Preparation method of separating zinc oxide-based photocatalyst by magnetic control

A zinc oxide and catalyst technology, which is applied in the field of preparation of a zinc oxide-based photocatalyst that can be separated by magnetic control, can solve the problems of high production and use costs, cumbersome preparation processes, unstable performance and the like, and achieves low production and use costs, high preparation The effect of simple process and small operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

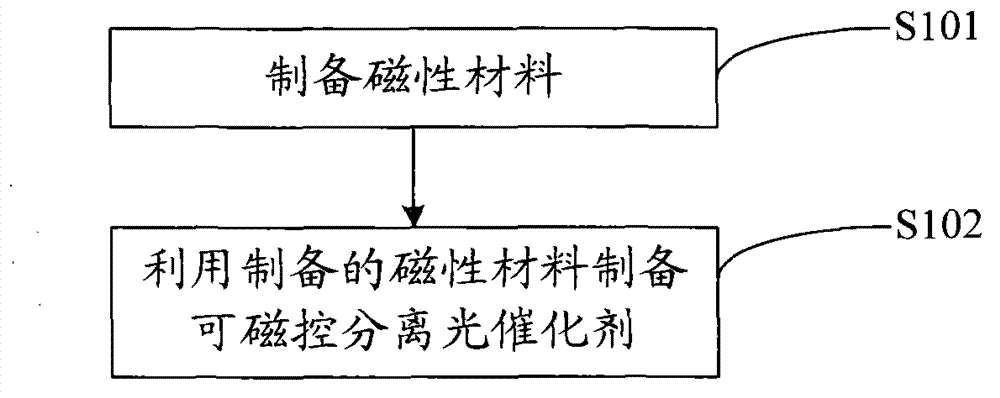

[0027] The preparation method comprises the following steps:

[0028] In step S101, a magnetic material is prepared;

[0029] In step S102, using the prepared magnetic material as a core to prepare a magnetic control separable core-shell photocatalyst.

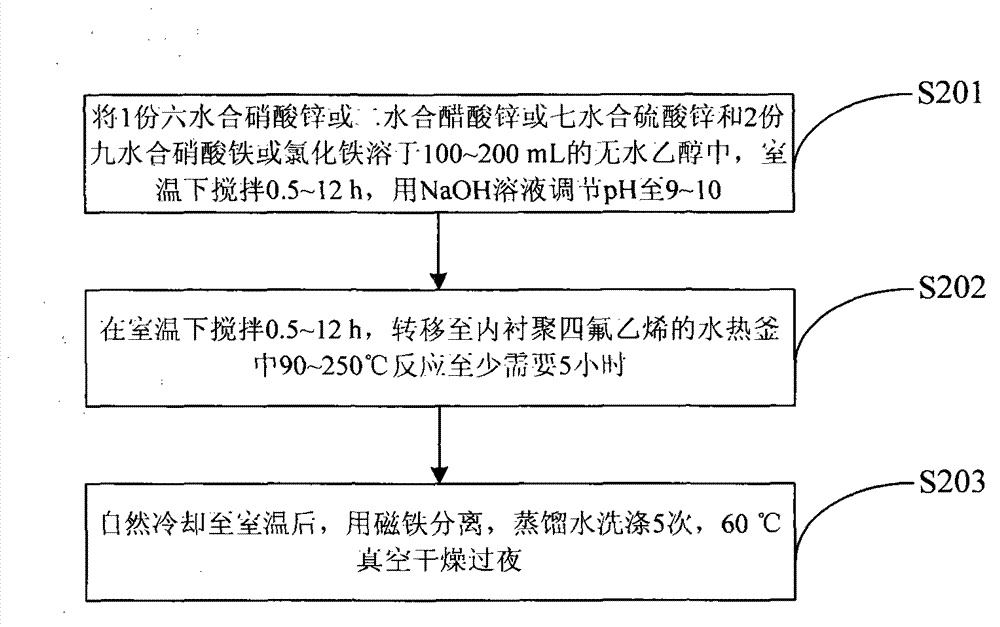

[0030] Such as figure 2 As shown, in the embodiment of the present invention, the realization method of preparing the magnetic material is:

[0031] In step S201, 1 part of zinc nitrate hexahydrate or zinc acetate dihydrate or zinc sulfate heptahydrate and 2 parts of ferric nitrate nonahydrate or ferric chloride are dissolved in 100-200 mL of absolute ethanol, and stirred at room temperature for 0.5-12 hours , adjust the pH to 9-10 with NaOH solution;

[0032] In step S202, stir at room temperature for 0.5-12 hours, transfer to a polytetrafluoroethylene-lined hydrothermal kettle at 90-250°C for at least 5 hours;

[0033] In step S203, after naturally cooling to room temperature, they were separated with a magnet, washed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com