Patents

Literature

77 results about "Automotive gasoline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exposure to automotive gasoline most likely occurs from breathing its vapor at a service station while filling a car's fuel tank. At high levels, automotive gasoline is irritating to the lungs when breathed in and irritating to the lining of the stomach when swallowed.

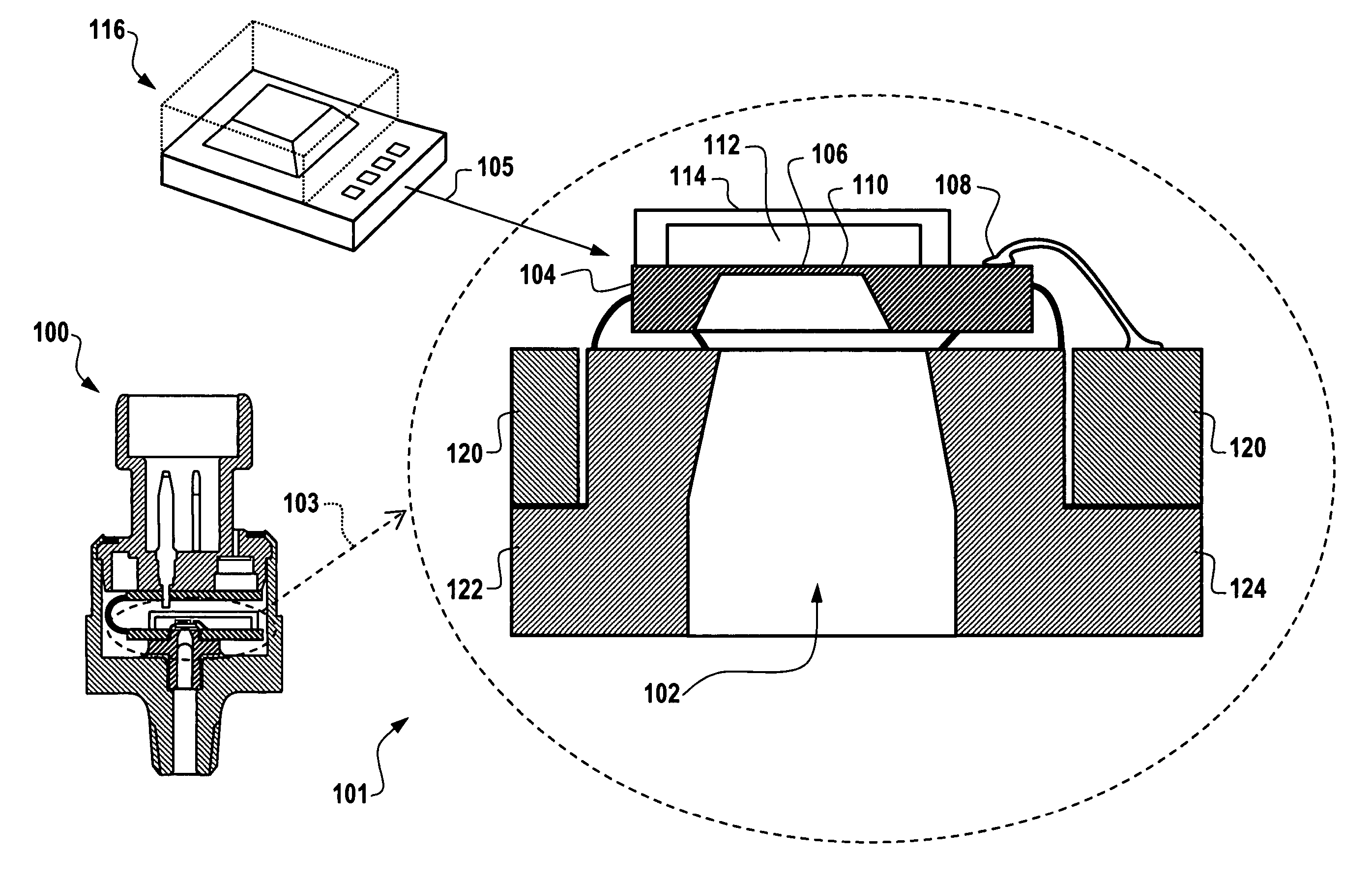

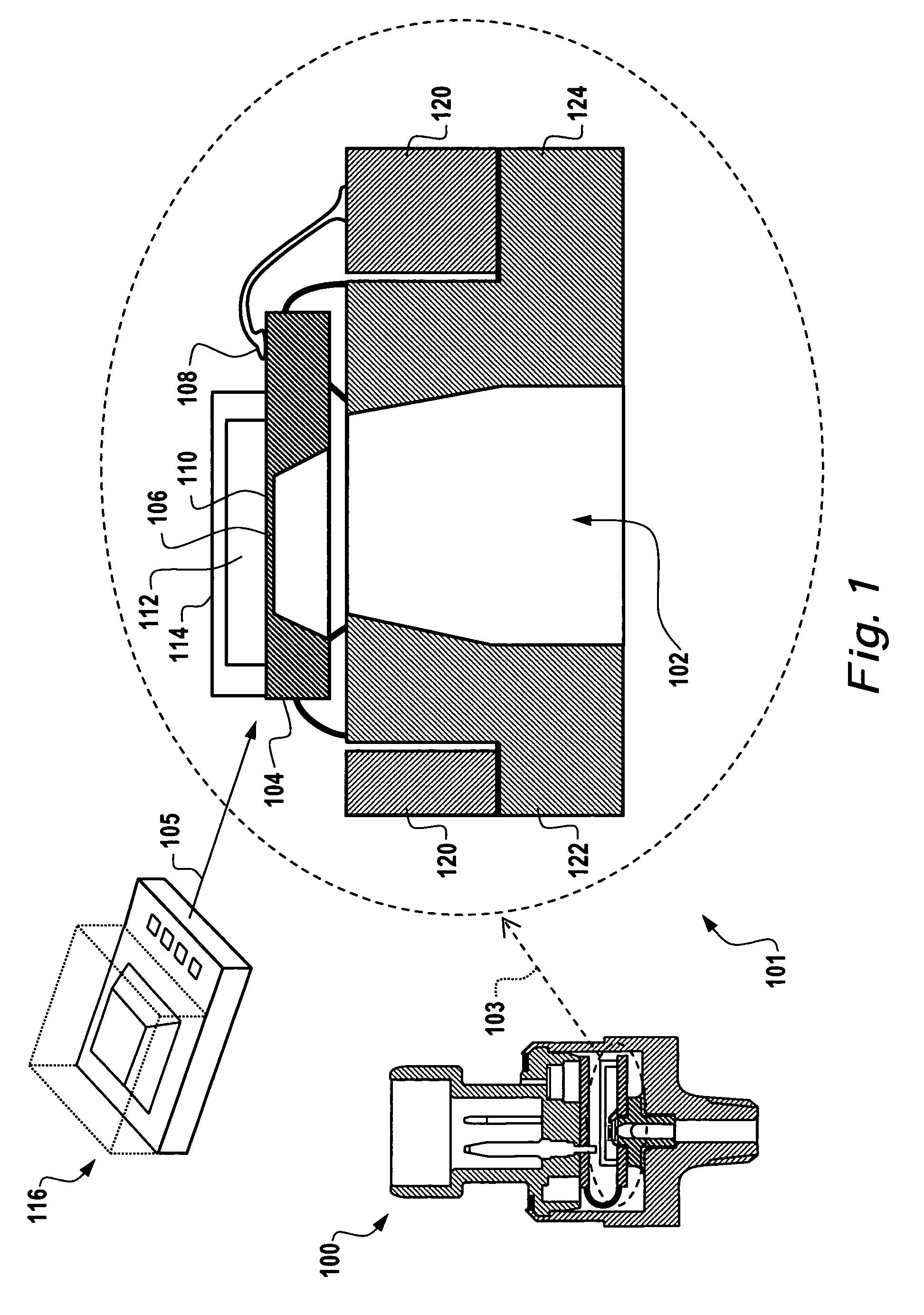

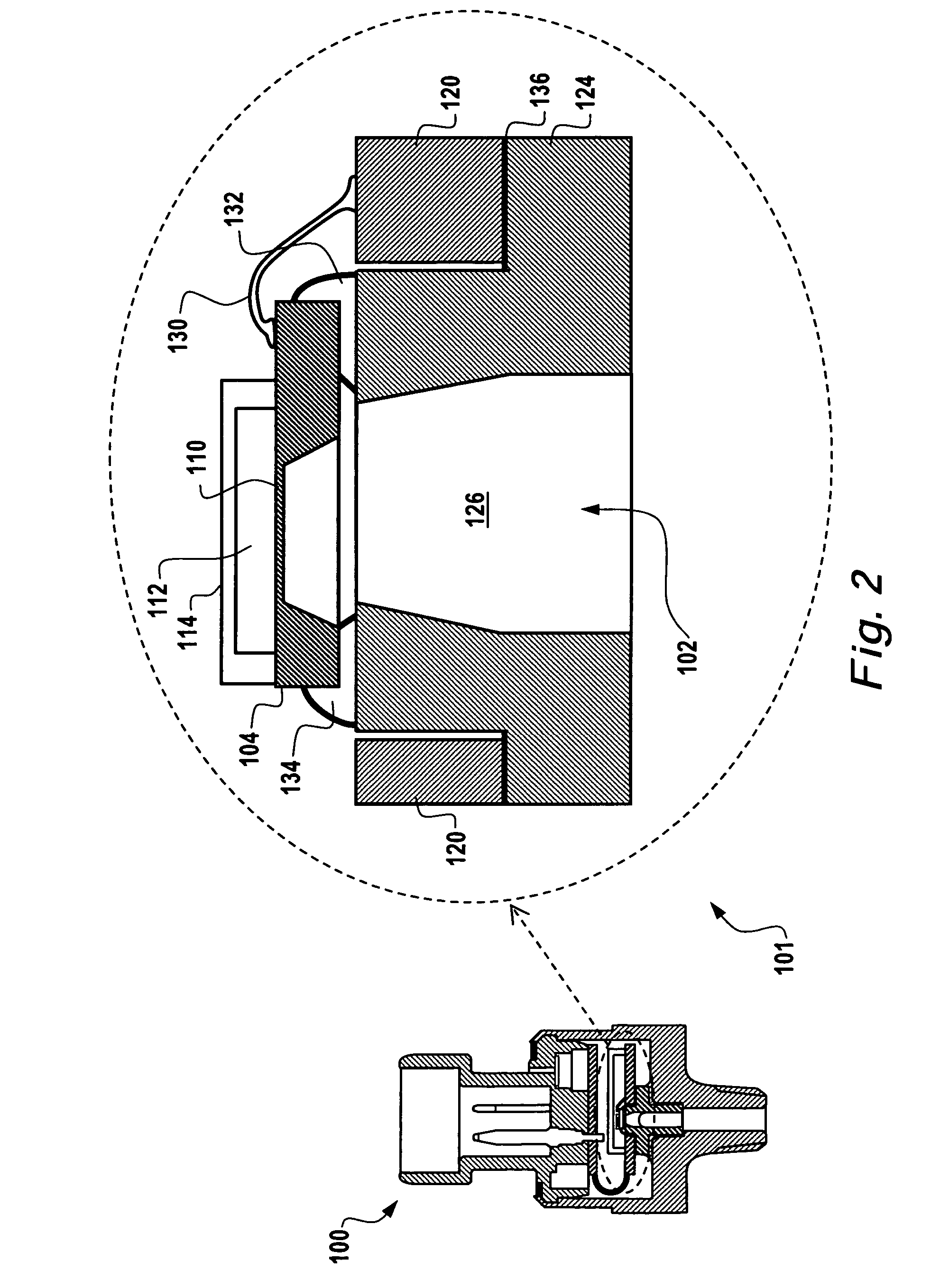

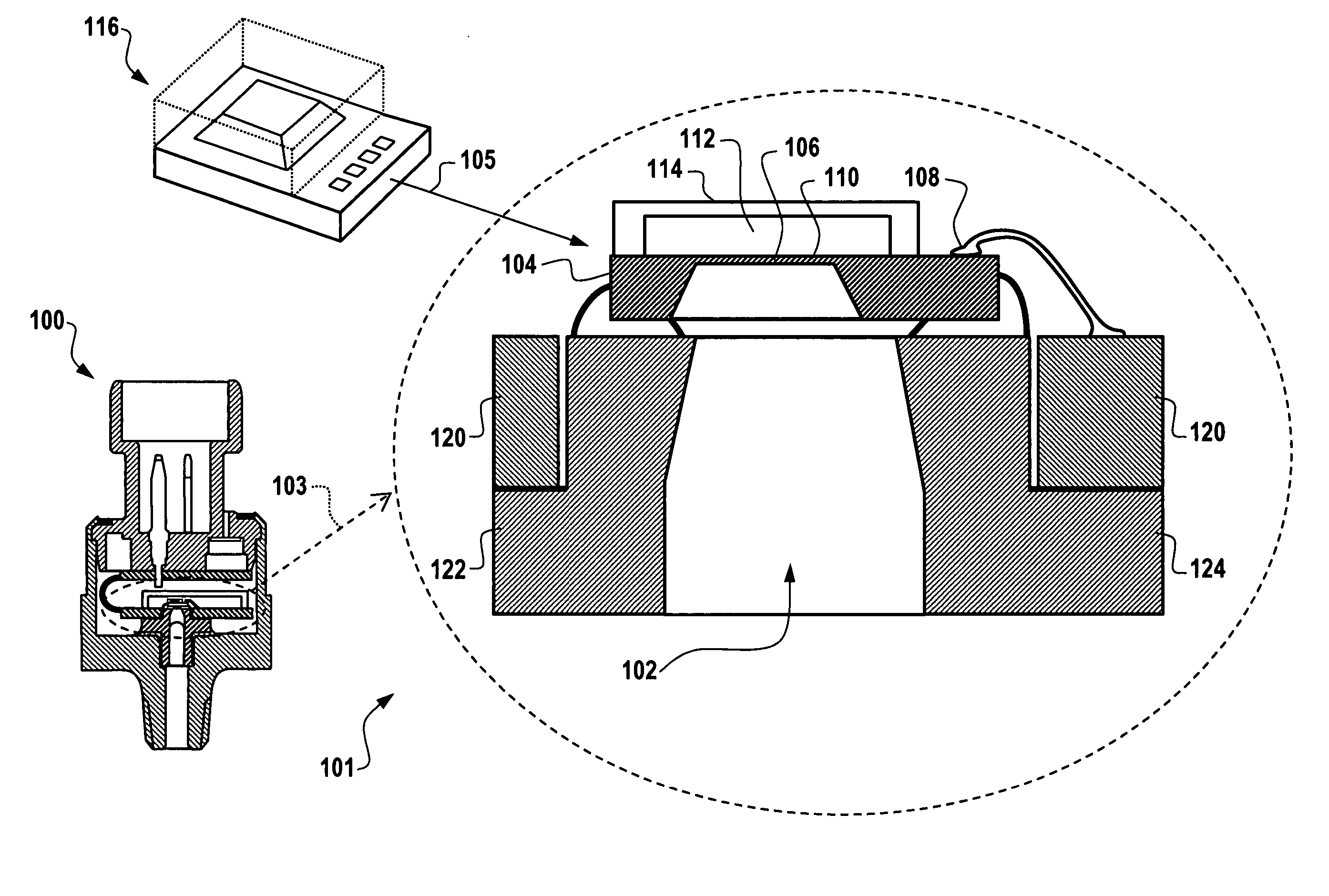

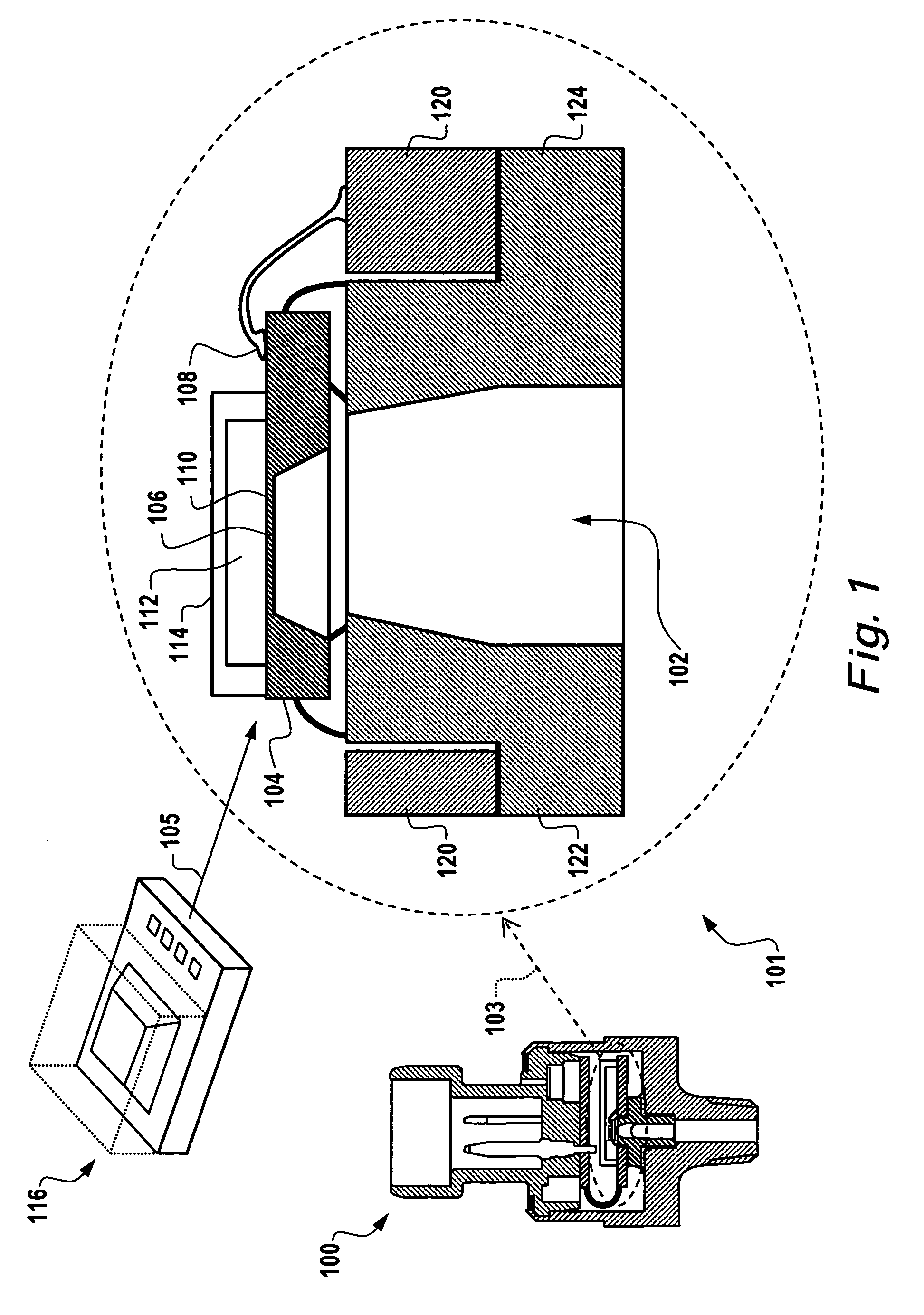

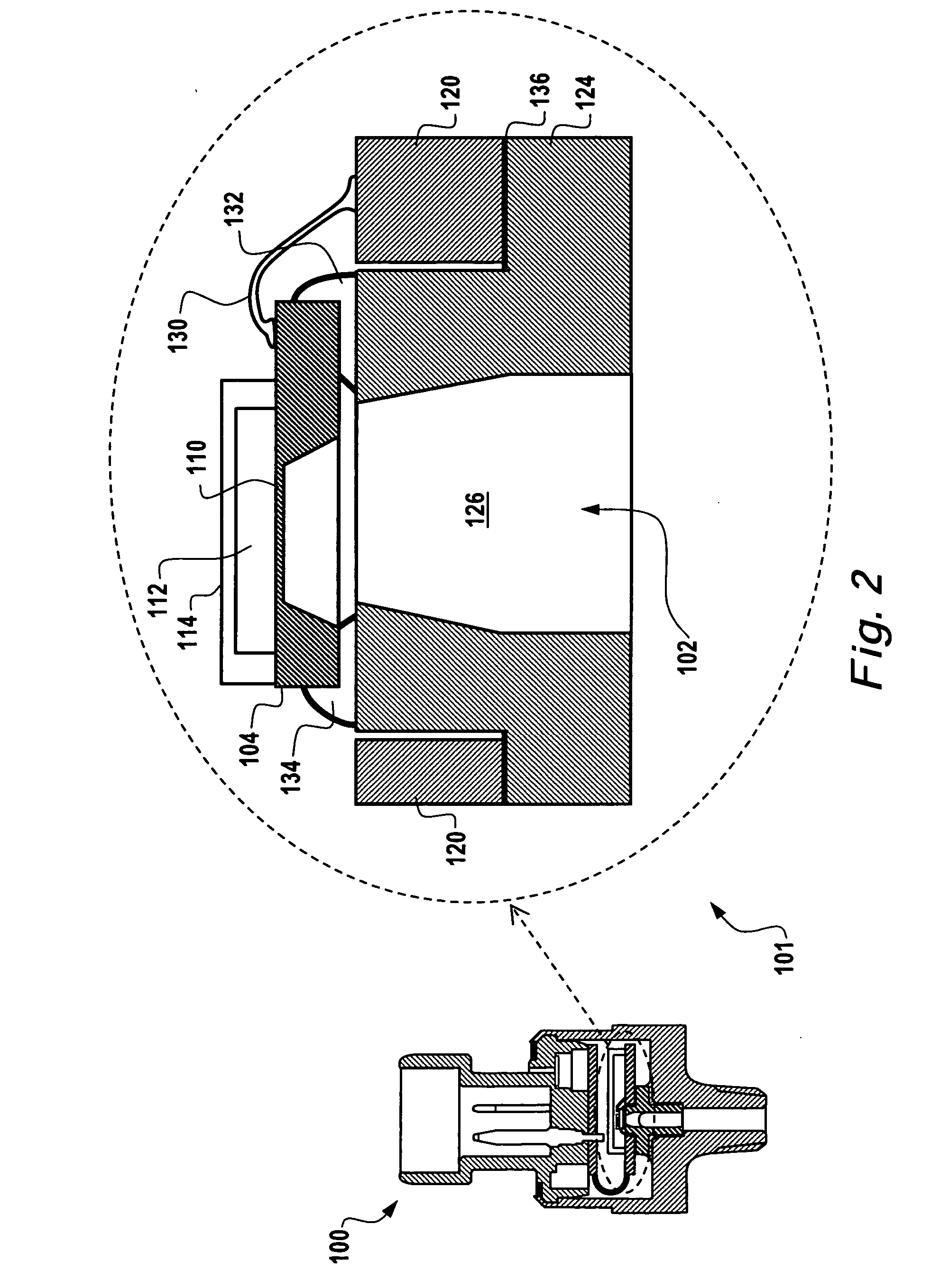

Exhaust back pressure sensor using absolute micromachined pressure sense die

ActiveUS7073375B2Internal combustion piston enginesExhaust apparatusDifferential pressurePressure sense

Sensor systems and methods are disclosed, which generally incorporate isolation between the sensor's electronics and the sensed media. The sensor's electronic circuit can incorporate one or more application specific integrated circuit (ASIC) that processes and outputs the signal for both absolute and differential measurements. Such a sensor can be adapted for use in exhaust gas re-circulation (EGR) systems utilized with automotive gasoline engines. Such a sensor can also be utilized for measuring differential pressure across diesel particular filters and / or applications in which differential pressure is required for system control and / or monitoring purposes. The absolute pressure sensor disclosed herein can therefore sense the exhaust pressure on automotive engines and other mechanical and / or electromechanical devices and machines.

