Patents

Literature

137results about How to "Moderate operating conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

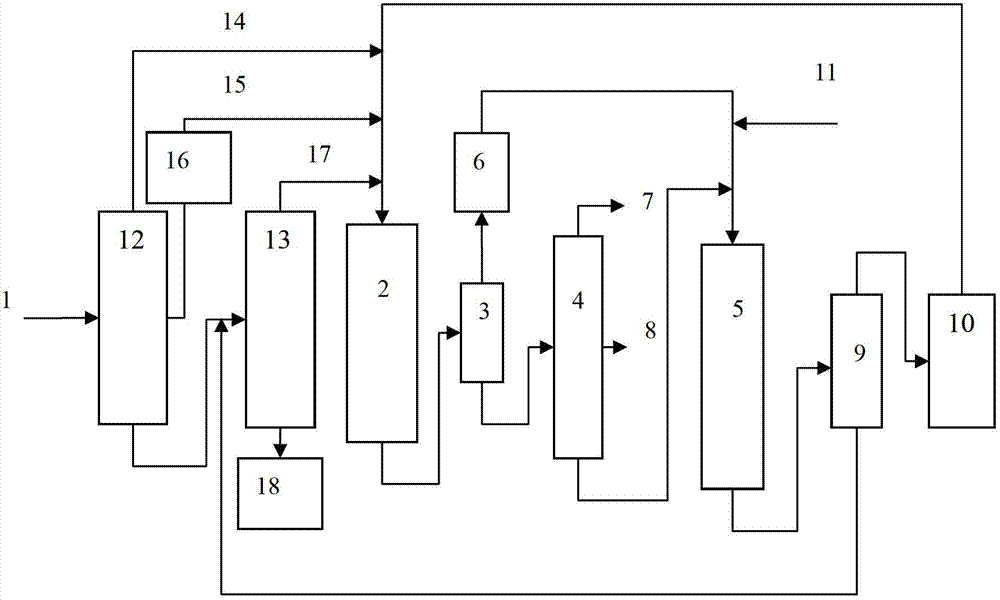

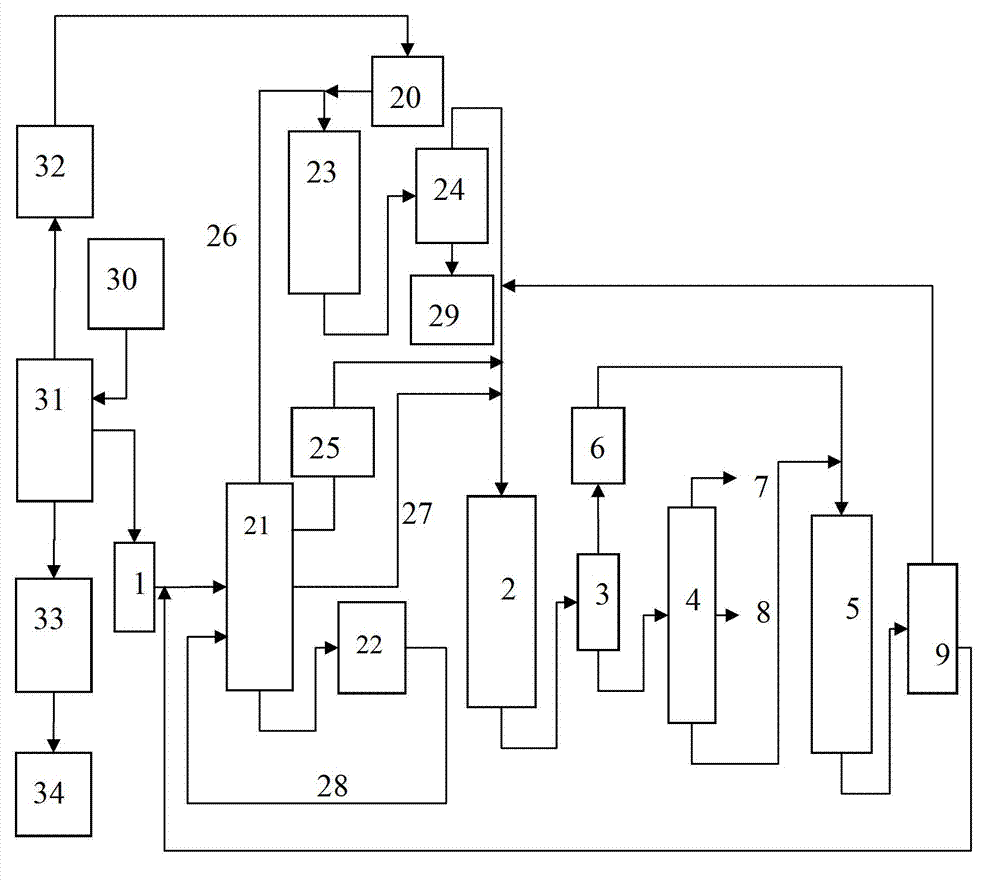

Combined process for processing heavy oil

ActiveCN1844325AEasy to handleExtended service lifeTreatment with hydrotreatment processesKeroseneFuel oil

The invention discloses a group technology for heavy oil upgrading, in which the job steps include: (1) full or moiety of heavy oil individually or mixed with catalytic clarified oil entering solvent deasphalting plant, after the solvent deasphalting treatment, obtaining a deasphalted oil and a degreasing asphalt; (2) the degreasing asphalt obtained by step (1) individually or mixed with another moiety of heavy oil entering coking plant for coking treatment, in which the obtained tar heavy oil returns to solvent deasphalting plant or enters heavy oil hydrotreating plant, or moiety of tar heavy oil returns to solvent deasphalting plant and another moiety of tar heavy oil enters heavy oil hydrotreating plant, catalytic plant or hydrocracking plant; (3) the deasphalted oil obtained by step (1) individually or mixed with vacuum residual oil, non-pressure residual oil, pressure-relief residual oil, catalytic cycle stock and one or more than one heavy oil of tar heavy oil obtained by step (2) entering heavy oil hydrotreating plant for hydrotreatment, after hydrotreatment, obtaining fractions of benzin naphtha, plane kerosene and diesel and hydrogenating heavy oil. The invention can improve the charge-in nature, alleviate the operating condition and prolong the cycle length of the heavy oil hydrotreating plant, which provides better raw oil for downstream plants including catalytic plant.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Modifying method for naphtha and light hydrocarbon aromatization

ActiveCN101747933ALower end pointReduce carbon deposition rateCatalytic naphtha reformingLiquid productHydrogen

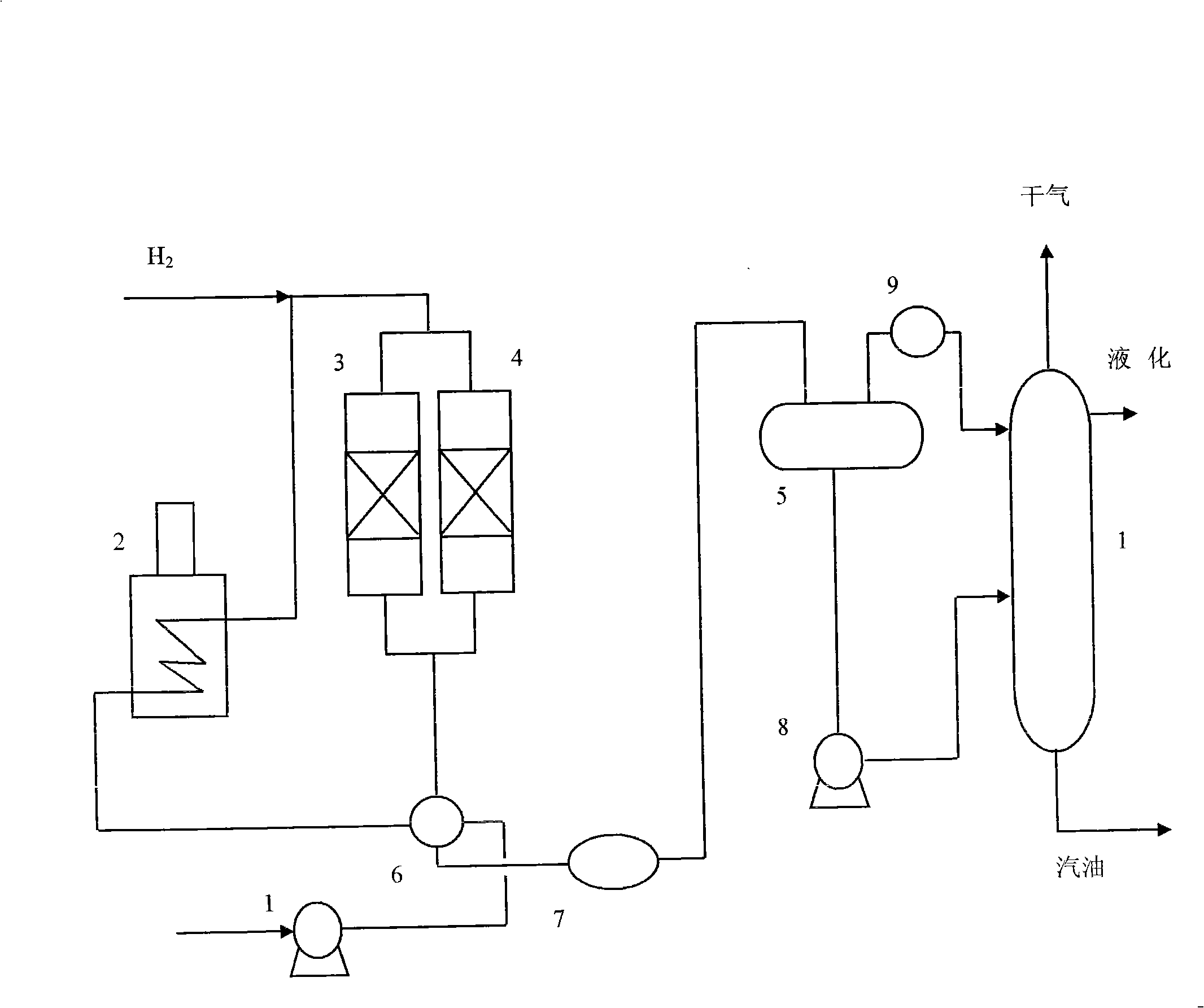

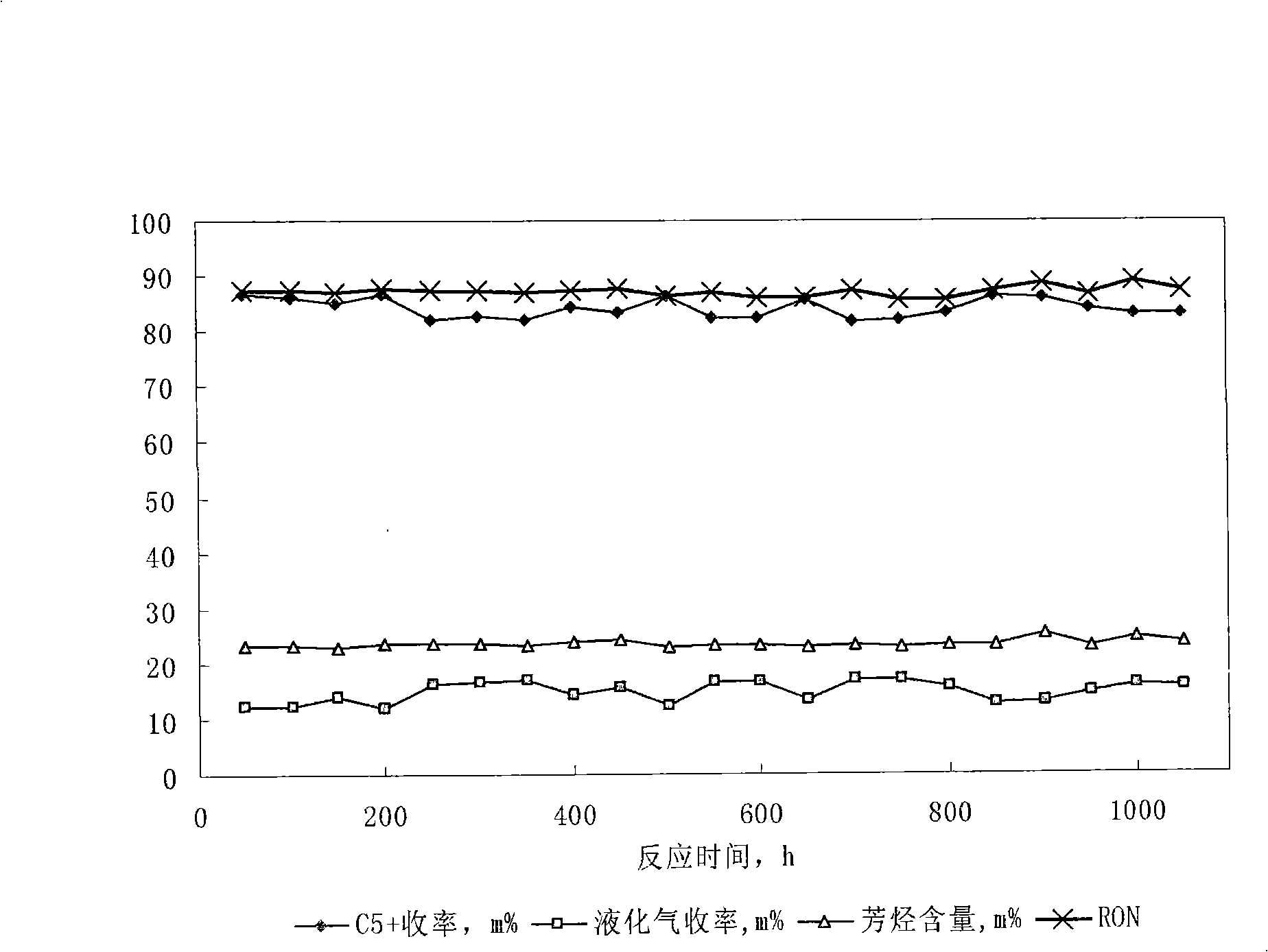

A modifying method for naphtha and light hydrocarbon aromatization comprises: contacting naphtha and C3-C5 light hydrocarbon with aromatization catalyst in the presence of hydrogen-containing gas to carry out aromatization modifying reaction, wherein the reaction temperature is 250-600 DEG C, and the volume ratio of hydrogen to naphtha is 20-400. The method can convert naphtha with low octane value and low-carbon hydrocarbon into gasoline component with high octane value and excellent liquefied gas, the final distilling point of liquid product and the carbon-accumulating speed of catalyst areobviously reduced, and the service life of catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

