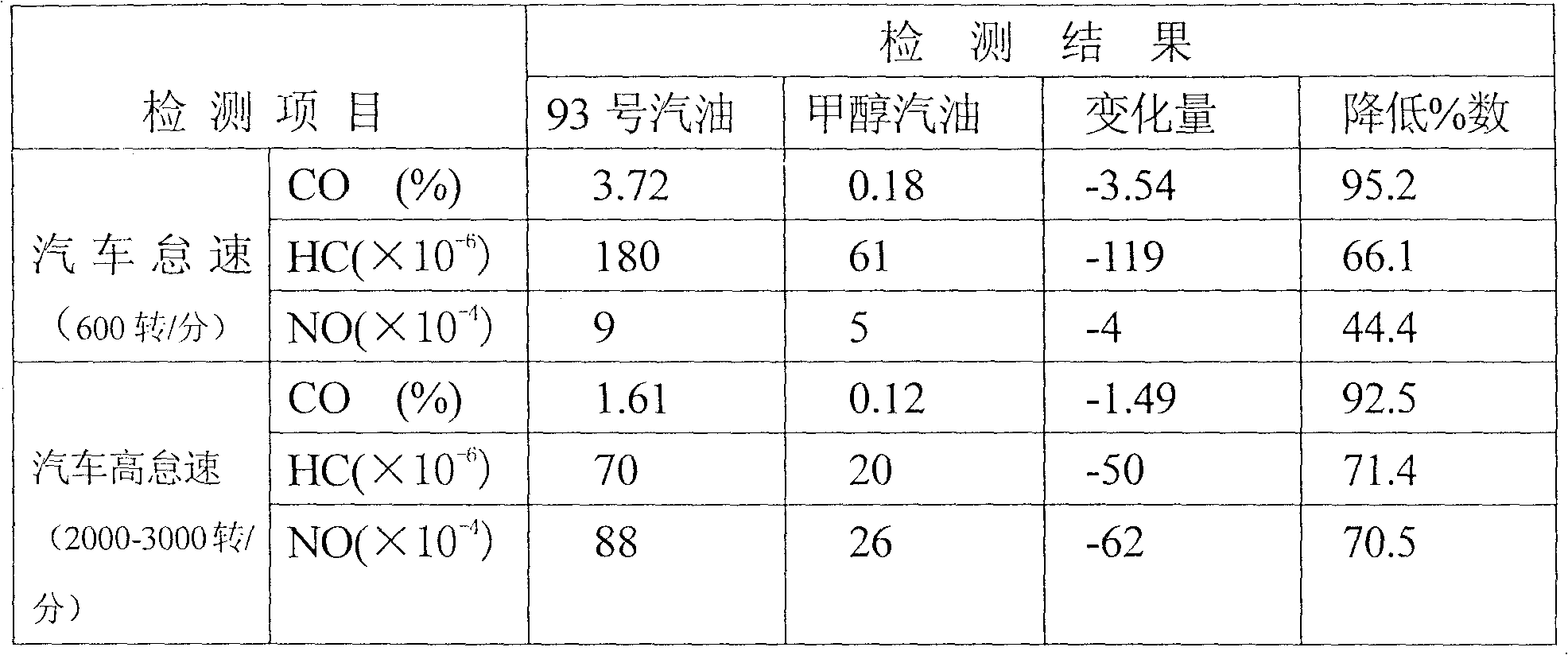

Methanol gasoline

The invention discloses methanol gasoline which is characterized by being prepared from the following raw materials in percent by weight: 40-52 percent of methanol, 50-60 percent of gasoline and 4-15 percent of additive, wherein the additive is prepared from the following raw materials in percent by weight: 3.5-10 percent of methyl tertiary butyl ether, 0.5-2 percent of dimethylbenzene and 0.1-0.5 percent of ethylene glycol monobutyl ether. The methanol gasoline is equivalent to traditional NO. 90, 93 or 97 gasoline in the aspect of combustion dynamic performance and has the advantages of low production cost and less environment pollution.

