Patents

Literature

320 results about "Isopropyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isopropyl ether is made either by the sulfuric-acid dehydration of isopropanol or directly from propylene and water in the presence of sulfuric acid. It has limited use as a solvent for oils and fats.

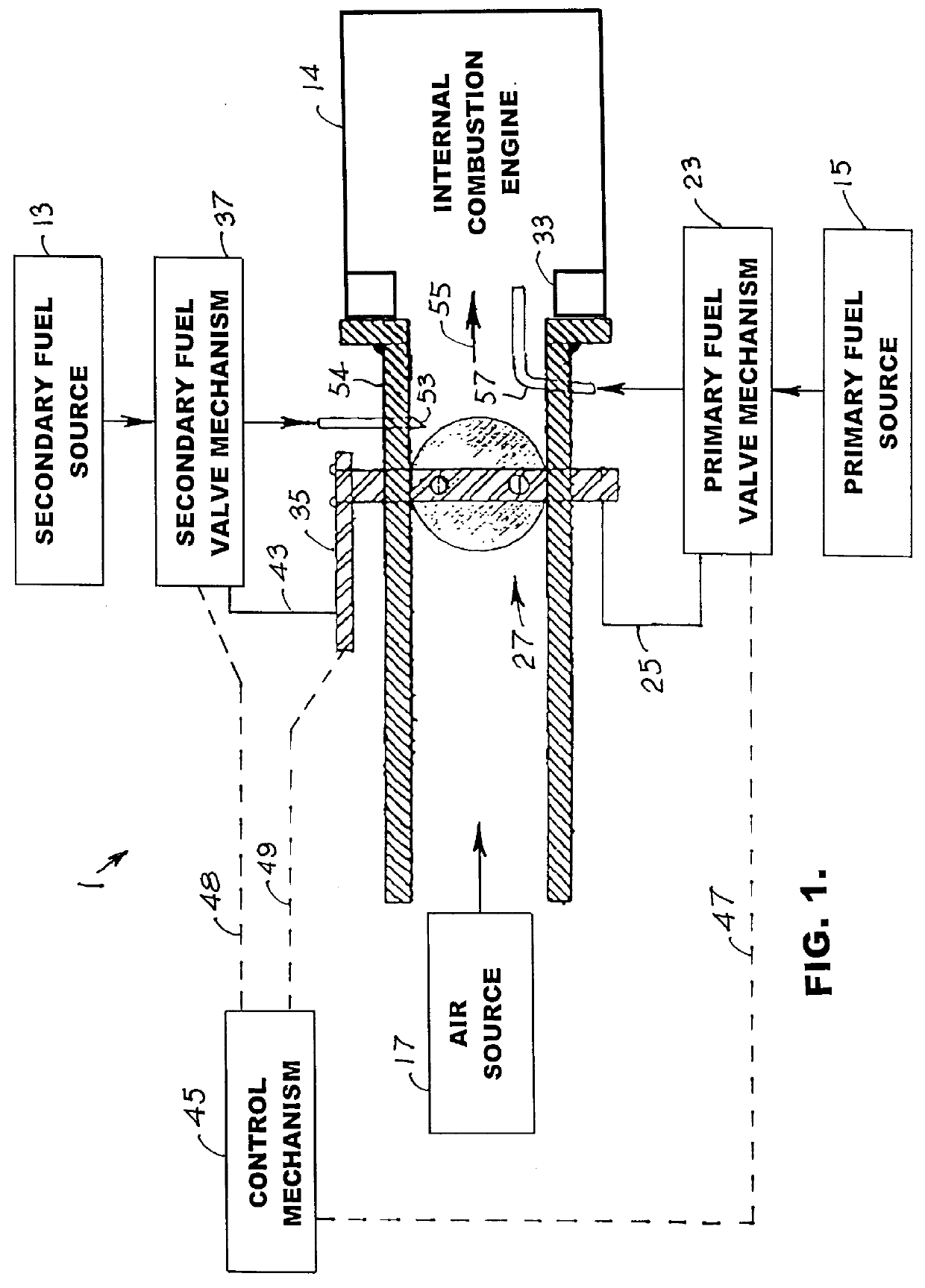

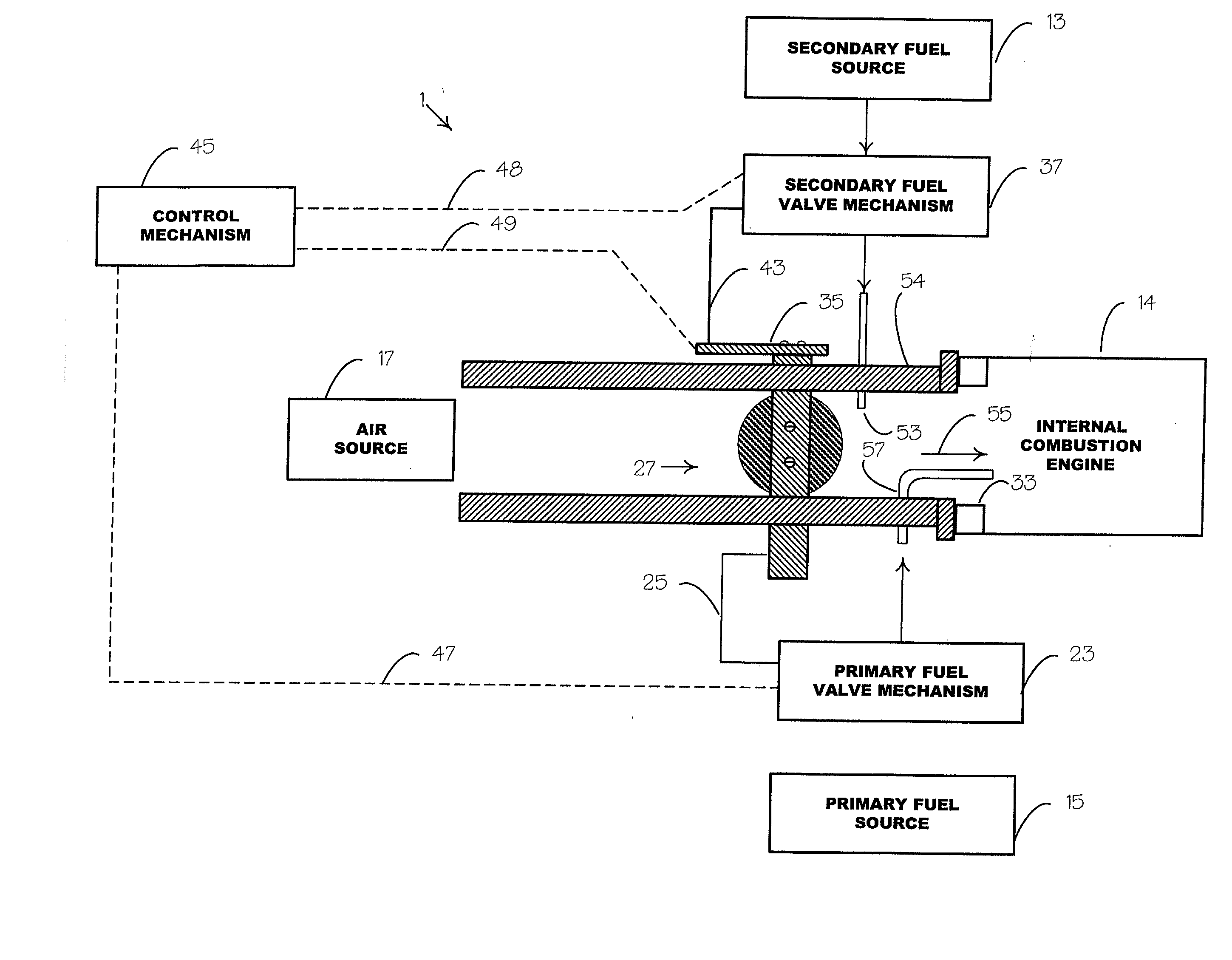

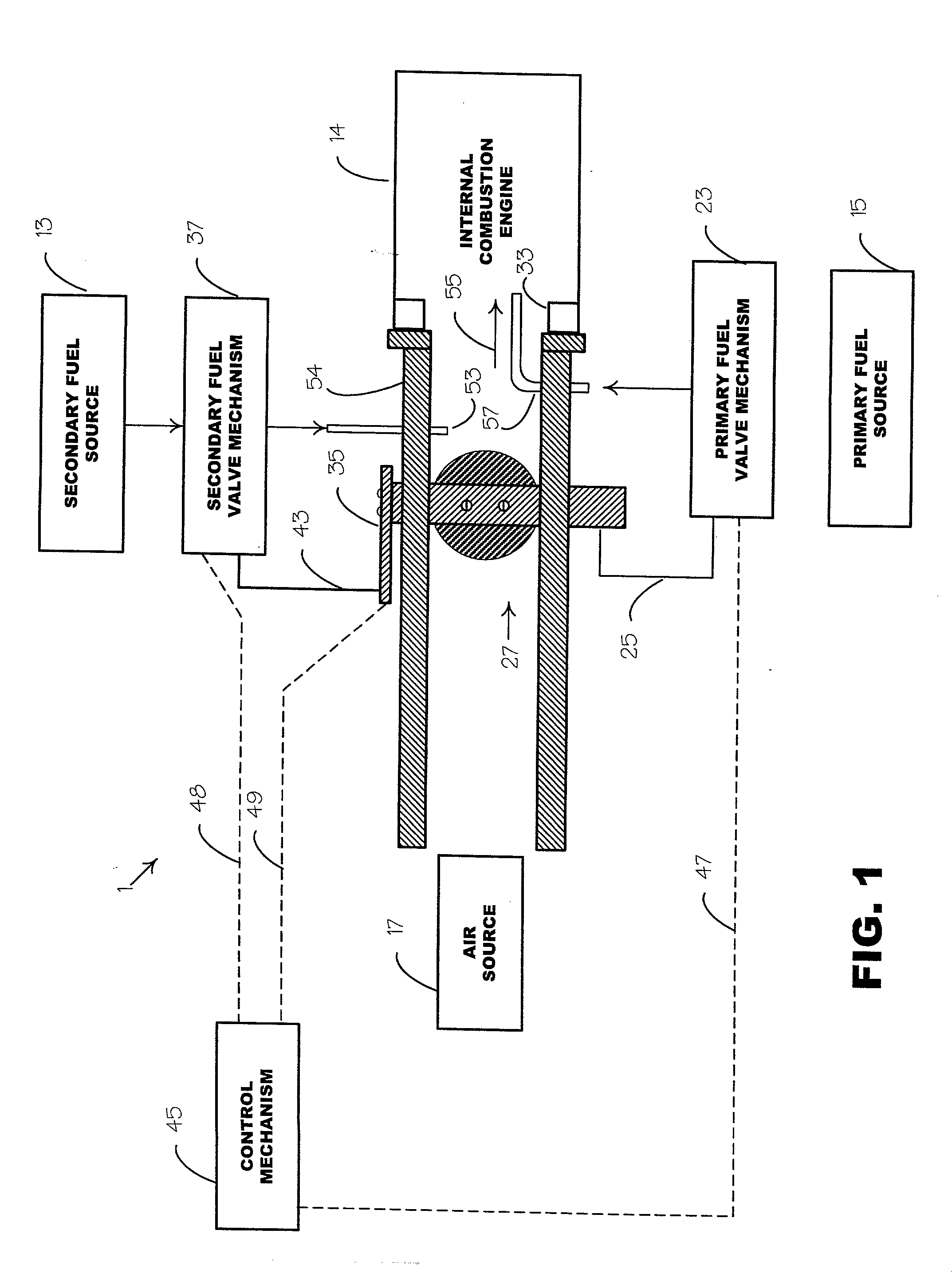

Internal combustion system using acetylene fuel

InactiveUS6076487AInternal combustion piston enginesNon-fuel substance addition to fuelCarbon chainInternal combustion engine

An environmentally clean dual fuel for an internal combustion engine, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C20 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel. The dual fuel, internal combustion system, which generally utilizes a two-stage process for start-up and operation and can be operated with air- or liquid-cooling, is environmentally clean with hydrocarbon, CO, NOx, and SOx emissions substantially eliminated.

Owner:GOTEC

Cleaning gasoline with alcohol ether base

InactiveCN1597873AMeet power requirementsIncrease oxygen contentLiquid carbonaceous fuelsCleansing AgentsNuclear chemistry

The invention discloses a clean alcohol ether-base gasoline, prepared of alcohol-base fuel mixed solution, naphtana etherified liquid, C-5 and cleaning agent; and its components in weight percent (wt%): alcohol-base fuel mixed solution 40-50, C-5 10-20, naphtana etherified liquid 30-45, cleaning agent 0.1. The alcohol-base fuel mixed solution is composed of methanol, acetone, hydrogen peroxide, ferrocene-benzene solution and camphor powder. The naphtana etherified liquid is prepared by etherifying naphtana, methyl-tert-butyl ether and isopropyl ether. The finished oil has rich HO molecular groups, high oxygen content and can fully burn. After it is used, the indexes of various harmful matters in the discharged tail gas from engines are obviously lower than those of ordinary gasoline and environmental protection.

Owner:于雷

Vehicle high-methanol content gasoline

InactiveCN102161919AImprove starting performanceCold start problem solvedLiquid carbonaceous fuelsIsobutanolButanedioic acid

The invention discloses vehicle high-methanol content gasoline, relates to carbon-containing fuels and solves the problems of difficult low-temperature startup, serious metal corrosion, inadequate power and susceptibility to generating precipitates of the conventional methanol gasoline. The vehicle high-methanol content gasoline comprises the following components in part by volume: 70 to 86 partsof methanol, 14 to 30 parts of gasoline component oil, 0.5 to 1 part of cosolvent, 0.1 to 0.2 part of antiseptic and rubber swelling inhibitor, 0.2 to 0.3 part of detergent and 0.01 to 0.05 part of coloring agent. The cosolvent consists of isobutanol, isopropyl ether, 2-isobutanol and tetrahydrofuran, the antiseptic and rubber swelling inhibitor consists of propargyl alcohol, butanedioic acid, hexakis(dihydrogen phosphate), N-methyl morpholine, cyclohexane and dimethyl phthalate, the detergent consists of normal propyl alcohol, isopropanol, limonene and cyclohexane, and the coloring agent is Sudan IV solution. The vehicle high-methanol content gasoline has high startability, high dynamic performance, high environmental protection performance, obvious anticorrosion effect and high safety.

Owner:山西丰喜新能源开发有限公司

Internal combustion system adapted for use of a dual fuel composition including acetylene

InactiveUS20020014226A1Early ignition be preventEfficient in operationInternal combustion piston enginesNon-fuel substance addition to fuelChemistryFormate Esters

An internal combustion engine adapted to use an environmentally clean multi-fuel composition, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C12 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate, ethyl malate, butyl malate, and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel.

