Superposition oil hydrogenation device and method capable of producing isooctane

A technology of hydrogenation unit and superimposed oil, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment. It can solve the problems of excessive olefin content in ethanol gasoline, achieve high octane number, low saturated vapor pressure, and save investment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

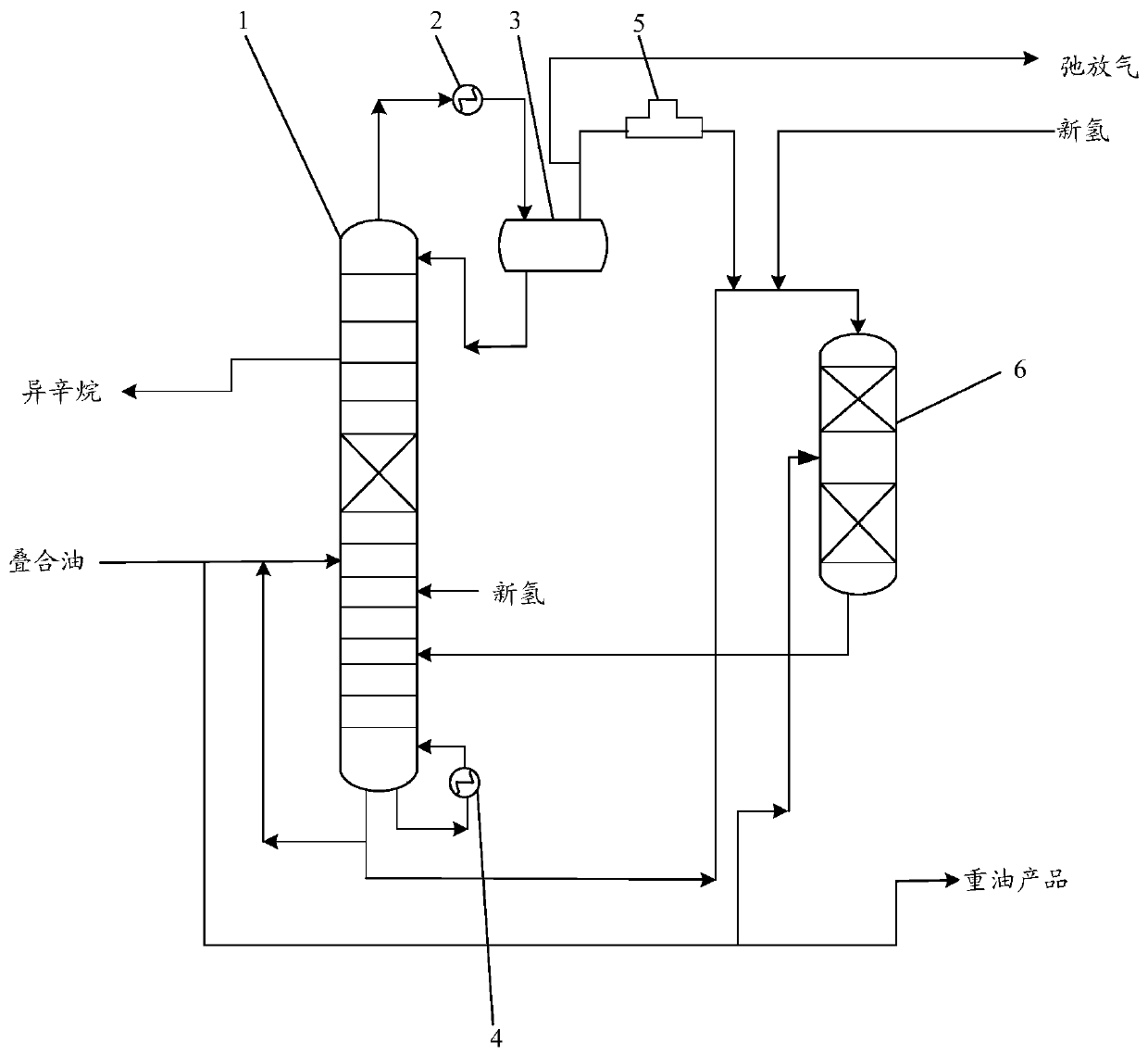

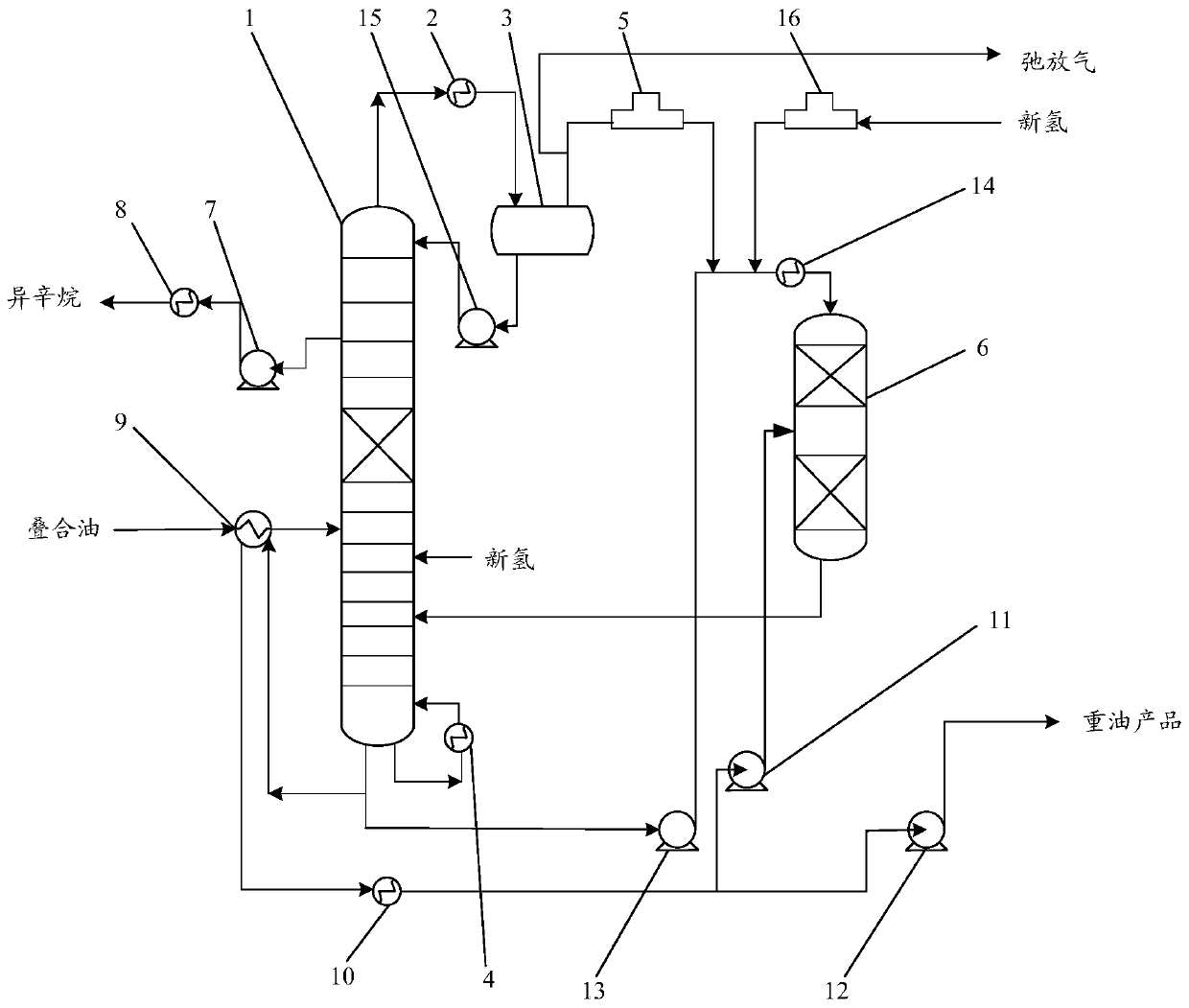

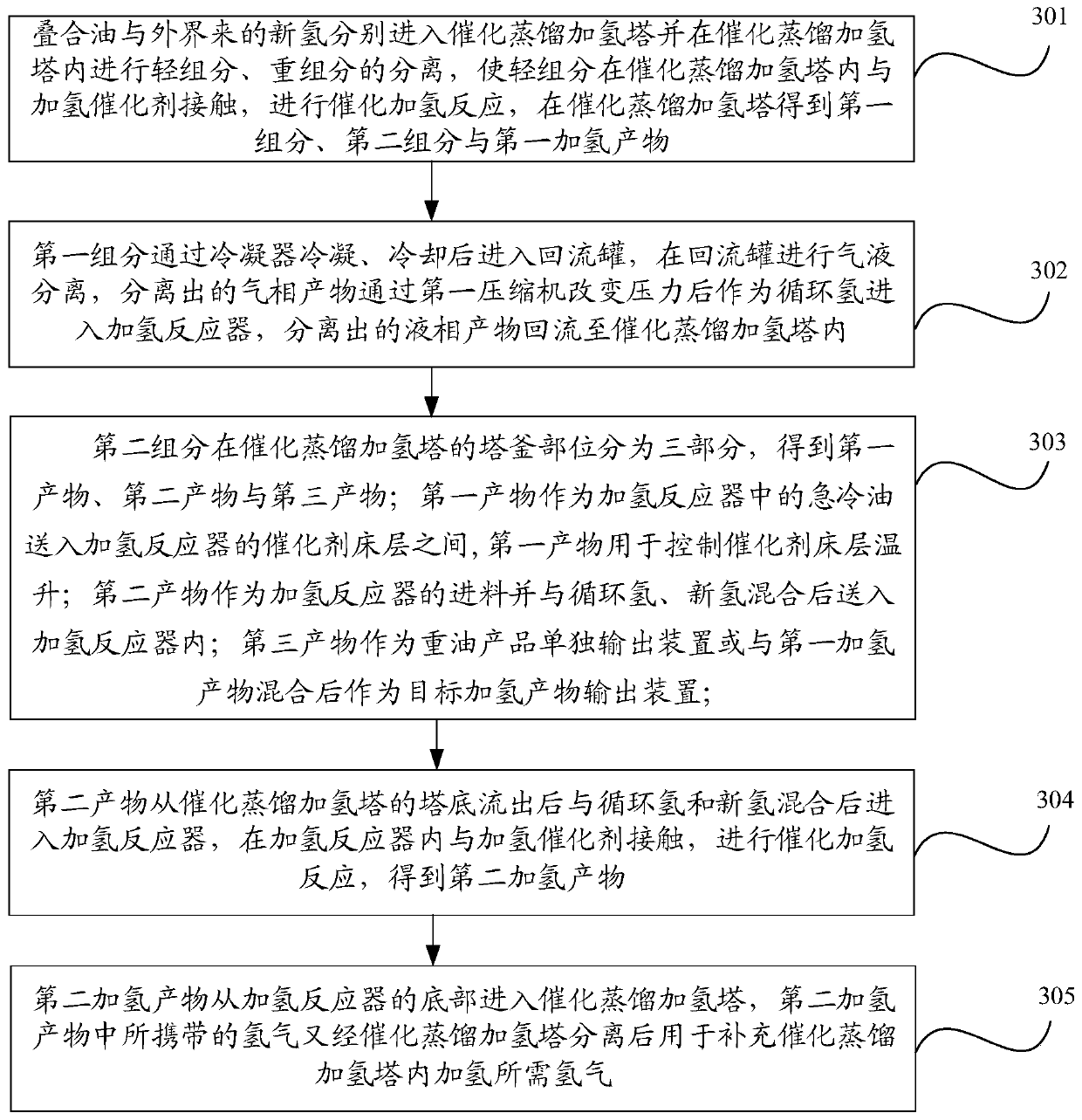

Method used

Image

Examples

Embodiment 1

[0127] The composition of superimposed oil produced by oligomerization of isobutene in a refinery is shown in Table 3. The superimposed oil flow rate is 10.0 tons / hour, and the annual processing capacity is 84,000 tons. The sulfur content in the composite oil is 40mg / kg.

[0128] Table 3 Composite oil composition

[0129]

[0130] In order to produce gasoline blending components that meet the requirements of the olefin volume fraction ≤ 15% as required by the automotive gasoline standard (GB 17930-2016), the superimposed oil is treated with the hydrogenation unit provided in the embodiment of the application, The main operating conditions are shown in Table 4.

