Patents

Literature

71results about How to "Solve decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-toughness and highly heat-resistant polylactic acid (PLA) alloy material and preparation method thereof

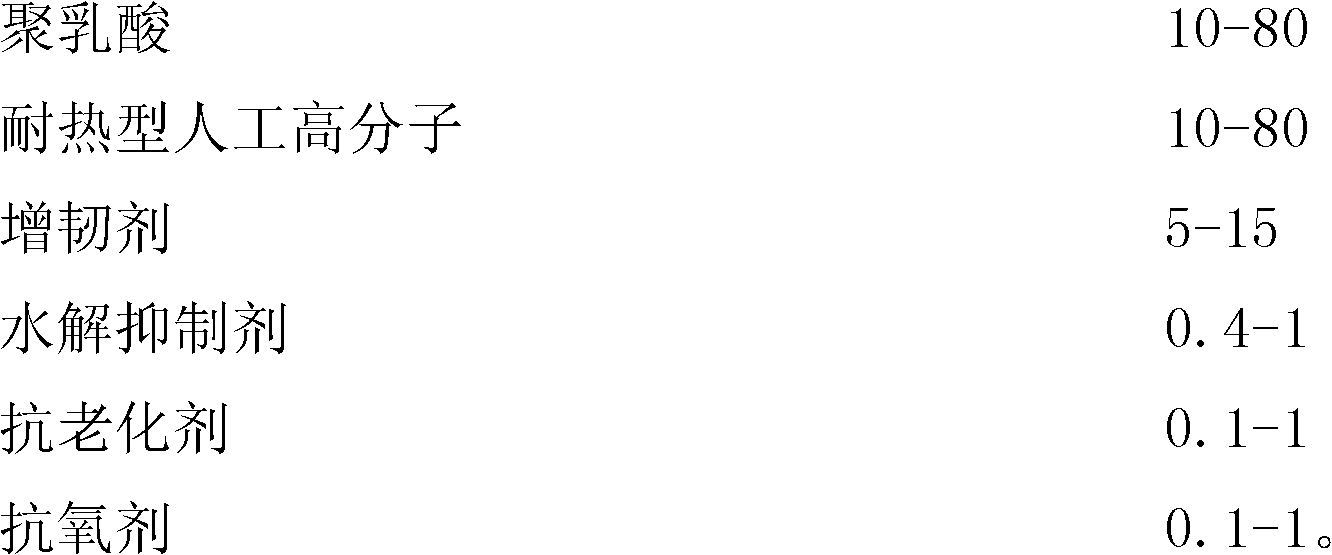

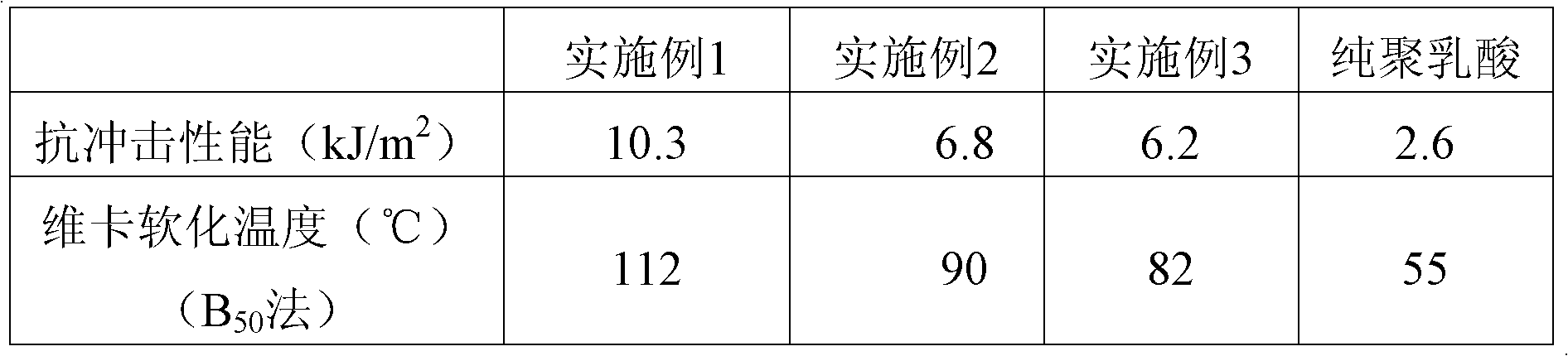

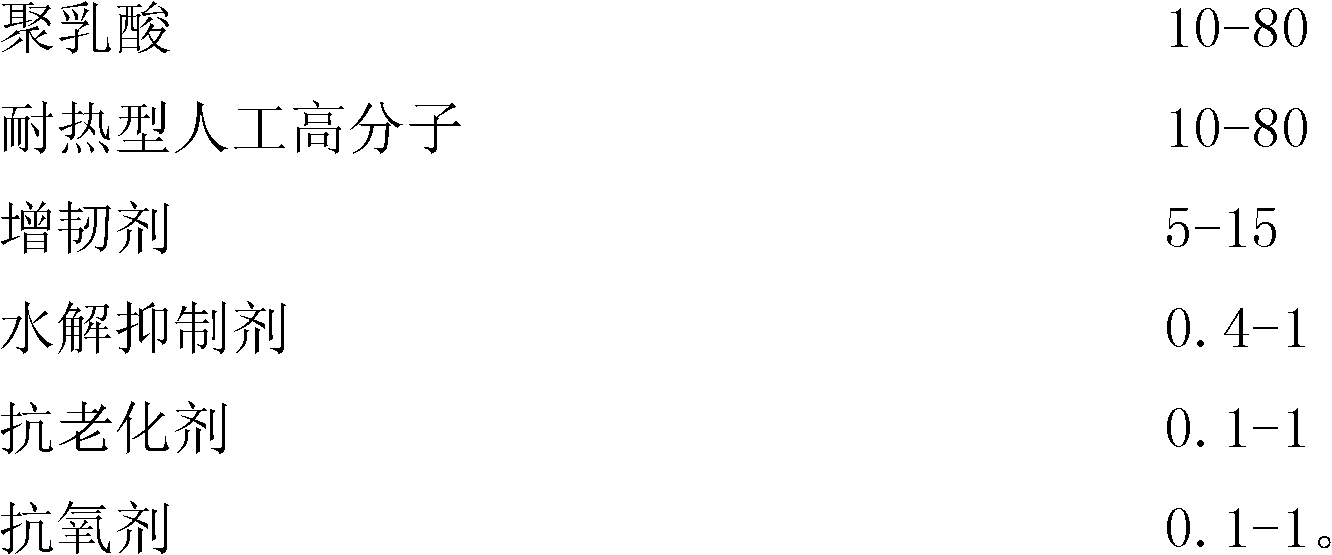

The invention discloses a high-toughness and highly heat-resistant polylactic acid (PLA) alloy material and a preparation method thereof. The material comprises the following components in part by weight: 10 to 80 parts of PLA, 10 to 80 parts of heat-resistant artificial macromolecules, 5 to 15 parts of toughening agent, 0.4 to 1 part of hydrolysis inhibitor, 0.1 to 1 part of anti-aging agent and 0.1 to 1 part of antioxidant. Compared with the prior art, the material has the advantages that: the toughness and heat resistance of a PLA composite material are improved simultaneously; blending modification which is an important way of polymer modification is simple and practicable and low in cost; and by a blending system, the performance of the components can be comprehensively balanced, the components are complemented, and the performance weakness of each single component is avoided, so that a polymer material with ideal comprehensive performance is obtained.

Owner:CHERY AUTOMOBILE CO LTD

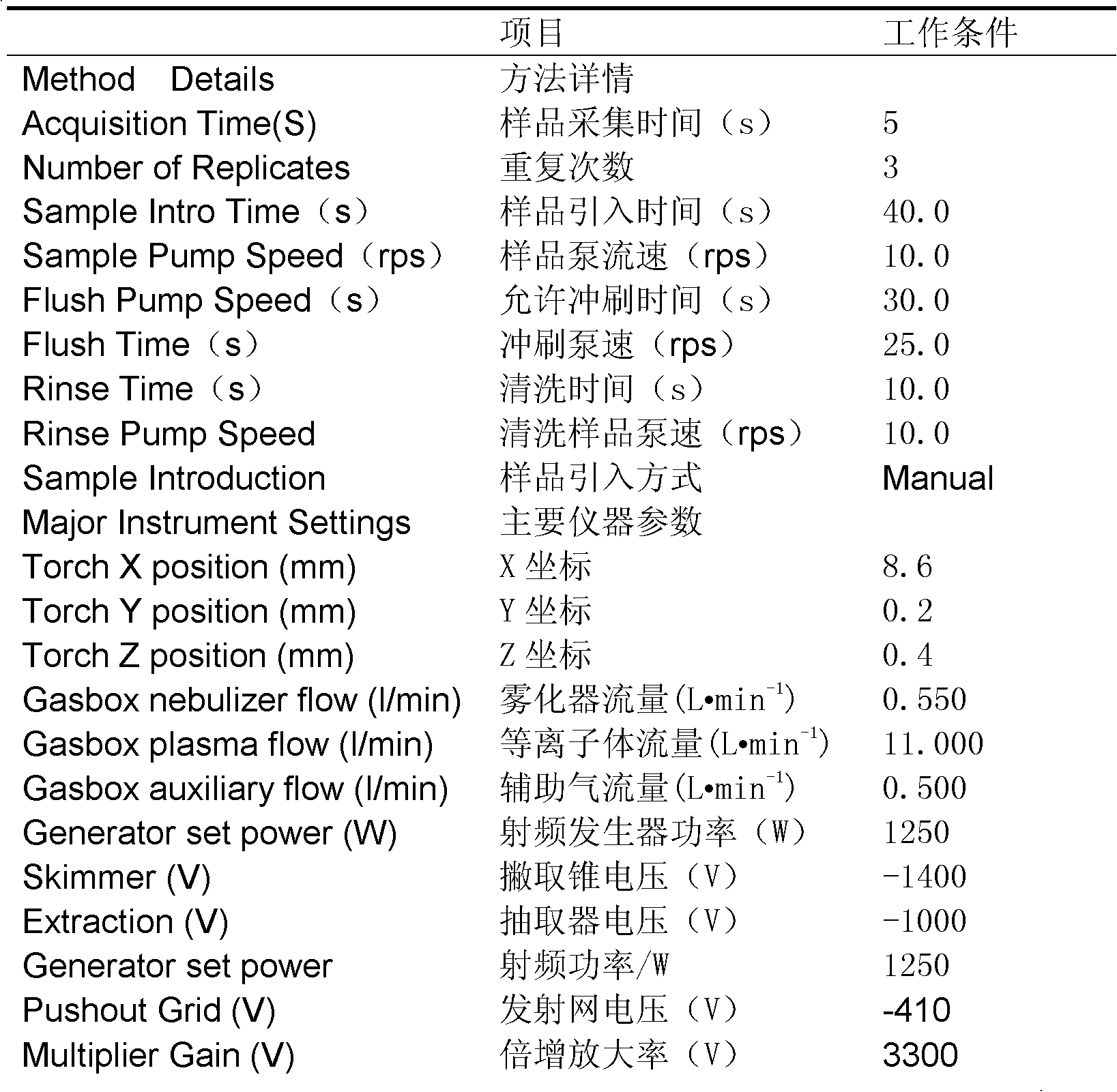

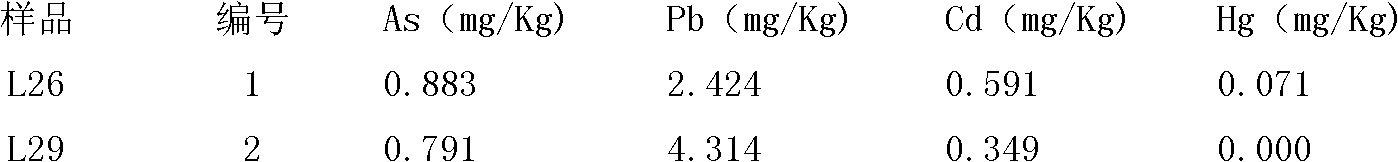

Method for simultaneously detecting content of four heavy metal elements in tobacco leaves

InactiveCN102607933ADigestion takes less timePrecise and thorough digestionPreparing sample for investigationMaterial analysis by electric/magnetic meansAshingDecomposition

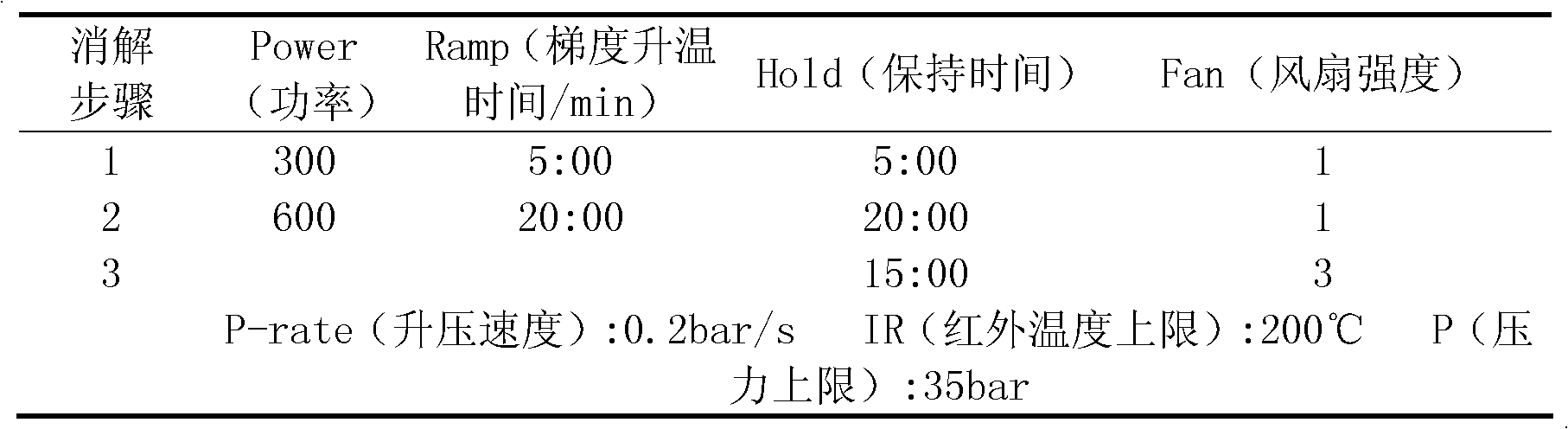

The invention discloses a method for simultaneously detecting the content of four heavy metal elements in tobacco leaves. The method comprises the steps of standard solution preparation, sample pretreatment and sample analysis. According to the invention, a tobacco leaf sample is subjected to pretreatment by adopting a closed microwave digestion technology, so that the method disclosed by the invention has the advantages of short digestion time, accuracy and completeness in digestion and capability of effectively avoiding result deviation and environmental pollution caused by heating and volatilization compared with the conventional digestion methods such as a dry ashing method and an acid digestion method; As, Cd, Hg and Pb can be detected simultaneously, so that the problems on the decomposition of the sample and the interference of residual organic matters are effectively solved, and element detection limit is obviously reduced compared with that of other methods; the method disclosed by the invention has the characteristics of high accuracy and density, low detection limit, short analyzing time, simultaneous detection of a plurality of elements and the like, and can be used for detecting a plurality of samples to be analyzed; and moreover, sample detection quality and efficiency is increased to a larger extent.

Owner:YUNNAN AGRICULTURAL UNIVERSITY +2

Preparation method and using method of carbon fiber compounded polyether sulfone resin sizing agent

The invention provides a preparation method and a using method of a carbon fiber compounded polyether sulfone resin sizing agent. A new carbon fiber sizing agent component for polyether sulfone resin is prepared for solving the problem that an epoxy sizing agent is not suitable for the carbon fiber compounded polyether sulfone material, and can effectively improve the interface bonding property of carbon fibers and polyether sulfone and improve the high temperature resistance of a composite material. A preparation method comprises the steps of processing polyether sulfone resin with a sulfonating agent to obtain a main component (sulfonic polyether sulfone) of the sizing agent; preparing a sizing solution and dipping the carbon fiber to obtain the sizing carbon fiber. The method can improve the interface bonding property of the carbon fiber compounded polyether sulfone resin and can fully achieve high specific strength of the carbon fiber and high temperature resistance of the polyether sulfone.

