Vacuum impregnation nano hole sealing agent with high permeability as well as preparation method and application thereof

A technology of vacuum impregnation and high permeability, applied in metal material coating process, melt spraying, coating and other directions, can solve the problems of poor permeability, low temperature resistance, low wear resistance, etc., achieve low viscosity, good resistance High temperature characteristics, the effect of good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

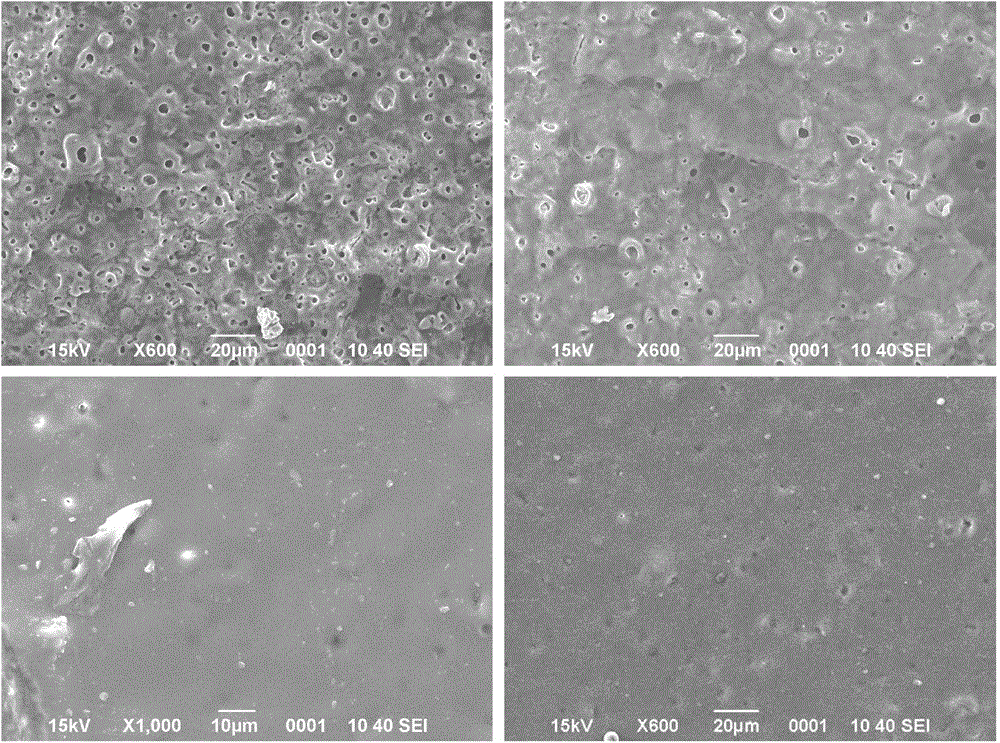

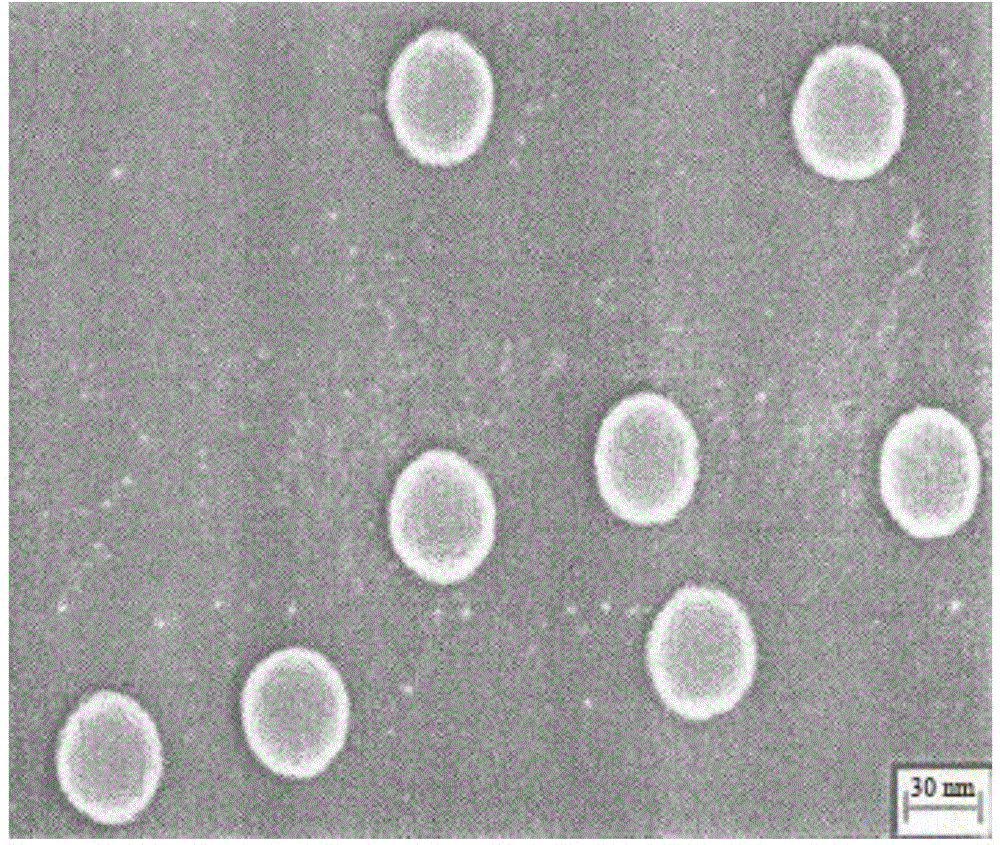

Problems solved by technology

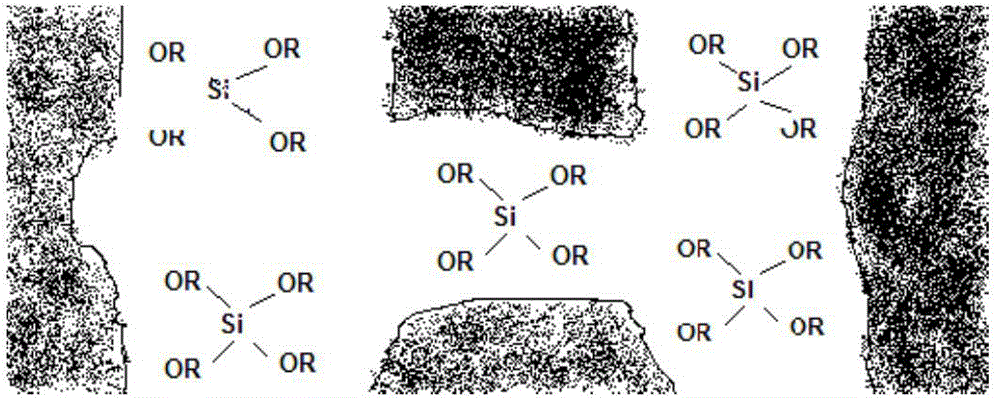

Method used

Image

Examples

Embodiment 1

[0038] The vacuum-impregnated nano-sealing agent with high permeability described in this example is made of the following mass ratio raw materials:

[0039] Silicon carbide: silicon dioxide: auxiliary agent: isopropanol = 1%: 5%: 0.1%: 65%, wherein the mass ratio of the auxiliary agent is polyurethane: tetrafluoropropanol = 1:1.

[0040] The preparation process of the vacuum impregnation nano-sealing agent described in this embodiment includes the following steps:

[0041] (1) According to the mass ratio, it is silicon carbide: silicon dioxide: polyurethane: tetrafluoropropanol: isopropanol=1%: 5%: 0.05%: 0.05%: 65% and weigh the quality of each substance;

[0042] (2) Adjust the speed of the disperser to 300r / m, first slowly add silicon carbide and silicon dioxide, and then add an appropriate amount of isopropanol, so as not to make the slurry too viscous and inconvenient to use, add tetrafluoropropanol, Finally, depending on the viscosity of the overall slurry, add polyure...

Embodiment 2

[0045] The vacuum-impregnated nano-sealing agent with high permeability described in this example is made of the following mass ratio raw materials:

