Fully-organic multiply-fluorinated epoxy super-hydrophobic composite coating and preparation method and utilization method thereof

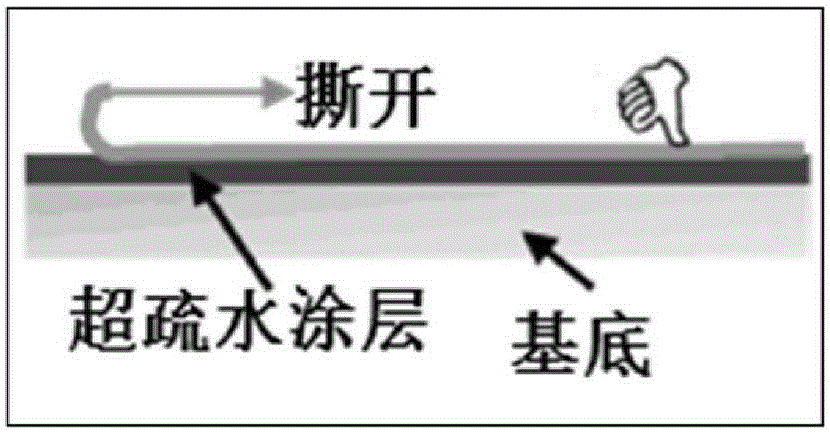

A technology of fluorinated epoxy and composite coatings, which is applied in the direction of epoxy resin coatings, anti-corrosion coatings, polyether coatings, etc., and can solve the problems of superhydrophobic surface resistance to hydraulic shock, wear resistance and corrosion resistance that are difficult to apply on a large scale , to achieve the effects of excellent superhydrophobic properties, excellent wear resistance, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] An all-organic multi-fluorinated epoxy super-hydrophobic composite coating of the present invention, the super-hydrophobic composite coating includes a coating system and a curing agent.

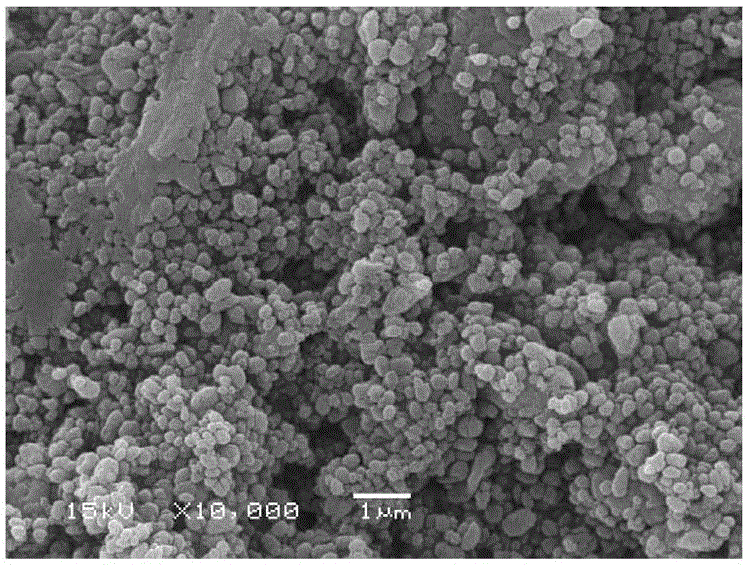

[0045] The coating system includes 3g of E-51 epoxy resin, 10.5g of polytetrafluoroethylene microparticles, 0.3g of polyperfluoromethyl isopropyl ether and 35ml of acetone; the average particle size of polytetrafluoroethylene microparticles is 100nm.

[0046] The curing agent is prepared by fluorinating diethylenetriamine and perfluorobutyric acid, and the molar ratio of diethylenetriamine to perfluorobutyric acid is 1:1.

[0047] The mass ratio of E-51 epoxy resin to curing agent is 10:4.

[0048] A preparation method of the above-mentioned all-organic multiple fluorinated epoxy superhydrophobic composite coating of the present embodiment, including the preparation of the coating system and the preparation of the curing agent.

[0049] The preparation process of the coating system is ...

Embodiment 2

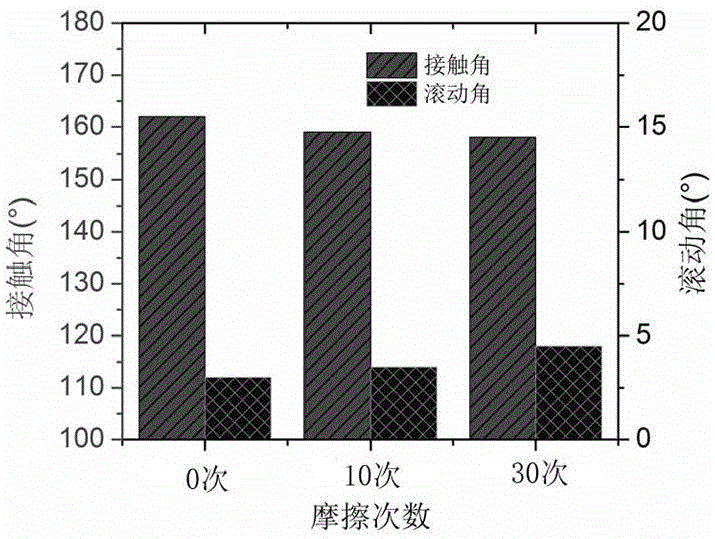

[0064] A kind of all-organic multiple fluorinated epoxy superhydrophobic composite coating of the present invention and its preparation method and use method are basically the same as Example 1, the only difference is: when in use, the substrate used is glass or A4 paper, epoxy resin Board, steel plate. The coating surface of the obtained superhydrophobic composite paint has a contact angle with water of 160° to 165°, and a rolling angle of less than 2°.

Embodiment 3

[0066] A kind of all-organic multiple fluorinated epoxy superhydrophobic composite coating of the present invention and its preparation method and using method are basically the same as Example 1, the only difference is that in the superhydrophobic composite coating, the polytetrafluoroethylene particles used are 4.5g . The contact angle between the coating surface of the obtained superhydrophobic composite coating and water is 150°-153°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com