Owner:BEIJING UNIV OF CHEM TECH

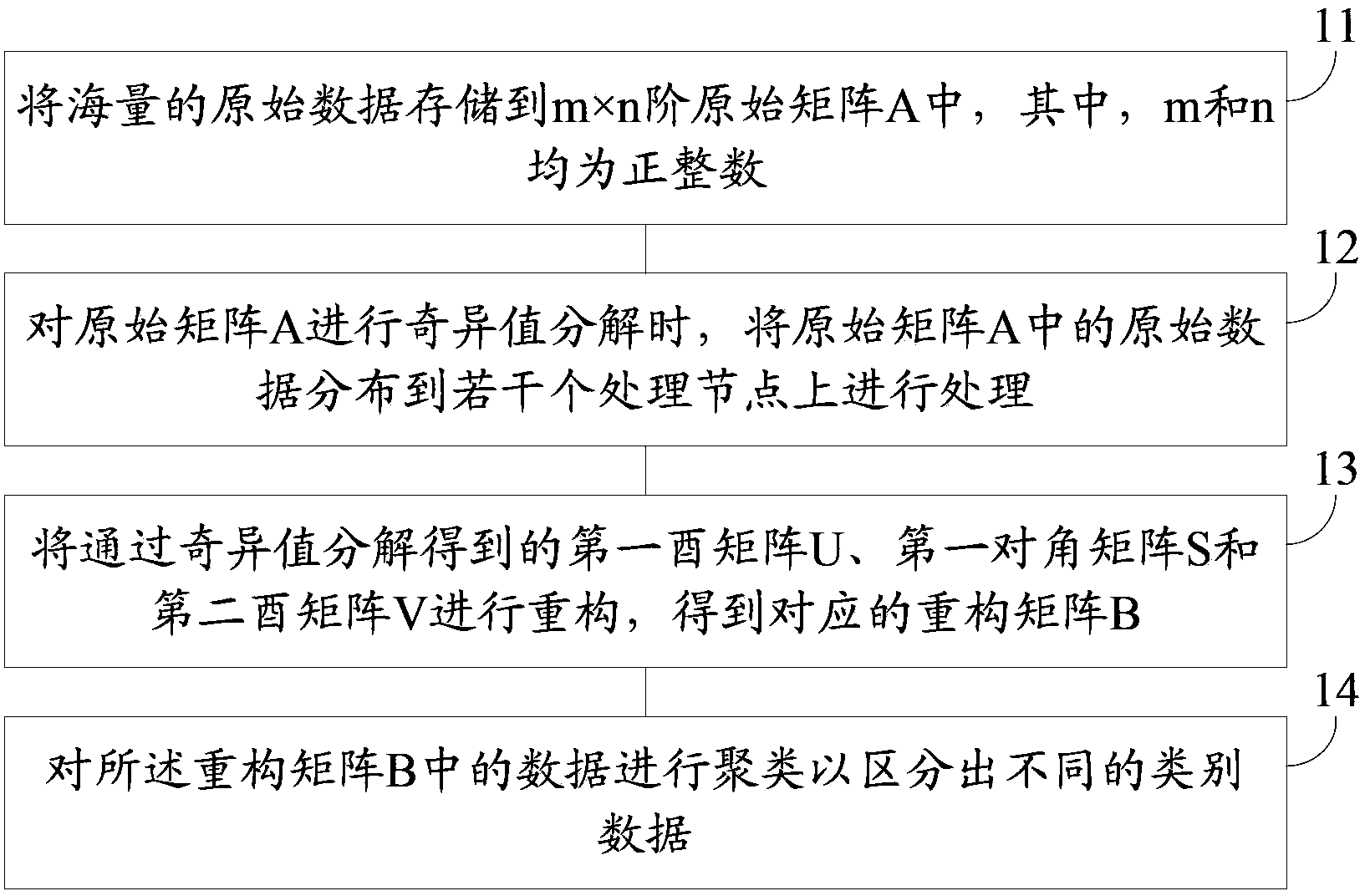

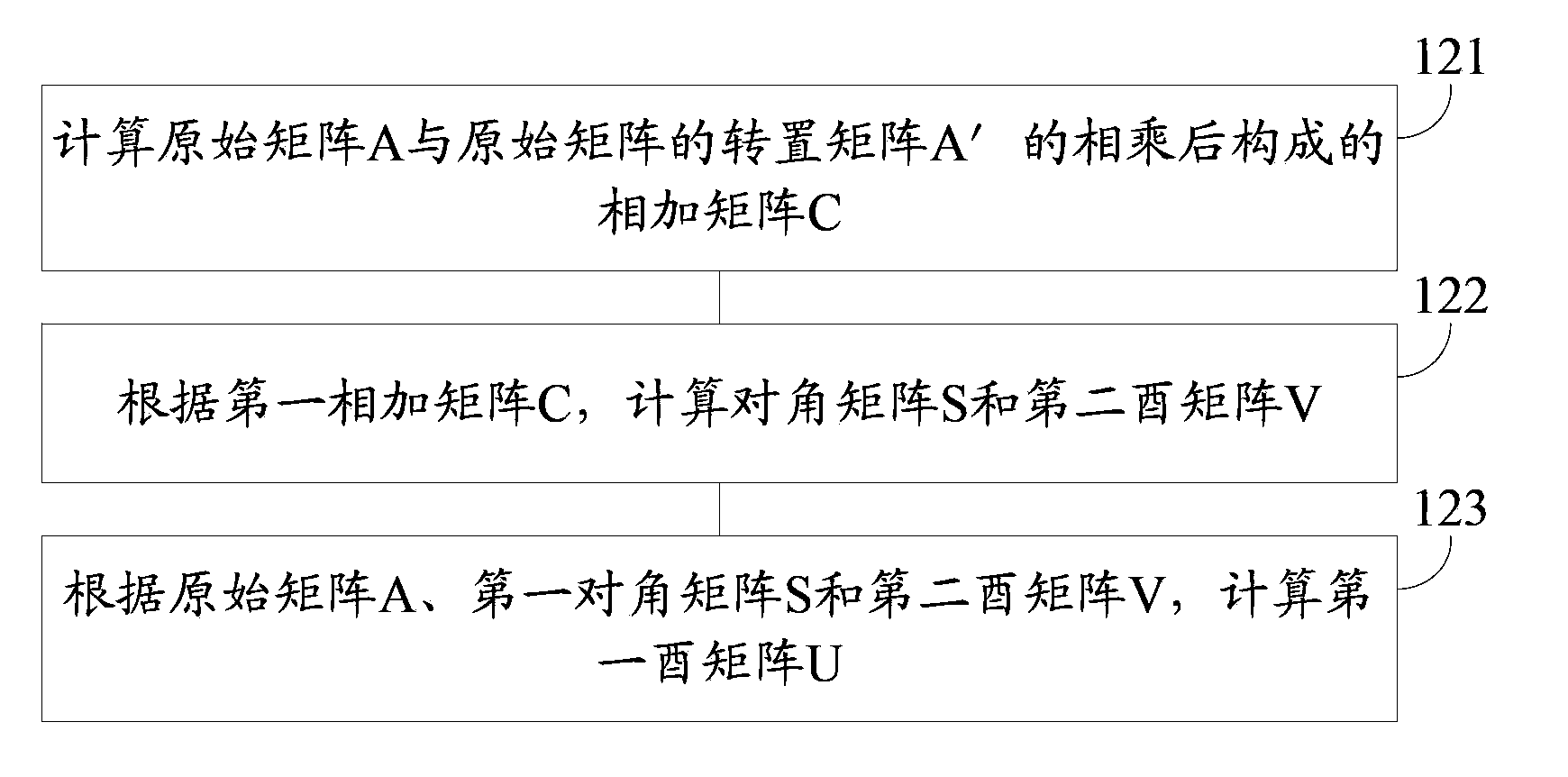

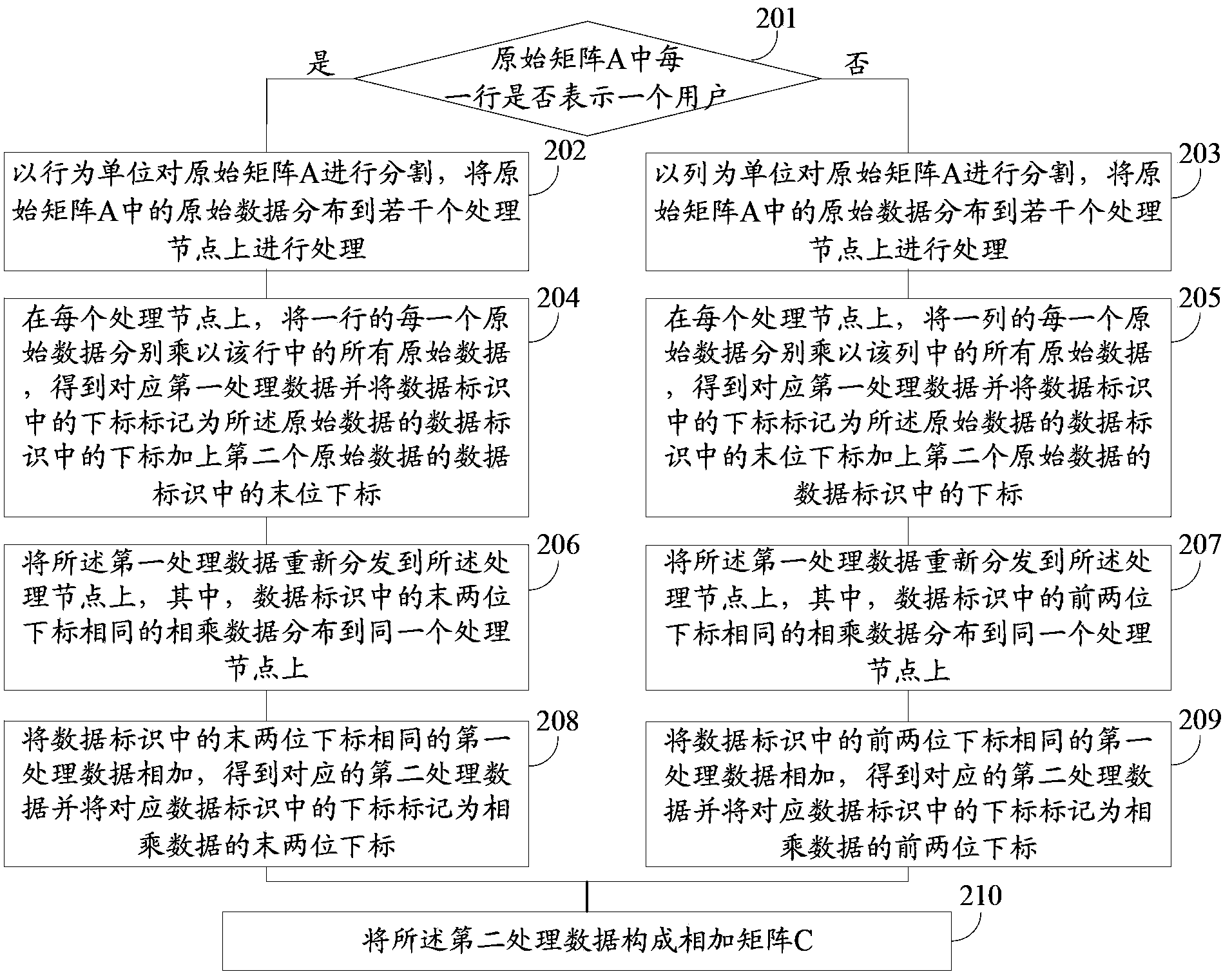

Massive data processing, searching and recommendation methods and devices

InactiveCN103389966AReduce sparsitySolve the problem of large sparsityComplex mathematical operationsSingular value decompositionClustered data

The invention provides a massive data processing method and a massive data processing device, and aims to solve the problem of unremarkable data discrimination effects caused by higher sparsity of original data. The method comprises the following steps of storing the massive original data into an (m*n)th-order original matrix A, wherein m and n are positive integers, and the original data is operating data for each user; when the original matrix A is subjected to singular value decomposition, distributing the original data in the original matrix A to a plurality of processing nodes for processing; reconstructing a first unitary matrix U, a first diagonal matrix S and a second unitary matrix V, which are obtained by the singular value decomposition, to obtain a corresponding reconstructed matrix B; and clustering data in the reconstructed matrix B to discriminate the data of different types. According to the method and the device, the problem of higher sparsity of the original data is radically solved, so that higher data discrimination performance during subsequent massive data processing is ensured.

Owner:ALIBABA GRP HLDG LTD

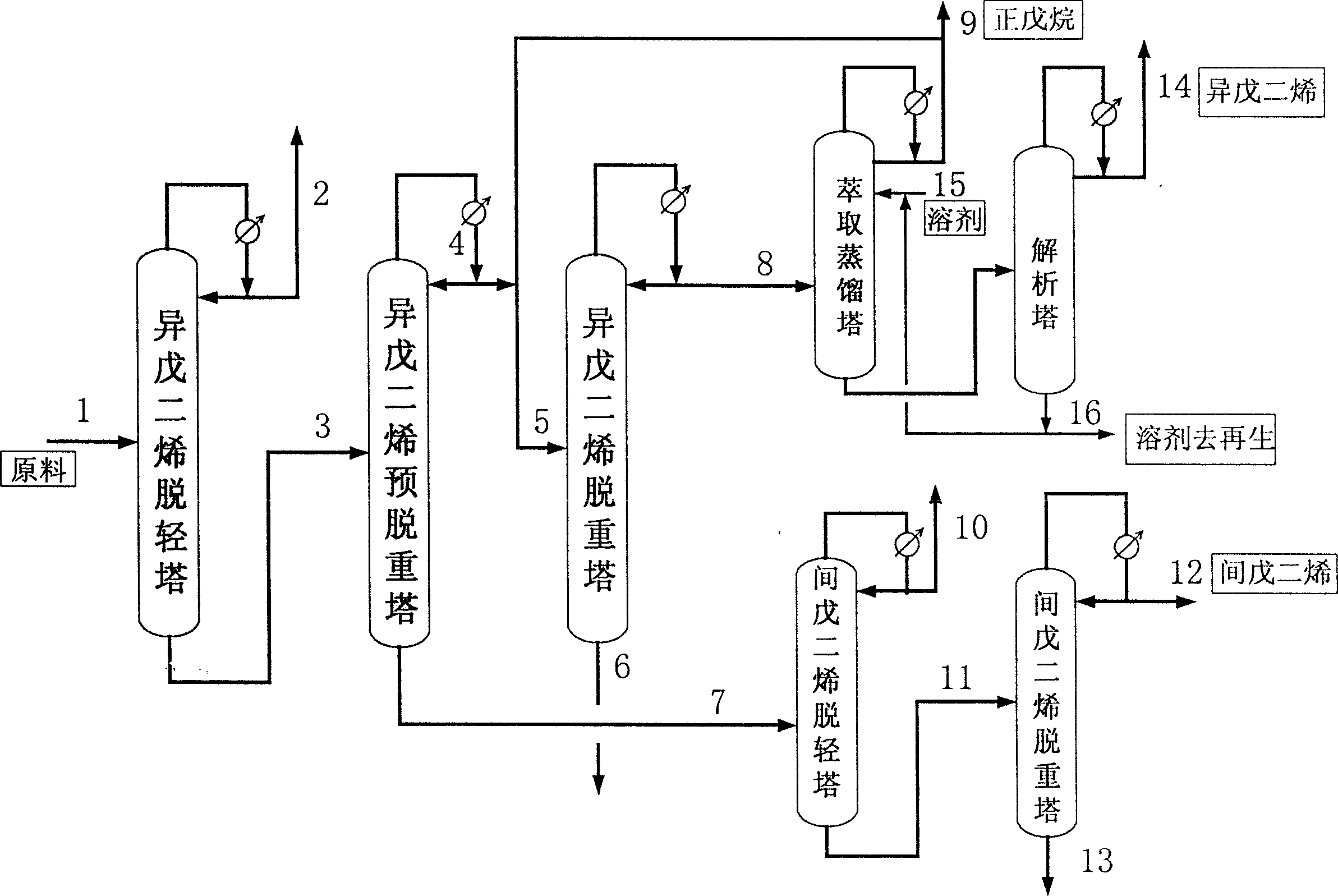

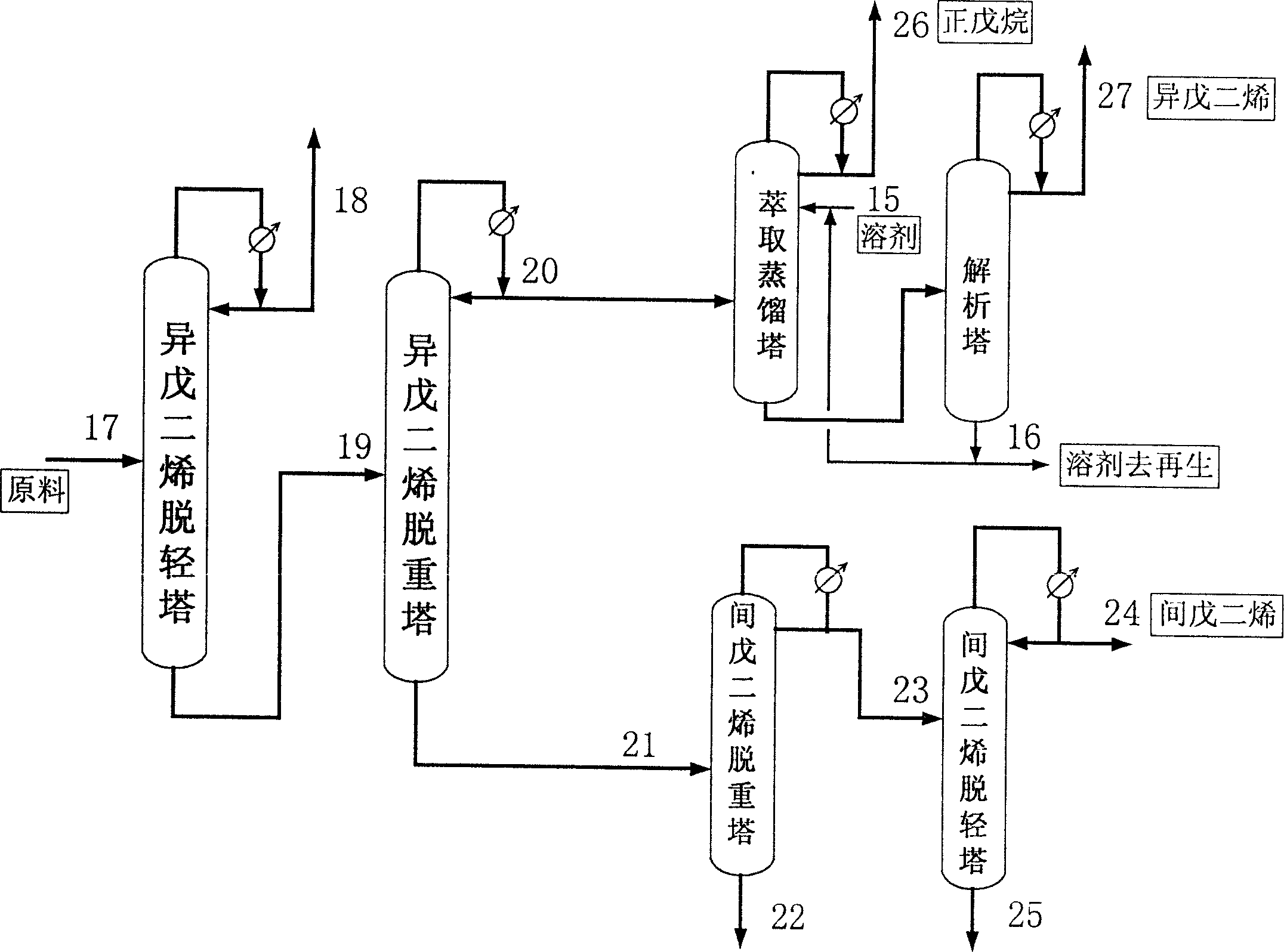

Method for separating cracked carbon 5 using azeotropic super fractionation and extractive distillation coupling

InactiveCN1709842AReduce dosageSolving Recycling ProblemsOrganic chemistryHigh concentrationExtractive distillation

This invention has disclosed a method of separating carbon5 by azeotropic rectification and extractive distillation. Its characteristic is it adopts azeotropic rectification to take off light-unit and heavy-unit gained isoprene- n-pentane azeotrope accord with polymerisation grade, then with extractive distillation make isoprene separated from n-pentane to get t polymerisation grade isoprene. Because targets that this invention extracts the distillation and deals with are only mixture of isoprene and n-pentane, but not make up carbon five hydrocarbon, thus greatly alleviated the questions of using solvents, such as solvent toxicity, retrieving , resolving , environmental protection, etc. When producing pure isoprene and n-pentane, this invention also could get 1,3-piperlene of high concentration.

Owner:NANJING UNIV OF TECH

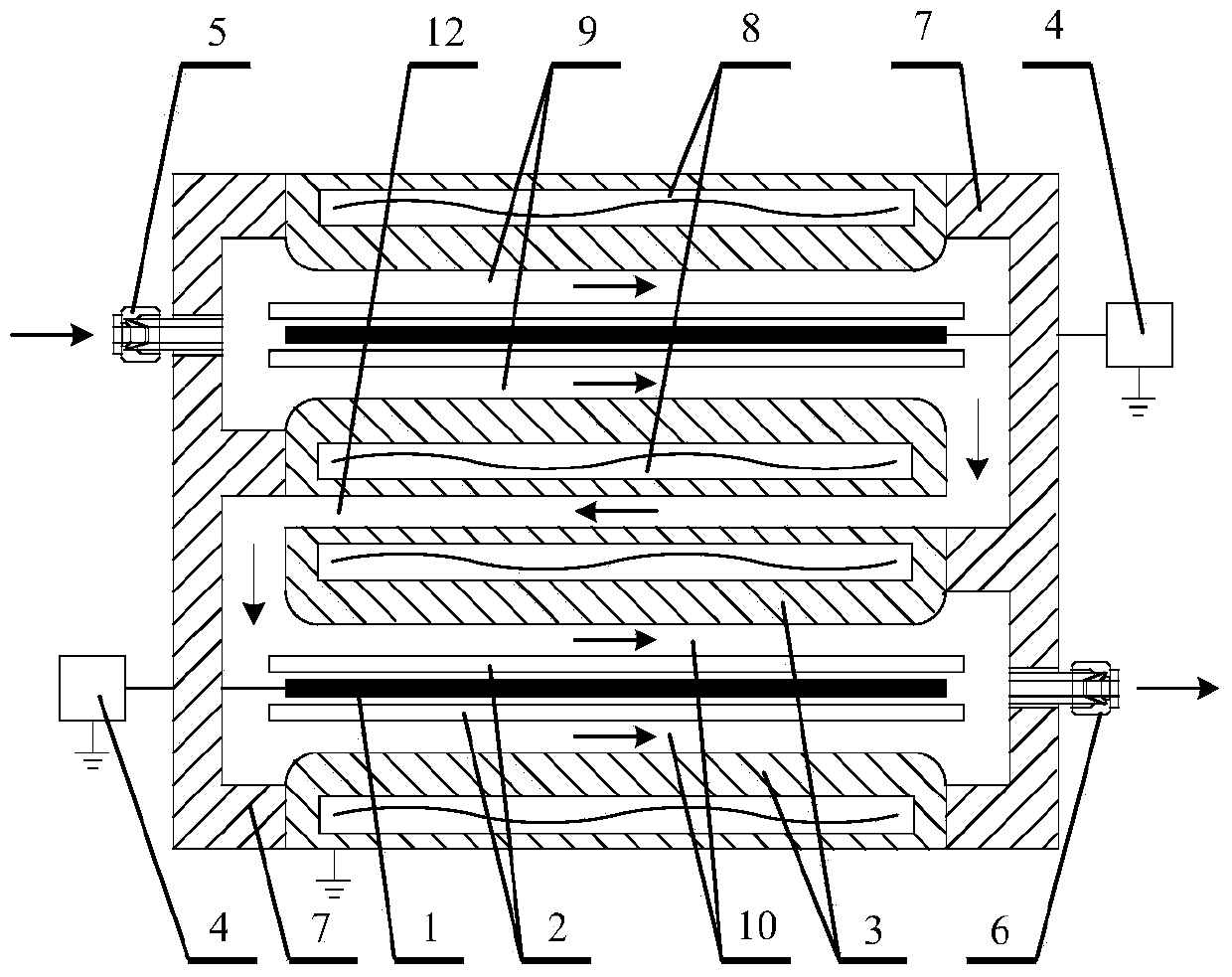

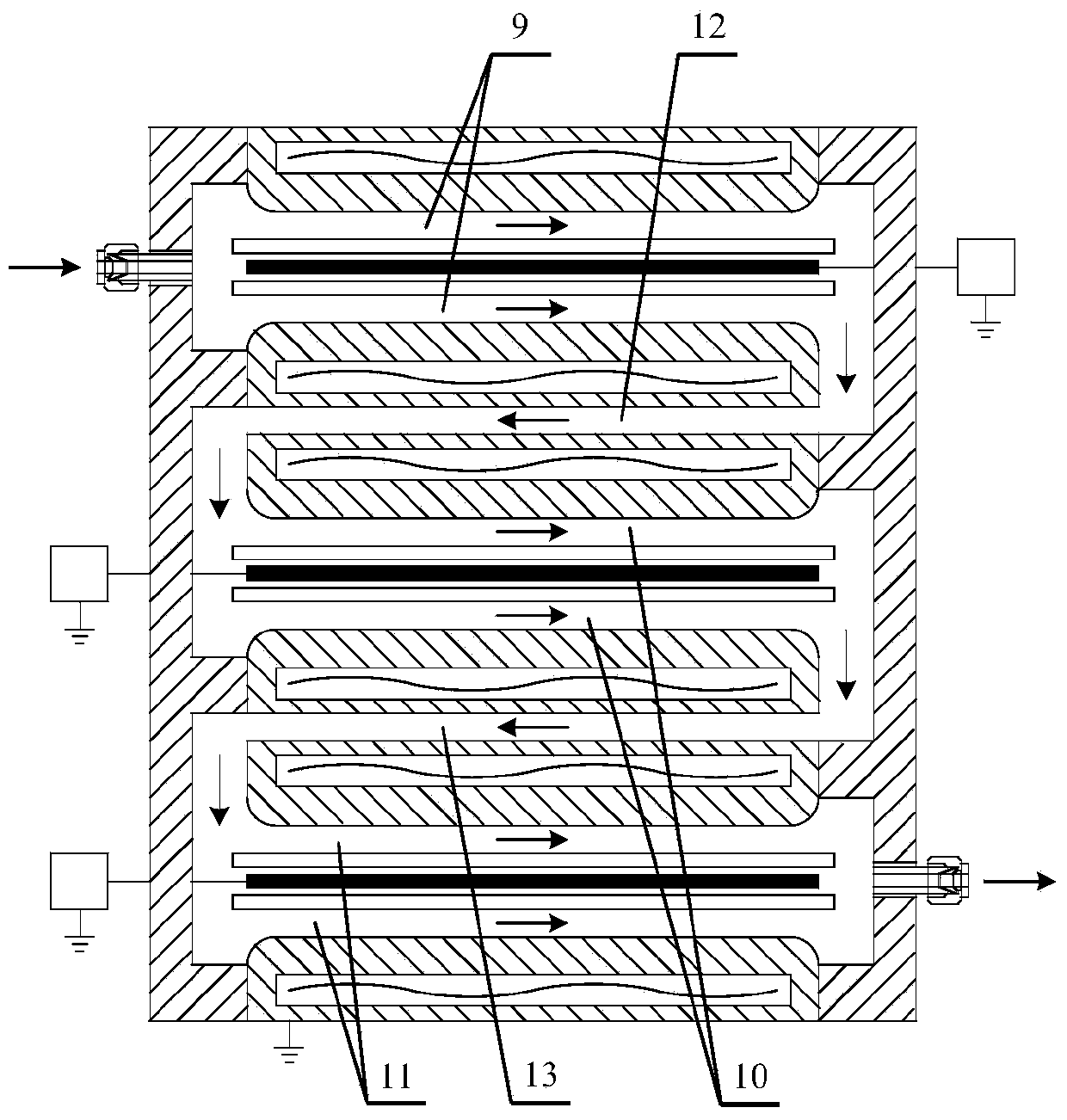

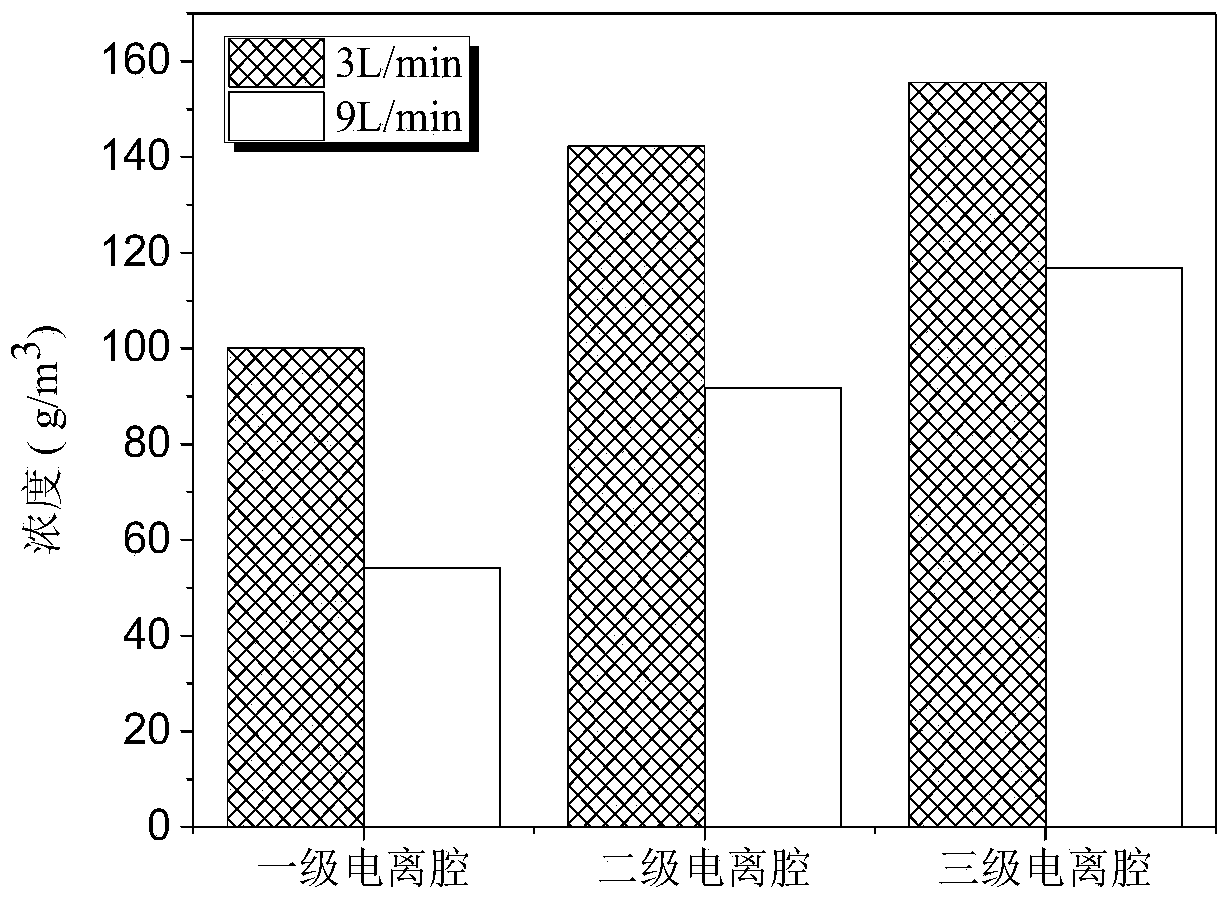

Reciprocating type multi-ionization-cavity atmospheric-pressure unbalance plasma reactor

InactiveCN103442509AImprove the effect of chemical reactionsExtended retention timePlasma techniqueChemical reactionEngineering

Provided is a reciprocating type multi-ionization-cavity atmospheric-pressure unbalance plasma reactor. A plurality of unbalance plasma ionization cavities are formed between a plate ground electrode and an alpha-A12O3 dielectric medium layer covering the surface of a plate high-voltage electrode, the plate ground electrode is provided with cooling liquid cavities, and reaction gas cooling cavities are further arranged between the cooling liquid cavities of the plate ground electrode. When the atmospheric-pressure unbalance plasma reactor works, after entering the reactor uniformly, raw material gas alternately passes through the unbalance plasma ionization cavities and the reaction gas cooling cavities, and is output through reaction gas outlets finally, electricity can be supplied to the unbalance plasma ionization cavities by adopting the same excitation power supply, and each ionization cavity can also utilize an independent excitation power supply. According to the reciprocating type multi-ionization-cavity atmospheric-pressure unbalance plasma reactor, plasma chemical reaction is conducted more sufficiently, the effect of the plasma chemical reaction is improved, so that discharging performance of each ionization cavity is optimized, and the progress of the plasma chemical reaction can be regulated and controlled more conveniently.