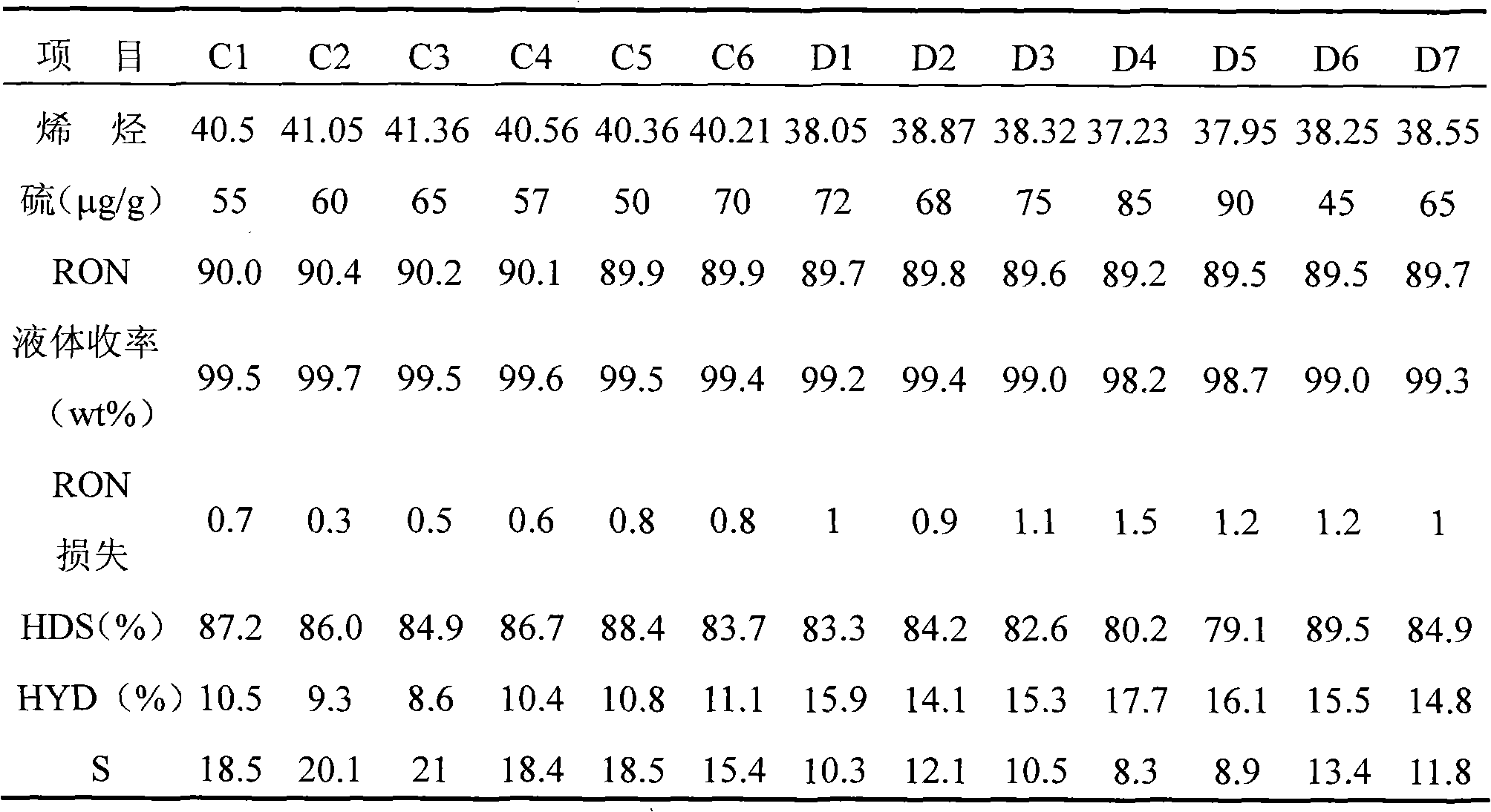

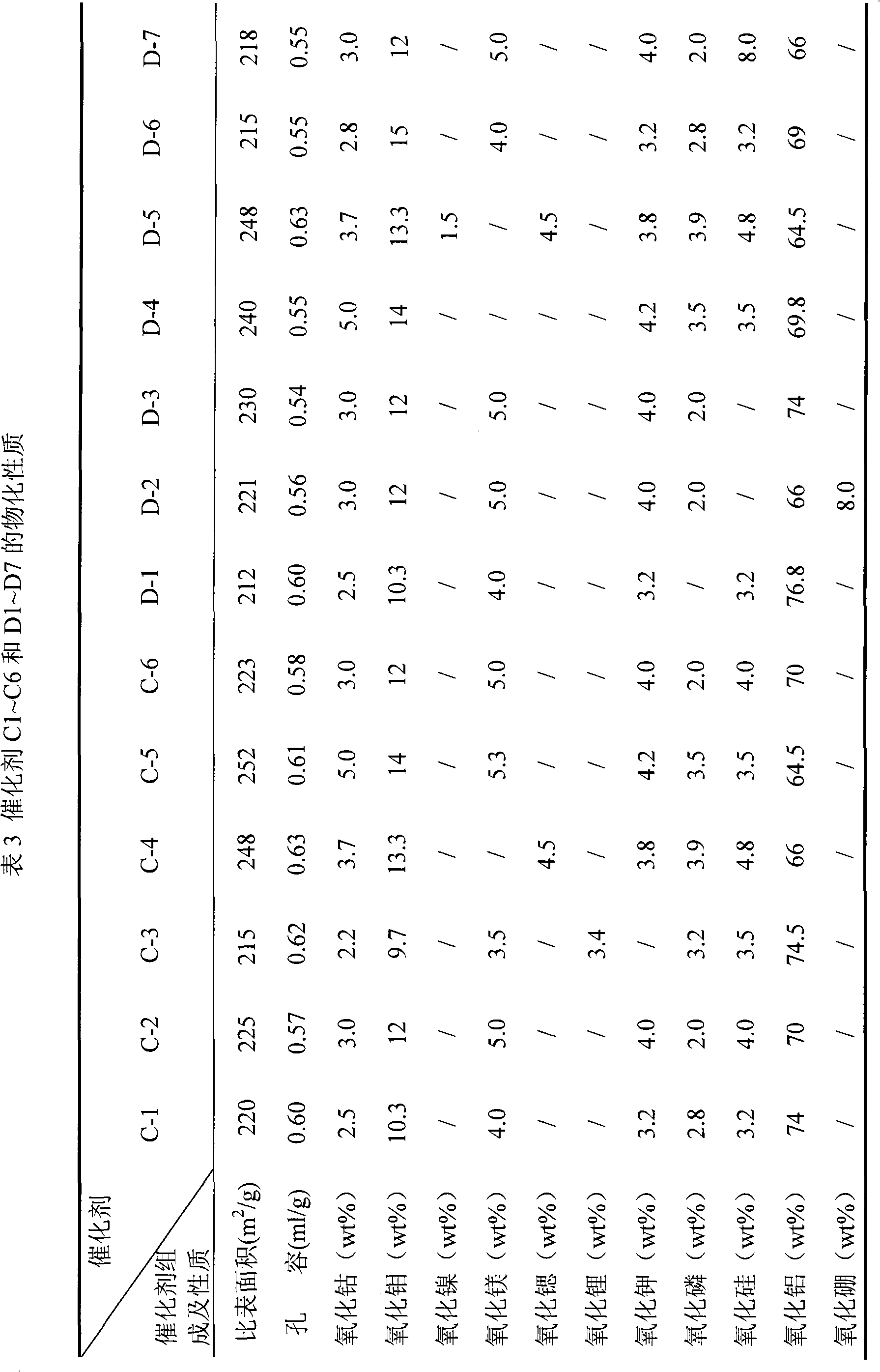

Selective hydrodesulfurization catalyst and preparation method thereof

ActiveCN102335612AReduce acid strengthEnhance the interaction strengthMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAlkaline earth metalHydrodesulfurization

The invention relates to a selective hydrodesulfurization catalyst contains cobalt and molybdenum as active components. The selective hydrodesulfurization catalyst is characterized in that silicon oxide and aluminum oxide are used as carriers of the catalyst; based on the total weight of 100%, the catalyst comprises 2-6wt% of cobalt oxide, 9-15 wt% of molybdenum oxide, 2-8wt% of alkaline earth metal oxide, 2-6wt% of phosphorus oxide, 3-5wt% of alkali metal oxide, 2-6wt% of silicon oxide and 54-80 wt% of aluminum oxide; and the catalyst has the specific surface area of 200-300m<2> / g and the pore volume of 0.5-0.7mL / g. The catalyst has high hydrogenation activity and selectivity, good stability, low research octane number loss and high liquid yield. The catalyst is suitable for selective hydrodesulfrization of low-quality gasoline and is particularly suitable for selective hydrodesulfrization of low-quality FCC (Family Car China) gasoline.

Owner:PETROCHINA CO LTD

Diesel fuel fraction hydrotreating method

ActiveCN1769387AHigh gross airspeedImprove efficiencyTreatment with hydrotreatment processesLiquid productHydrogen

The invention discloses the diesel oil distillate hydrotreating method. The method comprises the following steps: dividing the raw oil into light cut and heavy cut, entering the light cut into the first reaction area to touch the hydrofining catalyst, entering the heavy cut into the second reaction area to touch the hydrofining catalyst, mixing the liquid product of the two reaction areas to prepare the refined distillate oil. The first reaction area uses the hydrogenation catalyst which possesses high desulfurizing activity, and the second reaction area uses hydrogenation catalyst which possesses the high hydrogenation activity. Comparaed with the general diesel oil refined process, the said method can realize the deep hydrogenation and desulfuration. The method possesses the characteristics of simple process flow and easy operation. The said method can be used for various hydrotreating processes containing the diesel oil fraction raw oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

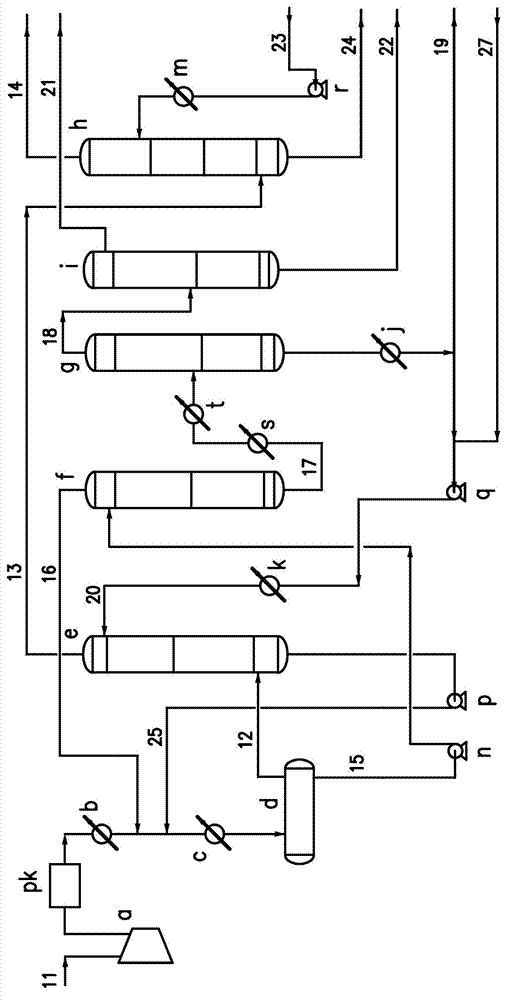

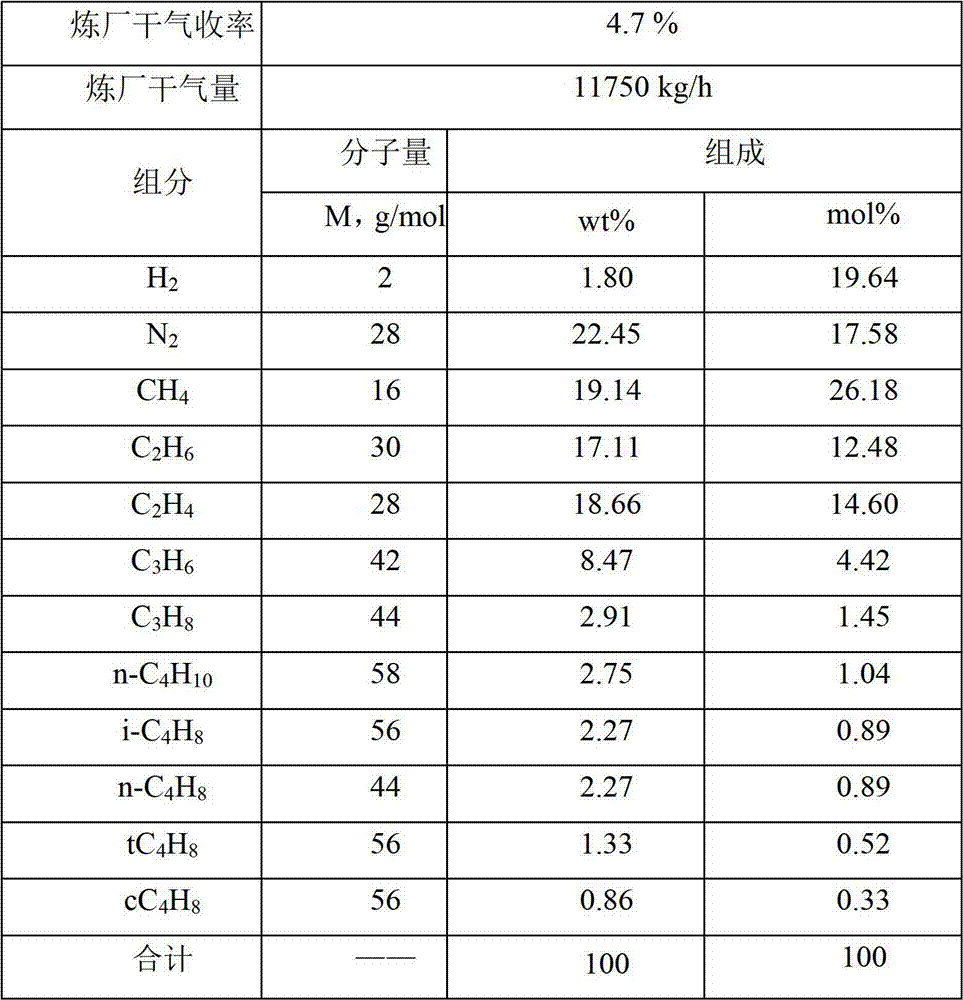

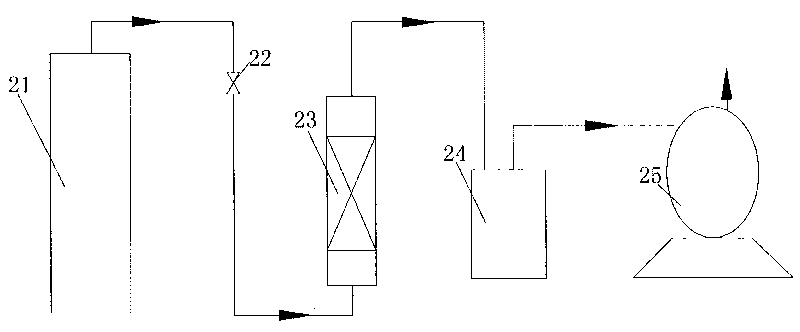

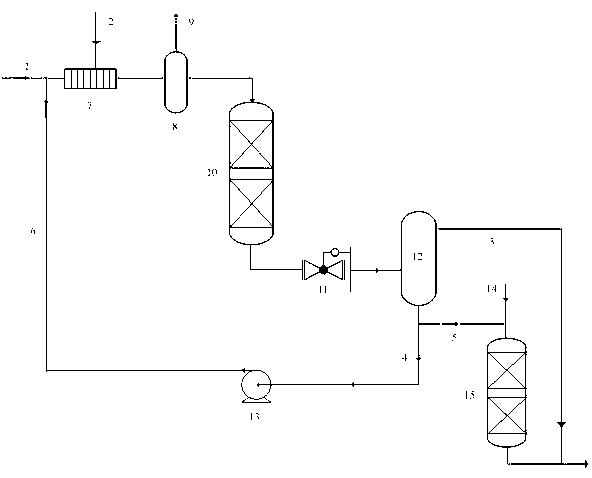

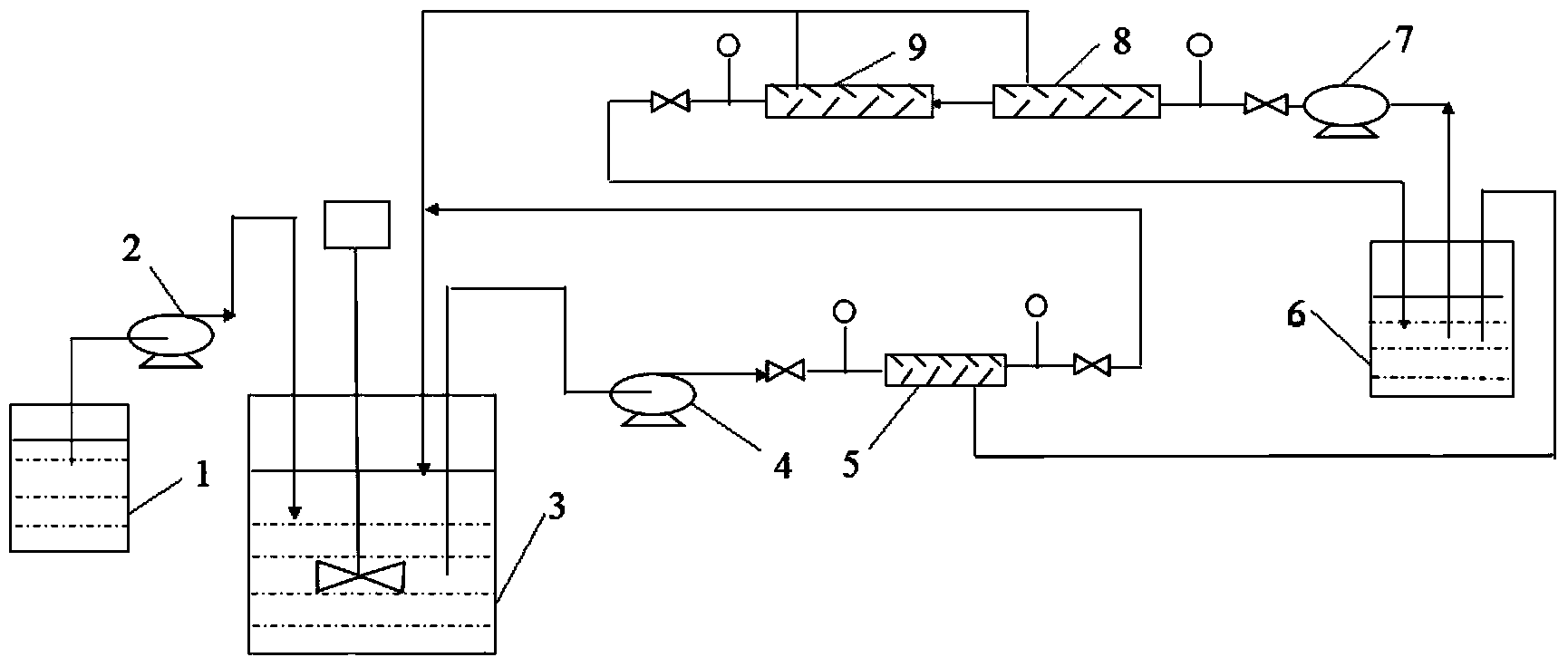

Recovering system and method of C2 in refinery dry gas by compound adsorption method

ActiveCN103588604AModerate operating conditionsGuaranteed RecoveryEthylene productionAbsorption purification/separationFluid phaseProcess engineering