Owner:HONEYWELL INT INC

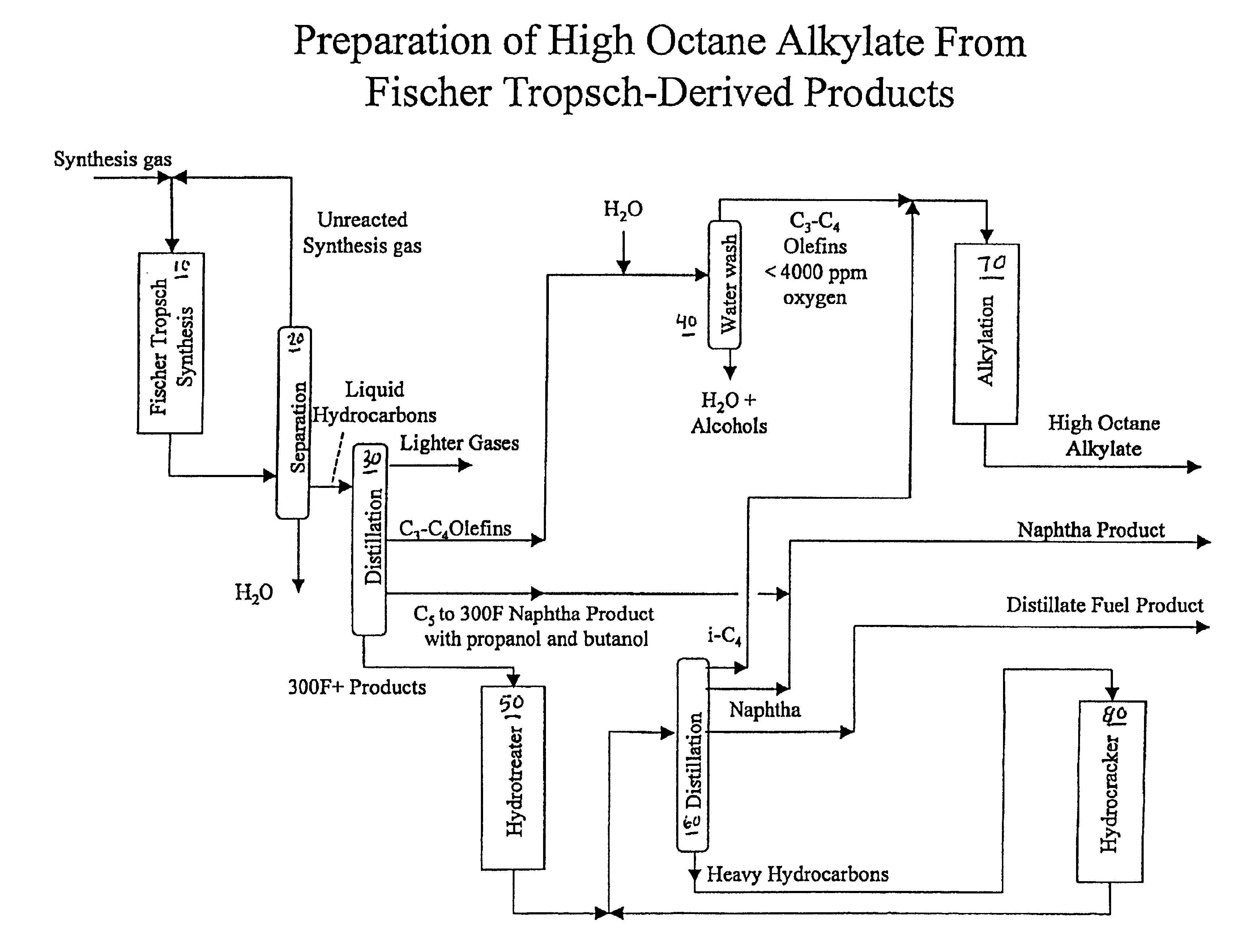

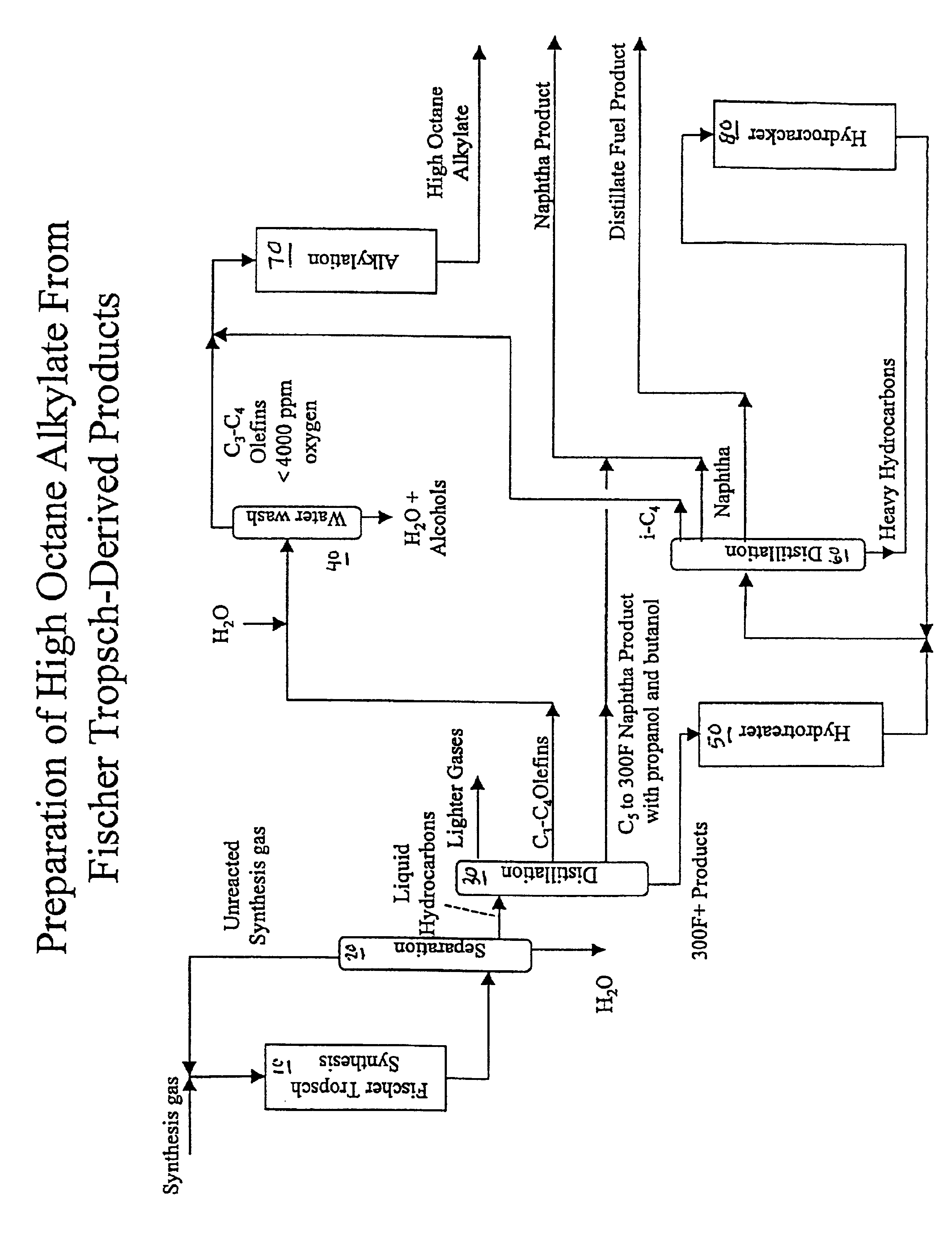

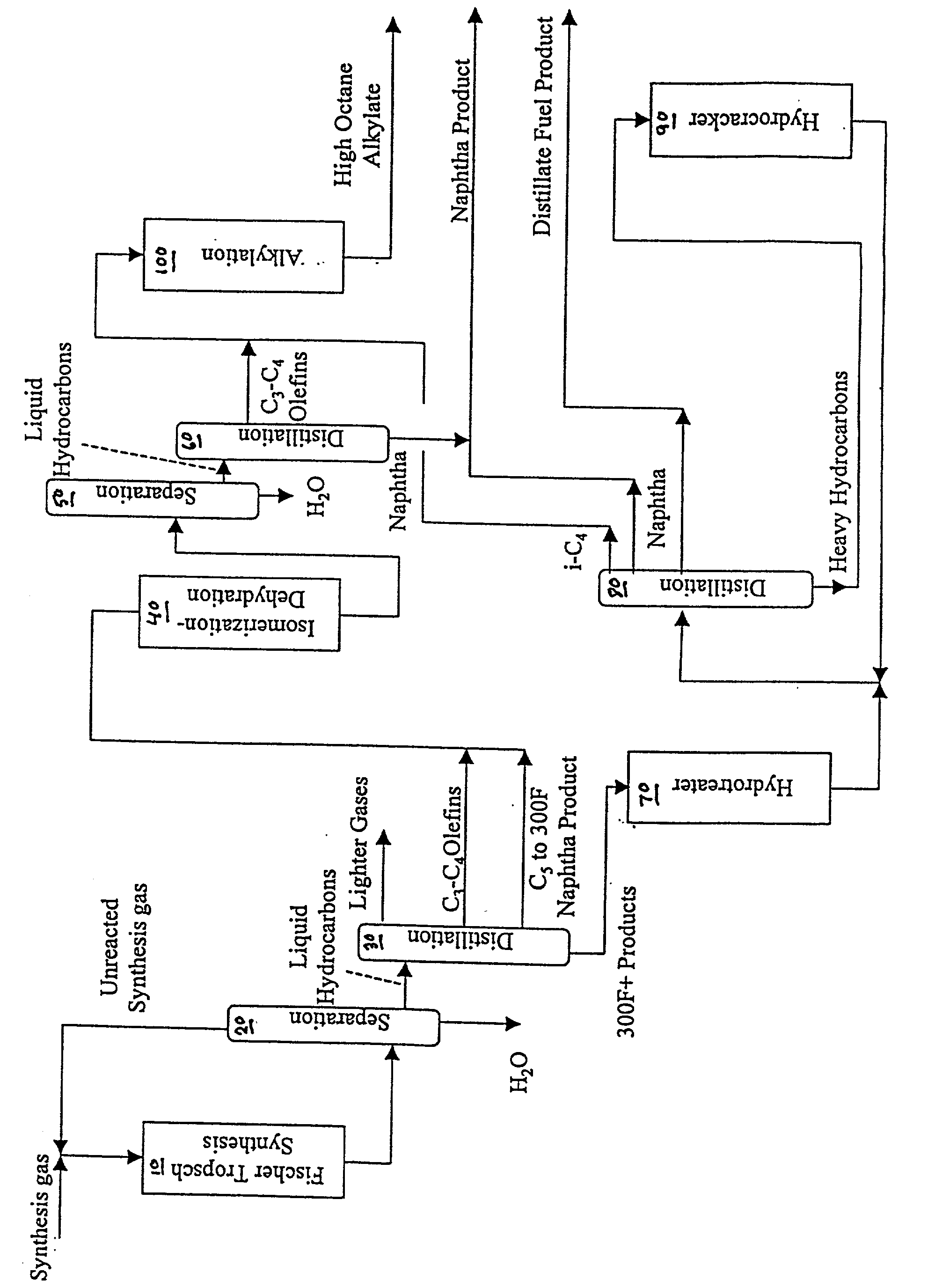

Preparation of high octane alkylate from Fischer-Tropsch olefins

InactiveUS6743962B2Refining to change hydrocarbon structural skeletonOrganic chemistry methodsAlkyl transferGasoline

A Fischer-Tropsch C3-C4 olefin stream is treated to lower the oxygenate content to below 4000 ppm. Another Fischer-Tropsch fraction is hydrotreated and hydrocracked to provide an isobutane-containing stream. The treated C3-C4 olefin stream is reacted with the isobutane stream in an alkylation reactor to provide a highly branched, high octane isoparaffinic alkylate. The alkylate is useful as a blending component in motor gasoline.

Owner:CHEVROU USA INC

Exhaust back pressure sensor using absolute micromachined pressure sense die

ActiveUS20060000265A1Internal combustion piston enginesExhaust apparatusDifferential pressurePressure sense

Sensor systems and methods are disclosed, which generally incorporate isolation between the sensor's electronics and the sensed media. The sensor's electronic circuit can incorporate one or more application specific integrated circuit (ASIC) that processes and outputs the signal for both absolute and differential measurements. Such a sensor can be adapted for use in exhaust gas re-circulation (EGR) systems utilized with automotive gasoline engines. Such a sensor can also be utilized for measuring differential pressure across diesel particular filters and / or applications in which differential pressure is required for system control and / or monitoring purposes. The absolute pressure sensor disclosed herein can therefore sense the exhaust pressure on automotive engines and other mechanical and / or electromechanical devices and machines.

Owner:HONEYWELL INT INC

Method for deeply desulfurizing methyl tertiary butyl ether

ActiveCN102557888AReduce sulfur contentMeet the requirements of motor gasolineEther separation/purificationDistillationAutomotive gasoline

The invention provides a method for deeply desulfurizing methyl tertiary butyl ether. The method is characterized in that the sulfur-containing methyl tertiary butyl ether is mixed with light oil to form a mixture; the mixture enters a distillation column for distillation, so as to remove sulfur compounds in the sulfur-containing methyl tertiary butyl ether; and the column reactor temperature of the distillation column is 70 DEG C to 120 DEG C, the column top temperature is 50 DEG C to 60 DEG C, the pressure is 0.01 MPa to 0.15 MPa, the theoretical column plate number is 3 to 20 and the reflux ratio is 0.25 to 10. By adopting the method, the total sulfur content of the methyl tertiary butyl ether can be reduced from more than 1000 Mug*g-1 to less than 1000 Mug*g-1, and the distilled methyl tertiary butyl ether can well satisfy the requirement of mixing automotive gasoline of a production country IV or a production country V.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Detection system

InactiveUS20080190354A1Material analysis by observing effect on chemical indicatorPhenolphthaleinAutomotive gasoline

Method for detecting a basic target species in a fuel composition, by (i) adding a spectroscopically active indicator which is capable of reacting with the target species, and (ii) detecting the spectroscopic response (suitably a colour change) of the fuel composition to the presence of the indicator. The method may be used to detect an additive such as a detergent or dispersant additive, in particular in an automotive gasoline or diesel fuel or a lubricating oil. Also provided is a kit for carrying out the method, in particular in the field. The indicator may be a phenolphthalein indicator such as tetrabromophenolphthalein ethyl ester (HTBPE).

Owner:SHELL OIL CO

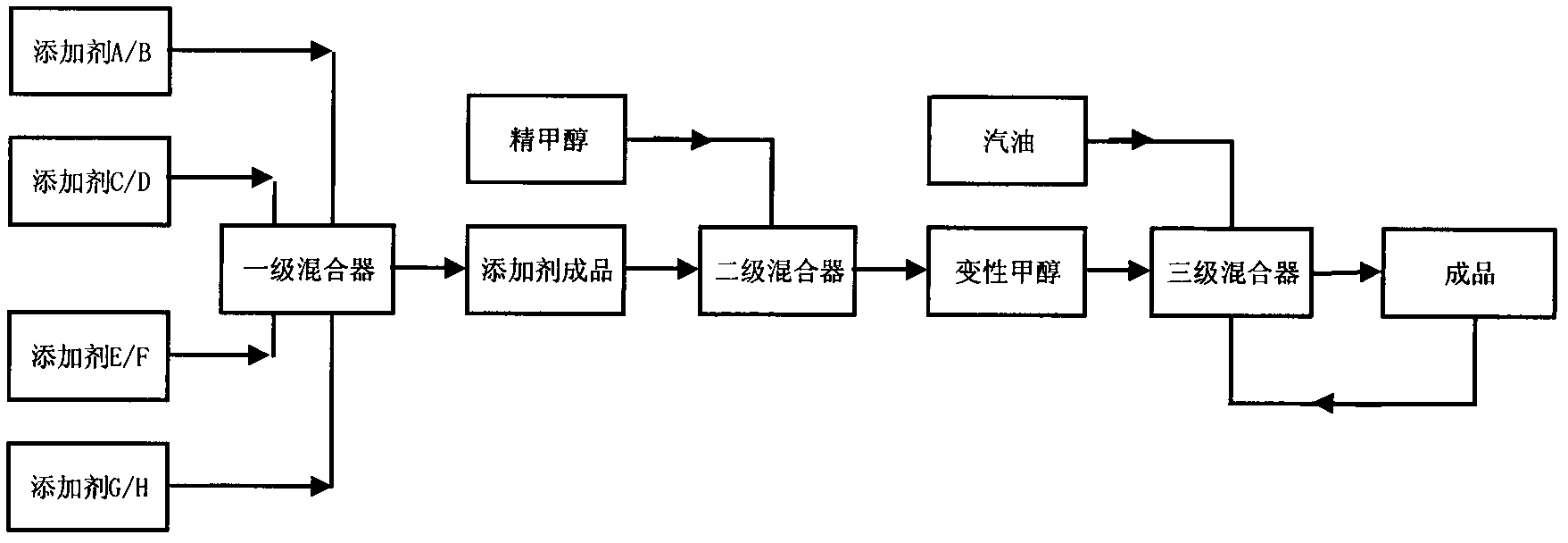

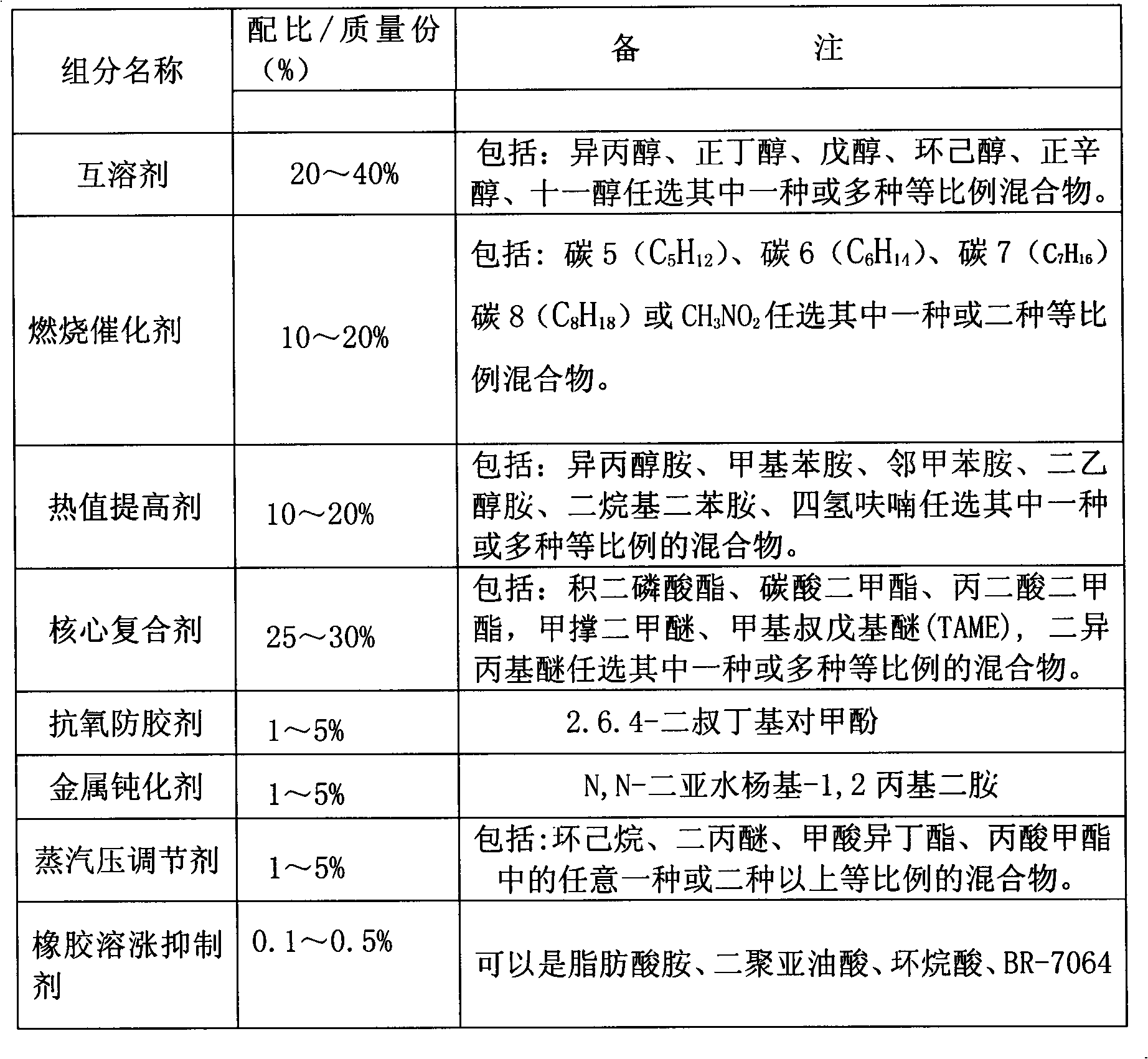

Large-proportion methanol gasoline catalyst and preparation method

InactiveCN103160344AGood miscibilityImprove water resistanceLiquid carbonaceous fuelsFuel additivesAlkaneNaphtha

The invention provides a large-proportion methanol gasoline catalyst and a preparation method thereof. A product mark of the large-proportion methanol gasoline can be expressed by M50 and M85, wherein M represents a first letter of methanol; 50 and 85 respectively represent 50% of methanol and 85% of methanol are added in the gasoline The large-proportion methanol gasoline catalyst is obtained by mixing refined methanol with a purity of 99.9% and national standard gasoline or naphtha and component oil in presence of a special catalyst. A preparation method of the special catalyst is composed of high alcohols (C3-C11), alkanes (C5(C5H12), C6(C6H14), C7(C7H16), C8(C8H18) or CH3NO2), an organic amine, a plurality of esters and auxiliary inhibitors. The large-proportion methanol gasoline produced by the invention passes through a road test longer than 10,000 KM, without changing an engine structure. The large-proportion methanol gasoline is powerful, can be easily started at a low temperature, has no gas block at a high temperature, is not stratified when being contacted with water, can resist rubber swelling, and is low in production cost and flexible in operations. Besides, all project technical indicators are superior to those of national standard gasoline for vehicles. Practice proves that the large-proportion methanol gasoline catalyst has the advantages in a plurality of aspects such as technology, economy, feasibility for large-scale application, and the like, and has obvious competitive advantages as alternative energy.

Owner:杨军

Manufacture of high octane alkylate

InactiveUS20030158456A1Hydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonAlcoholGasoline

A Fischer-Tropsch C3-C4 olefin stream is simultaneously dehydrated and isomerized to convert alcohols to olefins and 1-butenes to 2-butenes and thereby lower the oxygenate content. Another Fischer-Tropsch fraction is hydrotreated and hydrocracked to provide an isobutane stream. The treated C3-C4 olefin stream having an oxygenate content less than 4000 ppm, is reacted with the isobutane stream to provide a highly branched, high octane isoparaffinic alkylate. The alkylate is useful as a blending component in motor gasoline.