Owner:DALIAN MARITIME UNIVERSITY

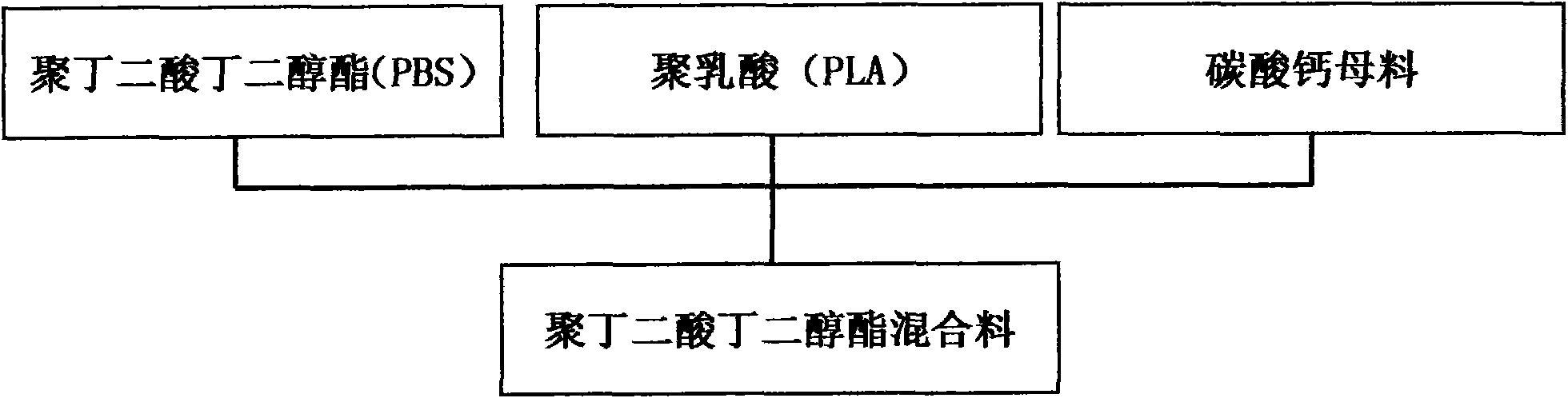

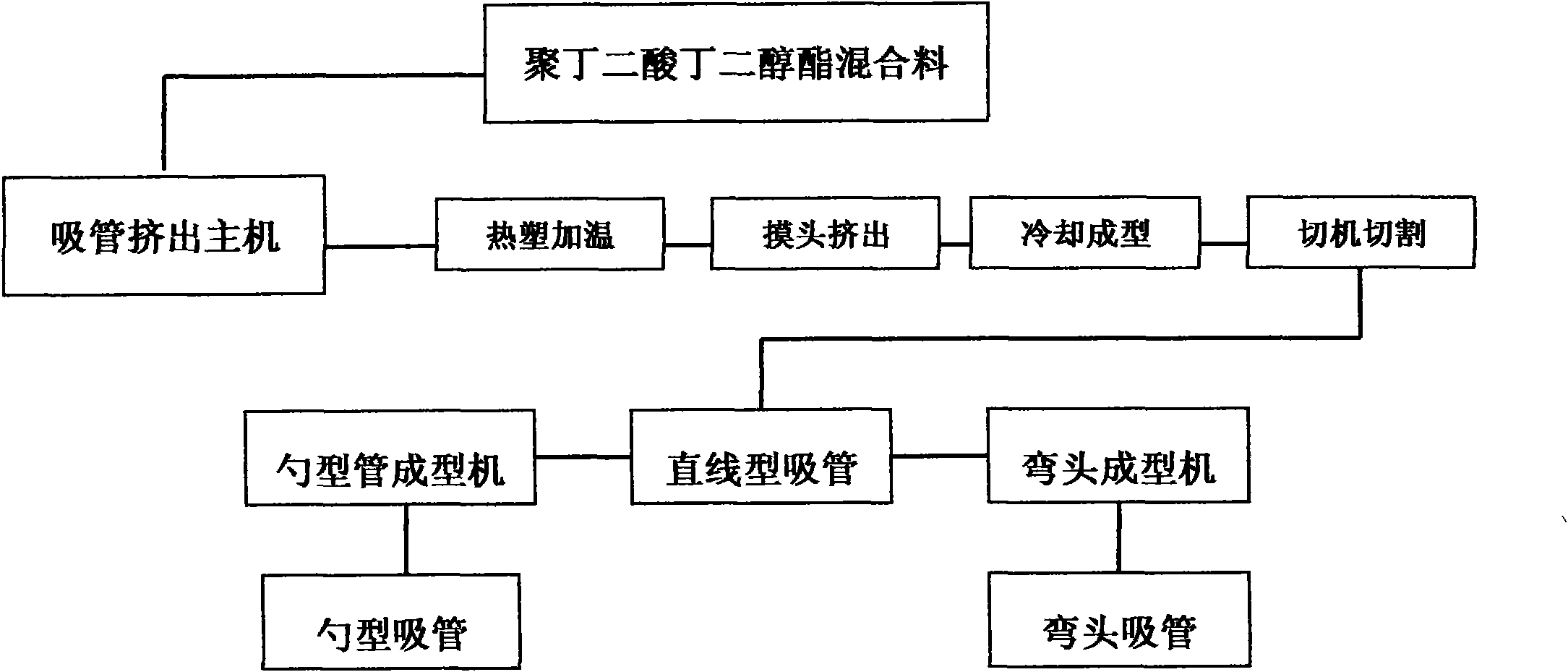

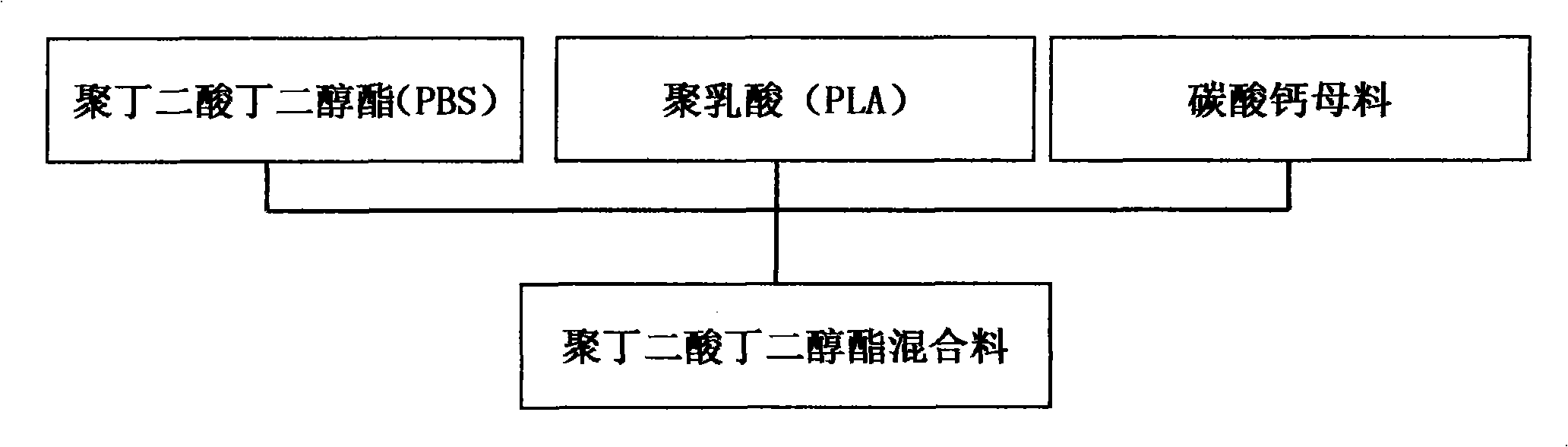

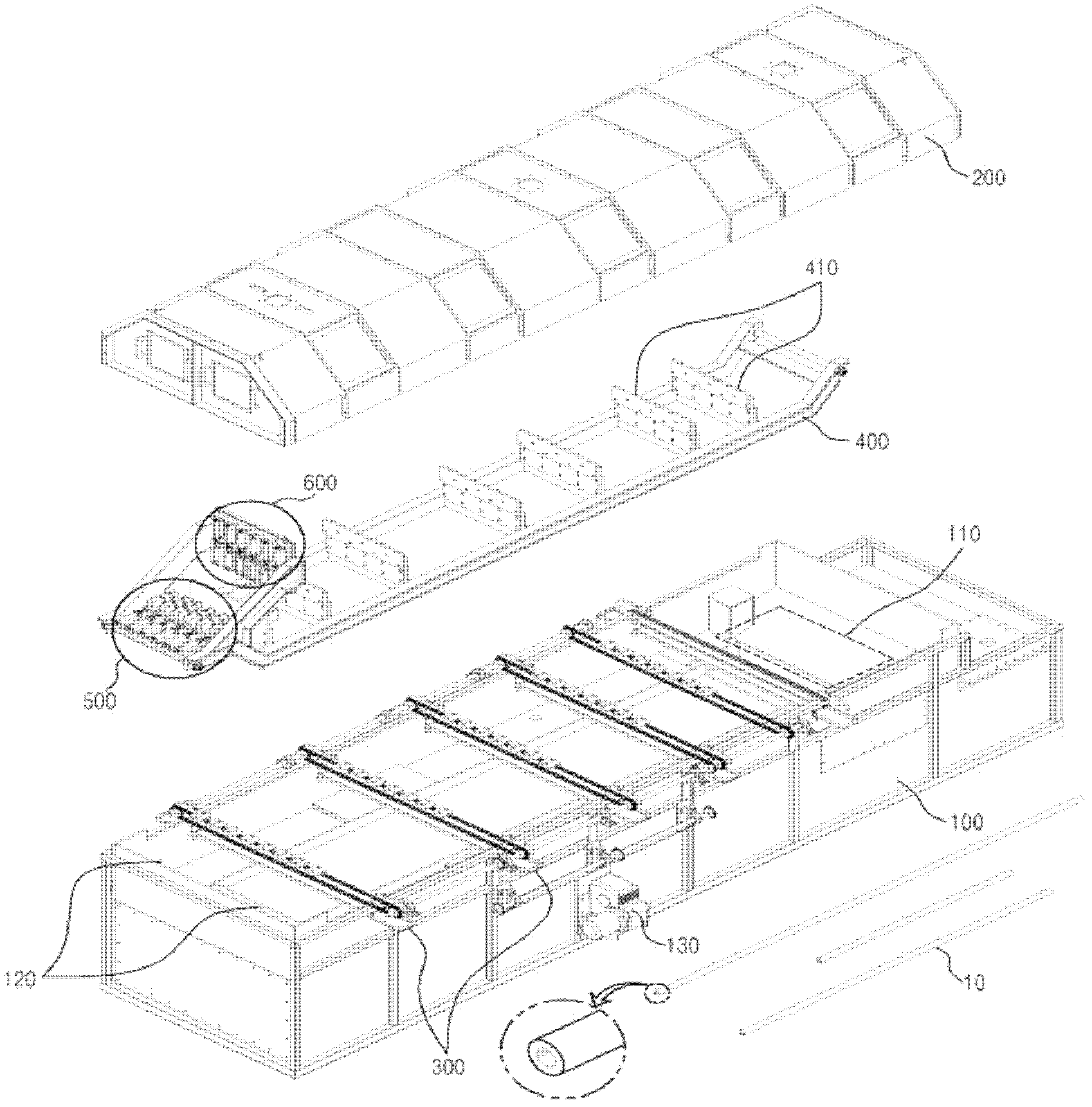

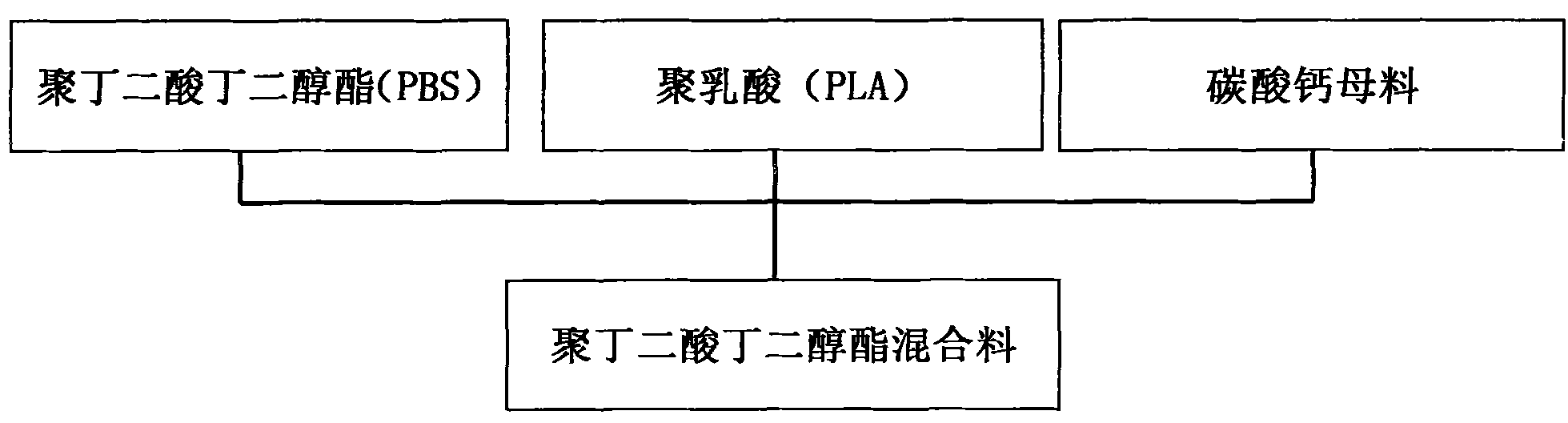

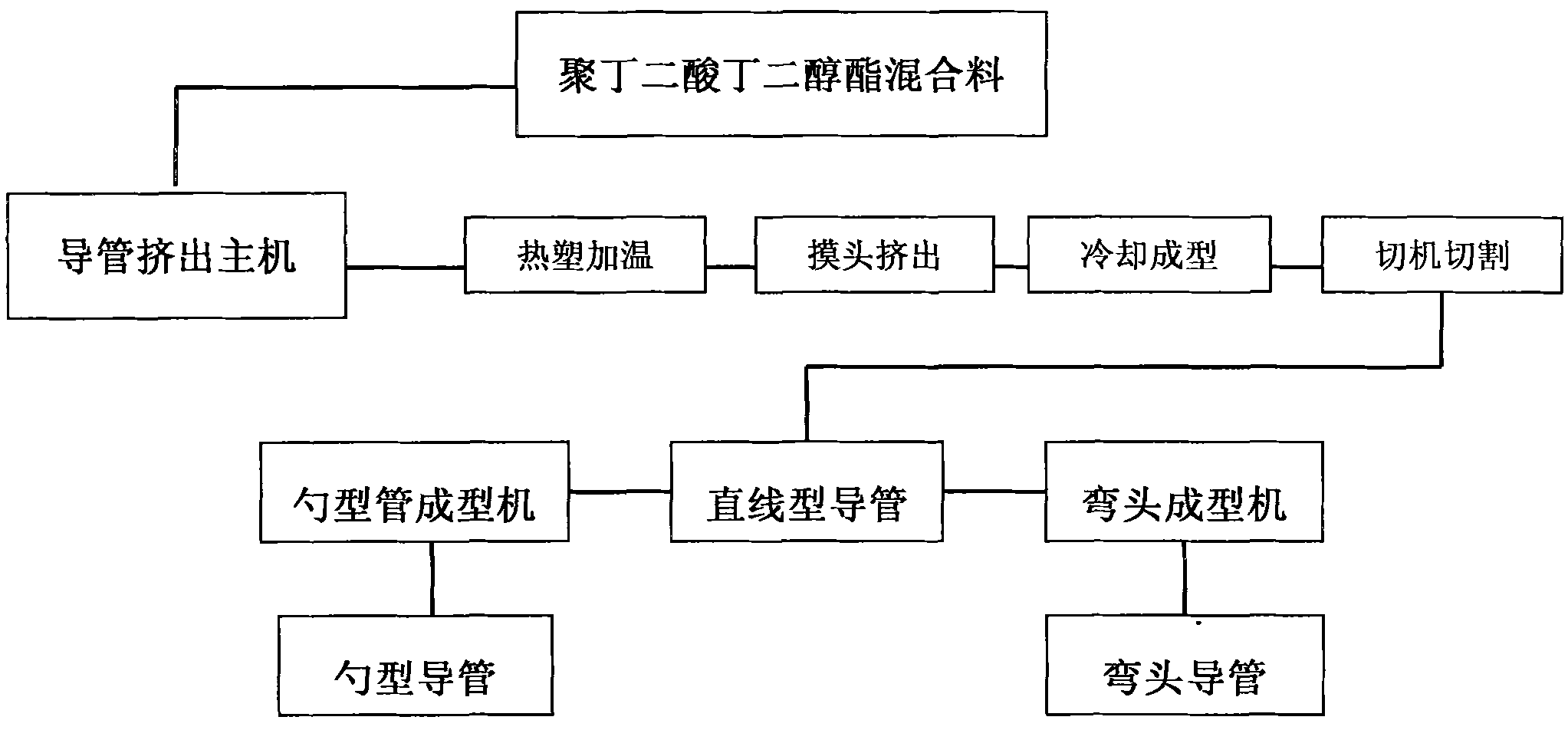

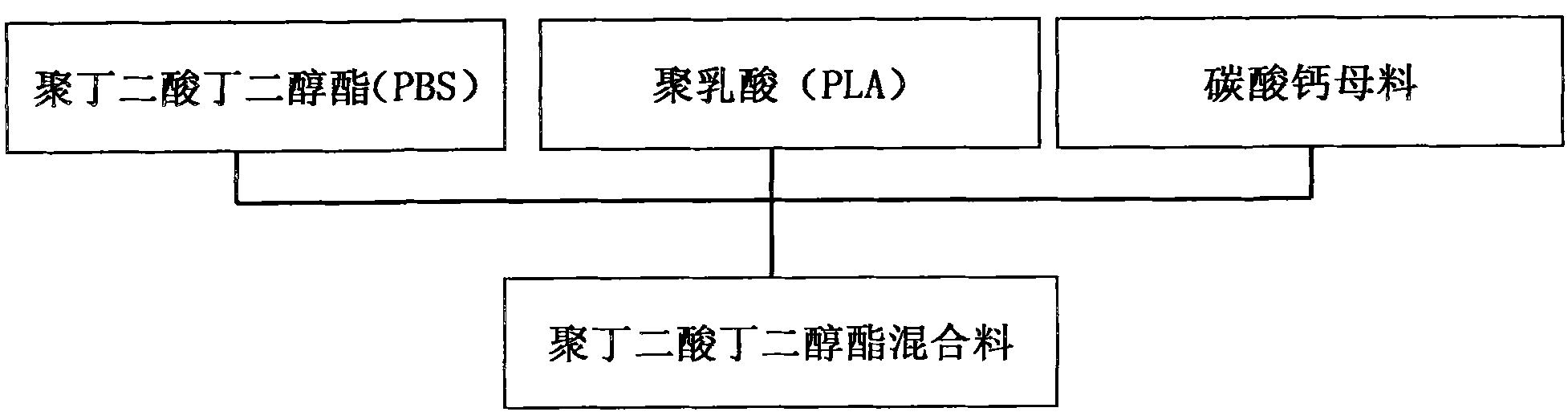

Biomass degradable material preparation method and straw

InactiveCN102079849AReduce investmentImprove the decomposition cycleTubular articlesTablewaresMaterials preparationMixed materials

The invention provides a biomass degradable material preparation method. The method is characterized by comprising the following steps of: 1) preparing raw materials, namely weighing the following raw material components in percentage by weight: 40 to 60 percent of poly(butylene succinate) serving as a main material, 40 to 60 percent of polylactic acid serving as a modified material and 0.1 to 20 percent of calcium carbonate master batch serving as a filler; 2) mixing the components to form a modified poly(butylene succinate) mixed material; and 3) standing the modified mixed material at a low temperature for later use. The invention also discloses a method for preparing a straw by using the material, which comprises the following steps of: 4) preparing a straw extruding main machine and a circular die head which is matched with the main machine for use; 5) feeding the modified poly(butylene succinate) mixed material into the extruding main machine to obtain a continuous circular hollow straw; and 7) cutting into straw sections. The invention also provides the straw which is prepared by the method. The material provided by the invention can be completely degraded; the method is scientific and rational and has high production efficiency; and a product has high performance and is low in cost.