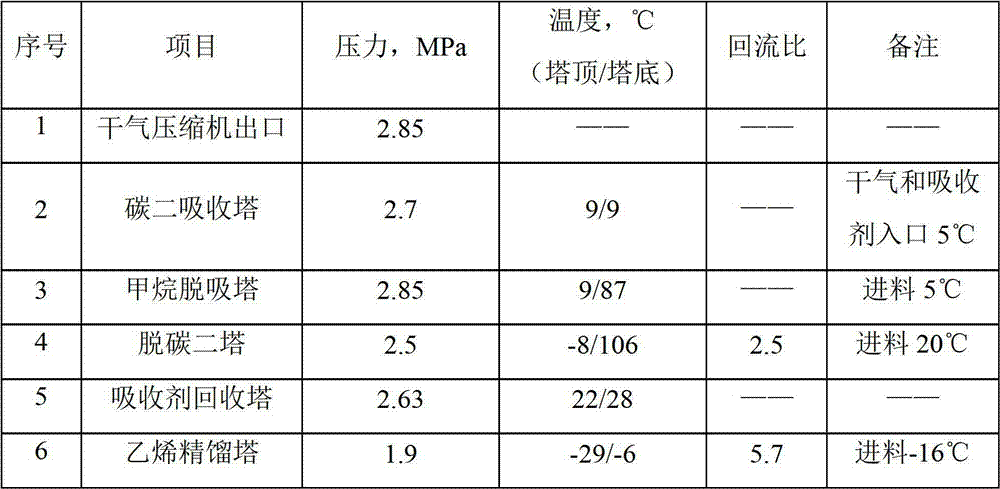

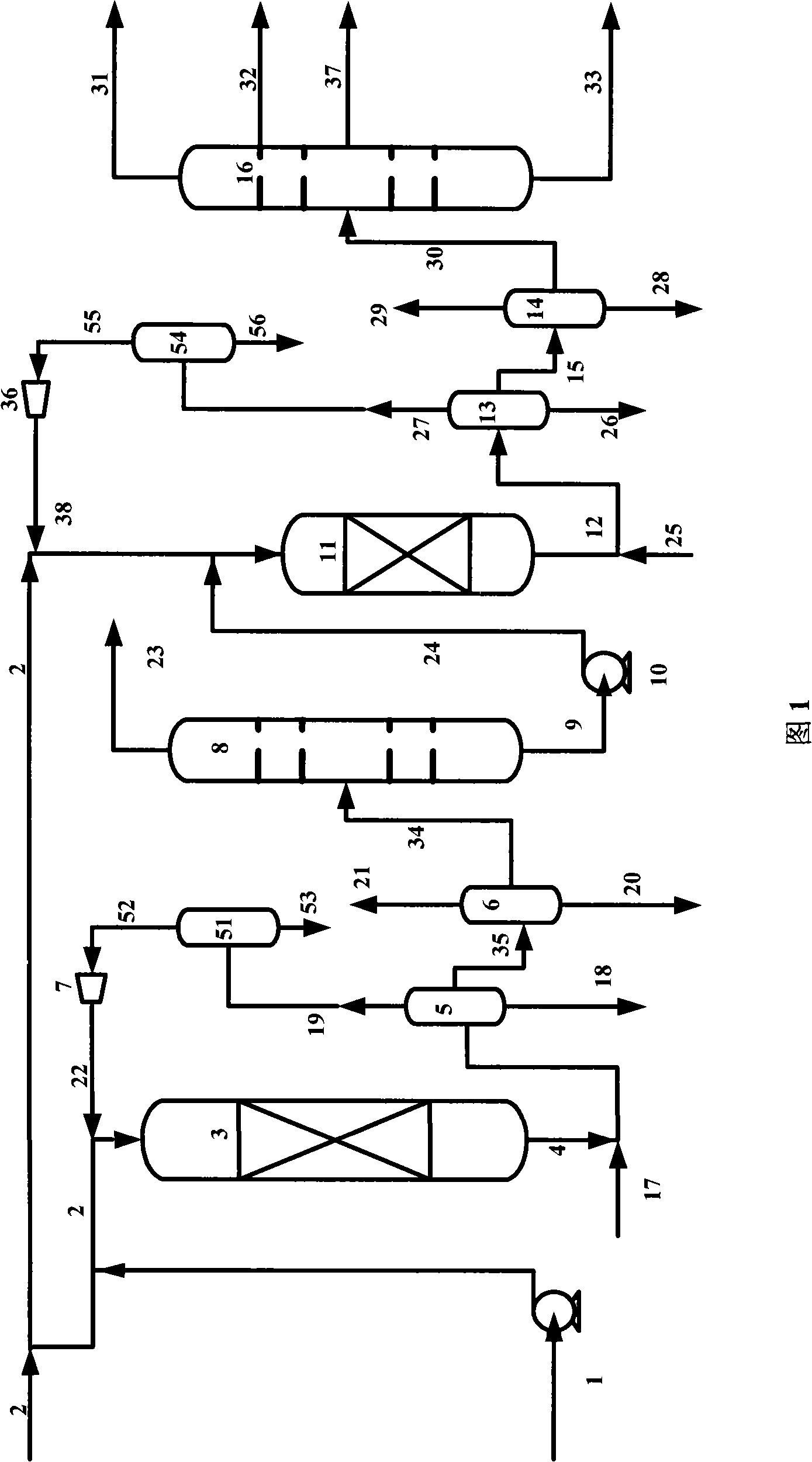

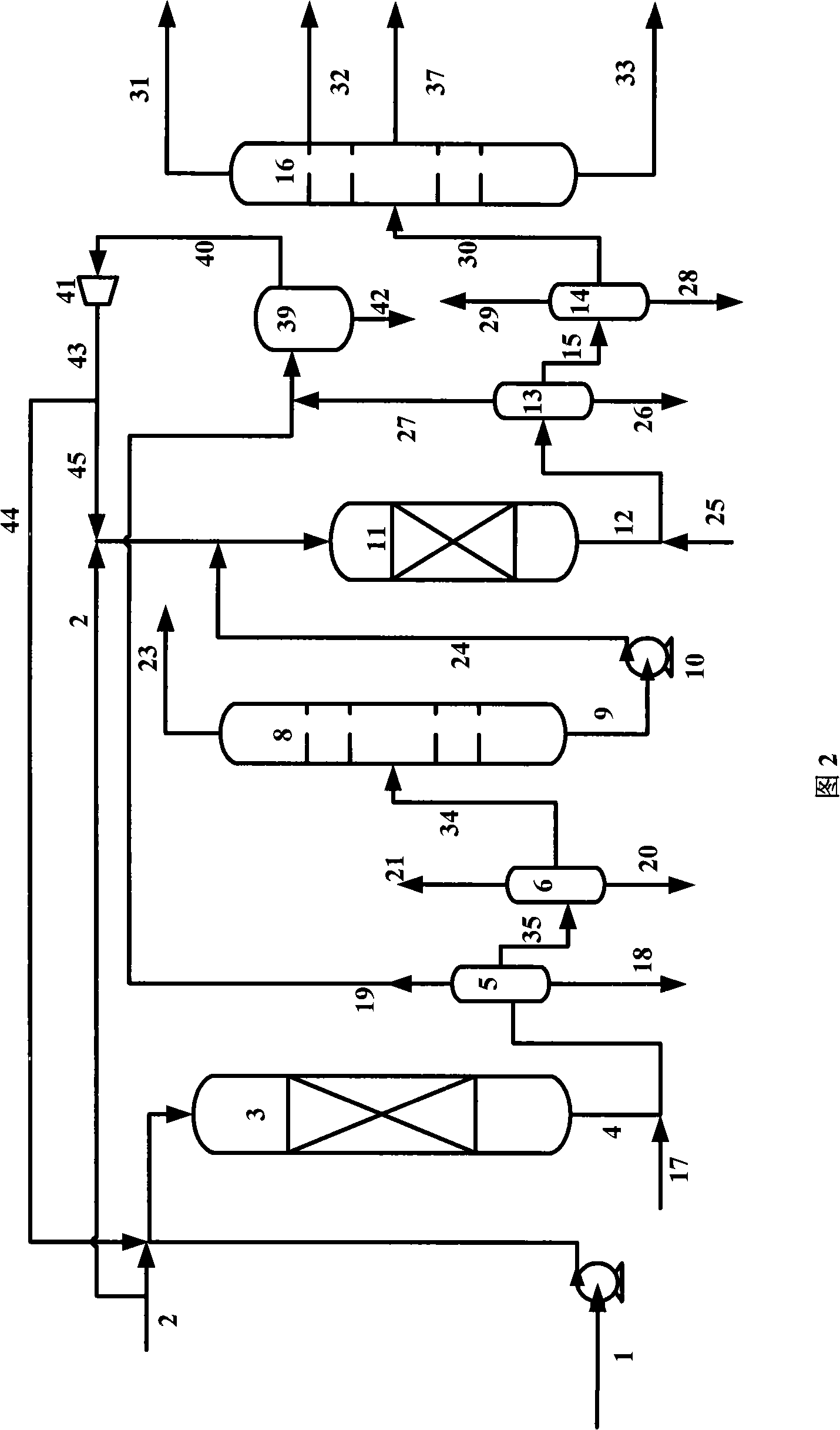

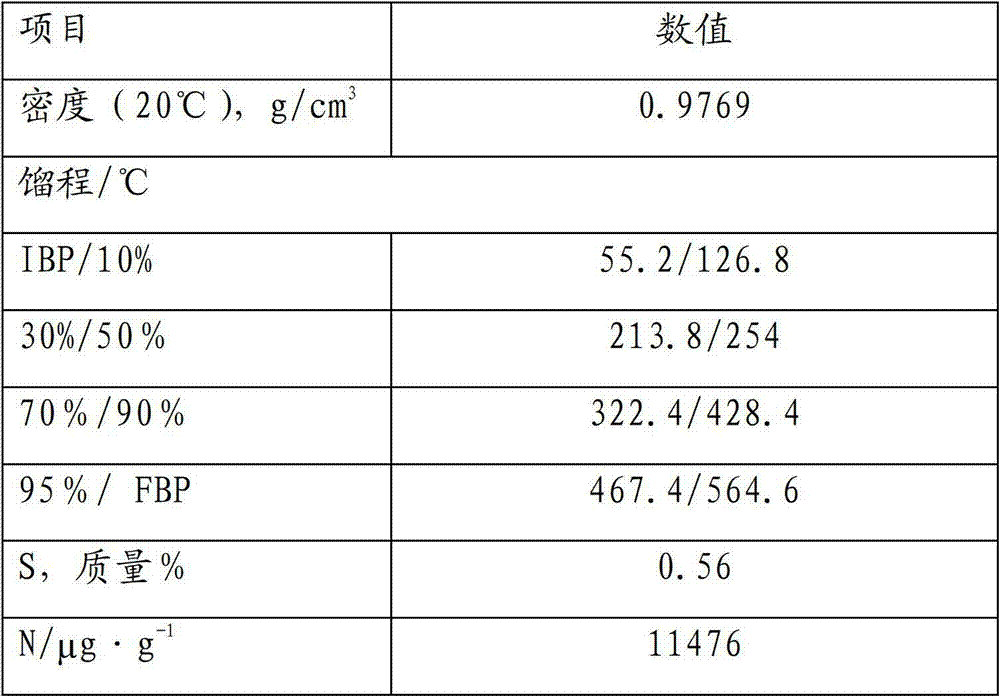

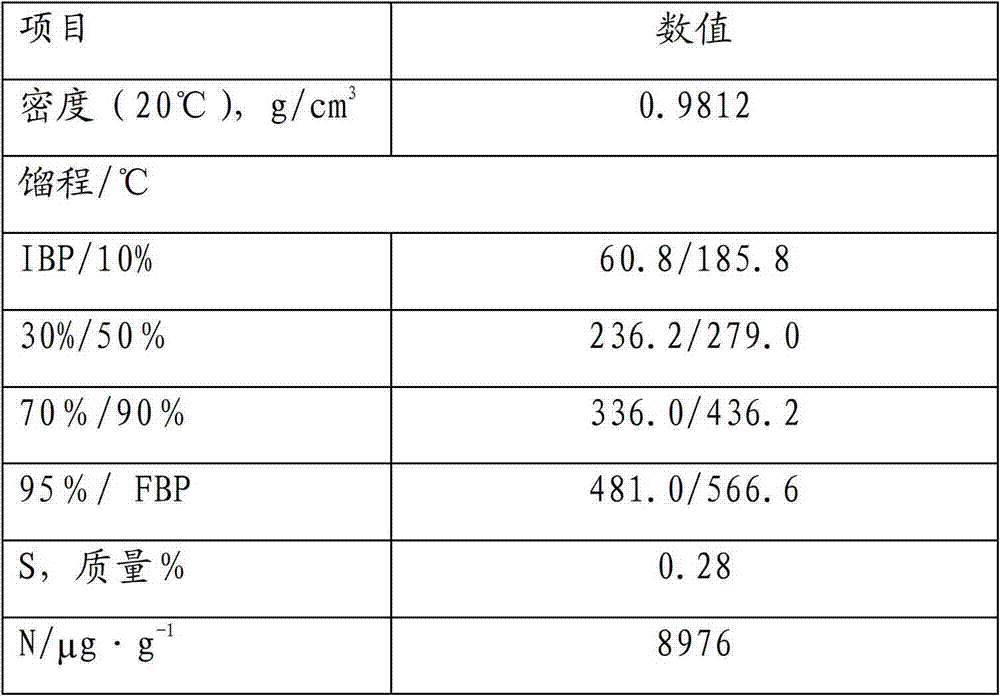

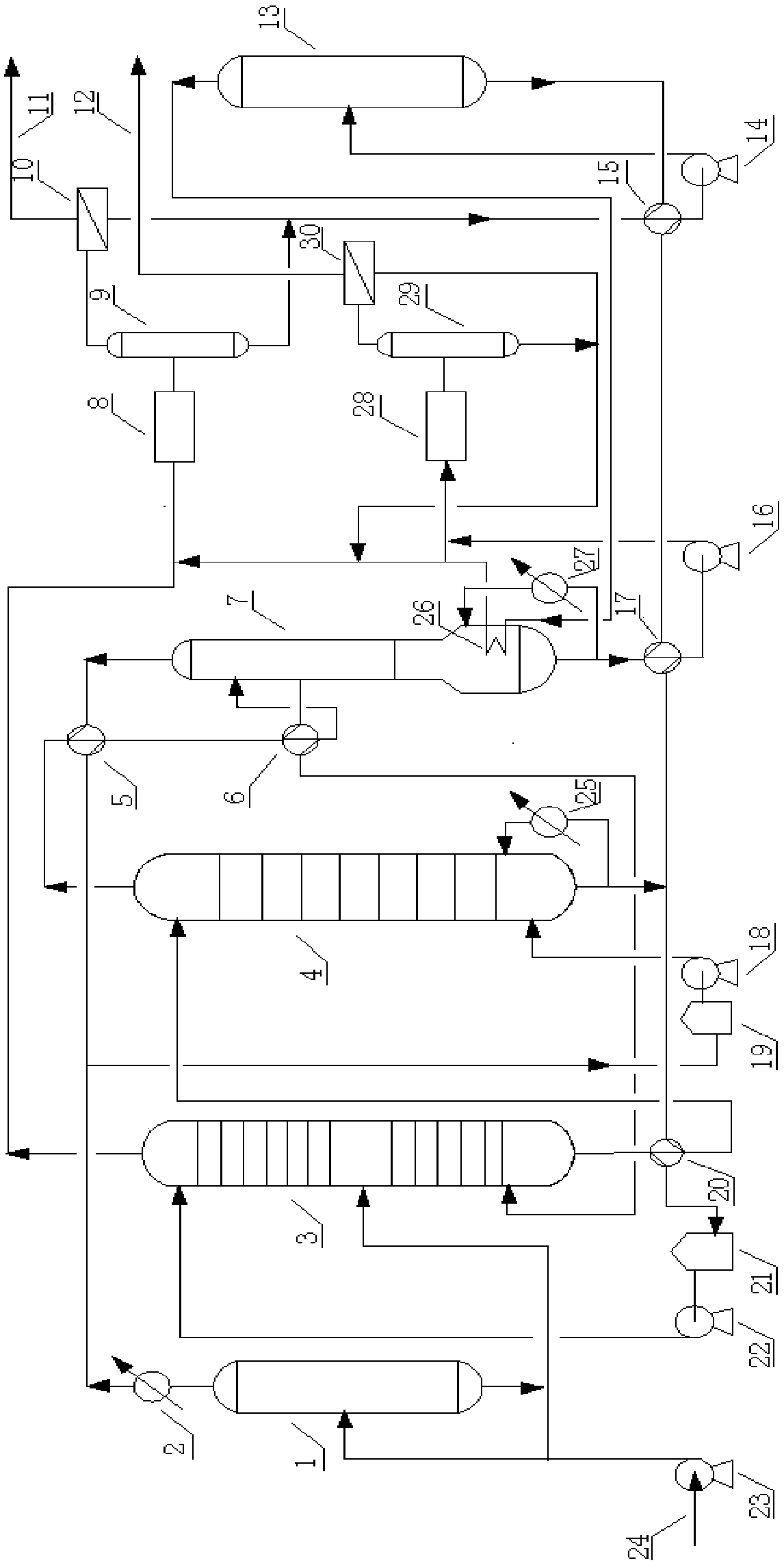

The invention provides a recovering system and a method of C2 in refinery dry gas by a compound adsorption method. The recovering system comprises a compressor, a pretreatment unit, a refinery dry gas cooling unit, a compound adsorption unit and a rectification unit. The adsorption unit comprises a gas-liquid separating tank, a C2 adsorption tower, and a methane desorption tower. The rectification unit comprises a C2 removing tower and an ethylene rectification tower. The refinery dry gas, after being compressed, pretreated and cooled, is subjected to gas-liquid separation to obtain a gas phase and a liquid phase. The gas phase is fed into the C2 adsorption tower and subjected to C2 adsorption by using a C4 mixture or a C5 mixture as an absorbent. The liquid phase is fed into the methane desorption tower, and subjected to methane desorption through stripping. The mixed adsorption oil at the bottom of the C2 adsorption tower and desorption gas at the top of the methane desorption tower are returned to the gas-liquid separation tank after being mixed and cold with the refinery dry gas. Tower bottom of the methane desorption tower is cooled and fed into the C2 removing tower and the ethane rectification tower to be rectified to obtain an ethylene product and an ethane product. The method provided by the invention adopts moderate operating conditions. The ethylene and the ethane both have the high recovering rate and the high purity.