Owner:CHEVROU USA INC

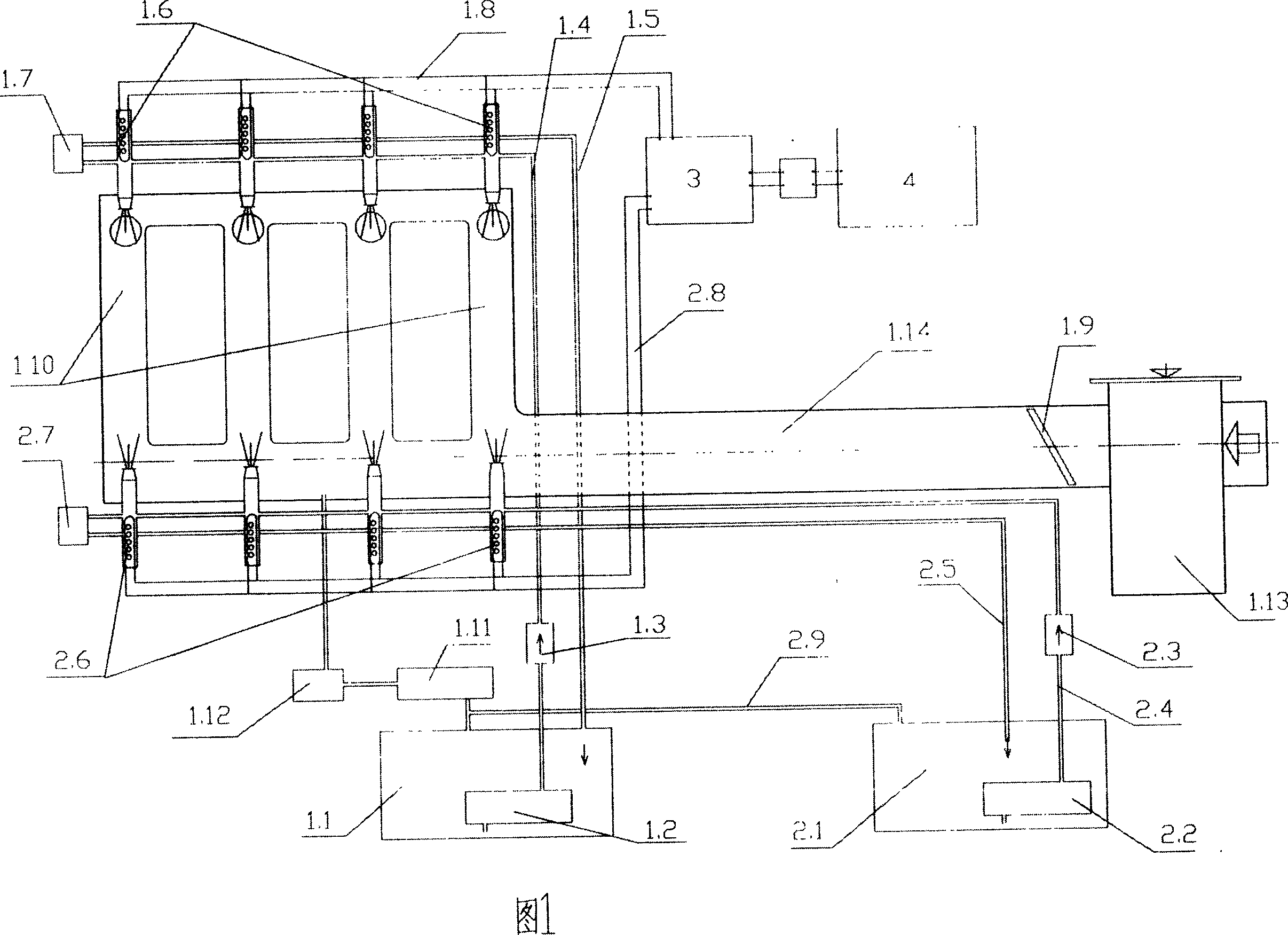

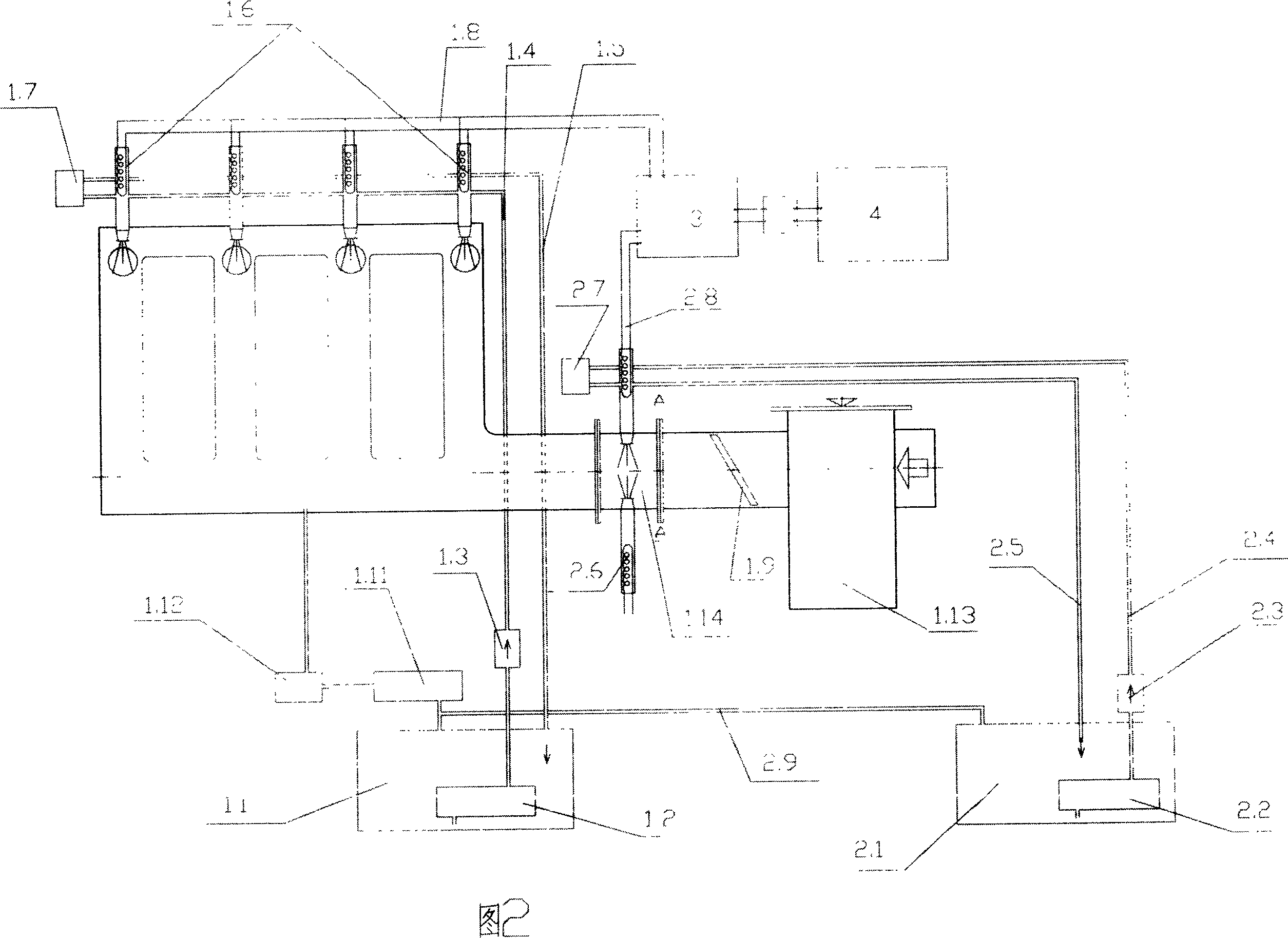

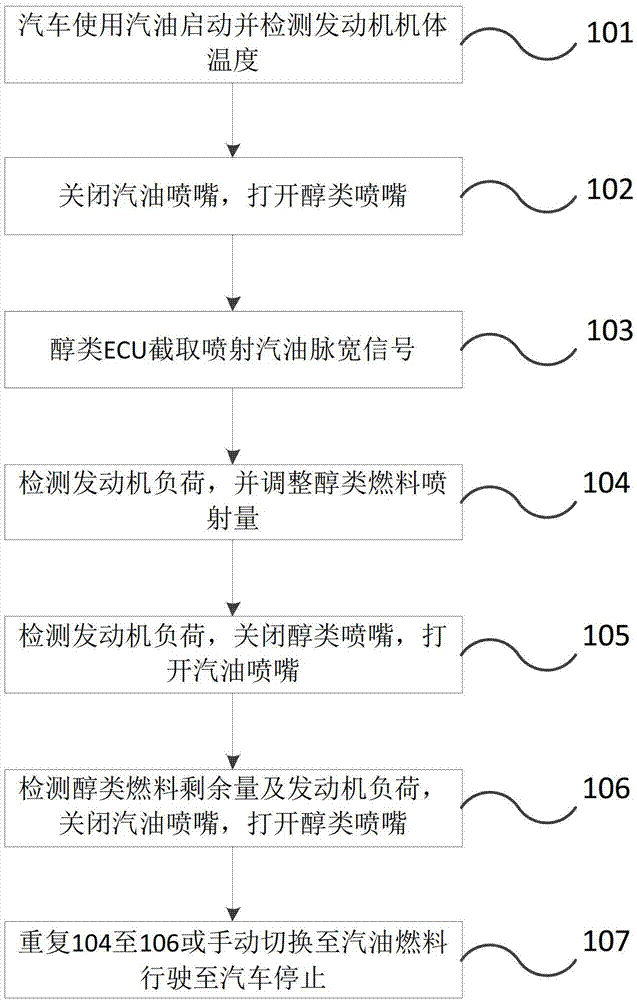

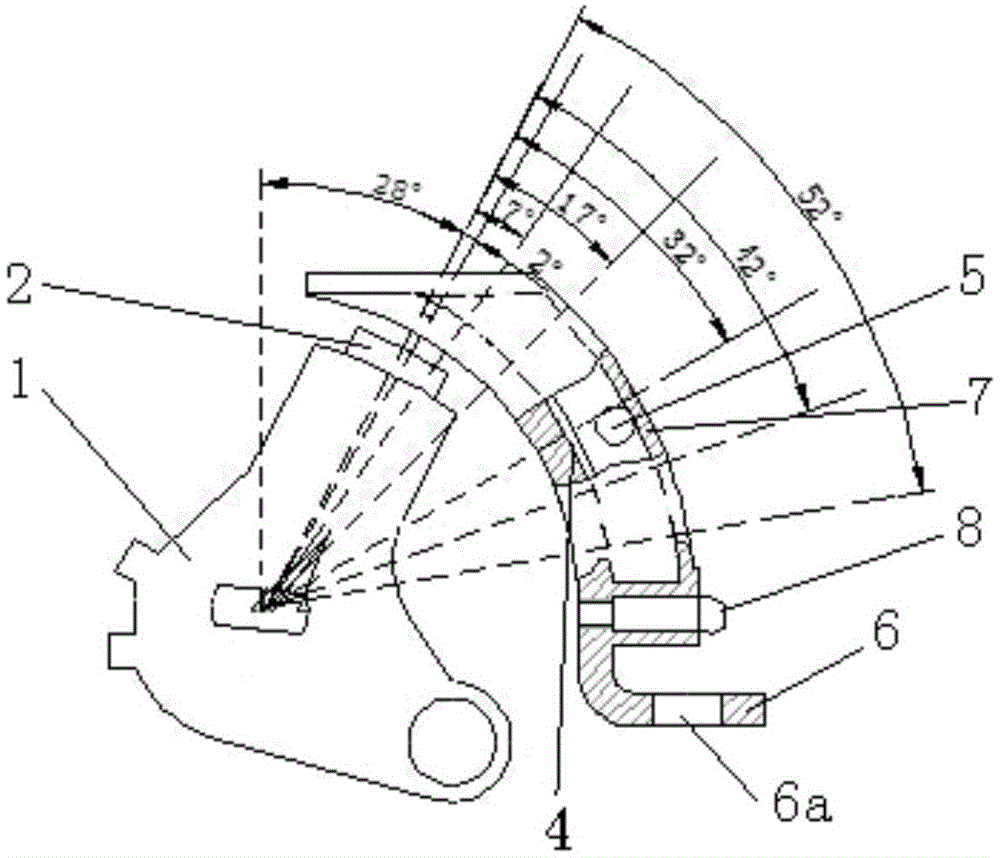

Automobile gasoline and alcohols mixed using method, fuel supplying system and controller

ActiveCN101078376AReduce consumptionSave resourcesElectrical controlInternal combustion piston enginesSocial benefitsAlcohol

The invention provides a mixed using method of vehicle gasoline and alcohol, the fuel supply system and the controller. When the engine is in idling condition the alcohol nozzle is in closed condition and the assistant controller receives control data of main controller to control gasoline nozzle so that the engine works. When the idling load of engine changes the oil injection quantity can be adjusted according to the presetting condition by main controller. After the engine deviates from the idling speed the oil injection quantity of gasoline nozzle is locked in the oil injection quantity in idling speed. Alcohol nozzle works according to the oil injection quantity set by main controller and the function of accelerating enrichment and decelerating oil cutoff is maintained. Under the precondition that good running performance of vehicle can be insured, alcohol adding quantity with the maximum proportion is realized; gasoline consumption can be decreased; gasoline resource can be saved; economic cost of vehicle fuel is decreased; and the pollution to atmosphere circumstance. It is provided with good economical benefit and social benefit.

Owner:武汉中醇化汽车新能源有限公司

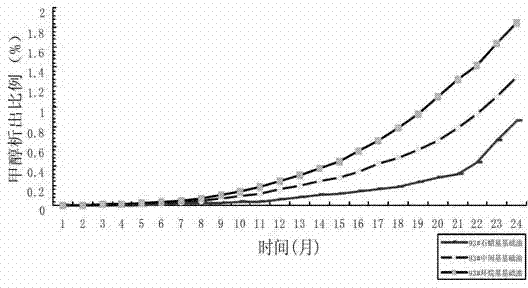

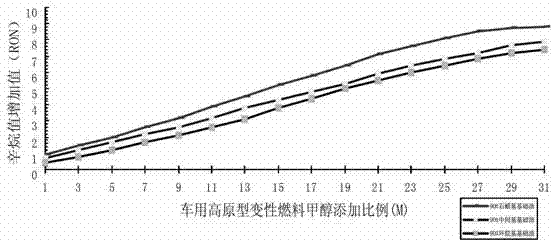

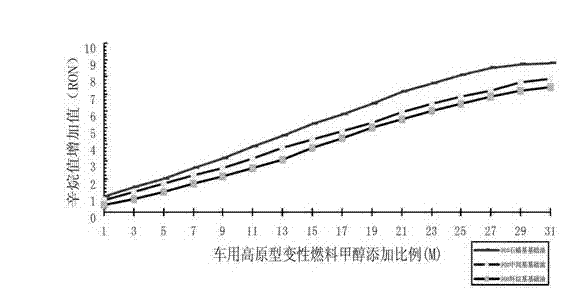

Carbinol group clean fuel concoction accessory ingredient and purpose thereof

ActiveCN103160345AImprove combustion stabilityBoost octaneLiquid carbonaceous fuelsAdjuvantCombustion

The invention relates to a carbinol group clean fuel concoction accessory ingredient, a preparation method of the carbinol group clean fuel concoction accessory ingredient and a purpose of the carbinol group clean fuel concoction accessory ingredient. The carbinol group clean fuel concoction accessory ingredient is composed of hydrotropy adjuvant, denaturation improving agent, antioxidant anti-glue agent, synergism complexing agent and combustion improver. The increase of octane value of methanol gasoline which is tempered by the carbinol group clean fuel concoction accessory ingredient is stable. A direct ratio relation exists between additive amount and octane value. Combustion stability of fuel is strengthened, and efficiency of transferring chemical energy into kinetic energy is improved. The carbinol group clean fuel concoction accessory ingredient is good in storage stability and is not prone to causing oxidative deterioration when stored for a long time. Compared with existing gasoline 93 motor gasoline, motor plateau type clean methanol gasoline which is tempered by the carbinol group clean fuel concoction accessory ingredient has the advantages of improving power, reducing emission and reducing environment pollution in high altitude anoxia areas.

Owner:李晏 +5

Biological alcohol ether fuel

InactiveCN101974355AClean combustion exhaust gasReduced soot contentLiquid carbonaceous fuelsFuel oilDiethyl ether

The invention relates to a biological alcohol ether fuel. The biological alcohol ether fuel is totally free from fossil fuel, prepared by combining the biological alcohol ether resource or coal chemical industry alcohol ether resource and biological fatty oil and can replace gasoline, diesel oil, boiler fuel oil and oil for ships. 50-70% of methanol (or ethanol), 20-40% of dimethyl ether (or diethyl ether, methylal and the like), 3-7% of IPB (or isopropanol), 1.27-7.27% of normal butanol, 0.09-0.11% of castor oil, 0.1-0.3% of rape seed oil, 0.005-0.015% of pentafluoride butane, 0.01-0.03% of ferrocene, 200.2-200.6% of tween are added to a pressure vessel and evenly mixed to form a basic alcohol ether fuel, the basic alcohol ether fuel is used as the main raw material to be further blended into the biological alcohol ether fuel which can replace gasoline and diesel oil for vehicles, the boiler fuel oil and the oil for ships according to different uses. The biological alcohol ether fuel is a low-carbon oxygen-containing fuel which features clean combustion gas and obviously reduced soot.

Owner:贾崇新

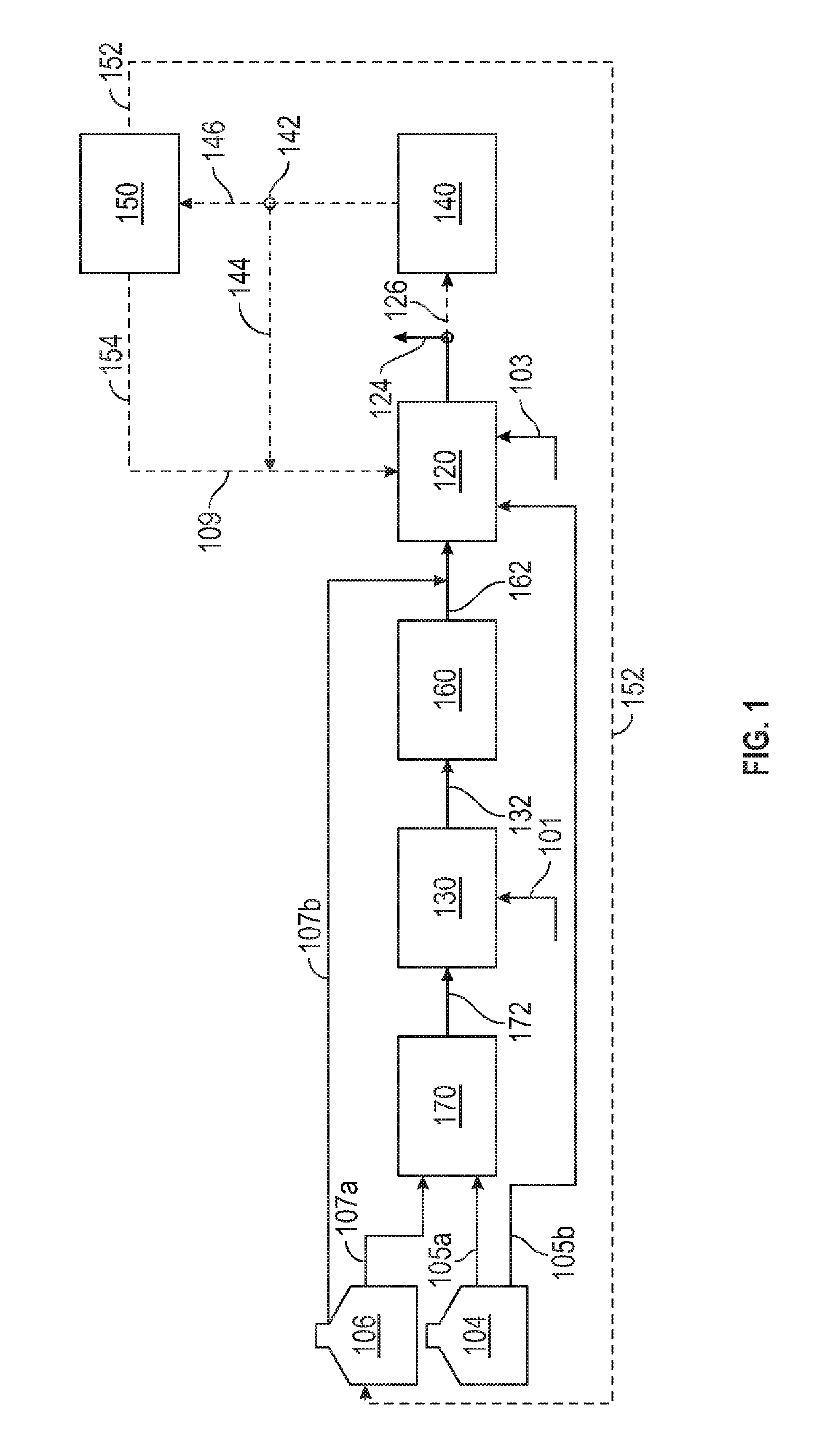

Water injection to increase hydrogen production by on-board reforming of fuel for automotive internal combustion engines