[0131] Table 4 Main Equipment Operating Conditions

[0132]

[0133]

[0134] In catalytic distillation hydrogenation tower 1, C 8 Olefins are hydrogenated to C 8 The single pass conversion rate of alkane is 99%; In hydrogenation reactor 6, C 12 Olefins are hydrogenated to C 12 The one-pass conversion ra...

Embodiment 2

[0140] The hydrogenation reactor feed rate is 3000kg / h, and other conditions are with embodiment 1. After hydrogenation, the flow rate and composition of the resulting mixture of isooctane and heavy oil are shown in Table 6.

[0141] Table 6 Composition and flow rate of mixture of isooctane and heavy oil

[0142]

[0143]It can be seen from Table 6 that the olefin mass content of the produced isooctane-heavy oil mixture is 2.88%, and the liquid standard volume content is 2.72%, which are 1.30 percentage points and 1.20 percentage points lower than those of Example 1, respectively. When the feed flow rate of the reactor and the quench oil flow rate increase, that is, when the material circulation volume between the catalytic distillation hydrogenation tower 1 and the hydrogenation reactor 6 increases, the olefin content in the mixture will decrease.

Embodiment 3

[0145] The produced isooctane was taken out of the device as a product, and other conditions were the same as in Example 2.

[0146] After hydrogenation, the content of 2,4,4-trimethylpentane in the produced isooctane is 77.0% (mass), and this part of isooctane is taken out of the device separately as a product; the composition and flow of the produced heavy oil are shown in Table 7. As can be seen from Table 7, C in the heavy oil product 12 Olefin, C 16 The volume fractions of olefins are 19.40% and 0.75% respectively, the overall fraction is 20.15%, and the liquid standard volume flow rate is 1.34m 3 / h, its volume flow is very small, only accounting for 134.00m of the total raw gasoline in the gasoline pool of the refinery 3 1.0% of / h. When transferred into the gasoline blending pool of the plant, the total olefin volume content in the gasoline pool increased from 14.12% to 14.18%, and the increase was very small. The olefin volume fraction after blending met the index...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com