Patents

Literature

54 results about "Radio clock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

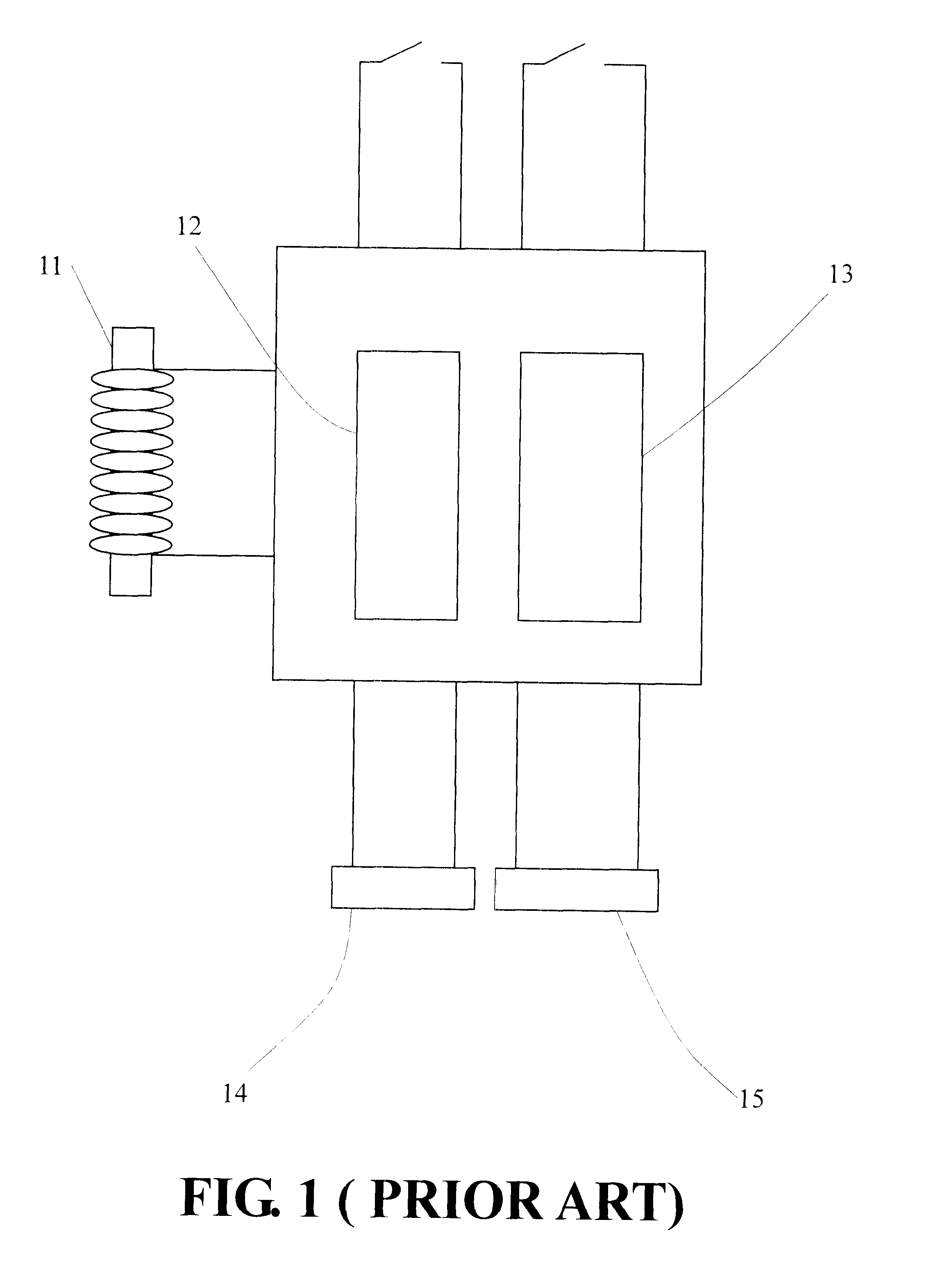

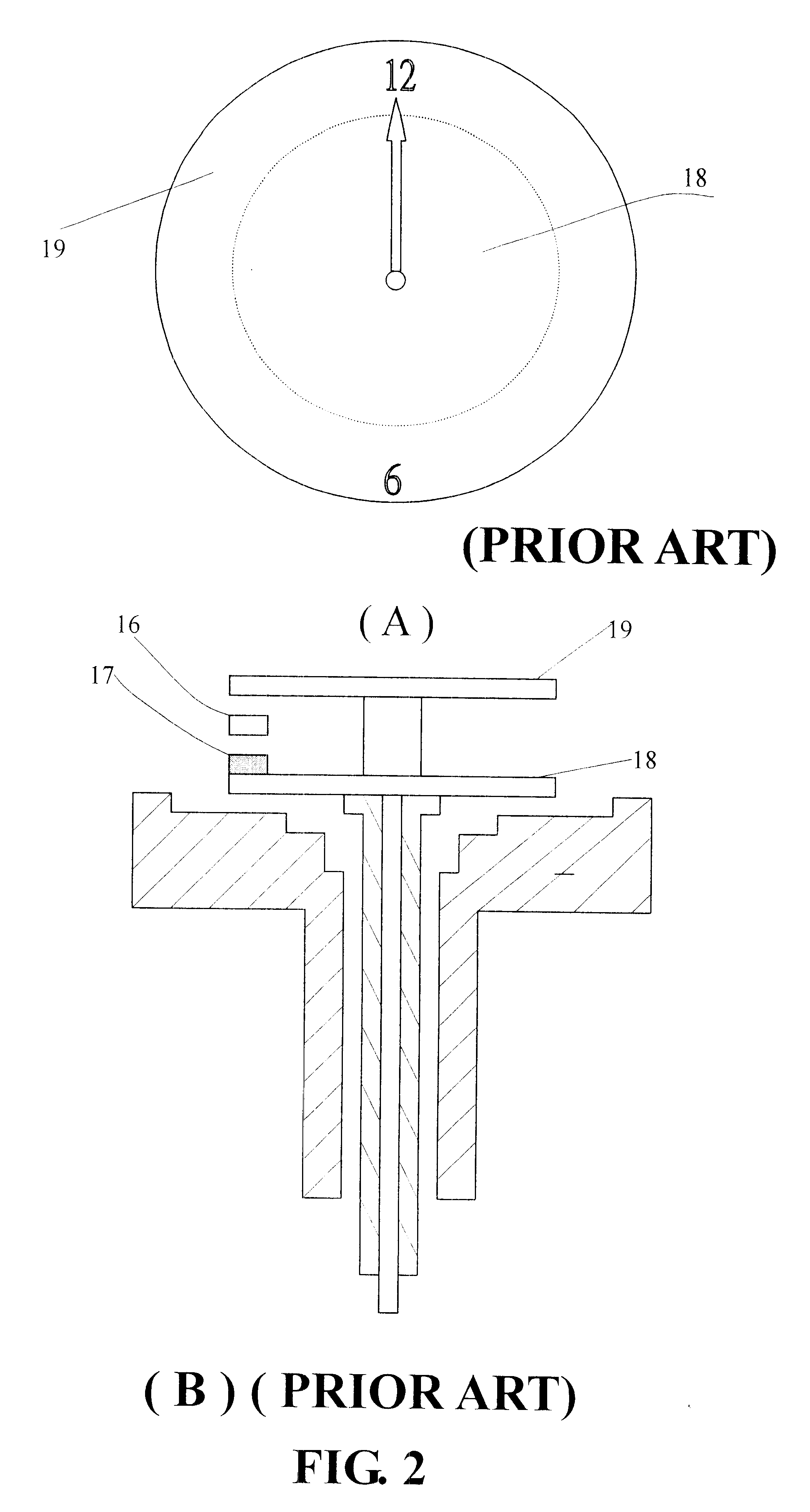

A radio clock or radio-controlled clock (RCC) is a clock or watch that is automatically synchronized to a time code transmitted by a radio transmitter connected to a time standard such as an atomic clock. (Alarm clocks with broadcast radio receivers, a totally different concept, are often called "clock radios".) Such a clock may be synchronized to the time sent by a single transmitter, such as many national or regional time transmitters, or may use the multiple transmitters used by satellite navigation systems such as GPS. Such systems may be used to automatically set clocks or for any purpose where accurate time is needed. RC clocks may include any feature available for a clock, such as alarm function, display of ambient temperature and humidity, broadcast radio reception, etc.