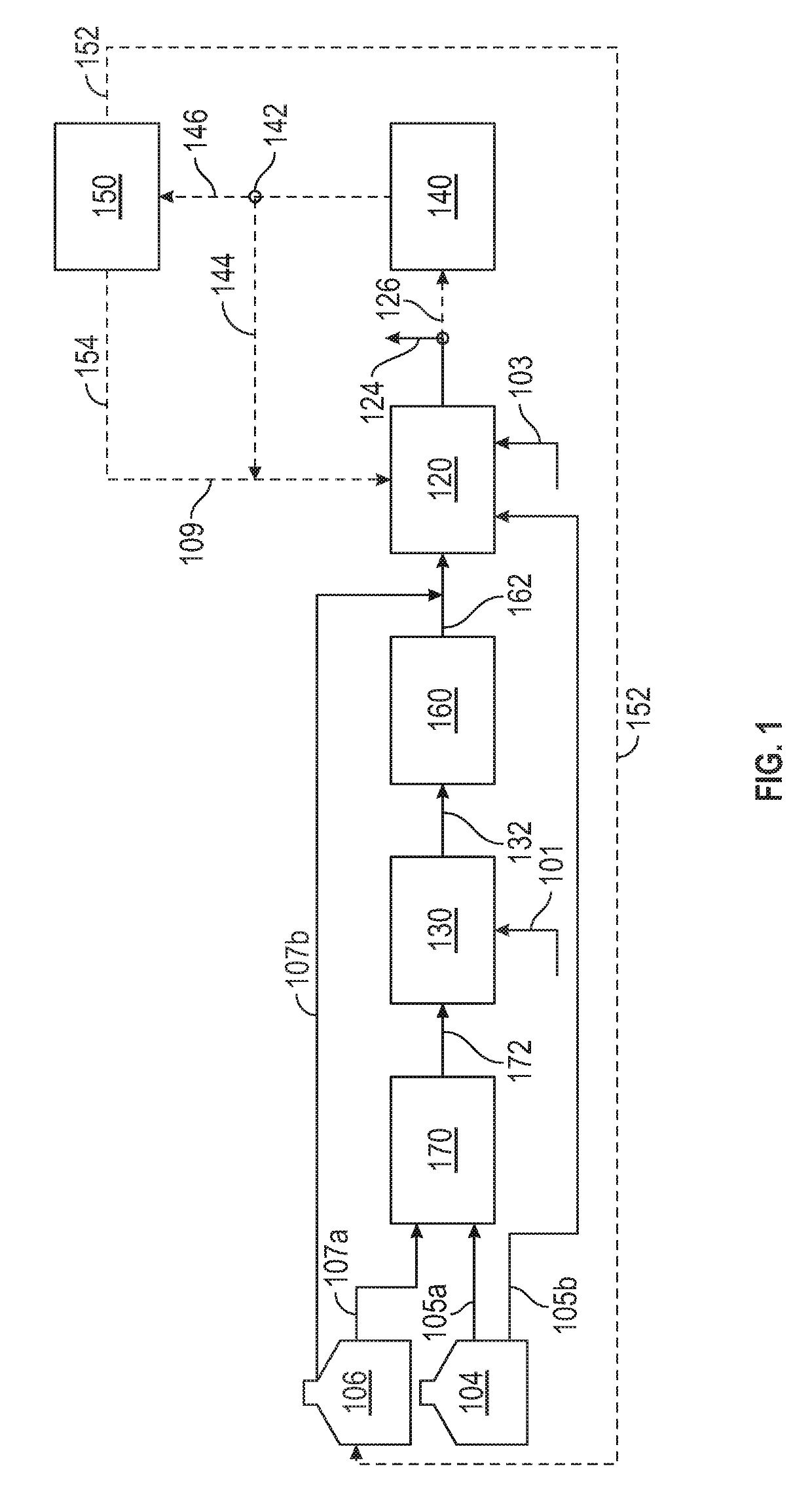

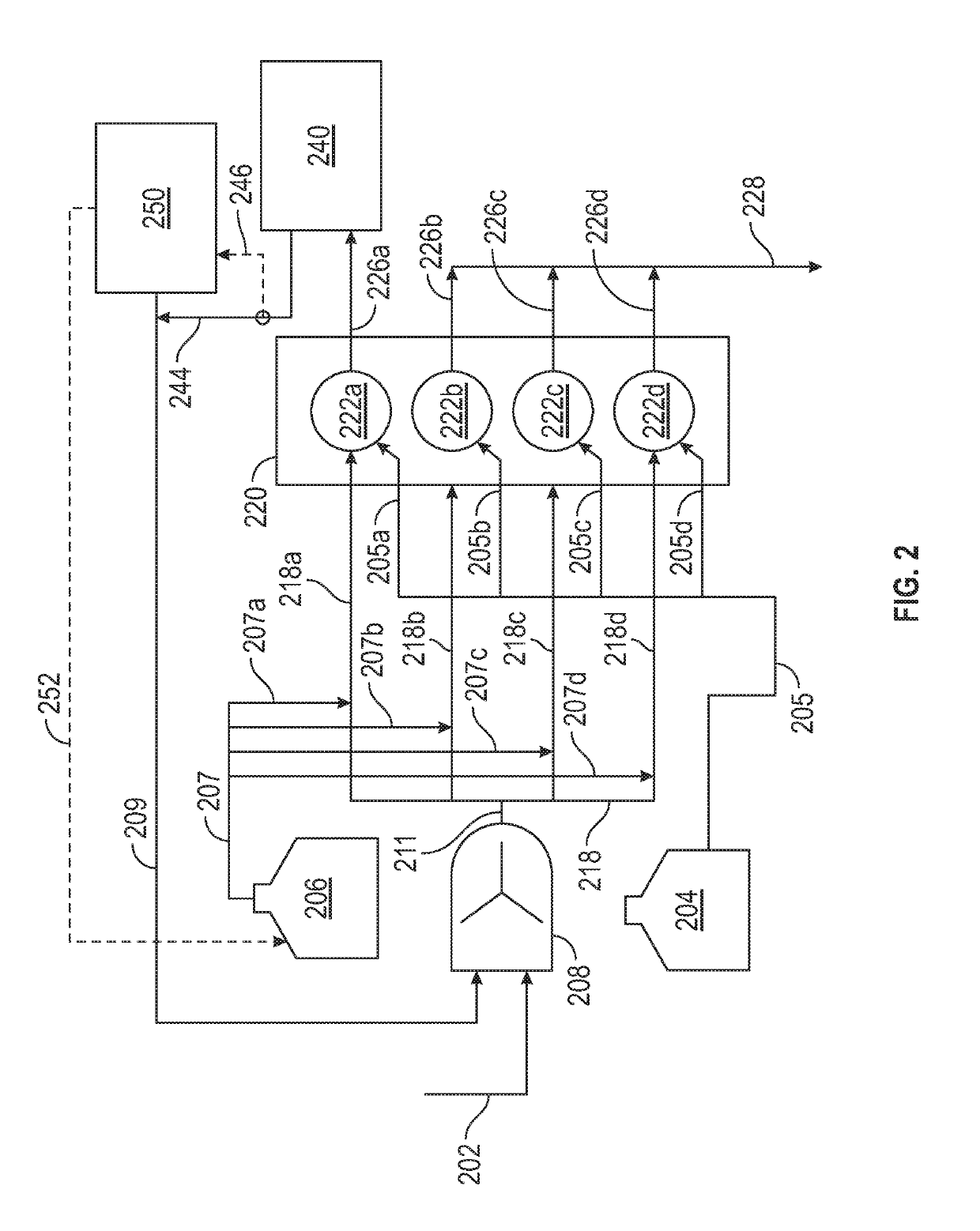

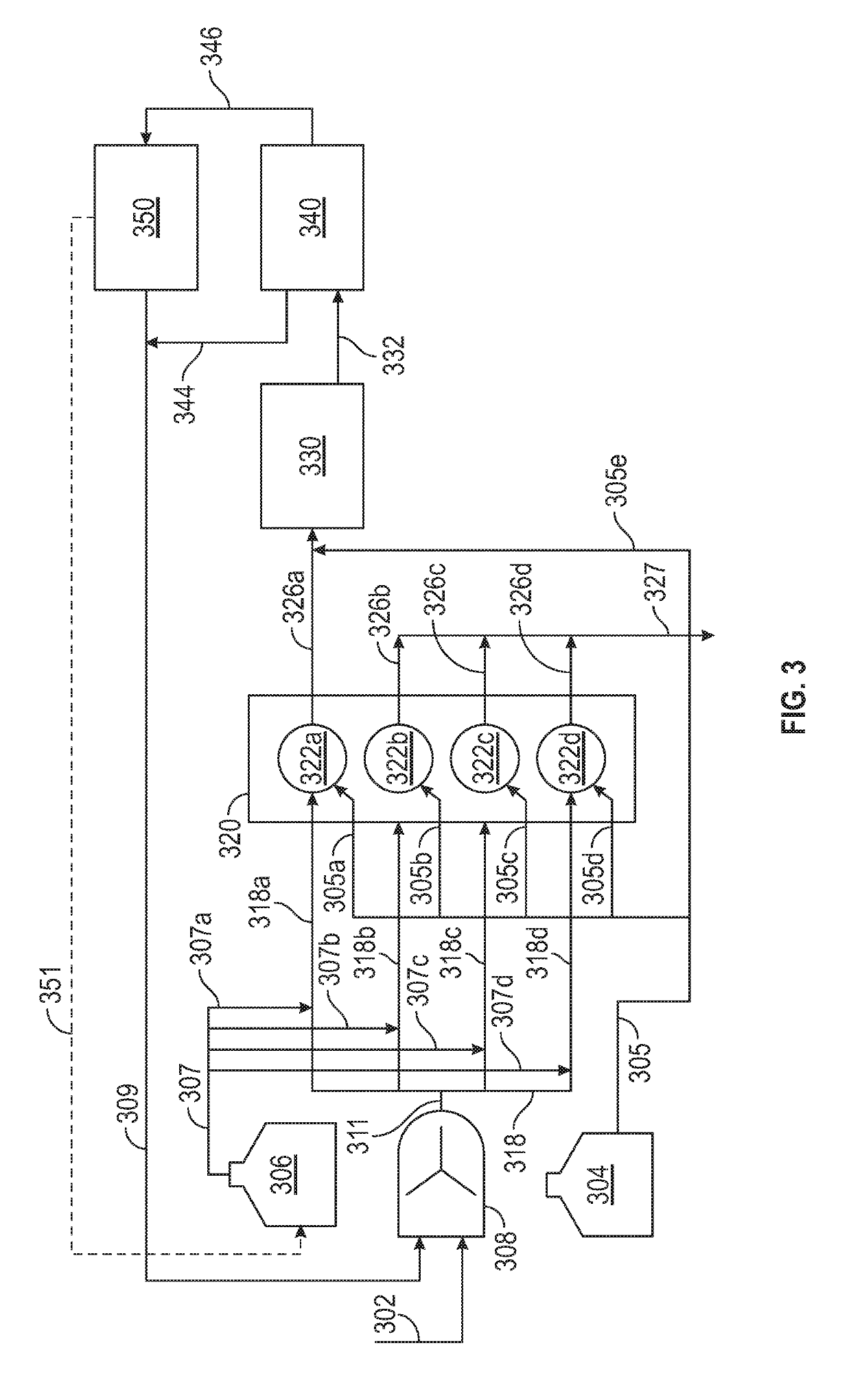

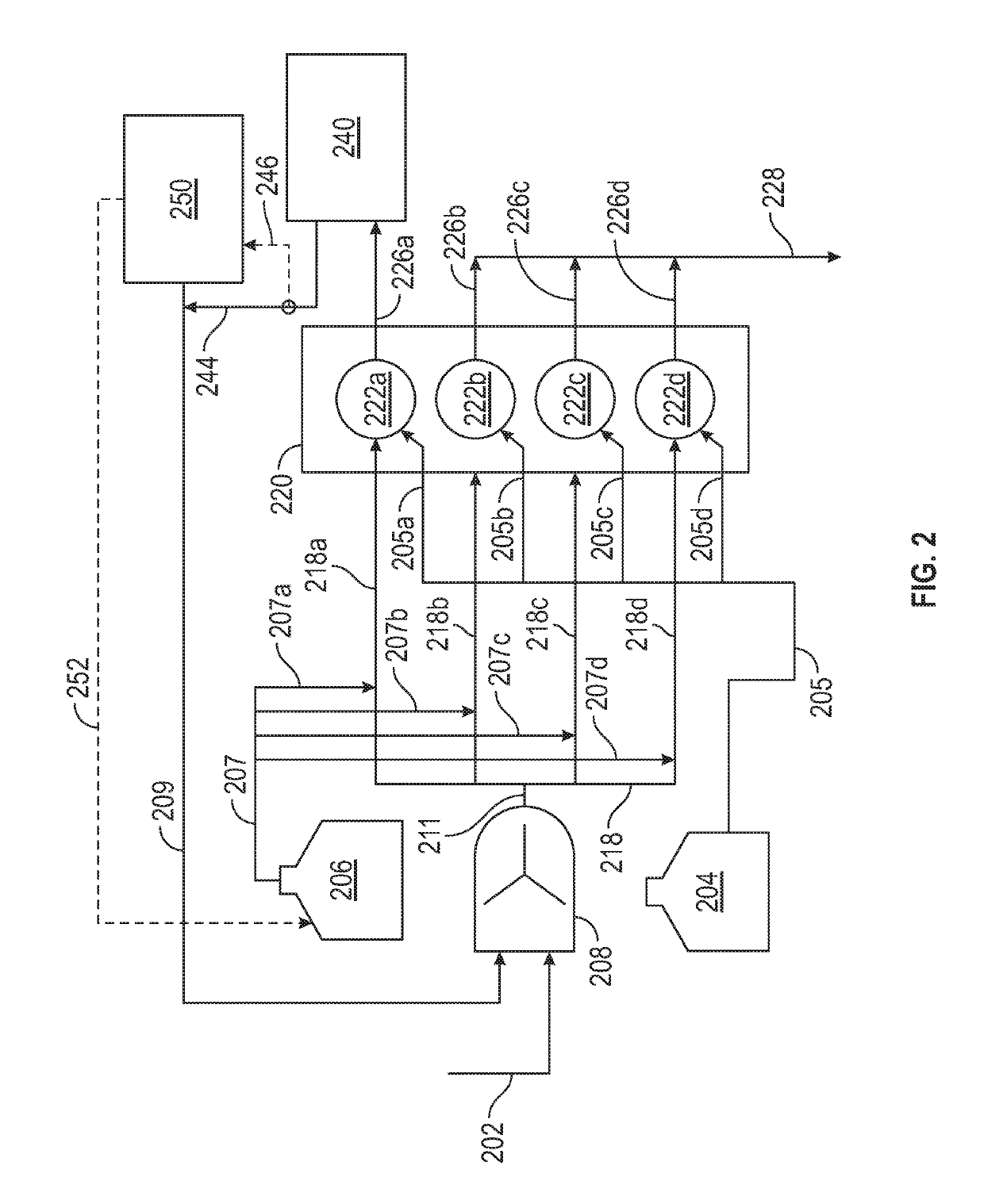

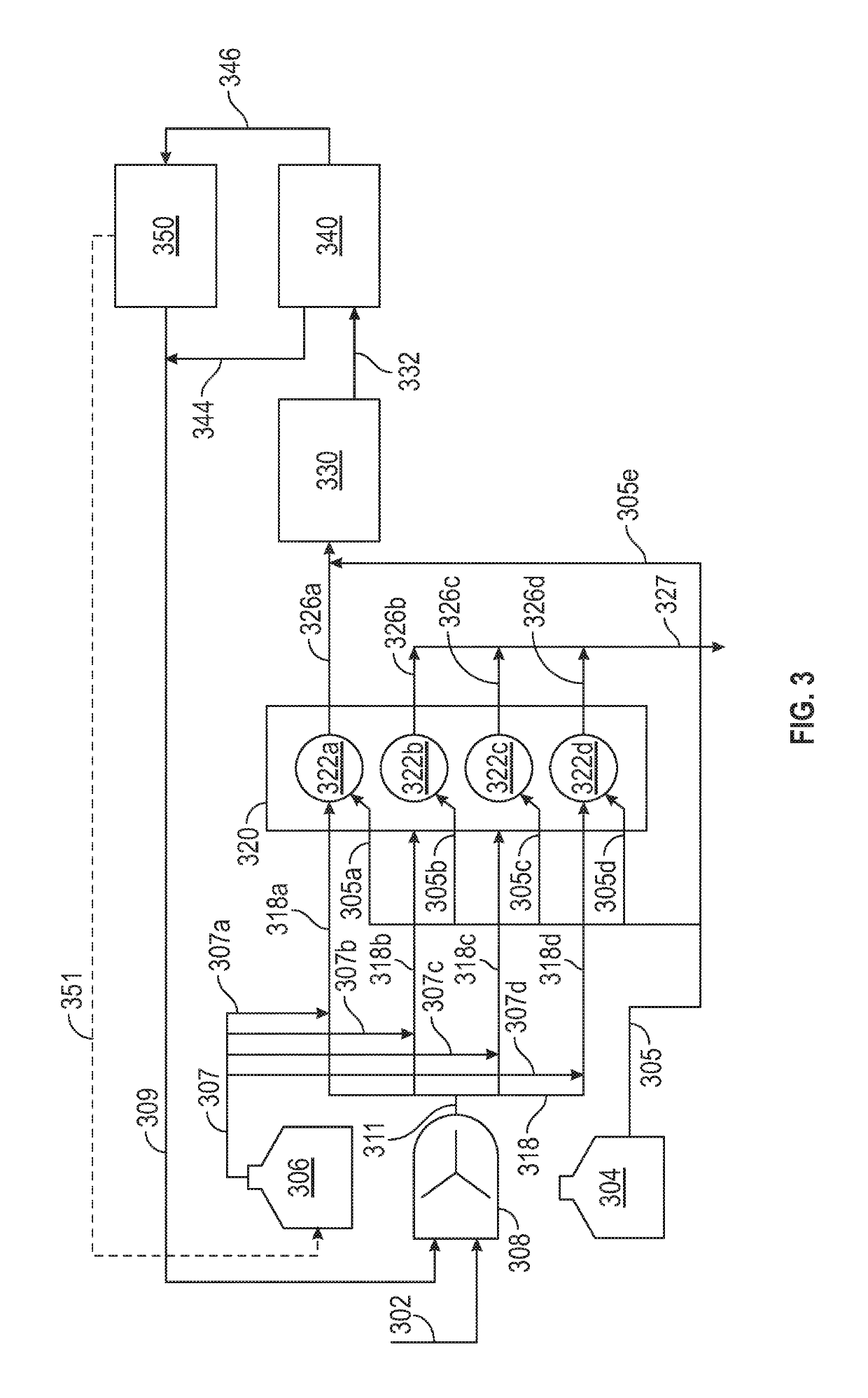

The performance of an automotive gasoline fueled spark-ignited internal combustion engine (ICE) optionally operated with a dedicated exhaust gas recycle system is enhanced by reforming the fuel in the presence of injected water to increase the yield of hydrogen which permits higher compression ratios and suppresses engine knock associated with pre-ignition of the fuel. Reforming can occur (a) in the cylinder with the reaction of a fuel-rich mixture and steam from the water injected into the intake manifold of one or more dedicated exhaust gas recirculation cylinders; (b) in a catalytic reformer located upstream of the engine; (c) in a catalytic reformer located downstream of the engine that receives fuel and the exhaust gas stream from the dedicated exhaust gas recirculation cylinder(s), and returns cooled reformate to the intake manifold; and (d) in a catalytic reformer that receives fuel and the exhaust gas stream from the engine exhaust gas manifold, and delivers reformate to the intake manifold.

Owner:SAUDI ARABIAN OIL CO

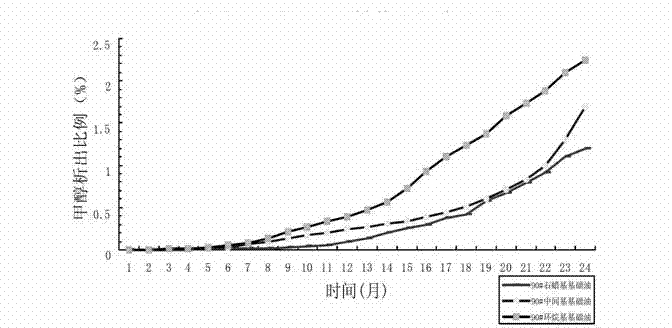

Additive capable of reducing methanol gasoline saturated vapor pressure

InactiveCN102876404AEasy to operateEasy to useLiquid carbonaceous fuelsFuel additivesAutomotive gasolineFatty alcohol

The invention relates to an additive capable of reducing methanol gasoline saturated vapor pressure. The additive is characterized in that the additive is prepared by mixing raw materials of, by volume, 50%-100% of fatty alcohol, 0%-38% of ethers and 0%-29% of esters. The saturated vapor pressure of the additive can be reduced by 4-9 units, and distillation range data, especially the distillation volume number at the temperature of 70 DEG C, are closer to those of car gasoline, so that air resistance is effectively prevented, volatilization loss is reduced, and production and usage requirements of methanol gasoline are satisfied.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

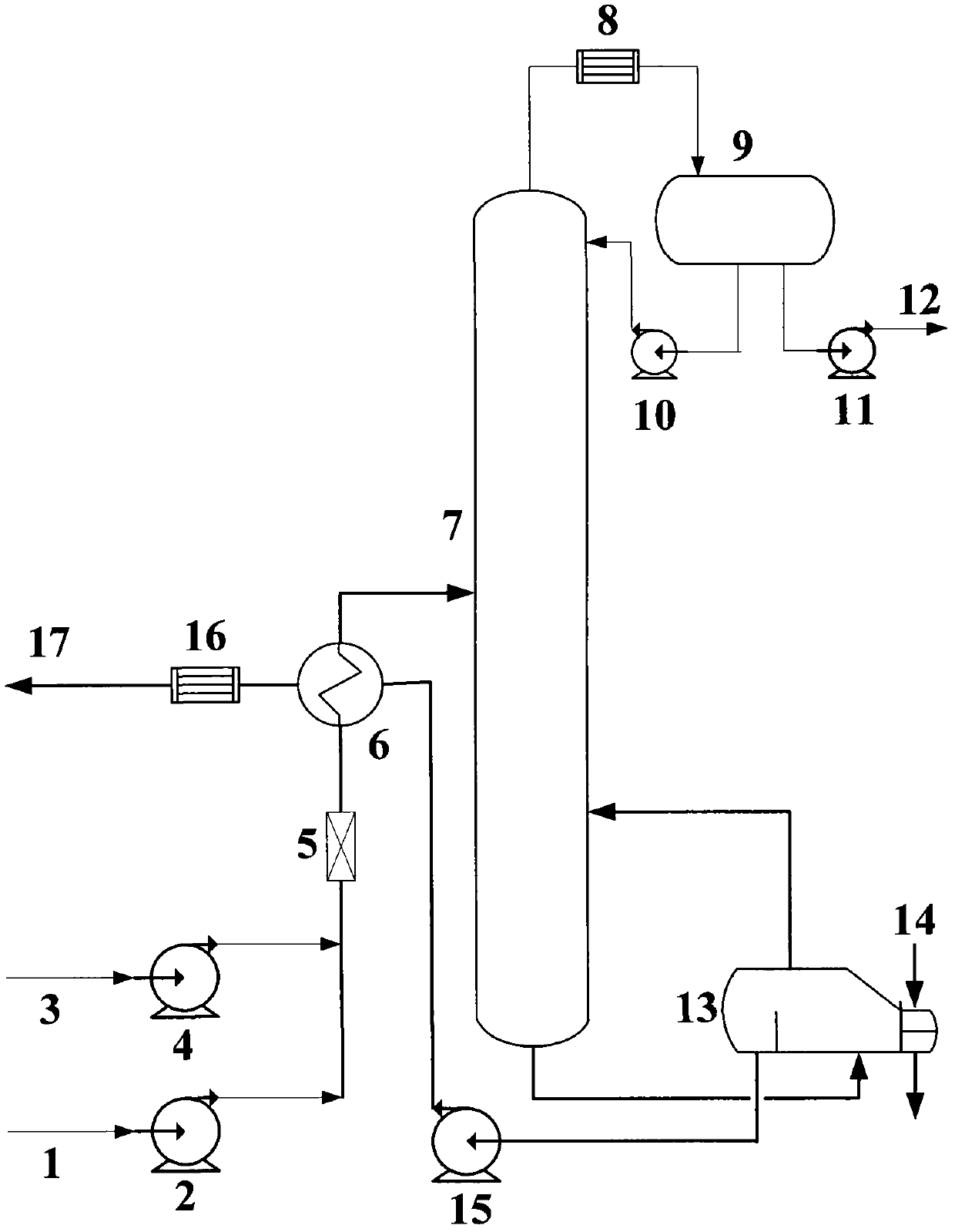

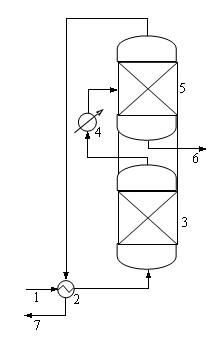

Catalytic gasoline alkylation desulfuration method and device

InactiveCN102079993ASimple processEasy to operateHydrocarbon oils treatmentPtru catalystFractionating column

The invention relates to a catalytic gasoline alkylation desulfuration method and device. The method comprises the following steps: carrying out heat transfer on catalytic gasoline under the pressure of 0.2-1.0 MPa; heating to 50-110 DEG C, and then introducing the catalytic gasoline into an alkylation reaction tower at a liquid hour volume space velocity of 0.5-6.0 hour<-1>; carrying out alkylation reaction in the presence of an alkylation desulfuration catalyst, and introducing the alkylation gasoline after reaction into a fractionating column; fractionating the alkylation gasoline into a low-sulphur light fraction (alkylation desulfuration gasoline) and a sulphur-rich heavy fraction at the temperature of 175-185 DEG C; and recovering the alkylation desulfuration gasoline from the top of the fractionating column, and recovering the heavy fraction from the kettle of the fractionating column. By using the method provided by the invention, the octane value of the gasoline is maintained to be basically unchanged while the sulfide in the gasoline is removed; the method has the advantages of simple flow process, less equipment construction investment, low operation expense, mild operation condition and good desulfuration effect; and the process is easy to control, and the content of the sulphur in the alkylation desulfuration gasoline meets the national standard of motor gasoline.