Owner:CHINA PETROCHEMICAL CORP +1

Method for producing butadiene

ActiveCN101665399ASeparation efficiency is not affectedHigh yieldHydrocarbon by hydrogenationDistillation purification/separationHydrogenation reactionAlkyne

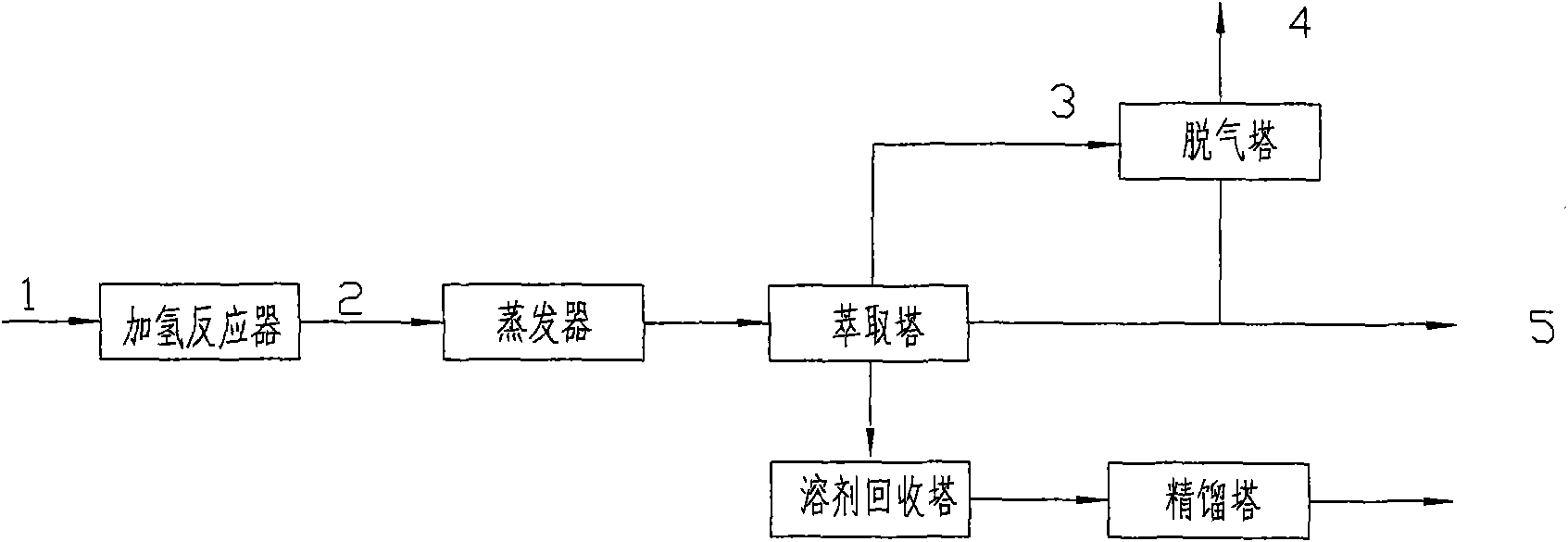

The invention relates to a method for producing butadiene, which belongs to the technical field of alkenes production. In order to solve the problems that the prior process for producing the butadieneby combining selective hydrogenation alkyne removal and extraction has fluctuation operating pressure for an extracting tower and an uneconomic lightness-removing column, the invention discloses a novel process for producing the butadiene. Apart from the adoption of the process flow in combination of selective hydrogenation and extraction processes, the novel process sets a degassing tower at anextraction position on the top of the extracting tower so as to separate out the residual hydrogen and light components with less than four carbons after the hydrogenation reactions. The method can eliminate the adverse factors which influence the operation of the extracting tower in the prior art, avoids butadiene losses while removing the light components, and improves the yield of the butadiene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Separation and pressure reduction combining system for suspended bed hydrocracking reaction products

ActiveCN104449824AModerate operating conditionsAchieve separationTreatment with plural serial refining stagesHydrogenProcess engineering

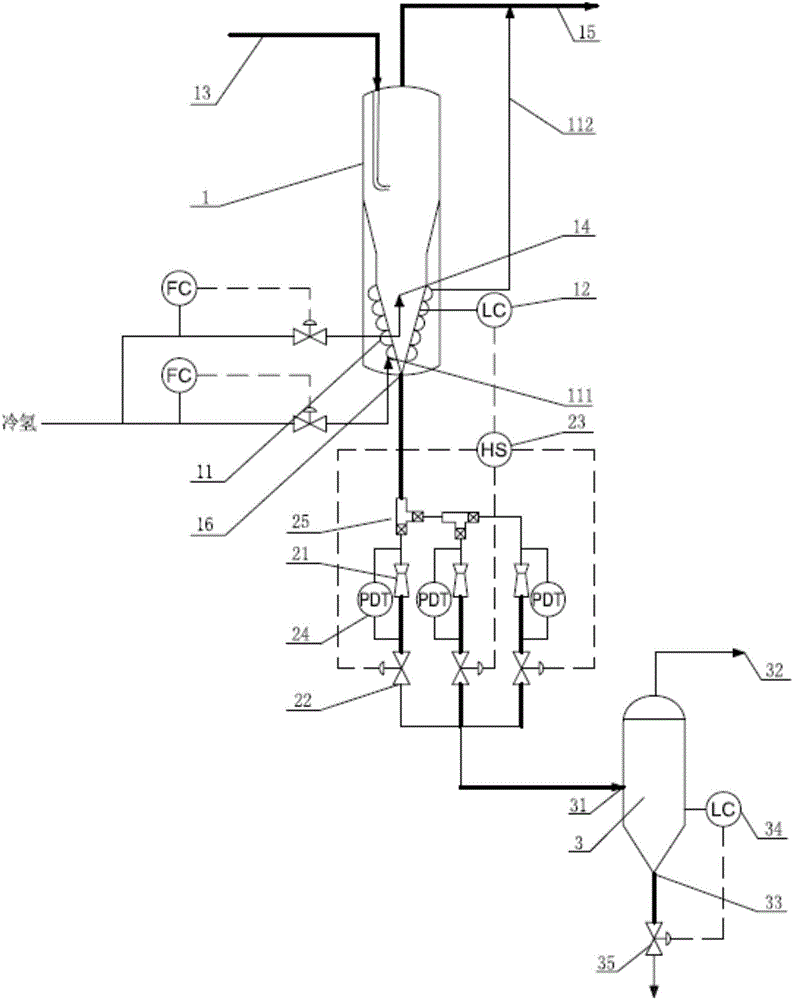

The invention provides a separation and pressure reduction combining system for suspended bed hydrocracking reaction products. The system comprises a heat high-pressure separator, a pressure relief valve bank and a heat low-pressure separator, wherein a feeding hole for the suspended bed hydrocracking reaction products is formed in the upper part of the heat high-pressure separator; a cold hydrogen feeding hole is formed in the lower part of the heat high-pressure separator; a heat high-pressure separating gas outlet is formed in the top part of the heat high-pressure separator; a heat high-pressure separating liquid outlet is formed in the bottom of the heat high-pressure separator; the pressure relief valve bank comprises at least one set of valve bank; each set of valve bank comprises a venturi throttling element and an angle adjusting valve which are communicated with each other; a heat low-pressure feeding hole is formed in the upper part of the heat low-pressure separator; a heat low-pressure separating gas outlet is formed in the top of the heat low-pressure separator; a heat low-pressure separating liquid outlet is formed in the bottom of the heat low-pressure separator; the heat high-pressure separating liquid outlet is communicated with the venturi throttling element of the pressure relief valve bank; and the angle adjusting valve is communicated with the heat low-pressure feeding hole. The invention also provides a pressure reduction and separation method for the suspended bed hydrocracking reaction products by using the separation and pressure reduction combining system.

Owner:BEIJING PETROCHEM ENG

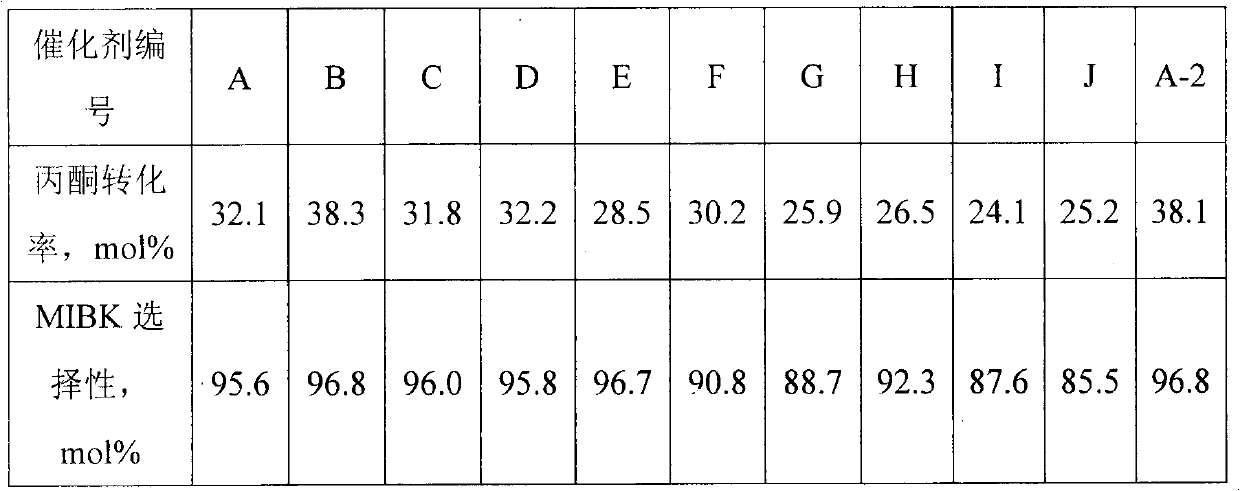

Preparation method of catalyst for hexone synthesis by acetone hydrogenation and application

InactiveCN102698761AReduce manufacturing costShort processOrganic compound preparationCarbonyl compound preparationCatalytic functionAcetone

The invention belongs to the technical field of catalysis, and relates to a preparation method of a catalyst for hexone synthesis by acetone hydrogenation and an application; the catalyst is composed of active component nickel loaded on an alumina carrier modified by transition metal oxides. The preparation method of the catalyst comprises two procedures: the first one is that transition metal oxides and alumina are mixed, molded, dried, roasted, and subject to hydro-thermal treatment, and the active component Ni is immersed to obtain the catalyst; the second one is that an alumina carrier is prepared firstly, then transition metal oxides and Ni are introduced by an immersion method, and finally hydro-thermal treatment is performed to obtain the catalyst. The catalyst of the invention adopts non-noble metal as the main active component, is simple in preparation, low in cost, strong in raw material adaptability, long in service life, and high in activity and selectivity, and combines three catalytic functions of acetone condensation, dehydration, and hydrogenation as a whole, and the reaction process flow is simplified greatly.

Owner:CHINA NAT OFFSHORE OIL CORP +1

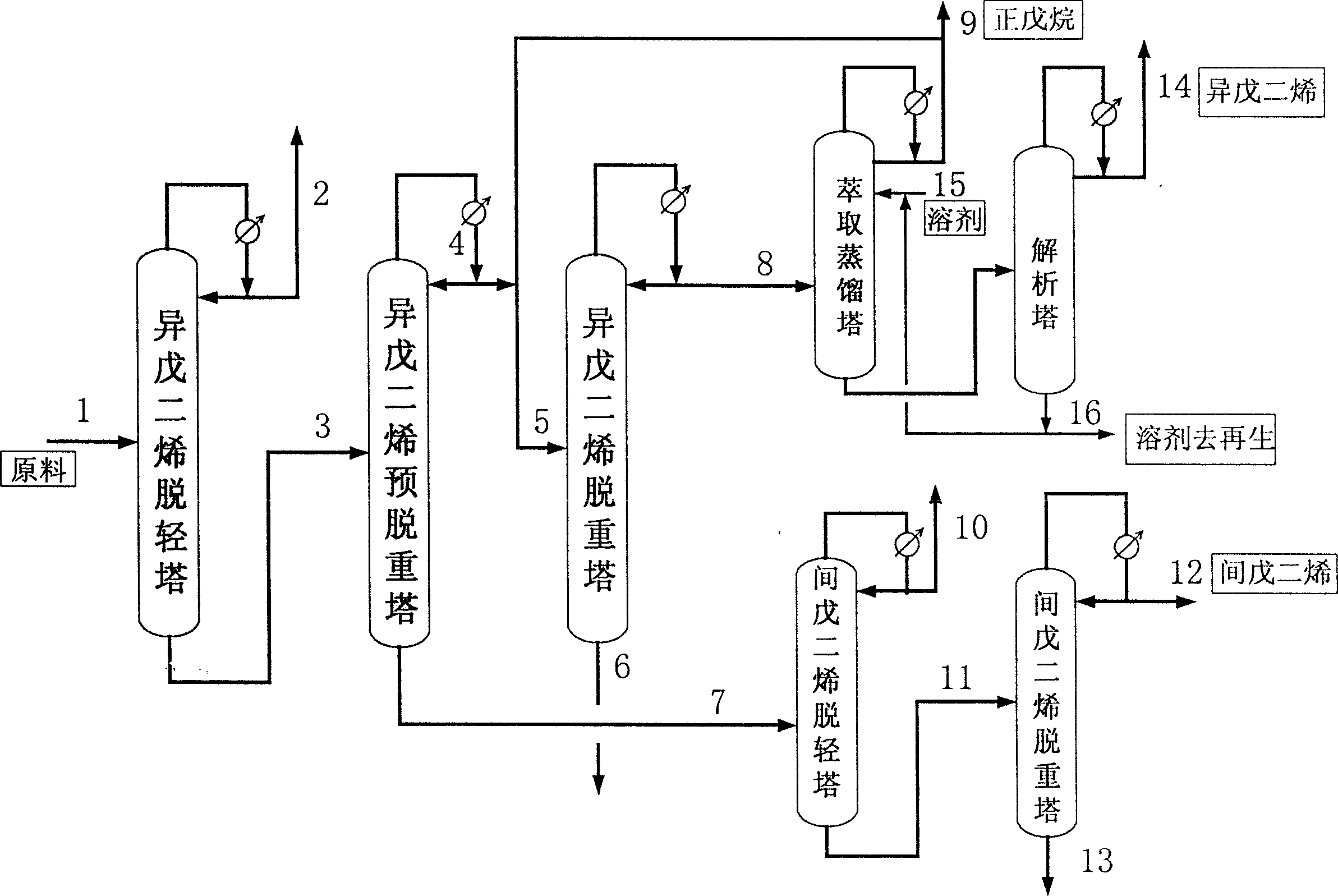

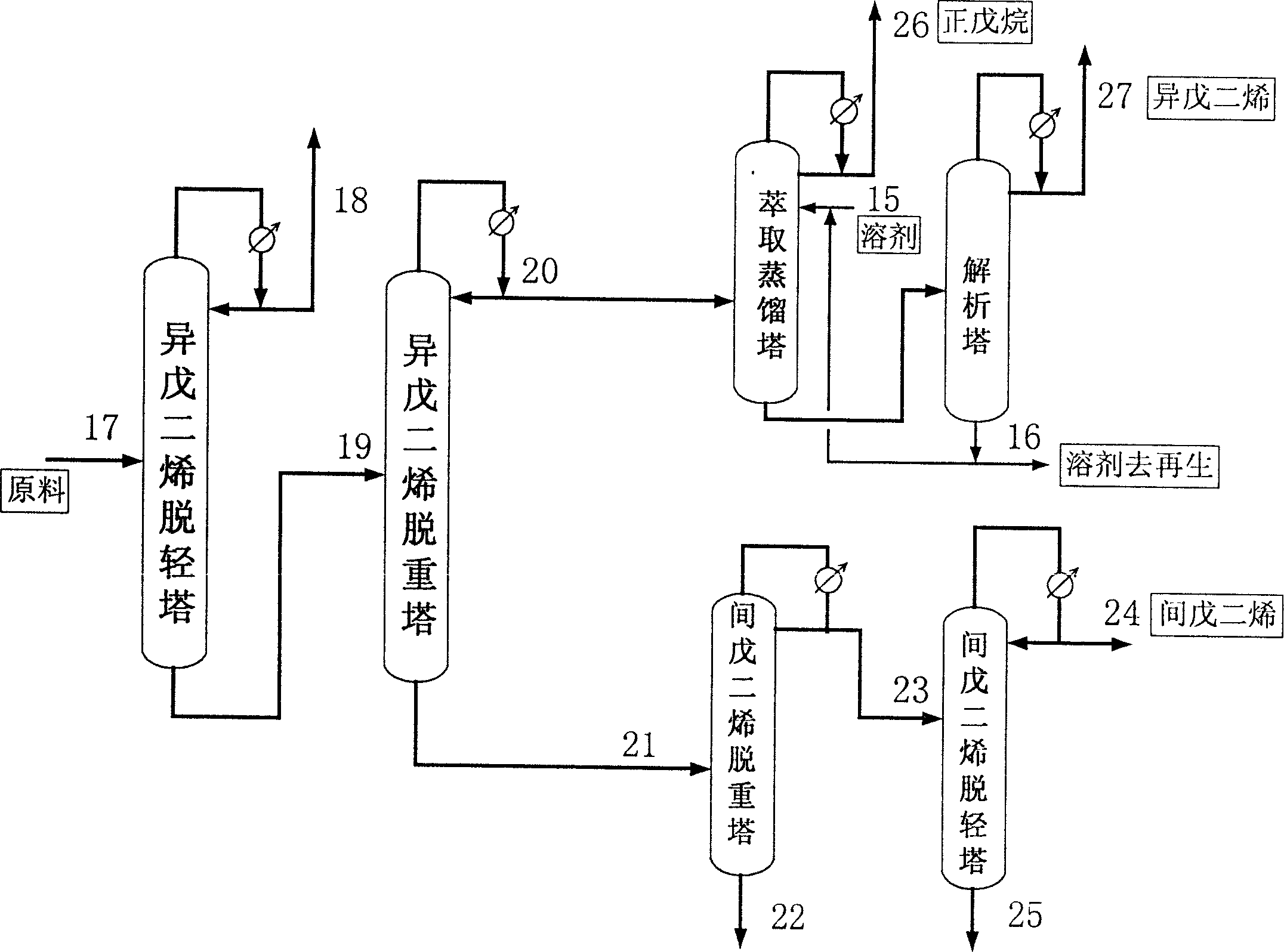

Method for separating cracked carbon 5 using azeotropic super fractionation and extractive distillation coupling

InactiveCN1709842AReduce dosageSolving Recycling ProblemsOrganic chemistryHigh concentrationExtractive distillation

This invention has disclosed a method of separating carbon5 by azeotropic rectification and extractive distillation. Its characteristic is it adopts azeotropic rectification to take off light-unit and heavy-unit gained isoprene- n-pentane azeotrope accord with polymerisation grade, then with extractive distillation make isoprene separated from n-pentane to get t polymerisation grade isoprene. Because targets that this invention extracts the distillation and deals with are only mixture of isoprene and n-pentane, but not make up carbon five hydrocarbon, thus greatly alleviated the questions of using solvents, such as solvent toxicity, retrieving , resolving , environmental protection, etc. When producing pure isoprene and n-pentane, this invention also could get 1,3-piperlene of high concentration.