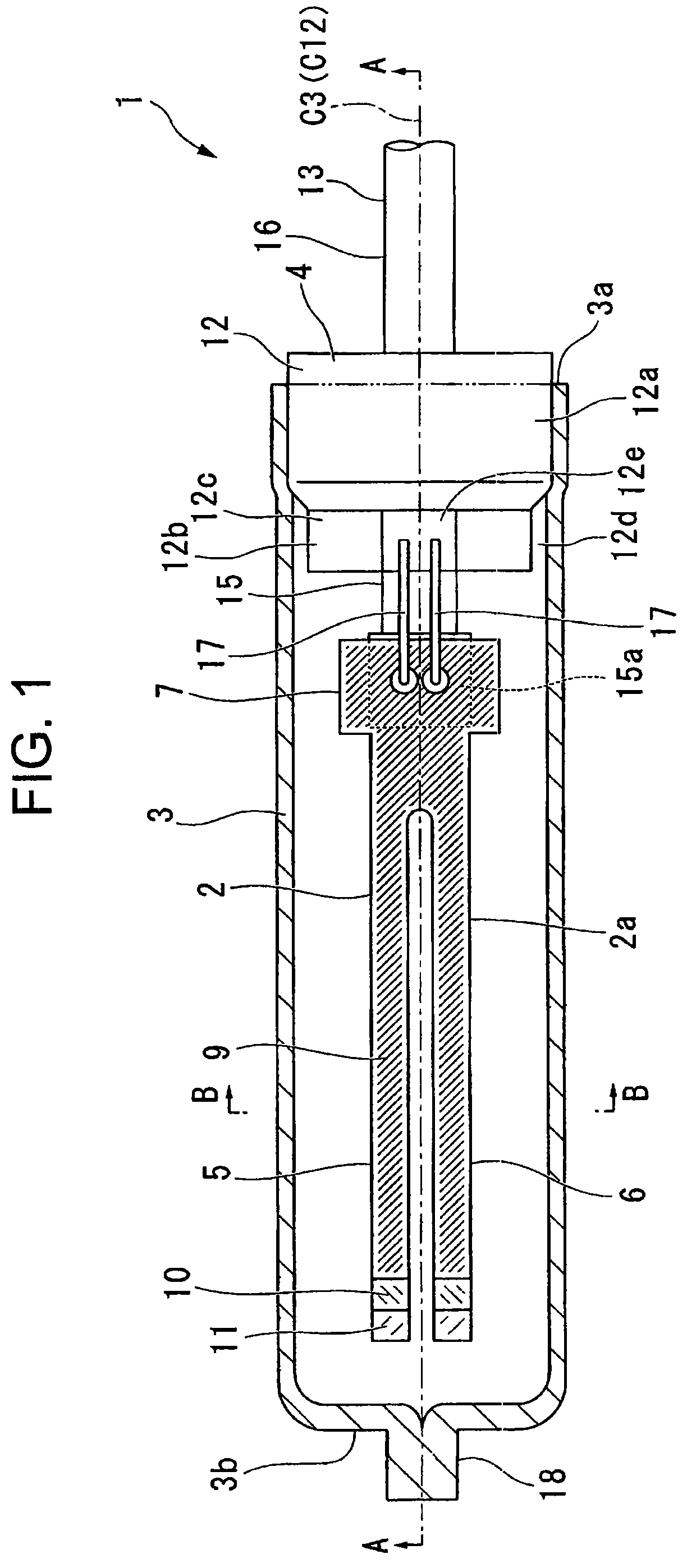

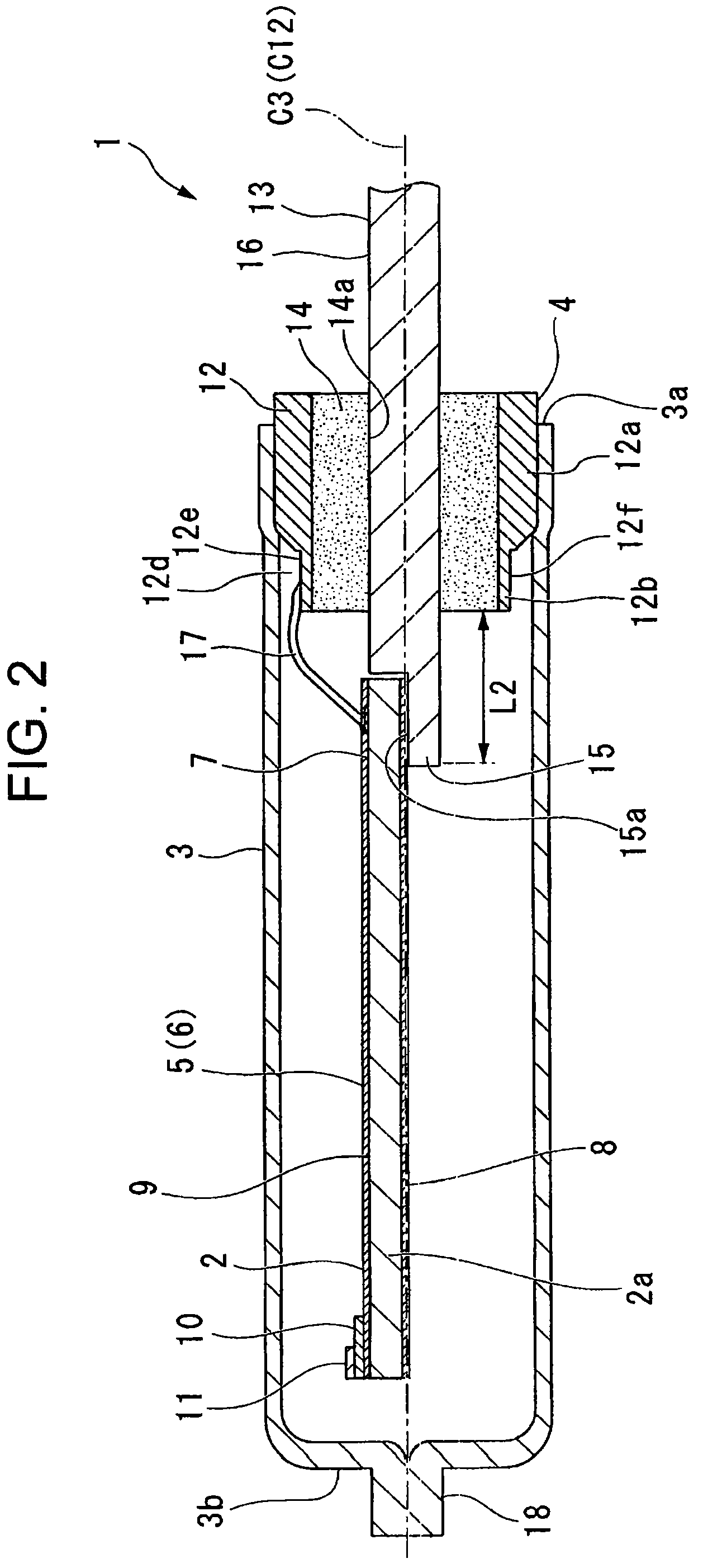

Piezoelectric vibrator, manufacturing method thereof, oscillator, electronic equipment, radio clock

InactiveUS7294951B2Minimize fluctuationReduce manufacturing costPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesRadio clockAnodic bonding

