Method for preparing sulphur-containing condensate oil modifying catalyst and use

A technology for sulfur condensate and catalyst, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult application of catalysts, high liquefied gas yield, and low liquid yield, etc., and achieve excellent The effect of catalytic conversion ability, high oil yield, and simple product separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

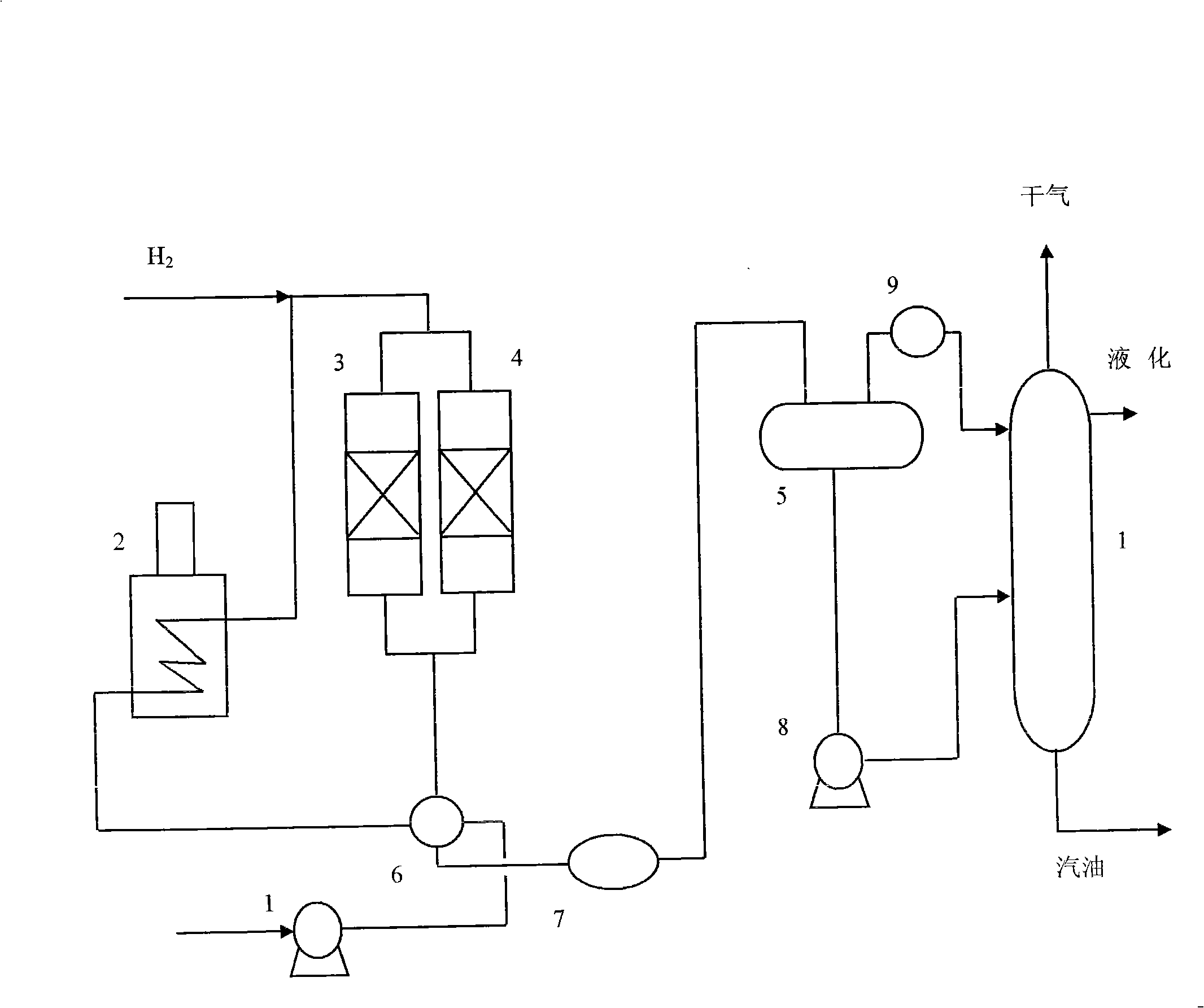

Method used

Image

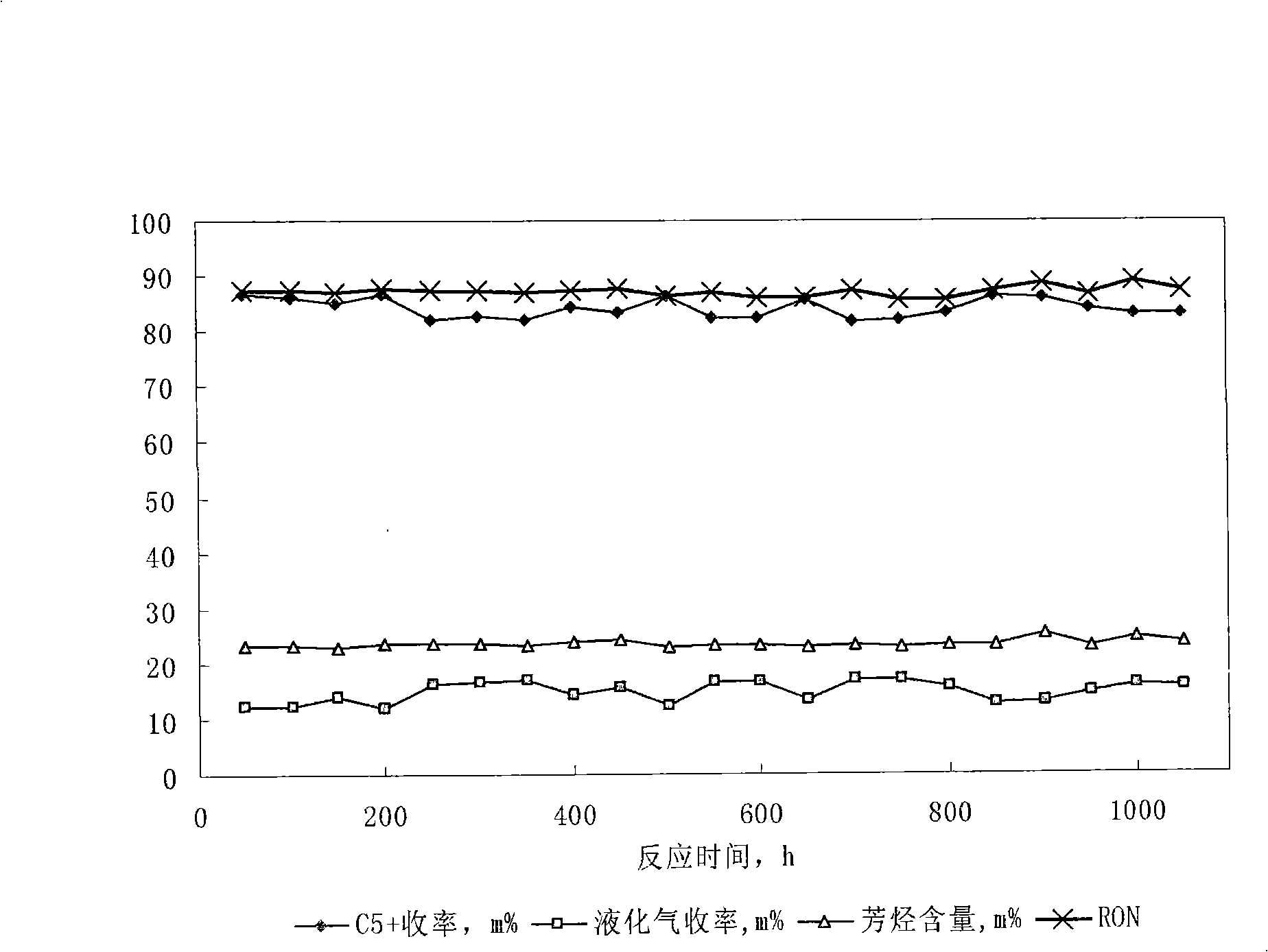

Examples

Embodiment 1

[0034] Preparation of the catalyst of the present invention.

[0035] (1) Preparation of molecular sieve carrier: take 130 g of nanometer HZSM-5 molecular sieves with a silicon-aluminum ratio of 38, 70 g of pseudo-boehmite powder, mix well, add 1.8 milliliters of 1: 1 solution of nitric acid and 50 milliliters of deionized water, and knead Finally, it is extruded into a strip with a diameter of 1.6 mm and a length of 3 to 5 mm in an extruder, dried at 110°C for 12 hours, and calcined at 550°C for 3 hours.

[0036] (2) Active metal loading: Take 100 g of the above-mentioned carrier, impregnate at 25° C. for 3 hours with 100 ml of an aqueous solution containing 20.5 grams of molybdenum trioxide and 7.41 grams of zinc nitrate, dry at 110° C. for 12 hours, and roast at 550° C. for 4 hours.

[0037] (3) Hydrothermal treatment: put the catalyst prepared in step (2) into a tubular reactor, heat up to 520°C in an air stream under normal pressure, then change to steam at this temperatu...

Embodiment 2

[0040] Prepare other several catalysts B-E by the method for embodiment 1, difference is to change the second metal type and content, be respectively B (aluminum 12.0%, nickel 2.5%), C (molybdenum 12.0%, tungsten 2.5%), D ( Molybdenum 12.0%, Cobalt 2.5%), E (Molybdenum 12.0%, Iron 3.0%).

Embodiment 3

[0042] Catalyst F is prepared by the method of embodiment 1, and difference is that the carrier that step (1) step is made is advanced steam treatment, then introduces active metal (molybdenum 12.0%, nickel 2.5%) with the method for (2) step .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com