Owner:叶景榕

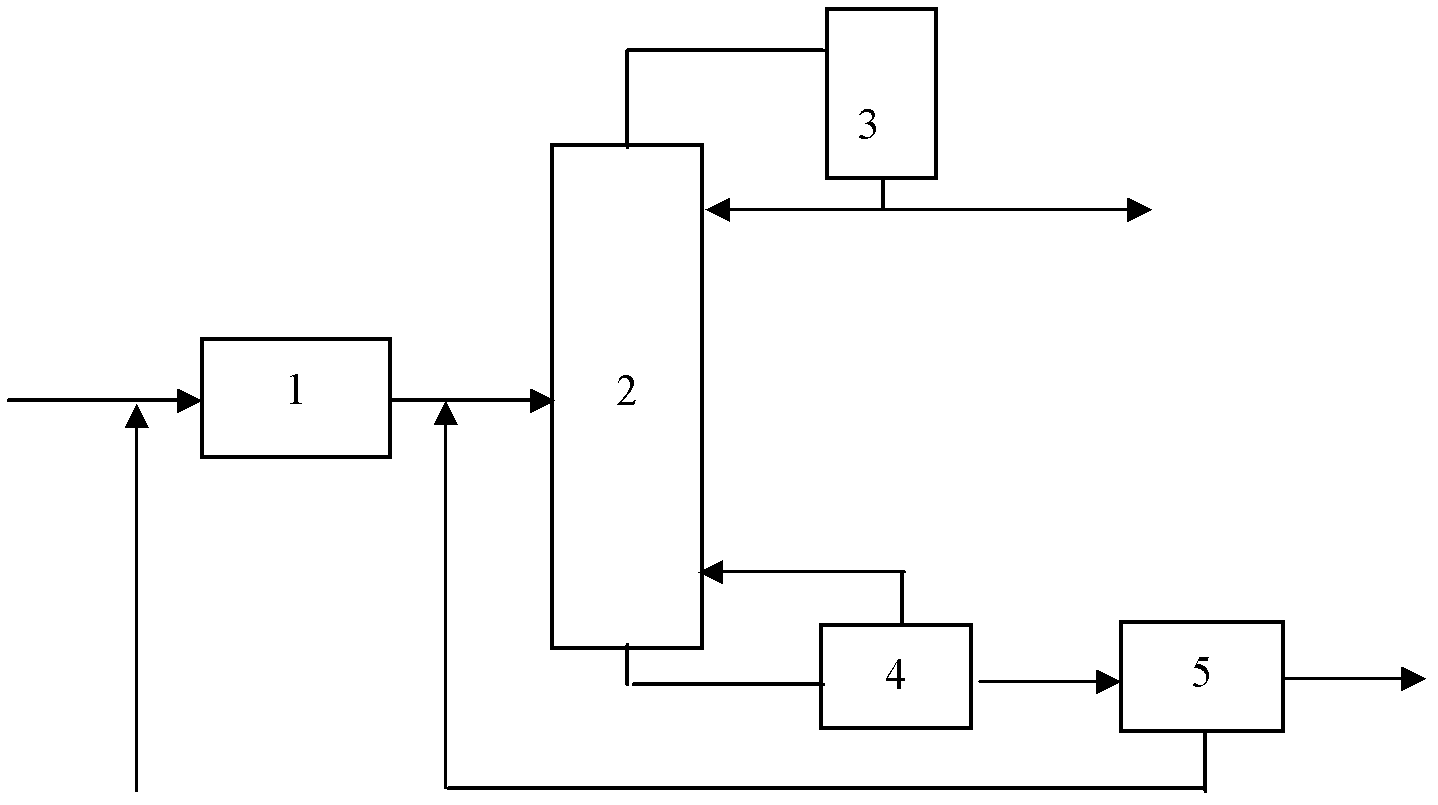

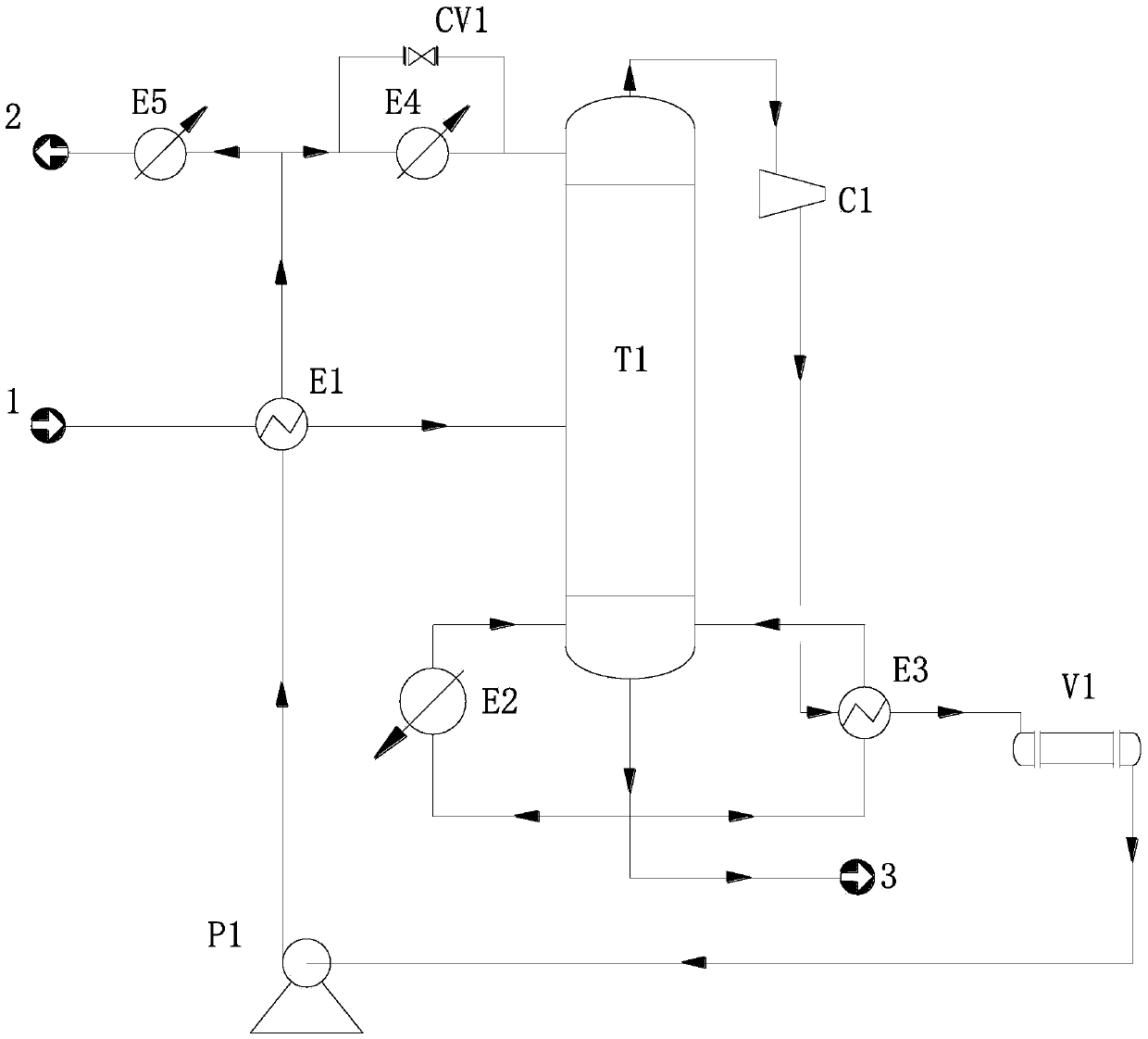

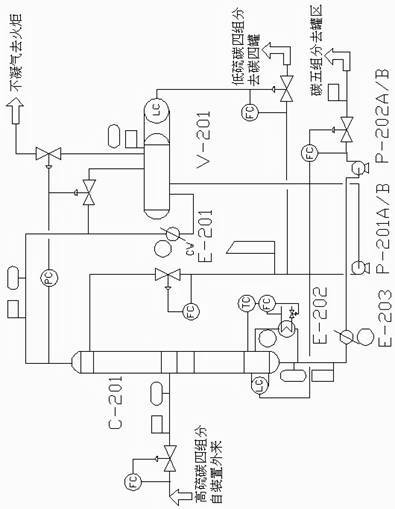

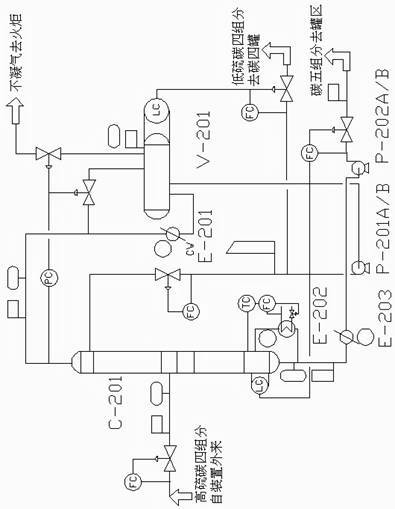

Heat pump rectification device and method for removing sulfide in MTBE

ActiveCN105363235AImprove utilization efficiencyReduce consumptionEther separation/purificationChemical industryRefluxReboiler

The invention relates to a heat pump rectification device and method for removing sulfide in MTBE (Methyl Tertiary Butyl Ether). The device mainly comprises a feed preheater, a rectification tower, a compressor, an auxiliary reboiler, a main reboiler, an auxiliary cooler, a product cooler, a buffer tank and a reflux pump. The gas the distillation tower top is compressed by the compressor into superheated steam, which is used as a heat source and introduced through the reboiler for heat exchange at the tower bottom; and condensed liquid after heat exchange enters the buffer tank, passes through a reflux pump and is preheated with the raw materials by the feed preheater; and part of the cooled liquid is pumped back to the rectification tower for reflux, and the other part of the cooled liquid is recovered as a top product. By using the heat pump distillation, the transfer of the heat taken by the tower top condenser to the reboiler at the tower bottom is realized, which greatly reduces the energy consumption. Sulfur content of MTBE at the distillation tower top is 5-9ppm, and the recovery rate of MTBE is 99.6-99.8%. The device is simple for operation, safe, reliable, efficient and energy-saving.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

Catalyst for producing isobutene by cracking methyl tert-butyl ether

InactiveCN1418729AMeet needsPhysical/chemical process catalystsOrganic chemistrySolid acidCracking reaction

The composition of solid acid catalyst for preparing isobutylene by cracking reaction of methyl tert-butyl ether contains (wt%) 20-95% of aluminium oxide, 0.1-20% of titanium dioxide, 0-5% of other oxide and 0.5-50% of loaded SO4, and its preparation method includes the following steps: adding aluminium oxide into the aqueous solution containing Ti(SO4)2 and other soluble metal salt, filtering, soaking filter cake in ammonia water, filtering, washing, drying, soaking in sulfuric acid solution, filtering, drying and baking so as to obtain the invented SO4 / M-TiO2 / Al2O3 type low-temp. catalyst.

Owner:EAST CHINA UNIV OF SCI & TECH

Environmental-friendly methanol gasoline multifunctional synergist

The invention provides an environmental-friendly methanol gasoline multifunctional synergist which comprises the following components in parts by weight: 35-45 parts of methyl tertiary butyl ether, 20-30 parts of methyl formate, 20-30 parts of dimethylbenzene, 10-20 parts of alkyl isopropanol, 3-20 parts of tertiary butanol, 0.1-0.5 part of dicyclopentadienyl iron, 0.05-0.1 part of hydroxy benzotriazole, 0.5-1 part of dodecyl 2-ethylhexanoate and 0.1 part of triethanolamine. The synergist has low cost, easy obtaining of raw materials and remarkable synergizing effect; the mixed methanol gasoline has power equal to No.93 gasoline and the addition amount of commonly 3-5 in the methanol gasoline, and ensures that the emission of Co in the tail gas is greatly reduced; and the methanol gasoline after the addition has good stability and comprehensive cost reduced by over 30 percent, and is mainly used as a methanol gasoline additive.