Owner:无锡蓝星石油化工有限责任公司 +1

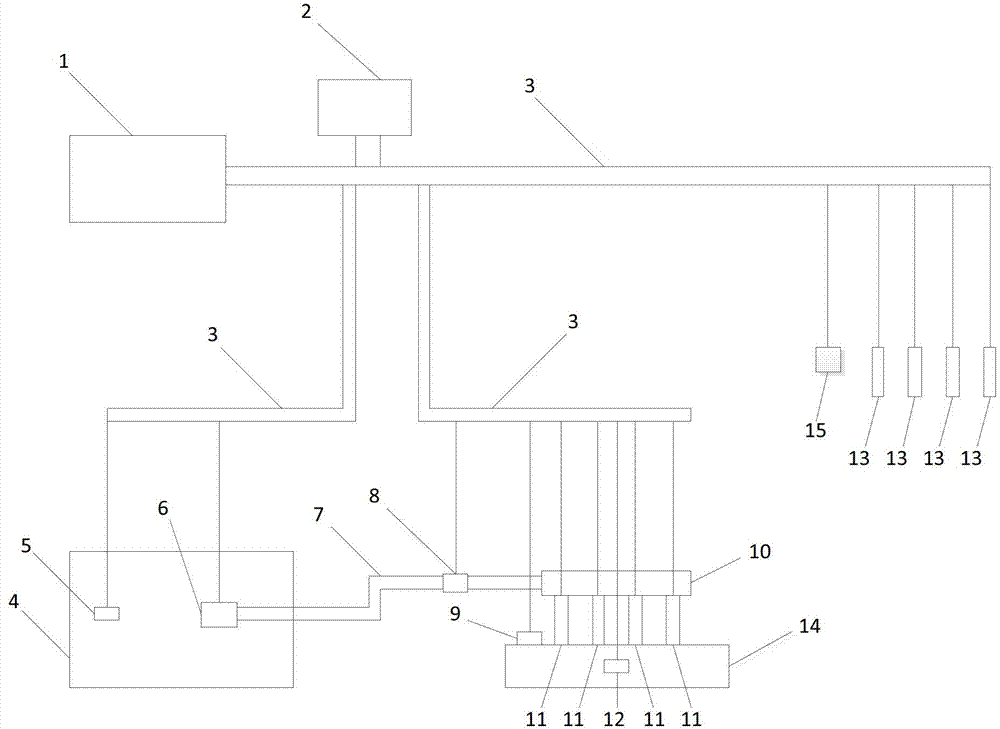

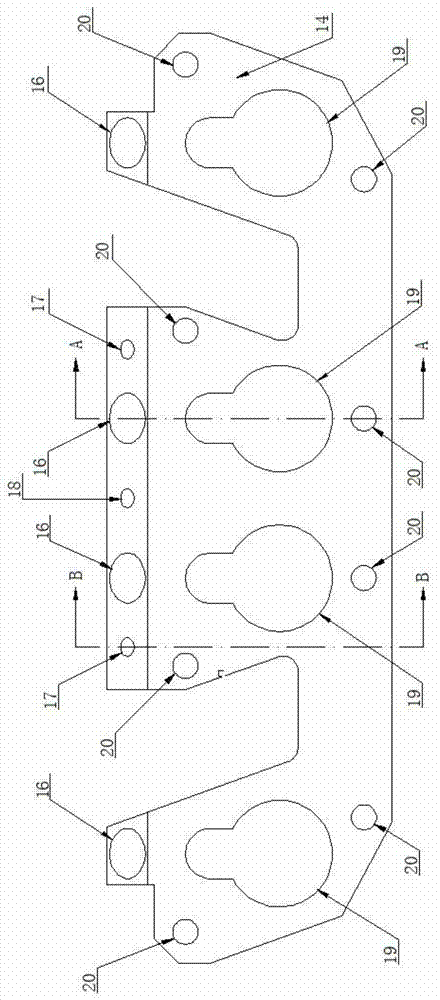

Automobile gasoline and alcohol dual-fuel supply control method and system and fixing cushion block

InactiveCN102953847ALow renovation costReduce lossInternal combustion piston enginesFuel injection apparatusCurrent loadAlcohol

The invention relates to the field of engine dual fuels, in particular to an automobile gasoline and alcohol dual-fuel supply control method and system and a fixing cushion block. After an engine is started, when the temperature of an engine body reaches the combustion temperature of the alcohol fuel, a gasoline spraying nozzle is automatically closed by an additional alcohol ECU (electronic control unit), an alcohol spraying nozzle is opened, and a gasoline spraying pulse width signal generated by a gasoline ECU is intercepted and is converted into an alcohol spraying pulse width signal according to the conversion ratio of the gasoline fuel to the alcohol fuel. When the amount of the fuel needed by the current load of the engine exceeds the maximum alcohol spraying amount or the alcohol fuel is totally consumed, the alcohol spraying nozzle is automatically closed by the alcohol ECU, the gasoline spraying nozzle is opened, and the engine continuously uses the gasoline fuel. On the premise of not losing the automobile property, the alcohol fuel is fully used, the cost of the automobile fuel is saved, the retrofit cost of the automobile is reduced, the retrofit difficulty is reduced, the loss of the engine is reduced, the environment pollution is reduced, and the automobile safety is improved.

Owner:林长军

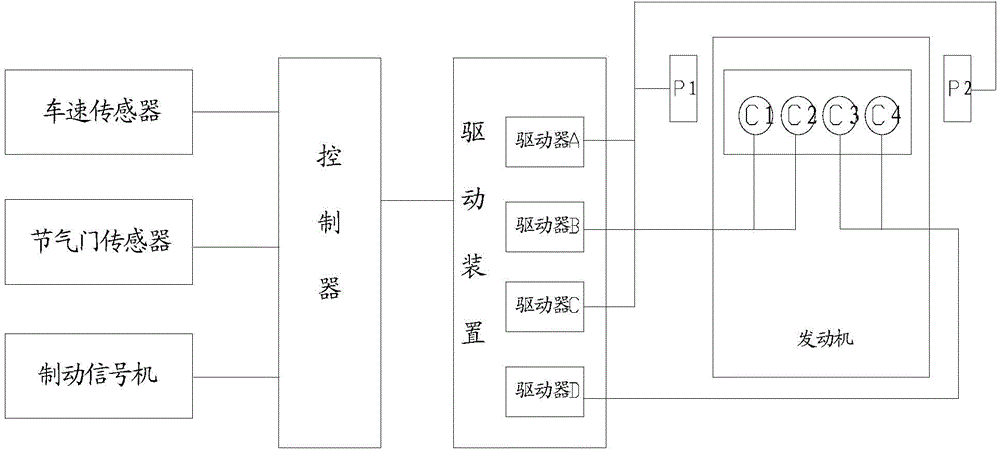

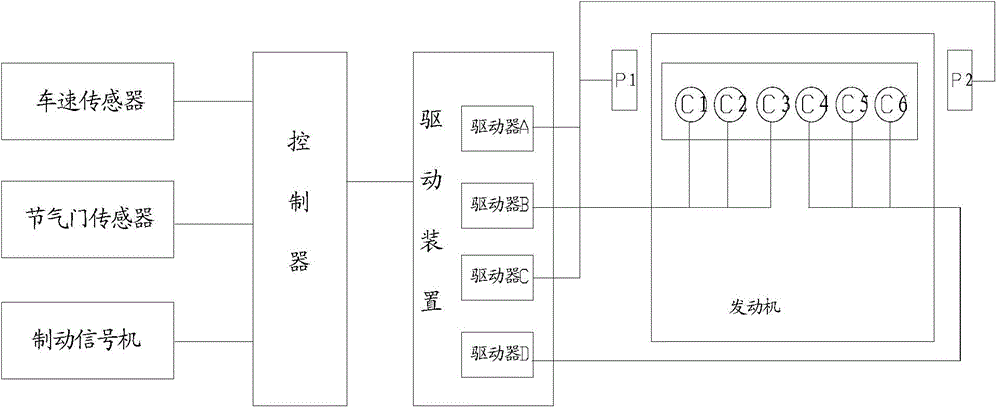

Management system and method for closing parts of cylinders of engine

InactiveCN104533638AReduce resistanceReduce specific fuel consumptionEngine controllersMachines/enginesAutomotive gasolineFuel oil

The invention discloses a management system and method for closing parts of cylinders of an engine. The management system can judge whether the current driving state of a vehicle meets the prestored partial cylinder closing driving conditions according to a driving speed signal, a throttle percentage signal and a brake signal and give out a control order of closing parts of cylinders and making the rest of cylinders work within a preset load range by taking the prestored partial cylinder closing driving conditions as conditions, namely control parts of the cylinders to be in a cylinder closing state and control the rest of the cylinders to work in the preset higher load range. Therefore, the throttle percentage of the cylinders working in this way is large, the airflow resistance is reduced greatly, air inflation performance is high, fuel oil is saved greatly, economical efficiency of an automobile gasoline engine is increased, specific fuel consumption of antifreeze and discharge of harmful gases can be reduced greatly, and environment protection is facilitated.

Owner:ZHEJIANG ZHENGAO AUTO PARTS

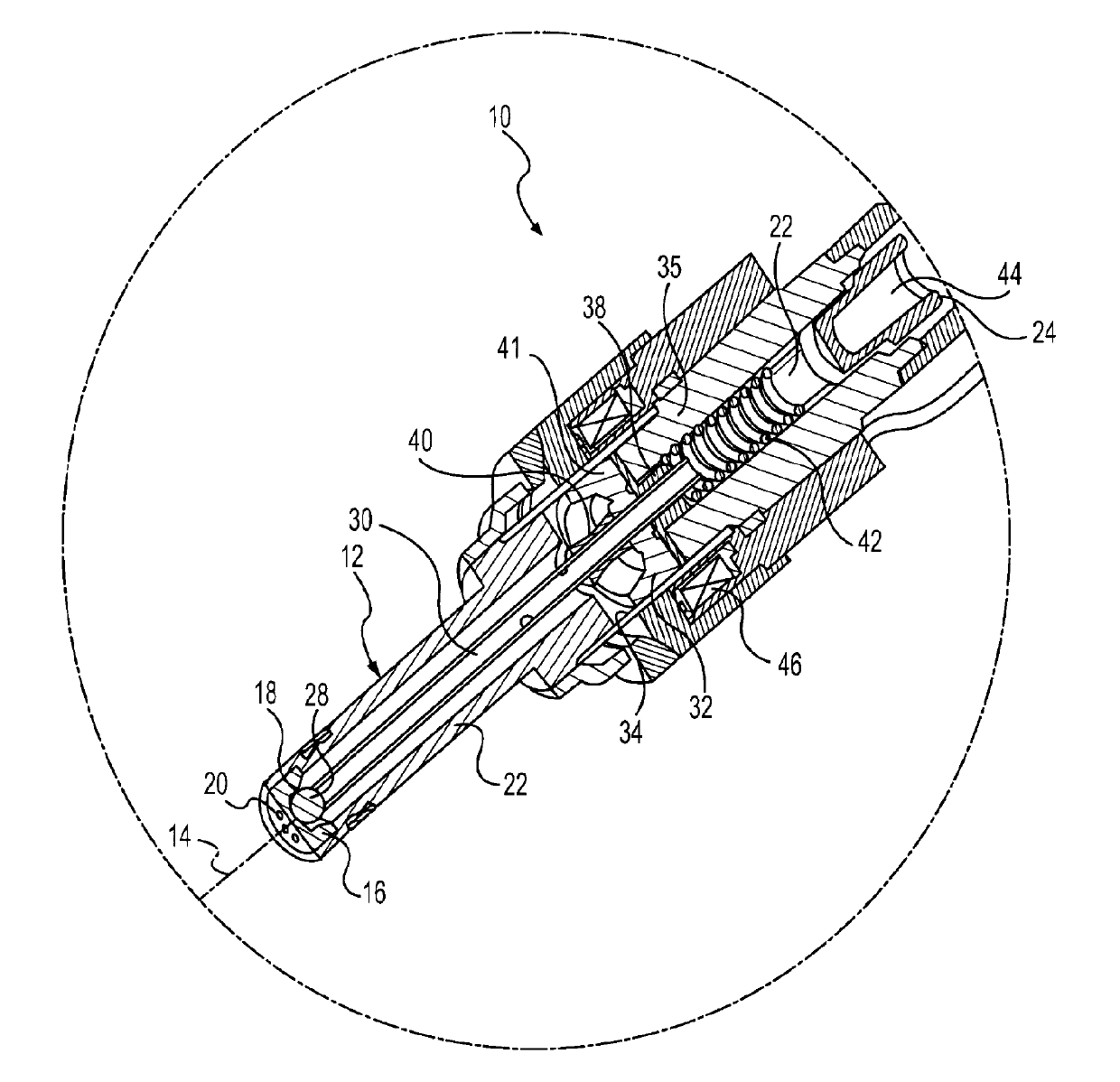

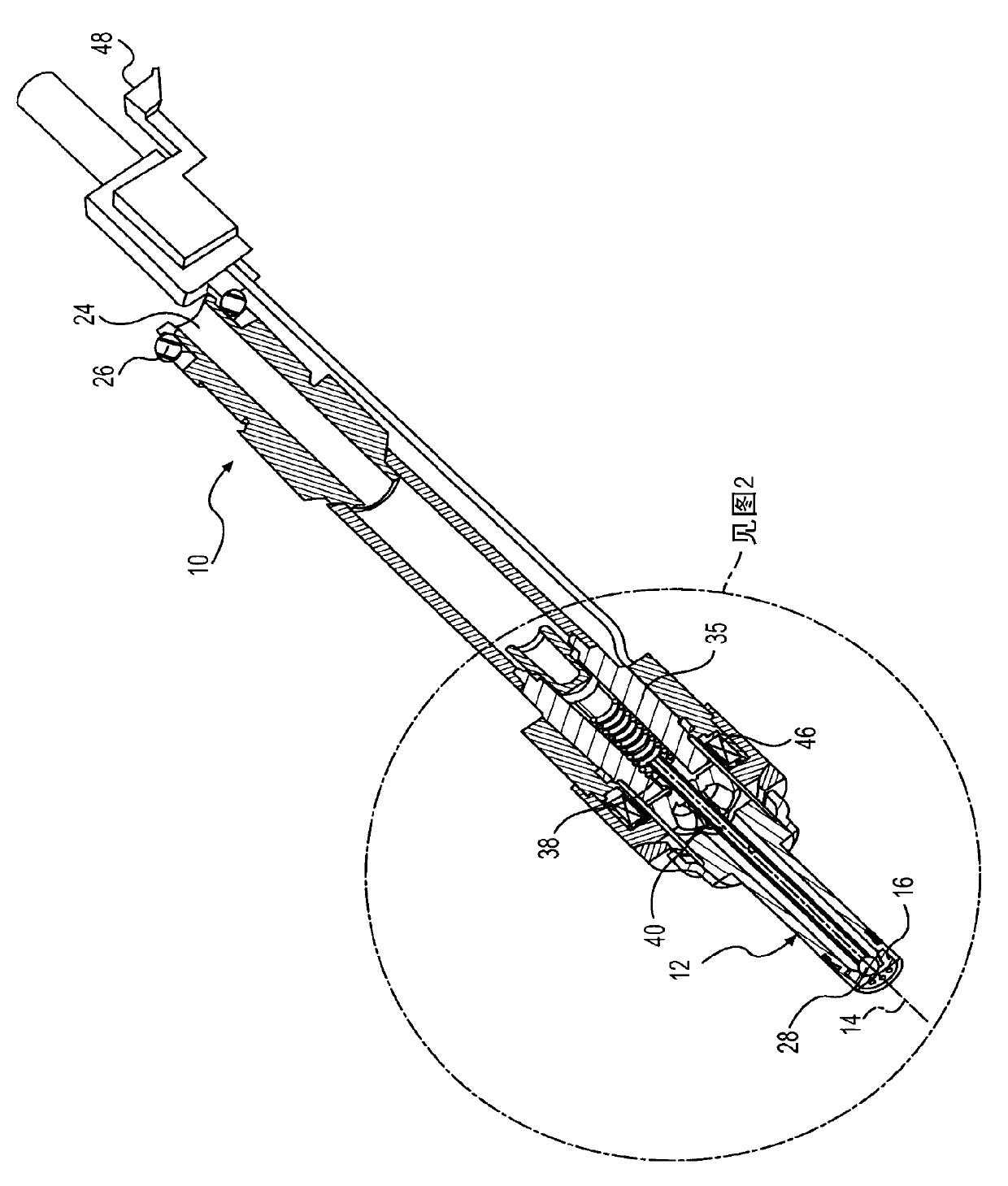

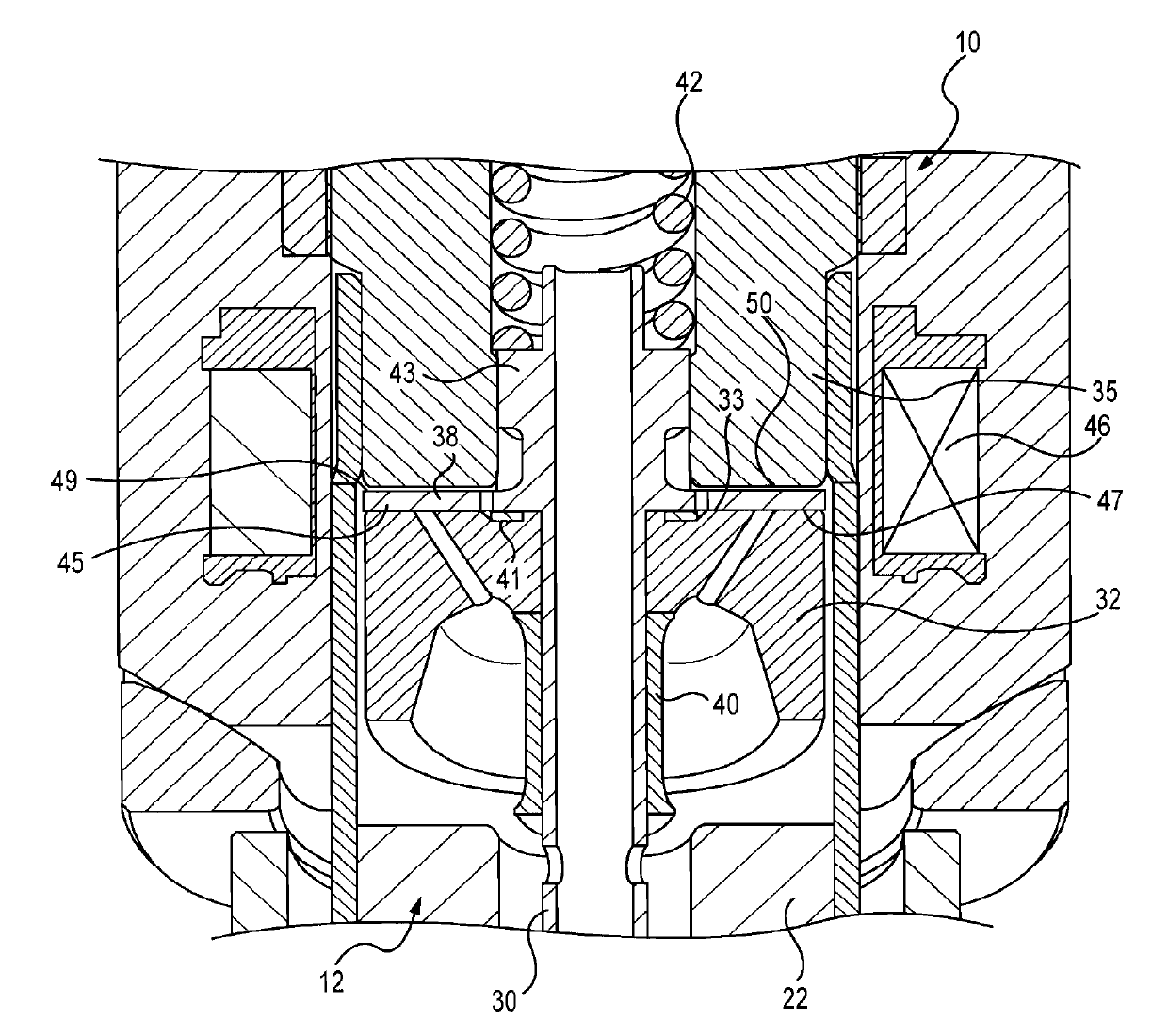

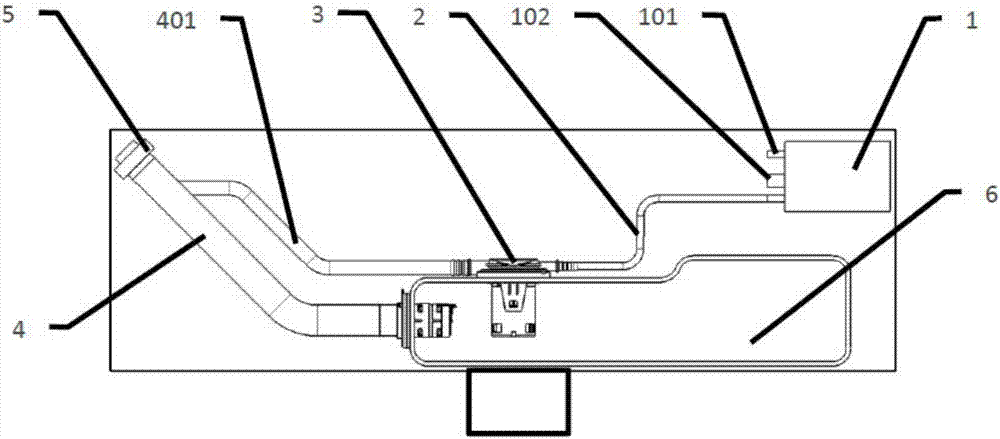

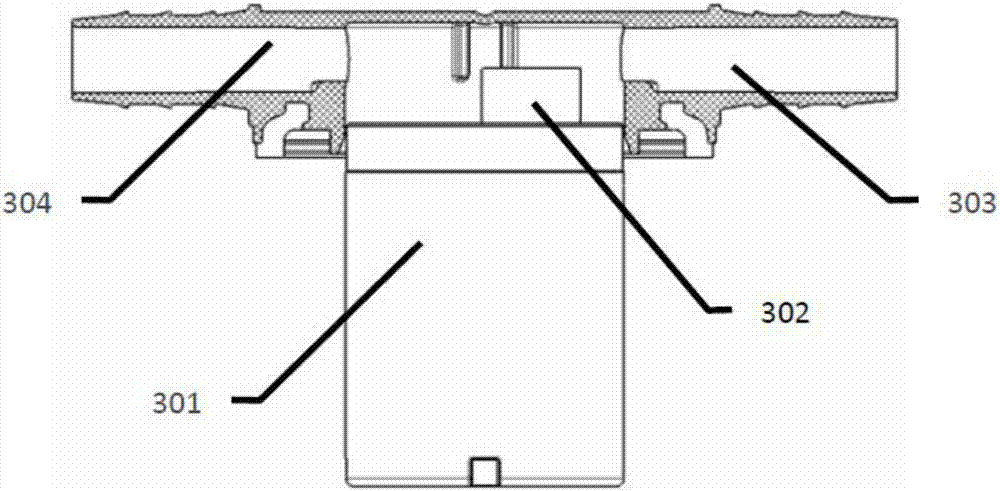

Automotive gasoline solenoid double pole direct injector

ActiveCN102869875ASpraying apparatusMagnetic flux influencing fuel injectionAutomotive gasolinePole piece

A direct fuel injector (10) includes a body (12) having a passage between inlet and outlet ends. A seat (16) is at the outlet end and a closure member (28) is associated with the seat. A needle member (30) is associated with the closure member and is movable with respect to a pole piece (35) between a first, closed position and a second, open position. A spring (42) biases the needle member to the first position. An armature (32) is free-floating with respect to the needle member. An intermediate pole structure (38) is coupled with the needle member and is disposed between the pole piece and the armature and is decoupled there-from. An armature stop (40) is coupled to the needle member and is spaced from the intermediate pole structure. An electromagnetic coil (46) is associated with the pole piece, intermediate pole structure and armature. The injector reduces bounce of the needle assembly.

Owner:VITESCO TECH USA

Low-carbon denatured alcohol gasoline and application

InactiveCN101597523ALow costSave resourcesLiquid carbonaceous fuelsFuel additivesDenatured alcoholMethanol fuel

The invention discloses a low-carbon denatured alcohol gasoline and application. The low-carbon denatured alcohol gasoline comprises the following components in percentage by weight: 60-80% of alcohol, 5-15% of fuel ethanol and 5-26% of additive, wherein the additive is composed of the following components in percentage by weight: 45-55% of ortho-nitrotoluene, 20-37% of dimethoxymethane, 5-8% of dimethyl malenate, 0.4-.06% of corrosion inhibitor for metal and 0.4% of antiswelling inhibitor for rubber. The low-carbon denatured alcohol gasoline is added into the national standard gasoline in percentage by weight of 20-85% to be applied. The low-carbon denatured alcohol gasoline is a motor gasoline with better cleanability, lower gasoline consumption rate, larger mixing amount and lower raw material cost; the cost of the motor gasoline is obviously lowered, resource is saved, and engine emission is further improved; at the same time, the motor gasoline solves the problems of high gasoline consumption, low-temperature layering, and the like, lowers saturation vapour pressure and prevents the air blocking phenomenon.

