Method for recovering aromatic hydrocarbons in oil with low aromatic hydrocarbon content

A low-aromatic and aromatic technology, which is used in the treatment of hydrocarbon oil, hydrocarbon oil treatment products, petroleum industry, etc., can solve the problems of many new dosages, high extraction temperature, low yield, etc., and achieves moderate operating conditions and avoids solvent decomposition. , the effect of low extraction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

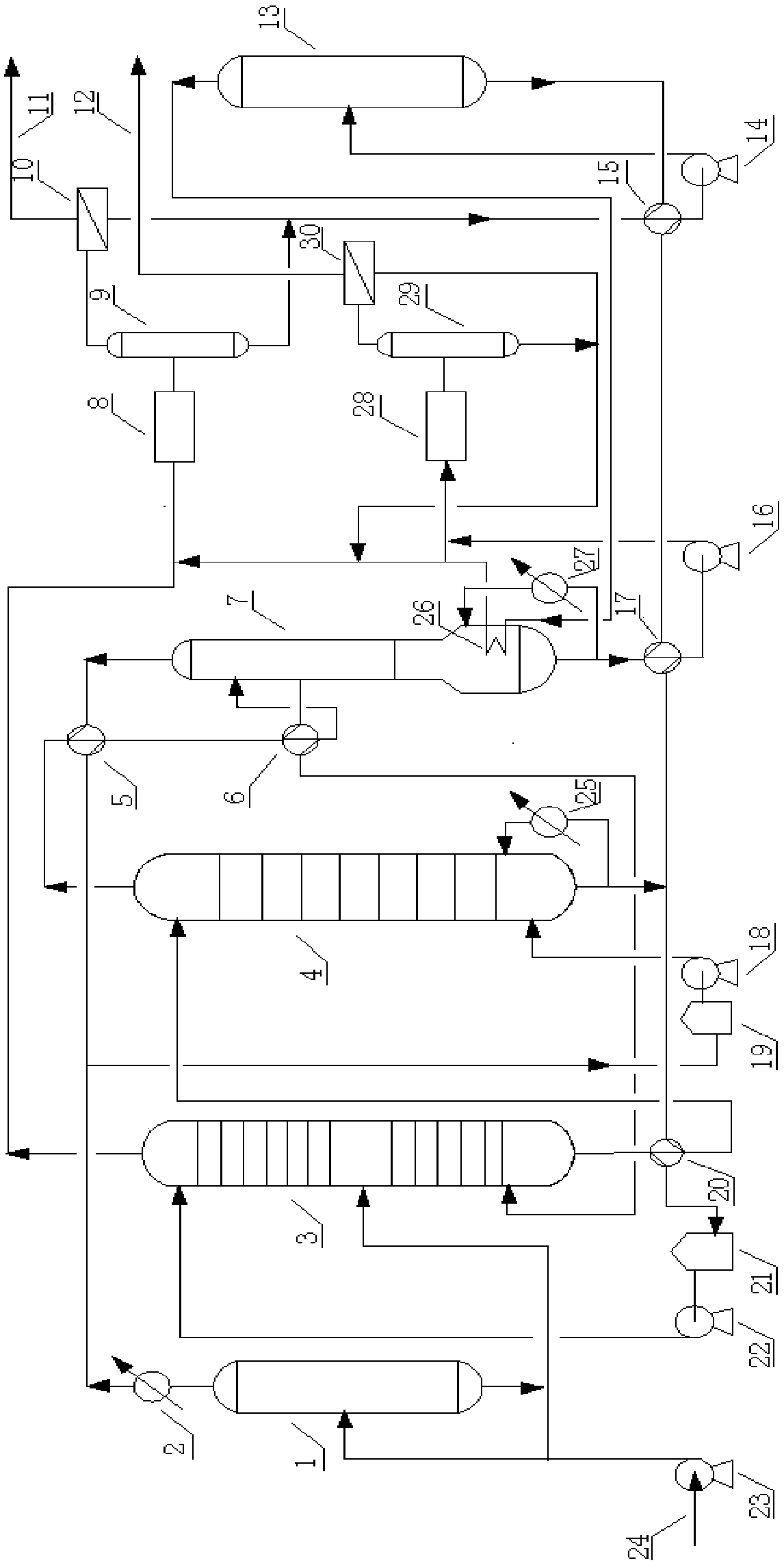

Image

Examples

Embodiment 1

[0026] The aromatic content of the raw oil is 5.83%, the ratio of the raw oil entering the pre-fractionator 1 and the extraction tower 3 is 1:1, and the feed volume space velocity of the pre-fractionator is 1.5h -1 , the temperature at the bottom of the tower is 75°C, the temperature at the top of the tower is 60°C, the operating pressure is 0.15MPa; the volumetric space velocity of the extraction tower is 0.53h -1 Sulfolane is used as the extractant, the solvent ratio (solvent feed amount / extraction raw material amount) is 1.6, the operating temperature is 55°C, and the operating pressure is 0.15MPa; the stripping dose / extracted oil volume ratio is 1.6, the stripping tower operating temperature is 55°C, and the operating pressure 0.15MPa; Distillation tower bottom temperature 85°C, tower top temperature 60°C, operating pressure 0.17MPa, side line production temperature 75°C, backwashing ratio 0.6; washing water volume / mass to be washed 0.1, washing unit operating temperature 2...

Embodiment 2

[0028] The aromatics content of the raw oil is 24.66%, the ratio of the raw oil entering the pre-fractionator 1 and the extraction tower 3 is 2:1, and the feed volume space velocity of the pre-fractionator is 1.5h -1 , the temperature at the bottom of the tower is 80°C, the temperature at the top of the tower is 65°C, the operating pressure is 0.13MPa; the volumetric space velocity of the extraction tower is 0.37h -1 , Sulfolane is used as the extractant, solvent ratio (solvent feed amount / extraction raw material amount) 3.0, operating temperature 70°C, operating pressure 0.25MPa; stripping dose / extracted oil volume ratio 2.0, stripping tower operating temperature 70°C, operating pressure 0.25MPa; Distillation tower bottom temperature 90°C, tower top temperature 65°C, operating pressure 0.31MPa, side line production temperature 75°C, backwashing ratio 0.8; washing water volume / mass to be washed 0.1, washing unit operating temperature 30°C, The operating pressure is 0.12MPa; th...

Embodiment 3

[0030] The aromatic content of the raw oil is 10.16%, the ratio of the raw oil entering the pre-fractionator 1 and the extraction tower 3 is 3:1, and the feed volume space velocity of the pre-fractionator is 1.5h -1 , the temperature at the bottom of the tower is 76°C, the temperature at the top of the tower is 61°C, the operating pressure is 0.12MPa; the volumetric space velocity of the extraction tower is 0.45h -1 Sulfolane is used as the extractant, the solvent ratio (solvent feed amount / extraction raw material amount) is 2.2, the operating temperature is 65°C, and the operating pressure is 0.20MPa; the stripping dose / extracted oil volume ratio is 1.8, the stripping tower operating temperature is 65°C, and the operating pressure 0.20MPa; Distillation tower bottom temperature 86°C, tower top temperature 61°C, operating pressure 0.27MPa, side line production temperature 75°C, backwashing ratio 0.7; washing water volume / mass to be washed 0.1, washing unit operating temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com