Owner:GOTEC

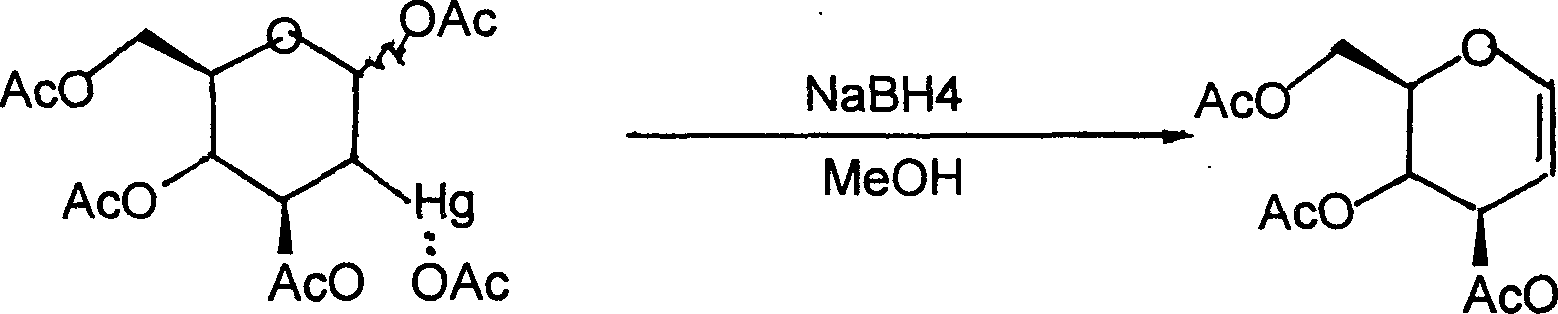

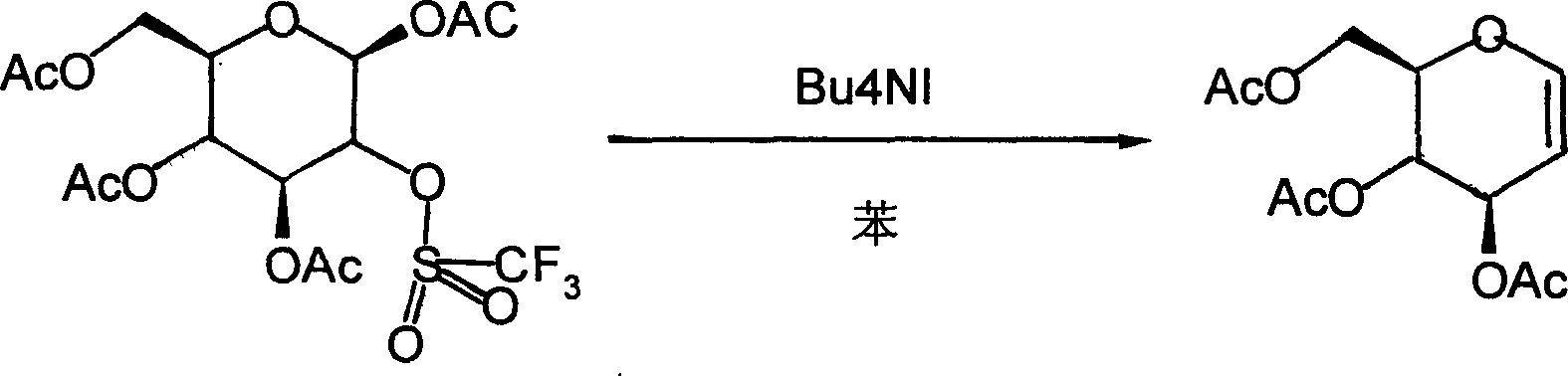

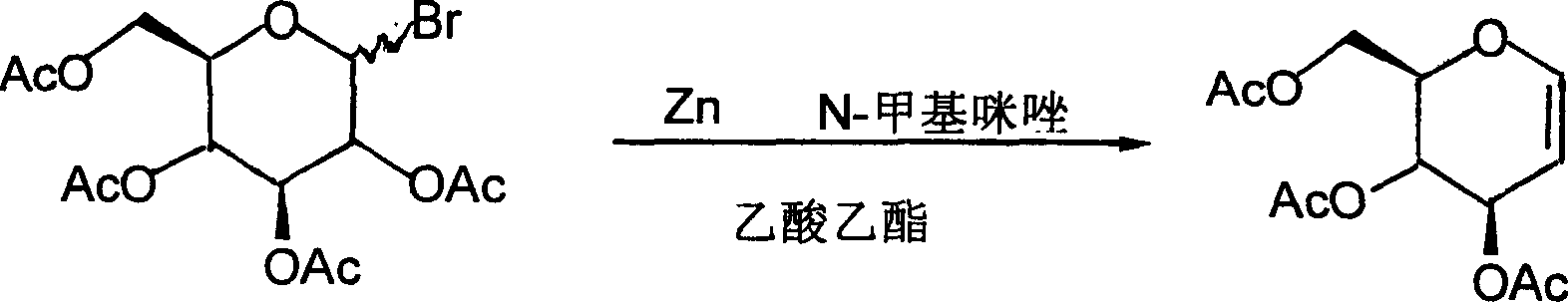

Method for preparing acetylated glucal

InactiveCN1803818ASimple and efficient synthesisWork lessSugar derivativesSugar derivatives preparationP-Toluenesulfonic acidMethanesulfonic acid

The disclosed preparation method for acetylized glucal comprises: preparing the D-acetylized glucose catalyzed by acids (HClO4, H2SO4, ZnCl2, AlCl3, p-toluenesulfonic acid and methanesulfonic acid); without separation or purification, leading directly the product into HBr or equivalent (such as PBr3 and water) to obtain and then recrystallize the coarse 1-bromoacetyl glucose with one of ethyl ether, propyl ether and isopropyl ether; adding Zn, ZnCl2, methanol and Co-ion catalyst to prepare the coarse target; recrystallizing with alcohol for the refined product. This invention saves step and reduces cost.

Owner:朱书汉

Co-solvent composition for compounding methanol gasoline

InactiveCN1740283APromote mutual solubilityHigh calorific valueLiquid carbonaceous fuelsAntioxidantMethyl carbonate

The co-solvent composition for compounding methanol gasoline consists of methyl tert-amyl ether 0-61 weight portions, dimethyl carbonate 0-52 weight portions, methyl tert-butyl ether 0-47 weight portions, allcyl polyoxyethylene ether 0.1-10 weight portions, isopropyl ether 0-10 weight portions, ethyl ether 0-30 wt%, tert-butanol 0-45 weight portions, iso-butanol 0-25 weight portions, isopropanol 0-15 weight portions, antioxidant í‹501íŒ 0-8 weight portions, xylene 0-20 weight portions, urotropin 0-7 weight portions, butanone 0-36 weight portions and acetone 0-20 weight portions. It is added while compounding methanol gasoline to raise the intersolubility between methanol and gasoline and raise the relevant physical and chemical performances of methanol gasoline.

Owner:翟雁萍

Methanol gasoline fuel and process for fuel production

InactiveCN101220301AImprove performanceMeet environmental protection requirementsLiquid carbonaceous fuelsEthylenedioxyGasoline fuel

The invention relates to a methanol gasoline fuel and a manufacturing method thereof; according to weight percentage, the components of the fuel are as follows: 22-47 of gasoline, 50-75 of methanol, 2-8 of sherwood oil, 0-3 of methylal, 0-3 of octane, 0-2.5 of toluene, 0-3 of diethyl carbonate, 0-2.5 of isooctane, 0.3-0.5 of 2-ethylenedioxy acetic ether, 0.1-3 of orthophosophorous dibutylphosphoric acid ester, 0.5-4 of ethyl acetate, 0-3 of 3-dihydroxyl butane, 0-2.5 of ether, 0-2 of isopropyl ether, 0-5 of acetic acetone, 0-2.5 of benzyl alcohol, 0-0.5 of 501 antioxidant, 0-2 of di-tert-butyl, 0-0.5 of ethanol, and 0-0.5 of corrosion inhibitor. When in preparation, auxiliary chemicals are firstly mixed, then the gasoline, methanol, and the mixed auxiliary chemicals are simultaneously put in a synthesis tank according to the formula ratio and poured in a finished tank after being mixed successfully; after a hand sample is examined to be qualified, a product is attained; the product has excellent performance and is environment friendly.

Owner:浙江赛孚能源科技有限公司

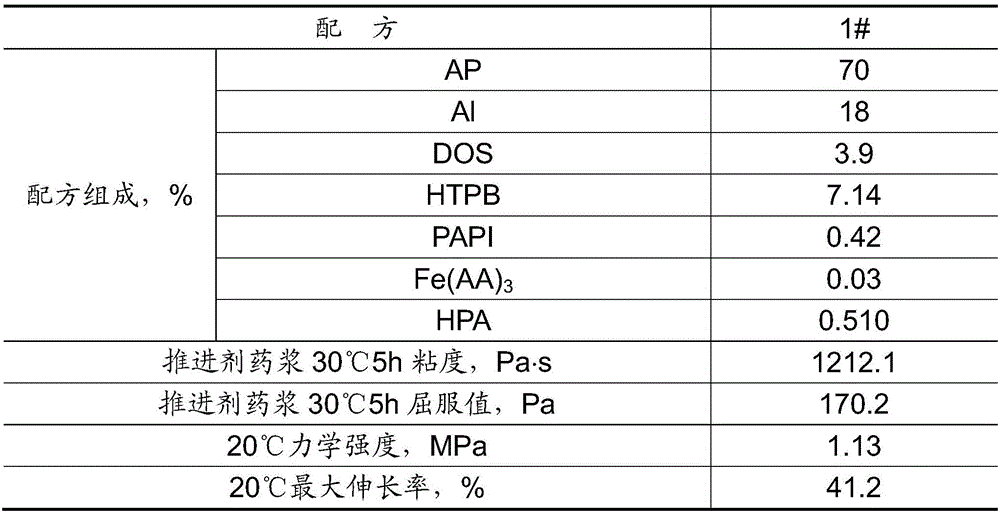

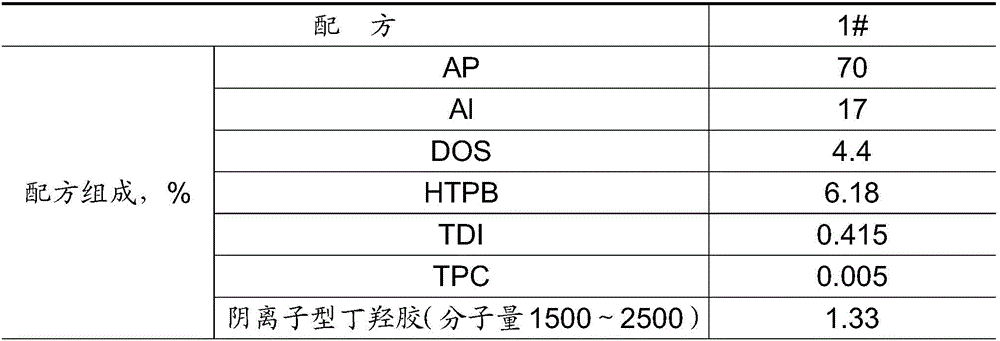

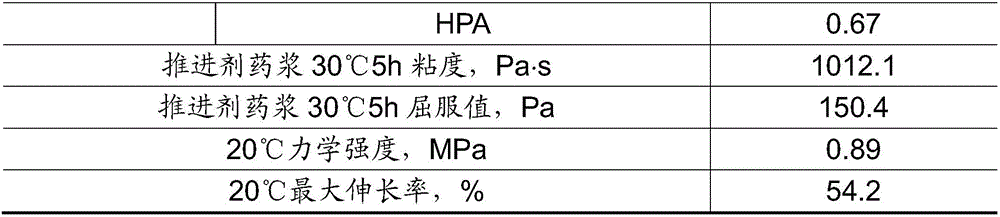

Room-temperature curing propellant

ActiveCN106831279AGood mechanical propertiesReduced activityExplosivesPressure gas generationAnilineMethylene diphenyl diisocyanate

The invention relates to a room-temperature curing propellant. The room-temperature curing propellant is prepared from the following components in percentage by mass: 69 to 77% of AP (ammonium perchlorate), 10 to 18% of Al (aluminum) powder, 1 to 5% of plasticizer DOS, 7 to 10% of adhesive HTPB and curing agent, 0.005 to 0.05% of curing catalyst, and 0.2 to 2.0% of network adjusting agent, wherein the network adjusting agent is an alcohol or amine compound with two degrees of functionality, and is one or combination of N-isopropyl alcohol-N-isopropyl ether-aniline, anionic HTPB (hydroxyl-terminated polybutadiene) or N,N'-dihydroxy(diisopropyl)aniline HPA; the curing agent is one or combination of PAPI (polyaryl polymethylene isocyanate), MDI (methylene diphenyl diisocyanate), XDI (xylylene diisocyanate), or TDI (toluene diisocynate). The room-temperature curing propellant has the advantages that the propellant with effective solid content of more than 85% is mixed and cast at the temperature of 20 to 35 DEG C, and can reach a curing point within 7d after curing; the normal-temperature mechanical strength can reach 0.85MPa or above, and the elongation rate is more than 35%.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Method for preparing mullite nanofibers by combination of non-hydrolytic sol-gel technology and electrostatic spinning technology

InactiveCN103225130ASolubleSimple manufacturing processInorganic material artificial filamentsFilament/thread formingFiberN dimethylformamide

The invention relates to a method for preparing mullite nanofibers by combination of a non-hydrolytic sol-gel technology and an electrostatic spinning technology, and belongs to the technical field of material science. The method comprises that anhydrous aluminum chloride and tetraethoxysilane as raw materials, isopropyl ether as an oxygen donor and anhydrous dichloromethane as a solvent are synthesized into mullite xerogel by the non-hydrolytic sol-gel method; anhydrous ethanol and tetrahydrofuran are mixed into a mixed solution A; the mullite xerogel is dissolved in the mixed solution A so that a mixed solution B is obtained; polyvinylpyrrolidone (PVP) and the mixed solution B are mixed by stirring; a less amount of N-N-dimethylformamide is dropwisely added into the mixture obtained by the previous step so that a spinning precursor is obtained; the spinning precursor is prepared into mullite xerogel / PVP composite fibers by an electrostatic spinning technology; and the mullite xerogel / PVP composite fibers are calcined at a temperature of 900 to 1200 DEG C and then are subjected to heat preservation for 0.5 to 5h to form the mullite nanofibers. The method has the advantages of simple processes, easy control and low preparation cost.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for extracting high-purity ursolic acid from rosemary

ActiveCN103102384AIncrease production capacityHigh ursolic acid contentSteroidsUrsolic acidDissolution

The invention discloses a method for extracting high-purity ursolic acid from rosemary, which is characterized by comprising the following steps of: A, adding ethanol into the leftovers obtained after grinding rosemary leaves and extracting carnosic acid for extraction; filtering and obtaining the filtrate; adding active carbon into the filtrate for decoloration; filtering and concentrating; adding 2-5 times water by volume while stirring to separate out precipitate; filtering to obtain a crude extract of ursolic acid; B, adding an organic solvent into the crude extract of ursolic acid in the step A for dissolution; adding diethylamine or triethylamine for backflow reaction to generate salt; and cooling to room temperature and filtering to obtain amine salt; C, adding water into the amine salt in the step B to dissolve the amine salt; adding isopropyl ether; adjusting the pH value to 2-5 by dilute acid; keeping the temperature at 20-40 DEG C for 1 hour; filtering; and drying the filter cake; and D, adding methanol into the dried filter cake in the step C for dissolution; adding neutral alumina for decoloration; filtering and concentrating the filtrate; cooling to minus10-20 DEG C for crystallization; and centrifuging, washing and drying to obtain the finished product of ursolic acid.

