Preparation method of catalyst for hexone synthesis by acetone hydrogenation and application

A technology of methyl isobutyl ketone and catalyst, applied in the field of catalysis, can solve problems such as high cost, reduce MIBK production cost, and easy loss of active components, and achieve the effects of low cost, strong raw material adaptability, and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

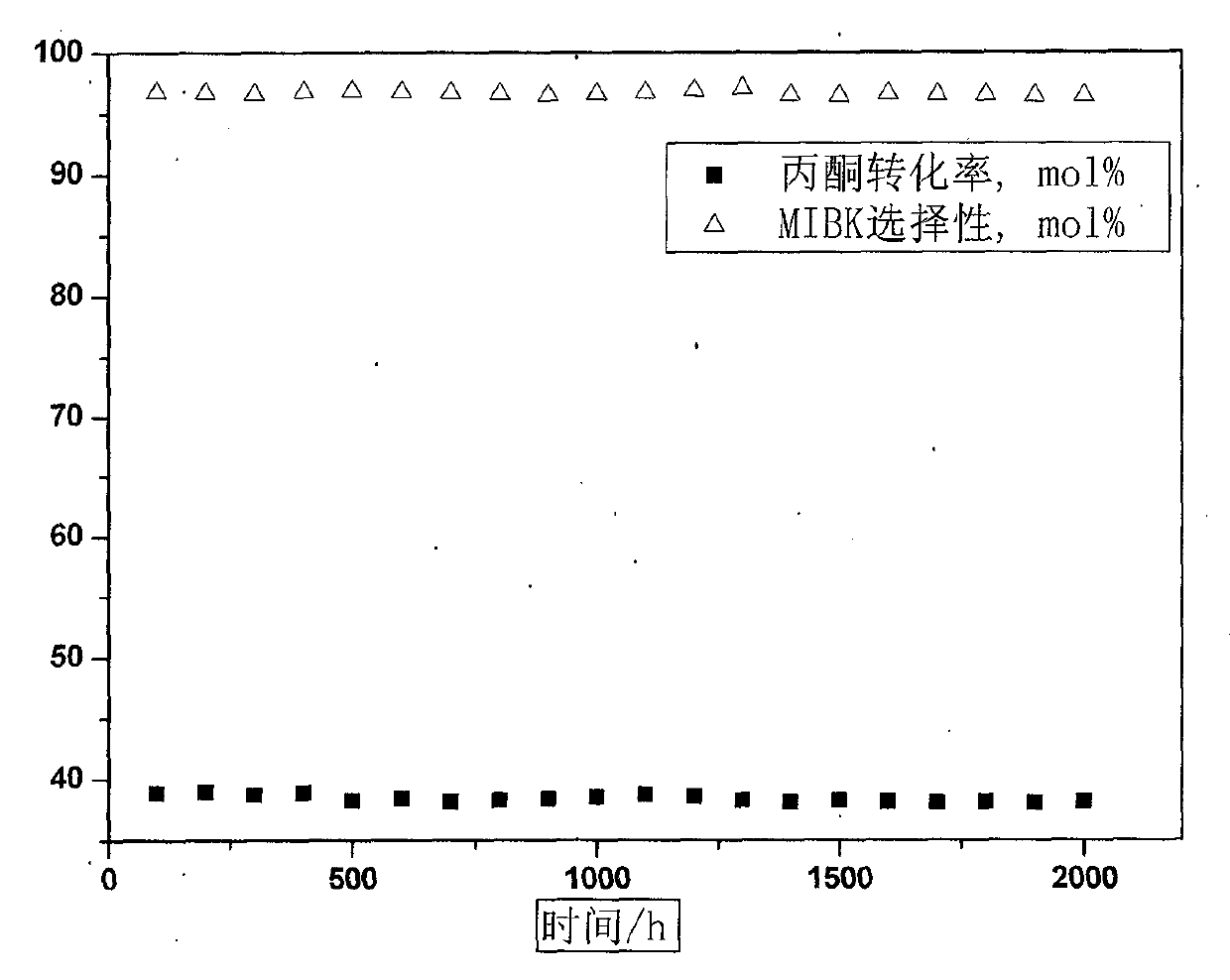

Examples

Embodiment 1

[0029] Prepare catalyst of the present invention

[0030] Mix 42.8g of aluminum oxide, 57.2g of zinc oxide and 2g of methylcellulose for 30 minutes, add 80ml of 3wt% dilute nitric acid solution, mix for 20 minutes, roll into a 3mm ball in a granulator, and dry at 120°C for 12 hours , calcined at 600°C for 3 hours to obtain a composite carrier; then dissolved 214.6g of nickel nitrate in water to obtain a clear solution, impregnated the composite carrier step by step, dried at 120°C for 12 hours, and calcined at 500°C for 3 hours to obtain NiO / Al 2 o 3 -ZnO catalyst; finally, put the prepared spherical catalyst into a tubular reactor, raise the temperature to 500°C in the air under normal pressure, and then change the water vapor treatment at this temperature for 6 hours, and then pass in dry air to purge and cool down , The total water intake during steam treatment is 250g.

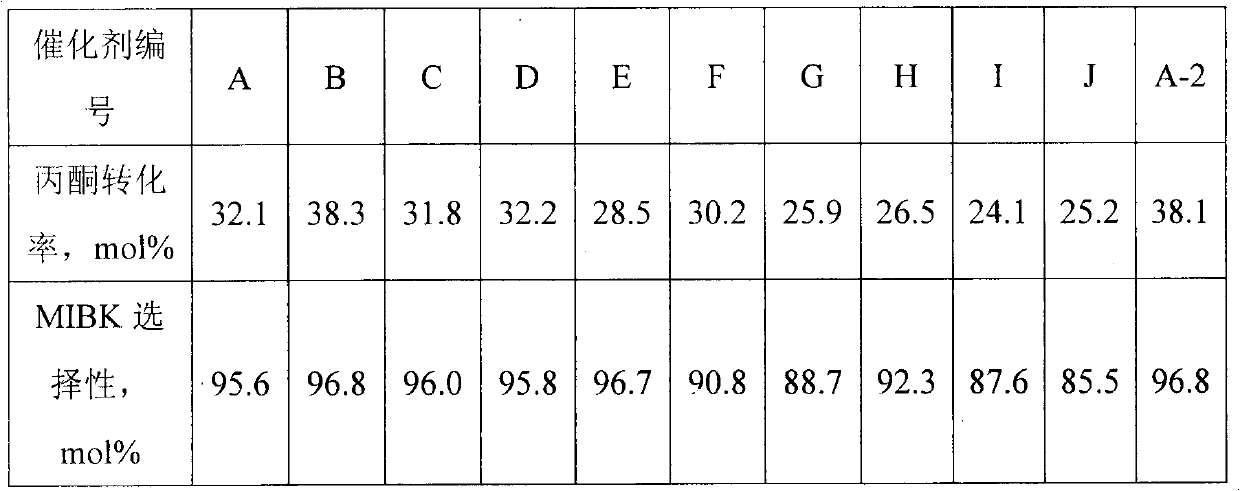

[0031] The number of the catalyst prepared above is A, wherein the nickel oxide content is 35.3 wt%, ...