Owner:莫春福

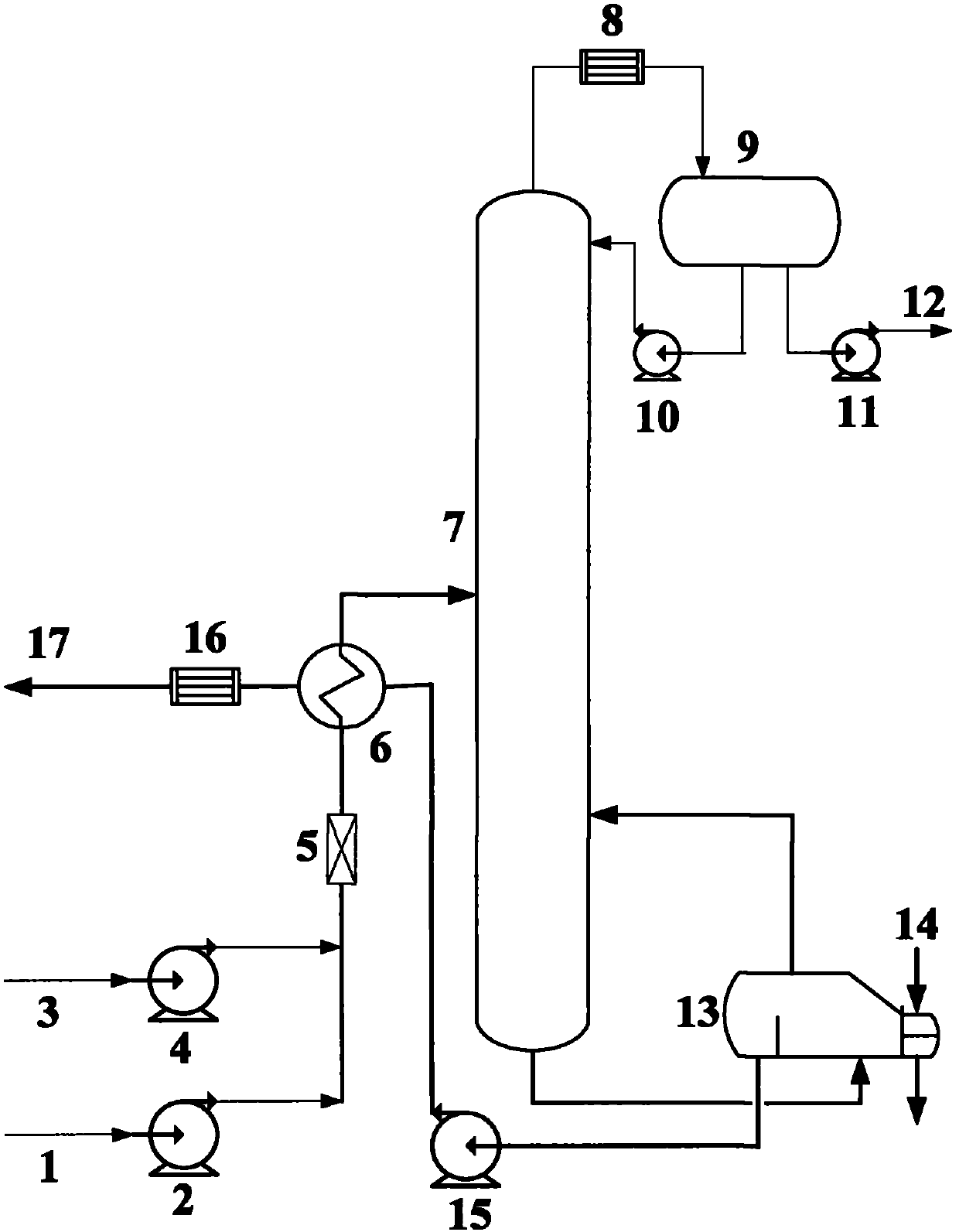

Alcohol-based vehicle fuel

The invention belongs to the technical field of fuels, and relates to an alcohol-based vehicle fuel, which has the advantages of energy saving, environmental protection, high power and no gasoline component.Methanol used as a base fuel is compounded with related auxiliary materials (additives) so as to prepare the methanol into the alcohol-based vehicle fuel for gasoline engines; and the alcohol-based vehicle fuel can be directly used as a substitute for various labels of gasoline and diesel which are widely used at present, and has the characteristics of low cost, energy saving, environmental protection, excellent properties and the like. Compared with vehicle gasoline, the alcohol-based vehicle fuel has the same vehicle indexes, and is characterized in that the alcohol-based vehicle fuel can be normally used under the condition of not changing any device of the automobile; and thus, the alcohol-based vehicle fuel is soluble in gasoline.

Owner:周鹏阳

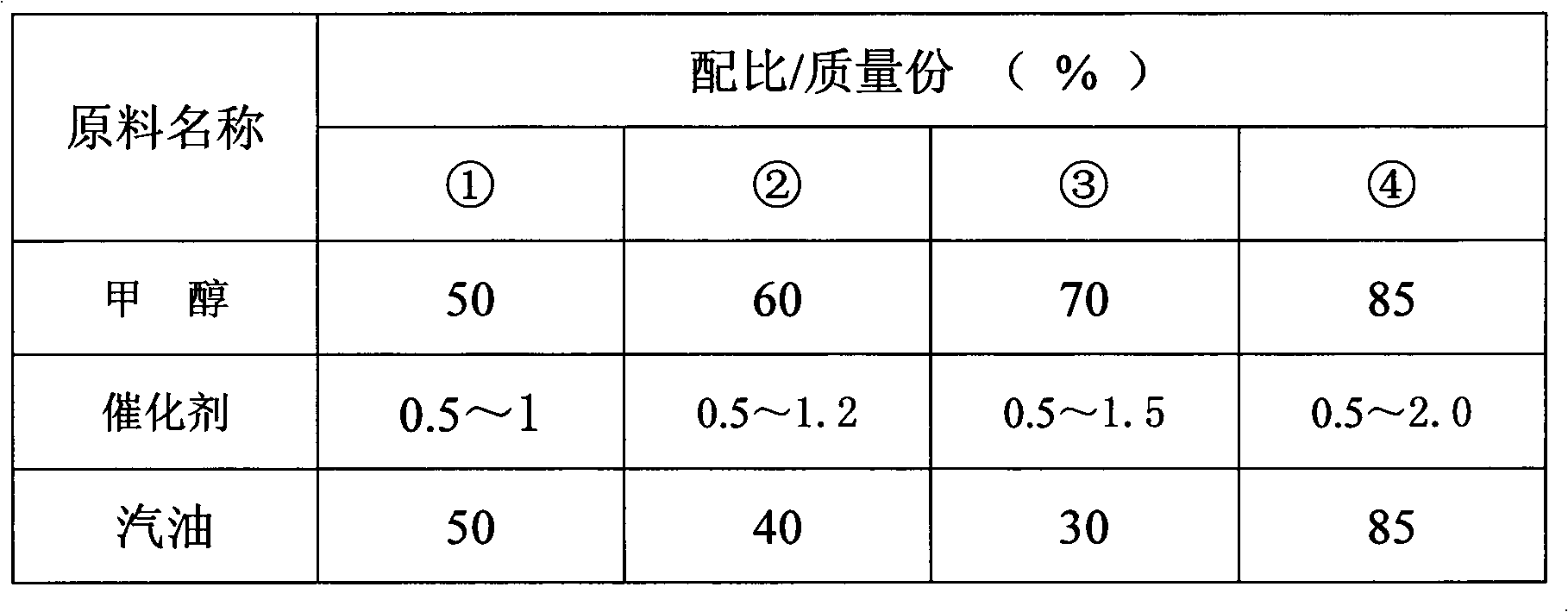

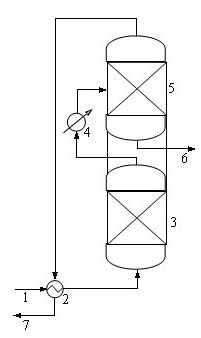

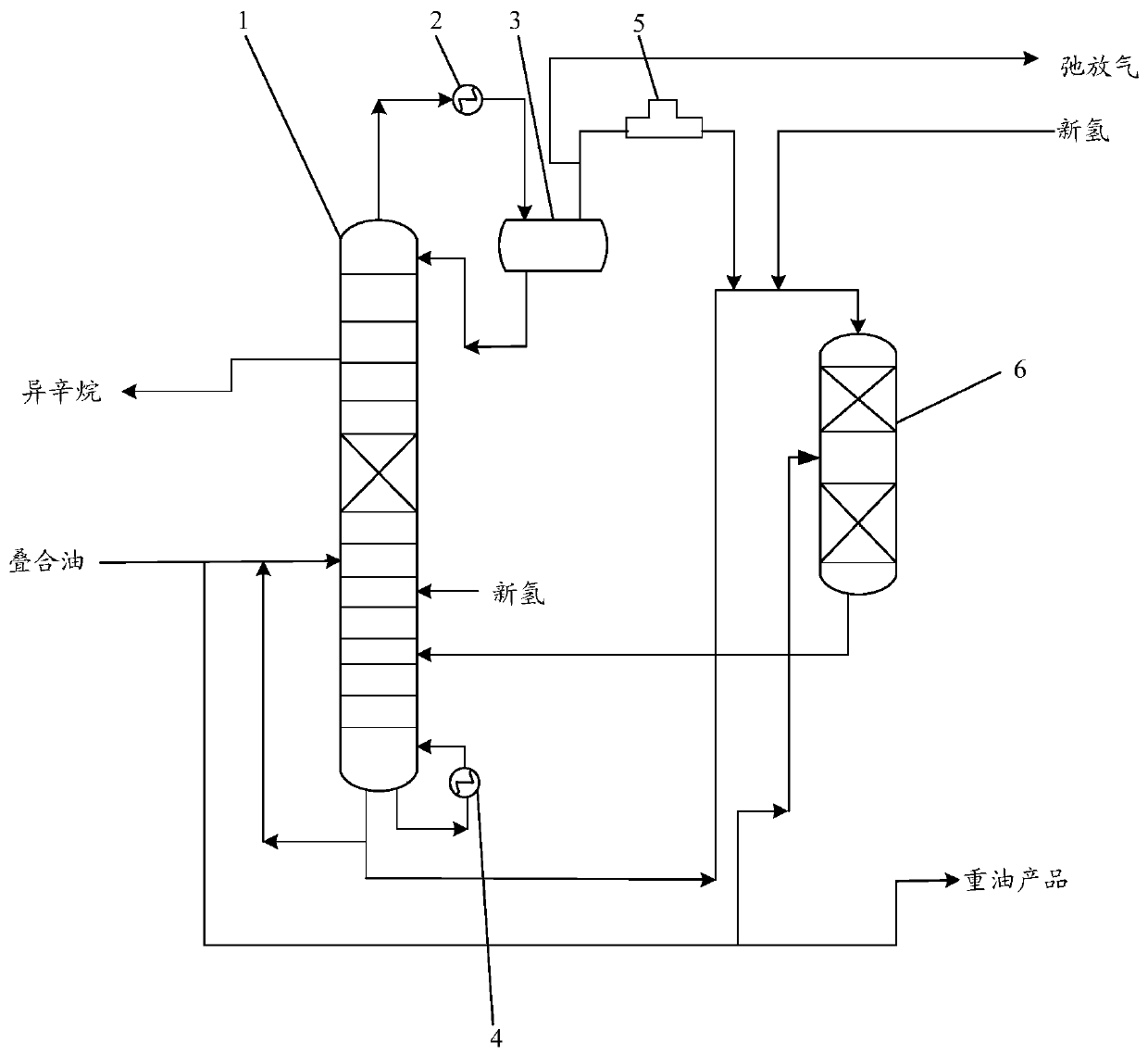

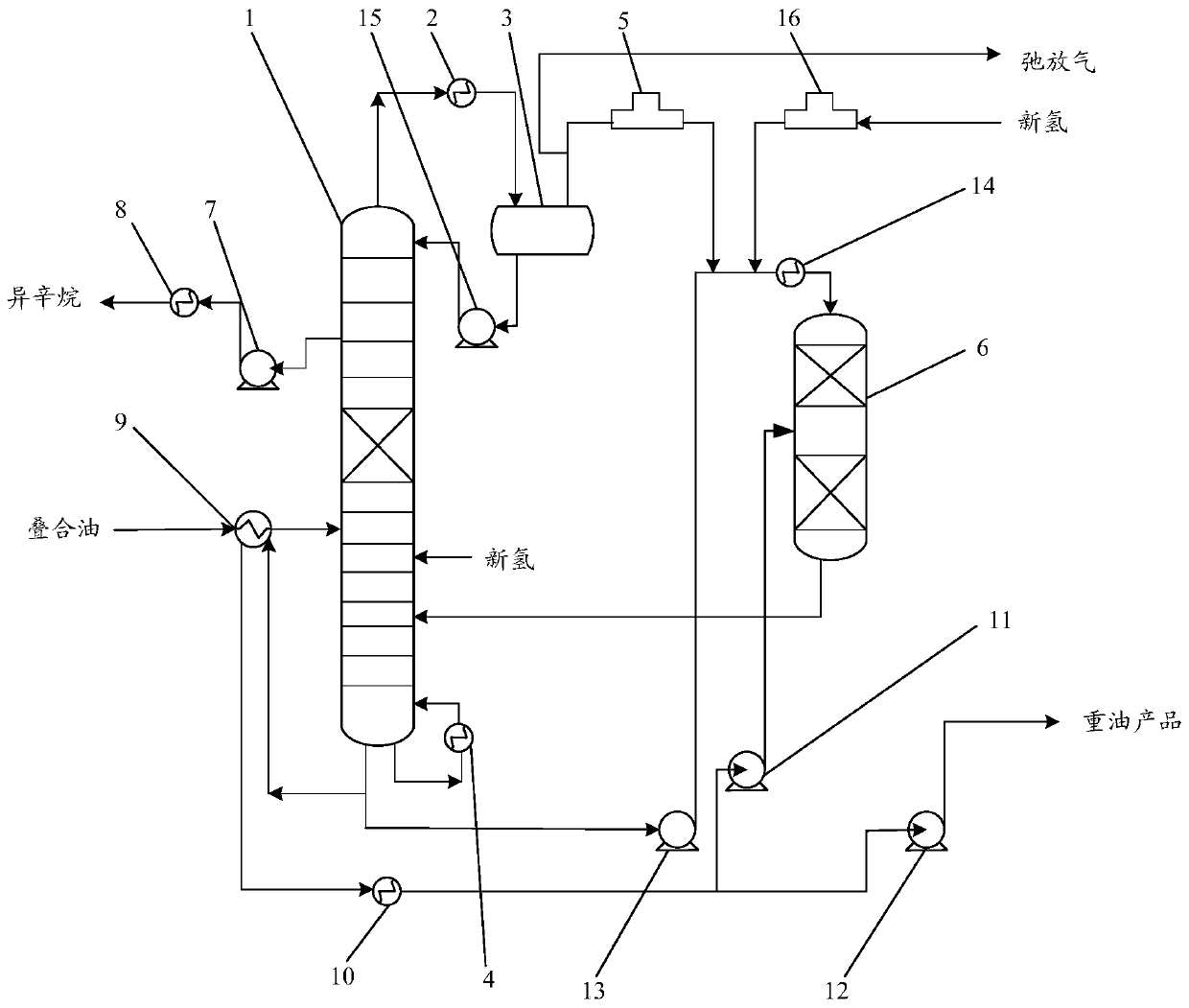

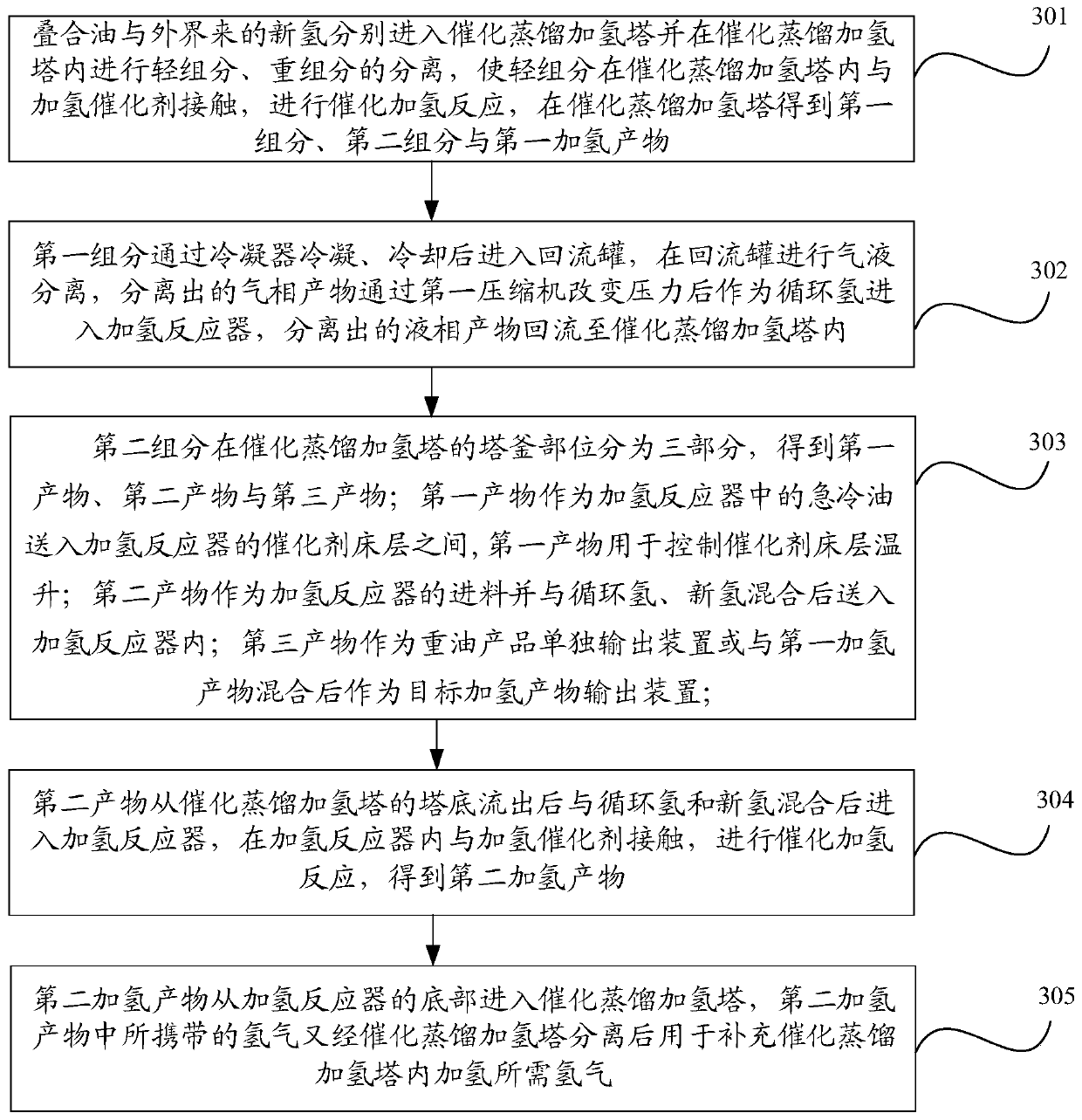

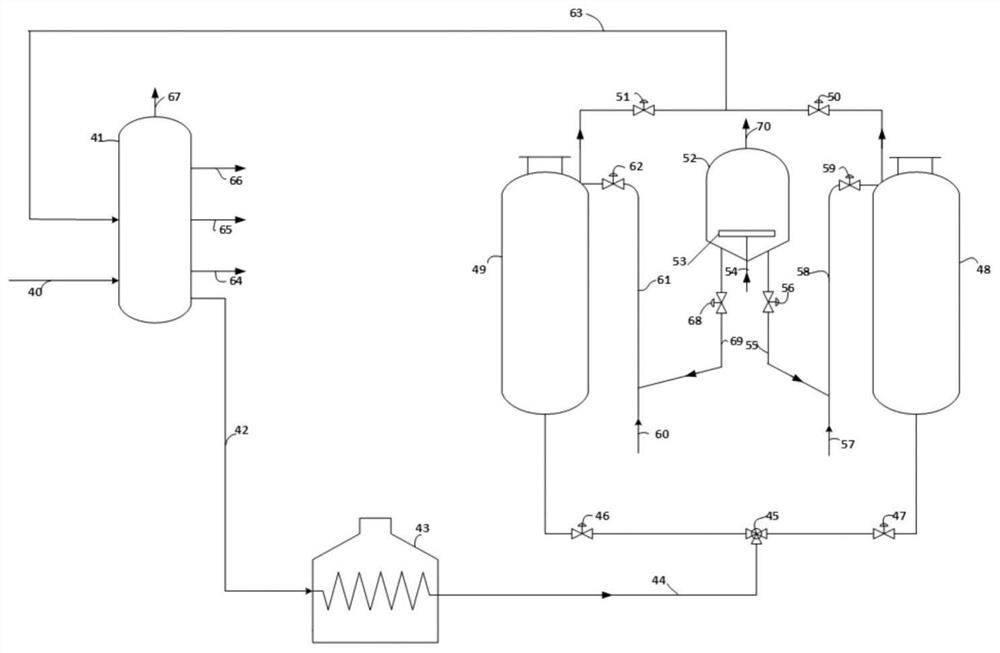

Superposition oil hydrogenation device and method capable of producing isooctane

PendingCN110776952ASimple processLow investment costTreatment with hydrotreatment processesIsooctanesHydrogenation reaction

The invention discloses a superposition oil hydrogenation device and method capable of producing isooctane, and belongs to the technical field of petrochemical engineering. The device comprises a catalytic distillation hydrogenation column, a condenser, a reflux tank, a reboiler, a first compressor and a hydrogenation reactor; the top of the catalytic distillation hydrogenation column is connectedwith the condenser, the condenser is connected with one inlet of the reflux tank, one outlet of the reflux tank is connected with the first compressor, and the other outlet of the reflux tank is connected with the catalytic distillation hydrogenation column; the reboiler is arranged at the bottom of the catalytic distillation column; and the bottom of the hydrogenation reactor is connected with the catalytic distillation hydrogenation column. According to the superposition oil hydrogenation device and method capable of producing the isooctane, olefin in superimposed oil can be saturated, requirements of the superposition oil as a vehicle gasoline blending component are met and the isooctane is produced as needed, a hydrogenation reaction is separately carried out on different components in the superimposed oil through the catalytic distillation column and the hydrogenation reactor, the equipment and operation costs can be reduced, and the purpose of energy saving and flexible operation is achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Mesitylene As An Octane Enhancer For Automotive Gasoline, Additive For Jet Fuel, And Method Of Enhancing Motor Fuel Octane And Lowering Jet Fuel Carbon Emissions

A motor fuel providing higher gas mileage comprising gasoline produced from petroleum and from about 1 to 30 wt % of mesitylene. This fuel can advantageously contain conventional additives used in gasoline. The use of mesitylene in gasoline blend yields a fuel blend with a higher research octane number and motor octane number. In addition, an improved jet fuel is provided, having from 1-10 wt % biomass-derived mesitylene added thereto, having improved carbon emission characteristics while maintaining required specifications. Further, an improved bio-fuel is provided, which may function as a replacement for conventional Jet A / JP-8 fuel and has lowered carbon emission specifications, the bio-fuel comprised of 75-90 wt % synthetic parafinnic kerosene (SPK) and 10-25 wt % mesitylene.