Owner:NANJING UNIV OF TECH

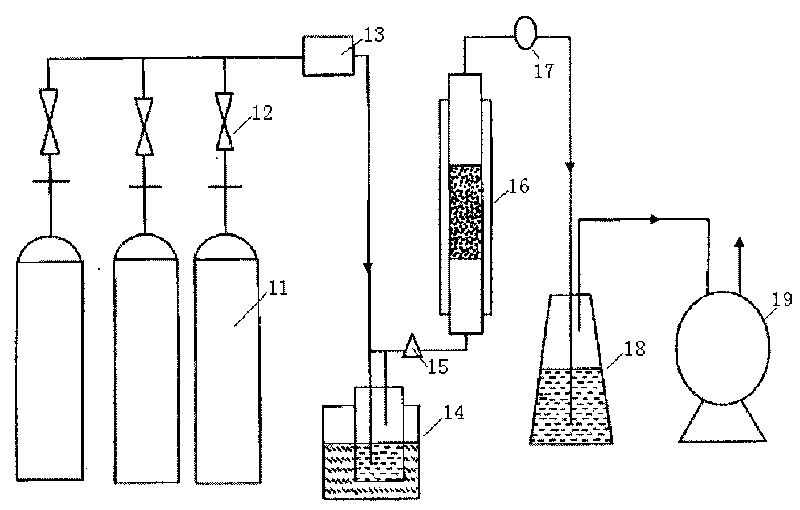

Device for measuring breakthrough sulphur capacity and using method thereof

InactiveCN101718766AAvoid large deviations in measurement resultsLower requirementChemical analysis using precipitationProduct gasProcess engineering

The invention relates to a device for measuring the breakthrough sulphur capacity, which comprises a reactor, a gas supply source connected with one end of the reactor, a wet gas flow meter connected with the other end of the reactor, a valve arranged between the gas supply source and the reactor, and a hydrogen sulfide detector, wherein the hydrogen sulfide detector is arranged between the reactor and the wet gas flow meter and contains solution of silver nitrate. The invention also relates to a method for measuring the breakthrough sulphur capacity of a desulfurizing agent by using the device. The device is simple in design, the method for measuring the breakthrough sulphur capacity is simple, and the accuracy for measuring the breakthrough sulphur capacity is high.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

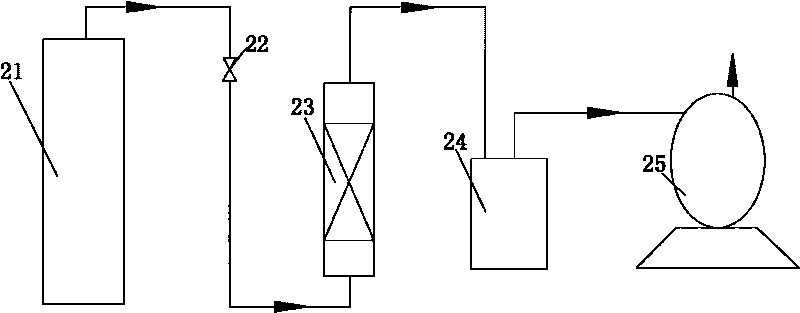

Integrated process method of producing low-carbon aromatic hydrocarbons and olefins from gas oil

ActiveCN110938464ALow yieldRealize oil reduction and increaseTreatment with hydrotreatment processesHydrocarbon oils treatment productsFuel oilProcess engineering

The invention provides an integrated process method of producing low-carbon aromatic hydrocarbons and olefins from gas oil. The method includes: feeding gas oil to a gas oil hydrogenation refining unit to perform a refining reaction to obtain refined gas oil; feeding the refined gas oil to a hydrocarbon adsorption separation unit to prepare a non-aromatic hydrocarbon component and a heavy aromatichydrocarbon component; feeding the non-aromatic hydrocarbon component to a non-aromatic hydrocarbon cracking unit to obtain olefin-rich gas, cracked gasoline and cracked heavy oil through catalytic cracking or vapor cracking; feeding the heavy aromatic hydrocarbon component and the cracked heavy oil into a heavy aromatic hydrocarbon mild-hydrogenation cracking unit to perform a selective crackingreaction, thus obtaining an extract raw material; feeding the cracked gasoline to a cracked gasoline hydrogenation refining unit to perform a refining reaction to obtain the extract raw material; feeding the extract raw material into an aromatic hydrocarbon extract unit to prepare the low-carbon aromatic hydrocarbons. In the invention, firstly, the hydrocarbons in the gas oil are separated, and secondly, a processing technology is selected specifically to maximumly produce the low-carbon aromatic hydrocarbons and olefins. The method has advantages of strong raw material adaptability, high target product yield and mild operation conditions.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

Method for producing good quality diesel oil

InactiveCN1415705AImprove acid resistanceImprove matchTreatment with hydrotreatment processesEngineeringProcess conditions

A process for preparing high quality diesel oil from poor-qualiry fraction oil includes such steps as hydrorefining, hydro-pour-depressing and arylhydrocarbon saturation. Its advantages are high hexadecame value, low pour point, and low contents of S and arylhydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

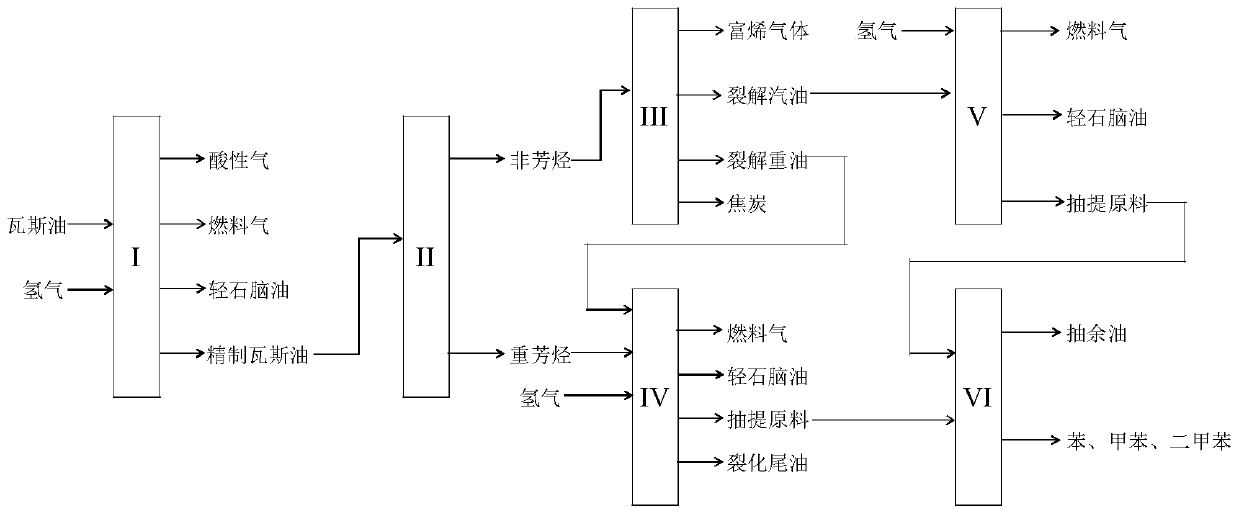

Hydrogenation catalysts and its manufacturing method and use

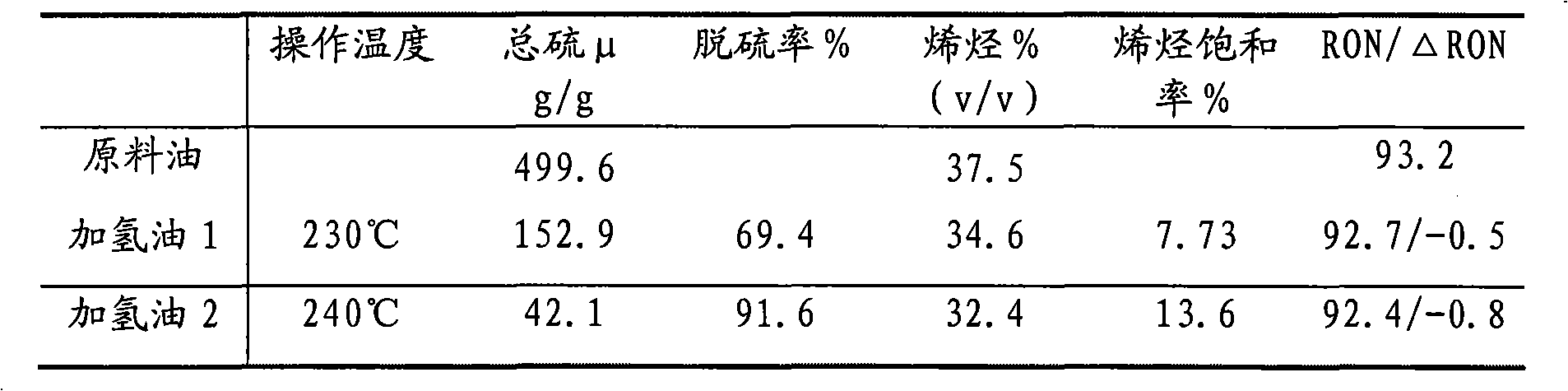

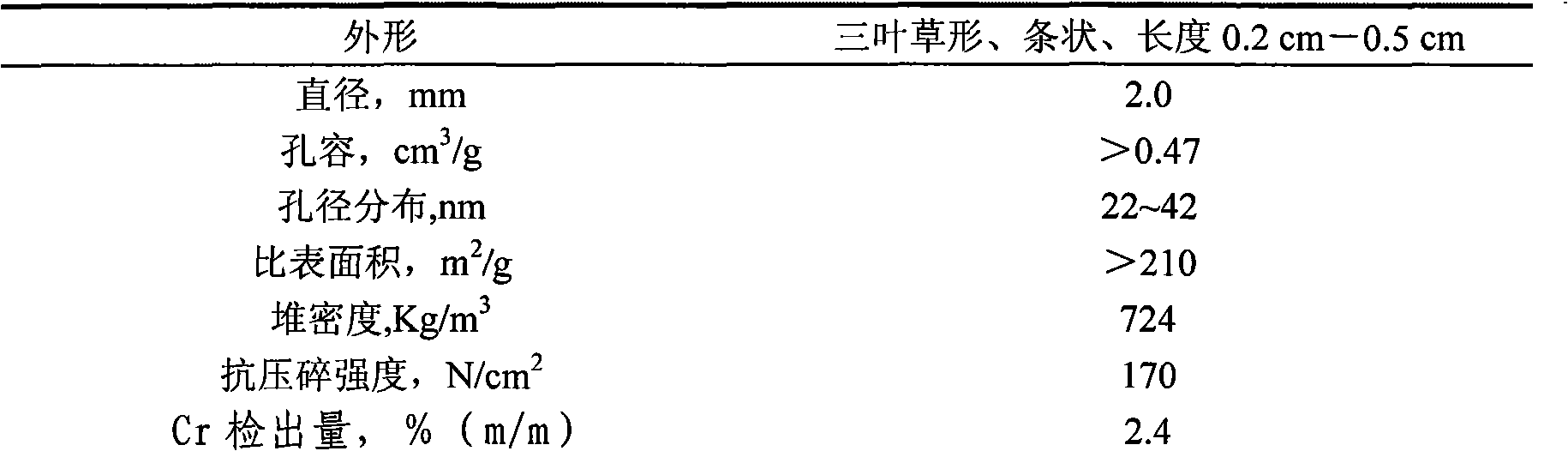

InactiveCN101259420AHigh selectivityImprove desulfurization effectPhysical/chemical process catalystsRefining to eliminate hetero atomsTO-18Metallurgy

The invention relates to a hydrogenation catalyst; alumina powder with an average grain diameter of 25nm and alumina powder with an average grain diameter of 250 Mu m are selected as carriers of the catalyst; the mixing ratio of the nanometer alumina powder to the micron alumina powder is 1 : 8 to 12. The catalyst carries the elements of Mo, Co, Cr, K, Cu, P, B and F; wherein, the contents of the elements are: 5.0 percent to 18.0 percent of Mo, 1.5 percent to 3.0 percent of Co, 1.5 percent to 2.5 percent of Cr, 1.2 percent to 2.0 percent of K, 1.2 percent to 2.0 percent of Cu, 1.5 percent to 2.5 percent of P, 0.8 percent to 1.2 percent of B and 0.5 percent to 1.0 percent of F. The specific surface of the catalyst is 200m<2> / g to 450m<2> / g; the pore volume is 0.4ml / g to 0.75ml / g; the average aperture distribution is 20nm to 60nm; the crushing strength is 120N / cm<2> to 260N / cm<2>. When used in gasoline hydrofining, the catalyst of the invention can work under a normal hydrogenation operation condition without needing a special working situation; the operation condition is tempered; the technique is flexible; the adaptation to various oil products is good. The hydrogenation catalyst can carry out deep desulfurization on the oil products and has small effects on the octane number of the oil products. The invention discloses a preparation method for the catalyst.

Owner:江苏佳誉信实业有限公司

Medium and low temperature combination processing method of coal tar

ActiveCN102851073AHigh yieldLow yieldTreatment with hydrotreatment processesTar working-up by distillationLighter fuelHigh pressure

The invention comprises a combination processing method of coal tar. The method comprises the steps of: (a) subjecting a coal tar raw material to atmospheric distillation to obtain light distillate oil, phenol oil and bottom oil; dephenolizing the phenol oil to obtain the dephenolized oil; sending the bottom oil and a liquid phase from a hot high pressure separator in a step (d) into a vacuum distillation tower to obtain a heavy distillate with asphaltene removed; and conducting a hydrotreating reaction on the light distillate, dephenolized oil and the heavy distillate; (b) fractionating a liquid phase from the hydrotreating reaction into a light fraction and a heavy fraction; (c) subjecting the heavy fraction from the step (b) to a hydrocracking reaction; and (d) sending an effluent from the hydrocracking reaction into the hot high pressure separator, and sending the separated liquid phase to the vacuum distillation tower in the step (a). Compared with prior art, the method provided by the invention increases yield of light fuel production from coal tar, prolongs the service life of catalyst, and improves operation cycle of the device.

Owner:吉林省弘泰新能源有限公司

Method for treating nickel-containing laterite by microwave reducing roasting-goethite precipitation conversion method

InactiveCN101392320AFast heatingImprove energy efficiencyProcess efficiency improvementSlurryHigh pressure

The invention relates to a method for processing laterite comprising nickel by means of microwave reduction roasting-goethite deposit transformation, which is characterized in that the method comprises the following steps: (1) a carbonaceous reducing agent is added into the laterite, and heated for 5min to 20min under microwave radiation after even blending so as to obtain laterite calcine; and (2) the laterite calcine is blended into slurry and leached, the concentration of the mine slurry is 10wt percent to 30wt percent, the leaching temperature is 80 DEG C to 120 DEG C, the duration for leaching is 2h to 5h, and nickel cobalt in the laterite enters the leached liquid, with iron transformed to goethite deposit. The method consumes less acid which is equal to that of the high-pressure acid leaching method, but the operation temperature and pressure at the leaching stage are greatly lowered by reduction roasting, which is favorable to the decrease in manufacturing cost of leaching equipment.