Embodiment 2

[0033]Mix 100g of alumina and 2g of methyl cellulose for 30 minutes, add 85ml of 3wt% dilute nitric acid solution, mix for 20 minutes, roll into a 3mm ball in a granulator, dry at 120°C for 12 hours, and bake at 600°C for 3 hours , to obtain an alumina carrier; then dissolve 115.8g of nickel nitrate, 148.1g of manganese nitrate and 10g of citric acid in water to form a clear solution, impregnate the alumina carrier step by step, dry at 120°C for 12 hours, and roast at 500°C for 3 hours to prepare The finished catalyst was obtained; finally, the above-mentioned catalyst was loaded into a tubular reactor, and the temperature was raised to 500°C in the air under normal pressure, and then changed to steam at this temperature for 6 hours, and then dry air was introduced to purge and cool down. The total water intake during the steam treatment is 250g.

[0034] The catalyst number prepared above is B, wherein the nickel oxide content is 16.3 wt%, the manganese oxide content is 28.4 ...

Embodiment 3

[0036] Another catalyst C was prepared according to the method of Example 1, except that the composite support was subjected to hydrothermal treatment first, and then the active component nickel was introduced by an impregnation method. The content of the components is the same as that of catalyst A, wherein the nickel oxide content is 32.5 wt%, the zinc oxide content is 39.2 wt%, and the balance is aluminum oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com