Owner:SWIFT FUELS

Novel gasoline refueling system for automobile

A novel automobile gasoline refueling system, which includes a fuel tank and a carbon tank, wherein: a combined gravity valve is arranged in the fuel tank, and the combined gravity valve includes: a large flow gravity valve and a small flow gravity valve, and the small flow gravity The closing plane of the valve is higher than the closing plane of the high-flow gravity valve, and the high-flow gravity valve is connected to the fuel tank; and the flow channel for the carbon tank and the flow channel for refueling, and the flow channel for the carbon tank is connected to the flow channel for the fuel tank. The carbon tank is connected, the refueling channel is connected to the refueling pipe exhaust pipe, and the system is realized through the combined gravity valve to simultaneously realize the control of the refueling process and the evaporative emission control process through the combined gravity valve.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

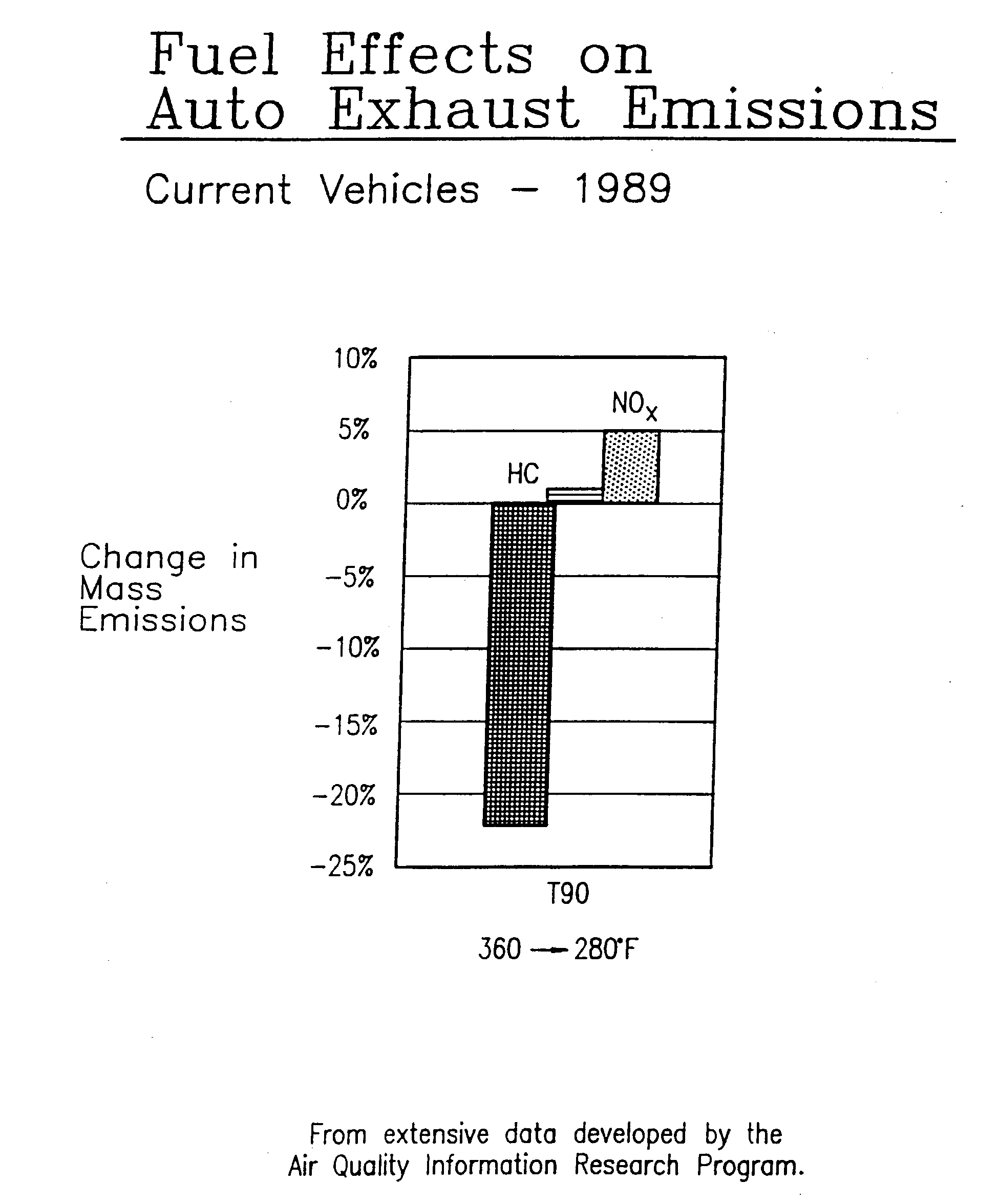

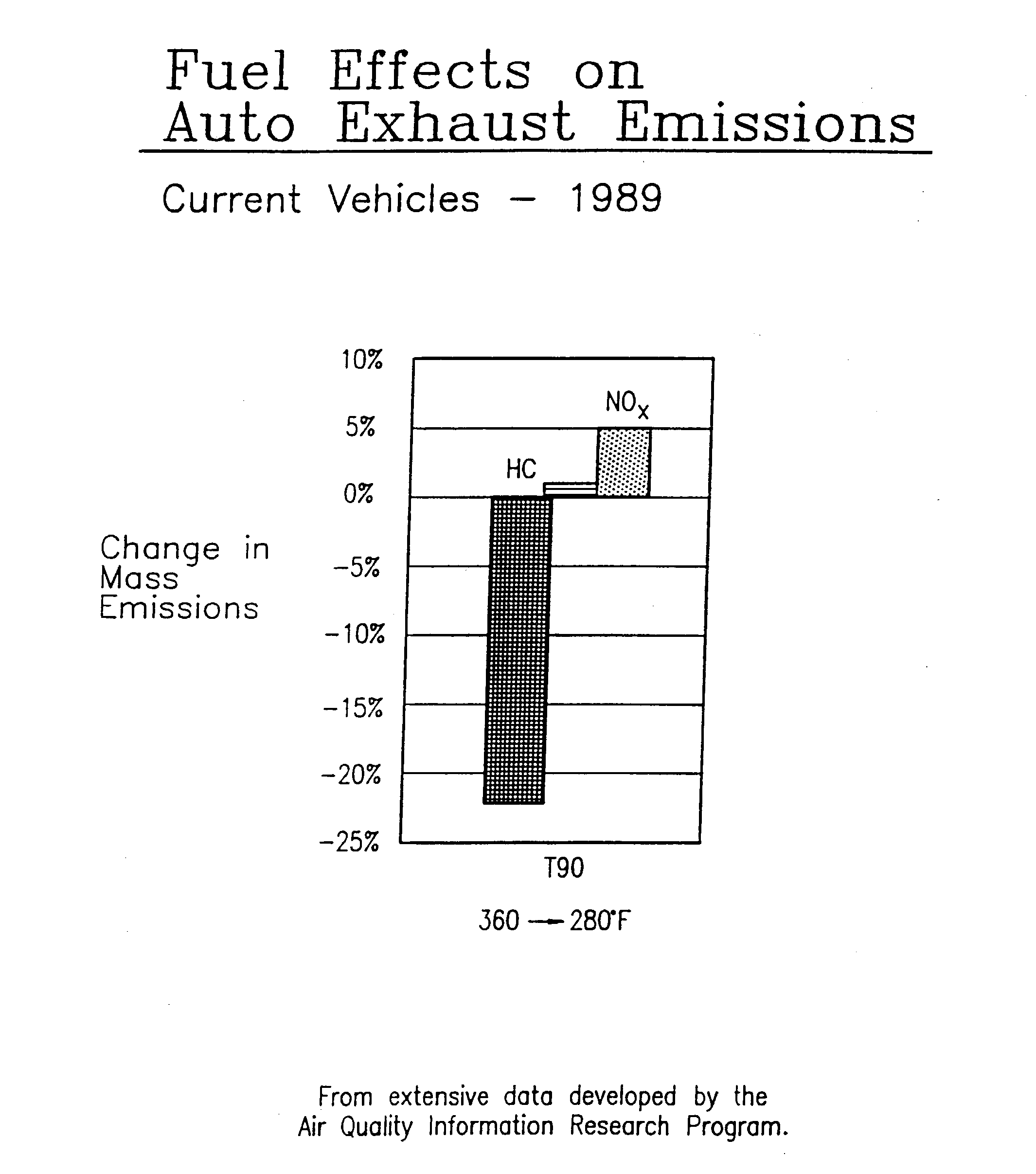

Automotive gasoline fuel for internal combustion engine

InactiveUS20030204986A1Lower levelClean burningLiquid carbonaceous fuelsFuel additivesDistillationExternal combustion engine

A fast burning, gasoline type composition for spark ignited internal combustion engines having a ASTM D-86, 90% distillation temperature of 310° F. or less and an octane number (R+M) / 2 of 82 or less that can be used with a reduced spark advance in the engines to effect a reduction in NOx exhaust emissions. Also disclosed is a gasoline having low octane (82-87) which can be used interchangeably in engines having a reduced spark advance and in engines having conventional spark advance.

Owner:TALBERT FUEL SYST

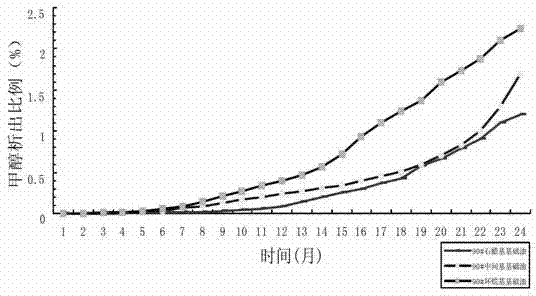

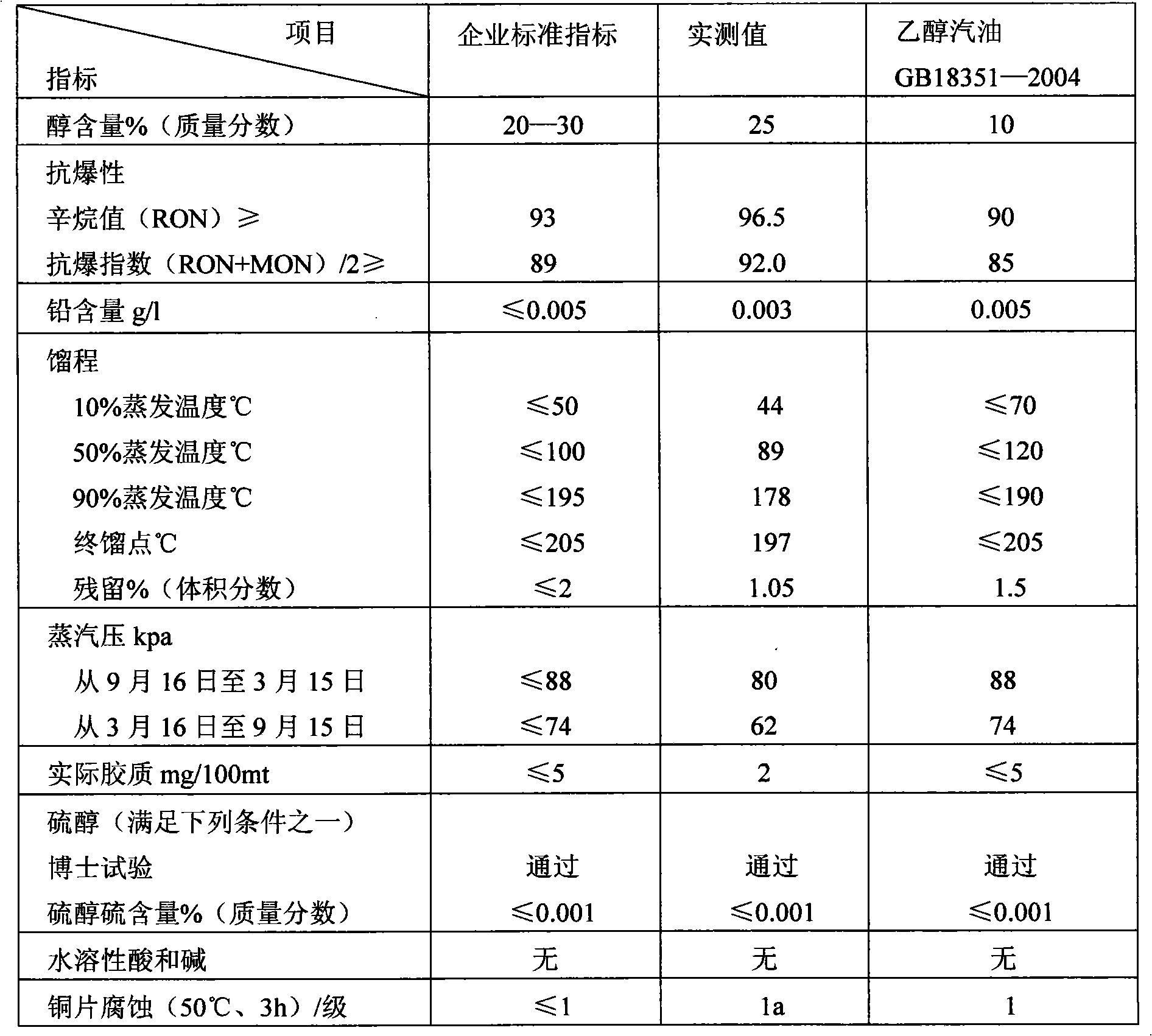

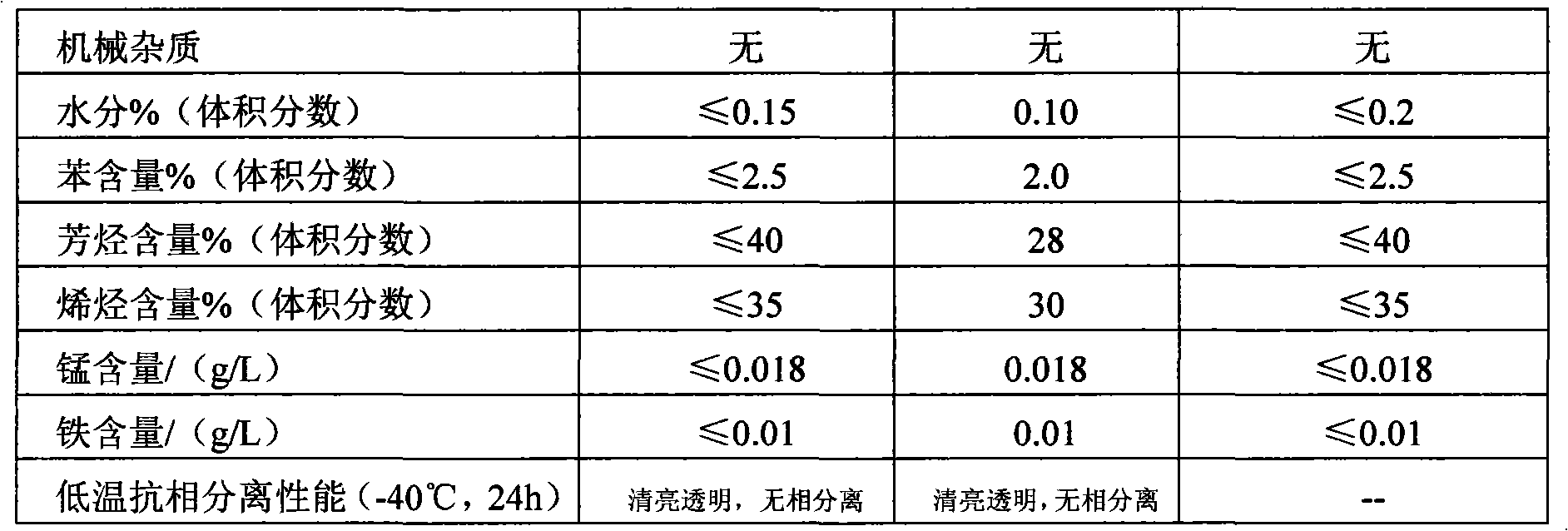

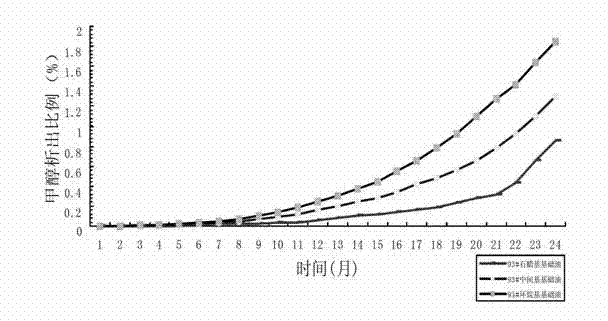

Automotive plateau-type modified fuel methanol and purposes thereof

ActiveCN103160335ABoost octaneImprove combustion stabilityLiquid carbonaceous fuelsCombustionAutomotive gasoline

The invention relates automotive plateau-type modified fuel methanol and a production method and purposes of the automotive plateau-type modified fuel methanol. The automotive plateau-type modified fuel methanol is composed of methanol-based clean fuel blending additives and automotive fuel methanol. When methanol gasoline blended with the plateau-type modified fuel methanol is used, the increase of octane value is stable, a direct ratio relationship exists between additive amount and the octane value, the combustion stability of the fuel is strengthened, the efficiency of converting chemical energy into kinetic energy is improved, the storage stability is good, and the methanol gasoline is not oxidized and deteriorates after long-time storage. Compared with existing 93# automotive gasoline, the methanol gasoline blended with the plateau-type modified fuel methanol has the advantages of improving power, lowering emission, and reducing environmental pollution when used in plateaus and anoxic areas.

Owner:李晏 +5

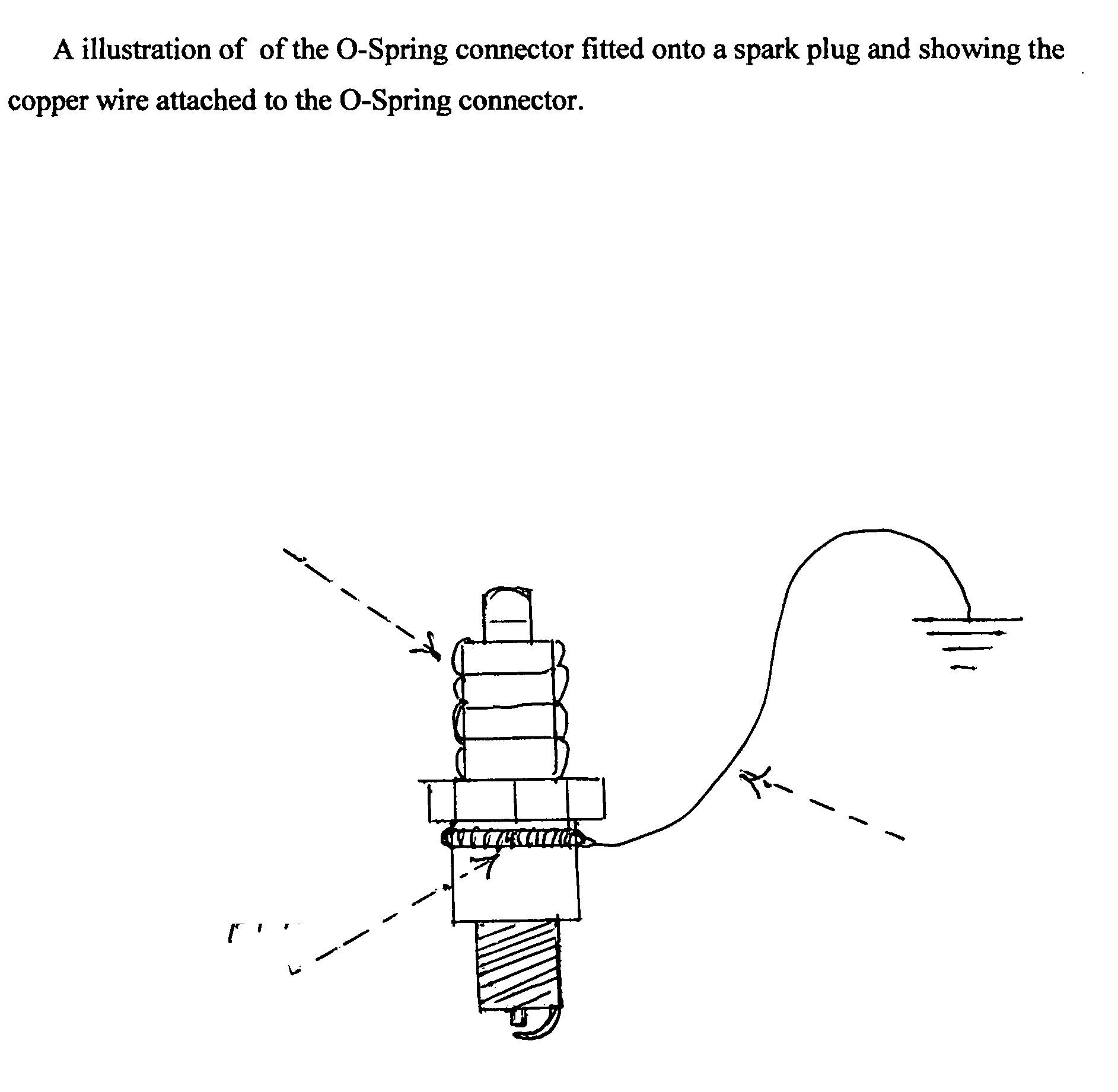

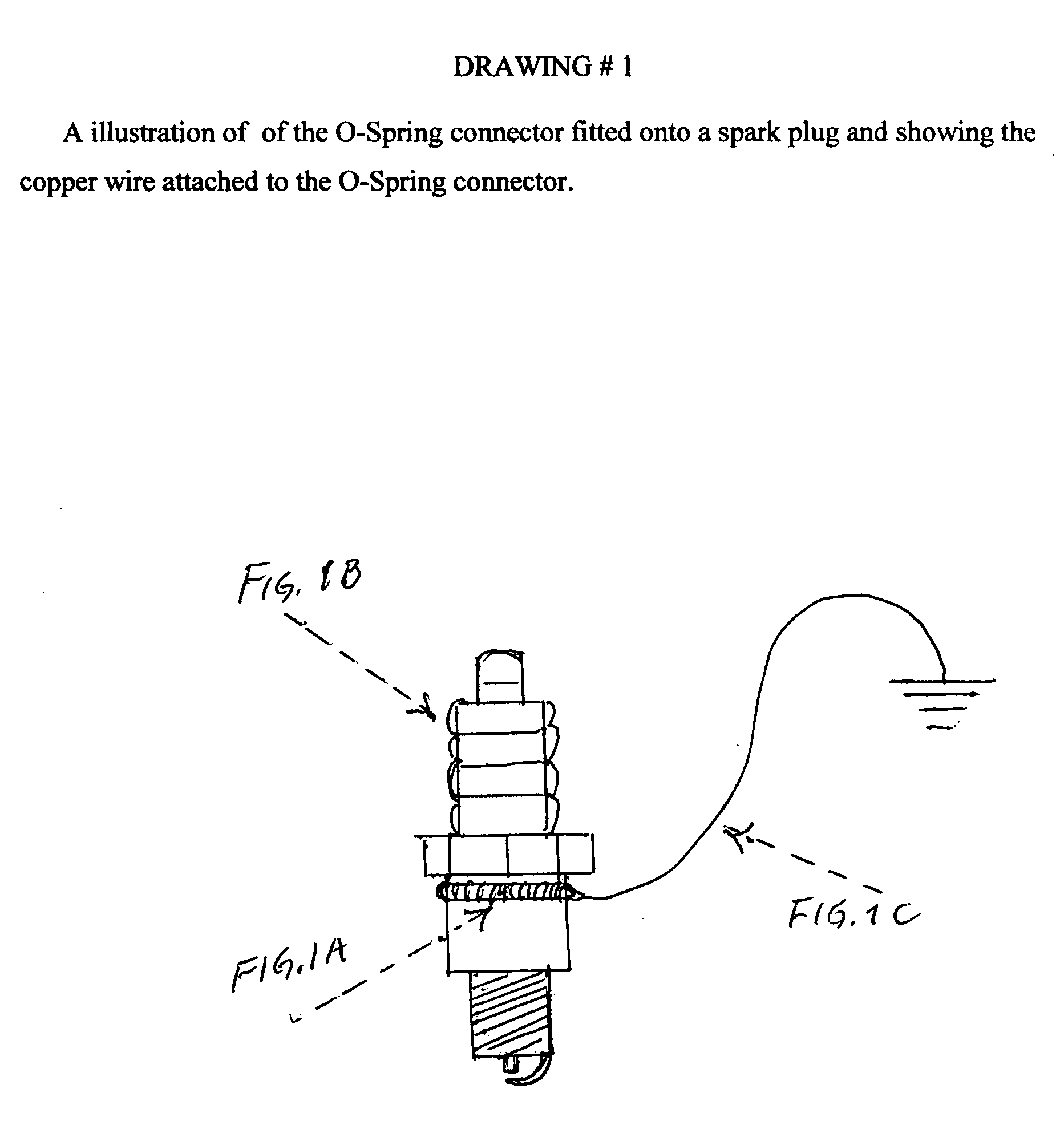

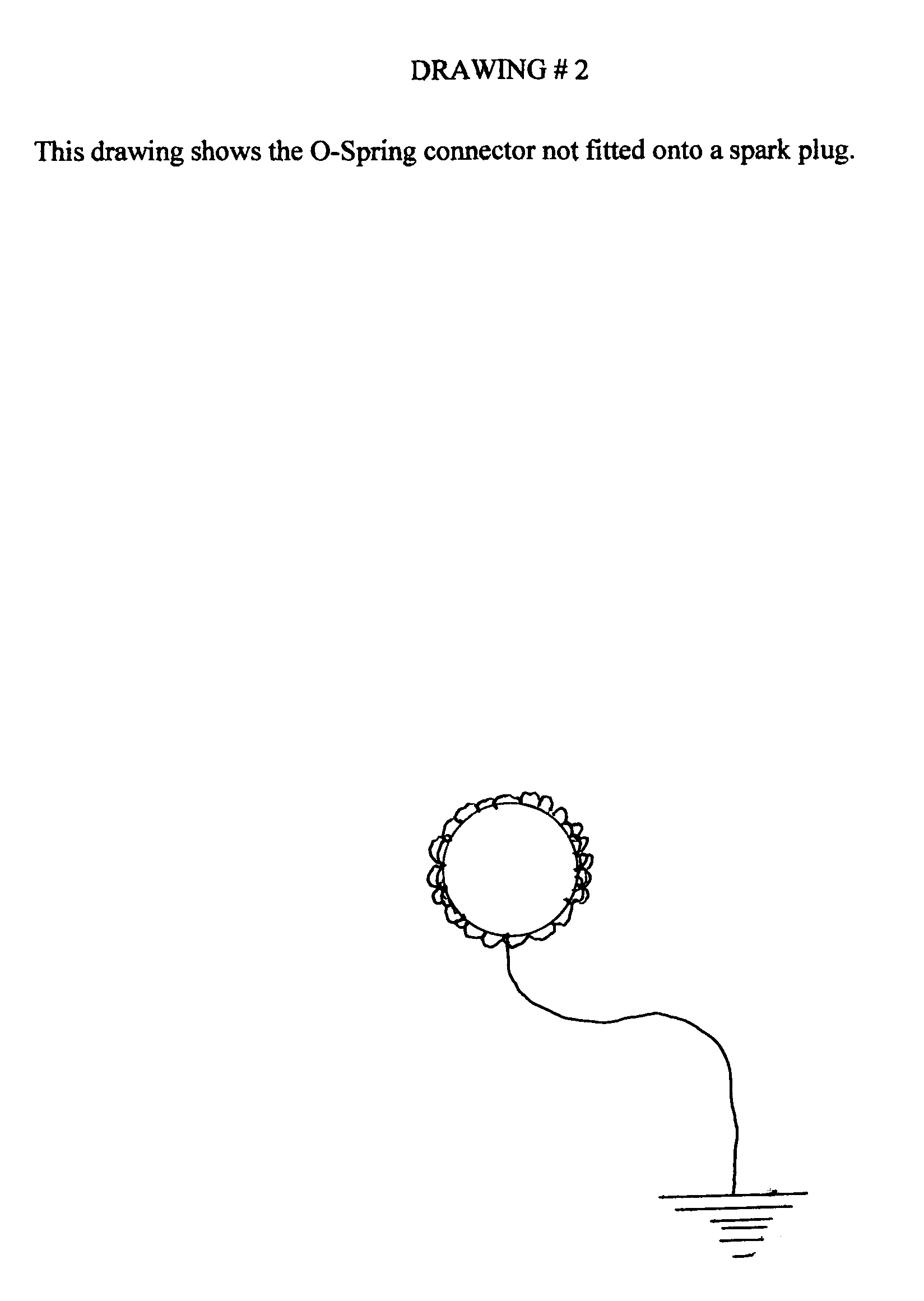

O-spring automotive spark plug grounding system

InactiveUS20050224033A1Increase resistanceGood adhesionSparking plugsMachines/enginesHigh resistanceElectricity