Owner:ZHONGSHAN BAILING BIOTECHNOLOGY CO LTD

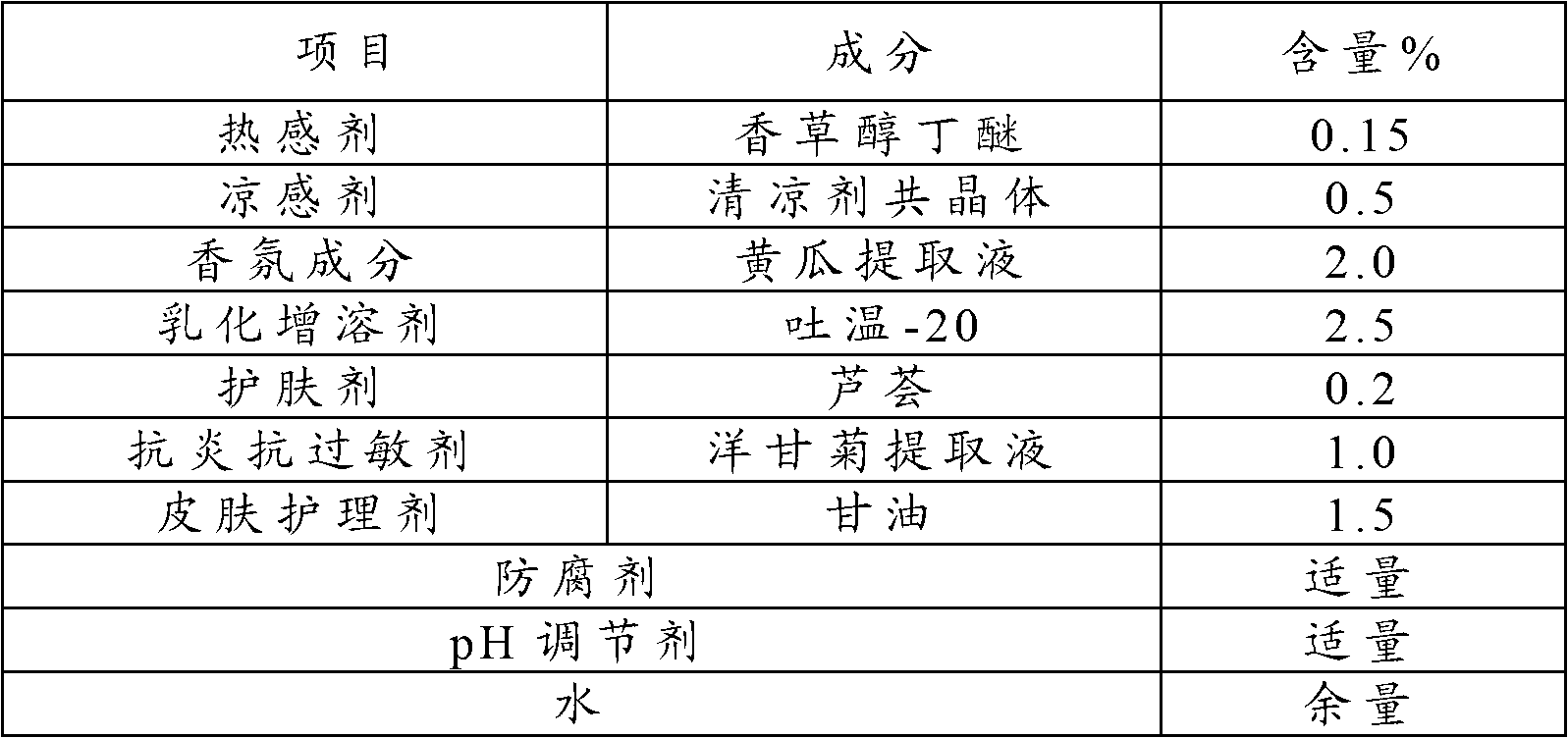

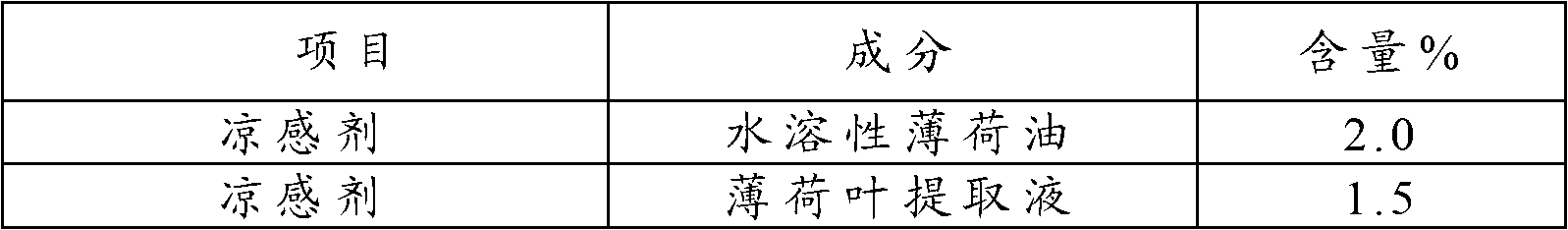

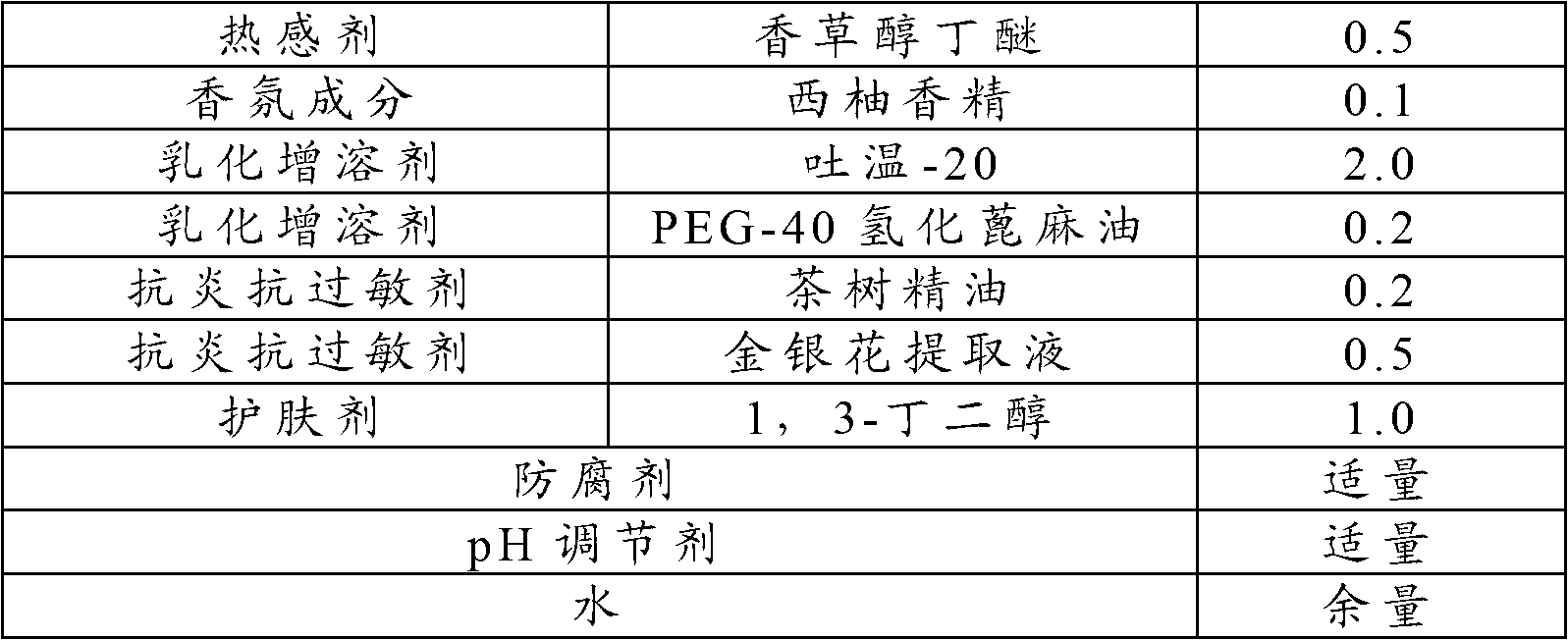

Emulsion composition and wet tissue applying emulsion composition

ActiveCN103006509AImprove coolnessEnhance the cool feelingCosmetic preparationsToilet preparationsEmulsionZingerone

The invention discloses an emulsion composition which comprises a cold sensitizer, a heat sensitizer and water, wherein the mass ratio of the cold sensitizer to the heat sensitizer is 1:0.01-100; the cold sensitizer comprises at least one of piperitol, menthyl lactate, hexa-carbon cyclic amide derivative, non-carbon cyclic amide derivative, mint raw oil, mint oil, mint essence, mint leaf extract, water-soluble menthol and water-soluble mint oil; and the heat sensitizer comprises at least one of vanillyl butyl ether, citronellol n-propyl ether, citronellol isopropyl ether, citronellol isobutyl ether, citronellol n-amino ether, citronellol isoamyl ether, citronellol n-hexyl ether, citronellol methyl ether, citronellol ether, gingerol, shogaol, zingerone, capsaicin and capsaicine. According to the emulsion composition and a wet tissue applying emulsion composition, the preparation process is simple, and the cost is low; a plurality of feeling organs of the skin of a human body can be simulated; and compared with a product which only stimulates a single feeling organ of the human body, the emulsion composition has relatively long refreshing time.

Owner:GOLD HONG YE PAPER

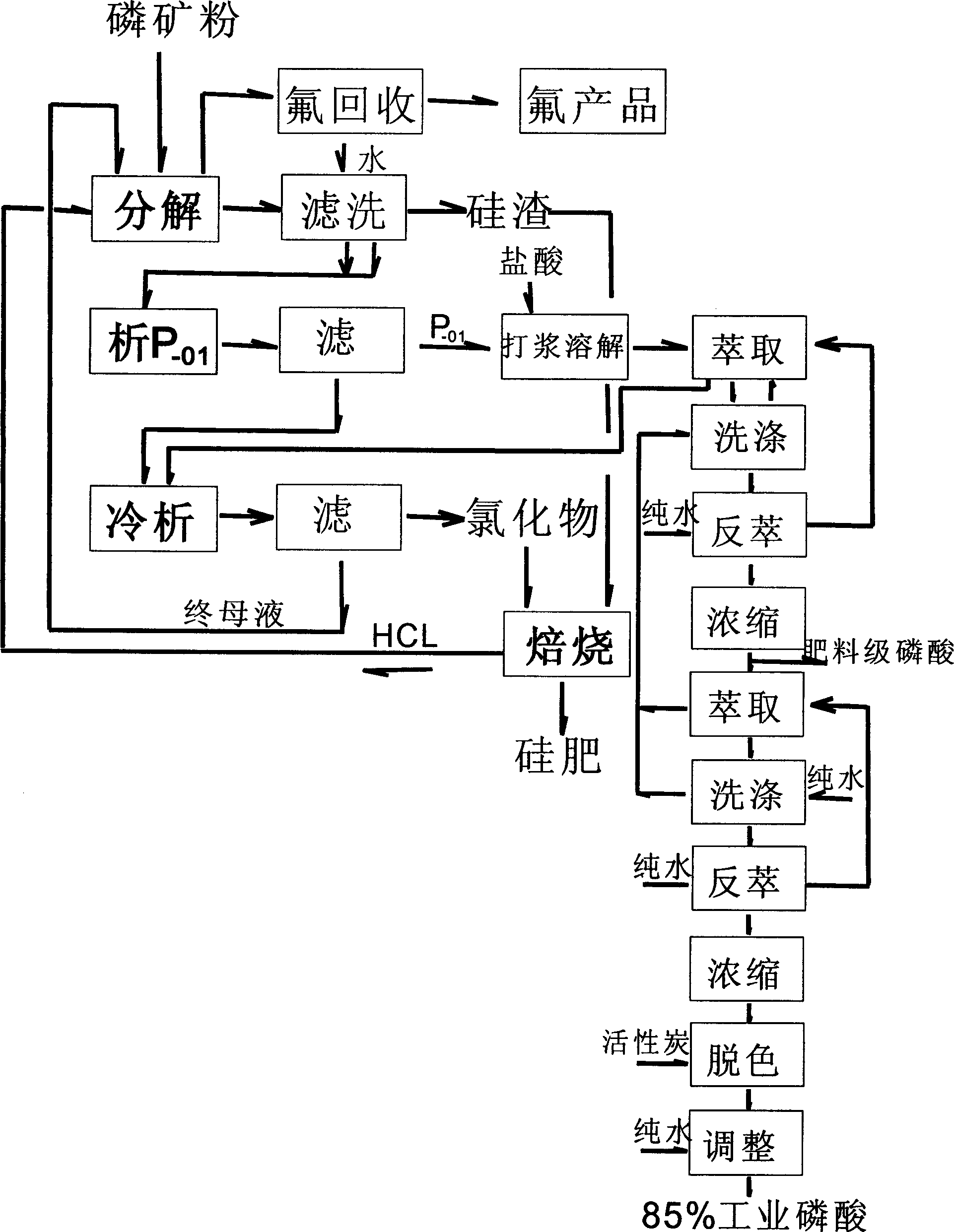

Process for mfg. industrial phosphoric acid by low-grade phosphorus deposit in hydrogen chloride decomposition

A process for preparing industrial phosphoric acid by use of hydrochloric acid to decompose the low-and medium-grade phosphorus ore includes such steps as using hydrochloric acid to decompose phosphorus ore to obtain calcium chlorophosphate, using hydrochloric acid to prepare slurry, dissolving the calcium chlorophosphate in it, extracting by tri-butyl phosphate, concentrating, extracting by tri-butyl phosphate and isopropyl ether, concentrating, and de-coloring to obtain 85% industrial phosphoric acid. Its advantage is no environmental pollution.