Owner:李珍发

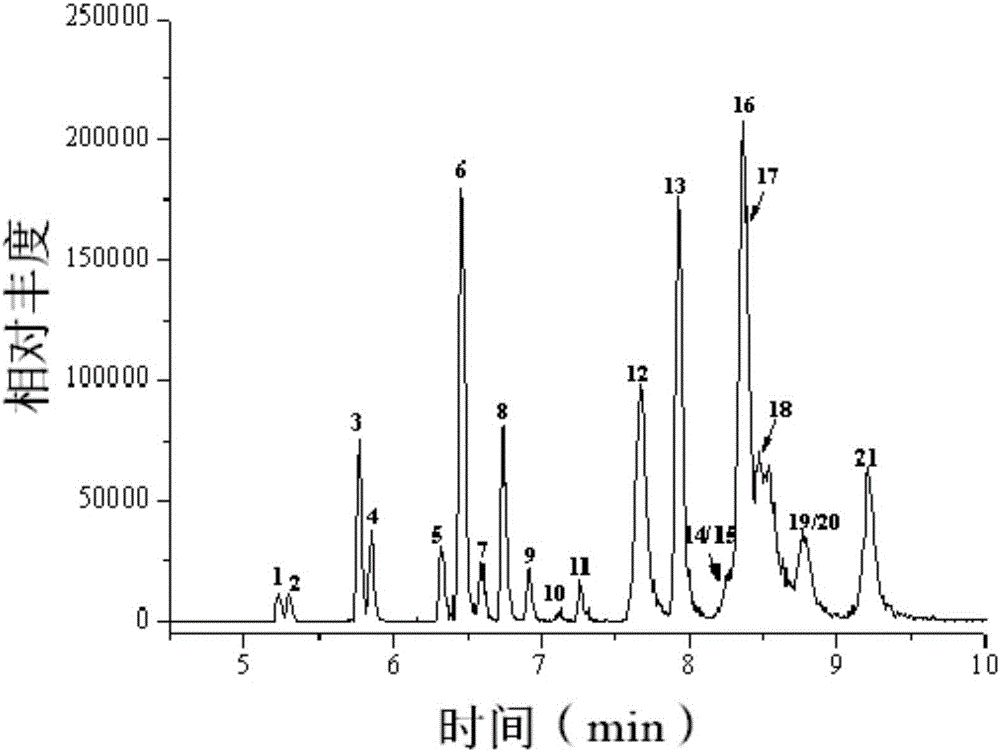

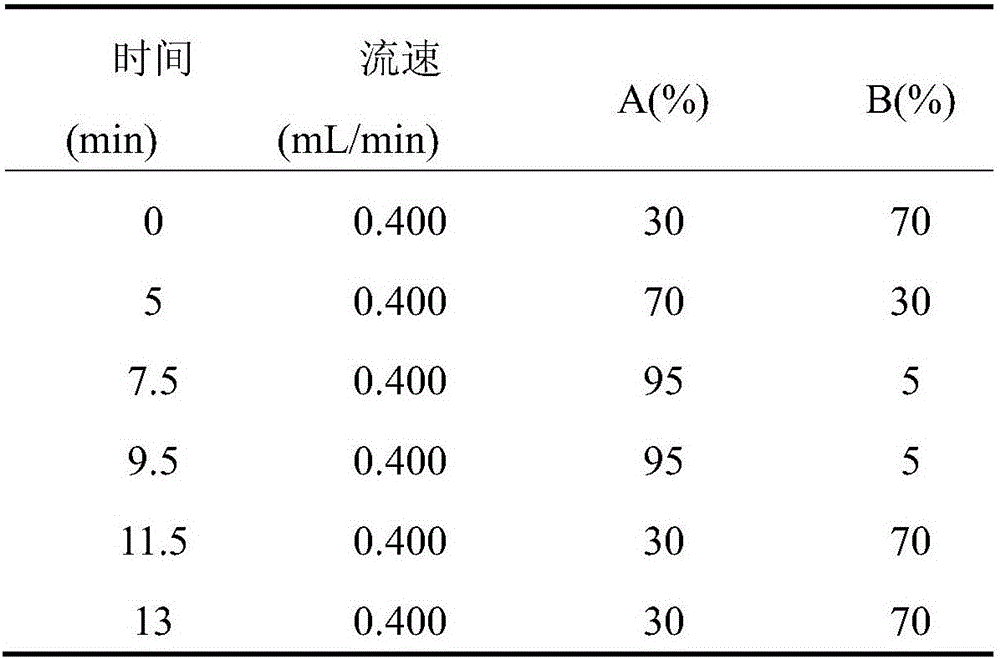

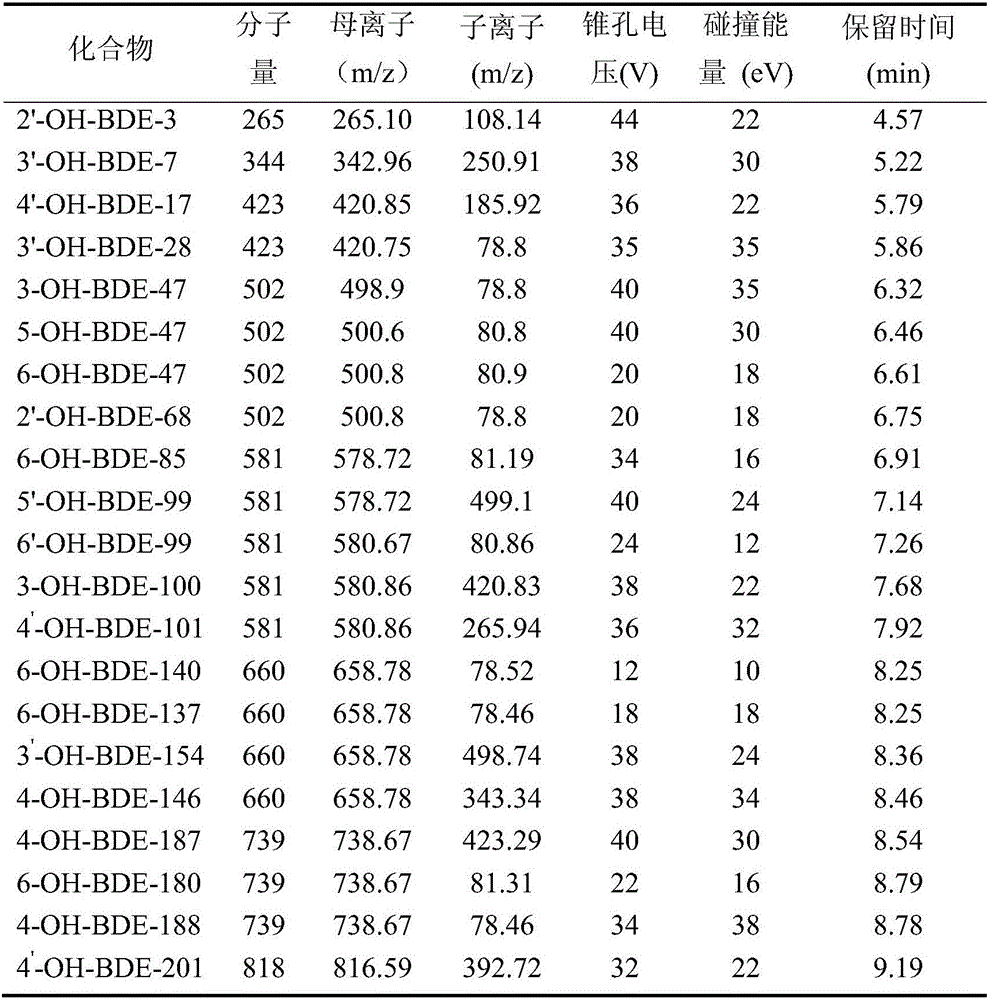

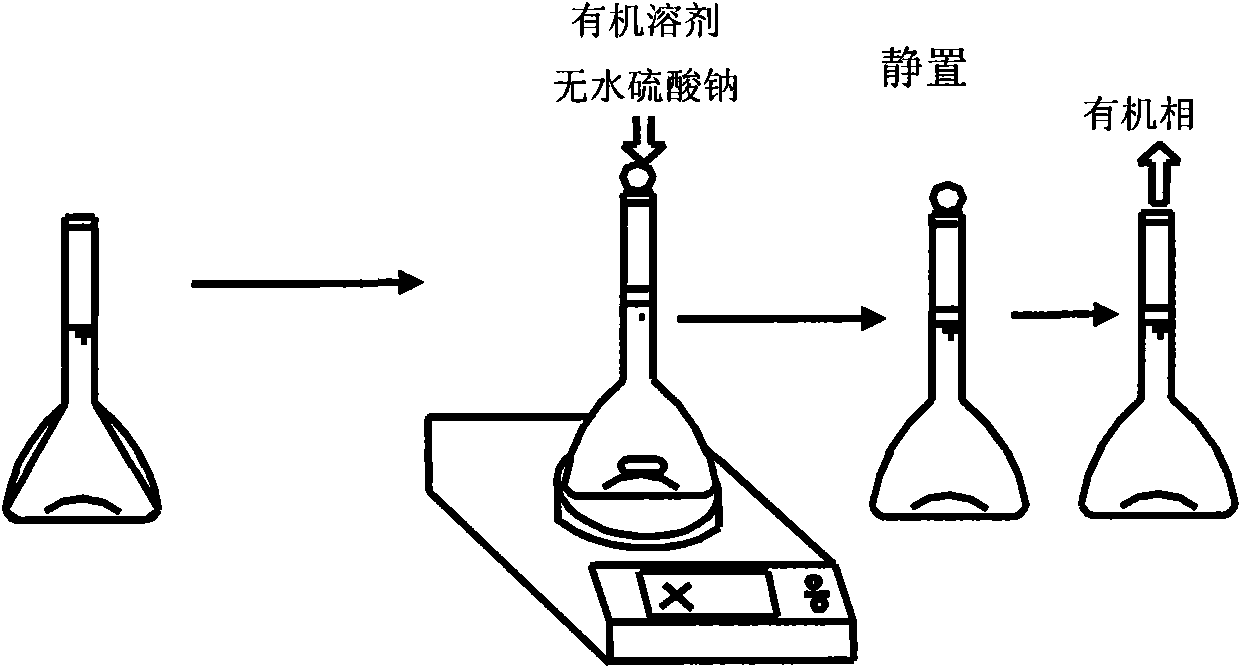

Method for simultaneously detecting 21 hydroxyl polybrominated diphenyl ethers (OH-PBDEs) in soil

The invention discloses a method for simultaneously detecting 21 hydroxyl polybrominated diphenyl ethers (OH-PBDEs) in soil. The method includes the following steps that 1, a soil sample to be detected is extracted with organic solvent, and the organic solvent is selected from normal hexane, acetonitrile, methyl alcohol, dichloromethane, methyl tertiary butyl ether and NaOH-ethyl alcohol; 2, an extracting solution obtained in the step 1 is concentrated and purified; 3, a product in the step 2 is detected through an ultra-high performance liquid chromatography-triple quadrupole tandem mass spectrometer and compared with a hydroxyl polybrominated diphenyl ether standard substance in parallel operation to obtain quantitative results. The method has the advantages of being high in detection speed, accurate in result, high in recovery rate, low in detection limit, high in sensitivity and matrix interference resistance and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

