Method for producing gasoline blend component with high octane value by using cracking gasoline heavy fractions

A technology for high-octane gasoline and pyrolysis gasoline, which is applied in hydrocarbon oil cracking, petroleum industry, etc., to achieve the effects of low operating cost, simple process flow, and guaranteed operation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

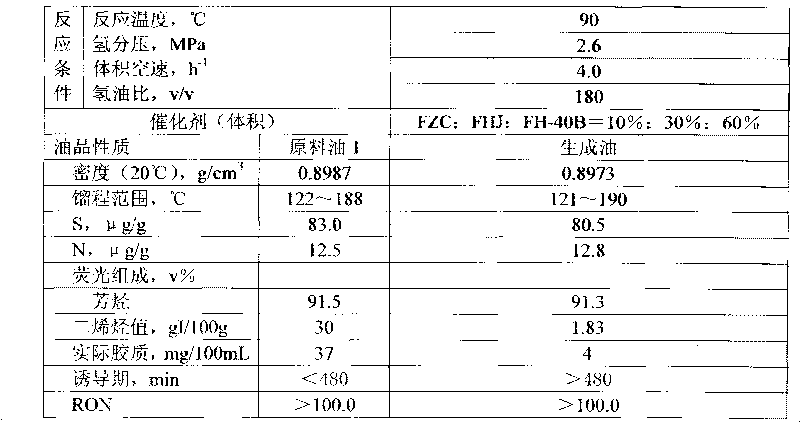

[0026] pyrolysis gasoline C 9 + Distillate raw material 1 enters the reactor after being contacted with hydrogen, and undergoes hydrofining reaction. The main process conditions are: hydrogen partial pressure 2.6MPa, volume space velocity 4.0h -1 . The reaction temperature is 90° C., the volume ratio of hydrogen to oil is 180:1, and there is no circulation operation. The properties of raw oil and test results are listed in Table 2.

[0027] It can be seen from Table 2 that this technology can effectively improve the stability of the oil, basically no loss of octane number, the actual gum content is less than 5mg / 100mL, and the induction period is more than 480 minutes, which meets the quality index of motor gasoline.

[0028] Table 2 Raw oil properties and test results

[0029]

Embodiment 2

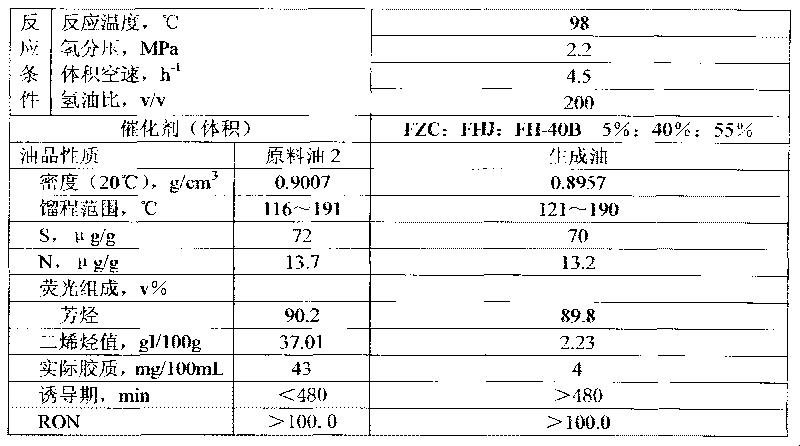

[0031] pyrolysis gasoline C 9 ~C 10 Distillate raw material 2 enters the reactor after being contacted with hydrogen, and undergoes hydrofining reaction. The main process conditions are: hydrogen partial pressure 2.2MPa, volume space velocity 4.5h -1 , The reaction temperature is 98°C, the volume ratio of hydrogen to oil is 200:1, and the volume ratio of circulating oil to fresh raw oil is 0.5:1. The properties of raw oil and test results are listed in Table 3.

[0032] It can be seen from Table 3 that the technology can effectively improve the stability of the oil, basically no loss of octane number, the actual gum content is less than 5mg / 100mL, and the induction period is more than 480 minutes, which meets the quality index of motor gasoline.

[0033] Table 3 Raw oil properties and test results

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com