Owner:楼仲平

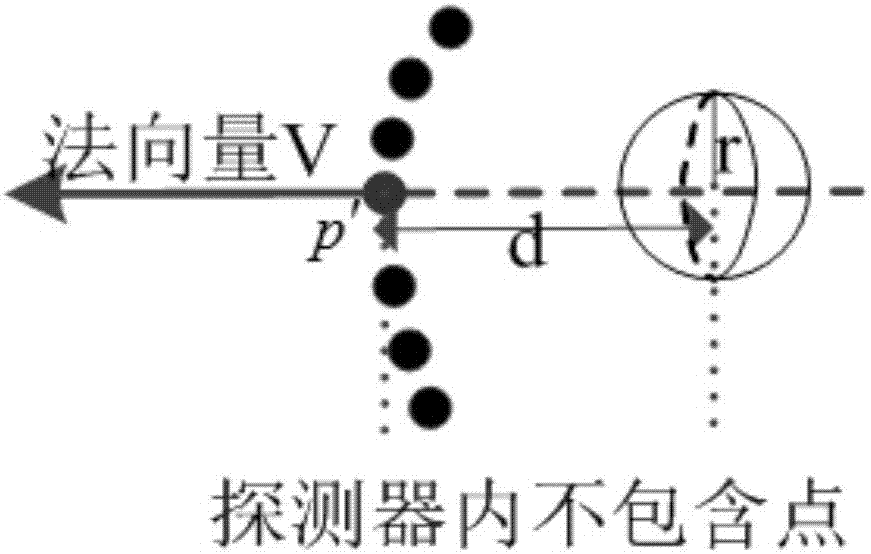

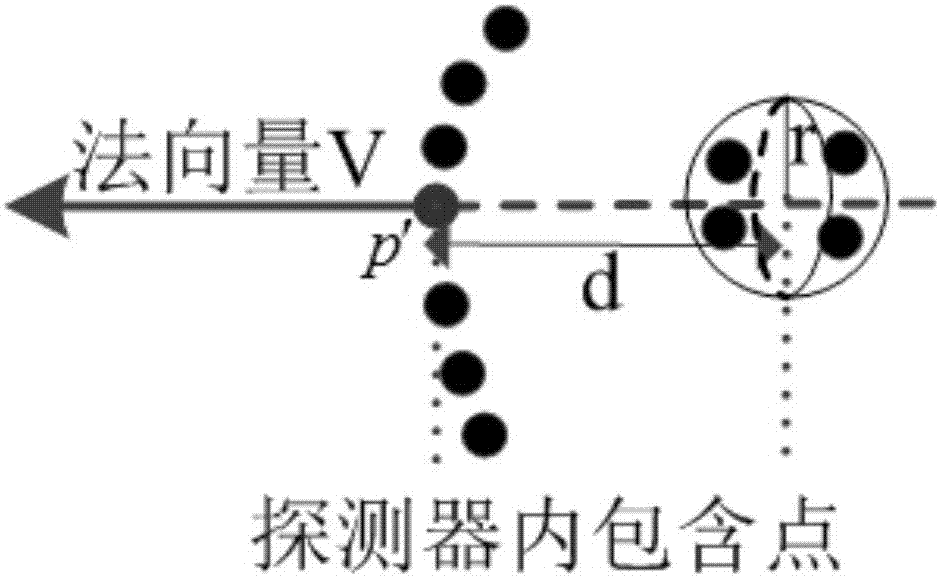

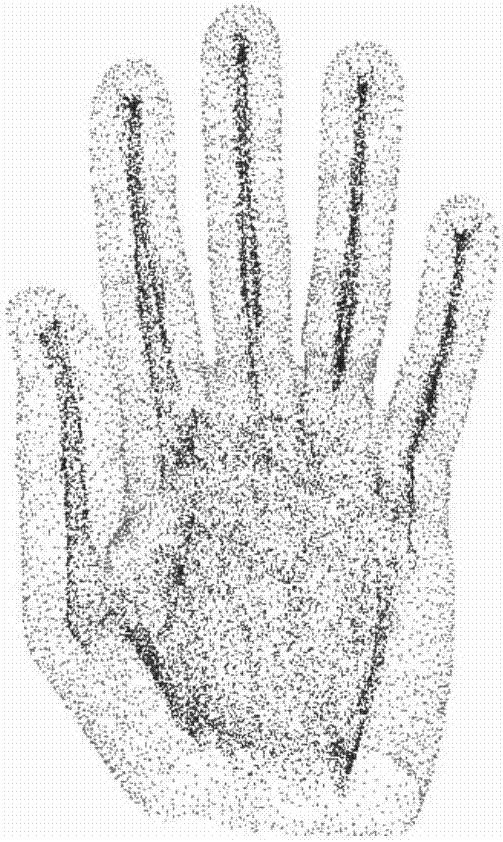

Skeleton-based object component decomposition method

The invention discloses a skeleton-based object component decomposition method, which specifically includes the steps of establishing a k-d tree for each point on an original point cloud model, and obtaining a normal vector of a point with k neighbor points and the point itself by the least-squares fitting plane; then normalizing the direction of the normal vector of each point on the point cloud model; based on the normal vectors, iteratively contracting in an opposite direction, determining the constraint for stopping the contraction of each point, and finally obtaining a contraction point set of an object; conducting clustering for a contraction model and solving for a cluster center point, connecting the cluster center point, establishing a topology map, and optimizing the topology map; and solving for segmentation points in the skeleton topology map, solving for ridge and valley points, then, solving for a segmentation plane by combining the segmentation points and the ridge and valley points, and finally, decomposing the original point cloud model using region growth according to the segmentation plane. The problem that the object is decomposed only by using related features of the object in the prior art is solved.

Owner:XIAN UNIV OF TECH

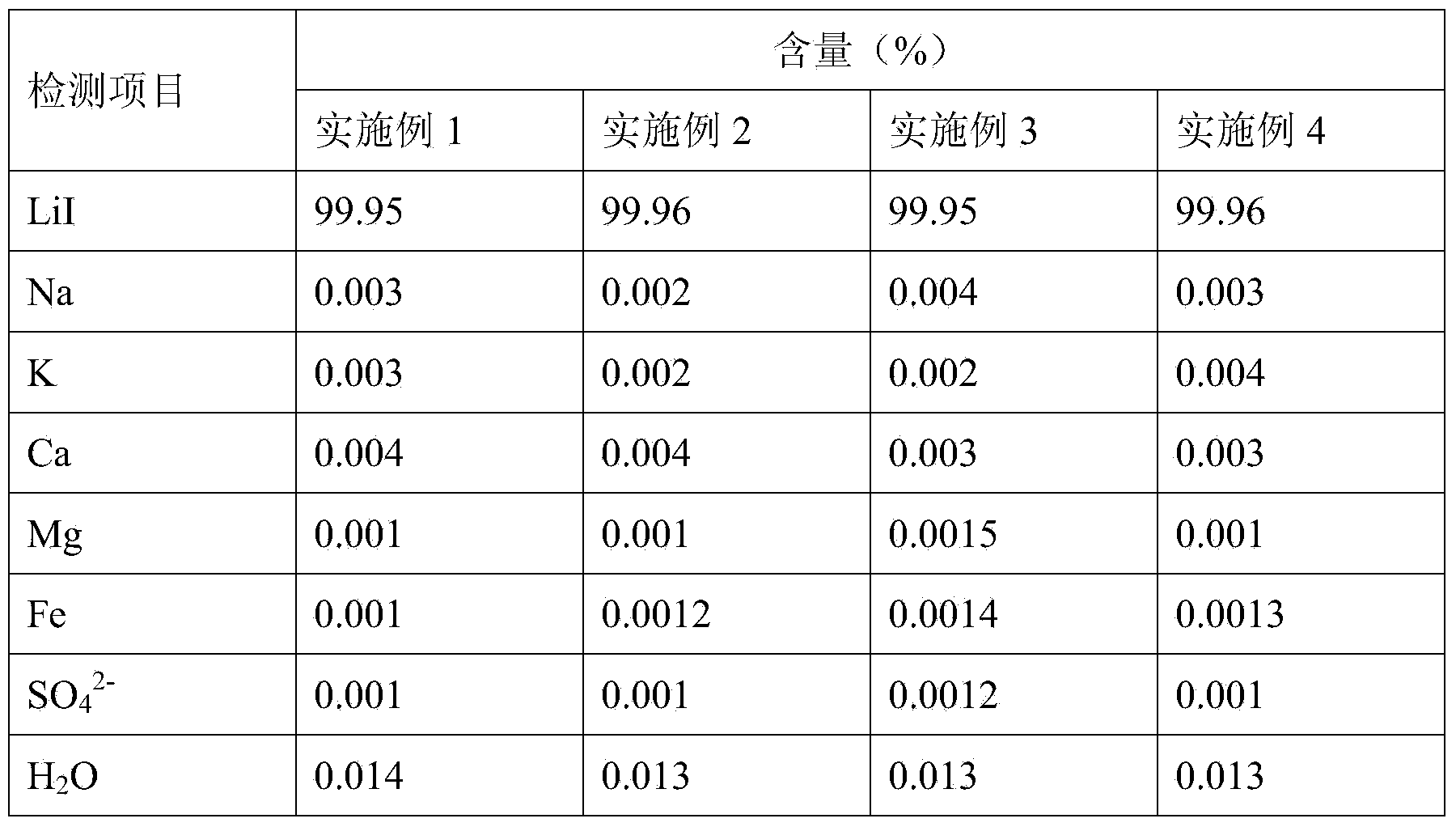

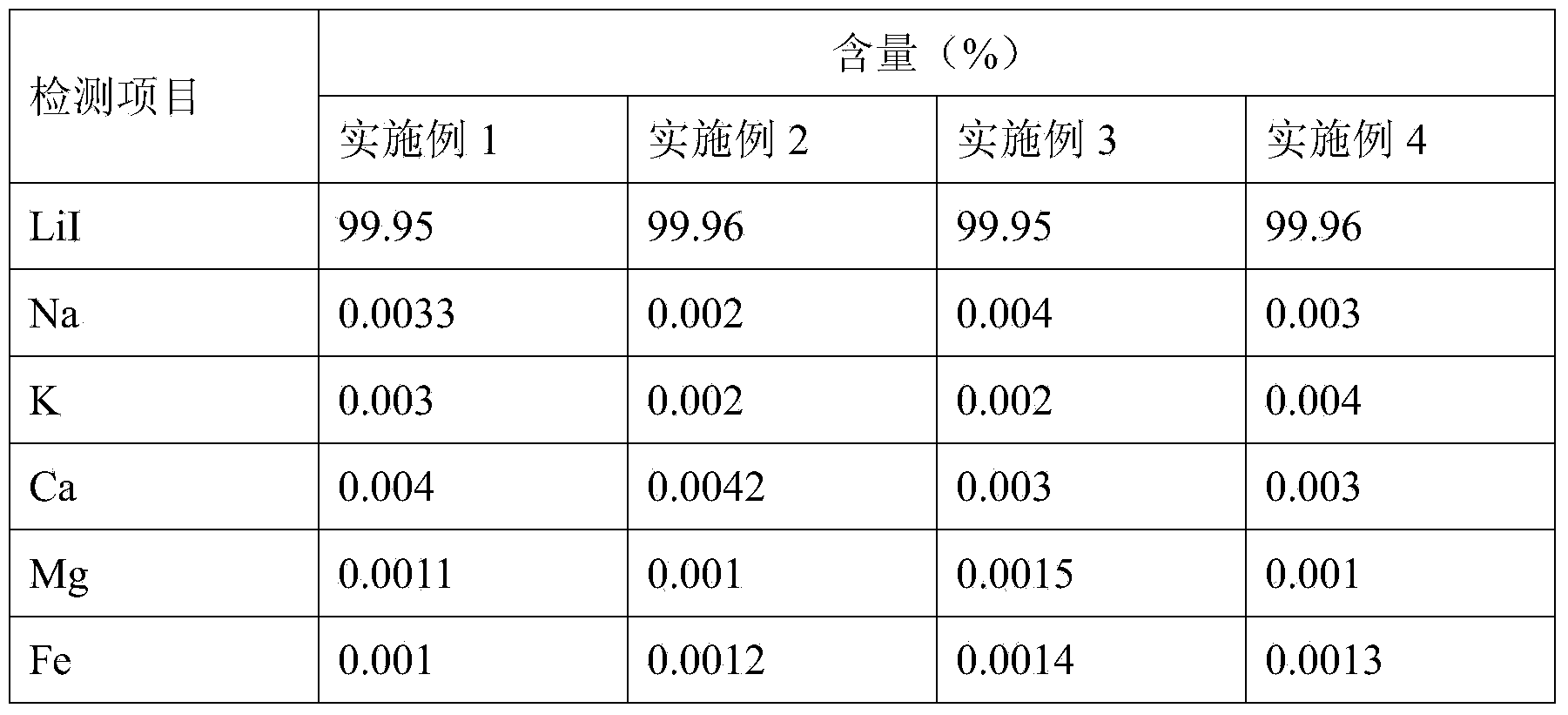

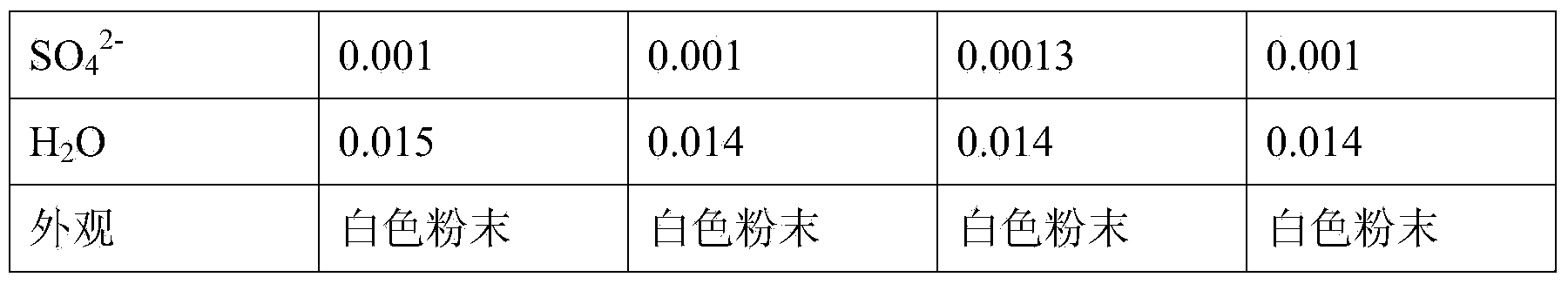

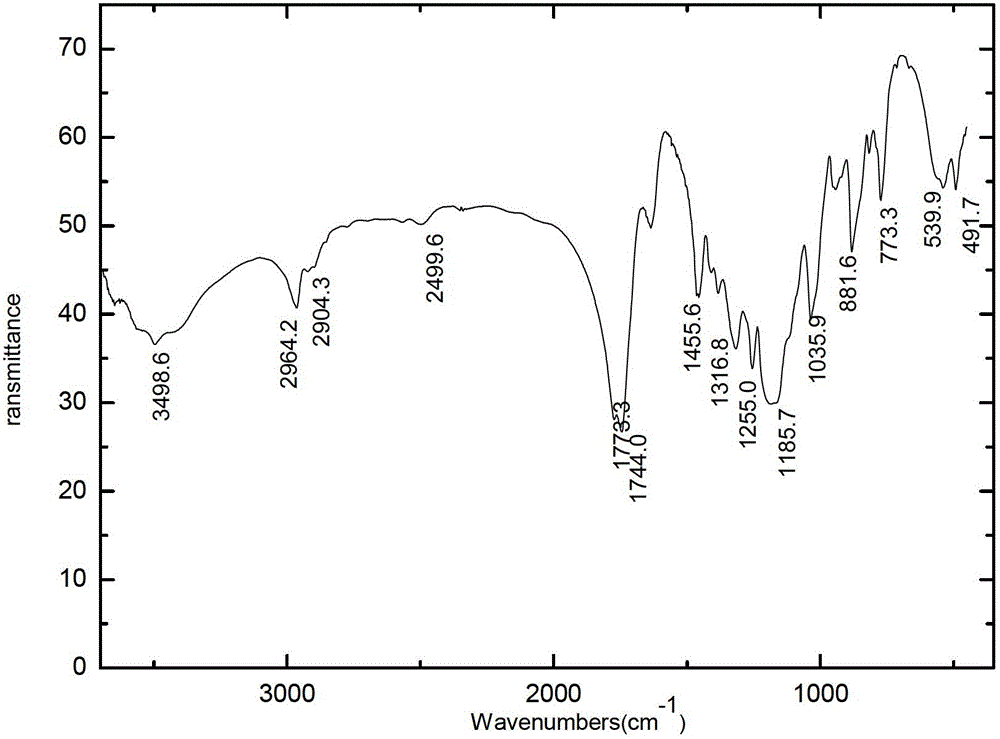

Preparation method of anhydrous lithium iodide

The invention belongs to the technical field of electrolyte preparation of lithium battery electrolytic liquids, and particularly relates to a preparation method of anhydrous lithium iodide. The preparation method of anhydrous lithium iodide comprises the following steps of reacting iodine, hydrazine hydrate and lithium hydroxide by using an aqueous liquid method, sequentially carrying out evaporation and concentration, filtration, and heated concentration on the obtained product, feeding inert gas into the obtained product to dehydrate, and packaging the obtained product under the protection of the inert gas. No organic solvent is added in the whole process; and the method is simple in technological process and short in time consumption, and solves the problems that traditional production methods are long in time consumption, iodide lithium packages are deliquescent, and the like.

Owner:HUBEI BAIJIERUI ADVANCED MATERIALS

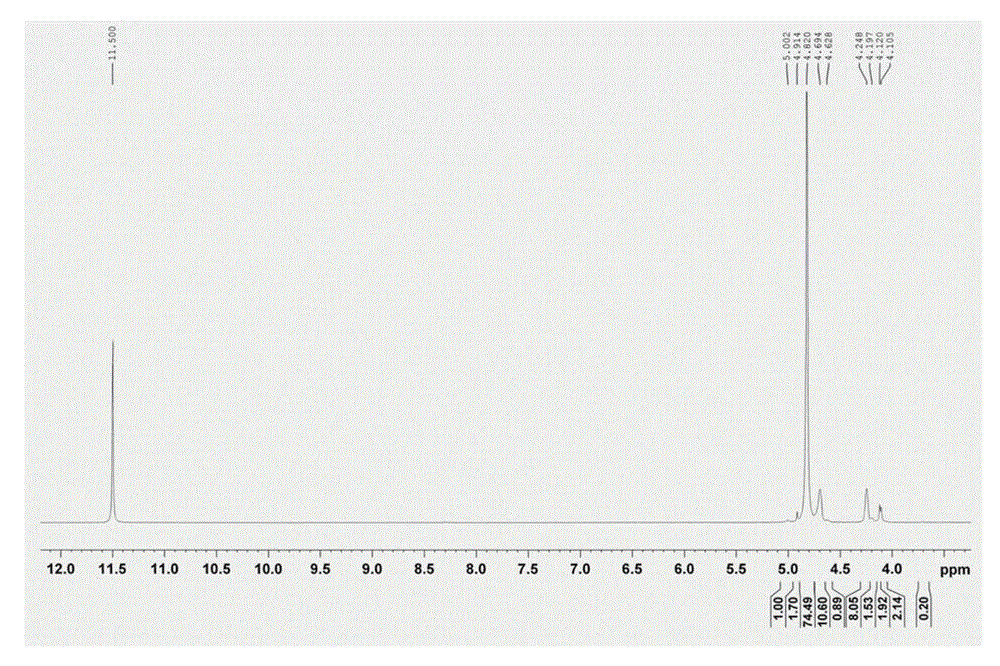

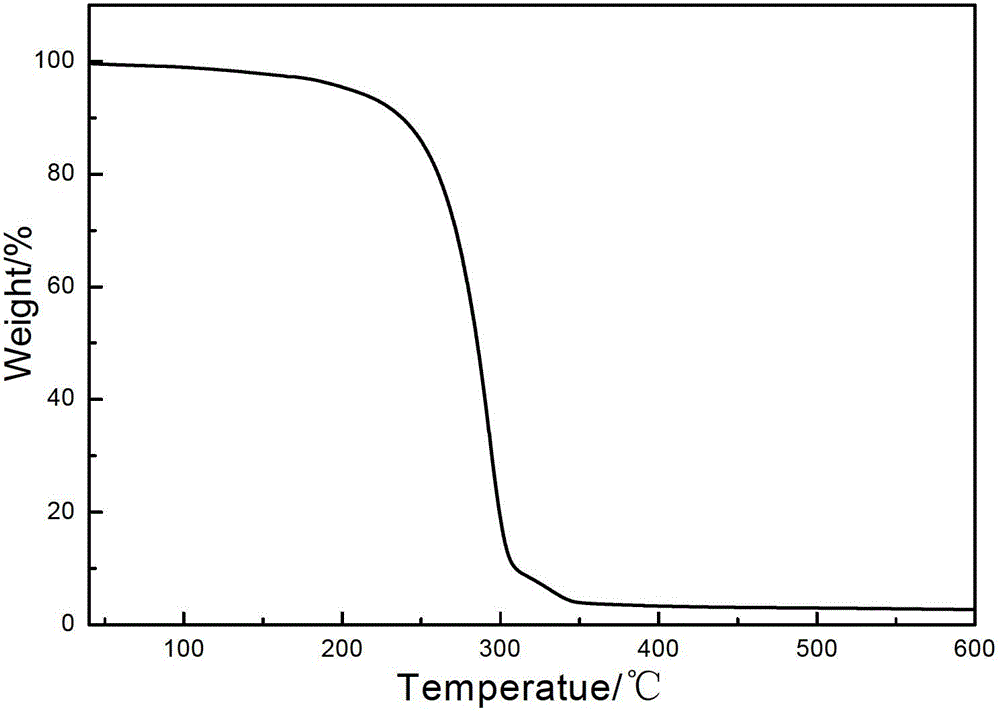

Method for preparing aliphatic polyoxalate

The invention relates to a method for preparing aliphatic polyoxalate. The method includes the following steps of A, placing R1OOCCOOR2, dihydric alcohol, a catalytic agent and a stabilizing agent in a reaction device, under the nitrogen protection, increasing the temperature to 120 DEG C to 180 DEG C until reactants are completely melted, stirring the reactants at a constant temperature and maintaining an absolute pressure of the reaction at 200kPa to 600kPa to react for 2 to 6 hours; B, vacuumizing, maintaining an internal temperature at 150 DEG C to 155 DEG C and the absolute pressure at 30kPa to 40kPa for 1 to 2 hours, maintaining for 1 to 2 hours at the internal temperature of 160 DEG C to 165 DEG C and the absolute pressure of 5kPa to 15kPa, maintaining for 1 to 4 hours at the internal temperature of 180 DEG C to 200 DEG C and the absolute pressure below 100 Pa, discharging materials and performing vacuum drying; and C, smashing solids, and performing a solid phase polycondensation at the temperature of 100 DEG C to 125 DEG C and the absolute pressure below 100 Pa for 30 to 55 hours. According to the method for preparing the aliphatic polyoxalate, the decomposition problem of oxalate or oxalic ester is solved, and the molecular weight and viscosity of the obtained polyoxalate are high.