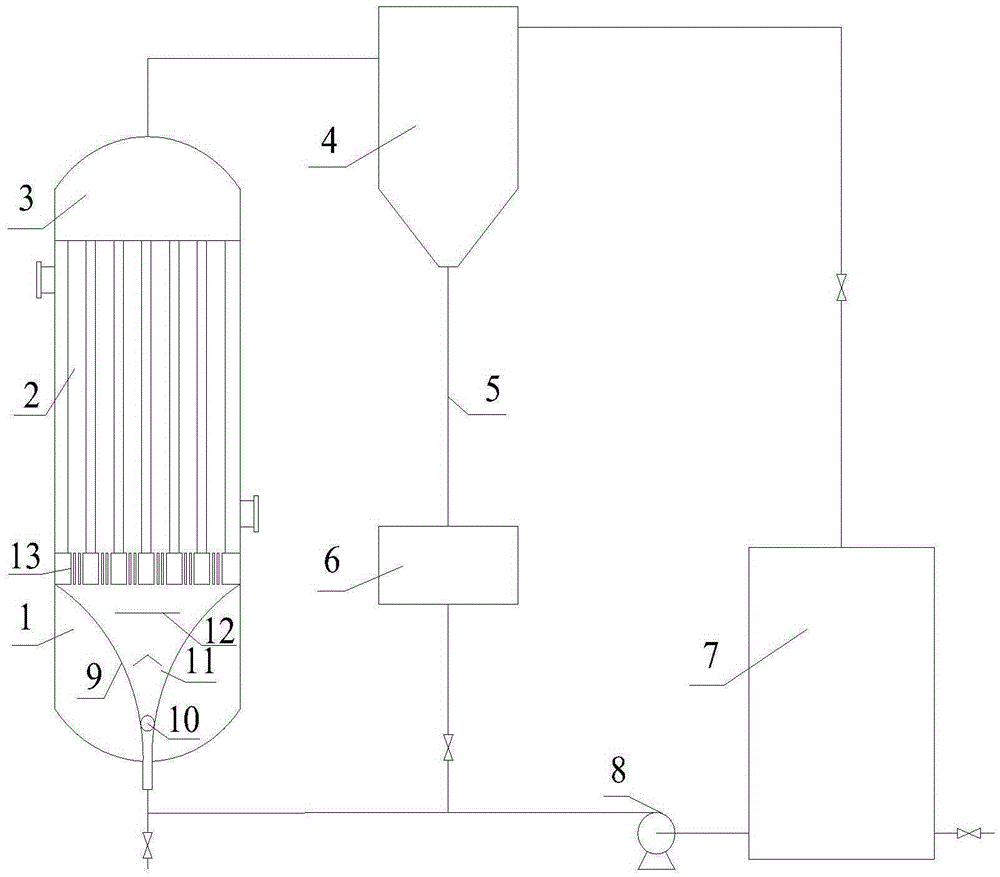

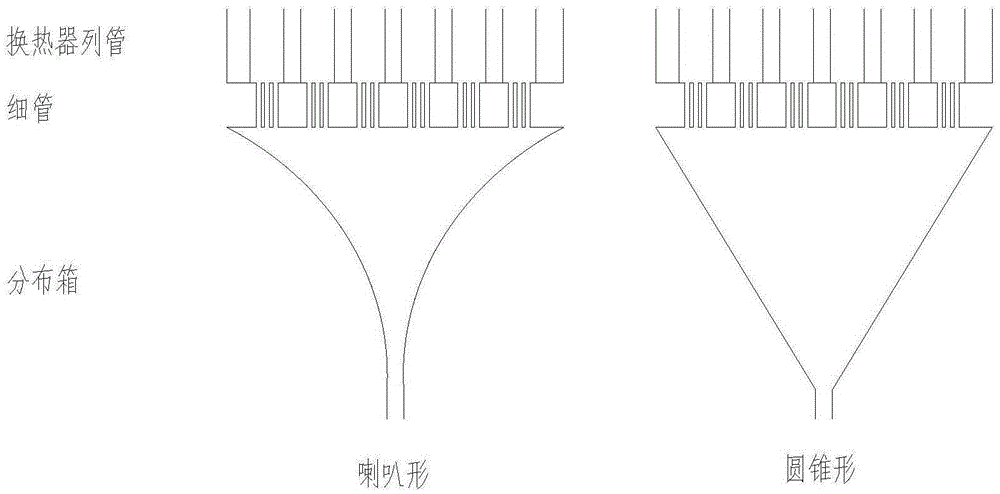

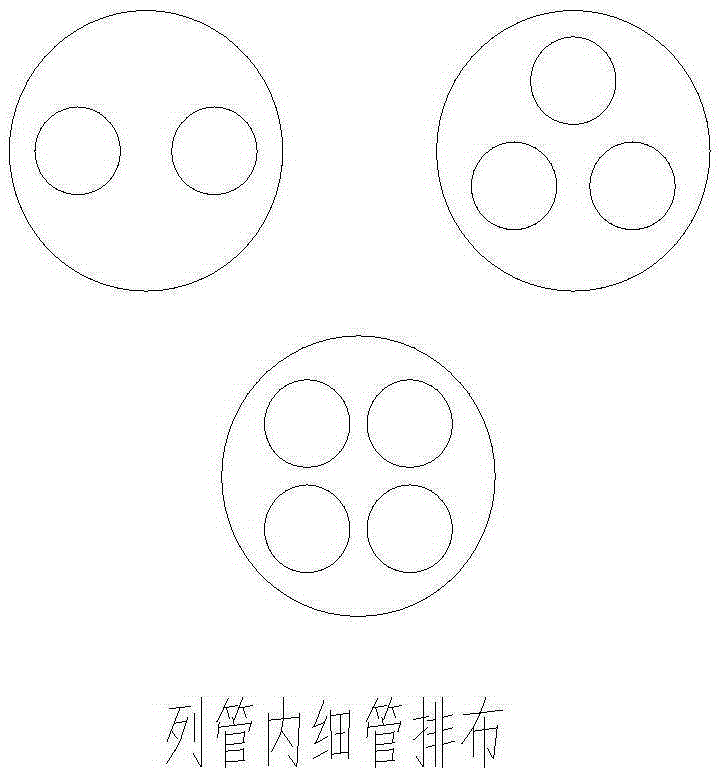

No-scaling fluidized bed heat exchanger

ActiveCN106595348AGood heat transfer coefficientCorrosion preventionStationary tubular conduit assembliesFluidized bedCirculator pump

The invention relates to a no-scaling fluidized bed heat exchanger. The no-scaling fluidized bed heat exchanger is mainly used for solving the technical problems that in the traditional technology, a methyl tertiary butyl ether device refining tower condenser tube pass is liable to scale, and the heat exchange effect is lowered significantly after a long period of usage. According to the adopted technical scheme of the no-scaling fluidized bed heat exchanger, a lower pipe box 1, a heat exchanger tube 2, an upper pipe box 3, a liquid-solid separator 4, a downtake 5, a solid particle trough 6, a liquid storage trough 7, a liquid circulation pump 8, a distribution box 9, a ball plug 10, a baffle 11 and a distribution plate 12 are included; the distribution box 9 is connected with the heat exchanger tube 2 through a thin tube 13; the heat exchanger tube 2 is connected with the upper pipe box 3; the upper pipe box 3 is connected with the liquid-solid separator 4; solid particles enter the solid particle trough 6 through the downtake 5 and then return to the lower pipe box 1; liquid enters the liquid storage trough 7 and is conveyed to the lower pipe box 1 through the liquid circulation pump 8, through the technical scheme, the technical problems are solved well, and the no-scaling fluidized bed heat exchanger can be used for prolonging the operation cycle of a methyl tertiary butyl ether device refining tower condenser.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of unleaded gasoline for vehicle

InactiveCN101787310AEmission reductionReduce fuel consumptionLiquid carbonaceous fuelsIsobutyl alcoholManganese

The invention discloses a production method of unleaded gasoline for a vehicle, wherein the unleaded gasoline is prepared from the following raw materials in parts by weight: 35-65 parts of methanol, 60-30 parts of gasoline, 2-4 parts of isobutyl alcohol, 1-3 parts of acetone, 2-4 parts of methyl tertiary butyl ether, 2-5.5 parts of toluene or dimethyl benzene, 0.01-0.03 part of methyl cyclopentadienyl manganese tricarbonyl, 0.03-0.1 part of butyl octyl zinc thiophosphate and 0.1-3 parts of dicyclopentadienyl iron; the unleaded gasoline is prepared by the method comprising the following steps of: sequentially adding the acetone, the toluene or the dimethyl benzene, the isobutyl alcohol, the methyl tertiary butyl ether, the butyl octyl zinc thiophosphate, the dicyclopentadienyl iron and the methyl cyclopentadienyl manganese tricarbonyl as the raw materials into a container at normal temperature and under normal pressure, fully stirring to obtain a yellow transparent liquid, then adding the yellow transparent liquid into the methanol and fully stirring to obtain modified methanol; adding the modified methanol liquid into the gasoline and uniformly stirring to obtain a finished product. The invention has the advantages of low cost, low pollution, low oil consumption, low corrosion and high power, and each item index of the invention exceeds that of the traditional gasoline.

Owner:刘超

Methanol diesel oil additive and methanol diesel oil

ActiveCN101033414ASolve power problemsSolve emulsification problemsLiquid carbonaceous fuelsOil additiveN-Butyl Alcohol

This invention relates to methyl alcohol diesel oil and its additive, in which, the additive is prepared in the volume ratio of the following raw materials: MTBE 10-15%, normal actane 5-10%, isopropyl acetone 15-20%, n-butyl alcohol 25-30% and methyl cyclopentane 10-35%, and said methyl alcohol is prepared in the volume ratio of the following materials: methyl alcohol 10-25%, diesel oil 70-88% and its additive 2-5%, which solves the technical problems of causticity, swellingness, difficulty of cold starting up, hot air-blocking, separation when meeting water, power reduction, fluidity and emulsification met when using the present methyl acohol.

Owner:CRPC INNOVATION ENERGY

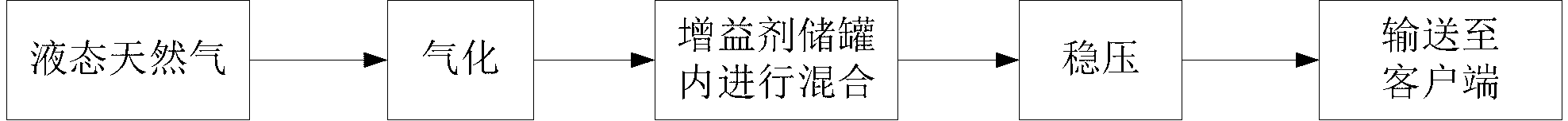

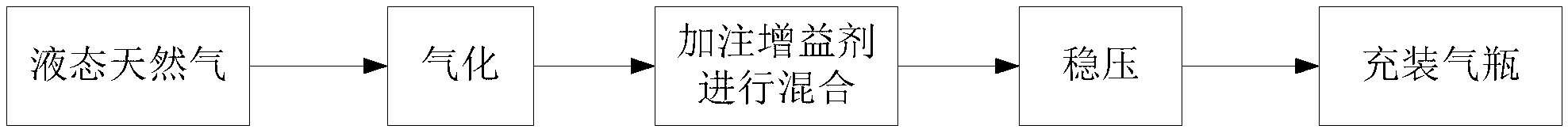

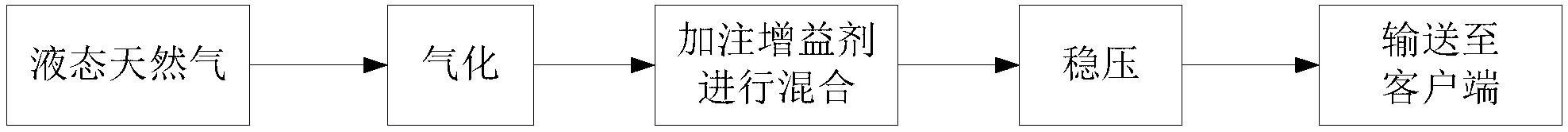

Welding and cutting gas and preparation method thereof

InactiveCN103320190AEasy to prepareNo pollution in the processGaseous fuelsNonaneRare earth metal compounds

The invention discloses a welding and cutting gas which consists of a natural gas and a gain agent, wherein the gain agent consists of a rare earth metal compound, a transition metallocene compound, methanol, toluene, methyl tertiary butyl ether, cyclohexane, nonane, decane and water. Compared with acetylene and propane, the welding and cutting gas is more economical, more energy-saving, more environment-friendly, safer and cleaner. The invention also provides a preparation method of the welding and cutting gas.

Owner:CANGXI COUNTY CHASE GAS INVESTMENT

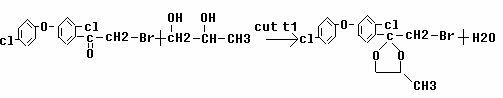

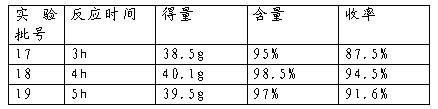

Preparing and refining methods of difenoconazole

The invention belongs to the technical field of raw pesticide preparation, particularly relates to preparing and refining methods of difenoconazole. The refining method comprises the following steps of: dissolving prepared raw difenoconazole with isopropanol, then dropwise adding hydrochloric acid (or introducing hydrochloric acid gas) to obtain crystals, filtering and recycling a solvent; filtering out residues, adding water and methylbenzene, and then regulating the pH value to be neutral with ammonia water, demixing and removing water, desolventizing a methylbenzene layer, and then refluxing with isopropyl ether and methyl tertiary butyl ether, freezing for crystallizing, filtering to obtain refined difenoconazole. The product prepared with the refining method has good dissolubility, few impurities and high crystallization rate (about more than 5 hours); and more finished products can be produced once with the method, and the prepared difenoconazole technical has good quality and moderate viscosity.

Owner:周保东

Methanol gasoline with low gas resistance

ActiveCN103695047ALow saturated vapor pressureGuaranteed uptimeLiquid carbonaceous fuelsNaphthaBase oil

The invention discloses methanol gasoline with low gas resistance. The methanol gasoline with low gas resistance is prepared by mixing and blending 60-80 wt% of base oil, 10-15 wt% of constituent oil and 10-30 wt% of denatured methanol, wherein the constituent oil is a mixture composed of 25-30 wt% of aromatic oil and 70-75 wt% of naphtha; the denatured methanol is formed by mixing methanol with a volume ratio of 95-98% and a depressurization additive with a volume ratio of 2-5%; the depressurization additive is prepared by blending the main materials of polymethoxy dimethyl ether with 3-6 polymerization degrees and dimethyl carbonate, and the auxiliary materials of ethanol, isopropanol, ethylene glycol monomethyl ether, methyl tertiary butyl ether, isoamylol and isooctanol. According to methanol gasoline with low gas resistance disclosed by the invention, the saturated vapour pressure of the low-proportion methanol gasoline is obviously decreased by changing the property of the base oil and adding the depressurization additive.

