Method for deeply desulfurizing methyl tertiary butyl ether

A technology of methyl tert-butyl ether and sulfur methyl tert-butyl ether, which is applied in the field of deep desulfurization of sulfur-containing methyl tert-butyl ether, can solve the problems of increased energy consumption and difficulty in stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

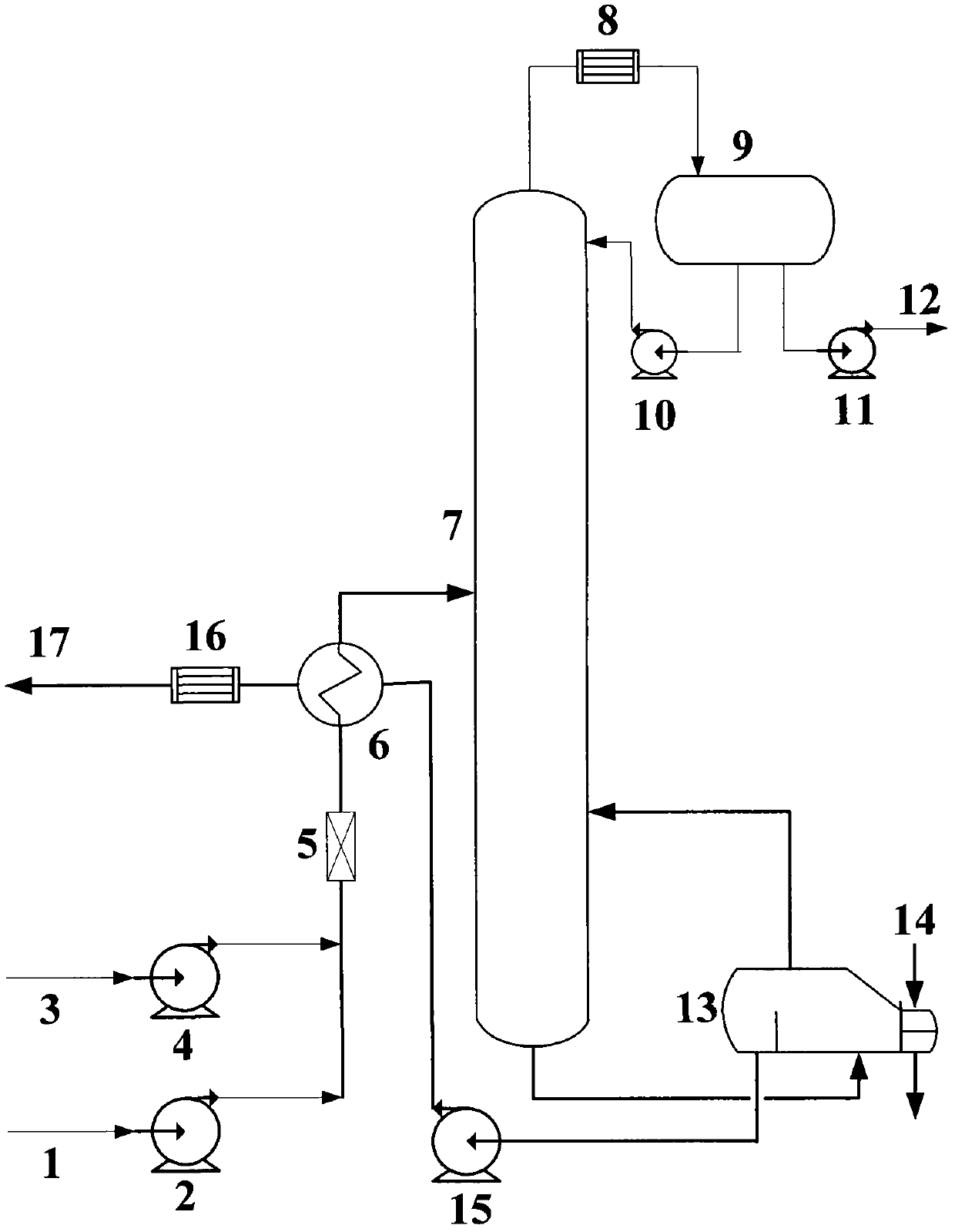

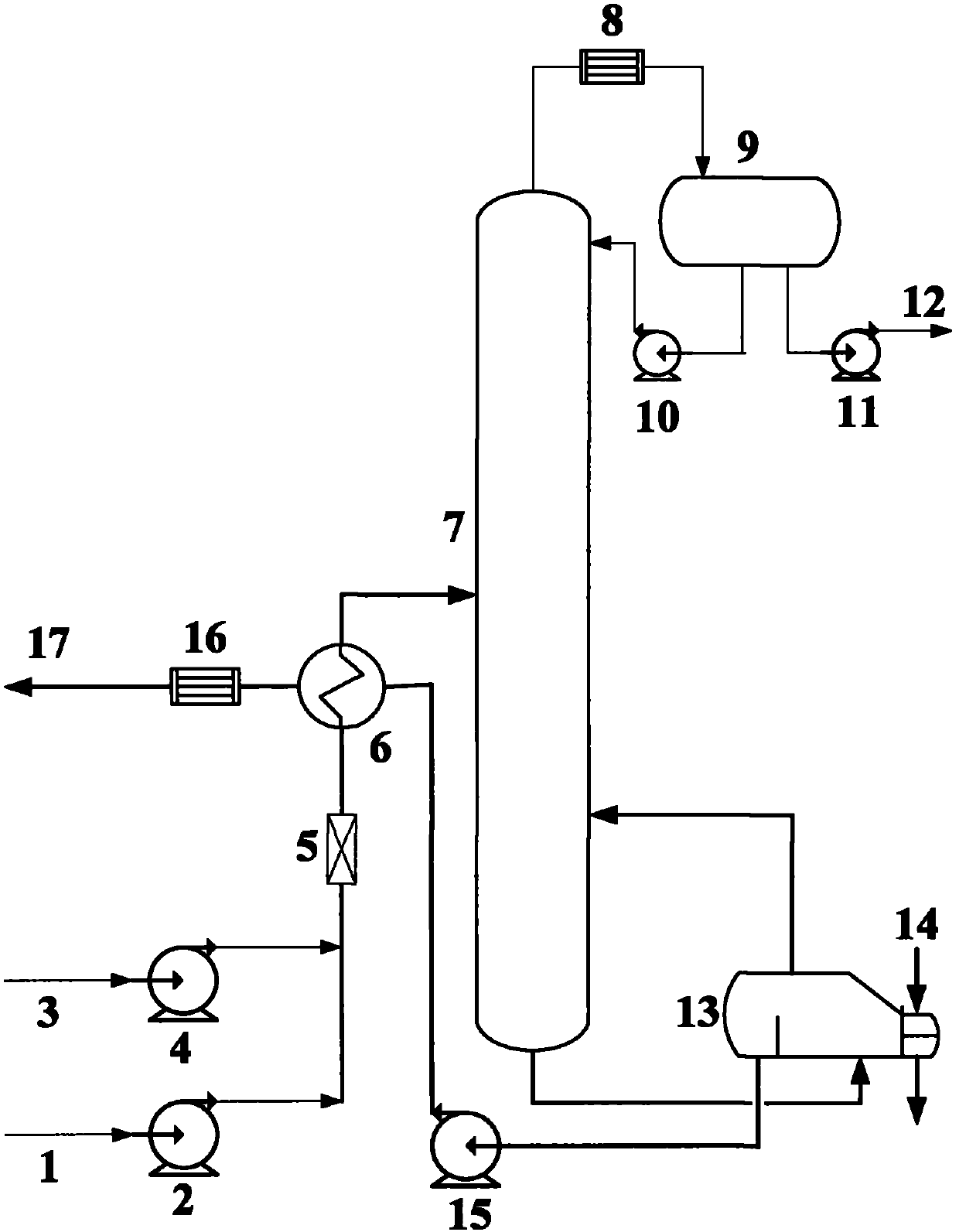

Image

Examples

Embodiment 1

[0025] Test in 500ml small-scale rectification device, raw material: 95wt% methyl tert-butyl ether (sulfur content 864 μ g·g -1 ) and 5wt% reformed gasoline (sulfur content 0μg·g -1 ), the operating conditions of the rectifying tower are: the pressure at the bottom of the tower is 0.025MPa, the pressure at the top of the tower is 0.02MPa, the temperature at the bottom of the tower is 72°C, the temperature at the top of the tower is 55°C, the number of theoretical plates is 8, and the reflux ratio is 2. The total sulfur content of methyl tert-butyl ether sulfur after rectification is 2 μg·g -1 .

Embodiment 2