Owner:南通药享科技有限公司

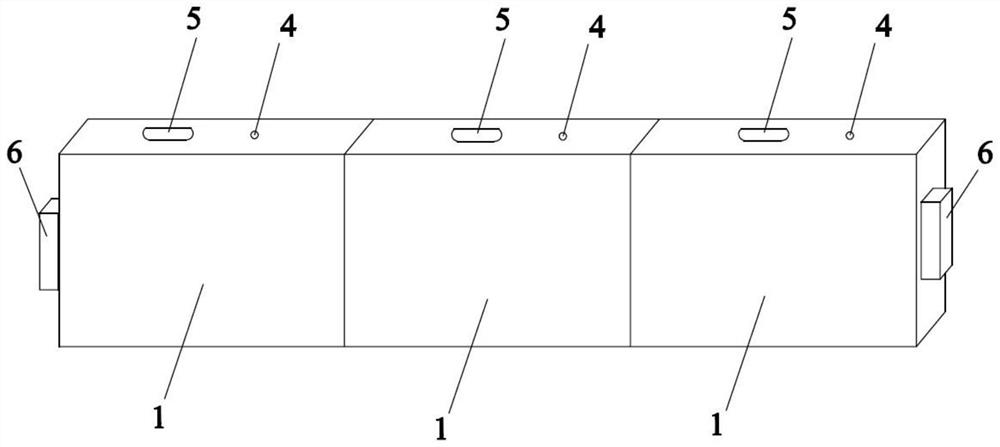

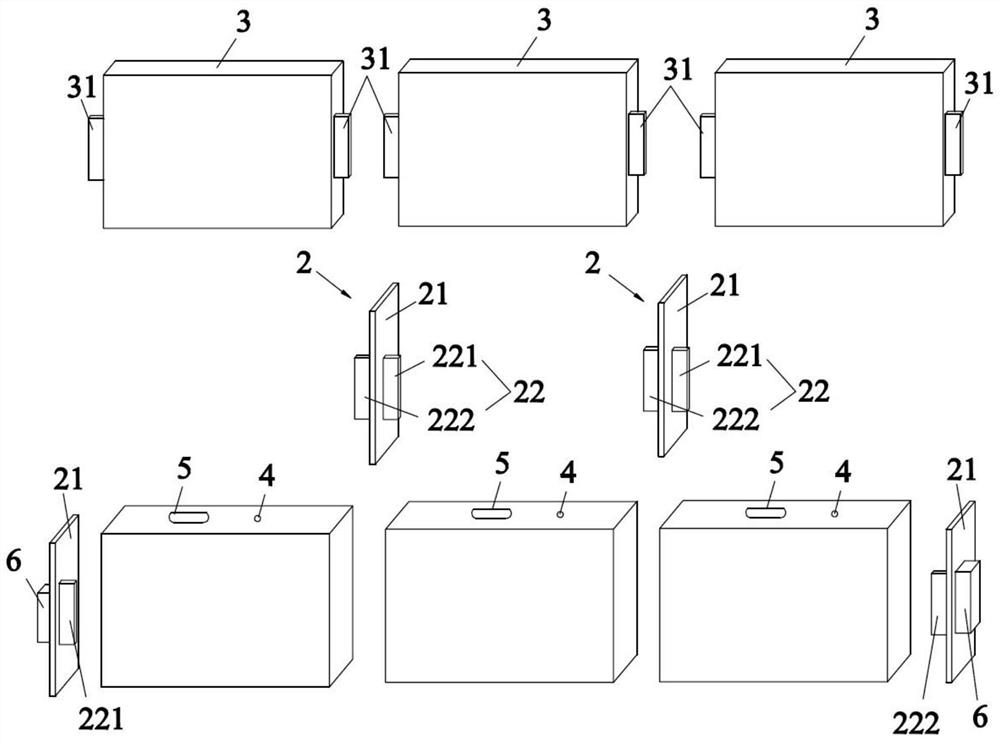

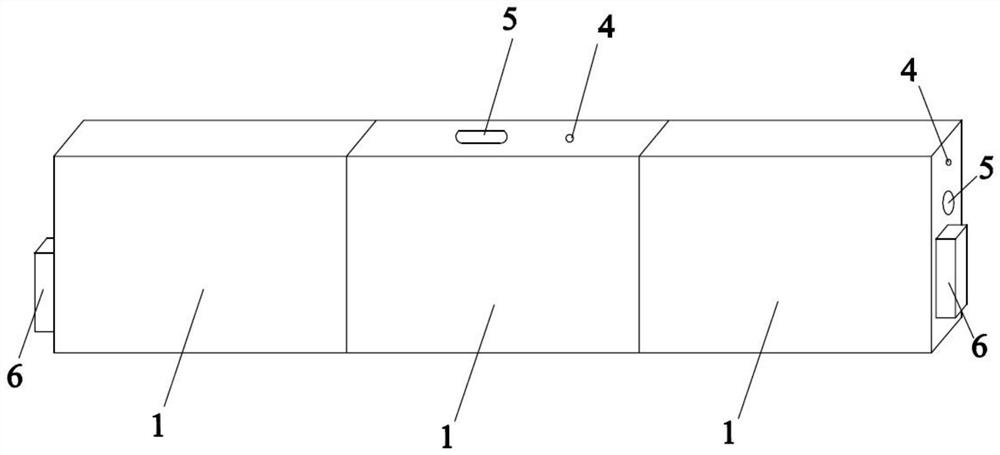

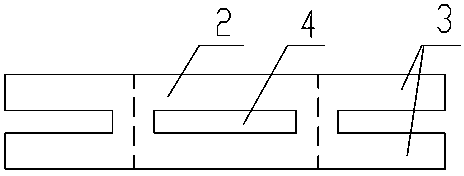

Battery structure and battery module

PendingCN111883731AImprove sealingEasy to chargeCell component detailsBatteriesTerminal voltageElectrical connection

The invention belongs to the technical field of battery production and manufacturing, and particularly relates to a battery structure, and the structure comprises a plurality of shells (1) with two communicated ends, wherein conductive connecting pieces (2) are fixed between the adjacent shells (1), and the shells (1) and the connecting pieces (2) enclose a plurality of sealing cavities for accommodating battery cells (3). And the adjacent battery cells (3) are electrically connected through the connecting pieces (2). Electrolyte circulation between the battery packs can be avoided, the problem that electrolyte in the battery is decomposed due to the fact that the voltage at the two ends of the battery is high is solved, and the performance of the battery can be improved. In addition, theinvention also discloses a battery module.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

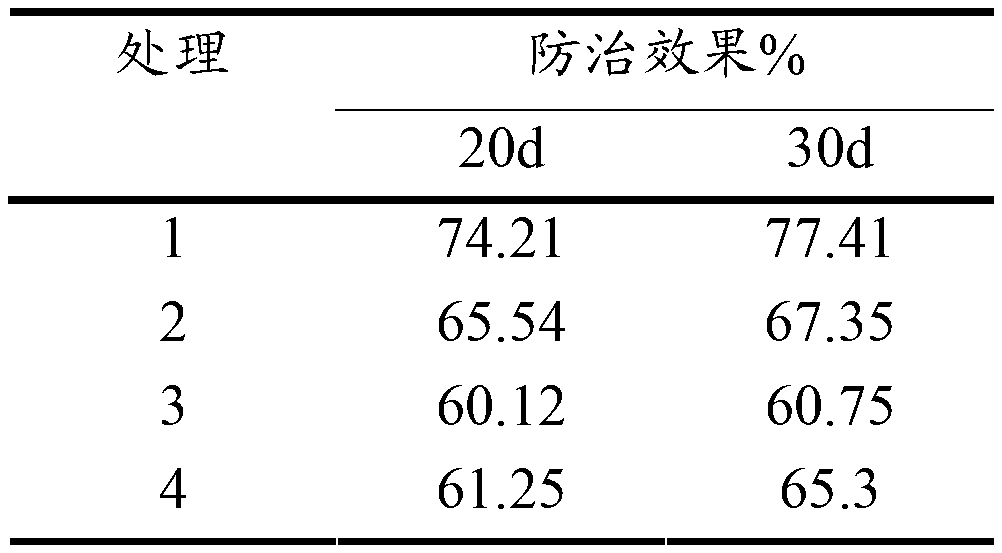

Method for preparing 2-amino-5-thiol-1, 3, 4-thiadiazole copper controlled-release microcapsule and prepared microcapsule

ActiveCN103222463AReduce tedious work such as manual sprayingStable storageBiocideFungicidesDecompositionUltraviolet lights

The invention provides a 2-amino-5-thiol-1, 3, 4-thiadiazole copper controlled-release microcapsule which comprises a capsule core and a capsule wall. The capsule core comprises 2-amino-5-thiol-1, 3, 4-thiadiazole copper, capsule core solvent and co-solvent. Components of the capsule wall comprise urea, formaldehyde solution and performed polymers. The 2-amino-5-thiol-1, 3, 4-thiadiazole copper controlled-release microcapsule is prepared in an emulsion polymerization mode. The 2-amino-5-thiol-1, 3, 4-thiadiazole copper controlled-release microcapsule has the advantages that in the process of application, inert ingredients, such as a wetting agent, do not need to be added, long-time action on a target object can be achieved; the problem that after the microcapsule application, due to ultraviolet light, illumination and raining, decomposition is affected is solved; after the application of the 2-amino-5-thiol-1, 3, 4-thiadiazole copper controlled-release microcapsule, the capsule core automatically releases the agents as time goes by, and tedious work, such as manual mist spray, in the process of production is reduced; under the environment of normal temperature and normal pressure, the microcapsule is stable in storage.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +2

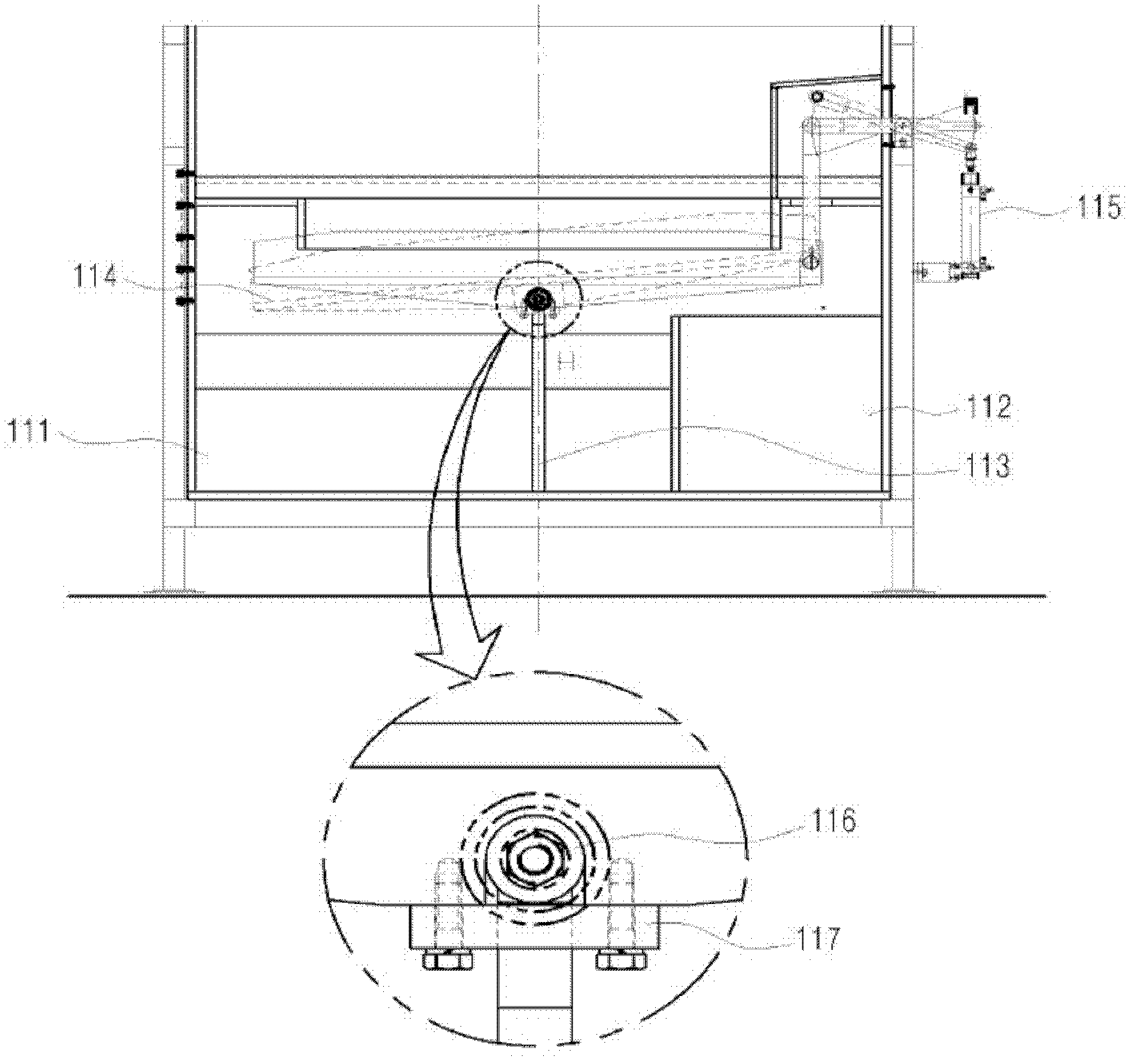

Acid dipping device used for nuclear rod jacketing tube and having function of preventing acid wash from leaking

ActiveCN103184463AEasy maintenanceFree from harmNuclear energy generationRadioactive decontaminationMedicineAcid washing

The invention relates to a zirconium alloy tube acid dipping device and more specifically relates to an acid dipping device used for removing surface defects and irregular faces of the inner surface of the nuclear rod jacketing tube in Pilger rolling operation. According to the invention, the function of preventing the acid wash from leaking is improved and units forming the acid dipping device can be dissolved and assembled easily and a ladder assembly is prevented from shaking. The zirconium alloy tube acid dipping device has following advantages that final product quality decrease caused by the corrosion of the surface of the nuclear rod jacketing tube because of the leakage of the acid wash can be prevented. A part of structural components of the acid dipping device can be maintained easily. And errors caused by that centers of the nozzle and the nuclear rod jacketing tube are not aligned in an acid dipping process is prevented.

Owner:KEPCO NUCLEAR FUEL CO LTD +1

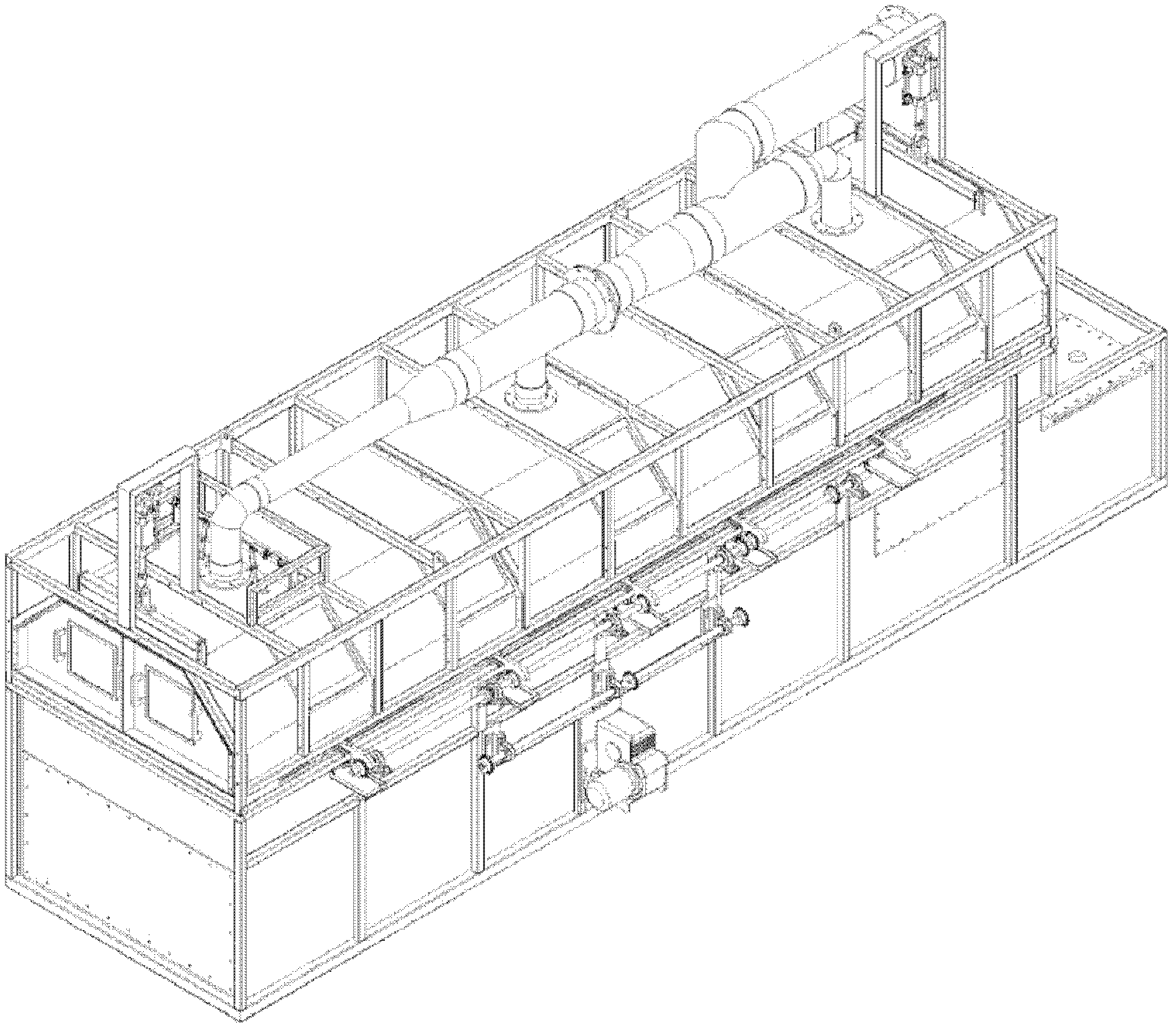

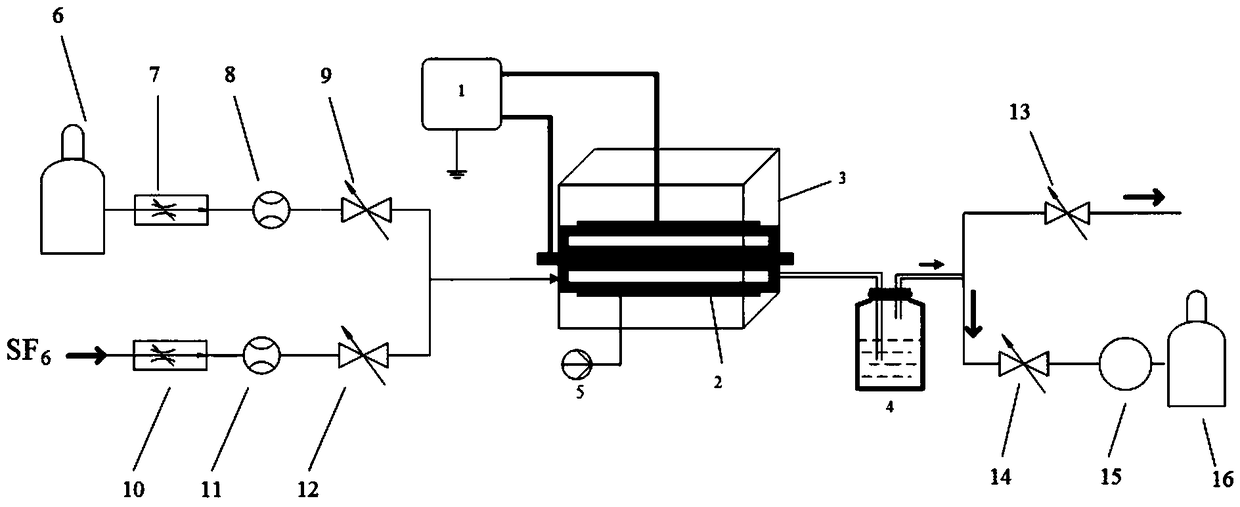

Oil immersion type sulfur hexafluoride degradation treatment device and treatment method based on medium discharging

PendingCN108298506AEffective destructionEfficient degradationSulfur and halogen compoundsSulfur hexafluorideProduct gas

The invention discloses an oil immersion type sulfur hexafluoride degradation treatment device and treatment method based on medium discharging. The oil immersion type sulfur hexafluoride degradationtreatment device comprises a medium blocking discharging reactor (2), and a high frequency alternating-current voltage source (1) is connected with an outer electrode and an inner electrode of the medium blocking discharging reactor through a wire; one end of the medium blocking discharging reactor is connected with a gas inlet; the other end of the medium blocking discharging reactor is connectedwith an alkali liquor absorption pool (4); the medium blocking discharging reactor (2) is placed in a sealed oil tank (3), and the sealed oil tank (3) is filled with transformer oil. The technical problems in the prior art are solved that only sulfur hexafluoride gas is collected, purified and stored, and sulfur hexafluoride is not decomposed and safely exhausted.

Owner:GUIZHOU POWER GRID CO LTD

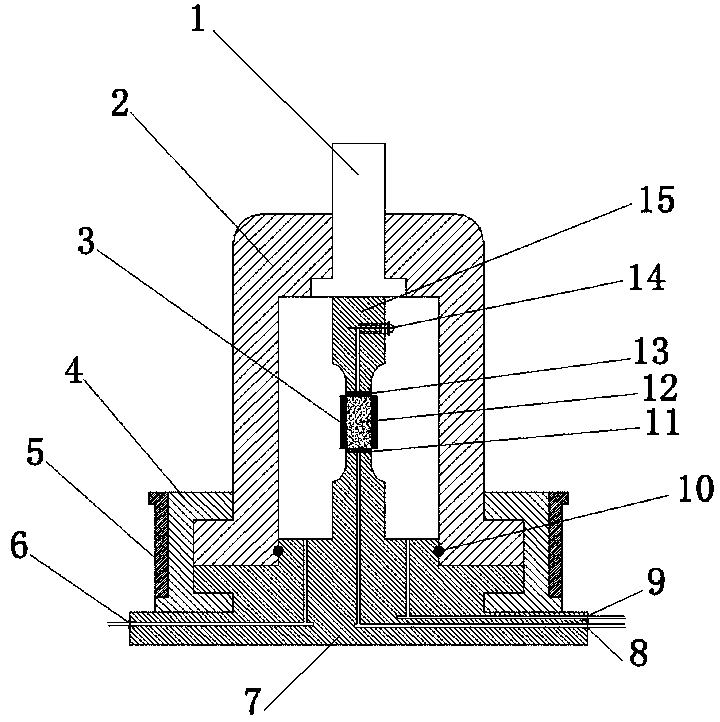

Testing method for mechanical property change of natural gas hydrate during decomposition

ActiveCN104034849ASolve decompositionThe measured results are reliableMaterial analysisDecompositionData acquisition

The invention relates to a testing method for mechanical property of natural gas hydrate, and in particular relates to a testing method for mechanical property change of natural gas hydrate during decomposition. The testing method is characterized in that a hydrate sample is placed in a (super) magnetizer temperature controller, the ambient temperature of the hydrate can be accurately controlled, the practical decomposition condition of the hydrate during extraction can be fully simulated, and the mechanical property change of the hydrate during decomposition can be tested. The method comprises the following steps: sample preparation, selection of the testing method, and data acquisition. The method can be used for simulating to test the mechanical property change of the in-situ formation hydrate.