Owner:CRPC INNOVATION ENERGY

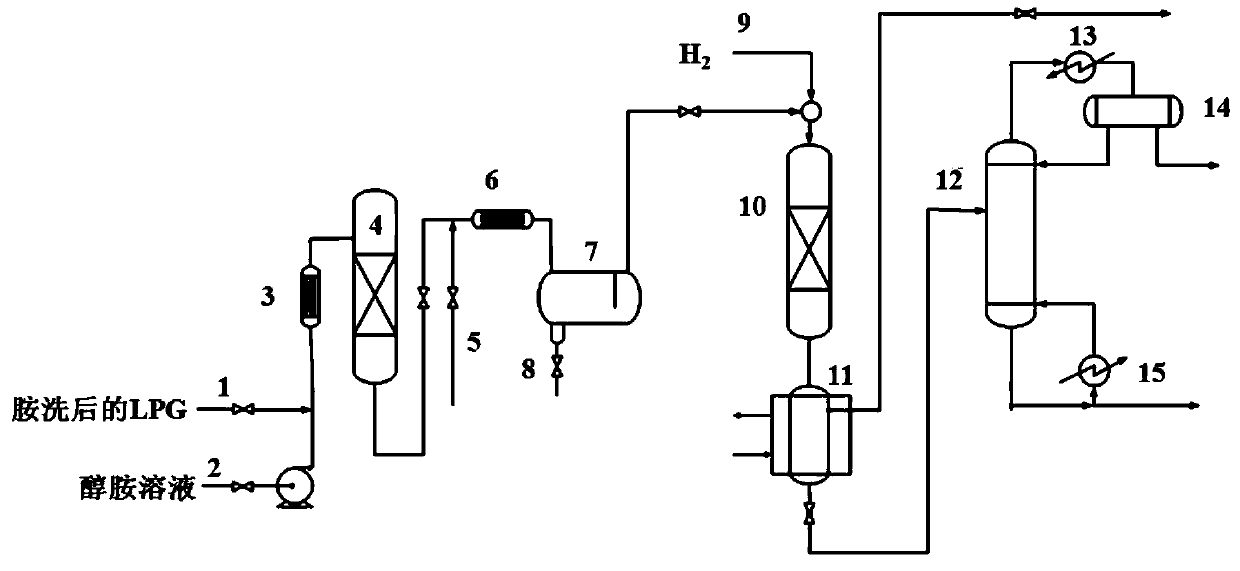

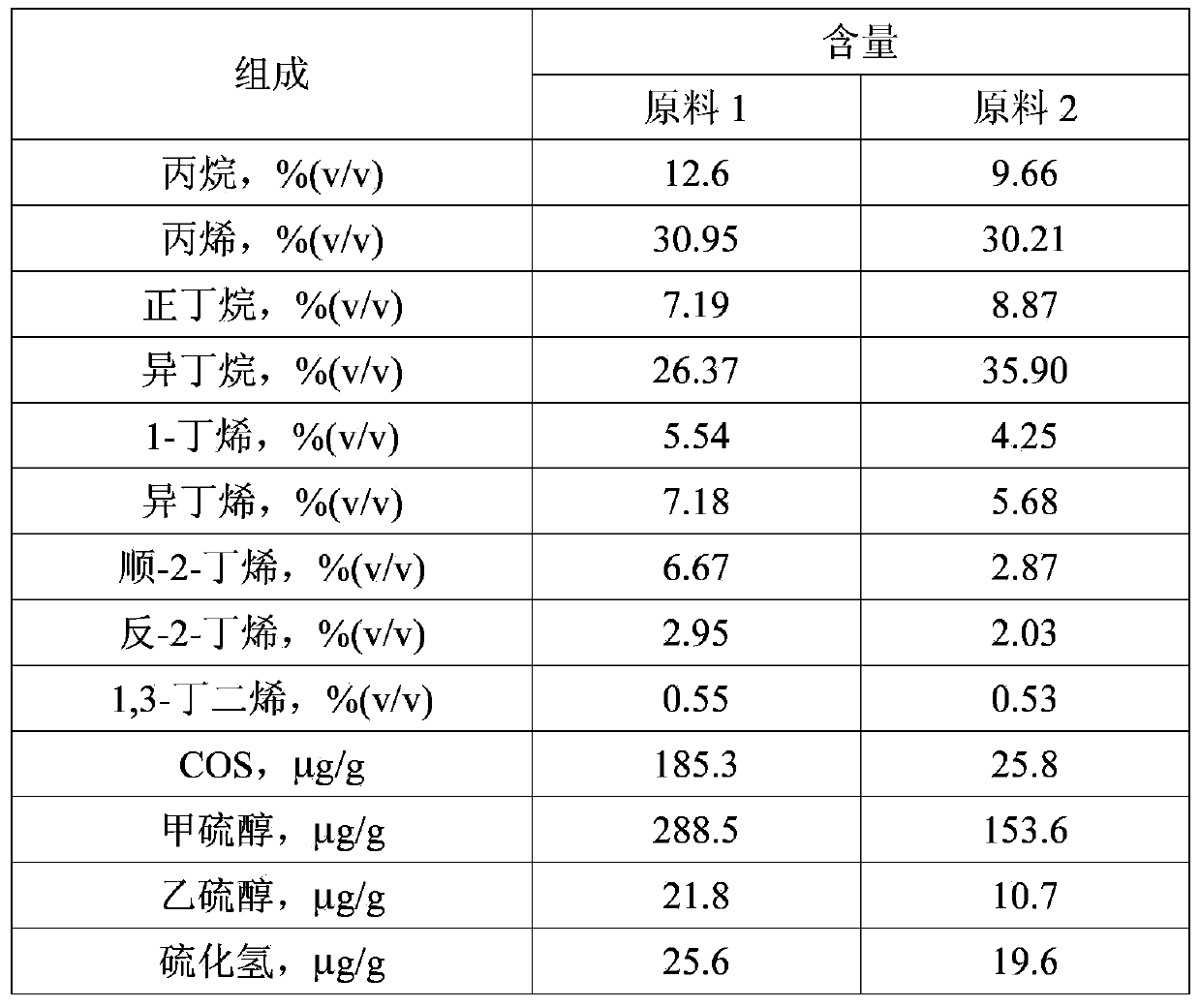

Method for refining liquefied petroleum gas

ActiveCN103992832AAdvantages of refining methodSimple processGaseous fuelsPetroleum productDistillation

The invention provides a method for refining liquefied petroleum gas. The method comprises the following steps: mixing amine-washed liquefied petroleum gas and an alcohol amine solution, and removing carbonyl sulfide and hydrogen sulfide from the liquefied petroleum gas under the coaction of a carbonyl sulfide hydrolysis catalyst and the alcohol amine solution; performing sulfur etherification reaction in contact with a sulfur etherification catalyst to ensure that mercaptan in the liquefied petroleum gas is reacted with olefin and converted into a thioether compound with a high boiling point, and simultaneously performing selective hydrogenation saturation on diolefin; performing distillation treatment, and separating the liquefied petroleum gas fraction from the thioether compound with the high boiling point to obtain a deep desulfurized liquefied petroleum gas product, wherein the refined liquefied gas can be used for producing low-sulfur methyl tertiary butyl ether and alkylation gasoline. According to the method disclosed by the invention, the carbonyl sulfide and the hydrogen sulfide are removed by adopting a one-step method, and the mercaptan is removed by using the catalytic reaction between the raw material components, so that no alkali residue is discharged, the existing process for refining the liquefied petroleum gas is simplified, meanwhile, the purpose of deep desulfurization is achieved, and the sulfur content of the refined liquefied petroleum gas is reduced to below 5mu g / g.

Owner:BC P INC CHINA NAT PETROLEUM CORP +3

Fuel methanol additive and fuel methanol

InactiveCN101033415AClean dischargeSolve corrosiveLiquid carbonaceous fuelsMethanol fuelIsopropyl ether

This invention relates to a fuel methyl alcohol and its additive, in which, the additive is prepared by the following materials in volume: MTBE 15-20%, 2, 2-dimethylpropane 15-20%, n-butyl alcohol 10-15%, alicyclic acid amine 20-25%, nitroacid liquid 5-10% and isopropyl ether 15-20%, and said fuel methyl alcohol is prepared like this: methyl alcohol 80-90% and additive 10-20%.

Owner:CRPC INNOVATION ENERGY

Efficient compound additive of methanol gasoline and preparation method thereof

InactiveCN102888259ABoost octaneAvoid stabilityLiquid carbonaceous fuelsFuel additivesAntioxidantTetrahydrofuran

The invention discloses an efficient compound additive of methanol gasoline. The additive is prepared by mixing the following raw materials by weight percent: 10-15% of isopropanol, 40-70% of isooctanol, 2-10% of methyl tertiary butyl ether, 2-10% of tetrahydrofuran, 5-15% of dimethylbenzene, 0.2-0.5% of metal corrosion inhibitors, 0.1-0.4% of rubber swelling inhibitors, 3-10% of detergent dispersants, 0.5-2% of anti-wear lubricant and 0.05-0.3% of antioxidant. The compound additive has the following beneficial effects that the octane number of the methanol gasoline prepared by adopting the additive is high; the additive can be used for preparing 90#, 93#, 95#, 97# and 98# series of products; containing the metal corrosion inhibitors and the rubber swelling inhibitors, the additive can effectively relieve corrosion of the prepared methanol gasoline to the engines and swelling of rubber parts; with reasonably selected and proportioned raw materials and the detergent dispersants, the additive can effectively avoid unstable weight and easy layering of the methanol gasoline; and the additive has the characteristics of safety in use and convenience in preparation.

