Composite fibre membrane with unidirectional water permeable performance and preparation method thereof

A composite fiber membrane, unidirectional water permeability technology, applied in textiles, papermaking, non-woven fabrics and other directions, can solve problems such as failure to achieve unidirectional water permeability, stability needs to be further improved, and achieve low cost, large specific surface area, The effect of good breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

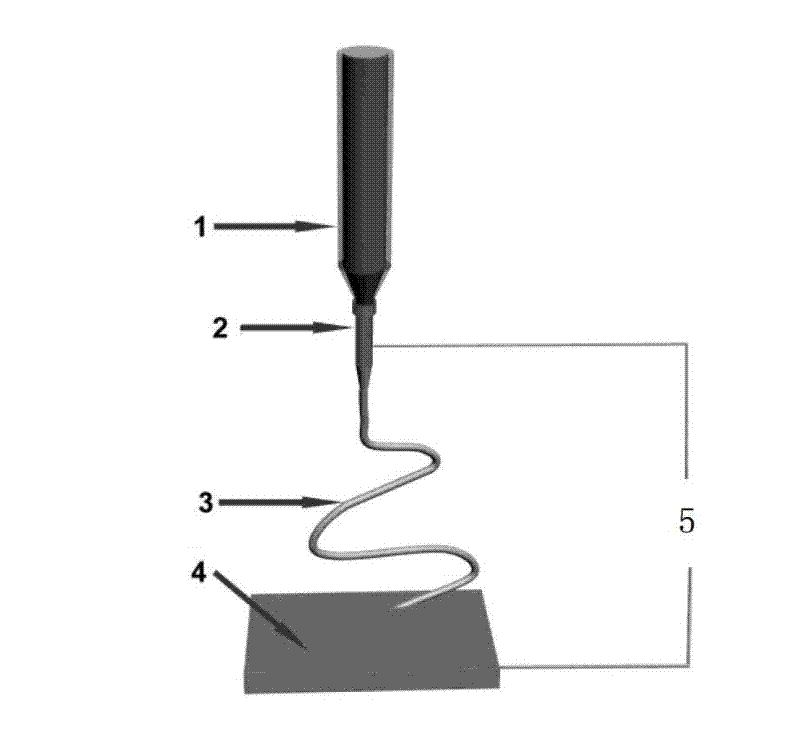

[0028]A preparation method of a composite fiber membrane with unidirectional water permeability proposed by the present invention adopts electrospinning technology, and specifically includes the following steps:

[0029] Step 1. Preparation of spinning solution: Dissolve analytically pure polymer A in solvent A at room temperature at 20-25°C, and stir until polymer A is completely dissolved to obtain an electrospinning solution of polymer A. The resulting solution The mass of polymer A is 10-30%. Dissolve analytically pure polymer B in solvent B at room temperature of 20-25°C, stir well until the polymer is completely dissolved, and obtain an electrospinning solution of polymer B. The obtained solution contains polymer B in a mass fraction of 10~ 35%.

[0030] The polymer A is analytically pure granular or powdered polyvinyl alcohol, cellulose acetate or polyacrylate and the like. Polymer B is analytically pure granular or powdered polyurethane, polystyrene, polymethyl metha...