Owner:SHANDONG UNIV OF SCI & TECH

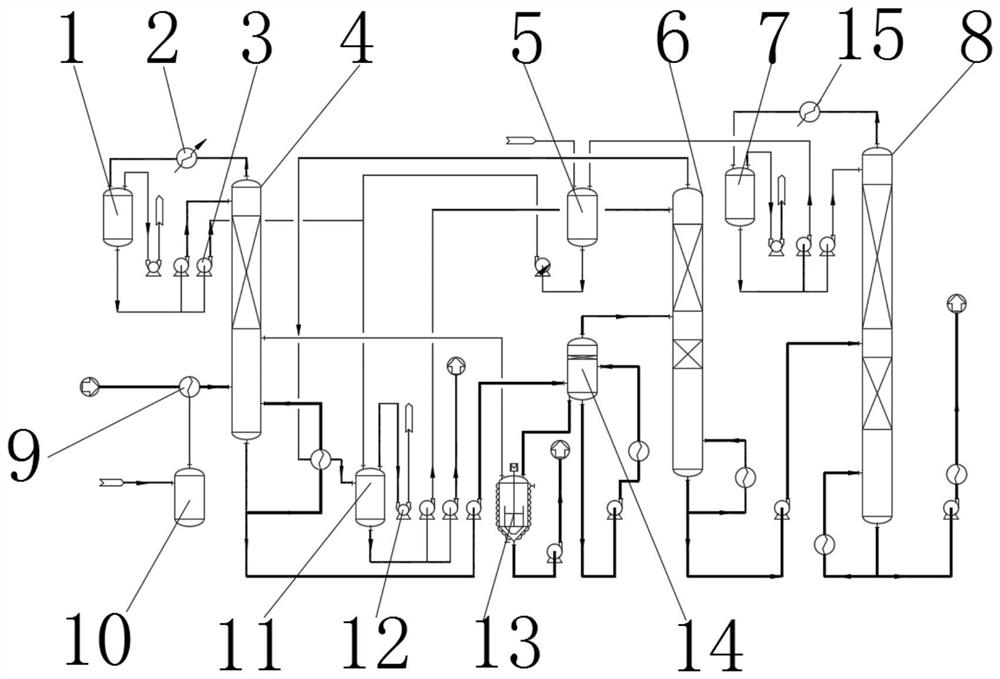

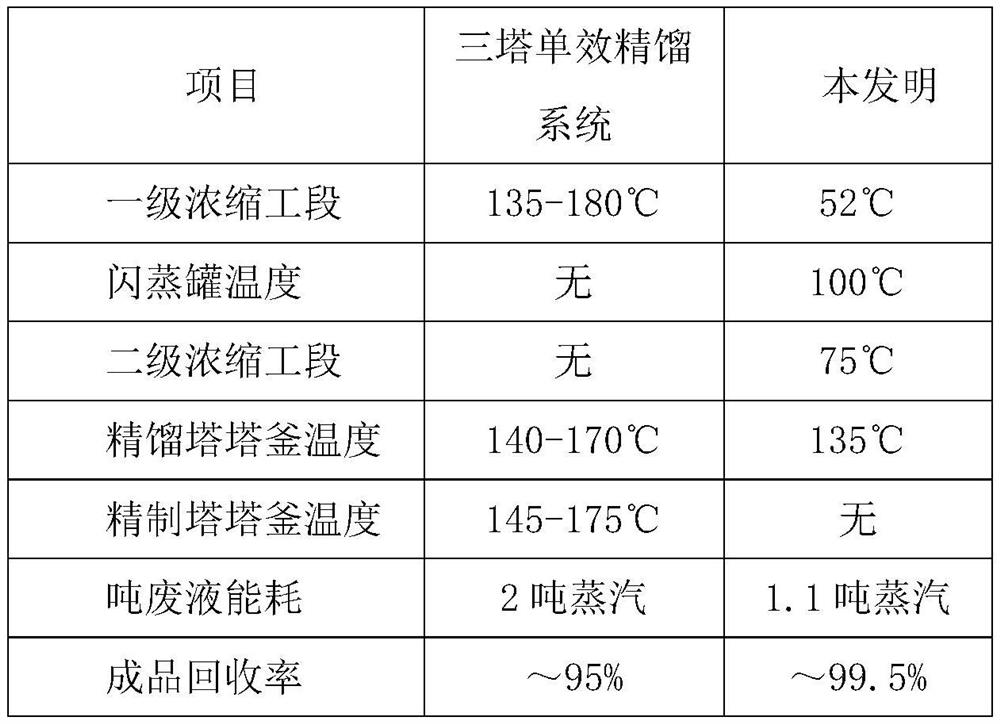

Three-tower two-effect rectification system and recovery method for NMP waste liquid

InactiveCN112807732ASolve decompositionSolve the problem of hydrolysisOrganic chemistryVapor condensationProcess engineeringChiller

The invention relates to the technical field of solvent recovery, in particular to a method for recovering NMP waste liquid. The method for recovering NMP in the waste liquid comprises the following steps: step 1, preheating the waste liquid containing NMP and then feeding the waste liquid into a primary concentration tower; step 2, preheating the waste liquid, and carrying out primary dehydration concentration in the primary concentration tower; step 3, feeding tower bottom liquid which is dehydrated and concentrated by the primary concentration tower into a flash tank through a discharging pump, and then feeding the tower bottom liquid into a feeding evaporator by using a forced circulation pump; step 4, carrying out secondary dehydration and concentration on gas of which the gas phase enters the secondary concentration tower in the secondary concentration tower; step 5, feeding tower bottom liquid dehydrated and concentrated by the secondary concentration tower to the middle part of a rectifying tower by a discharging pump so as to separate a mixed solution; and step 6, pumping the NMP finished product into a finished product cooler, cooling by circulating water, and then feeding into a finished product tank in a tank area. The whole technological process is carried out at low temperature, and NMP is basically not decomposed, so that the recovery rate of an NMP finished product is about 99.5%.

Owner:常州冀德环保科技有限公司

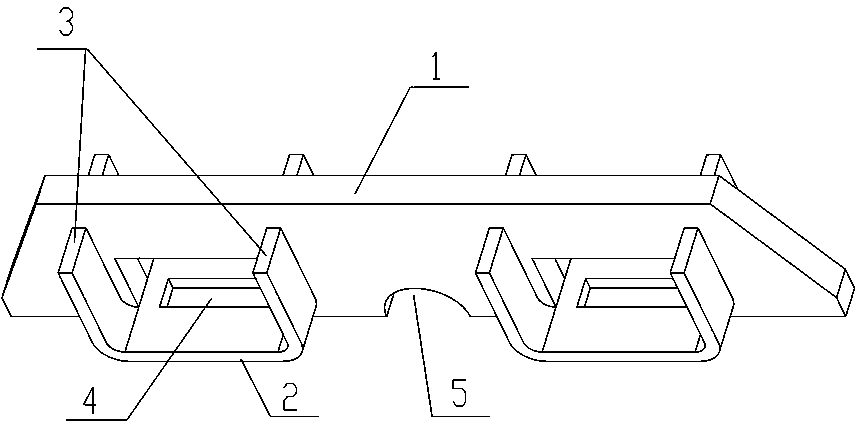

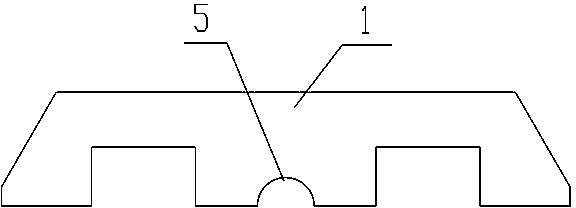

Steel member splicing pretensioner and method for connecting component elements with pretensioner

ActiveCN103341836ASimple structureEasy to operateWork holdersMetal-working hand toolsSheet steelKeel

The invention discloses a steel member splicing pretensioner which comprises a plate-shaped keel. The plate-shaped keel is longitudinally arranged. Rectangular arch grooves are formed in the lower portion of the plate-shaped keel. Fixing plates are horizontally clamped between the rectangular arch grooves of the plate-shaped keel. Two pairs of supporting side plates which are arranged upwards in an extending mode on the side faces of the plate-shaped keel on two side edges of the fixing plates are respectively and fixedly connected with two side faces of the plate-shaped keel. Rectangular through holes are defined by the upper surfaces of the fixing plates and two sides faces and the top faces of the rectangular arch grooves. Fixing through grooves are formed in the positions, corresponding to the rectangular through holes, of the fixing plates. The steel member splicing pretensioner has the advantages of being simple in structure, convenient to operate, strong in universality and capable of being used repeatedly. Meanwhile, the invention further provides a method for connecting component elements with the pretensioner, two thin elements (such as steel sheets) can be connected, and meanwhile the thicknesses and the directions of the component elements are not limited, and the problems of assembling, separating, lifting and the like of the component elements in a large steel structure equipment manufacturing industry are solved.

Owner:YELLOW RIVER ENG CONSULTING

Polyamide carrier flame-retarding master batch and preparation method

The invention discloses polyamide carrier flame-retarding master batch and a preparation method. The master batch includes, by weight, 15 to 36 parts of polycaprolactam, 48 to 63 parts of fire retardant, 16 to 21 parts of assistant fire retardant, and 0.4 to 0.6 parts of oxidation inhibitor. When the content of deca-bromine di-phenylethane ranges from 48% to 63%, proper flame-retarding master batch can be prepared, and further, flame-retarding polyamide of flame-retarding rating V0 can be molded in an injection manner according to proper proportion. The preparation method not only solves the problem of decomposition of the deca-bromine di-phenylethane but meets desires and requirements of customers, and the polyamide carrier flame-retarding master batch has wider market.

Owner:SHENZHEN KEJU NEW MATERIAL

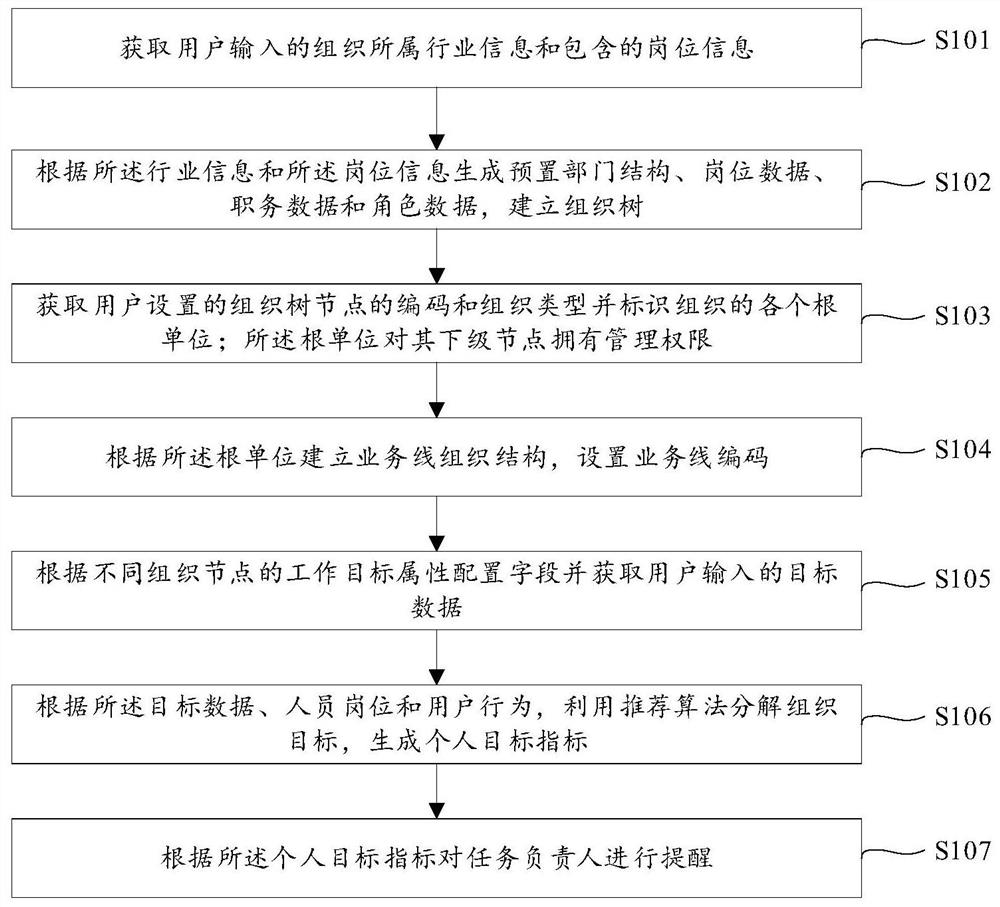

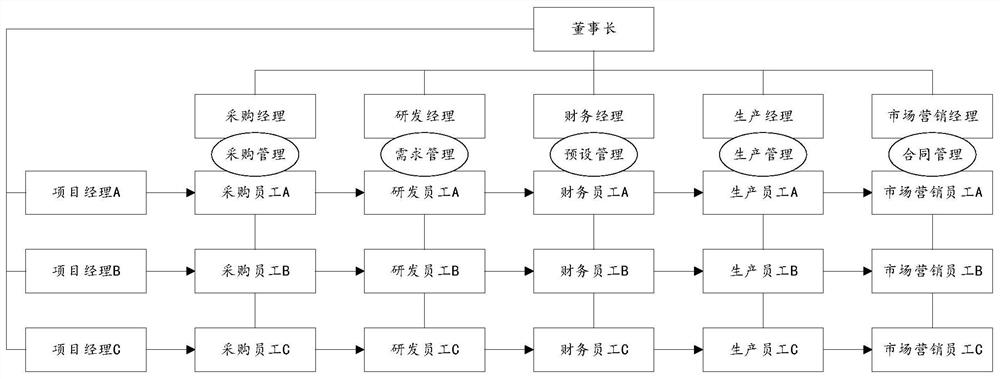

Target task management method and device for multi-level organization

PendingCN112149974AAchieve full coverageSolve the assignmentOffice automationResourcesEngineeringData mining

The invention provides a target task management method and device for multi-level organization. The method comprises the steps of obtaining organization industry information input by a user and post information contained in the organization industry information; generating a preset department structure, post data, job data and role data according to the industry information and the post information, and establishing an organization tree; obtaining a code and an organization type of an organization tree node set by a user and identifying each root unit of the organization; wherein the root unithas a management authority for a subordinate node; establishing a service line organization structure according to the root unit, and setting a service line code; configuring fields according to theworking target attributes of different organization nodes and obtaining target data input by a user; according to the target data, the personnel post and the user behavior, decomposing an organizationtarget by utilizing a recommendation algorithm to generate a personal target index; and reminding a task principal according to the personal target index.

Owner:成都明途科技有限公司

Polyurethane flexible tube and preparation method thereof

Owner:5ELEM HI TECH CORP

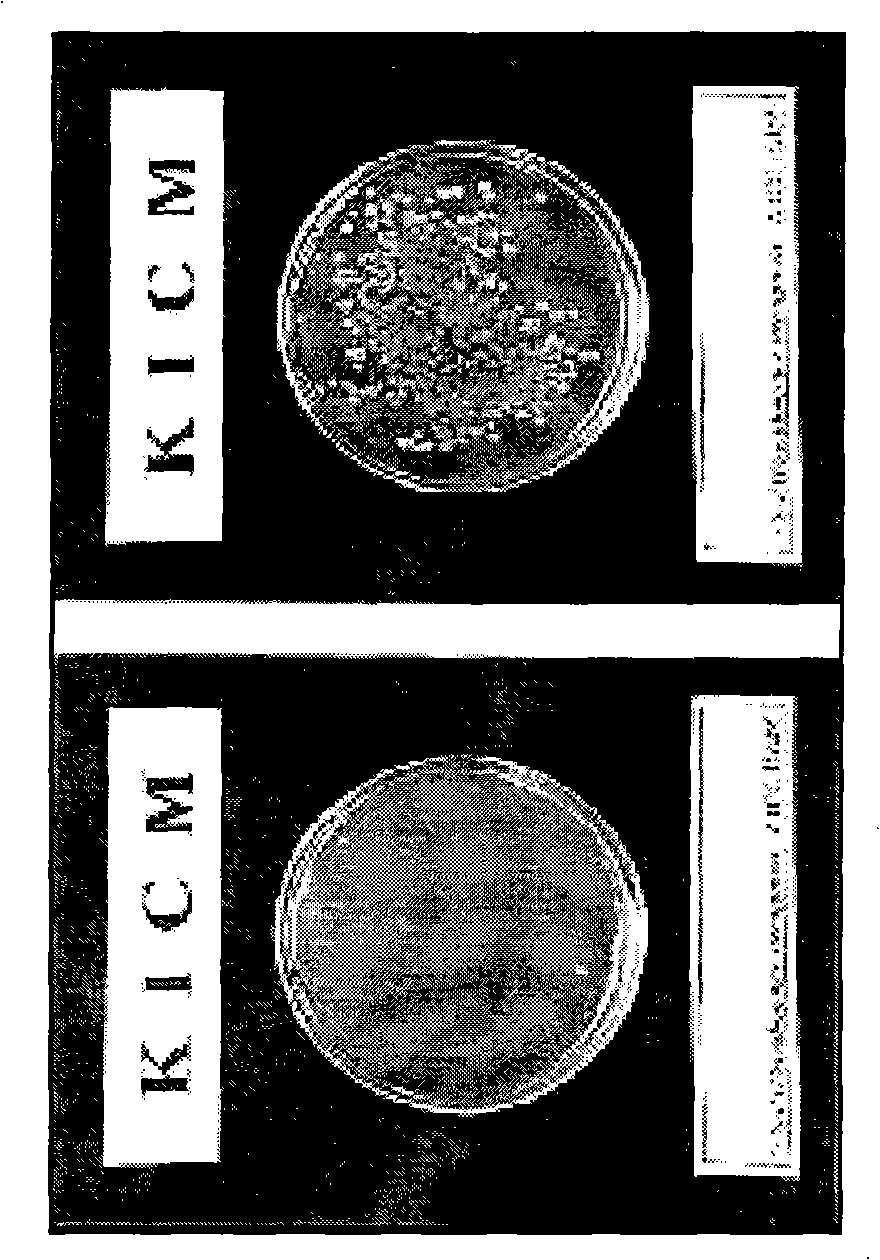

Eco friendly antifungal mortar

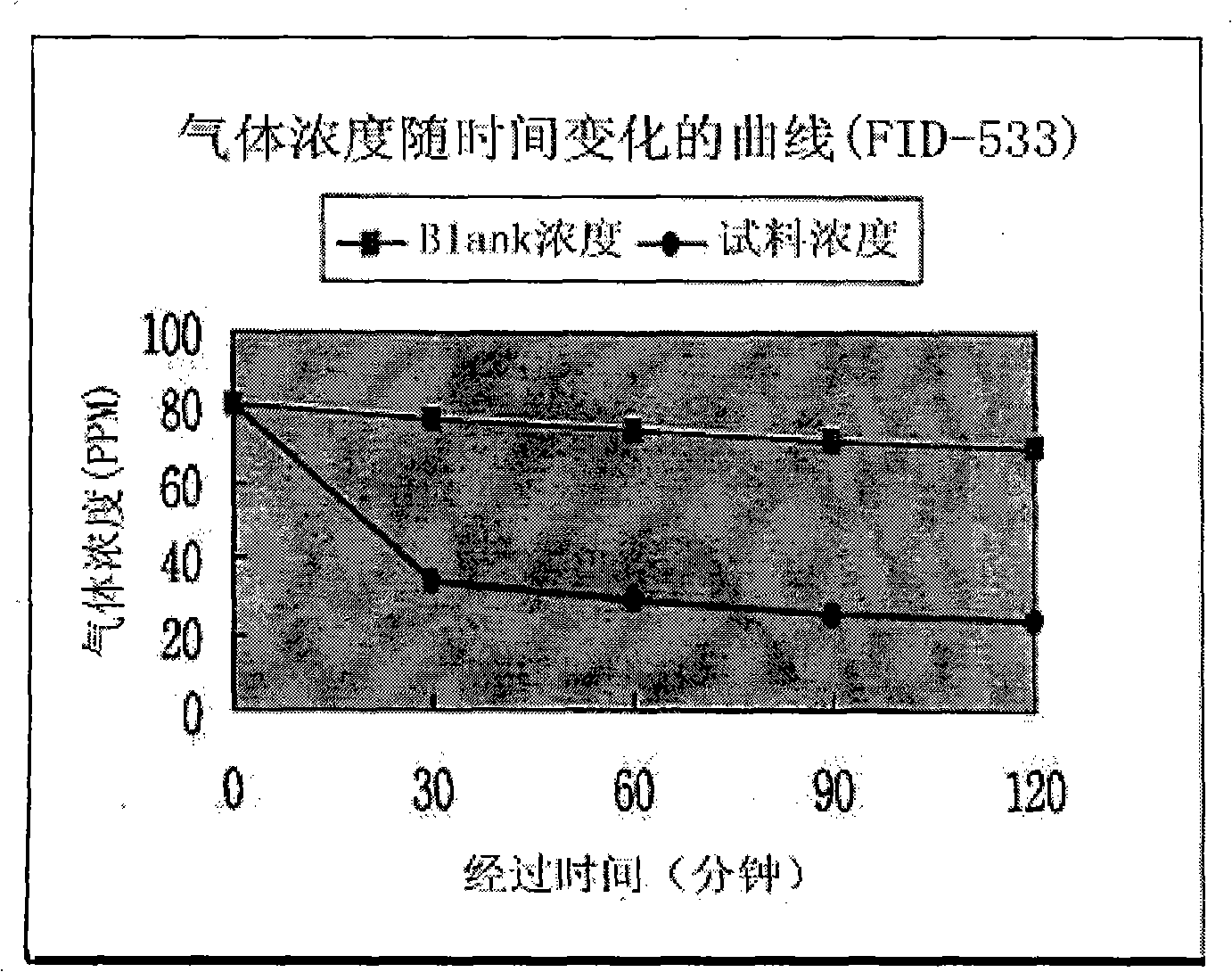

InactiveCN101293765ASolve decompositionComfortable indoor environmentSolid waste managementWater basedAntifungal

The invention provides an environment friendly antifungal dry mortar. The environment friendly antifungal dry mortar comprises a mixture (a) having 60-80 weight percent of mixed sand and 20-40 weight percent of cementing agent based on the total 100 weight percent, beneficial microorganisms (b) and water (c). The beneficial microorganisms (b) comprise a mixture consisting of more than one of the photosynthetic bacterium, aerobe, physiologically active substance, yeasts and lactobacillus. The water is prepared by replacing 1-20 weight percent of water based on the total 100 weight percent. The invention has functions of self-disinfection, antibiosis and deodorization, and is capable of removing bacterium, mould and so on, therefore greatly improving living environment, decomposing substances that induce syndrome of new residence such as volatile organic compounds (VOC), formaldehyde (HCHO) and toluene, as well as effectively deodorizing.