Owner:KAILUAN GRP

Novel carbinol gasoline fuel

InactiveCN101550363AEmissions are clean and environmentally friendlyGood environmental effectLiquid carbonaceous fuelsGasoline fuelEngineering

A novel carbinol gasoline fuel relates to an engine fuel, in particular to a novel liquid fuel for a gasoline engine. According to the weight parts, the novel carbinol gasoline fuel is mixed simply by the following raw materials of the composition: 20-80 of gasoline, 20-90 of carbinol, 2-10 of petroleum ether, 1-5 of 2-methylpentane, 0-5 of octane, 0-5 of isooctane, 0-5 of diethyl carbonate, 0-4 of cinnamene, 0.2-4 of trimethyl borate, 0-5 of dibutyl phosphite, 0.5-5 of dimethyl carbonate, 0-5 of methyl tertiary butyl ether, 0-4 of ether, 0-4 of isopropyl ether, 0-6 of acetone, 0-4 of isopropyl alcohol, 0-5 of isobutyl alcohol and 0-4 of anti-oxidant. The antiknock index is reinforced as the octane number is improved; and the compounding is optimized scientifically during the experiment and practice, thus leading the vehicle to keep the best stability on all aspects when the liquid fuel is in use.

Owner:SHANGHAI SAPPHINE FUEL DEV

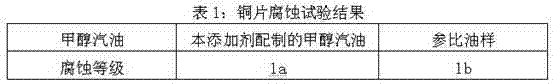

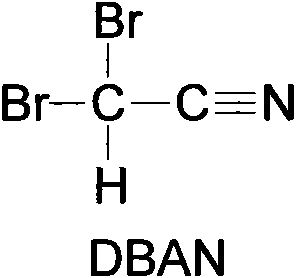

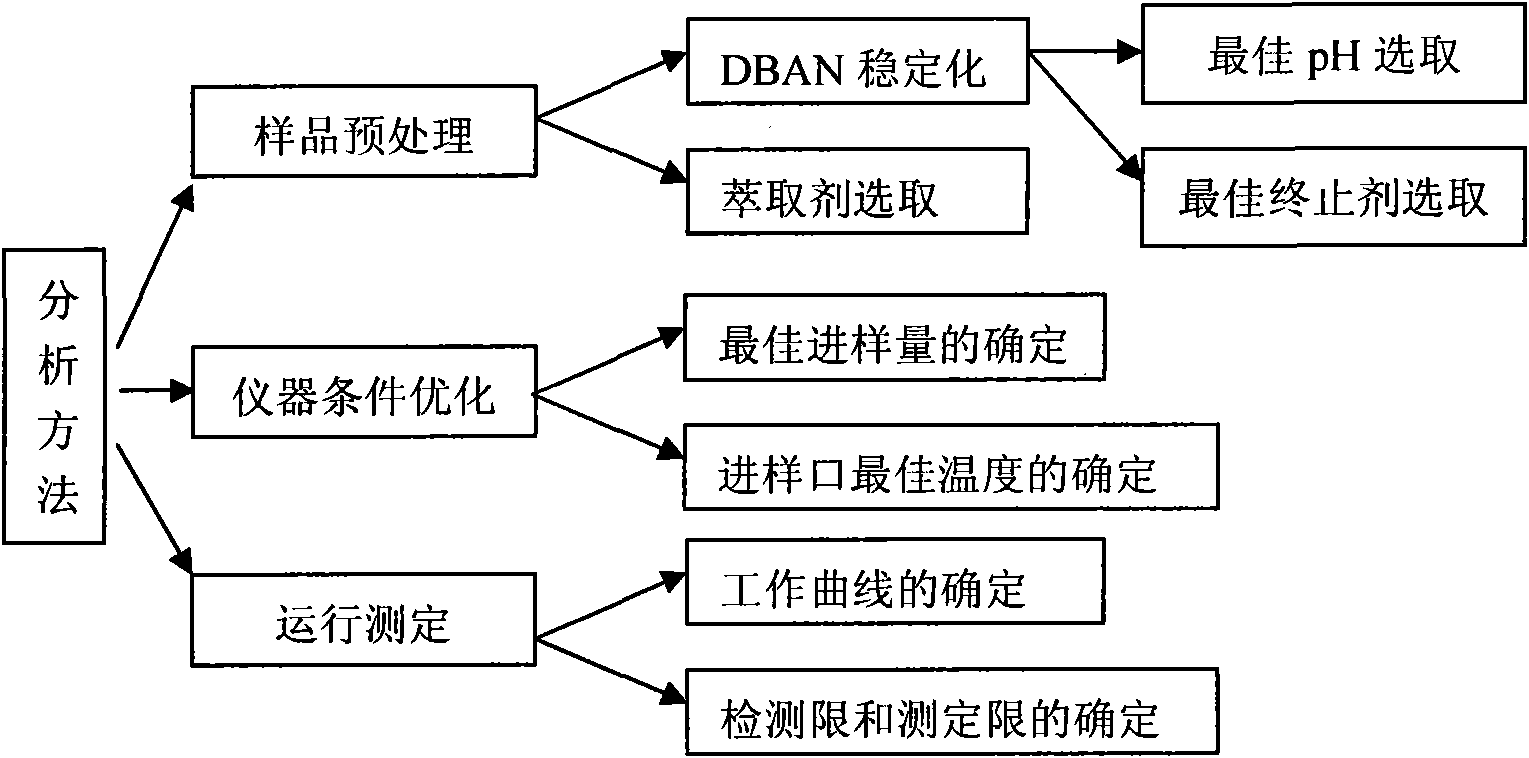

Rapid analysis method of disinfection side product dibromo-acetonitrile in drinking water

InactiveCN101561372AImproved preprocessing methodHigh recovery rateComponent separationPreparing sample for investigationPretreatment methodSulfite salt

Owner:TONGJI UNIV

Vehicular methanol petrol

InactiveCN1580204AReduce absorptionExtended stratification timeLiquid carbonaceous fuelsS systemThermal efficiency

The invention publishes a kind of carbinol for car, which can replace gas. The weight (or cubage) percentage of raw material follows this. Base gasoline is 47%-62%, industrial carbinol is 36%-50%, emulgator, which weight (or cubage) percentage of raw material composed by 36%-48% methyl tertiary butyl ether, 17%-37% methyl ester, 18%-28% aliphatic alcohol, 1%-10% tert butyl alcohol, is 2%-3%. The cost of gas in this invention is lower, its burning rate is more rapid, the capability of defending heat is less than no time and the heat efficiency is higher, so it can not ablate the engine's system offering oil and contaminants by end gas can be reduced very much, thus, it is good for environment.

Owner:XINYUAN PETRO CHEM PROD SUPPLYING STATION JINNIU DISTRICT CHENGDU

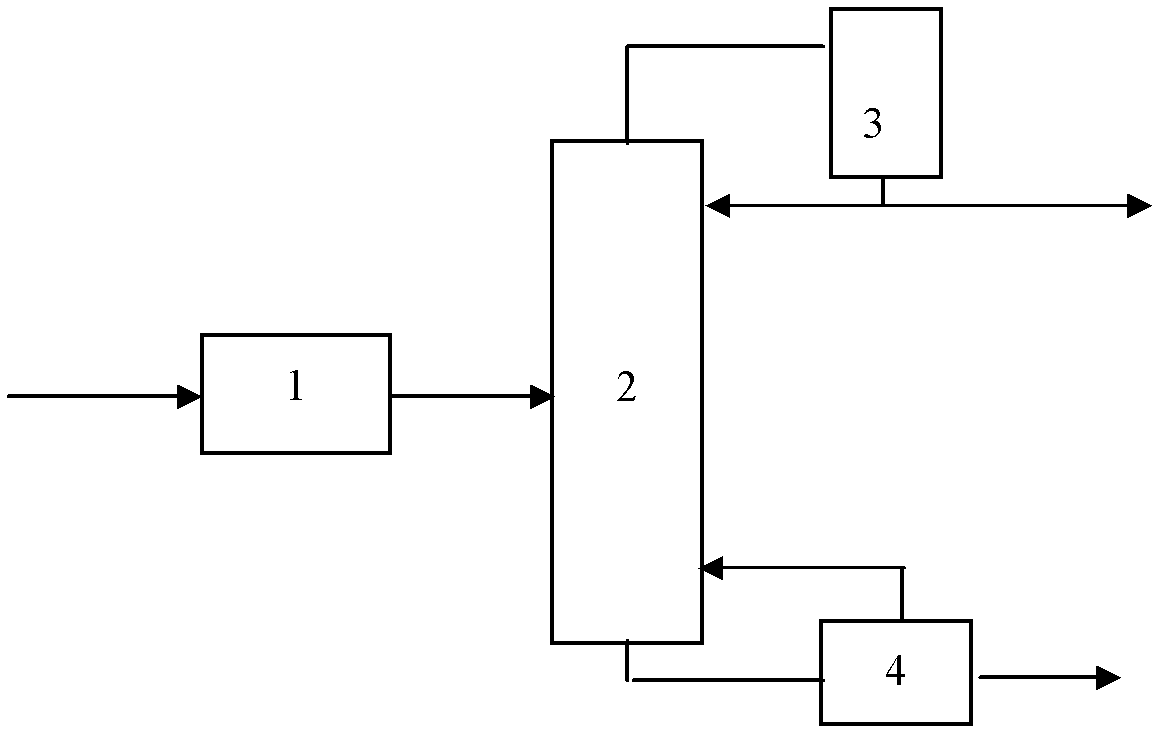

Integrated processing process for waste water generated during coproduction of epoxypropane and methyl tertiary butyl ether

ActiveCN106348546AEmission requirements are metImprove biodegradabilityWater treatment compoundsTreatment with aerobic and anaerobic processesActivated sludgeSulfate

The invention discloses an integrated processing process for waste water generated during coproduction of epoxypropane and methyl tertiary butyl ether. The process comprises the following steps: (1) anaerobic treatment: carrying out anaerobic treatment on waste water by using series connection of two stages of UASB anaerobic reactors in combination with zero-valent iron; (2) aerobic treatment: carrying out aerobic treatment on anaerobic effluent by adopting an activated sludge process; (3) oxidation treatment: carrying out advanced treatment on aerobic effluent by adopting a Fenton oxidizing process. The processing process integrates the advantages of two stages of UASB anaerobic technology, zero-valent iron technology, conventional activated sludge process and Fenton oxidizing technology, and can reach the removal rate of 98.33% for COD in production waste water; concentrations of SO4(2) and S(2) are reduced by the combination of the primary anaerobic reactor and zero-valent iron technology, thus shielding the influence of sulfate from the second stage of reactor, and reducing processing difficulty; refractory organic matters in waste water are further removed by Fenton oxidization, so that the effluent reaches discharge requirement, the processing cost is low, the effect is good, and resistance to impact load is strong.