[0046] Silicon carbide: silicon dioxide: auxiliary agent: isopropanol = 3.45%: 11.25%: 0.3%: 85%, wherein the mass ratio of the auxiliary agent is polyurethane: dipropylene glycol butyl ether = 1:1.

[0047] The preparation process of the vacuum impregnation nano-sealing agent described in this embodiment includes the following steps:

[0048] (1) According to the mass proportion, it is silicon carbide: silicon dioxide: polyurethane: dipropylene glycol butyl ether: isopropanol=3.45%: 11.25%: 0.15%: 0.15%: 85%, respectively weigh the quality of each substance;

[0049] (2) Adjust the speed of the disperser to 400r / m, first slowly add silicon carbide and silicon dioxide, and then add an appropriate amount of isopropanol, so as not to make the slurry too viscous and inconvenient to use, add dipropylene glycol butyl ether, Finally,...

Embodiment 3

[0053] The vacuum-impregnated nano-sealing agent with high permeability described in this example is made of the following mass ratio raw materials:

[0054] Silicon carbide: silicon dioxide: auxiliary agent: tetrafluoropropanol = 5%: 15%: 3%: 95%, wherein the mass ratio of the auxiliary agent is polyurethane: dipropylene glycol methyl ether = 1:1.

[0055] The preparation process of the vacuum impregnation nano-sealing agent described in this embodiment includes the following steps:

[0056] (1) According to the mass proportion, it is silicon carbide: silicon dioxide: polyurethane: dipropylene glycol methyl ether: tetrafluoropropanol=5%: 15%: 1.5%: 1.5%: 95%, respectively weigh the quality of each substance;

[0057] (2) Adjust the speed of the disperser to 500r / m, first slowly add silicon carbide and silicon dioxide, then add an appropriate amount of tetrafluoropropanol, so as not to make the slurry too high and inconvenient to use, add dipropylene glycol methyl ether , and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com