Owner:金斗镇

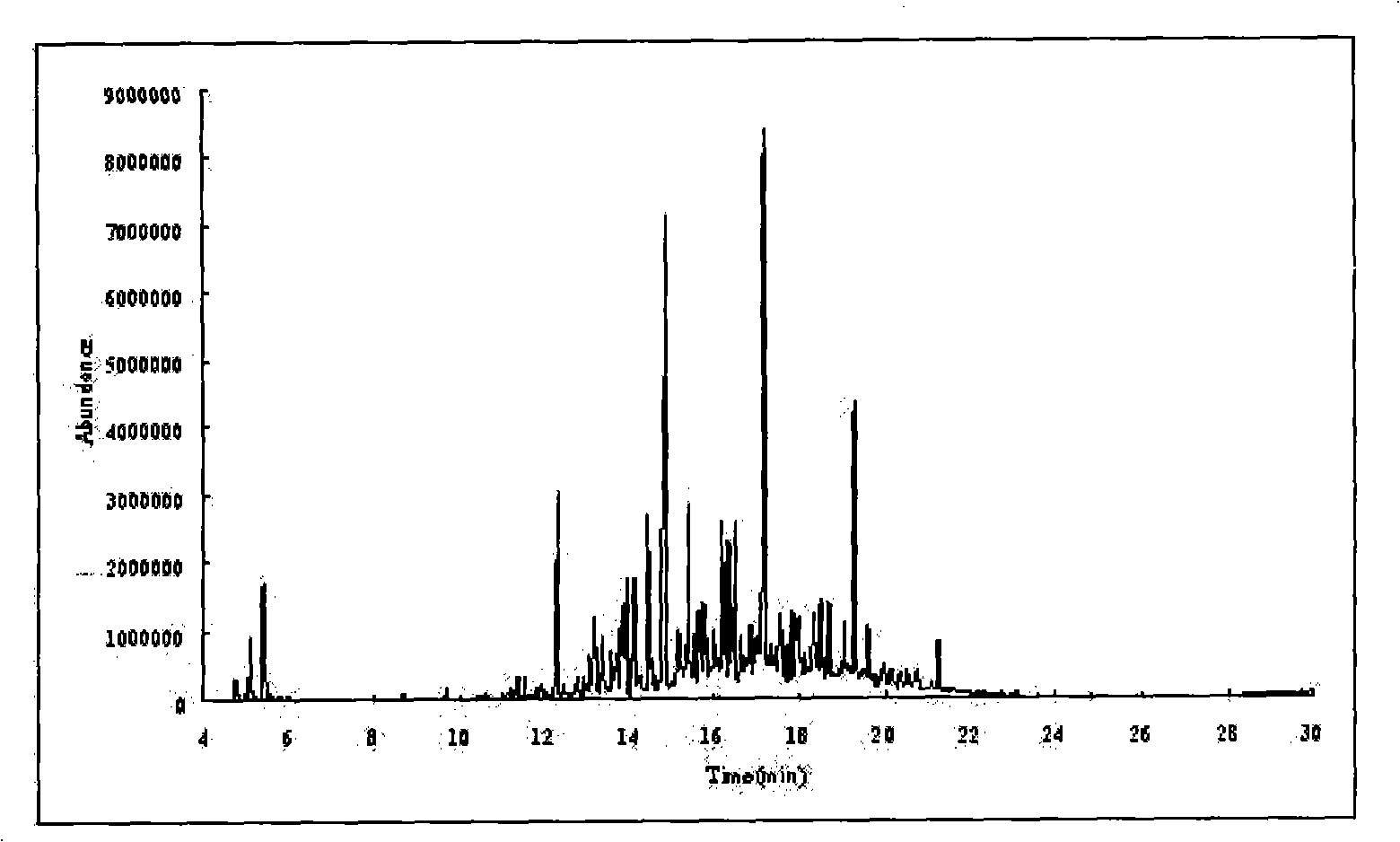

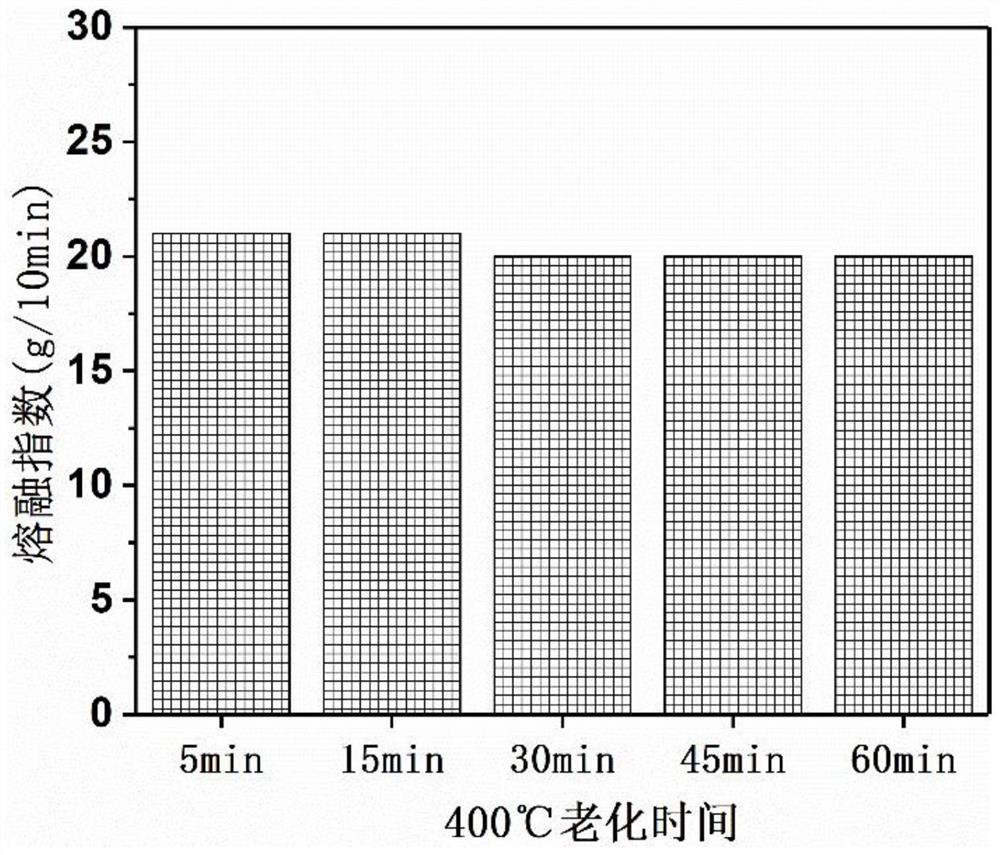

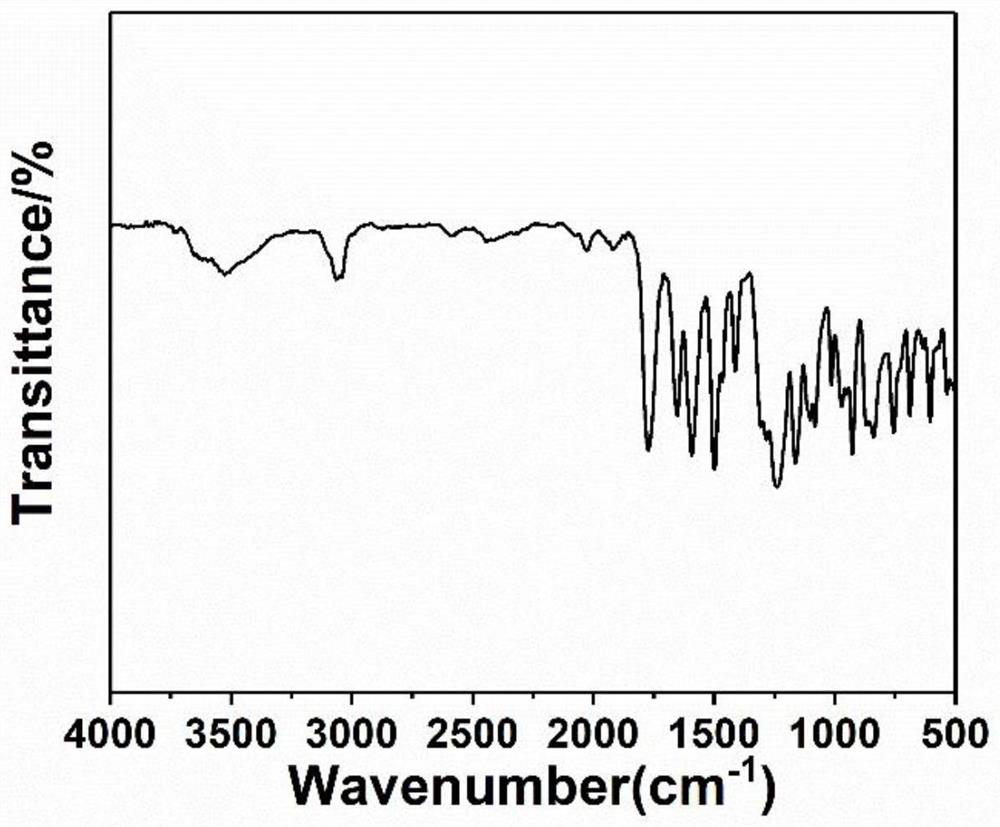

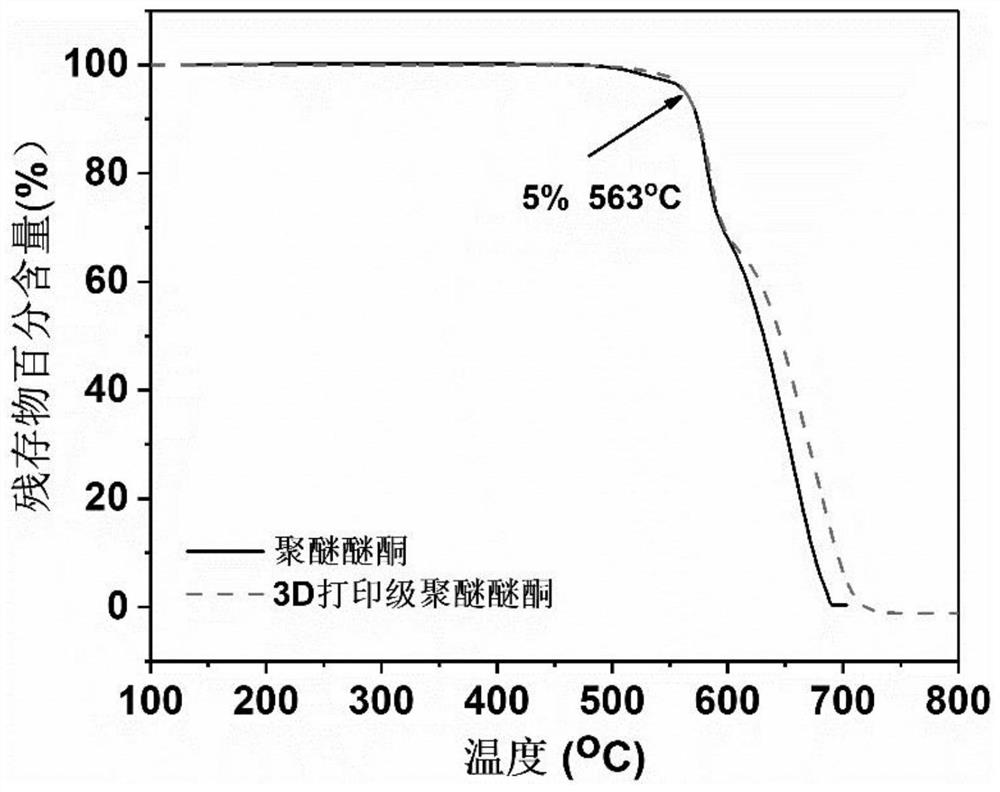

3D printing grade polyether-ether-ketone resin special material, preparation and application thereof, 3D printing interlayer reinforced polyether-ether-ketone alloy material and preparation thereof

ActiveCN113736044AImprove temperature resistanceImprove stabilityAdditive manufacturing apparatus3d printEndcapping

The invention provides a 3D printing grade polyether-ether-ketone resin special material, preparation and application thereof, a 3D printing interlayer reinforced polyether-ether-ketone alloy material and preparation thereof, and belongs to the technical field of 3D printing materials. According to the invention, 4-fluorodiphenyl sulfone with a higher temperature-resistant grade is used as an end-capping group, so that the polyether-ether-ketone resin has a very stable fluorine-containing end group, and polyether-ether-ketone can maintain good fluidity and stability under a higher-temperature processing condition, so that the requirement of 3D printing high-temperature processing is met. In addition, the special material is blended with an interlayer reinforced modifier, so that the prepared 3D printing interlayer reinforced polyether-ether-ketone alloy material keeps excellent mechanical properties of polyether-ether-ketone, and meanwhile, the interlayer bonding strength is greatly improved.

Owner:JILIN UNIV

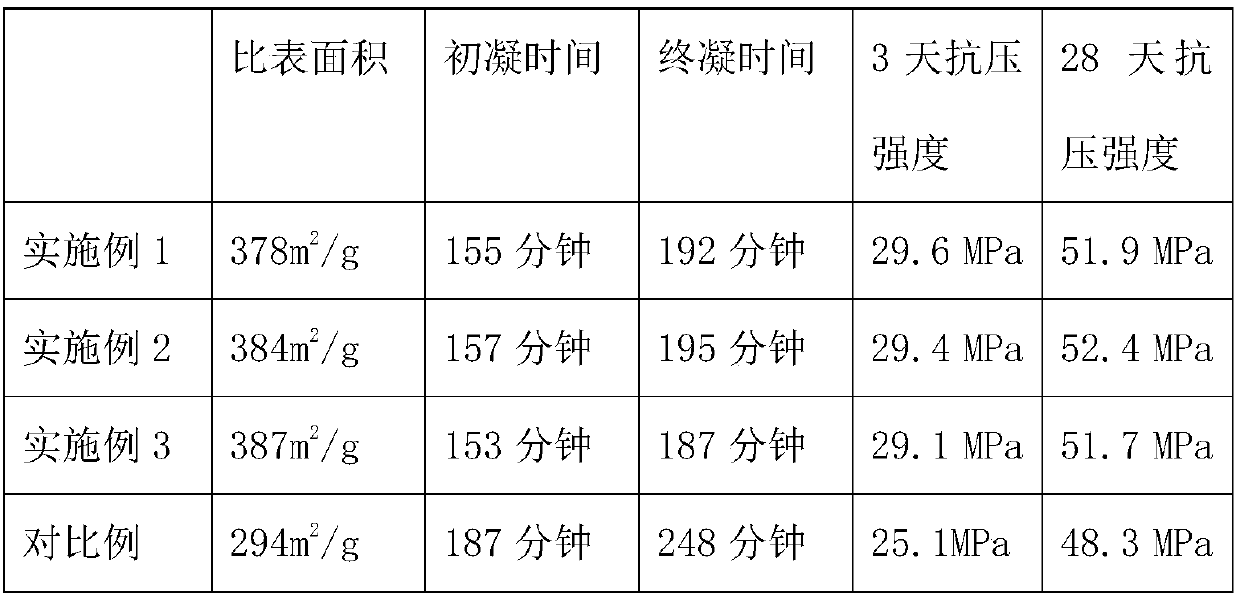

Efficient composite powder grinding aid and preparation method thereof

The invention discloses an efficient composite powder grinding aid and a preparation method thereof. The efficient composite powder grinding aid comprises the following raw materials in parts by weight: 0.8-1.5 parts of triethanolamine, 1-1.8 parts of polyalcohol, 0.3-0.6 part of sodium thiocyanate, 0.8-1.5 parts of a PC water reducing agent raw liquor, 0.3-0.4 part of sodium hydroxide and 94-97.5parts of steel slags. The efficient composite powder grinding aid disclosed by the invention is extensive in raw material sources; through compounding of various raw materials, organic compounds arenot used, and the difficult problem that the organic compounds are nonserviceable due to decomposition of components is effectively solved; the prepared finished products are harmless to cement and human bodies, and conform to the standard of relevant addition of grinding aids in China; and the product namely the efficient composite powder grinding aid is low in cost and stable in quality, the yield of the cement can be increased, the early intensity of the cement can be increased, the grinding aiding effect is good, and the application prospects are great.

Owner:RIGIDTECH MICROELECTRONICS CORP

Preparation method for biomass degradation material and magnetic powder catheter

InactiveCN102140234AImprove impact resistanceGood flexibilityRigid pipesBiomass degradationFiller Excipient

The invention provides a preparation method for biomass degradation material, which comprises the following steps: (1) preparing raw materials: weighing the following compositions of raw materials by weight percentage: 40 to 60 of major ingredient poly( butylene succinate), 40 to 60 of modified material polylactic acid and 0.1 to 20 of filler calcium carbonate master batch; (2) mixing the compositions to form modified poly( butylene succinate) mixture; and (3) statically placing the modified mixture at low temperature for standby application. The invention also discloses a method for manufacturing a magnetic powder catheter by adopting the raw materials, which comprises the following steps: (4) preparing a magnetic powder catheter extrusion main machine and a round die head matched with the main machine for use; (5) feeding the modified poly( butylene succinate) mixture into the extrusion main machine so as to manufacture a continuous round hollow magnetic powder catheter; and (7) cutting the continuous round hollow magnetic powder catheter into magnetic powder catheter sections. The invention also provides the magnetic powder catheter prepared by the method. The materials provided by the invention can completely degrade. The method is scientific and reasonable; the production efficiency is high; the product performance is good; and the cost is low.

Owner:广州高馨能生物科技有限公司

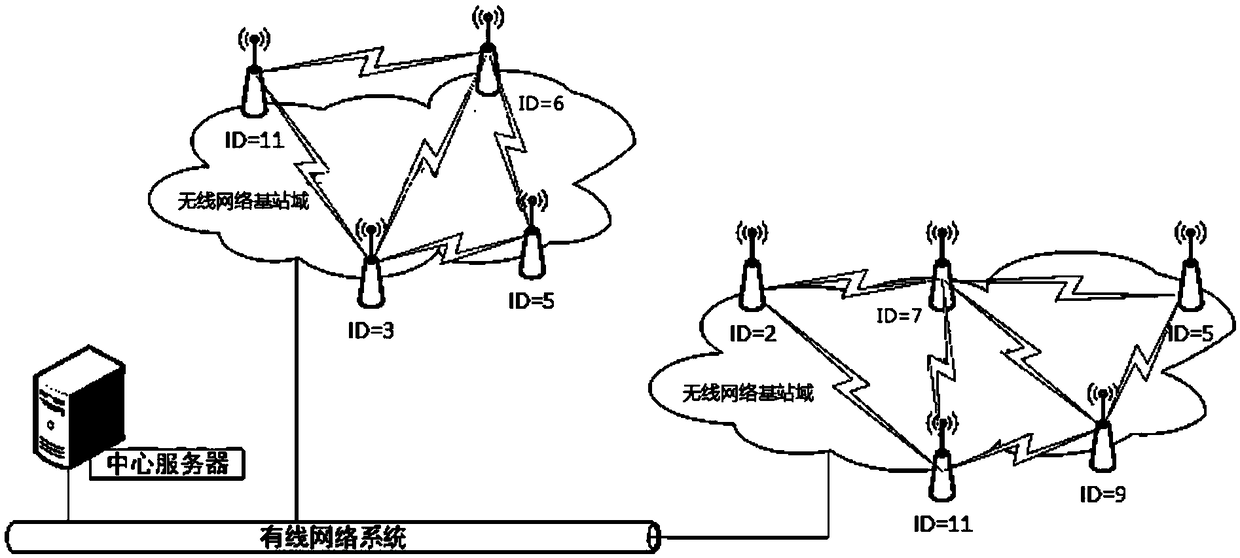

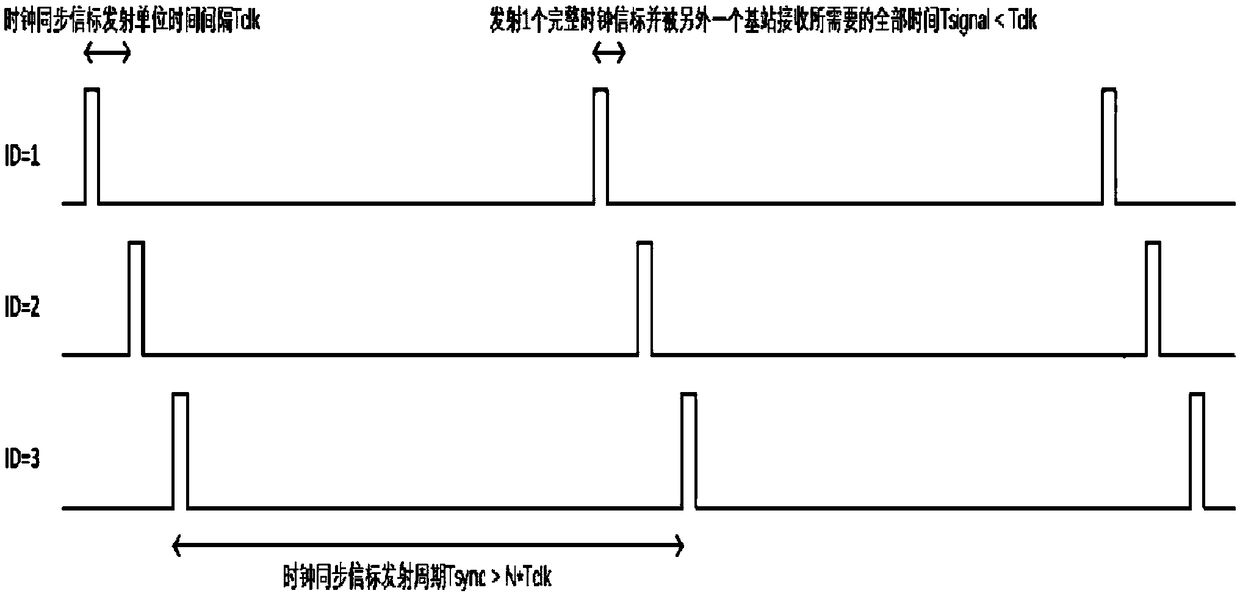

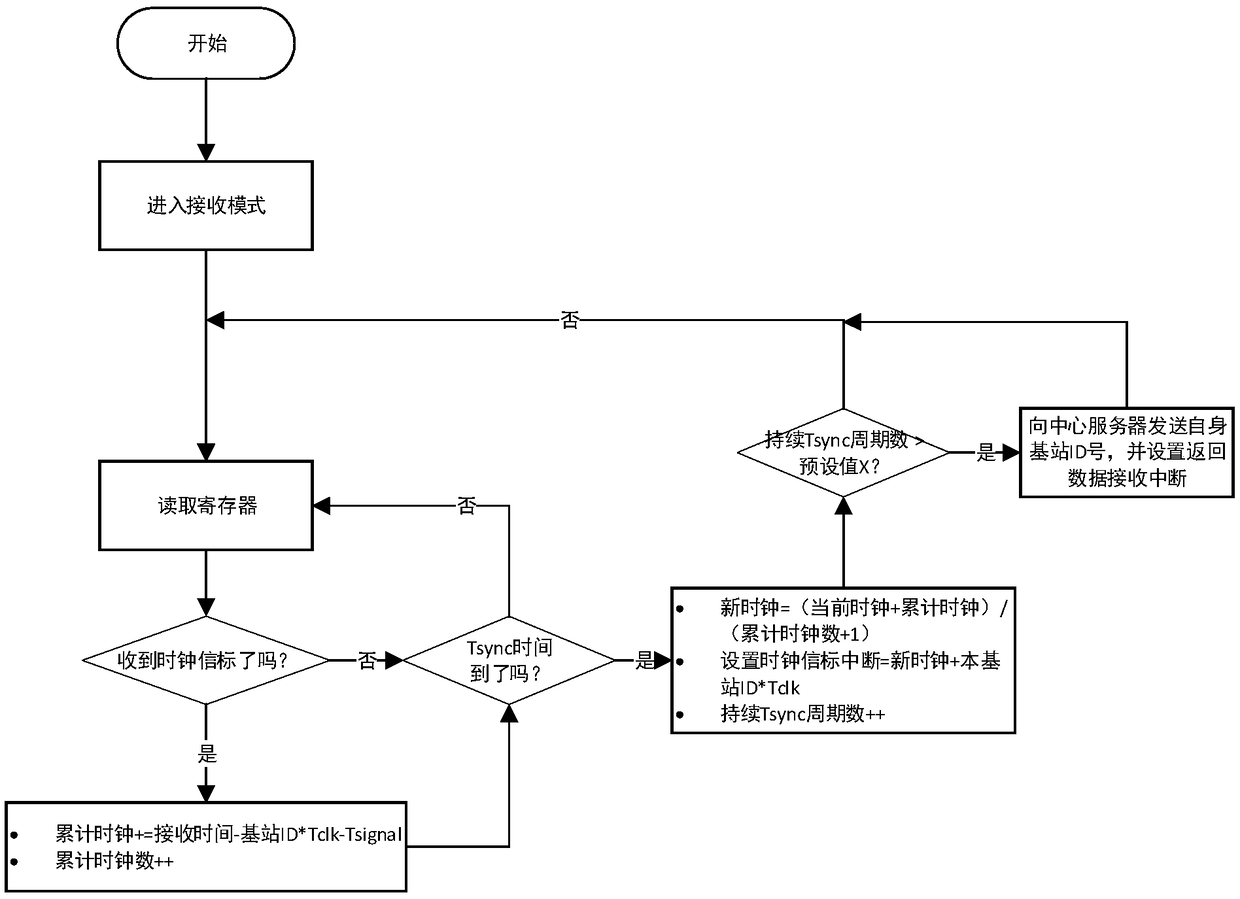

Radio clock synchronization method, system and medium without central base station

ActiveCN109067496AAchieve precise synchronizationSolve the accuracy problemSynchronisation arrangementTime-division multiplexRadio clockClock synchronization

The invention provides a wireless clock synchronization method without a central base station, a system and a medium, comprising the following steps: a base station domain dividing step: dividing eachbase station to obtain a divided base station domain; base station domain clock synchronization step: according to the divided base station domain, clock synchronization parameters corresponding to each base station in the base station domain are allocated to synchronize clock information of each base station in the base station domain. The invention can realize precise synchronization of clocksbetween base stations in a Tsync time period. The invention can solve the problems of low synchronization precision and clock out-of-step after synchronization and the like existing in the prior art.The invention can realize the dynamic division of the base station domain, and solve the problems of dynamic discrimination, decomposition and combination of the smallest base station domain when thebase station is dynamically increased, decreased or moved.