Owner:河南君和环保科技有限公司

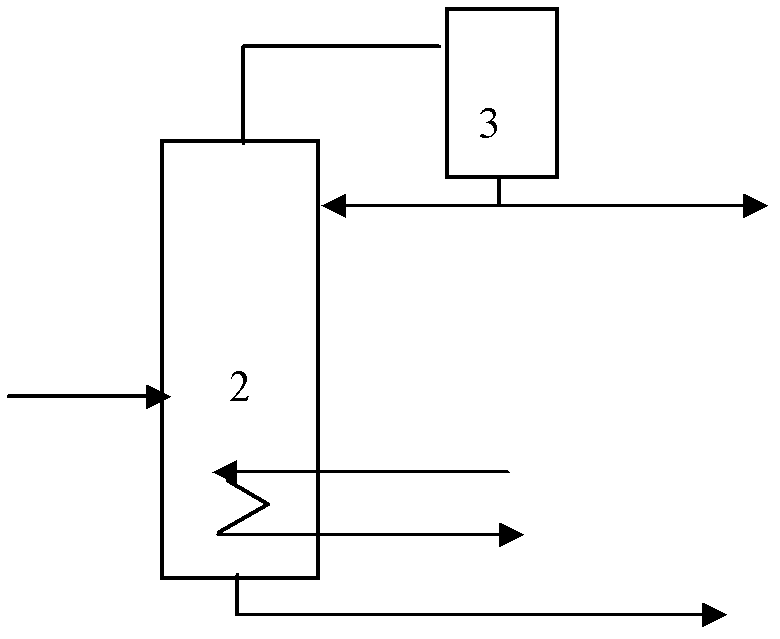

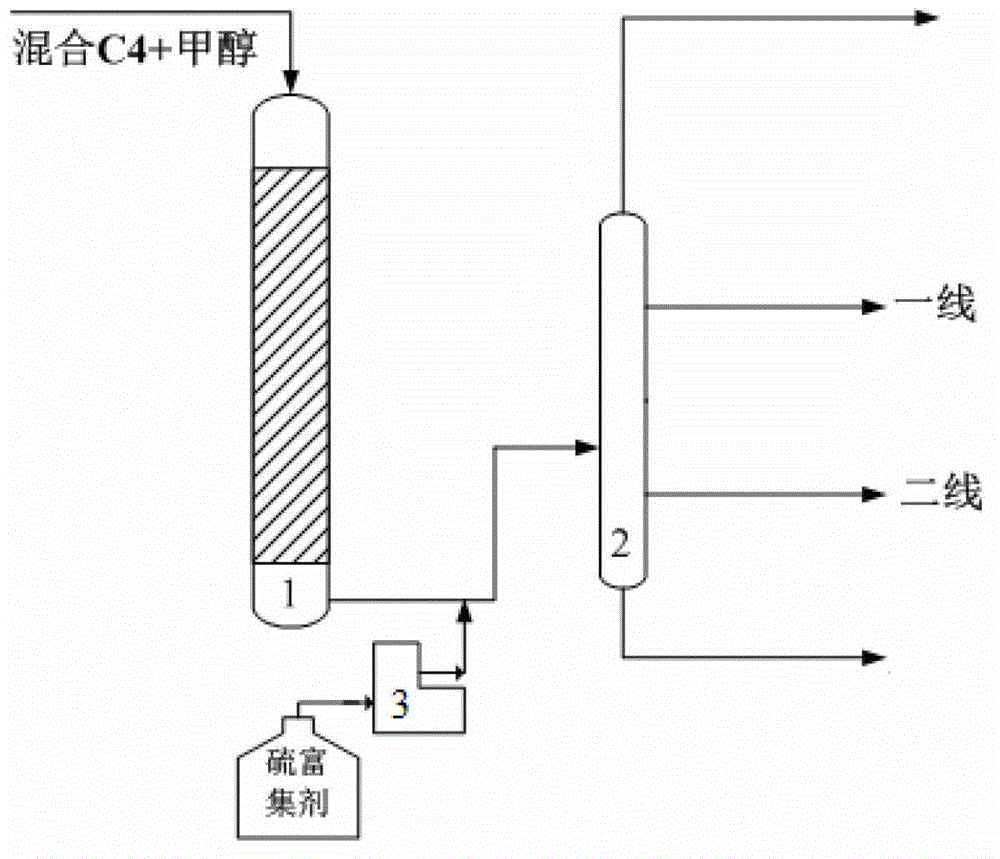

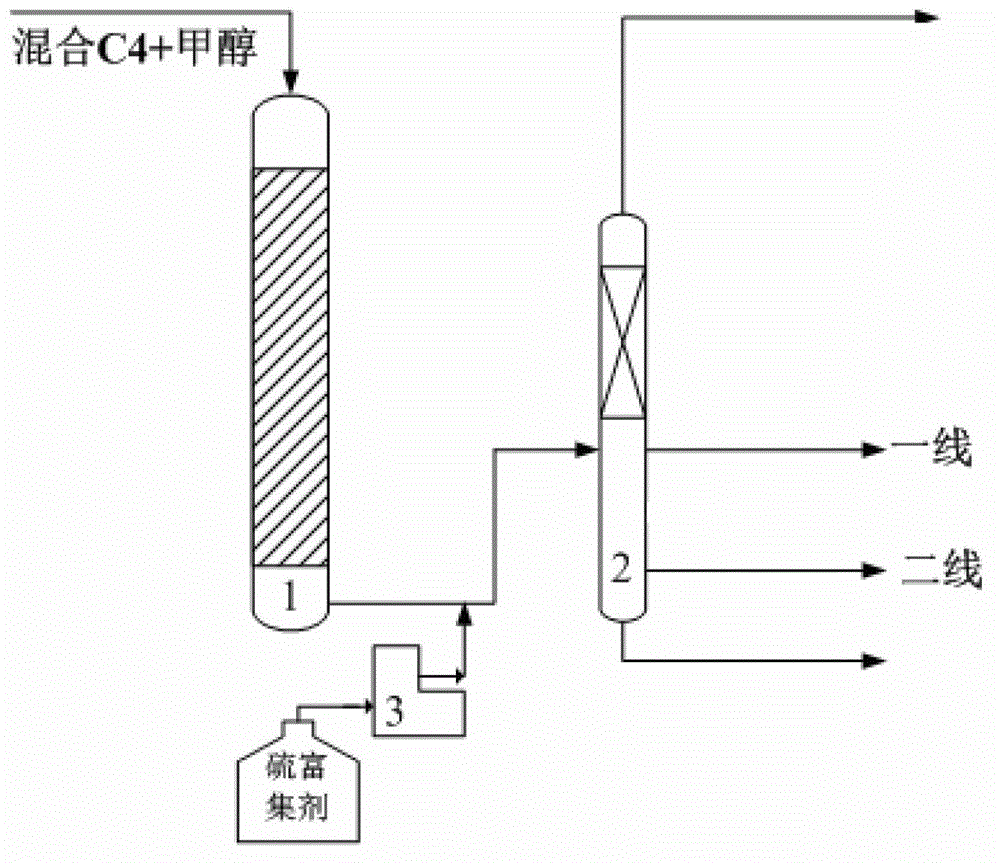

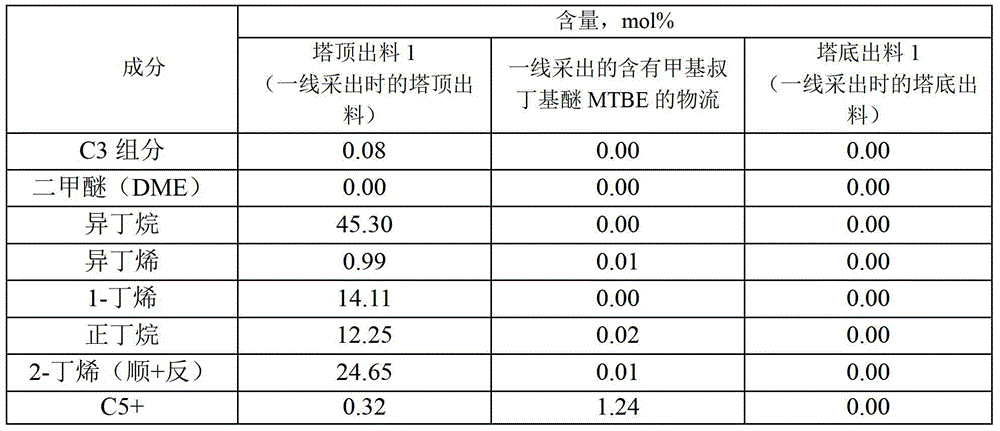

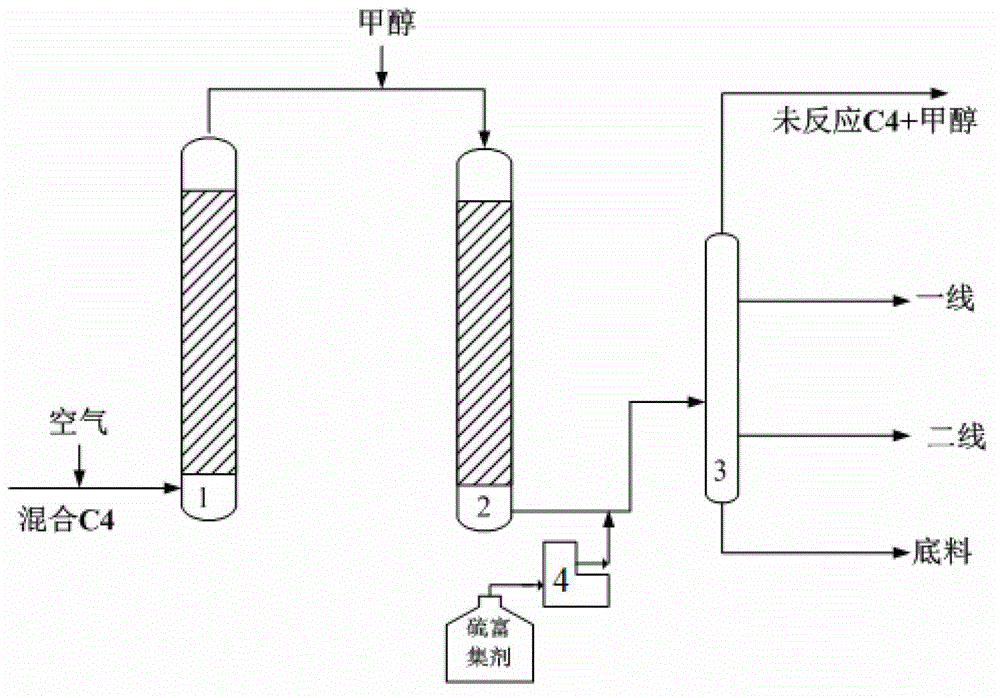

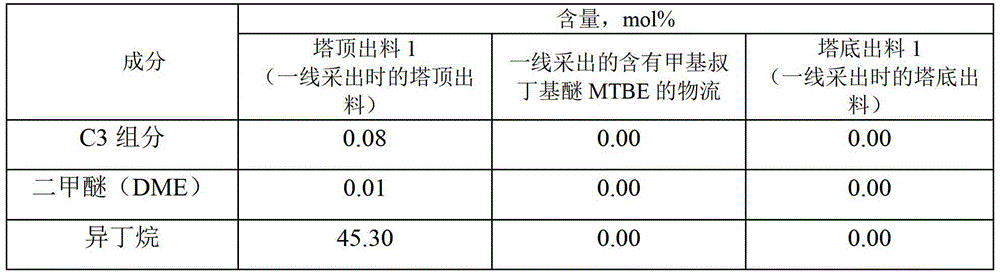

Methyl tert-butyl ether crude product purification method and methyl tert-butyl ether production method

