Flexible current collector for lithium battery and preparation method thereof

A technology of flexible current collectors and lithium batteries, which is applied in the direction of battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of poor electrical conductivity of flexible current collectors, achieve enhanced mechanical processability, ensure uniformity, reduce The effect of small contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

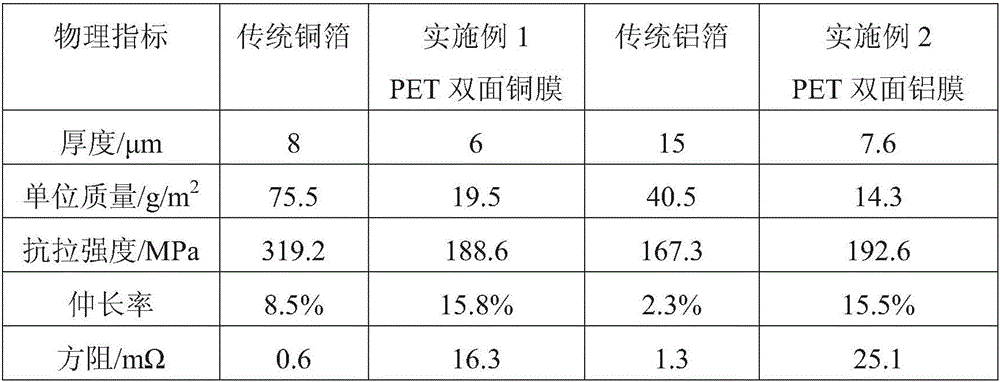

Embodiment 1

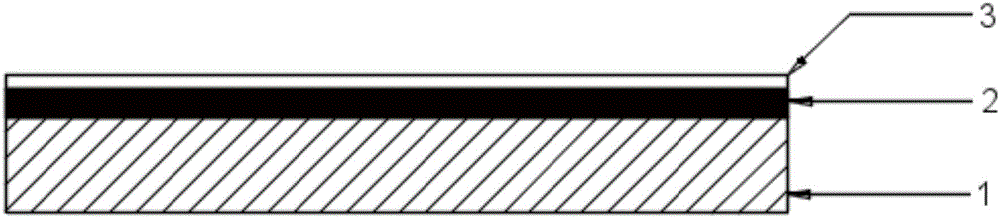

[0049] (1) Select a polyethylene terephthalate (PET) film with a thickness of 3.8 μm, first spray and clean it with acetone for 3 minutes, then clean it with alcohol in an ultrasonic water bath for 10 minutes, and then pass ultraviolet light on it. The surface of the film is cleaned and activated;

[0050] (2) Put the cleaned and activated PET film and industrial-grade pure copper substrate into the roll-to-roll vacuum evaporation equipment, debug the program, and prepare for evaporation; set the evaporation vacuum environment and process parameters, and vacuum the vacuum device to 1×10 -4 When the Pa is below, turn on the vacuum coating, set the voltage to 380V, the current to 50A, and the coating rate to ~60cm / min; execute the program to conduct evaporation, and the single layer thickness of the copper coating reaches 1μm;

[0051] (3) the film after copper plating is placed on the coating machine again, and the coating film rate is set to be ~ 2m / min, and the feed rate is ...

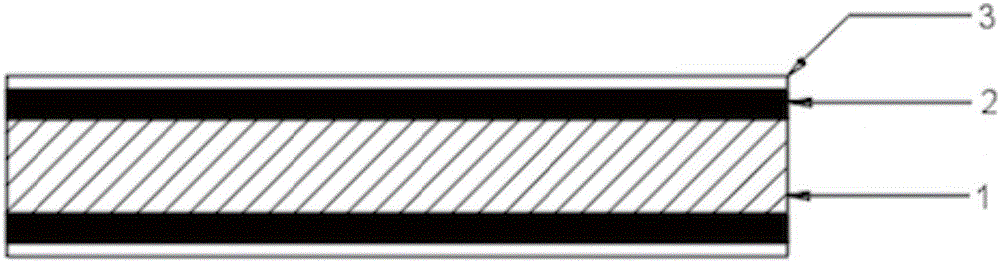

Embodiment 2

[0054] (1) Select a PET film with a thickness of 3.8 μm, spray it with acetone for 3 minutes, then wash it with alcohol in an ultrasonic water bath for 10 minutes, and then use ultraviolet light to clean and activate the surface of the film;

[0055] (2) Put the cleaned and activated PET film and industrial-grade pure aluminum substrate into the roll-to-roll vacuum evaporation equipment, debug the program, and prepare for evaporation; set the evaporation vacuum environment and process parameters, and vacuum the vacuum device to 1×10 -4 When the Pa is below, turn on the vacuum coating, set the voltage to 380V, the current to 50A, and the coating rate to ~100cm / min; execute the program to conduct evaporation, and the thickness of the single layer of copper coating reaches 1.8μm;

[0056] (3) the film after copper plating is placed on the coating machine again, and the coating film rate is set to be ~ 2m / min, and the feed rate is 5g / min, and the carbon nanotube (CNT ) / N-methylpy...

Embodiment 3

[0069] (1) Select a polypropylene (PP) film with a thickness of 1 μm, first spray and clean it with acetone for ~3 minutes, then clean it with alcohol in an ultrasonic water bath for ~10 minutes, and then clean and activate the surface of the film by ultraviolet light;

[0070] (2) Place the cleaned and activated PP film and industrial-grade pure copper substrate into the roll-to-roll vacuum evaporation equipment, debug the program, and prepare for evaporation; set the evaporation vacuum environment and process parameters, and vacuum the vacuum device to 1×10 -4 When the Pa is below, turn on the vacuum coating, set the voltage to 380V, the current to 50A, and the coating rate to 120cm / min; execute the program to conduct evaporation, and the single layer thickness of the copper coating reaches 0.1μm;

[0071] (3) the film after copper plating is placed on the coating machine again, and the coating film rate is set to be ~ 2m / min, and the feed rate is 5g / min, and the graphene / N-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com