Owner:昂科信息技术(上海)股份有限公司

Hollow nanofiber Co3O4/S composite material as well as preparation method and application thereof

ActiveCN110707307ASolve decompositionSolve the shuttle effectMaterial nanotechnologyCell electrodesPolymer scienceSpinning

The invention discloses a hollow nanofiber Co3O4 / S composite material as well as a preparation method and application thereof. The method comprises the following steps of (1) dissolving cobalt acetate, polyacrylonitrile and polyvinylpyrrolidone in an organic solvent, stirring at room temperature, and standing to obtain an electrospinning solution; (2) extracting an electrospinning solution, carrying out electrostatic spinning, collecting a sample by using a carbon paper, and preparing the nanofiber on the conditions that the voltage is 15kV, the distance between a needle head of the electrostatic spinning and the carbon paper is 12-15cm, the injection flow rate is 60mu L / min, the temperature is 21-25 DEG C, and the relative humidity is 80%; (3) oxidizing the nanofiber in air at 300 DEG C to obtain an HCON material; and (4) mixing sulfur and the HCON material, and carrying out heat preservation at 155 DEG C to prepare the hollow nanofiber Co3O4 / S composite material. The composite material provided by the invention can inhibit the shuttle effect of polysulfide, improves the specific capacity and has the very good rate capability.

Owner:XIJING UNIV

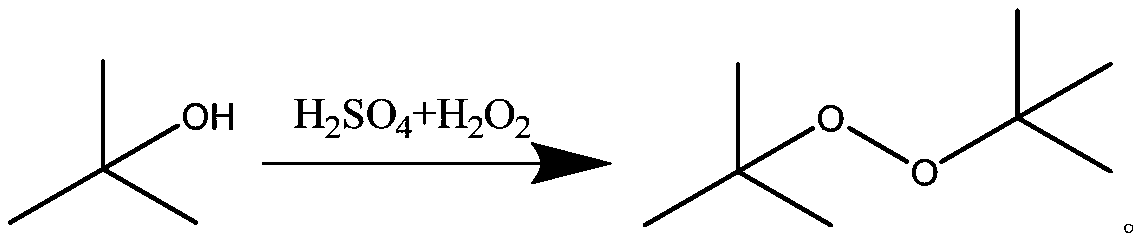

Di-tert-butyl peroxide synthesis method

ActiveCN110204472AImprove conversion rateHigh selectivityOrganic compound preparationChemical/physical/physico-chemical microreactorsChemical industryDecomposition problem

The invention belongs to the technical field of chemistry and chemical industry, and particularly relates to a di-tert-butyl peroxide synthesis method, which comprises: mixing tert-butanol and concentrated sulfuric acid in a first micro-channel continuous flow reactor, and carrying out a mixing reaction on the obtained product and hydrogen peroxide in a second micro-channel continuous flow reactor, wherein the temperature of the first micro-channel continuous flow reactor is 10-25 DEG C, the second micro-channel continuous flow reactor is formed by connecting 8-12 micro-channel mixer substrates, and the temperature of the second micro-channel continuous flow reactor is controlled at 45-65 DEG C. According to the present invention, the method has characteristics of extremely high heat transfer and mass transfer efficiency, segmental temperature control, energy consumption cost reducing and risk coefficient reducing, and can solve the product decomposition problem caused by temperature control loss and side reaction increasing; and by using the synthesis method, the reaction conversion rate is more than 99.3%, and the selectivity is more than 99.0%.

Owner:LINZIZHENGHUA ACCESSORY INGREDIENT ZIBO

A kind of preparation method of carbon fiber composite polyethersulfone resin sample

ActiveCN104018355BHigh glass transition temperatureSolve decompositionCarbon fibresFiberInterface bond

Owner:BEIJING UNIV OF CHEM TECH

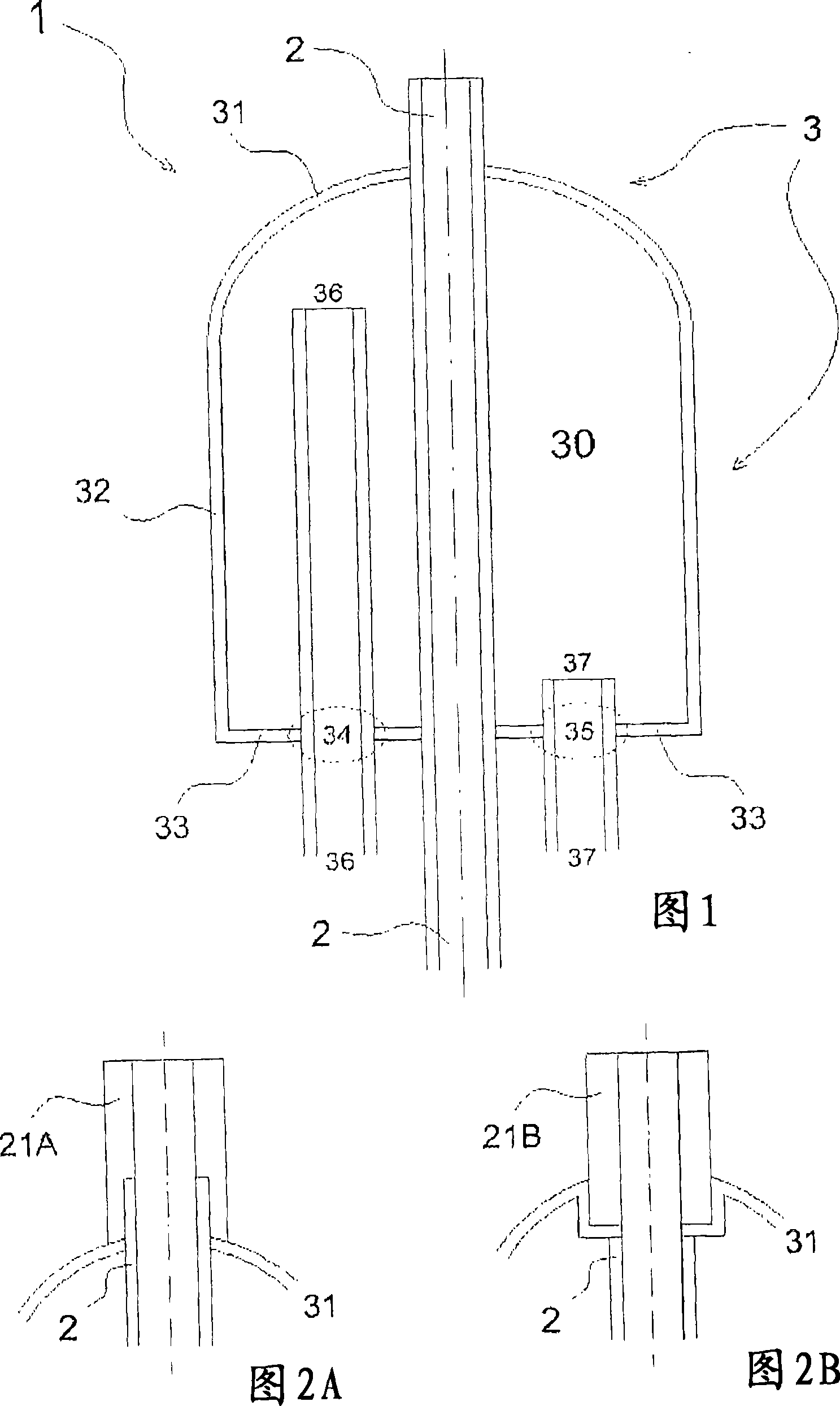

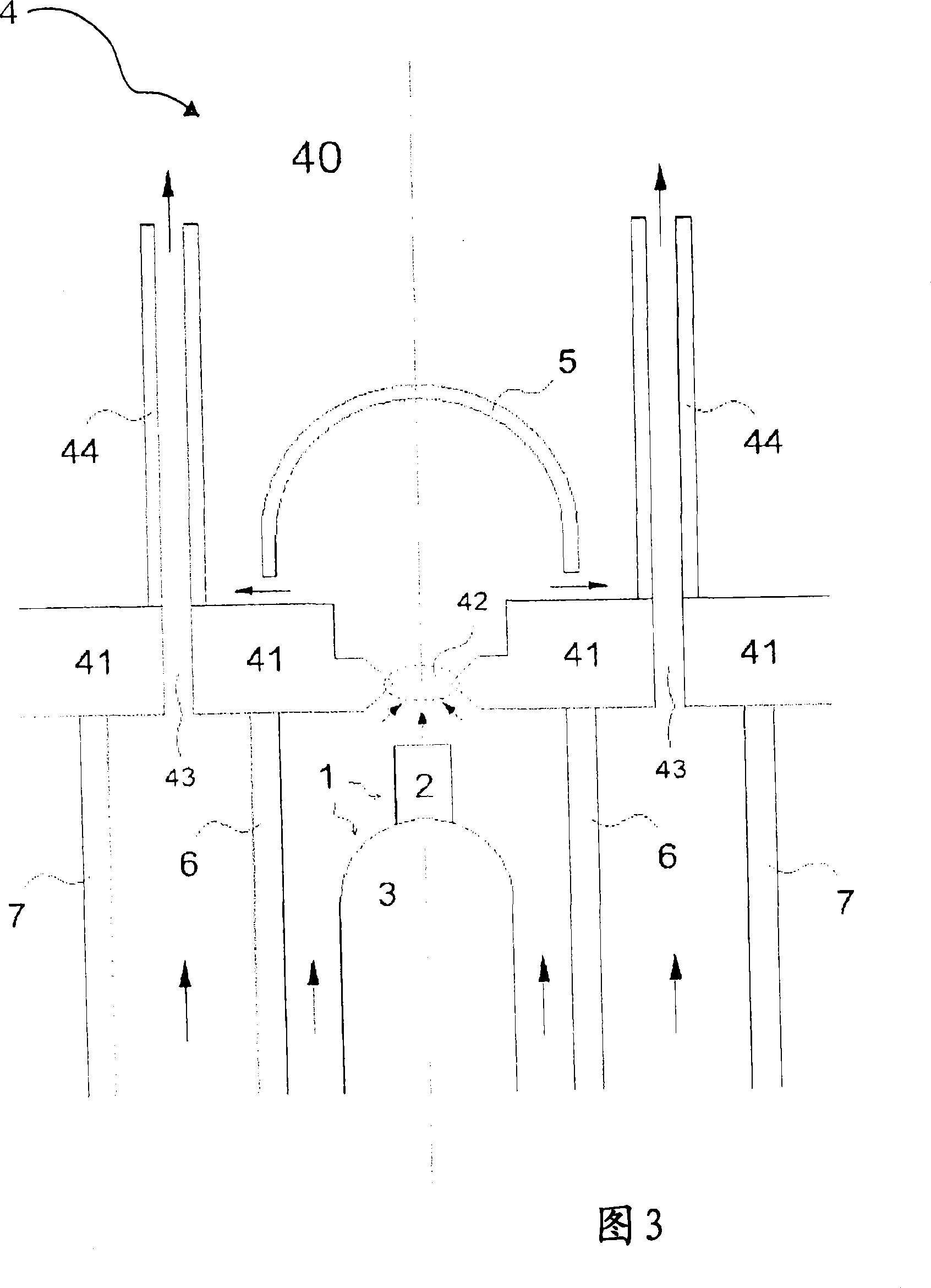

Device for introducing reaction gases into a reaction chamber and epitaxial reactor which uses said device

ActiveCN101203633ASolve decompositionGas-gas reaction processesFrom chemically reactive gasesProcess engineeringEngineering

The present invention relates to a device (1) for introducing reaction gases into a reaction chamber of an epitaxial reactor; the device (1) comprises a gas supply pipe (2) and a cooling member (3) situated at one end of the supply pipe (2) and able to cool the supply pipe (2) and thereby the gas flowing inside it.

Owner:LPE

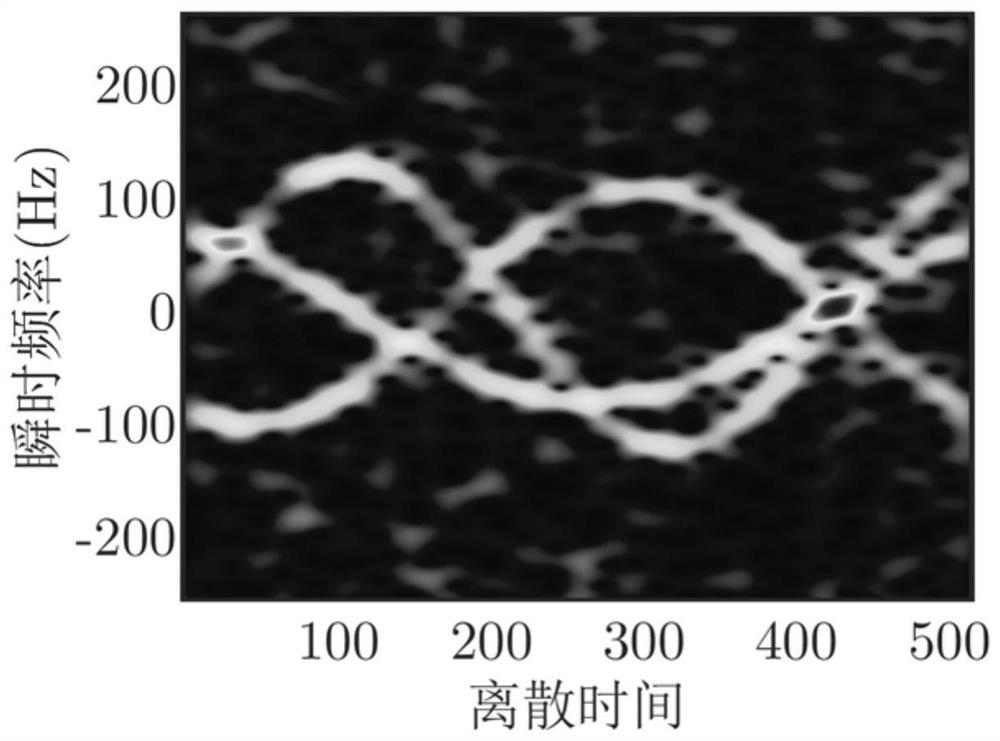

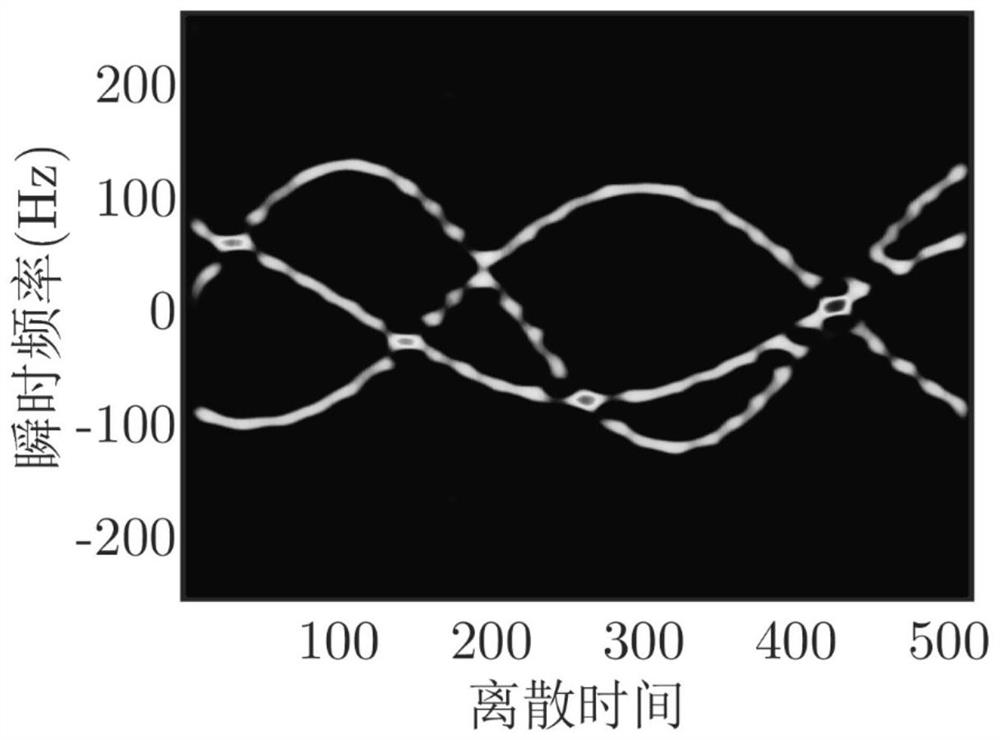

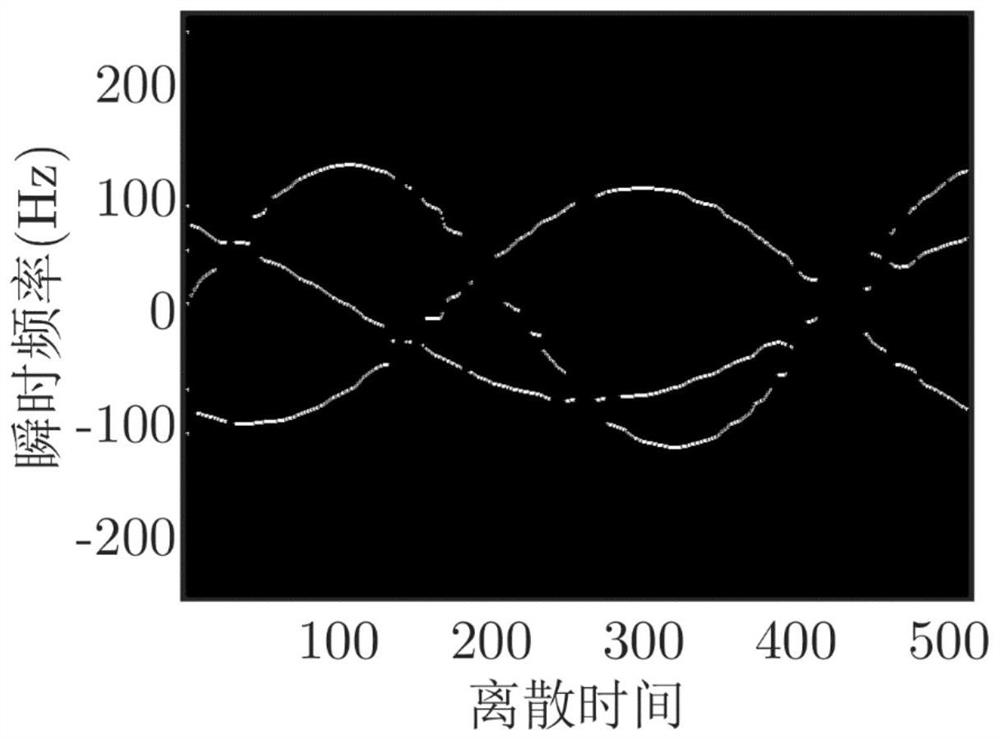

Micro-motion signal separation method based on radar missing sampling

ActiveCN113219416ASolve decompositionPromote decompositionRadio wave reradiation/reflectionFrequency spectrumAlgorithm

The invention relates to a micro-motion signal separation method based on radar missing sampling, which comprises the following steps: firstly, establishing a narrow-band radar micro-motion signal echo model of missing sampling, secondly, converting the signal model into a sparse regularization model, and solving through a soft threshold iterative algorithm (ISTA) to obtain reconstructed time-frequency distribution; then extracting a maximum value point of the frequency spectrum during reconstruction, defining a maximum value point association problem as an assignment problem, solving the problem through Kalman filtering and a Hungary algorithm to obtain an instantaneous frequency trajectory, and finally, separating a micro-motion echo signal of each scattering point on a trajectory target by adopting an intrinsic linear frequency modulation component decomposition (ICCD) algorithm. Compared with a traditional time-frequency filtering group decomposition method, the method can better decompose signal components which are crossed and overlapped in a time-frequency domain, and is more suitable for micro-motion signal decomposition under the condition of radar sampling defect.

Owner:AIR FORCE UNIV PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com