Owner:NORTHEASTERN UNIV

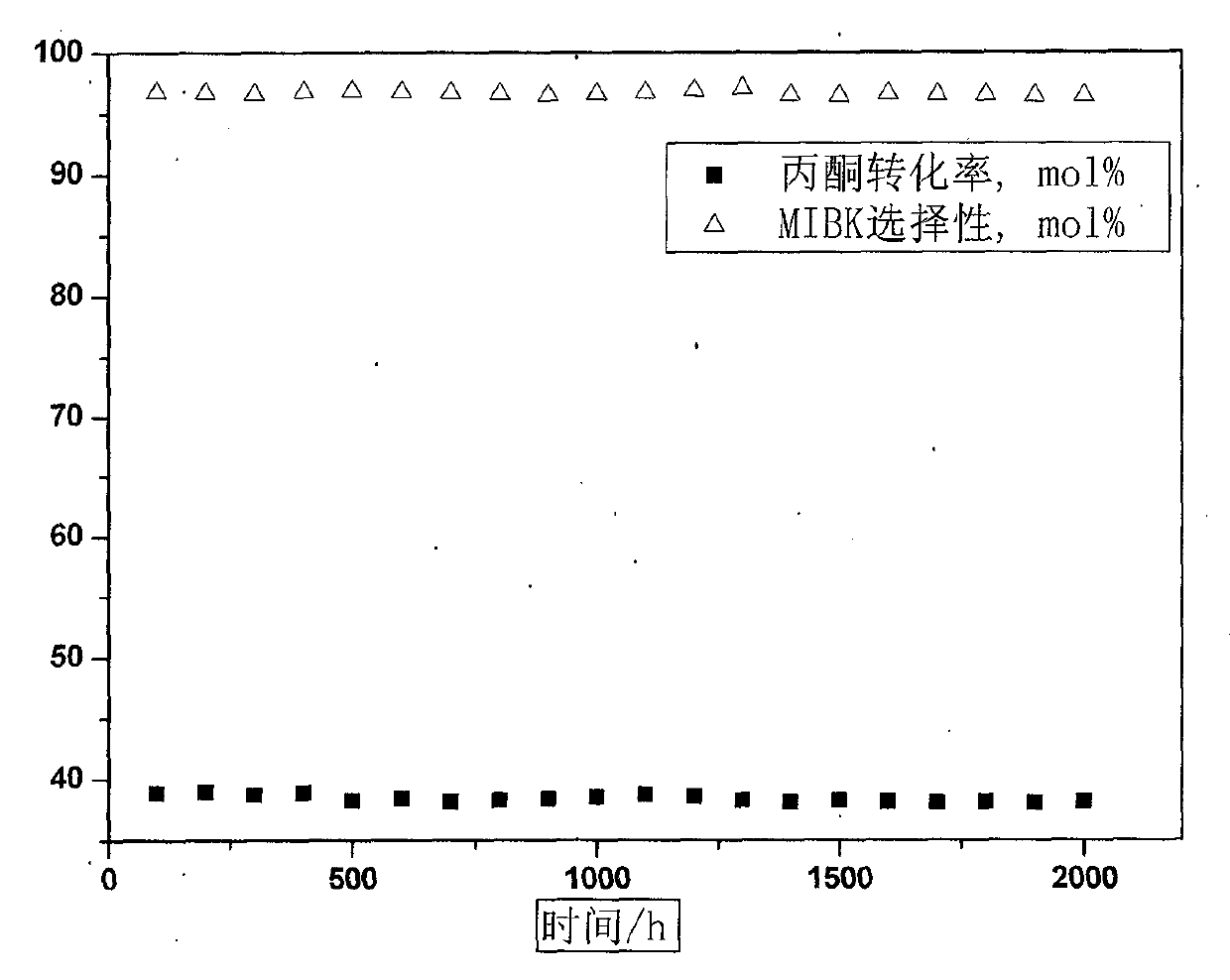

Method for synthesizing methyl isobutyl ketone from acetone by two-step process

ActiveCN104355975AHigh purityEasy to purifyOrganic compound preparationCarbonyl compound separation/purificationMolecular sieveMethyl isobutyl ketone

The invention relates to a method for synthesizing methyl isobutyl ketone from acetone by a two-step process. The method comprises the following steps: a fixed bed catalytic condensation reactor is filled with a solid catalyst, and acetone used as a reaction raw material is subjected to condensation-dehydration reaction on the catalytic condensation reaction bed to generate mesityl oxide and water; the product from the reactor enters a molecular sieve adsorption dehydration tank; the organic oil phase after dehydration enters a second fixed bed catalytic condensation reactor, and the acetone is further subjected to condensation-dehydration reaction to generate mesityl oxide and water; and the product enters a fixed bed catalytic hydrogenation reactor, the mesityl oxide is subjected to selective hydrogenation reaction on a Pd / Al2O3 catalyst to generate methyl isobutyl ketone, and the hydrogenation product is sent into a subsequent rectification separation system and subjected to separation to obtain the methyl isobutyl ketone product with the purity of greater than 99%. The invention provides a method for producing methyl isobutyl ketone from dimolecular acetone by a condensation-hydrogenation two-step process; and the acetone conversion rate is greater than or equal to 30.0%, and the methyl isobutyl ketone selectivity is greater than or equal to 99.0%.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Deep desulphurization dearomatization combination method of diesel oil

ActiveCN102876367AImprove efficiencyModerate operating conditionsTreatment with hydrotreatment processesHydrodesulfurizationSulfide

The invention discloses a deep desulphurization dearomatization combination method of diesel oil, comprising the following steps of: allowing fresh diesel oil feedstock to enter a hydrogen mixing pot, fully dissolving hydrogen, and entering a liquid phase hydrogenation reactor for refining reaction; allowing the obtained refined effluent to enter a high-temperature low-pressure flash evaporation pot for flash evaporation so as to obtain a liquid phase heavy fraction; allowing part of the heavy fraction to recycle and return to the hydrogen mixing pot and the other part of the heavy fraction to undergo hydrogenation modification, mixing the modified heavy fraction and the light fraction obtained by flash evaporation, and separating to obtain the diesel oil product. According to the method, liquid-phase hydrogenation is performed under mild conditions to remove simple sulfide in the diesel oil feedstock; after flash evaporation, the recycled heavy fraction continues to undergo hydrodesulfurization; and through hydrogenation modification, hardly-removed dibenzothiophene compounds and aromatic hydrocarbons in the heavy fraction are selectively removed. In comparison with a traditional technology, the method provided by the invention has advantages of deeper desulphurization and dearomatization and high yield of diesel oil. Under the same reaction depth, the operation condition is milder, which is beneficial to long-period running of equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

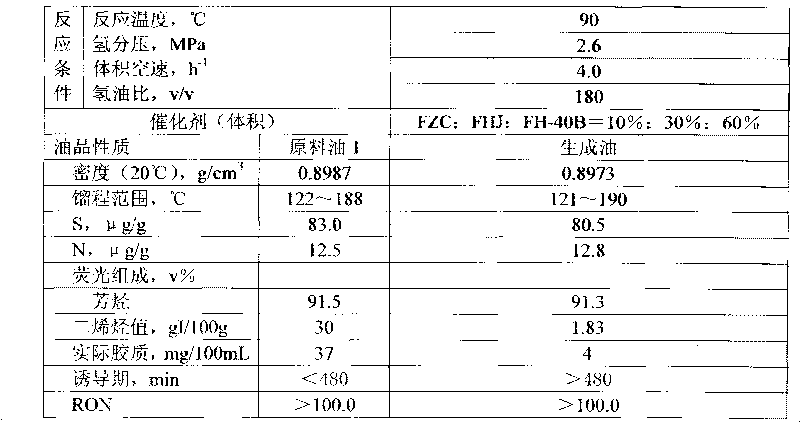

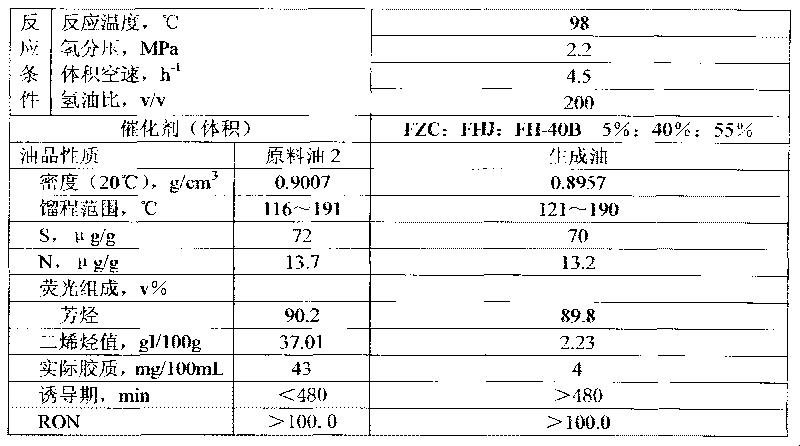

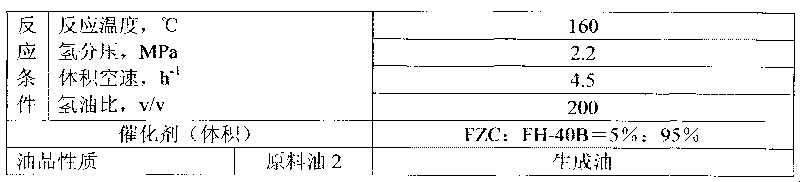

Method for producing gasoline blend component with high octane value by using cracking gasoline heavy fractions

ActiveCN101724447AImprove stabilitySolve the problem of coking too fastHydrocarbon oil crackingLiquid productHydrogen

The invention relates to a method for producing a gasoline blend component with a high octane value by using cracking heavy fractions of gasoline. In the method, a single segment double catalyst matching filling process is adopted, materials of cracking gasoline heavy fractions and hydrogen gas are contacted with two hydrogenation catalysts under a milder process condition, reaction products are separated in a separator, hydrogen enriched gas is recycled, and liquid products are the gasoline blend component with a high octane value. The method aims at the cracking gasoline C9+ fractions difficultly treated by petrochemical processing enterprises; and by the process method, the economic benefits are improved, the process flow is simple, the operation is stable, the product quality is better, the investment and operating costs are lower, and the process method is suitable for new building of a hydrogenation plant as well as modification of the old hydrogenation plant.