Owner:湖北中磷科技有限公司

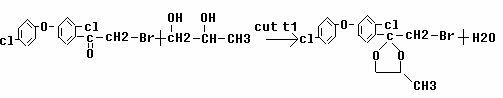

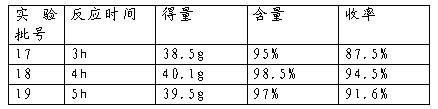

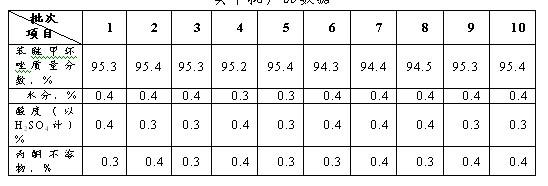

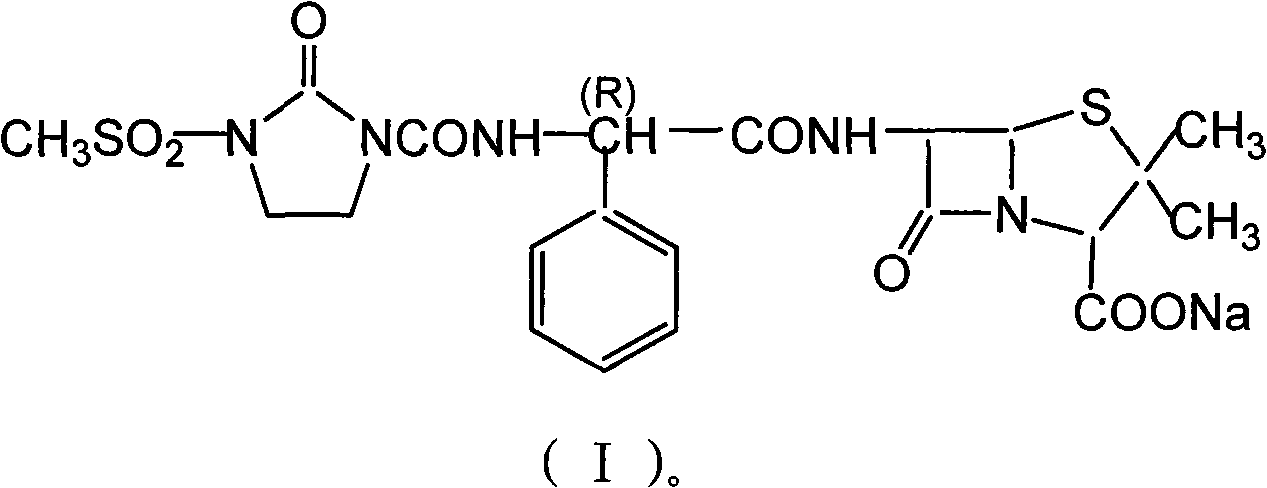

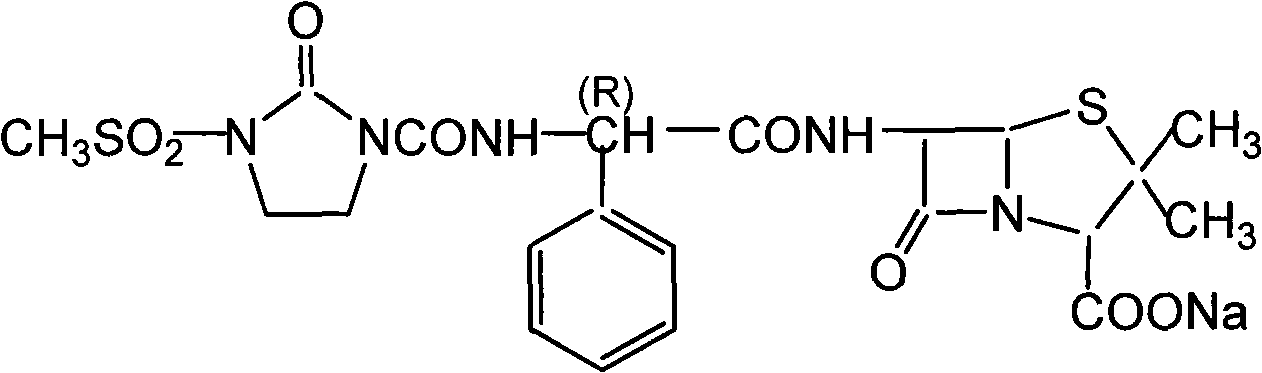

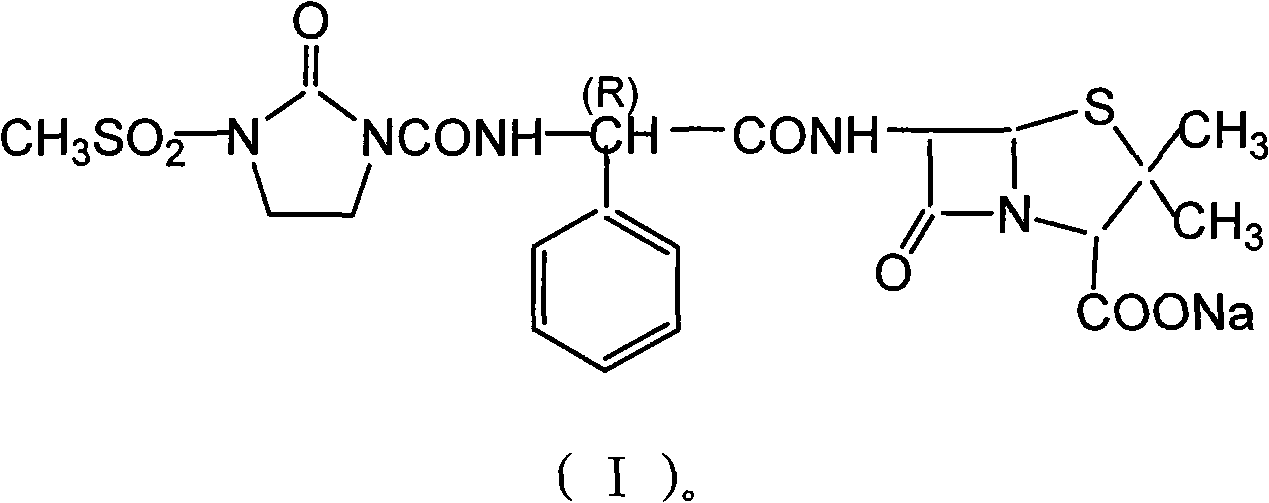

Method for preparing (+)-(s-)-clopiclogrel hydrogensulfate (I)

This invention relates to anti thrombus medicine (+)-(S-)-chlorine pyrrole rayl bisulfate preparation method. (+)-(S-)-chlorine pyrrole rayl free alkali shown as formula (I) is added in organic solvent, and weight concentration 10-100 perent sulphuric acid solution is dropwised at 6-20 degree centigrade, then the reaction is kept for 10 minute to 1.5 hours at 50-65 degree centigrade and the temperature is protected, finally formula (II) compound is got after filtration. The sulphuric acid solution is made by sulfuric acid dissolved in organic solvent, the organic solvent is one or more of the following, ethyl formate, methyl acetate, ethyl acetate, butyl acetate, aether, isopropyl ether, tertiary butyl methyl ether or methylene chloride. Mol ratio of compound (I) and sulfuric acid is 1:0.95-1.05. The synthesis in this invention is safe and high efficiency, it is propitious to industrial manufacture, product purity is high, yield is high, and crystal form fluidity is good.

Owner:ZHEJIANG HISOAR PHARMA

Preparing and refining methods of difenoconazole

The invention belongs to the technical field of raw pesticide preparation, particularly relates to preparing and refining methods of difenoconazole. The refining method comprises the following steps of: dissolving prepared raw difenoconazole with isopropanol, then dropwise adding hydrochloric acid (or introducing hydrochloric acid gas) to obtain crystals, filtering and recycling a solvent; filtering out residues, adding water and methylbenzene, and then regulating the pH value to be neutral with ammonia water, demixing and removing water, desolventizing a methylbenzene layer, and then refluxing with isopropyl ether and methyl tertiary butyl ether, freezing for crystallizing, filtering to obtain refined difenoconazole. The product prepared with the refining method has good dissolubility, few impurities and high crystallization rate (about more than 5 hours); and more finished products can be produced once with the method, and the prepared difenoconazole technical has good quality and moderate viscosity.

Owner:周保东

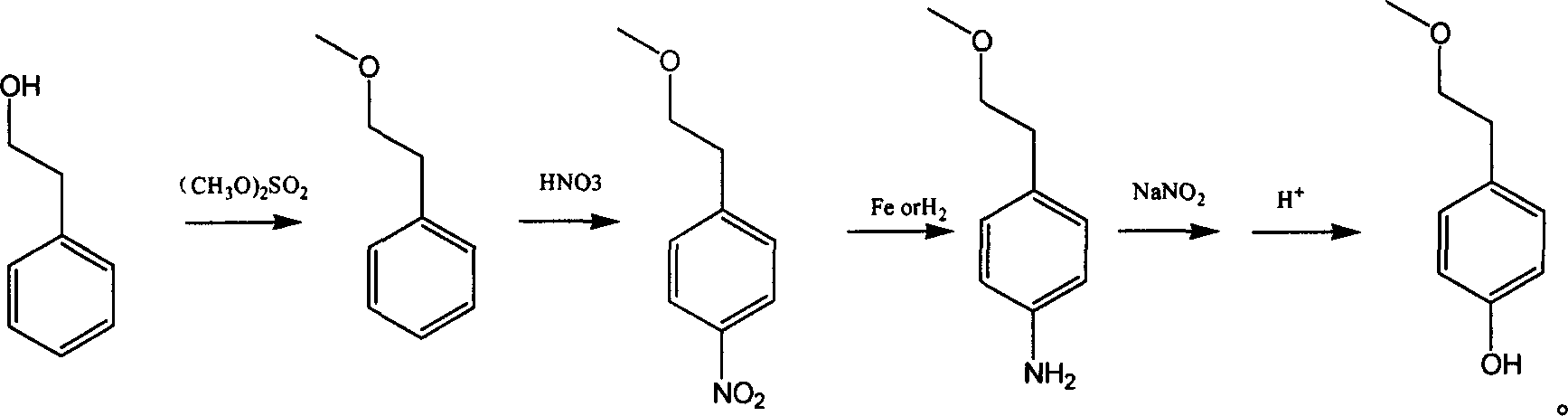

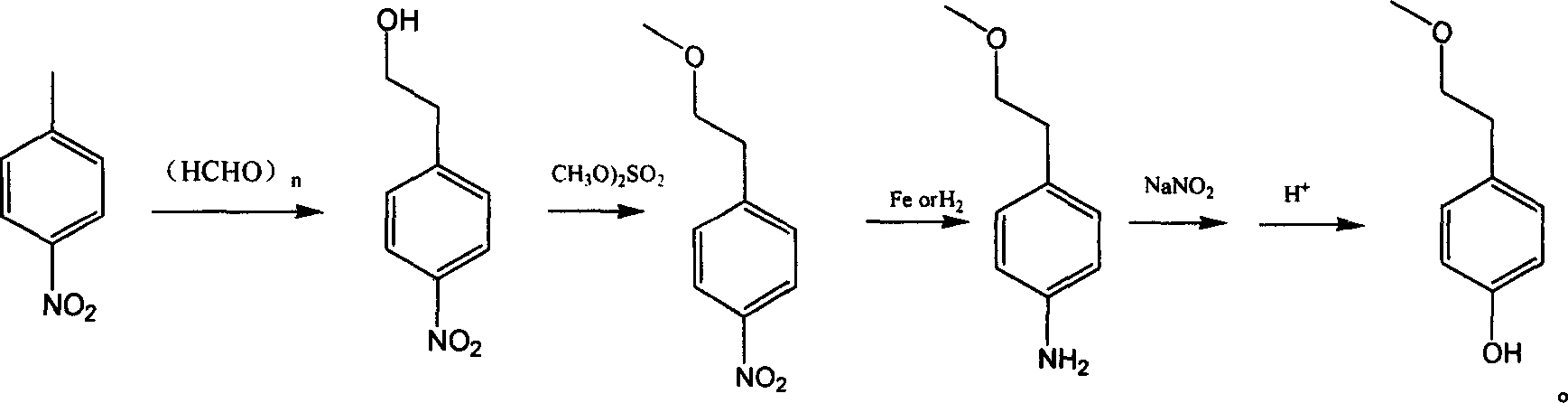

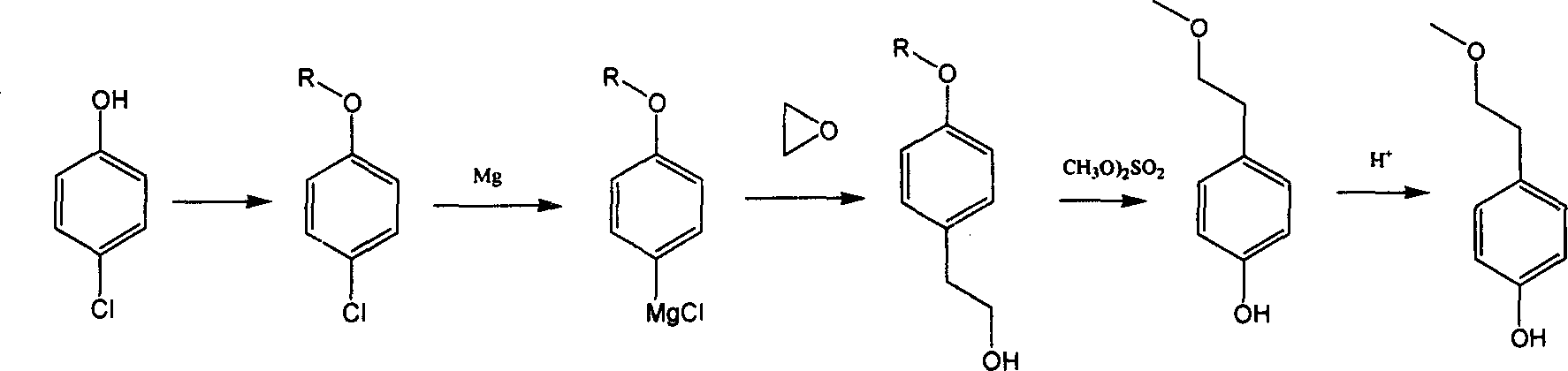

Para-(2-methoxyl) ethylphenol synthesis method

ActiveCN1800128AThe reaction route is simpleThree wastes lessEther preparation from oxiranesTyrosolMethyl carbonate

The invention discloses a method for synthesizing phenetyl, which uses p-chlorophehol or p-bromophenol as starting reaction raw material. It first uses methyl, benzyl or tert-butyl to protect the phenolic hydroxyl, the parivis which is protected by the phenolic hydroxyl reacts with the magnesium in the ether, tetrahydrofuran, tert-butyl methyl ether, isopropyl ether and its mixing solution to obtain the Grignard reagent, the Grignard reagent directly reacted with the etox to obtain the tyrosol which is protected by the phenolic hydroxyl, the tyrosol reacts with the dimethyl sulfate, dimethyl carbonate, trimethyl orthoformate to obtain the tyrosol ether which is protected by phenolic hydroxyl, which obtains the product in acid or hydrogenation protection.