[0027] Test in 500ml small-scale rectification device, raw material: 95wt% methyl tert-butyl ether (sulfur content 864 μ g·g -1 ) and 5wt% reformed gasoline (sulfur content 0μg·g -1 ), the operating conditions of the rectifying tower are: the pressure at the bottom of the tower is 0.025MPa, the pressure at the top of the tower is 0.02MPa, the temperature at the bottom of the tower is 72°C, the temperature at the top is 55°C, the number of theoretical plates is 8, and the reflux ratio is 0.5. The total sulfur content of methyl tert-butyl ether sulfur after rectification is 9μg·g -1 .

Embodiment 3

[0029] Test in 500ml small-scale rectification device, raw material: 97wt% methyl tert-butyl ether (sulfur content 864 μ g·g -1 ) and 3wt% straight-run gasoline after hydrodesulfurization at 60°C to 90°C (sulfur content 2μg·g -1 ), the operating conditions of the rectifying tower are: the pressure at the bottom of the tower is 0.025MPa, the pressure at the top of the tower is 0.02MPa, the temperature at the bottom of the tower is 72°C, the temperature at the top is 54°C, the number of theoretical plates is 8, and the reflux ratio is 2. The total sulfur content of methyl tert-butyl ether sulfur after rectification is 3 μg·g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com