Owner:CHINA PETROLEUM & CHEM CORP +1

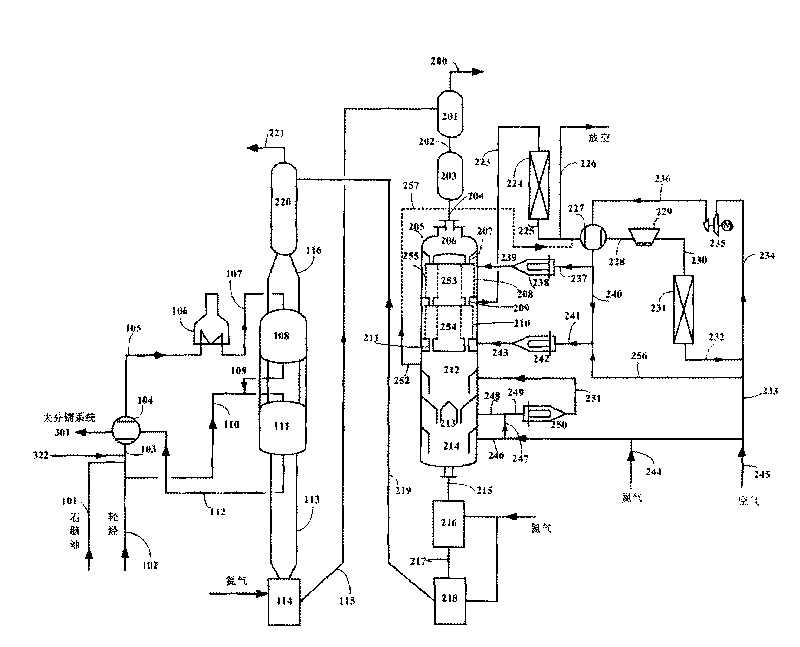

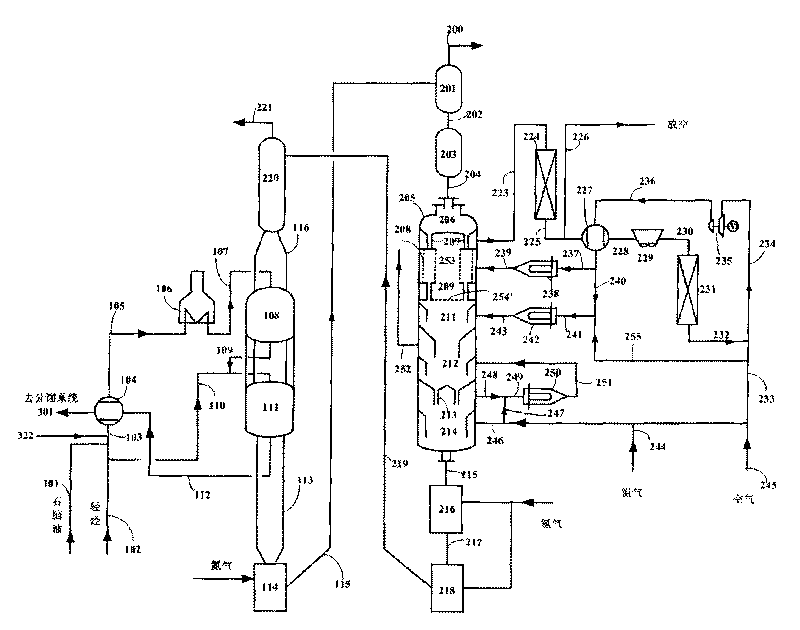

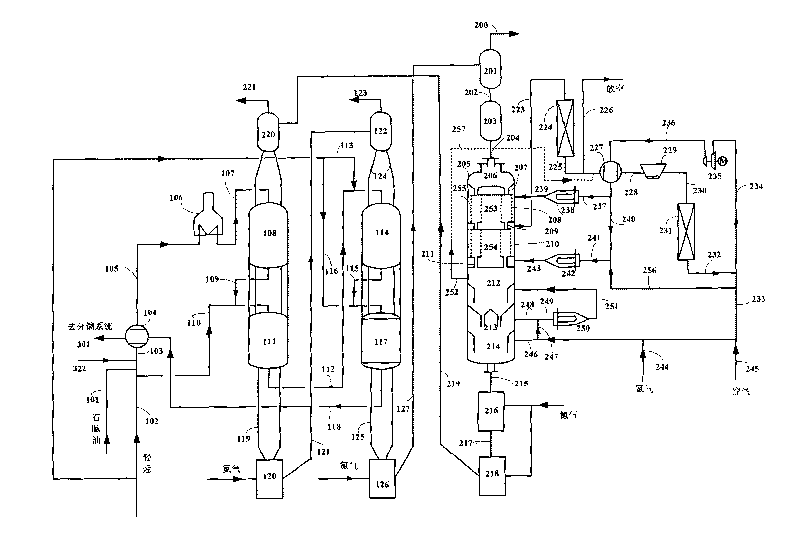

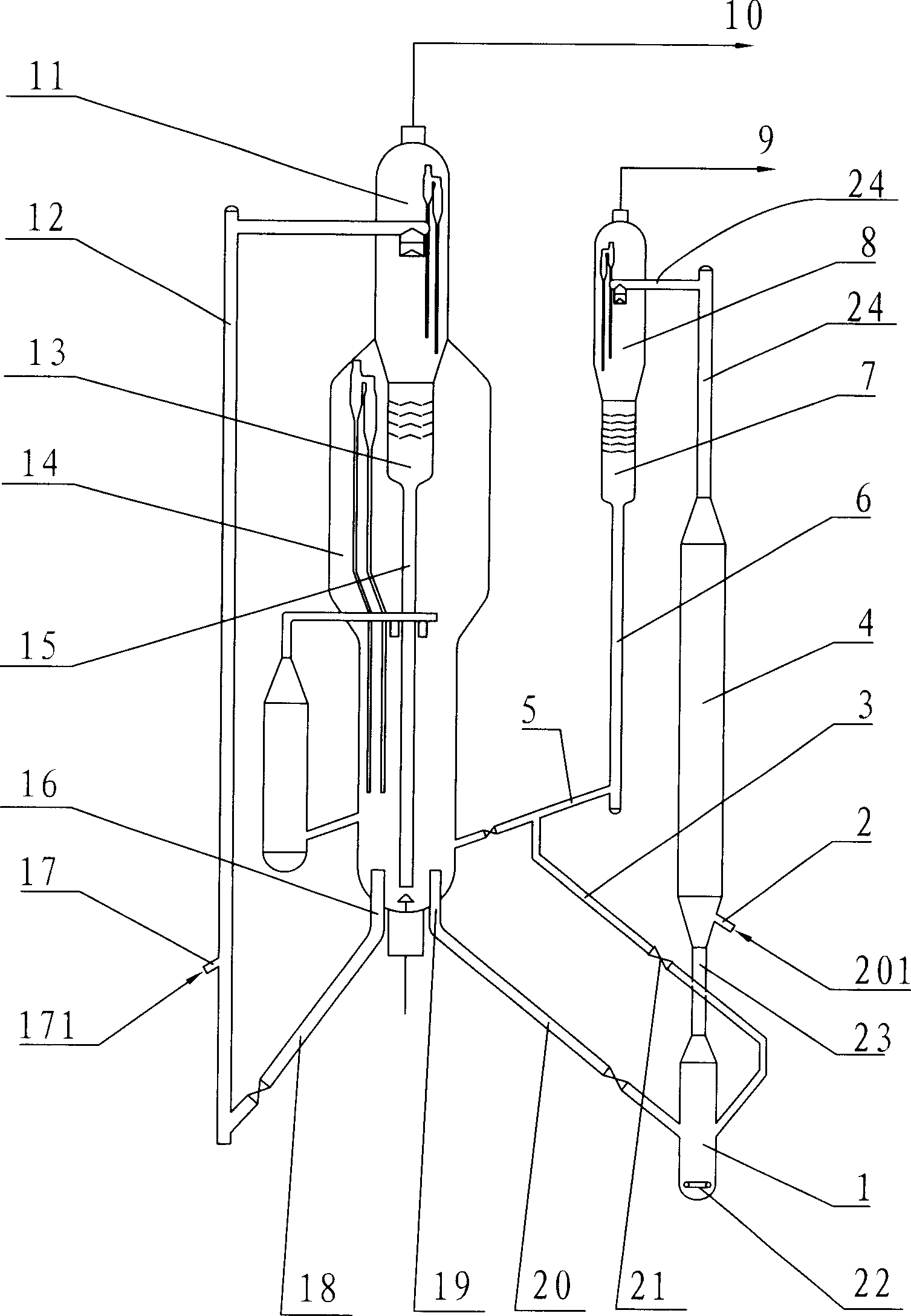

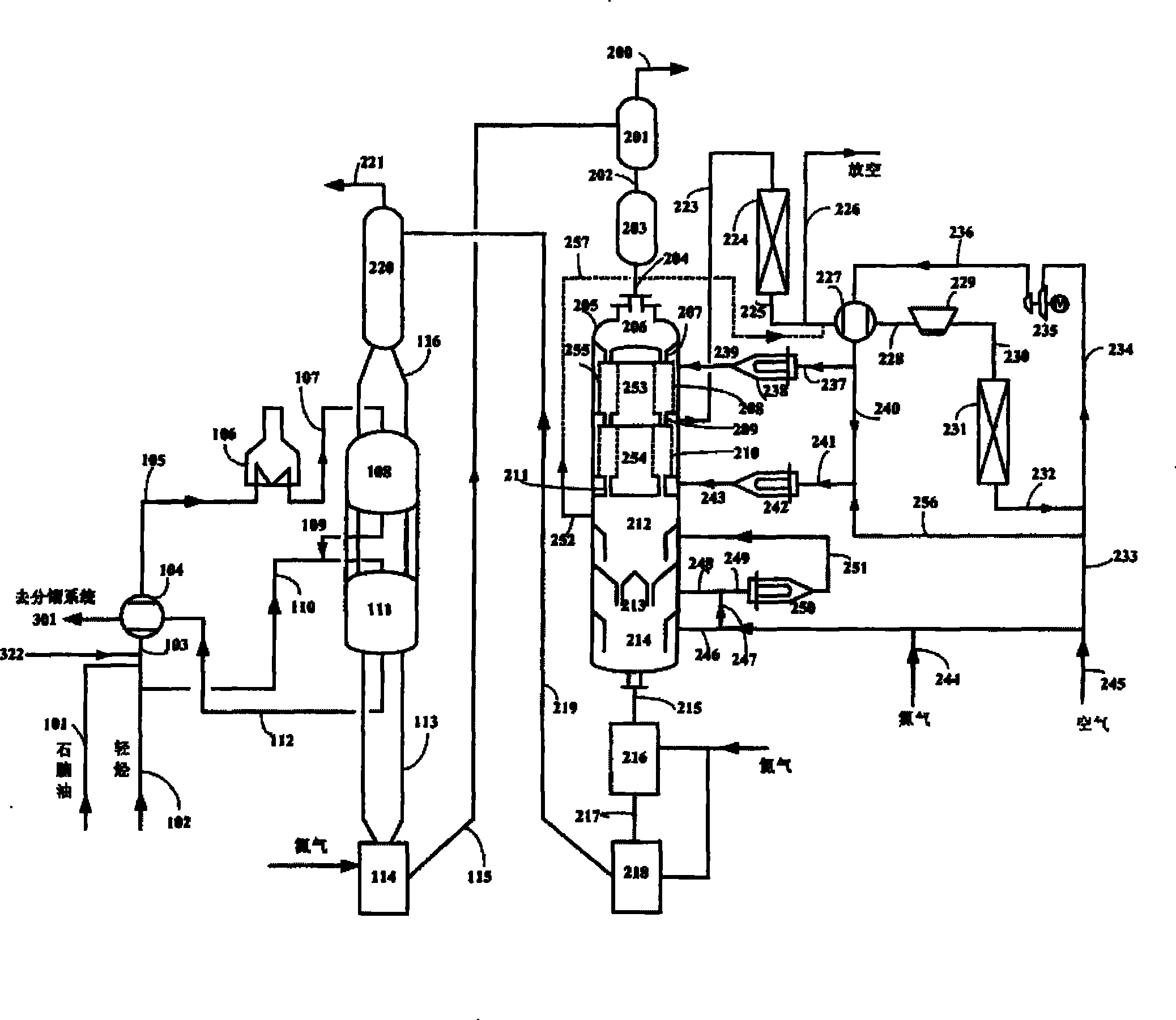

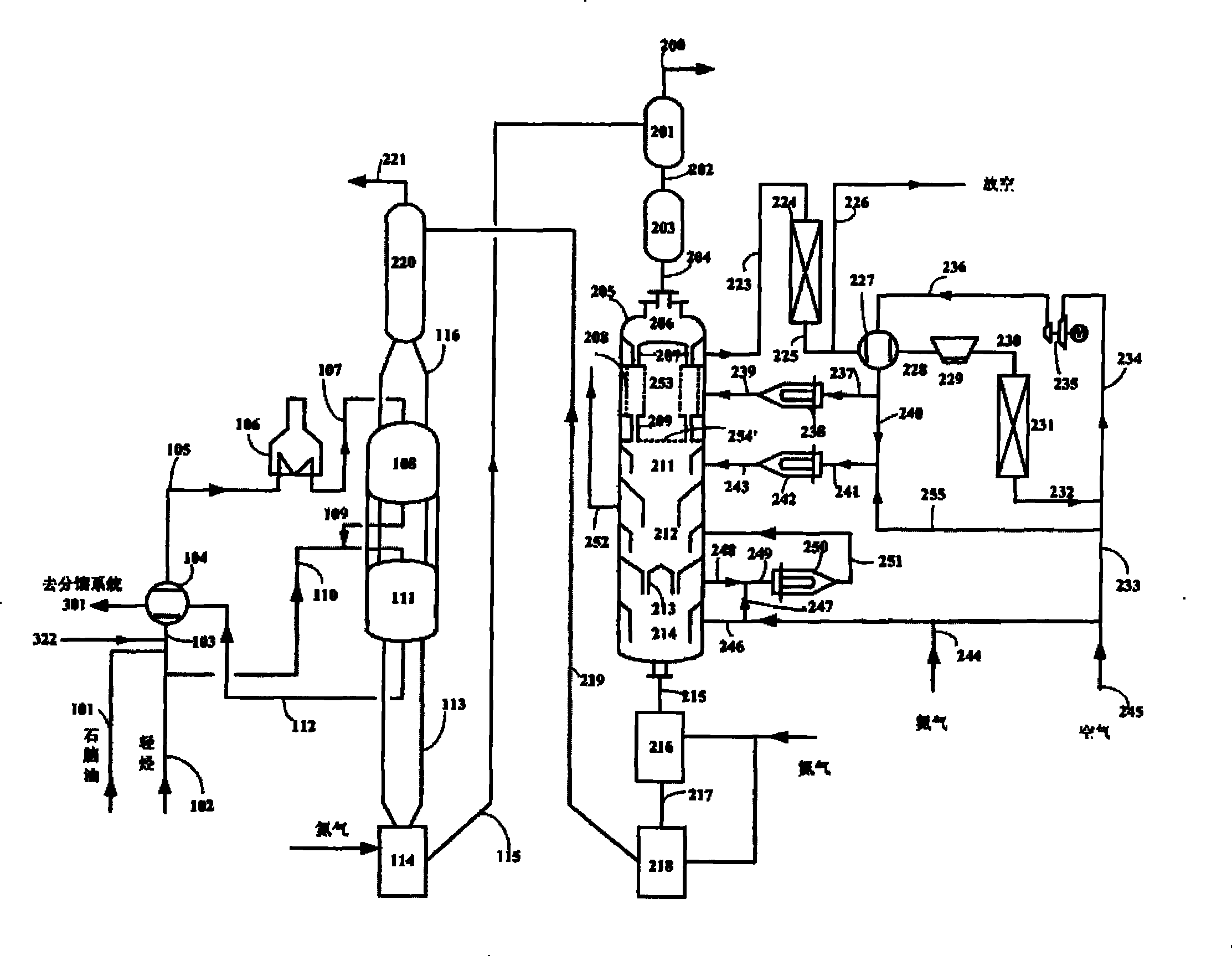

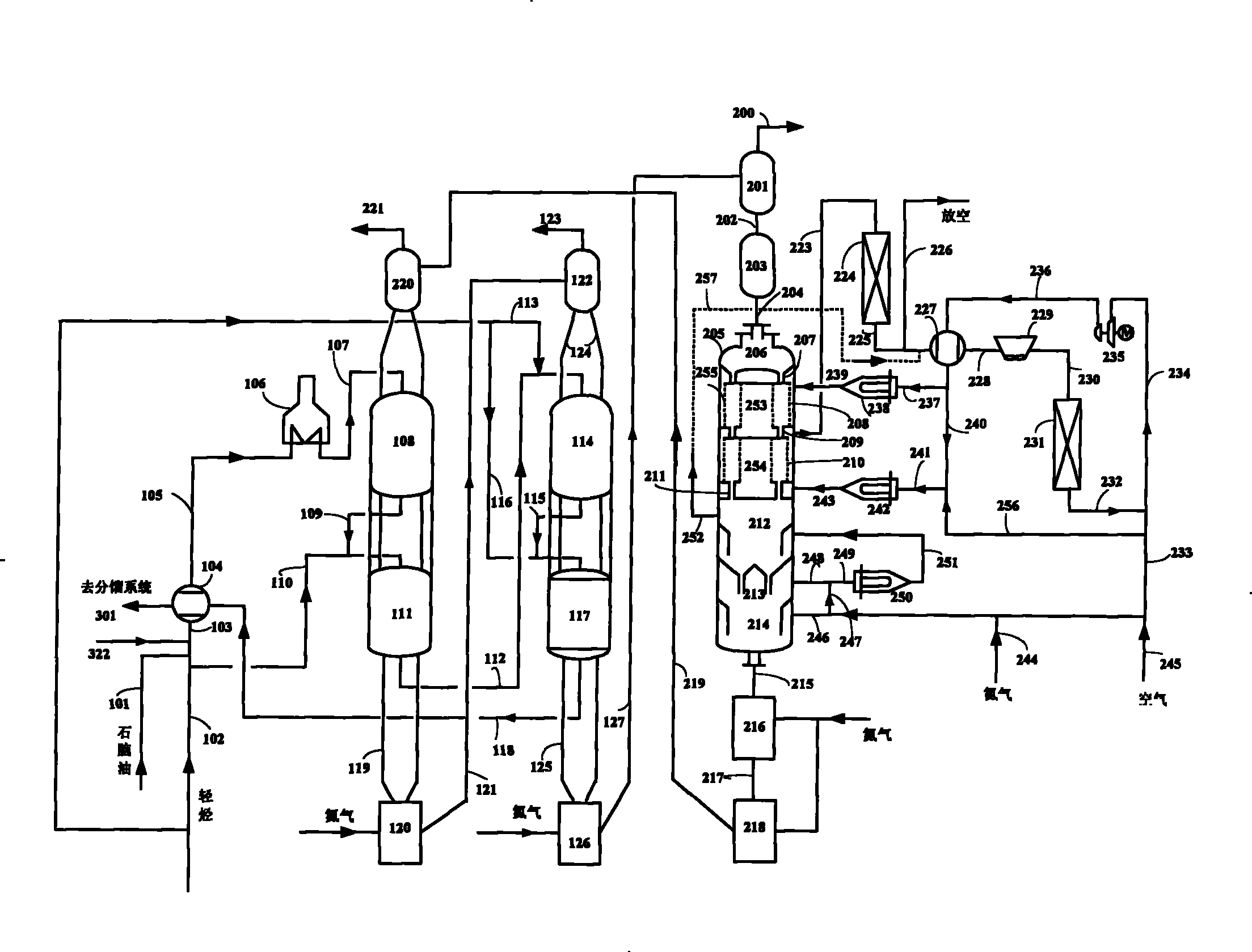

Catalytic cracking desulfur method of faulty gasoline and device thereof

ActiveCN1903989AHigh activityModerate operating conditionsCatalytic crackingOil processingIt equipment

The present invention discloses a catalytic cracking desulfurization method of low-grade gasoline in the field of petroleum processing technology and its equipment. It is characterized by that the invented gasoline upgrading reactor adopts gasoline fast bed reactor with cylindrical structure, a portion of spent catalyst can be passed through spent catalyst coveying pipeline with flow control valve and fed into catalyst mixer, and is mixed together with regenerated catalyst coming from regenerator under the action of aqueous vapor, then fed into gasoline fast bed reactor and is contacted with low-grade gasoline feed so as to make reaction to greatly reduce sulfur content of low-grade gasoline.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Mild hydrogenation purifying method for coal direct liquefaction oil

InactiveCN101311246AImprove economyHigh Hydrodenitrogenation ActivityLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesChemistryNaphtha

The invention relates to a mild hydrogenation extraction method for direct coal liquefaction oil, which comprises: blending the direct coal liquefaction oil with hydrogen to put into a steady hydrogenation reactor, carrying out desulfurization, denitrification, olefin saturation and aromatics saturation reaction under the action of a hydrotreating catalyst, separating and distilling the reaction product to obtain naphtha cut and diesel distillate, blending the obtained diesel distillate with the hydrogen, putting the mixture into a hydrogenation modification reactor to contact and react with a hydrogenation modification catalyst, separating and distilling the reaction product to obtain the diesel product. The method provided by the invention effectively combines a steady hydrogenation unit with a hydrogenation modification unit, and can product the diesel product with more than 45 of cetane number. The method has the advantages of mild operation condition, simple process, low investment, and low operation expense.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing hydrogenation aromatization catalyst

InactiveCN1621496AImprove hydrodesulfurization activityStrong aromatization abilityHydrocarbon oils refiningTungstateSulfide

The preparation process of hydrogenating and aromatizing catalyst includes: modifying titanian and SB aluminum hydroxide with two or three of ammonium tungstate, ammonium molybdenate, cobalt nitrate and nickel nitrate; modifying ZSM-5 molecular sieve with one or two of zinc nitrate, zirconium nitrate and ammonium dihydrogen phosphate; mixing modified titanian and SB aluminum hydroxide and modified ZSM-5 molecular sieve to form the mixture; and adding sesbania powder in the amount of 2-5 wt% of the mixture, citric acid of 1-3 wt% and expanding agent of 5-15 wt% to obtain the catalyst. The catalyst can eliminate impurity sulfide in catalytic cracked gasoline effectively, lowering the olefin content in gasoline and raise octane number of gasline in hydroforming condition.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Method for preparing sulphur-containing condensate oil modifying catalyst and use

ActiveCN101322945ASimple process transmissionEasy to separate and recycleMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveHydrogen

The invention relates to a preparation method for a modification catalyst of condensate oil containing sulphur and an application thereof which are characterized in that the catalyst formation is realized by loading molybdenum, Zn, Co, Ni, and the like, on a molecular sieve; the preparation method comprises two procedures, wherein, one procedure is that an active component is kneaded and added when a carrier is prepared; hydrothermal treatment is carried out after forming and roasting and the catalyst is obtained; the other procedure is that the carrier is first prepared; an active metal is brought into the carrier by the corporate immersion method; then hydrothermal treatment is carried out and the catalyst is obtained. The application is that the modification catalyst is used for modifying the condensate oil containing sulphur and a catalytic process is carried out under the condition with the presence of hydrogen or with the absence of hydrogen.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Deep processing method of non-caking coal or feebly caking coal

The invention discloses a deep processing method of non-caking coal or feebly caking coal, which comprises the following steps: performing medium-and-low-temperature carbonization reaction on non-caking coal or feebly caking coal to generate coal gas, semicoke and coal tar; treating the coal tar as follows: inputting the coal tar material, oil gas obtained through delayed coking reaction and a hydrocracking liquid-phase product into a distillation tower, and distilling out naphtha fractions, carbolic-oil-containing fractions, wax oil fractions and tower bottom oil; mixing the naphtha fractions with hydrogen, and inputting into a naphtha hydrofining reaction section; dephenolizing the carbolic-oil-containing fractions to obtain dephenolized oil, mixing with the wax oil fractions, and inputting into a hydrotreating reaction section; fractionating the hydrotreating reaction liquid phase into light fractions and heavy fractions, and performing hydrocracking on the heavy fractions; and inputting the tower bottom oil obtained through distillation into a delayed coker. Compared with the prior art, the method disclosed by the invention performs sufficient deep processing on coal, improves the yield of light fuel oil produced from coal tar, and simultaneously prolongs the service life of a catalyst in a hydrogenation device.

Owner:中铝能源有限公司

Method for producing epothilone B based on coupling of microbial fermentation and membrane separation techniques

InactiveCN103937851AImprove fermentation yieldReduce inhibitionOrganic chemistryMicroorganism based processesFiltration membraneSeparation technology

The invention discloses a method for producing epothilone B based on coupling of microbial fermentation and membrane separation techniques. The invention proposes a separation and fermentation coupling method mainly aiming at the problems that toxicity and feedback inhibition on cells are generated due to increase of a product epothilone B in the fermentation process, and bacteria growth in the fermentation process is affected. The method comprises the following steps: fermenting and cultivating, filtering by a micro-filtration membrane, carrying out ultrafiltration and nanofiltration, feeding materials, concentrating and extracting. The concentration of the fermentation liquor product epothilone B is reduced to a lower level, the growth inhibition action on the strain is relieved, the yield of the epothilone B is improved, the production cost is reduced, post-treatment of a fermentation liquor and refining of the product are facilitated, and large-scale production becomes possible, so that the method has a good industrial production prospect.