Owner:SHANDONG HANXING PHARM TECH CO LTD +1

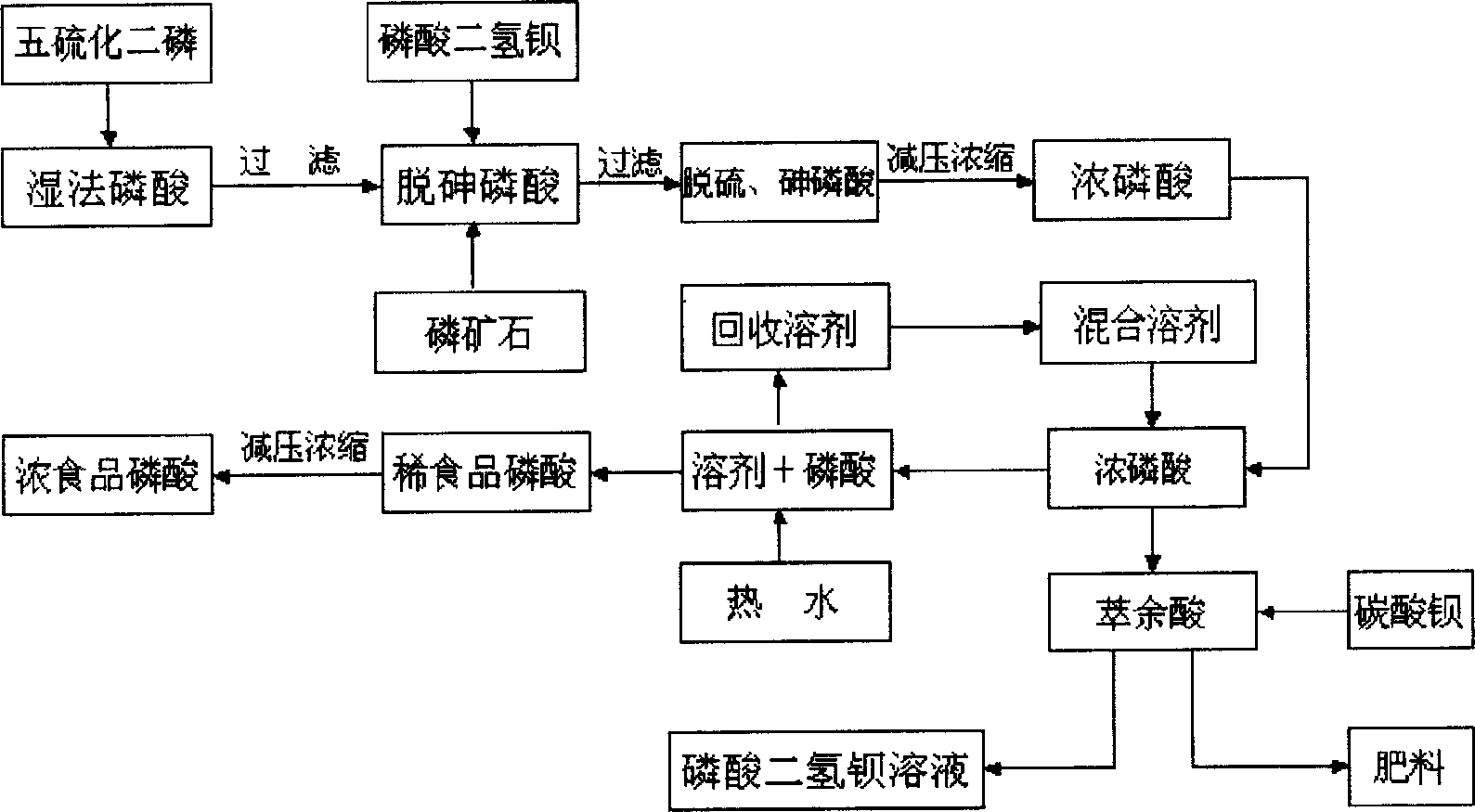

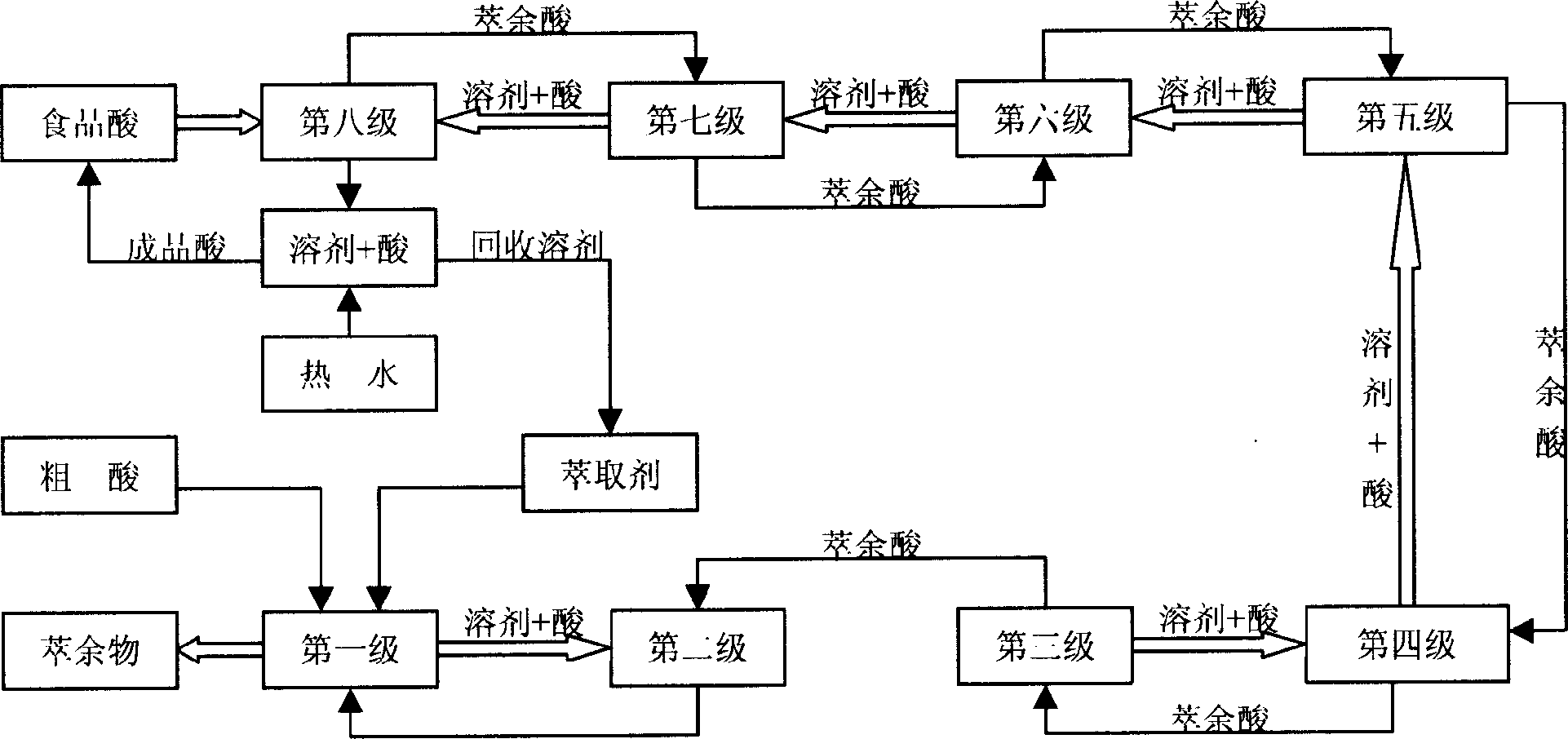

Process for purifying producing extracting solvent of food grade phosphoric acid by wet method phosphoric acid and extracting process thereof

An extracting solvent for preparing the food-class phosphoric acid from wet-process phosphoric acid is prepared from tributoxyethyl phosphate, isopropyl ether and cyclohexanol through proportional mixing. Its extracting process includes such steps as proportionally mixing said extracting solvent with wet-process phosphoric acid, oscillating for layering, taking upper-layer liquid, washing it with less food-class phosphoric acid, layering, taking the water phase, multi-stage extracting to the phosphoric acid, multi-stage back extracting by deionized water.

Owner:YIBIN TIANYUAN GRP CO LTD

Automobile exhaust PM2.5 pollutant treatment agent

InactiveCN102559336AIncrease oxygen contentBurn fullyLiquid carbonaceous fuelsFuel additivesSuccinic acidInternal combustion engine

The invention relates to an automobile exhaust PM2.5 pollutant treatment agent added in fuel oil. The formula of the treatment agent comprises the following components by weight percent: 10%-30% of methanol, 0.03%-0.07% of ferrocene, 13%-16% of butanol, 0.5%-0.8% of nanometer lanthanum oxide, 0.6-0.9% of nanometer cerium oxide, 0.05%-0.08% of potassium permanganate, 13%-15% of methyl isopropyl ether, 0.1%-0.5% of aluminum acetylacetonate, 12%-18% of dodecyl alkenyl succinic acid, 1%-3% of urea, 5%-10% of isopropanol, 1%-5% of multi-alkenyl succinimide, 0.02%-0.05% of manganese dioxide and 10%-30% of ethanol. The treatment agent is prepared through simple processes such as mixing, stirring, precipitating and filtering. The automobile exhaust PM2.5 pollutant treatment agent is non-toxic, has no bad smell, does not corrode the equipment and can be used to increase the power of the engine and greatly reduce the emission of PM2.5 in the exhaust; and after 10-20g of the automobile exhaust PM2.5 pollutant treatment agent added in fuel oil is added in 1L of oil and the engine runs for 10min, the effect can be realized and the PM2.5 concentration of the exhaust discharged by the kerosene internal combustion engine can be reduced from 330mg / m<3> to 60mg / m<3>.

Owner:洛阳万山高新技术应用工程有限公司

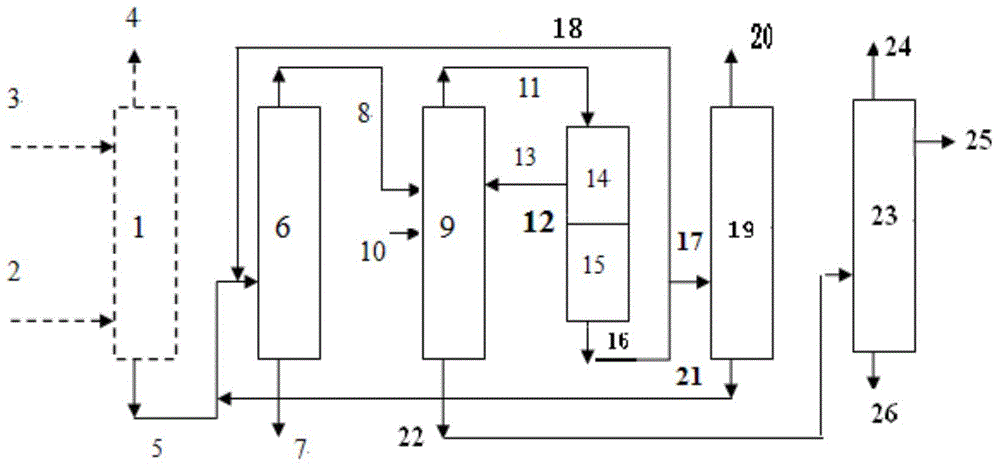

Separation method applicable to both propylene hydration and acetone hydrogenation for isopropyl alcohol preparation

ActiveCN105712839AHigh purityNo pollutionOrganic compound preparationHydroxy compound separation/purificationHydration reactionAmyl alcohol

The invention belongs to the technical field of petrochemical industry, and is a separation method suitable for preparing isopropanol by hydration of propylene and hydrogenation of acetone. The steps of the method are as follows: crude isopropanol produced by hydration of propylene passes through a deether tower and a concentration tower in sequence , the dehydration tower obtains anhydrous products; the water layer of the water separation tank of the dehydration tower is partially circulated back to the concentration tower, and part of it enters the acetone removal tower; the dehydration tower removes by-products isopropyl ether, 4-methyl pentanol and water and unreacted acetone , hydrogenation to produce crude isopropanol feed position can borrow hydrated isopropanol azeotrope to form the feed position, the feed position is located below the dehydration tower; the bottom material of the acetone removal tower is returned to the concentration tower for feed. The advantages of the present invention: provide a common isopropanol separation method for the two processes of propylene hydration and acetone hydrogenation, both of which can obtain isopropanol with high purity; compared with other processes, the process does not increase equipment and does not cause environmental pollution Pollution reduces production costs to a certain extent.

Owner:PETROCHINA CO LTD

Preparation method for high-purity esomeprazole sodium

ActiveCN103288801ASolve the prone to titanium complex suspensionSolve the difficulty of splittingOrganic chemistrySodium bicarbonateOmeprazole Sodium

The invention discloses a preparation method for high-purity esomeprazole sodium. The preparation method comprises the steps of: including and splitting esomeprazole sodium and D-(-)-diethyl tartrate, titanium iso-propylate, triethylamine and L-(+)-mandelic acid in the presence of a proper amount of water, and separating to obtain an inclusion complex; dissolving the inclusion complex with ethyl acetate, washing inclusion complex with sodium carbonate water solution, carrying out ammonia hydroxide eluting on an ethyl acetate layer, slowly regulating the pH value to 6-7 with glacial acetic acid, then extracting with dichloromethane, and concentrating to obtain crude esomeprazole free alkali product; carrying out silica gel adsorption and elution on the crude product to obtain a pure esomeprazole free alkali product; and enabling the pure product and the methanol-ethanol-acetonitrile solution of sodium hydroxide to form salt, and then crystallizing with isopropyl ether to obtain the high-purity esomeprazole sodium. According to the preparation method, the difficulties that when inclusion and splitting are carried out, the titanium complex suspension body are difficult to split and the ammonia complex of titanium is difficult to remove can be solved, the industrialization production can be realized, the industrialized production cost is low, the product purity is high, the yield is high, and no harmful gas is generated.

