Method for separating cracked carbon 5 using azeotropic super fractionation and extractive distillation coupling

A technology of extractive distillation and rectification, which is applied in the field of separation of mixed carbon five hydrocarbons, and can solve problems such as the inability to obtain pure isoprene and the explosion of alkynes without concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

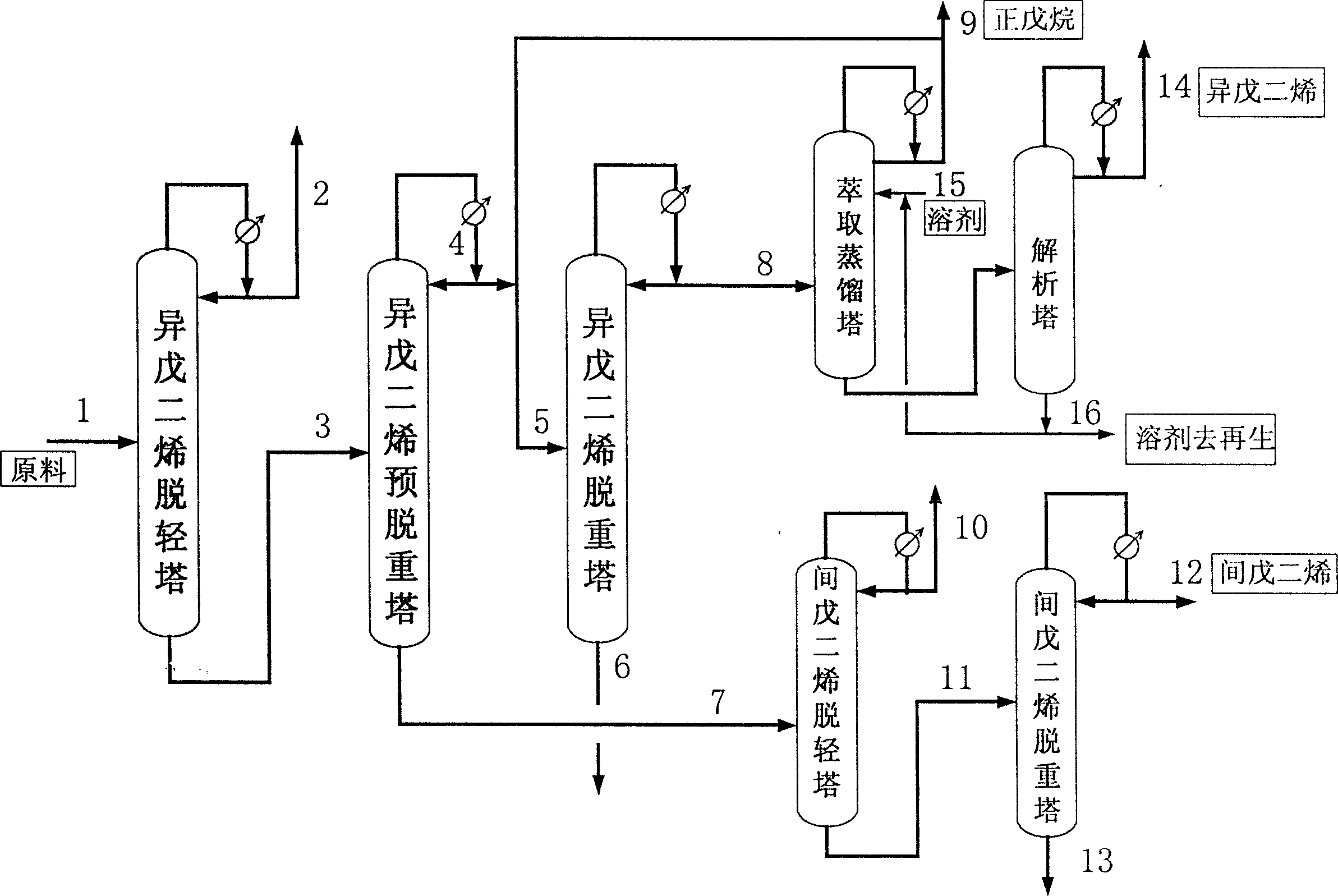

[0024] Embodiment 1: by appending figure 1It can be seen that the azeotropic ultra-rectification delightening unit of this embodiment is composed of an isoprene delightening tower, and the deweighting unit is composed of two deweighting towers (referred to herein as an isoprene pre-deweighting tower and an isoprene delightening tower). Diene weight removal tower) is composed of isoprene weight removal tower, isoprene pre-weight removal tower and isoprene weight removal tower. Cyclopentadiene and dicyclopentadiene have been removed, and the decyclization and cracking carbon pentahydrocarbon stream (raw material 1) with cyclopentadiene content<7% (mass) first enters the isoprene delightening tower, from the tower top stream (2) Separate the light components, including C4 hydrocarbons, isopentane, 3-methylbutene-1, 2-methylbutene-1, pentene-1, and butyne-2, iso Pentyne, isopentenyne, pentadiene-1,4 and other small but harmful impurities. The column stream (3) enters the isopren...