ActiveCN104370707AReduce energy consumptionLow investment costEther separation/purificationChemical industryPurification methodsDistillation

The invention provides a methyl tert-butyl ether crude product purification method and a super low sulfur methyl tert-butyl ether production method, the method comprises distillation separation of a methyl tert-butyl ether-containing solution in a distillation ctower, the methyl tert-butyl ether-containing solution contains methanol, sulfide, mixture C4 and methyl tert-butyl ether; the method also includes introduction of a sulfur enrichment agent into the methyl tert-butyl ether-containing solution during and / or before the distillation separation process, distillation conditions are controlled for collecting the methanol and the mixture C4 from the top of the tower, the sulfide absorbed by the sulfur enrichment agent of the sulfide which is not absorbed by the sulfur enrichment agent are collected from the bottom of the tower, and a methyl tert-butyl ether-containing material flow is collected from a side line. According to the method, super low sulfur methyl tert-butyl ether (MTBE) can be produced only by one-time distillation the production of ultra low sulfur, energy consumption, equipment investment and maintenance cost are reduced, and the method is very suitable for industrial application.

Owner:BEIJING ENERGY ENG TECH

Catalyst and method of producing unsaturated aldehyde and unsaturated carboxylic acid

InactiveCN102046289AImprove friction resistanceReduce the probability of selectionOrganic compound preparationOrganic chemistry methodsGas phaseIsobutylene

Provided is a catalyst which can prevent a lowering in selectivity for a target product in a gas-phase catalytic reaction and has an excellent frictional resistance. A catalyst which is a supported catalyst comprising an inert support that is coated with a catalyst powder, characterized in that the inert support is ring-shaped and has an outer periphery that is curved in the lengthwise direction of the support, and the catalyst is produced by granulation in a moisten environment. The above-described catalyst is useful in the gas-phase oxidation of propylene, isobutylene, tertiary-butyl alcohol or methyl tertiary-butyl ether to thereby produce an unsaturated aldehyde corresponding thereto, or in the gas-phase oxidation of such an unsaturated aldehyde as described above to thereby produce an unsaturated carboxylic acid.

Owner:NIPPON KAYAKU CO LTD

Gasoline additive

ActiveCN103540372ABoost octaneImprove antiknock performanceLiquid carbonaceous fuelsIsobutanolNaphtha

The invention belongs to the technical field of additives, and in particular relates to a gasoline additive. The gasoline additive consists of the following components in parts by weight: 30-40 parts of methanol, 5-6 parts of isobutanol, 10-15 parts of ethanol, 15-20 parts of methyl tertiary-butyl ether, 20-25 parts of naphtha, 0.1-0.5 part of dimethyl phosphate, 0.8-1.5 parts of tween 80 and 10-30 parts of a mixture of rosin and a camphor extracting solution, wherein the weight percent of rosin is 45% and the weight percent of the camphor extracting solution is 55%. The gasoline additive not only can greatly improve the octane value, but also is environment-friendly and safe, so that the gasoline quality is effectively improved, and the gasoline saving effect is obvious.

Owner:SHANDONG TAIDE NEW ENERGY

Method for producing low-sulfur methyl tert-butyl ether product

ActiveCN102219653ASolve the problem of high total sulfurImprove abilitiesEther preparation by compound additionRefluxPetrochemical

The invention relates to the field of petrochemical industry, and discloses a method for producing a low-sulfur methyl tert-butyl ether (MTBE) product. The method is characterized in the following steps that: isobutene-containing mixed C4 is delivered to a middle tray of a pentane removing tower; isobutene-containing mixed C4 is rectified and separated at a temperature of 35 to 45 DEG C, and under a pressure of 0.55 to 0.75Mpa; C4 discharged from the tower top is cooled through a cooler, and is delivered to a reflux accumulator; one part of the C4 is pumped by a reflux pump and is used for liquid phase refluxing, and the other part of the C4 is delivered to a mixed-C4 raw material tank and is used for feeding an MTBE reaction system; through processes of MTBE synthesis, azeotropic distillation, and methanol recovery, the low-sulfur MTBE product is obtained. The low-sulfur MTBE product provided by the present invention assists in solving the problem of high total sulfur content in oil refining MTBE. With the method provided by the present invention, the sulfur content of MTBE product can be reduced to 150ppm or lower.

Owner:山东东明石化集团有限公司

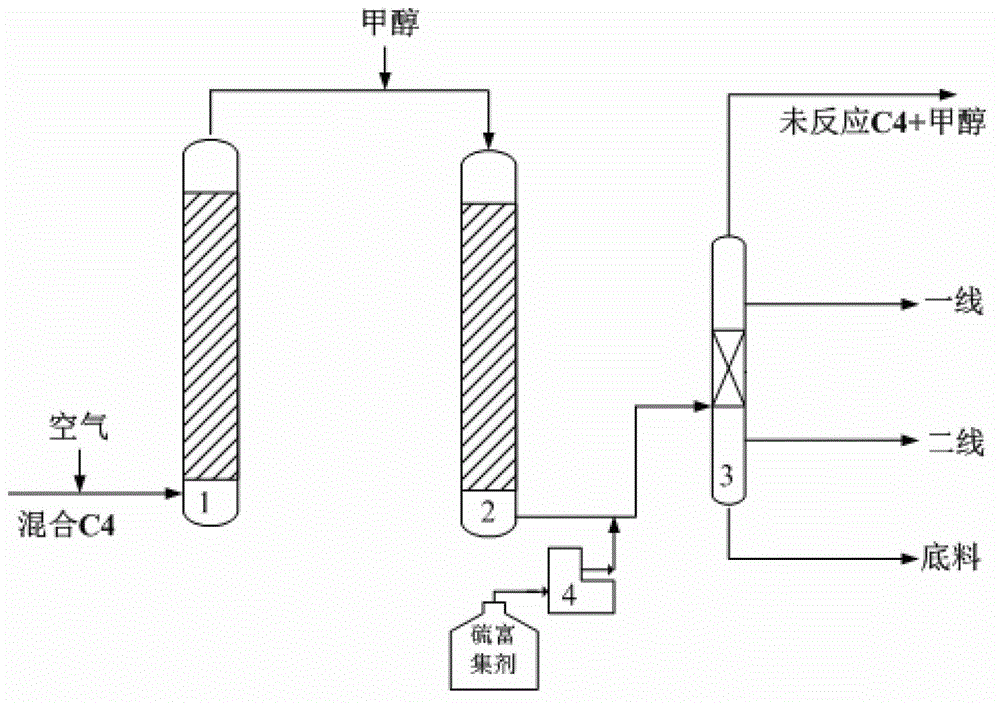

Methyl tert-butyl ether crude product purification method and methyl tert-butyl ether production method

ActiveCN104370708AReduce energy consumptionLow investment costEther separation/purificationChemical industryPurification methodsSulfide

The invention provides a methyl tert-butyl ether crude product purification method and a methyl tert-butyl ether production method, the method comprises distillation separation of a methyl tert-butyl ether-containing solution in a distillation ctower, the methyl tert-butyl ether-containing solution contains methanol, sulfides, mixture C4 and methyl tert-butyl ether; before the distillation separation, the sulfides capable of being oxidized, in the methyl tert-butyl ether-containing solution, are oxidized; distillation conditions are controlled for collecting of the methanol and the mixture C4 from the top of the tower, the oxidized sulfides and / or the sulfides which are not oxidized are collected from the bottom of the tower, and a methyl tert-butyl ether-containing material flow is collected from a side line. According to the method, super low sulfur methyl tert-butyl ether (MTBE) and low sulfur unreacted C4 can be produced only by use of a catalytic distillation or an azeotropic distillation device in the prior art, the method has the advantages of simple desulfurization process, low operation energy consumption, low investment of equipment and maintenance costs, and is very suitable for industrial application.

Owner:BEIJING ENERGY ENG TECH

Efficient natural gas

InactiveCN103710062AGood volatilization effectLess corrosiveGaseous fuelsTert-butylcatecholTurpentine

The invention discloses efficient natural gas. The efficient natural gas consists of natural gas with purity higher than 95% in percentage by weight, and 0.3-0.5% of a liquid-phase synergistic additive in terms of weight percentage of the natural gas, wherein the liquid-phase synergistic additive consists of the following raw materials: 200# solvent oil, isopropanol, petroleum ether, ethylene glycol monoethyl ether, turpentine, tung oil, isooctyl nitrate, dimethyl carbonate, tert-butylferrocene or ferrocene, methyl tertiary butyl ether or n-octyl ferrocene, p-tert-butylcatechol, azodiisobutyronitrile and polyether. The efficient natural gas, through adding little liquid-phase synergistic additive in the natural gas, can obviously improve burning temperature and burning efficiency; meanwhile, the liquid-phase synergistic additive is low in corrosion and good in volatility on containers.

Owner:BEIJING DATONG HONGYE TECH DEV

Reaction method of aromatics of tertiary butyl by using methyl tert-butyl ether as alkylating agent

InactiveCN1445204AConvenient sourceLow costOrganic compound preparationOrganic chemistry methodsSolventAromatic hydrocarbon

A process for using methyl tert-butyl ether as hydroxylating agent in tert-butylation reaction of aryhydrocarbon compound features use of acid as catalyst. Its advantages are mild reaction, short reaction time and low cost.

Owner:MAOMING COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com