Embodiment 1

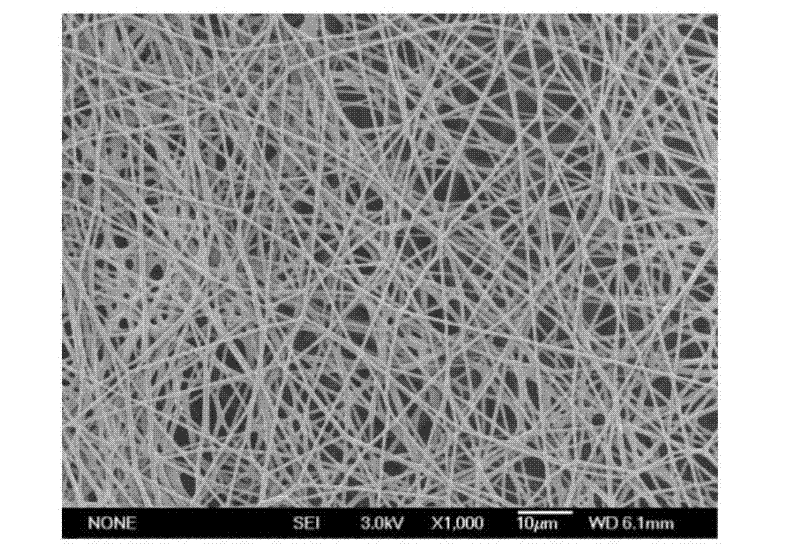

[0038] This implementation proposes a composite fiber membrane with unidirectional water permeability. The fiber membrane is composed of a two-layer structure tightly combined and seamlessly connected with a difference between hydrophilic and hydrophobic. The hydrophilic layer is a nanoscale fiber membrane composed of polyvinyl alcohol. , the fibrous membrane is composed of randomly arranged nano-scale fibers interlaced, showing a typical network shape of non-woven fabric, with a thickness of 25 μm, and the fiber diameter of polymer A in the fiber membrane is 300 nm. The hydrophobic layer is a micron-scale fiber membrane composed of polyurethane. The fiber membrane is composed of randomly arranged micron-scale fibers interlaced, showing a typical network shape of non-woven fabric. The thickness of the fiber membrane is 5 μm. The fiber diameter of B is 1.0 μm. The composite fiber membrane has a hydrophilic / hydrophobic difference, and has a special one-way water permeability. Wa...

Embodiment 2

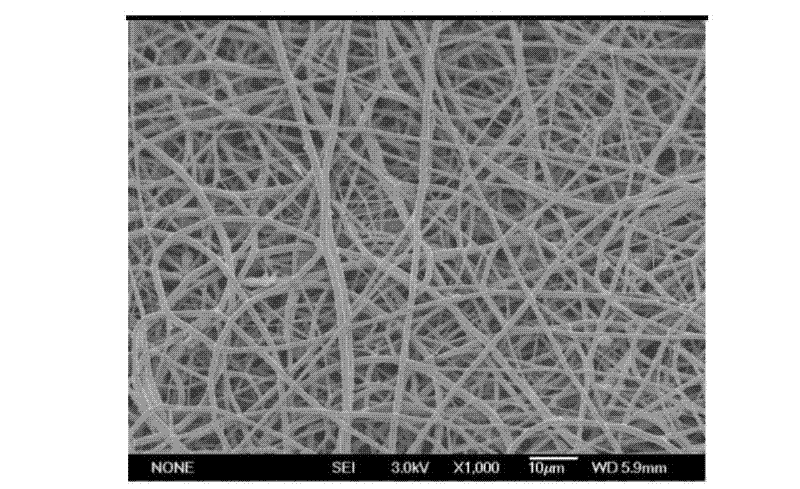

[0045] This embodiment proposes a composite fiber membrane with unidirectional water permeability. The fiber membrane is composed of a two-layer structure tightly combined and seamlessly connected with a difference in hydrophilicity and hydrophobicity. The hydrophilic layer is nano-scale fibers composed of polyvinyl alcohol. Membrane, the fiber membrane is composed of randomly arranged nano-scale fibers interlaced, showing a typical network shape of non-woven fabric, with a thickness of 35 μm, and the fiber diameter of polyvinyl alcohol in the fiber membrane is 800nm. The hydrophobic layer is a micron-scale fiber membrane composed of polyurethane. The fiber membrane is composed of randomly arranged micron-scale fibers interlaced, showing a typical network shape of non-woven fabric. The thickness of the fiber membrane is 5 μm, and the polyurethane in the fiber membrane The fiber diameter is 3.0 μm. The composite fiber membrane has a hydrophilic / hydrophobic difference, and has a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com