Owner:SICHUAN BAILI PHARM CO LTD

Fuel methanol additive and fuel methanol

InactiveCN101033415AClean dischargeSolve corrosiveLiquid carbonaceous fuelsMethanol fuelIsopropyl ether

This invention relates to a fuel methyl alcohol and its additive, in which, the additive is prepared by the following materials in volume: MTBE 15-20%, 2, 2-dimethylpropane 15-20%, n-butyl alcohol 10-15%, alicyclic acid amine 20-25%, nitroacid liquid 5-10% and isopropyl ether 15-20%, and said fuel methyl alcohol is prepared like this: methyl alcohol 80-90% and additive 10-20%.

Owner:CRPC INNOVATION ENERGY

Method for preparing porous mullite fiber through coaxial electrostatic spinning

InactiveCN106868632AUniform diameter distributionSimple manufacturing processInorganic material artificial filamentsFiberN dimethylformamide

The invention relates to a method for preparing porous mullite fiber through coaxial electrostatic spinning and belongs to the science and technology technical field of materialsmaterial science. The fiber preparing method comprises the following steps: preparing anhydrous aluminum chloride, tetraethoxysilane, isopropyl ether and anhydrous dichloromethane into a reaction solution according to a certain molar ratio, then heating the reaction solution, triggering non-hydrolytic sol-gel reaction to synthesize mullite gel; mixing absolute ethyl alcohol and a certain amount of polyvinylpyrrolidone (PVP) according to a certain ratio to obtain a PVP ethanol solution, dissolving the synthesized mullite gel in the PVP ethanol solution, then adding N,N-dimethylformamide (DMF) to obtain a spinning precursor solution; taking liquid paraffin as an inner solution, taking the mullite precursor solution as an outer solution, preparing mullite gel / PVP composite fiber through a coaxial electrostatic spinning process, then calcining the mullite gel / PVP composite fiber under high temperature to obtain the porous mullite fiber. The preparation method of the porous mullite fiber is simple; the porous structure is easy to control; the porous mullite fiber has excellent heat insulation and heat preservation properties; a novel high-temperature heat insulation material is provided for the fields such as aviation and military industry and the like.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Novel carbinol gasoline fuel

InactiveCN101550363AEmissions are clean and environmentally friendlyGood environmental effectLiquid carbonaceous fuelsGasoline fuelEngineering

A novel carbinol gasoline fuel relates to an engine fuel, in particular to a novel liquid fuel for a gasoline engine. According to the weight parts, the novel carbinol gasoline fuel is mixed simply by the following raw materials of the composition: 20-80 of gasoline, 20-90 of carbinol, 2-10 of petroleum ether, 1-5 of 2-methylpentane, 0-5 of octane, 0-5 of isooctane, 0-5 of diethyl carbonate, 0-4 of cinnamene, 0.2-4 of trimethyl borate, 0-5 of dibutyl phosphite, 0.5-5 of dimethyl carbonate, 0-5 of methyl tertiary butyl ether, 0-4 of ether, 0-4 of isopropyl ether, 0-6 of acetone, 0-4 of isopropyl alcohol, 0-5 of isobutyl alcohol and 0-4 of anti-oxidant. The antiknock index is reinforced as the octane number is improved; and the compounding is optimized scientifically during the experiment and practice, thus leading the vehicle to keep the best stability on all aspects when the liquid fuel is in use.

Owner:SHANGHAI SAPPHINE FUEL DEV

Alcohol base gasoline solubilizer and preparation method thereof

InactiveCN101544919ANo pollution in the processNo special smellLiquid carbonaceous fuelsFuranAntioxidant

The invention discloses alcohol base gasoline solubilizer and a preparation method thereof. The solubilizer comprises isopropyl ether, acetamide, alkylphenol polyether, methyl tert-butyl ether, fatty acid methyl ester, furan, tertiary butanol, antioxidant and anti-swelling agent. The preparation method comprises the following steps: weighing isopropyl ether, tertiary butanol, acetamide, alkylphenol polyether, methyl tert-butyl ether, fatty acid methyl ester, furan, antioxidant and anti-swelling agent according to a certain weight ratio, adding isopropyl ether and tertiary butanol in a reaction kettle for vacuumization, warming the reaction kettle, adding acetamide, stirring, adding alkylphenol polyether, stirring and cooling through a cooler, adding methyl tert-butyl ether, fatty acid methyl ester, furan, antioxidant and anti-swelling agent, and uniformly stirring to obtain the alcohol base gasoline solubilizer. The invention has no toxicity, no pollution and no special odor, less adding amount, good solubilizing effect, and no heavy metal component, no generation of new pollution and no mechanical impurity, and can increase the octane of 90# gasoline to 95-99#.

Owner:XIAN JIAHONG PETROCHEM TECH

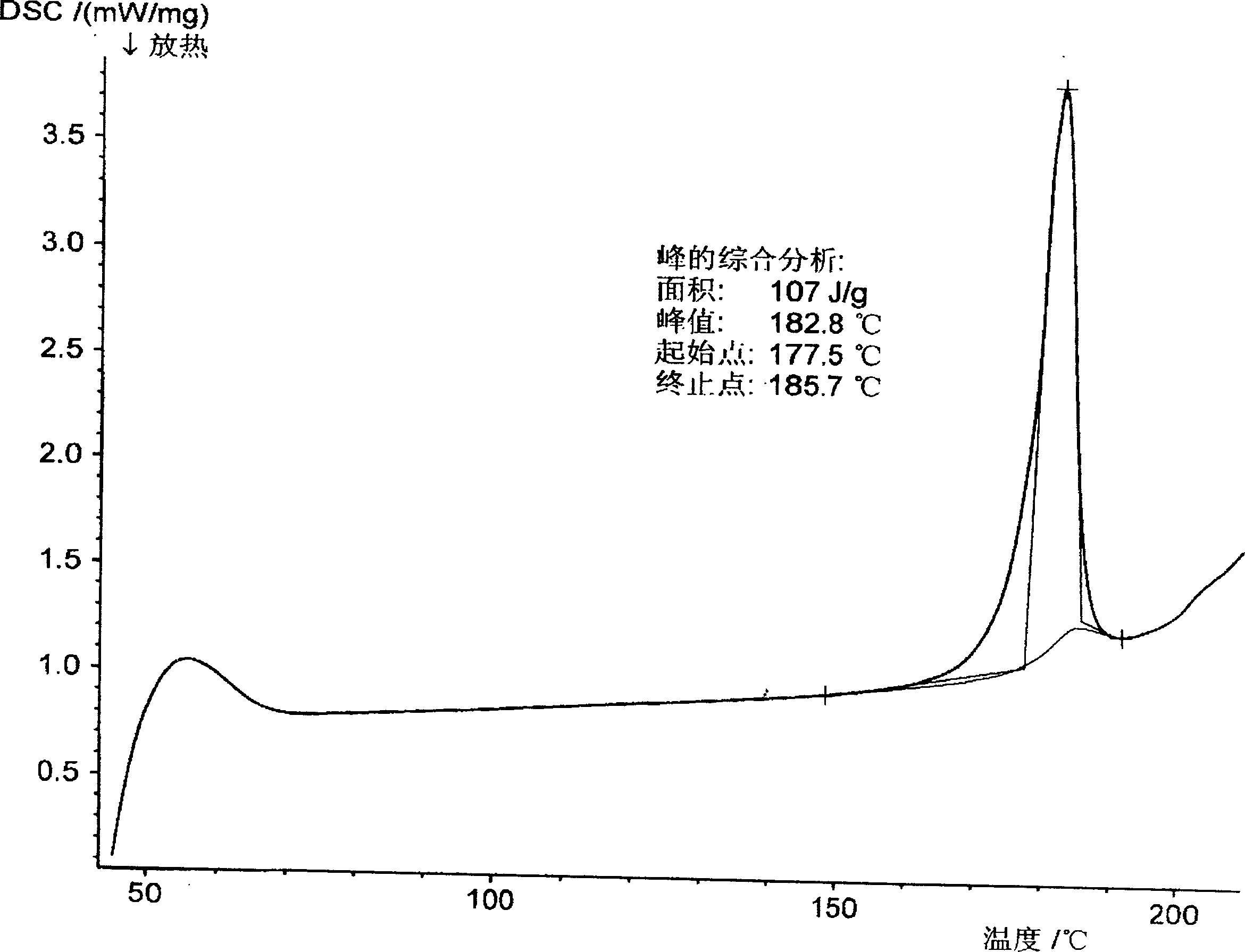

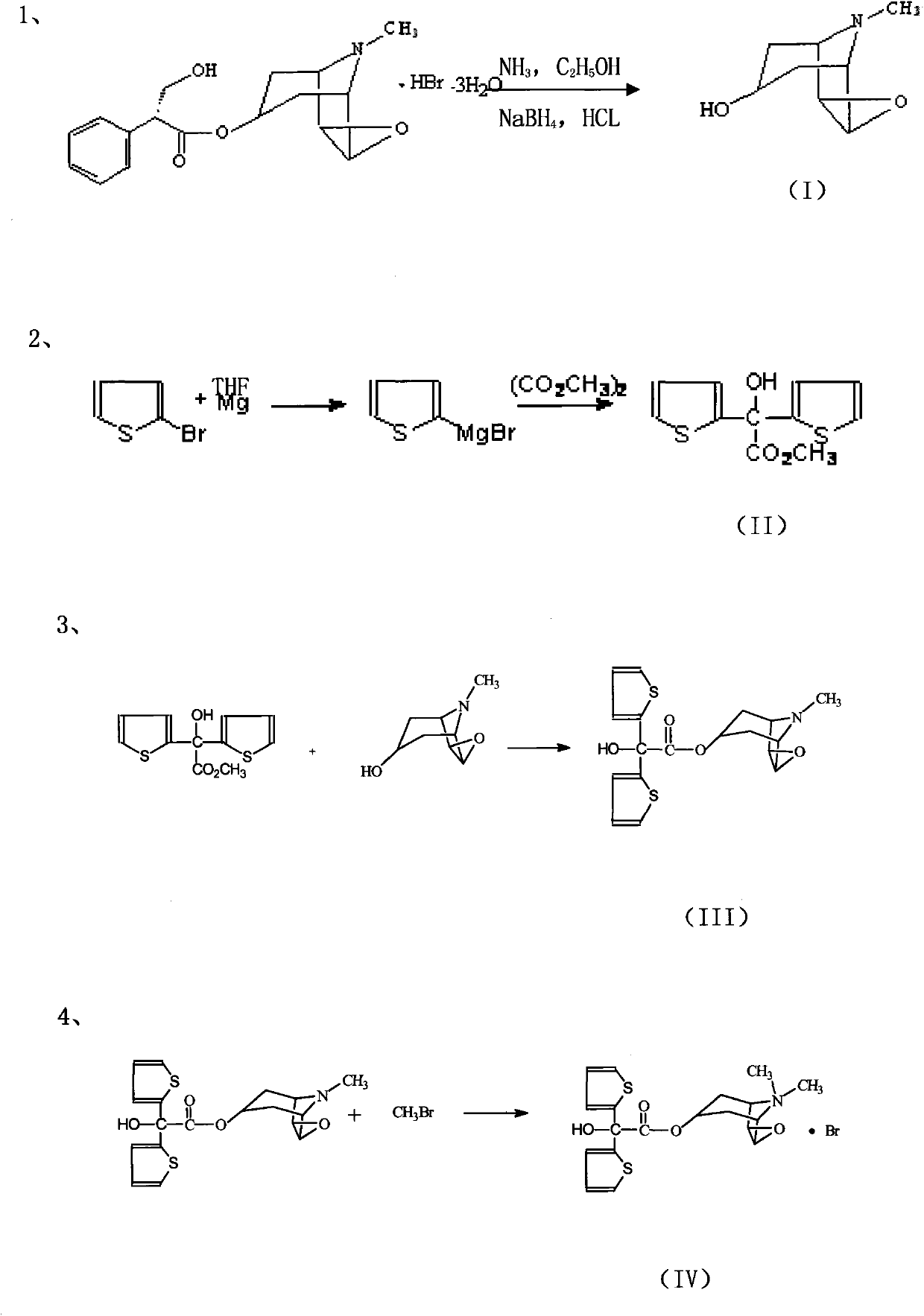

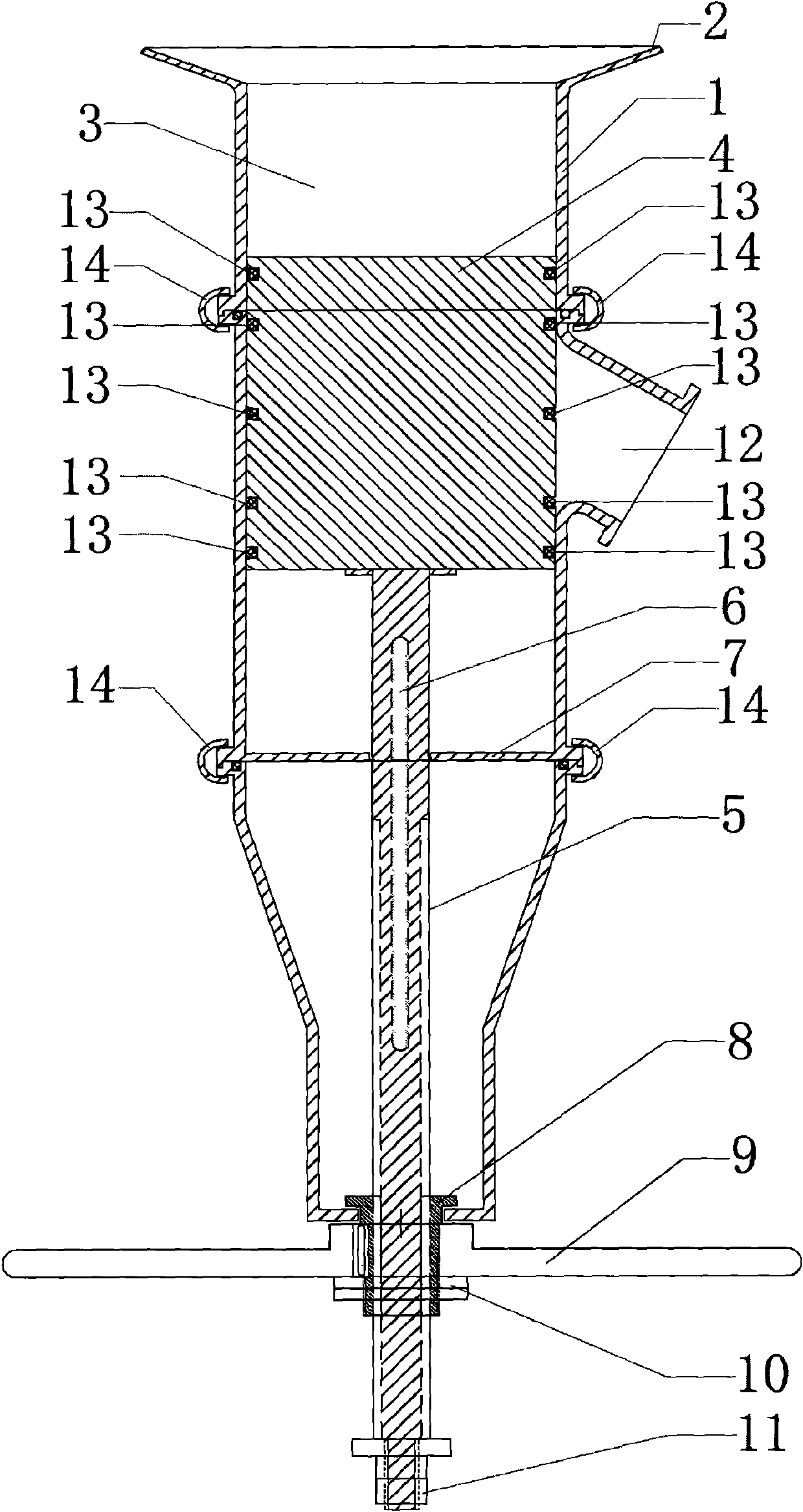

Tiotropium bromide anhydride and preparation method thereof

ActiveCN101768158AQuality improvementHigh yieldOrganic chemistryFiltration separationGrignard reagentDimethyl oxalate