Embodiment 2

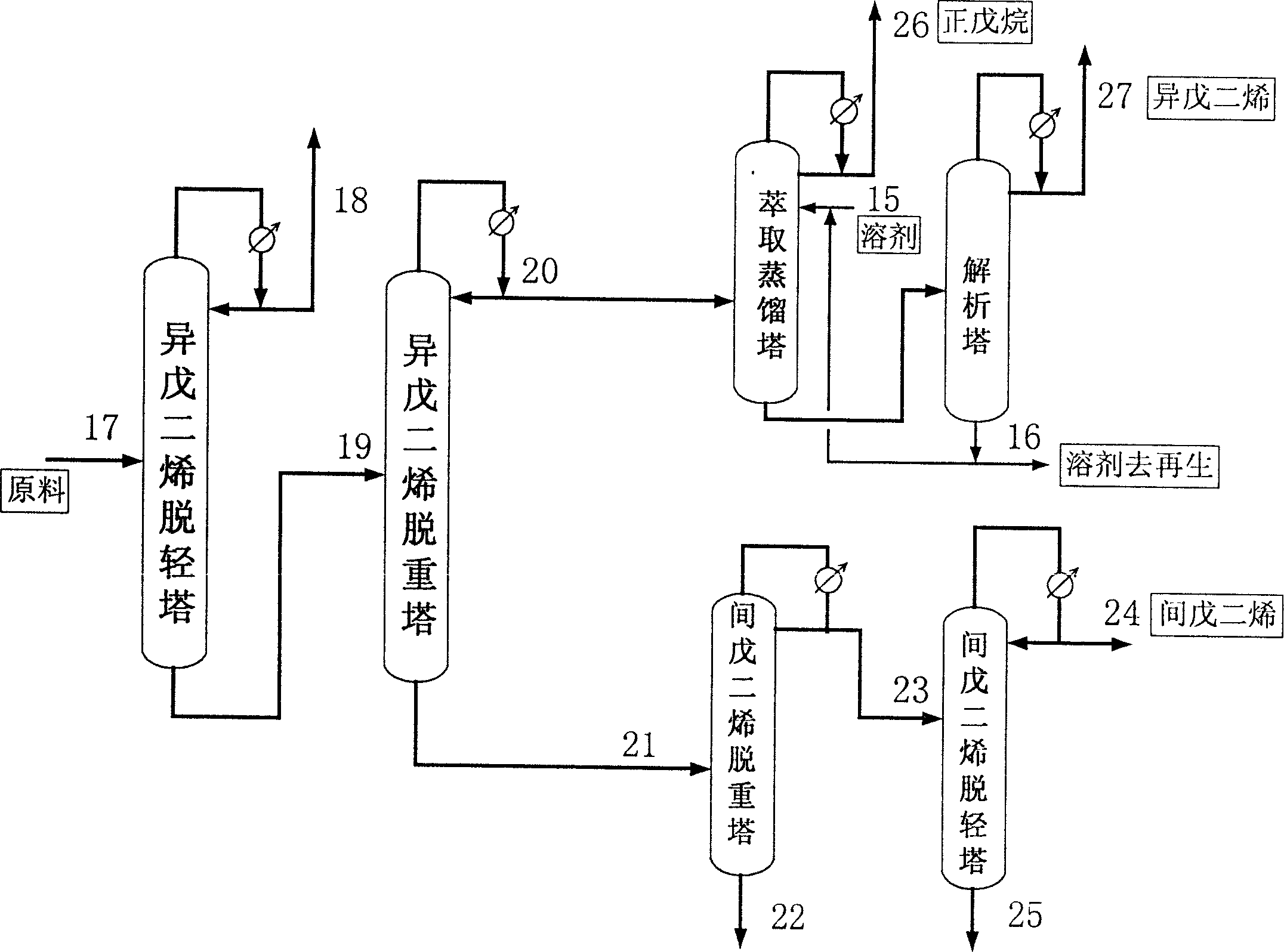

[0031] Embodiment 2: by appending figure 2 It can be seen that the azeotropic super-rectification light removal unit and the heavy weight removal unit in this embodiment are composed of only one tower, and are arranged in the order of the isoprene light removal tower and the isoprene heavy weight removal tower. C-pentahydrocarbons (stream 17) first enter the isoprene light removal tower, similar to embodiment 1, separate the light components with a boiling point lower than the isoprene-n-pentane azeotrope from the overhead stream (18) . The tower still stream (19) then enters the isoprene weight-removing tower, and the heavy component with a higher boiling point than the isoprene-n-pentane azeotrope is separated from the weight-removing tower still stream (21), and the weight-removing tower top obtains is the isoprene-n-pentane azeotrope (stream 20). Since the n-pentane content in the C5 raw material used in this example has exceeded the amount required to form the isoprene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com