Method and apparatus for co-converting waste plastic in delayed coker unit

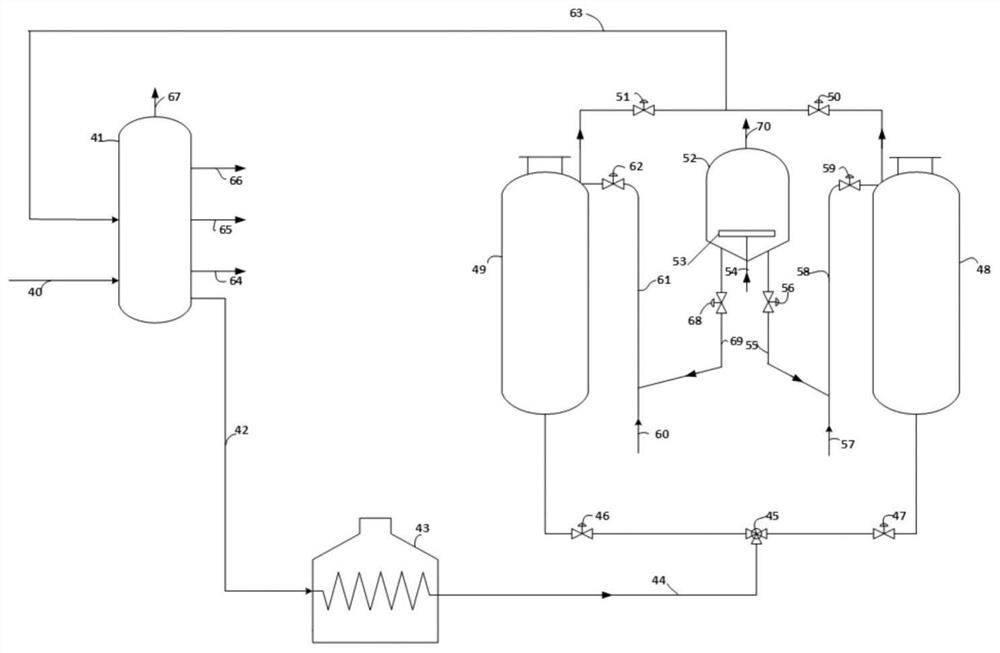

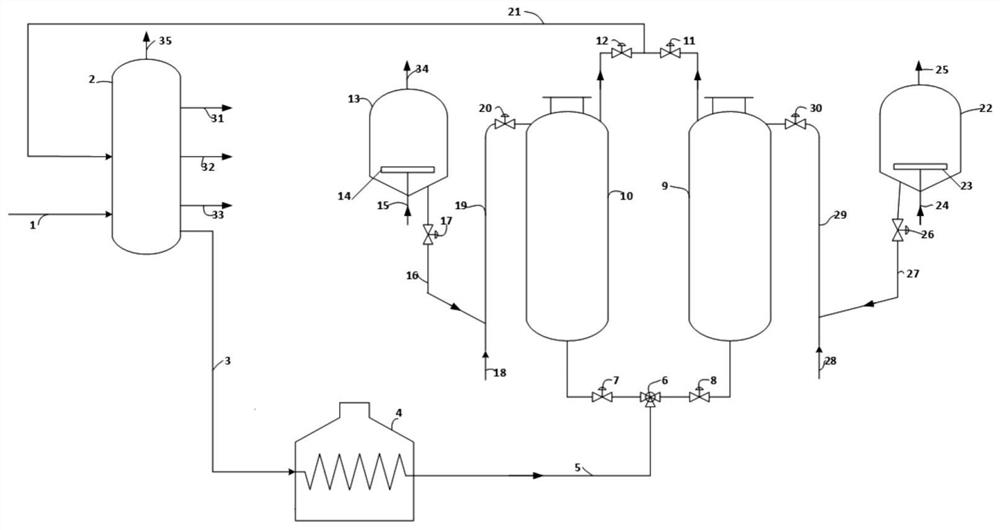

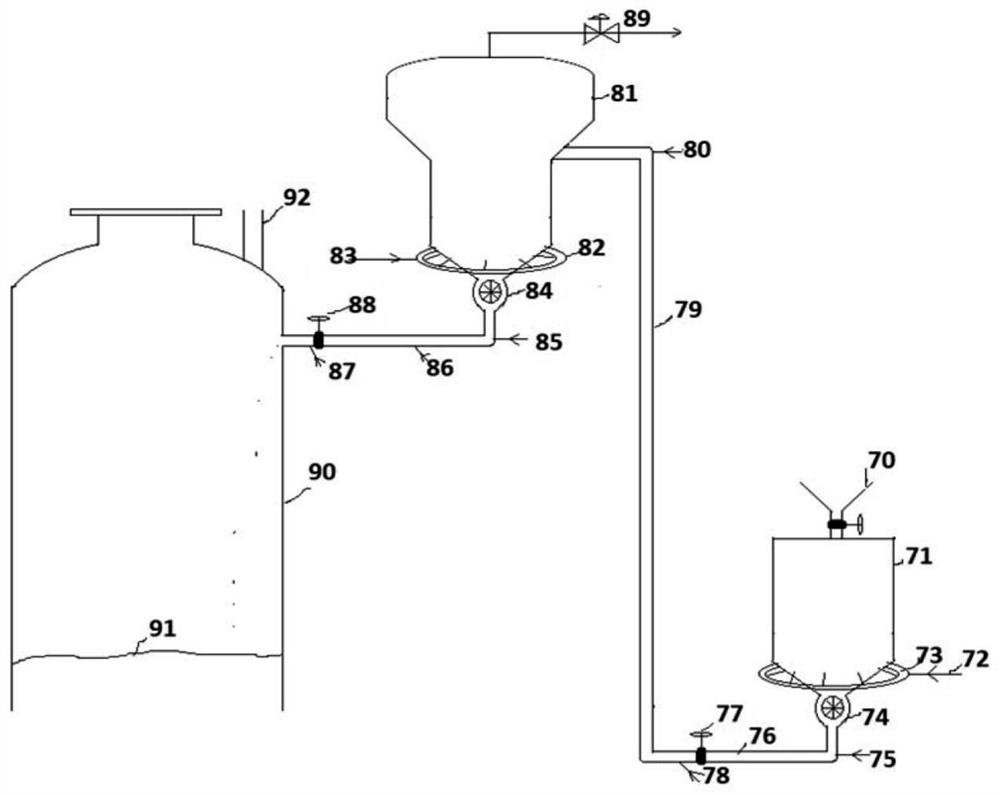

A technology for the conversion of waste plastics and waste plastics. It is used in coking carbonaceous materials, plastic recycling, and non-catalytic thermal cracking. It can solve problems such as density difference, furnace tube blockage and coking.

Active Publication Date: 2021-03-23

INDIAN OIL CORPORATION

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Also, in schemes where the polymer is melted and mixed with the feedstock, there can be problems with high viscosity and poor density of the polymer melt compared to the hydrocarbon feedstock

This change in the rheological properties of the hydrocarbon feedstock and polymer melt can cause changes in the flow patterns of both inside the furnace tubes of the delayed coker and can cause plugging and coking problems in the furnace tubes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0103] The method of the invention is illustrated by the following non-limiting examples.

[0104] Vacuum residue feedstocks were arranged from petroleum refineries and characterized. The properties of the vacuum residue feedstock are provided in Table-1.

[0105] Table-1: Properties of Vacuum Residue Feedstock

[0106]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to a process for converting waste plastic together with a petroleum residuum feedstock in a delayed coker unit employed in a refinery. It is an object of the process of the present invention to convert any type of waste plastic (including polystyrene, polypropylene, polyethylene, etc., including metal-added multilayer plastic) with petroleum residuum material from crude oil refining (e.g., reduced crude oil, vacuum