The invention discloses a method for preparing tiotropium bromide anhydride, which comprises the steps of: under the anhydrous and anaerobic condition, preparing an intermediate I by taking a special kettle bottom valve and a multi-functional reaction kettle as a reactor, taking a special filter as refining equipment and taking hydrobromic scopolamine as an initial raw material through reduction hydrogenation reaction; preparing an intermediate II by performing addition reaction of Grignard reagent and dimethyl oxalate in tetrahydrofuran, wherein the Grignard reagent is prepared from bromothiophene by taking tetrahydrofuran as a medium through iodine catalysis; preparing an intermediate III by performing ester exchange condensation reaction of the intermediate I and the intermediate II under the action of sodium; preparing an intermediate IV from the intermediate III through methylation bromination reaction; and preparing the tiotropium bromide anhydride by performing the activated carbon decoloration and recrystallization on the intermediate IV by using aqueous solution and acetonitrile methanol isopropyl ether solution. Compared with those in the prior art, reaction products of the method have the advantages of good quality, high yield, controlled reaction process, safe production and good environmental protection effect.

Owner:HONGYI SCI & TECH CO LTD NANCHANG

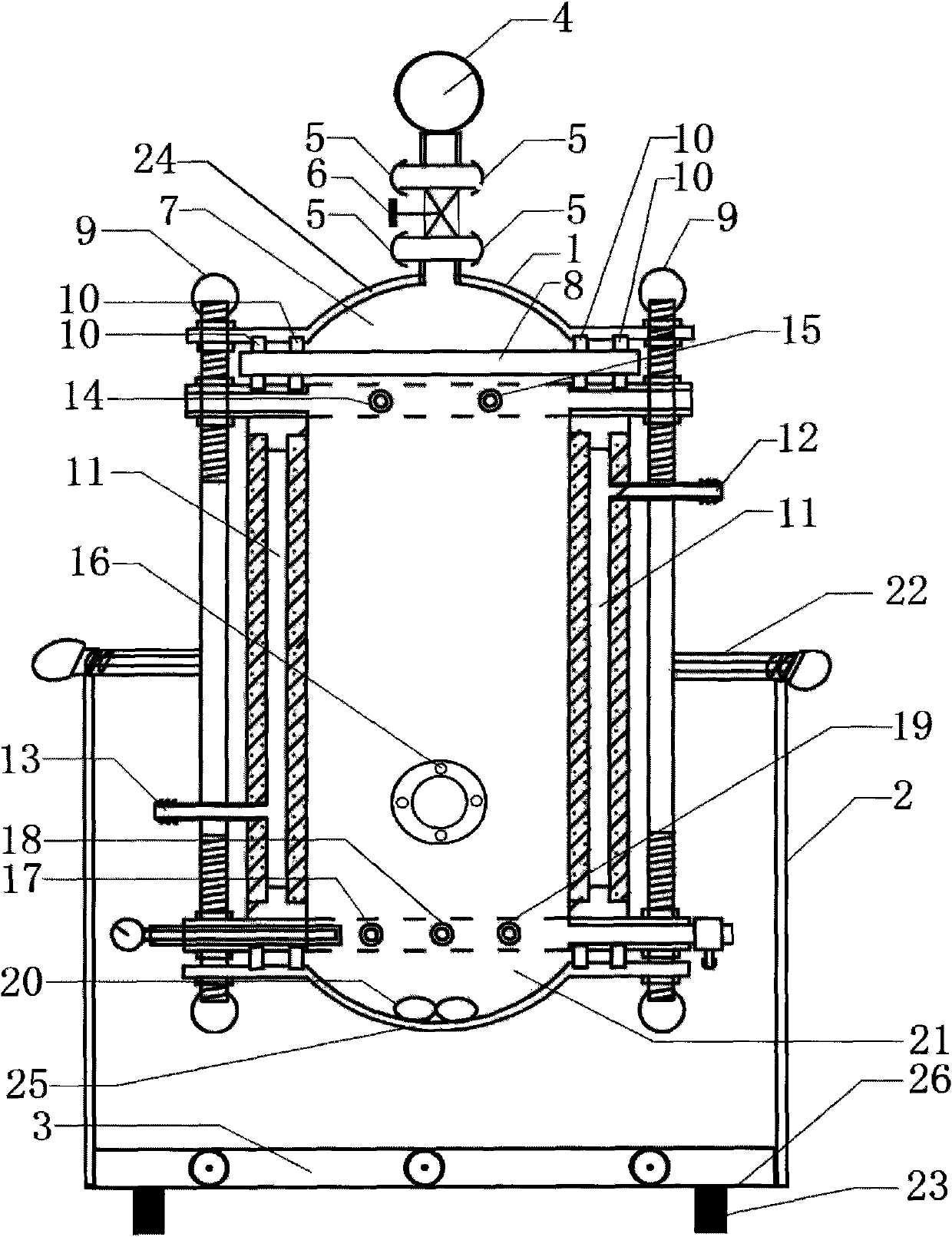

Preparation method of mezlocillin sodium solvent crystal

ActiveCN101570543AImprove product qualitySolubility problem solvingAntibacterial agentsOrganic chemistryEthyl acetateSodium hexanoate

The invention discloses a preparation method of mezlocillin sodium solvent crystal, comprising the steps of (1) dissolving crude mezlocillin acid in a reaction solvent A to obtain solution A; (2) dissolving organic salt forming agent in a reaction solvent B to obtain solution B; (3) after adding the solution A into the solution B for sufficient reaction, slowly adding a poor solvent, separating out sodium solvent crystal, filtering, obtain filtrate and filter mass, drying the filter mass; the organic salt forming agent is sodium iso-octoate, ethyl acetoacetate or 2-ethyl sodium hexanoate; the reaction solvent A or B is independently acetone or ethyl acetate; the poor solvent is methanol, ethanol, propanol, isopropanol, aether, isopropyl ether, tetrahydrofuran, ethyl formate orbutyl acetate. The method is simple to operate, and has high stability, large yield, excellent product quality and few impurity contents; the reaction solvents and crystallizing solvent can be recycled, thus having low production cost, high reaction yield, excellent implementing value, and social and economic benefits.

Owner:ZHEJIANG UNIV OF TECH

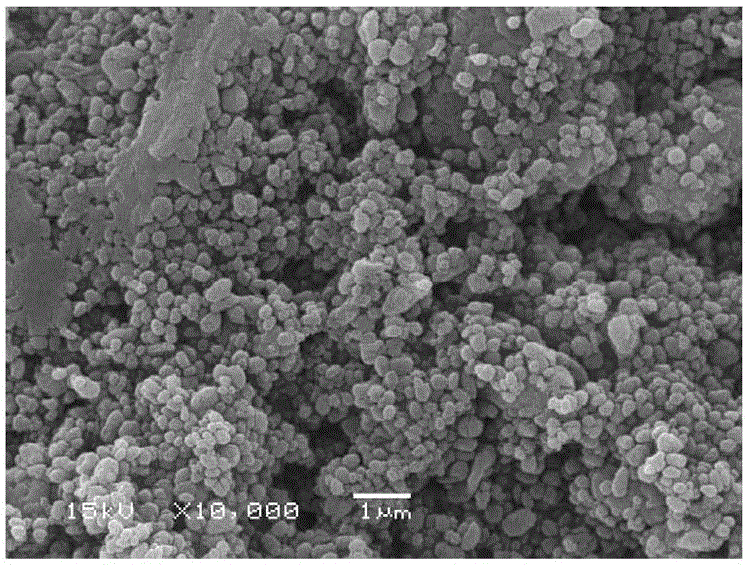

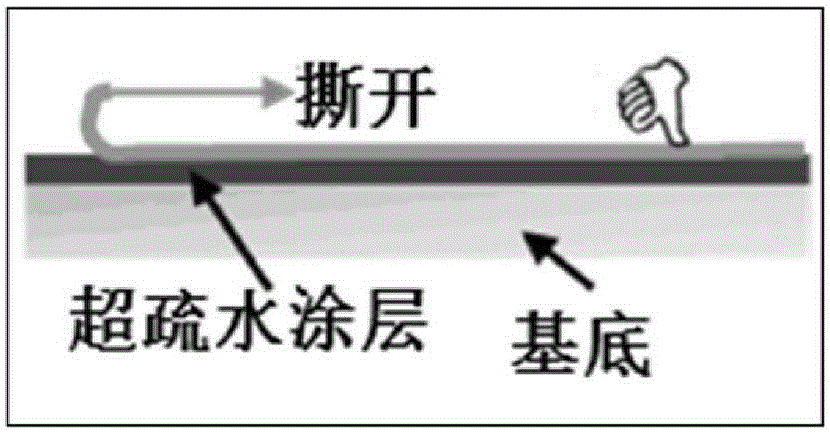

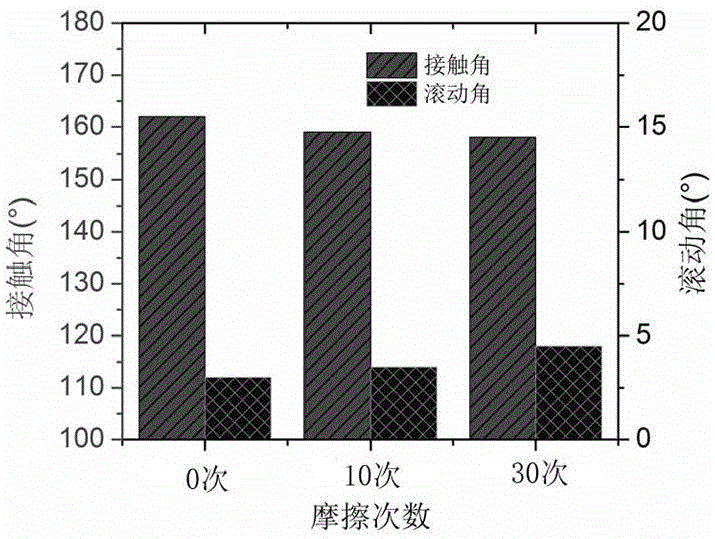

Fully-organic multiply-fluorinated epoxy super-hydrophobic composite coating and preparation method and utilization method thereof

ActiveCN105885564AImprove corrosion resistanceImprove wear resistanceAnti-corrosive paintsPolyether coatingsPolymer scienceCoating system

The invention discloses a fully-organic multiply-fluorinated epoxy super-hydrophobic composite coating and a preparation method and a utilization method thereof. The coating comprises a coating system and a curing agent; the coating system comprises epoxy resin, polytetrafluoroethylene particles, polyperfluoromethyl isopropyl ether and an organic solvent; the curing agent is prepared by reaction of diethylenetriamine and perfluorobutyric acid. The preparation method includes preparation of the coating system and preparation of the curing agent. The utilization method includes: dissolving the curing agent into a diluent, adding an obtained curing agent solution into the coating system, well mixing, coating to a required surface and curing. The fully-organic multiply-fluorinated epoxy super-hydrophobic composite coating has advantages of excellent super-hydrophobic property, favorable abrasion resistance, water impact resistance, corrosion resistance, high adhesive power, wide application range and the like. The preparation method is simple and easy to implement and suitable for large-scale application.

