Methanol gasoline additive, methanol gasoline prepared from same and production methods for methanol gasoline additive and methanol gasoline

A technology for methanol gasoline and additives, applied in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of large food consumption, large engine damage, easy oxidation of oil products, etc., to reduce exhaust emissions and achieve good anti-knock performance. , the effect of long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with specific embodiment:

[0072] One, the background, design and preparation method of the invention of methanol gasoline additive of the present invention

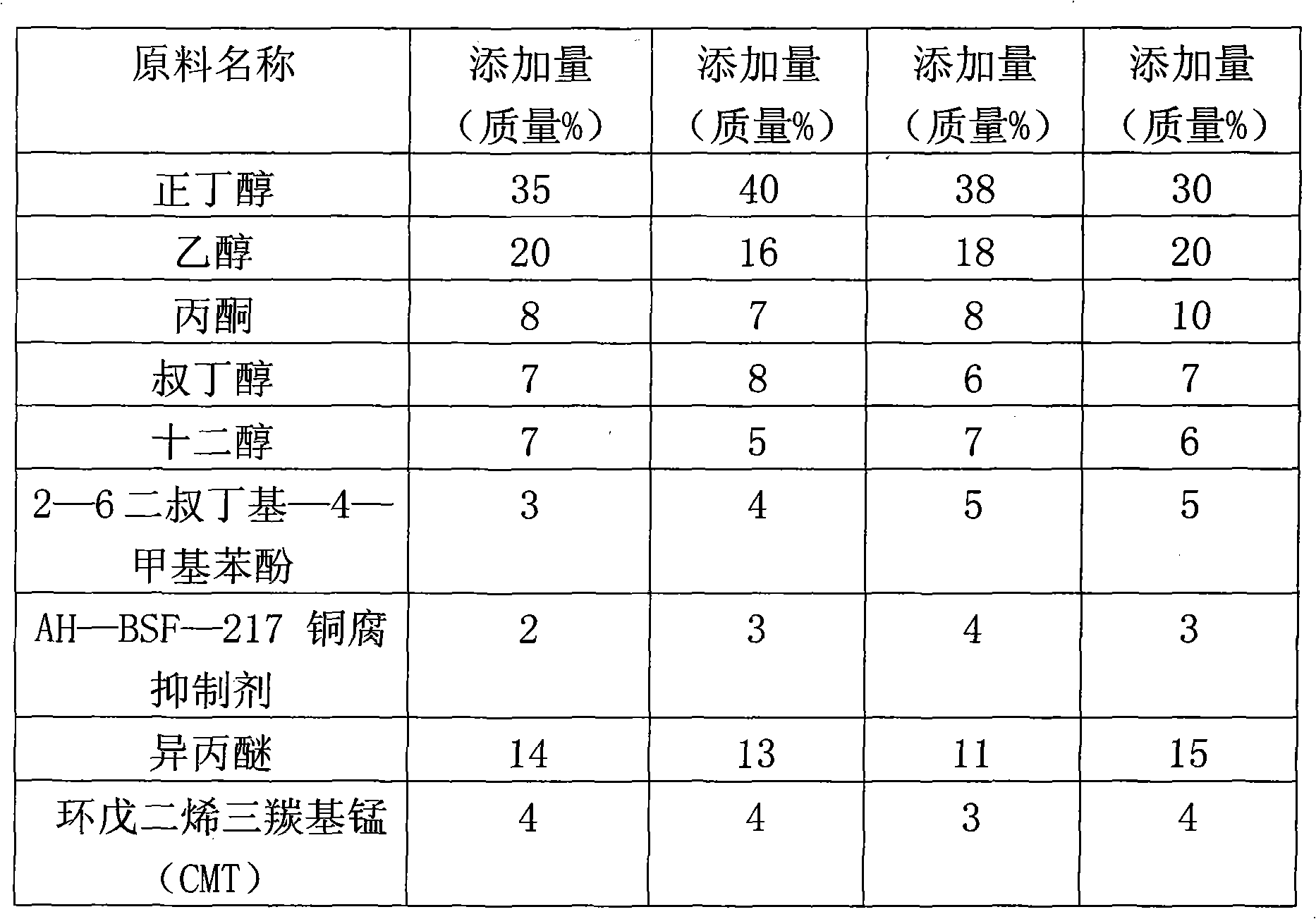

[0073] The research found that the physical and chemical properties of methanol and gasoline have similarities and differences in many aspects. See Table (1).

[0074] Table 1)

[0075] project

Gasoline (isooctane)

C 8 h 18

CH 3 Oh

theoretical air-fuel ratio

15.1

6.45

Calorific value (kcal / kg)

10600

4800

Latent heat of vaporization (kcal / kg)

65

263

Octane number (RON)

100

106

Octane number (motor method)

100

92

275

500

99.4

64.4

[0076] Note:

[0077] (1) From the perspective of molecular structure, gasoline does ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com