residuum, etc.). Value-added light distillate products, such as automotive gasoline, LPG, intermediate distillates, and the like, are produced during co-conversion in the process of the invention and are recovered and treated together with thermal cracking products of hydrocarbon residuum. When co-conversion is carried out in the process of the invention, residual metals in the metal-added plastic will deposit in the solid petroleum coke.

Description

technical field [0001] The present invention relates to a process for converting waste plastics together with a petroleum residue feedstock in a Delayed Coker unit employed in a refinery. Background technique [0002] The problem of waste plastic disposal is already a serious problem worldwide and in India in particular, where a staggering 6 million tons of waste plastic are generated every year. Using disposal methods such as landfills suffers from issues such as groundwater pollution, land use patterns, and the incineration of plastics leads to air pollution, which affects the health of plants and animals. In particular, there are no effective recycling or disposal options for metal-containing polyethylene and polypropylene multilayer plastic films. With increased public awareness about cleaning and waste separation in public places, it is now becoming more feasible to collect and separate waste plastics from the rest of the waste material. It has also been observed that...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G1/00C10L3/00C10G9/00

CPCC10G1/00C10L3/00C10G9/00C10B53/07C10B55/00C10B55/02C10G1/002C10G1/10C10G2300/1003C10G2300/202C10G2300/206C10G2300/308C10G2300/4006C10G2300/4012C10G2400/06C10G2400/26

Inventor P.R.普拉德普T.H.V.D.普拉萨德S.A.迪克西特P.蒙达尔V.K.科蒂亚思S.K.达斯A.乔普拉M.萨乌G.S.卡普尔S.S.V.拉玛库马尔S.辛格

Owner INDIAN OIL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com