Owner:NAT UNIV OF DEFENSE TECH

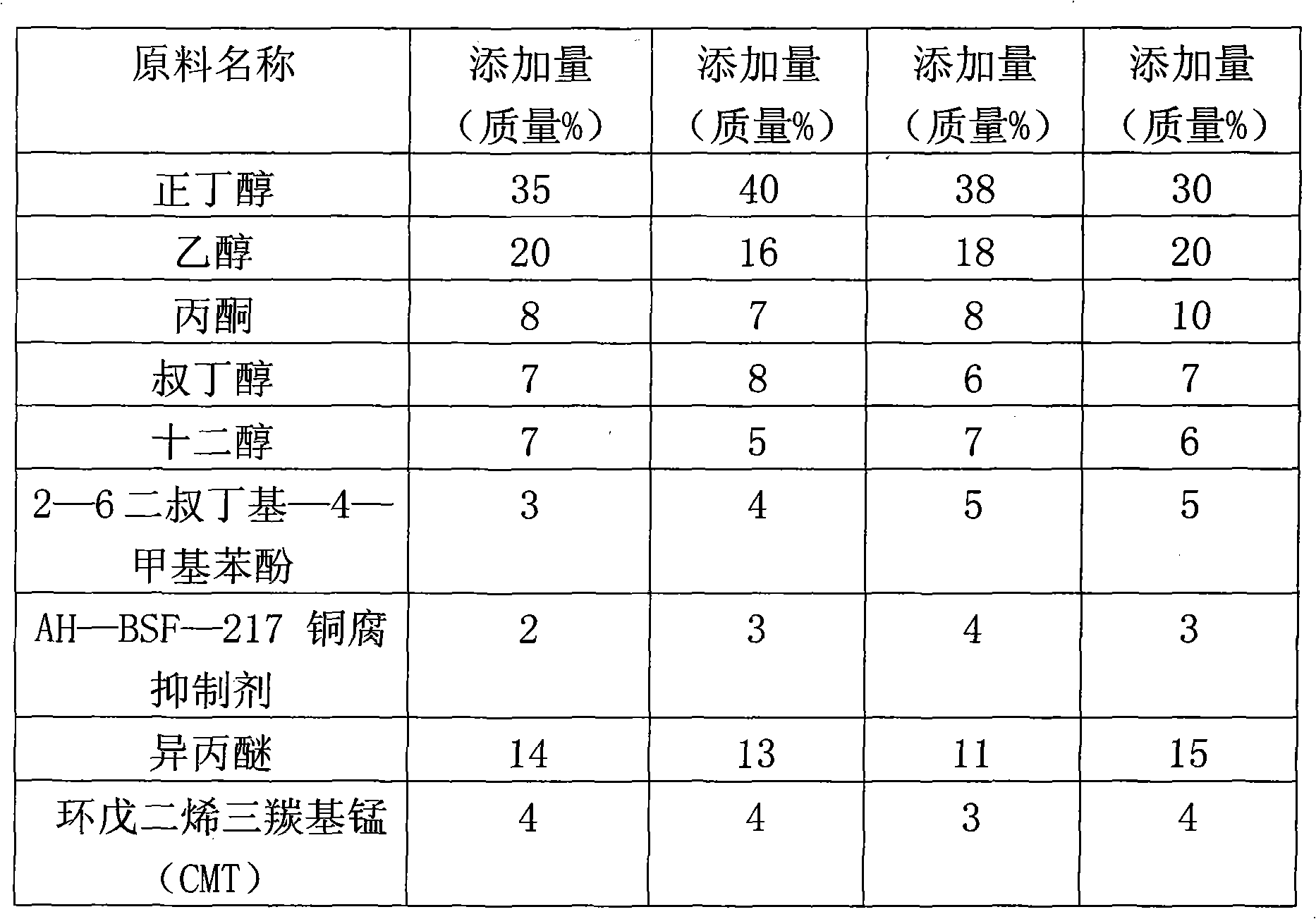

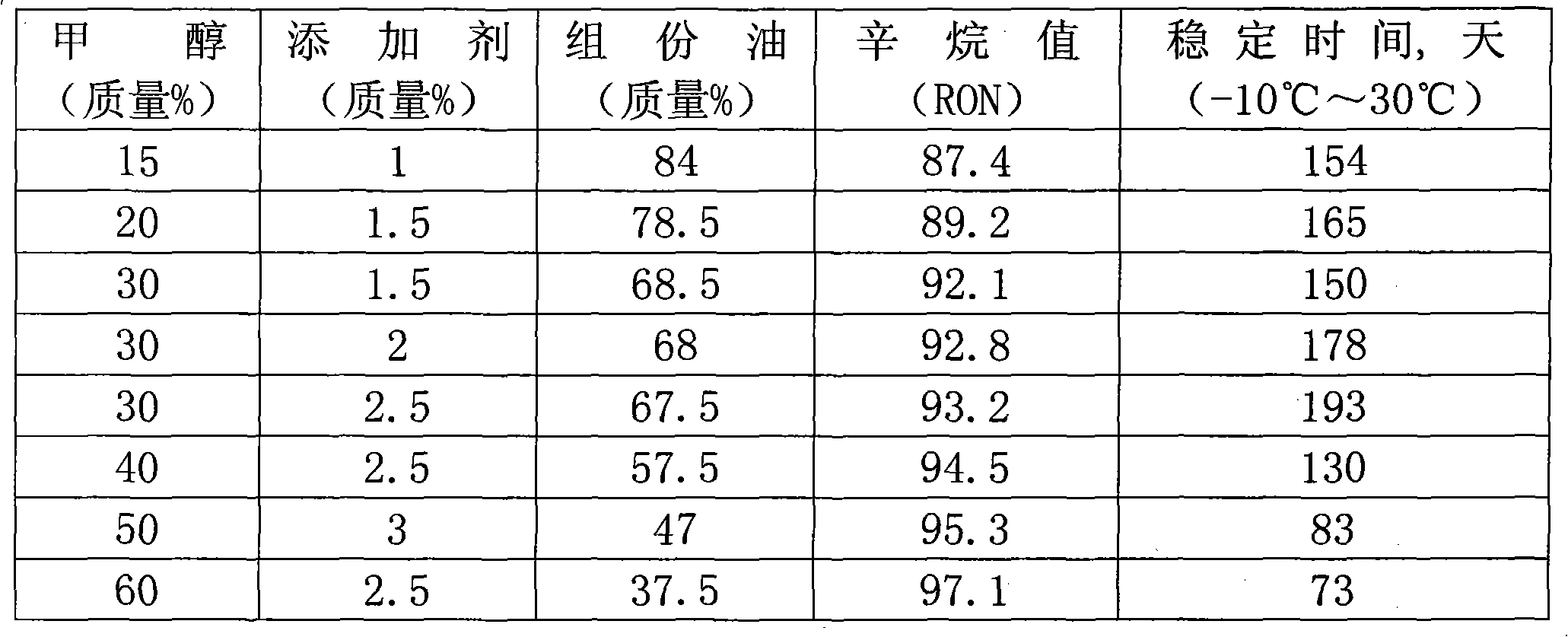

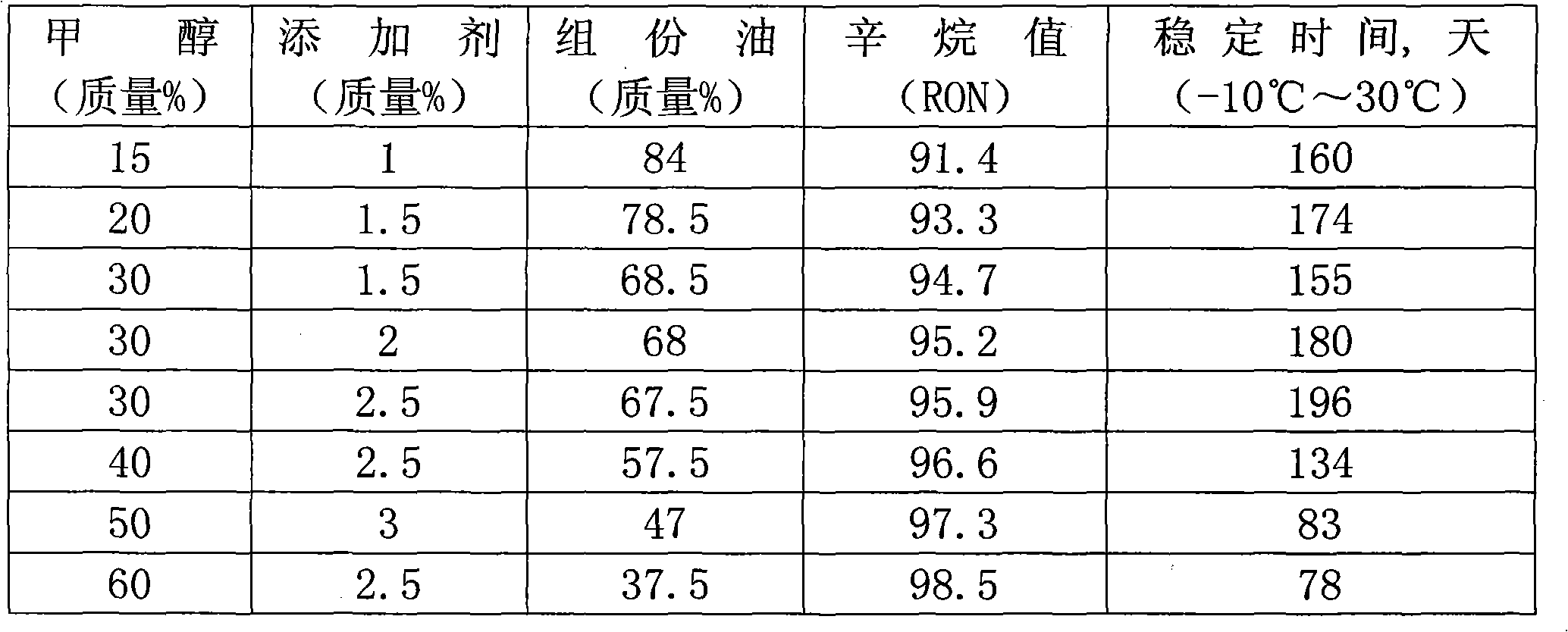

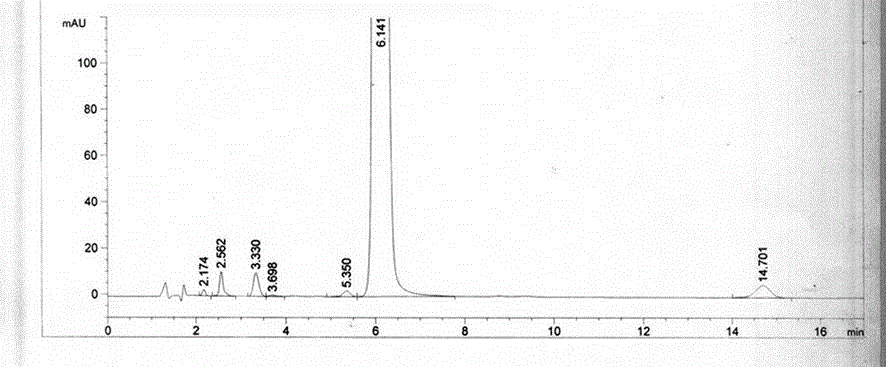

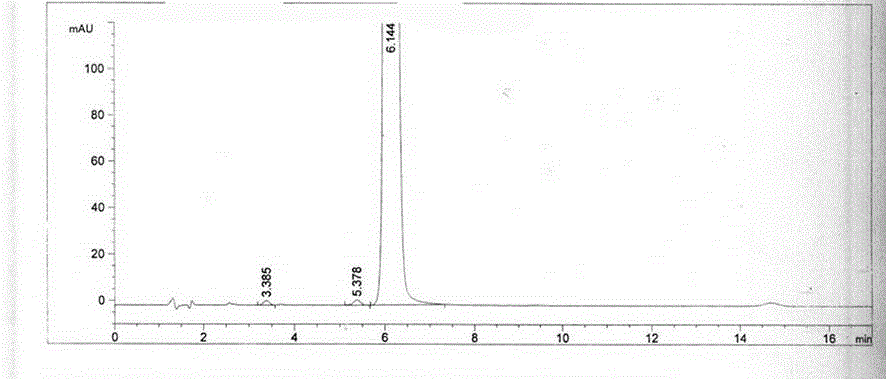

Methanol gasoline additive, methanol gasoline prepared from same and production methods for methanol gasoline additive and methanol gasoline

ActiveCN101886004ABoost octaneExtended storage timeLiquid carbonaceous fuelsFuel additivesOil additiveColor changes

The invention discloses a methanol gasoline additive, methanol gasoline prepared from same and production methods for the methanol gasoline additive and the methanol gasoline. The methanol gasoline additive is prepared from the following components in percentage by mass: 20 to 40 percent of n-butyl alcohol, 5 to 25 percent of ethanol, 3 to 13 percent of acetone, 2 to 10 percent of tertiary butanol, 4 to 9 percent of dodecanol, 2 to 6 percent of 2,6-di-tert-butyl-4-methylphenol, 1.5 to 5 percent of AH-BSF-217 copper corrosion inhibitor, 5 to 15 percent of isopropyl ether and 2 to 4 percent of cyclopentadienyl manganese tricarbonyl. The production method for the methanol gasoline additive comprises the following steps of: adding the raw materials in turn, fully stirring in a reaction kettlefor 30 to 60 minutes, sampling to observe color change, and stopping stirring when the liquid is changed to transparent yellow or rosiness; and putting into a finished product tank. The methanol gasoline is prepared from the following components in percentage by mass: 0.5 to 5 percent of methanol gasoline additive, 15 to 60 percent of methanol and 34.7 to 84 percent of component oil. The methanolgasoline prepared from the methanol gasoline additive has the advantages of high octane number, good anti-explosion, full combustion, reduction of discharge of automobile exhaust, no air blockage, easy cold start of the automobile and the like.

Owner:山东亿源石化有限公司 +1

Refining method of crude epalrestat product

The invention discloses a refining method of a crude epalrestat product, which comprises the following steps of: firstly, dissolving the crude epalrestat product into a tetrahydrofuran solvent, heating to completely dissolve the crude epalrestat product, and stopping heating after the crude epalrestat product is completely dissolved; then adding isopropyl ether so that a small amount of red solids are separated out, further heating to completely dissolve the red solids, then stopping heating, naturally cooling, crystallizing and filtering, and then drying to obtain initially refined epalrestat; and then adding the tetrahydrofuran solvent, heating till the initially refined epalrestat is completely dissolved, stopping heating, then slowly adding petroleum ether so that a small amount of red solids are separated out, continuously heating till the red solids are completely dissolved, then stopping heating, naturally cooling, crystallizing and filtering, and then drying to obtain a refined epalrestat product. The refining method disclosed by the invention can be used for obtaining the high-purity epalrestat and has the advantages that the solvent raw material is available, reaction condition is mild, operation is simple and yield is high, and is suitable for industrial production.

Owner:KAIFENG MINGREN PHARMA

Alcohol ether fuel additive

InactiveCN1876774ARaise MethanolIncrease ethanol contentLiquid carbonaceous fuelsAlcohol fuelDiethyl carbonate

The invention relates the alcohol ether fuel and addition agent. The addition agent comprises methyl formate, methyl methacrylate, trimethyl phosphate, dimethyl carbonate or 10-50wt% diethyl carbonate, dimethyl ether, isopropyl ether, propyl ether, 15-40wt% ethyl ether, isoamyl alcohol, isobutyl alcohol or 15-50wt% isoheptyl alcohol, aminoethyl alcohol, diethyl ethanolamine, triethylamine, hexadecylamine, octadecyl ammonium, 0.5-5wt% nitroaniline, and 0.1-1wt% nufenoxole. The invention has the advantages of non emulsification, non three wastes, low energy consumption and high productivity.

Owner:SHANGHAI FINE ALCOHOL PETROCHEM TECH DEV

High-clean methanol composite gasoline for vehicle and production thereof

The invention is about the high clearing methanol compound petrol which is composed of the methanol, the petrol, the acetone, the isopropyl ether, the isopropanol, the isoamylol, the tert-butyl alcohol and the synthetic addition agent. The addition agent is modulated by the ZnO, the Na2O2, the ferrum naphthenate and the isopropyl nitrate. The compound petrol can solve the problem of the corrosivity to the red copper and the swelling to the rubber. It can be mixed with the normal petrol arbitrarily and not need to change the structure of the engine, also it can remove the carbon and the colloid of the engine. The cost of the technique is low and the operability is high.

Owner:肖军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com