Catalytic gasoline alkylation desulfuration method and device

A technology for catalytic cracking gasoline and alkylation desulfurization, which is applied in the petroleum industry, processing hydrocarbon oil, etc., can solve the problems of difficult operation, large temperature gradient, low intermediate temperature, etc. The effect of easing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

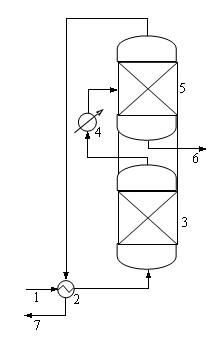

Image

Examples

Embodiment 1

[0026] A catalytic cracking gasoline alkylation desulfurization method, the method steps are as follows:

[0027] a. First fill the alkylation desulfurization catalyst in the alkylation reaction tower, then heat the catalytically cracked gasoline through a heat exchanger at a pressure of 0.2~1.0MPa to 50~110℃, and then increase the temperature at a liquid hourly volume space velocity of 0.5~ 6.0h -1 Introduce into the alkylation reaction tower, and carry out the alkylation reaction under the action of the alkylation desulfurization catalyst to generate alkylated gasoline;

[0028] b. Extract the alkylated gasoline from the top of the alkylation reaction tower, heat it up to 180-185°C through a heat exchanger, and then introduce it into the fractionation tower, where it is fractionated at 175-185°C and cut into low-sulfur light fractions and The sulfur-rich heavy fraction and the low-sulfur light fraction are alkylated desulfurized gasoline, which is extracted from the top of ...

Embodiment 2

[0032] Fill the Hβ molecular sieve alkylation desulfurization catalyst in the alkylation reaction tower, under the reaction pressure of 0.5MPa, the catalytic cracked gasoline with the sulfur content of 164μg / g is charged at a liquid hourly volume space velocity of 0.5h -1 It is input through the raw oil input pipe and sent to the heat exchanger of the alkylation reaction device. After heat exchange, the temperature of the catalytic cracked gasoline is raised to 50°C, and the alkylation reaction is carried out in the reaction tower to generate alkylated gasoline; The alkylated gasoline is extracted from the top of the alkylation reaction tower, enters the heat exchanger, and after heat exchange, it is cut into low-sulfur light fractions at 175~185°C - alkylated desulfurized gasoline and sulfur-rich gasoline The heavy fraction is extracted from the top of the fractionating tower, and the alkylated desulfurized gasoline is extracted from the top of the fractionating tower, and the...

Embodiment 3

[0036] Et 2 O-AlCl 3 It is an alkylation desulfurization catalyst, and catalytically cracked gasoline with a sulfur content of 505 μg / g is used as feedstock oil. According to the method described in Example 2, the reaction temperature is 50 ° C, the reaction pressure is 0.2 MPa, and the liquid hourly volume space velocity is 4.0 h. -1 Under the conditions of alkylation reaction, other steps are the same as steps in Example 2. The sulfur content of alkylated desulfurized gasoline was measured to be 127μg / g, the mass yield was 85.70%, and the desulfurization rate was 74.85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com