The spark plugs on a automotive gasoline engine are and have always been dependent on the metal body of the engine for its path of least resistance for the flow of electricity from the spark plugs back to the vehicle battery. No doubt there is a disadvantage to this because this path is subjected to high heat which increases the resistance to the flow of electricity. In addition to the high heat there are mating surfaces of metal to metal which are internal within the engine and become corroded over time and they also offer a higher resistance to the flow of electricity. To solve this problem I have developed a spark plug connector which I call the O-Spring spark plug grounding connector which is attached to the external metal section of the spark plug and eliminates the need for the metal body of the engine as the path of least resistance to the flow of electrical current from the spark plugs to the vehicle battery. The combination of the spark plug connector and copper wire make a excellent ground return circuit for the spark plugs as described in the Detailed Description Of The Invention.

Owner:LINKENHOGER THOMAS ELLEN

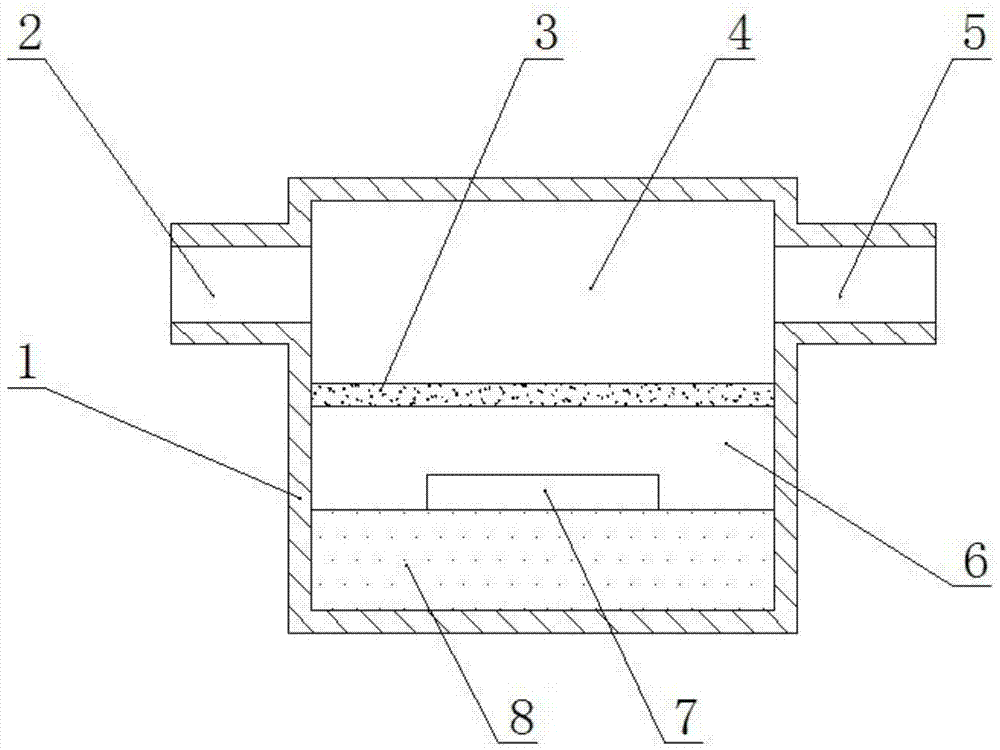

Automotive gasoline economizer

InactiveCN103590931ABurn fullyIncrease telekinetic energyInternal combustion piston enginesCombustion-air/fuel-air treatmentFiberHydrogen

The invention relates to an automotive gasoline economizer and belongs to the field of automotive gasoline economizing accessories. The automotive gasoline economizer comprises a gasoline activating chamber which is divided into a first chamber and a second chamber, the first chamber is provided with a feed inlet and a discharge outlet, the second chamber is internally provided with a far infrared heating element and ceramic fibers, the ceramic fibers are fixed at the bottom of the second chamber, and the far infrared heating element is fixed on the ceramic fibers. The automotive gasoline economizer has the advantages that carbon-hydrogen bonds can be destroyed by far infrared rays emitted from the far infrared heating element and the ceramic fibers so as to thin gasoline molecular groups and increase gasoline molecular telecontrol energy, so that gasoline burning is more sufficient.

Owner:南宁明航节能科技有限公司

Additive applied to liquid fuels for internal combustion engines

InactiveUS20090151238A1Less pollutant materialLow costLiquid carbonaceous fuelsFuel additivesBiodieselAlcohol

Additive applied to liquid fuels for internal combustion engines, represented by a solution in the liquid fuels such as kerosene; aviation kerosene, automotive gasoline, Diesel oil; Bio Diesel oil among others application field. This field is where this additive is anchored in the anhydrous ethyl alcohol (C2H5OH) component, which associated to a isopropyl alcohol (C3H8O) component, and also to the decahydronaphthalene (C10H18) component, becomes soluble to each of these fuels, ensuring thus that the same transmit less pollutant material to the environment.

Owner:DE QUEIROZ EVANDRO LOPES

Saver and cleanser for gasoline

InactiveCN1204235CImprove atomization qualityLower activation energyLiquid carbonaceous fuelsGasoline fuelEthylene Dichloride

A gasoline fuel-saving purifying agent, relating to an automobile gasoline fuel-saving purifying agent using gasoline as fuel, the invention includes a detergent dispersant, a combustion aid, an antiknock agent, a polar solvent, and a non-polar solvent. The dispersant is a mixture of dichloroethane and N-methyl-2-pyrrolidone, wherein the content of dichloroethane is 5-20%, and the content of N-methyl-2-pyrrolidone is 5-20%; It is benzene alcohol with a content of 2-10%; the antiknock agent is a mixture of ferrocene and isopropanol, wherein the content of ferrocene is 3-5%, and the content of isopropanol is 5-15%; polarity The solvent is methanol or ethanol with a content of 20-40%; the non-polar solvent is benzene, toluene, xylene or their mixtures with a content of 20-40%. It has the advantages of improving the performance of gasoline, improving the cleanliness of fuel, promoting the full combustion of fuel, reducing automobile exhaust pollution, and keeping the car in good working condition.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

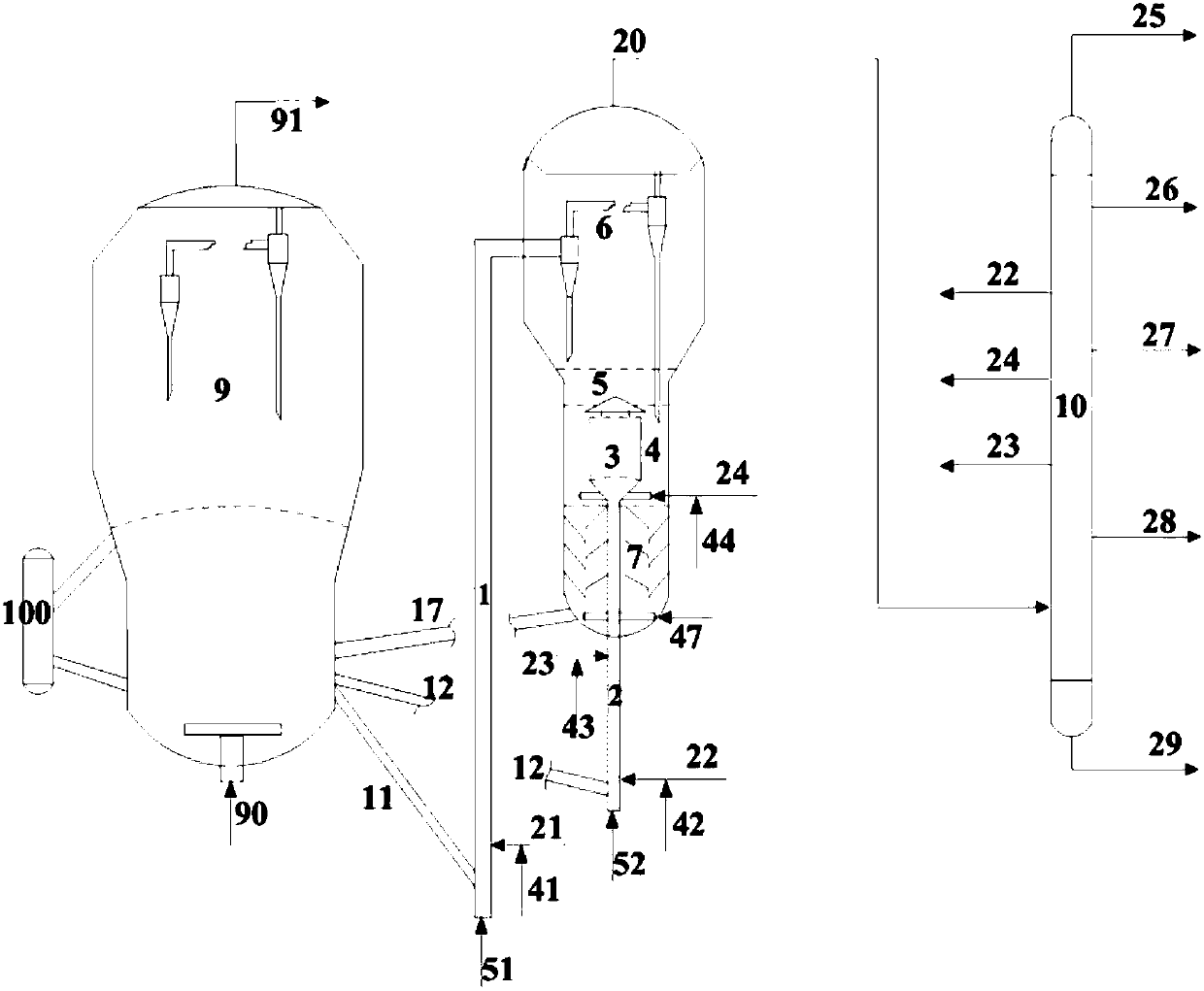

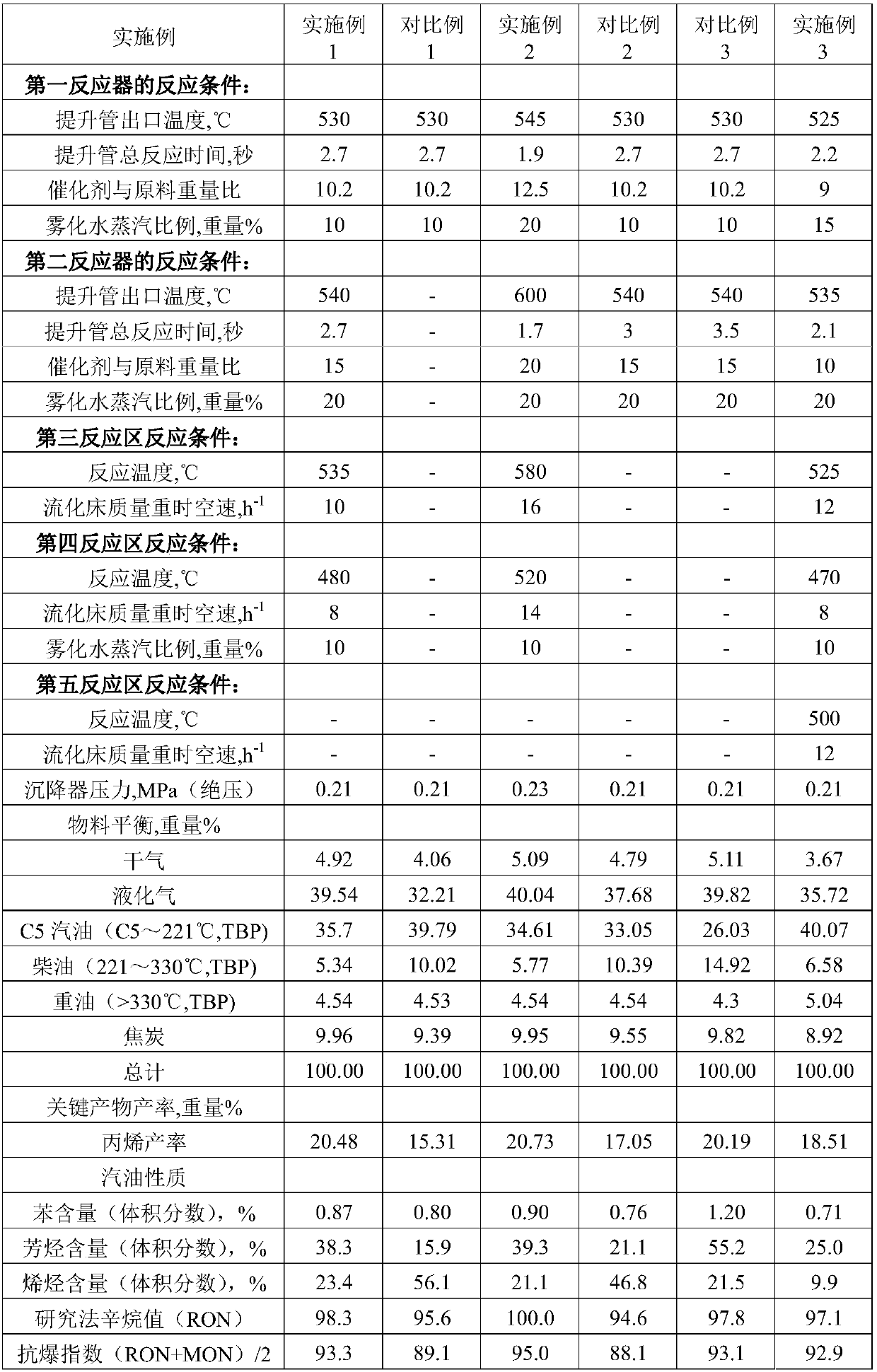

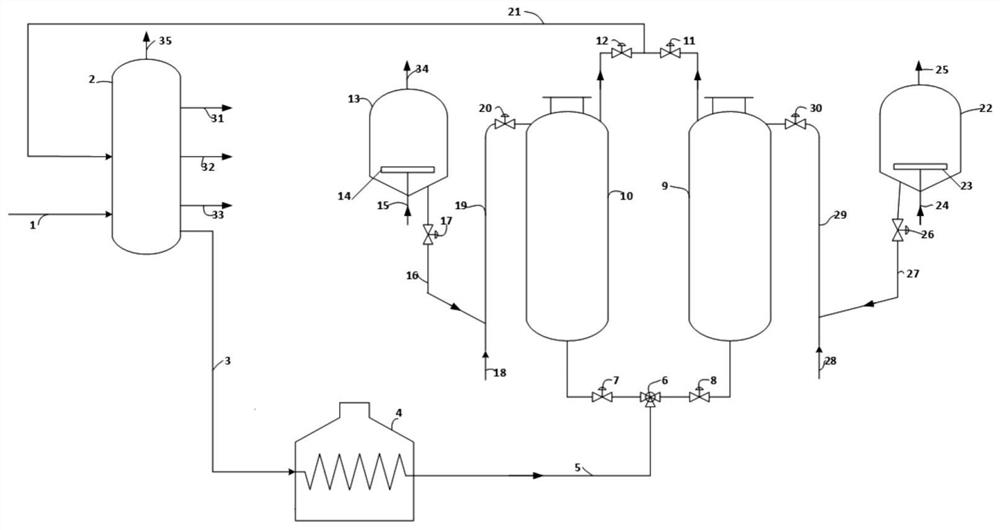

Catalytic conversion method for high-yield production of propylene and improvement of quality of light oil, and system for catalytic conversion method

ActiveCN109722287AMass productionCatalytic crackingHydrocarbon oils treatmentDistillationAutomotive gasoline

The present invention relates to a catalytic conversion method for high-yield production of propylene and improvement of the quality of light oil, and a system for the catalytic conversion method. Thecatalytic conversion method comprises: carrying out a first catalytic reaction on a heavy hydrocarbon oil raw material in a first reactor; injecting the light distillate component having a distillation range of 8-88 DEG C into a second reactor, carrying out a second light distillate catalytic reaction, injecting the heavy distillate component having a distillation range of 145-253 DEG C into a section reactor from the downstream of the light distillate component, and carrying out a second heavy distillate catalytic reaction; introducing a second reaction mixture into a third reactor, and continuously carrying out a third catalytic reaction; injecting the medium distillate component having a distillation range of 41-190 DEG C into a fourth reactor, and carrying out a fourth catalytic reaction; and introducing the first product, the third product and the fourth product into a product separation device, and carrying out product separation. With the method of the present invention, a large amount of propylene can be produced, and the gasoline component having high octane number and meeting the GB17930-2013 automotive gasoline hydrocarbon composition index requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

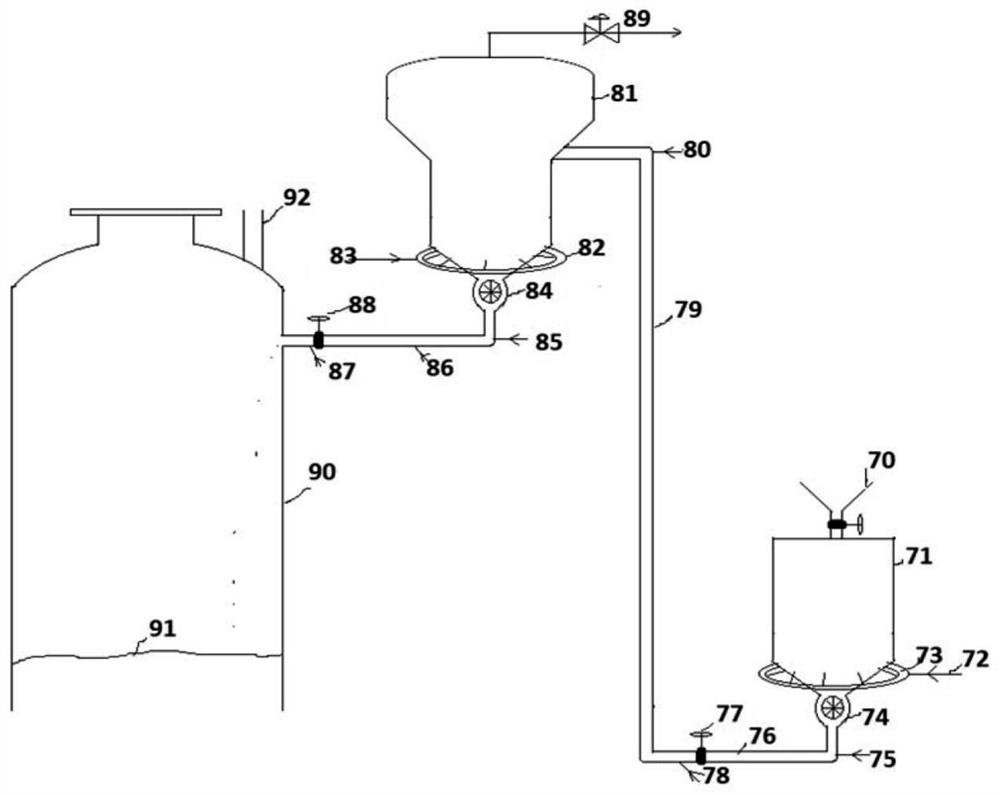

Method and apparatus for co-converting waste plastic in delayed coker unit

The present invention relates to a process for converting waste plastic together with a petroleum residuum feedstock in a delayed coker unit employed in a refinery. It is an object of the process of the present invention to convert any type of waste plastic (including polystyrene, polypropylene, polyethylene, etc., including metal-added multilayer plastic) with petroleum residuum material from crude oil refining (e.g., reduced crude oil, vacuum residuum, etc.). Value-added light distillate products, such as automotive gasoline, LPG, intermediate distillates, and the like, are produced during co-conversion in the process of the invention and are recovered and treated together with thermal cracking products of hydrocarbon residuum. When co-conversion is carried out in the process of the invention, residual metals in the metal-added plastic will deposit in the solid petroleum coke.

Owner:INDIAN OIL CORPORATION

Water injection to increase hydrogen production by on-board reforming of fuel for automotive internal combustion engines

The performance of an automotive gasoline fueled spark-ignited internal combustion engine (ICE) optionally operated with a dedicated exhaust gas recycle system is enhanced by reforming the fuel in the presence of injected water to increase the yield of hydrogen which permits higher compression ratios and suppresses engine knock associated with pre-ignition of the fuel. Reforming can occur (a) in the cylinder with the reaction of a fuel-rich mixture and steam from the water injected into the intake manifold of one or more dedicated exhaust gas recirculation cylinders; (b) in a catalytic reformer located upstream of the engine; (c) in a catalytic reformer located downstream of the engine that receives fuel and the exhaust gas stream from the dedicated exhaust gas recirculation cylinder(s), and returns cooled reformate to the intake manifold; and (d) in a catalytic reformer that receives fuel and the exhaust gas stream from the engine exhaust gas manifold, and delivers reformate to the intake manifold.

Owner:SAUDI ARABIAN OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com