Owner:SHAANXI UNIV OF SCI & TECH

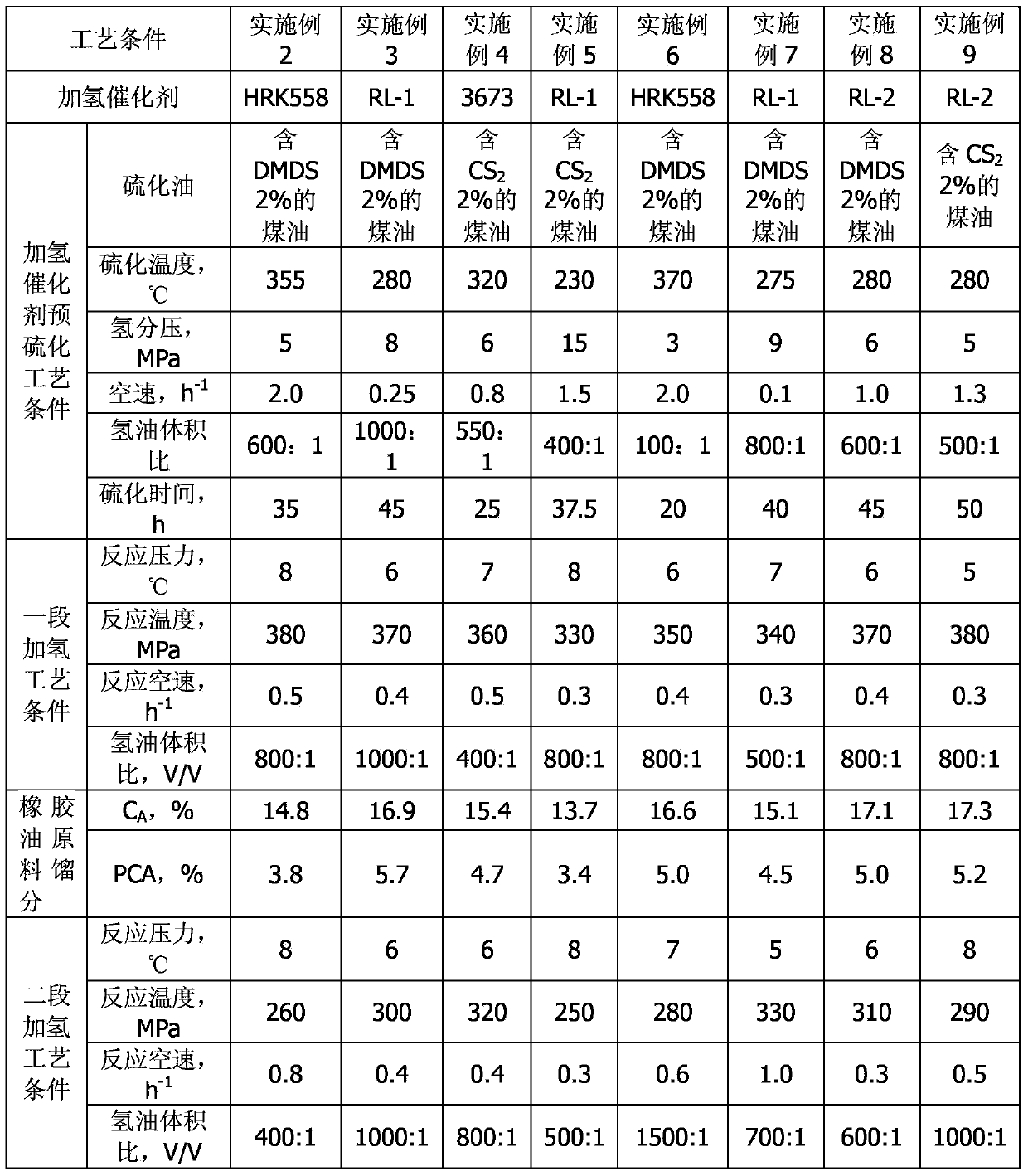

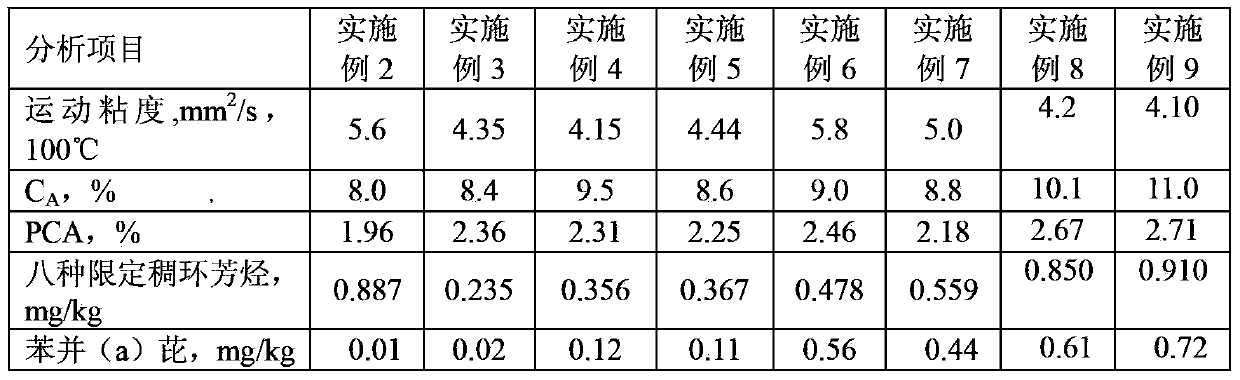

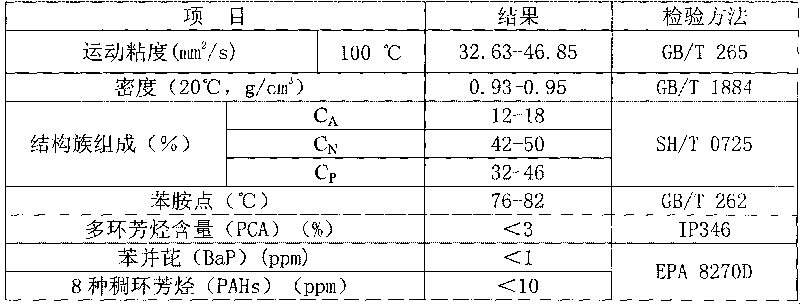

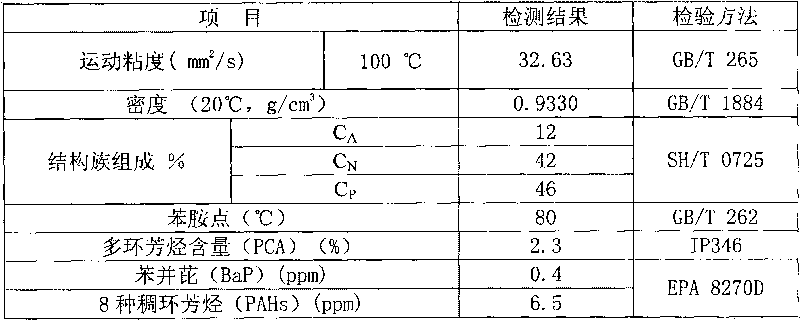

Environment-friendly rubber oil and preparation method thereof

ActiveCN104212488AEase of industrial scale productionProcess environmental protectionTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonHydrogen

The invention relates to an environment-friendly rubber oil and a preparation method thereof. The method includes: taking 280-530DEG C petroleum fractions as raw materials, passing the materials through a fixed bed hydrogenation reactor, letting the reaction material flow enter an atmospheric and vacuum fractionating tower to obtain 290-520DEG C rubber oil raw material fractions, keeping the reaction pressure at 5-8MPa, the temperature at 330-390DEG C, the space velocity at 0.3-0.5h<-1>, and the volume ratio of hydrogen to oil at 100:1-2000:1; passing the rubber oil raw material fractions through the fixed bed hydrogenation reactor, letting the reaction material flow enter the atmospheric and vacuum fractionating tower to obtain 300-510DEG C fractions; and keeping the reaction pressure at 5-8MPa, the temperature at 250-340DEG C, the space velocity at 0.3-1.0h<-1>, and the volume ratio of hydrogen to oil at 100:1-2000:1. The rubber oil has a 100DEG C kinematic viscosity of less than 6mm<2> / s, an aromatic hydrocarbon content CA% of not less than 8%, a PCA content of less than 3%, a benzopyrene content of not more than 1mg / kg, and a total content of 8 polycyclic aromatic hydrocarbons of not more than 10mg / kg.

Owner:PETROCHINA CO LTD +1

Asphalt mixture additive and preparation method thereof

ActiveCN104559258APerformance is easy to controlImprove road performanceBuilding insulationsCrack resistanceAntioxidant

The invention relates to an asphalt mixture additive and a preparation method thereof. The asphalt mixture additive comprises the following components in parts by mass: 10-20 parts of a polymer, 5-10 parts of a cross linker, 10-20 parts of padding, 0.5-2 parts of a smog inhibitor, 1-2 parts of a plasticizer, 0.1-1 part of an antioxidant and 50-70 parts of matrix asphalt, wherein the matrix asphalt is one of Shell 70#, Shell 90#, SK70# or SK90#. Compared with the prior art, the asphalt mixture additive has the advantages that the anti-rutting performance and water damage resistance of an asphalt mixture can be significantly improved, the low-temperature cracking resistance and ageing resistance of asphalt concrete can be effectively improved, and the service life of asphalt roads is prolonged; meanwhile, the asphalt mixture additive can substitute about 15-25% of asphalt raw materials in the asphalt mixture, so that the production temperature is reduced to 140 DEG C, then the smoking phenomenon in the production and spreading processes is effectively reduced, and the asphalt mixture additive is energy-saving and environment-friendly; and the production method is simple, low in cost and suitable for industrialized production.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

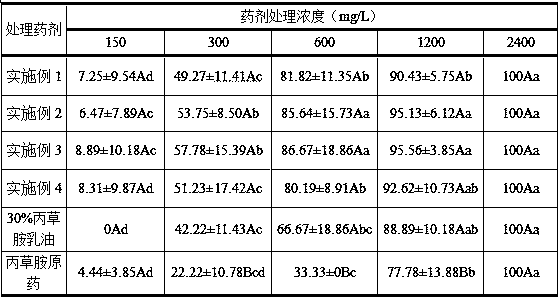

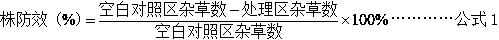

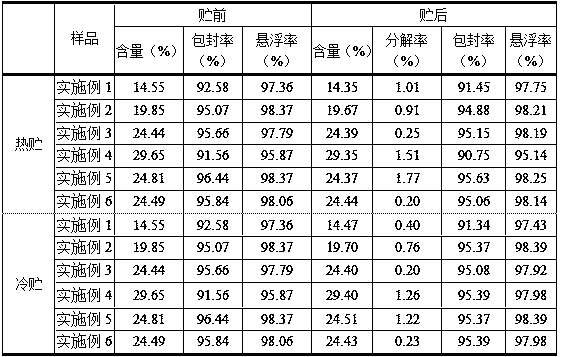

Pretilachlor microcapsule suspension and preparation method thereof

The invention discloses a pretilachlor microcapsule suspension and a preparation method thereof. The pretilachlor microcapsule suspension comprises following components in percentage by weight: 10 to30% of pretilachlor, 2 to 6% of capsule wall material, 1.5 to 5% of emulsifier, 1 to 5% of dispersant, 2.5 to 8% of solvent, 0 to 0.3% of thickening agent, and the balance being water. Pretilachlor isthe effective component, isocyanate and matched dispersant and emulsifier are taken as the auxiliary materials; and the prepared high quality pretilachlor microcapsule suspension has the advantages of high encapsulation rate, high dispersibility, and high suspension rate, has a long-lasting and stable effect on killing weeds in rice fields such as barnyard grass, is safe for the paddy rice, can effectively protect crops, and kills multiple weeds in fields such as barnyard grass.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

Method for recovering aromatic hydrocarbons in oil with low aromatic hydrocarbon content

ActiveCN108690658AAvoid decompositionLow extraction temperatureTreatment with plural serial refining stagesHydrocarbon oils treatment productsDistillationFractionation

The invention relates to a method for recovering aromatic hydrocarbons in oil with low aromatic hydrocarbon content. According to the method, raw oil is subjected to pre-fractionation, extraction, re-extraction, distillation, washing with water and water distillation so as to obtain a mixed aromatic hydrocarbon product. The method has the advantages of mild operation conditions, low comprehensiveenergy consumption and good dearomatization effect, and is applicable to recovery of aromatic hydrocarbons from a mixture with low aromatic hydrocarbon content.

Owner:PETROCHINA CO LTD

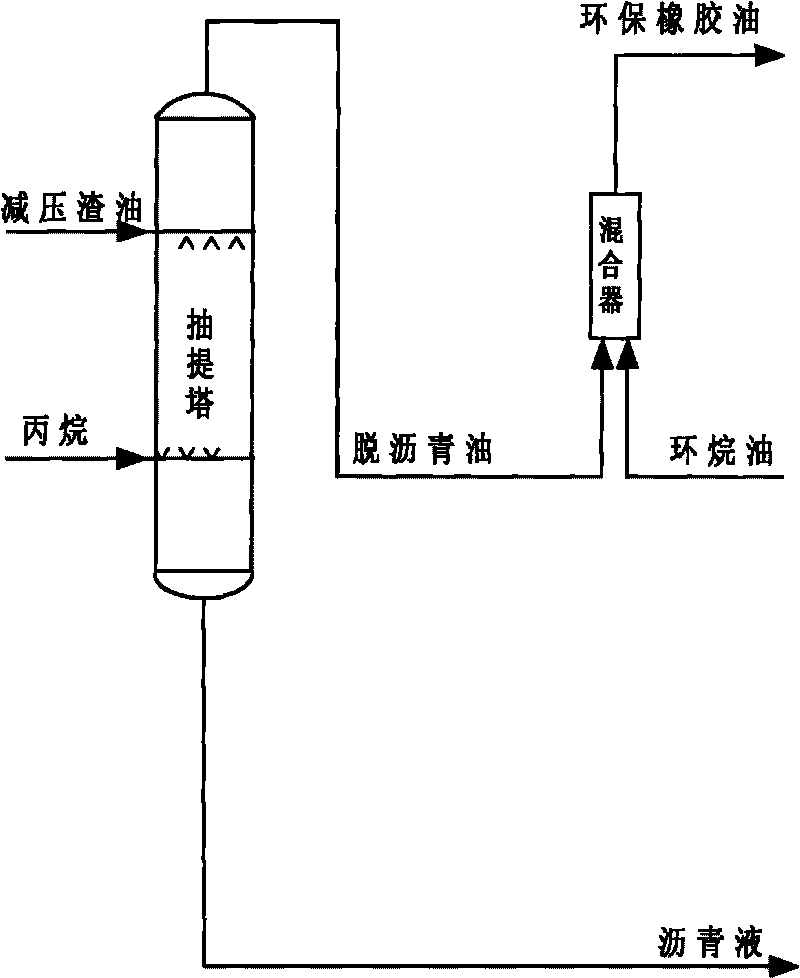

Method for producing environment-friendly rubber oil through blending method

ActiveCN101693772AImprove wet skid resistanceHigh aromatic contentHydrocarbon oils refiningResidual oilTower

The invention discloses a method for producing environment-friendly rubber oil through blending method. The method provided by the invention comprises the following steps that firstly extracting decompressed residual oil with solvent to obtain deasphalted oil, wherein the solvent for extraction is propane, the ratio by volume of the solvent and the decompressed residual oil is (6-8):1, and the extraction conditions are that the temperature of a tower top is 60-95 DEG C, the temperature of a tower bottom is 50-80 DEG C, and the pressure is 2.8-7.0 MPa, secondly mixing deasphalted oil obtained in the first step with naphthenic oil for 30-120 min with 70-90 DEG C to obtain environment-friendly rubber oil, wherein the mass ratio of the deasphalted oil and the naphthenic oil is (0.2-0.6):(0.8-0.4). The environment-friendly rubber oil produced by the invention accords with the environment-friendly instruction requirement of EU 2005 / 69 / EC, wherein aromatic-carbon rate is 12%-18%, the content of PCA is smaller than 3%, the content of aromatic hydrocarbons is high, and the rubber oil is environment-friendly, nontoxic, and has no carcinogenic effect. The environment-friendly rubber oil can be used as succedaneum of existing aromatic oil, and has great economic values.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Modifying method for naphtha and light hydrocarbon aromatization

ActiveCN101747933BLower end pointReduce carbon deposition rateCatalytic naphtha reformingLiquid productHydrogen

A modifying method for naphtha and light hydrocarbon aromatization comprises: contacting naphtha and C3-C5 light hydrocarbon with aromatization catalyst in the presence of hydrogen-containing gas to carry out aromatization modifying reaction, wherein the reaction temperature is 250-600 DEG C, and the volume ratio of hydrogen to naphtha is 20-400. The method can convert naphtha with low octane value and low-carbon hydrocarbon into gasoline component with high octane value and excellent liquefied gas, the final distilling point of liquid product and the carbon-accumulating speed of catalyst areobviously reduced, and the service life of catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com