Owner:SII CRYSTAL TECH

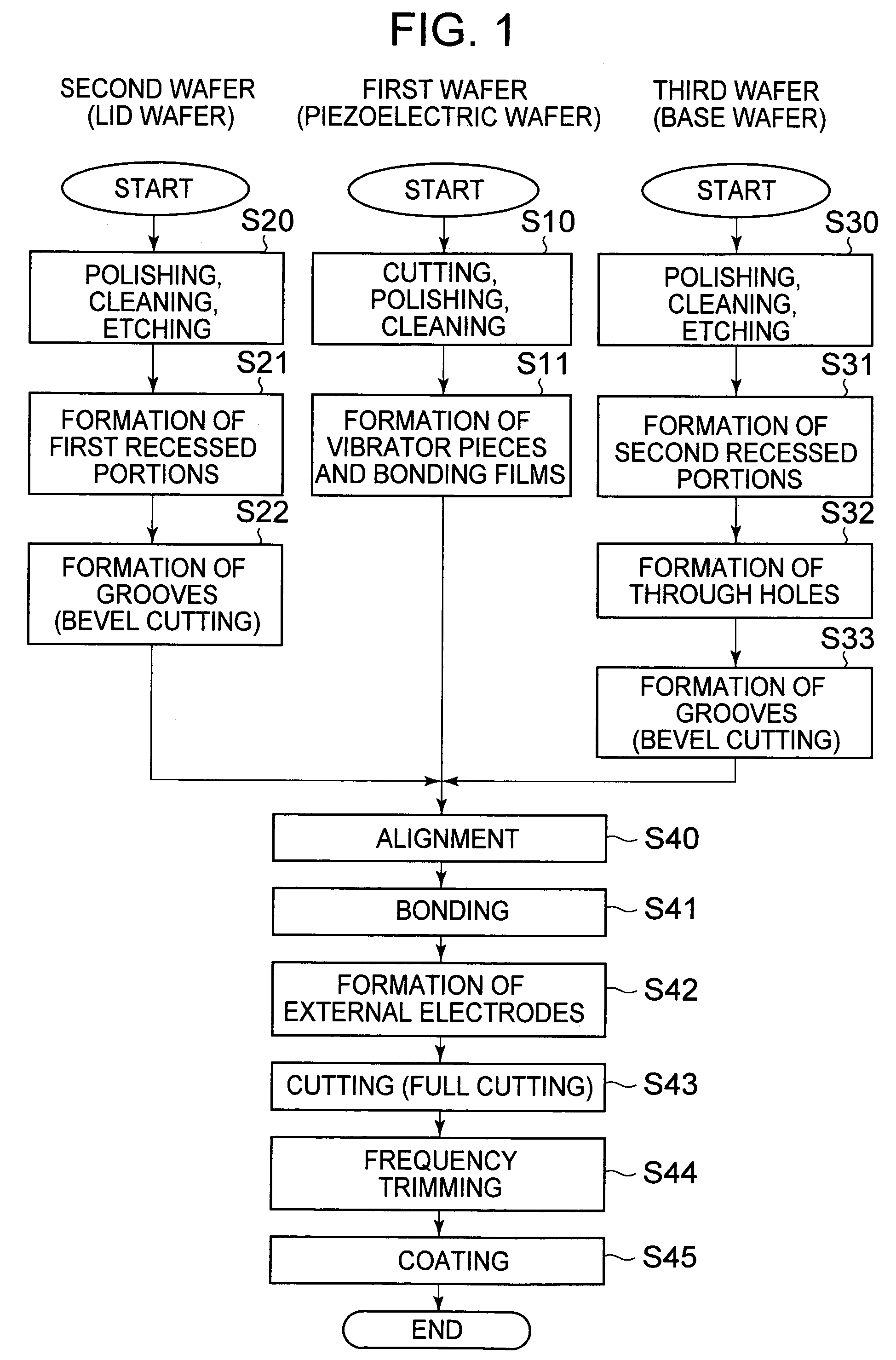

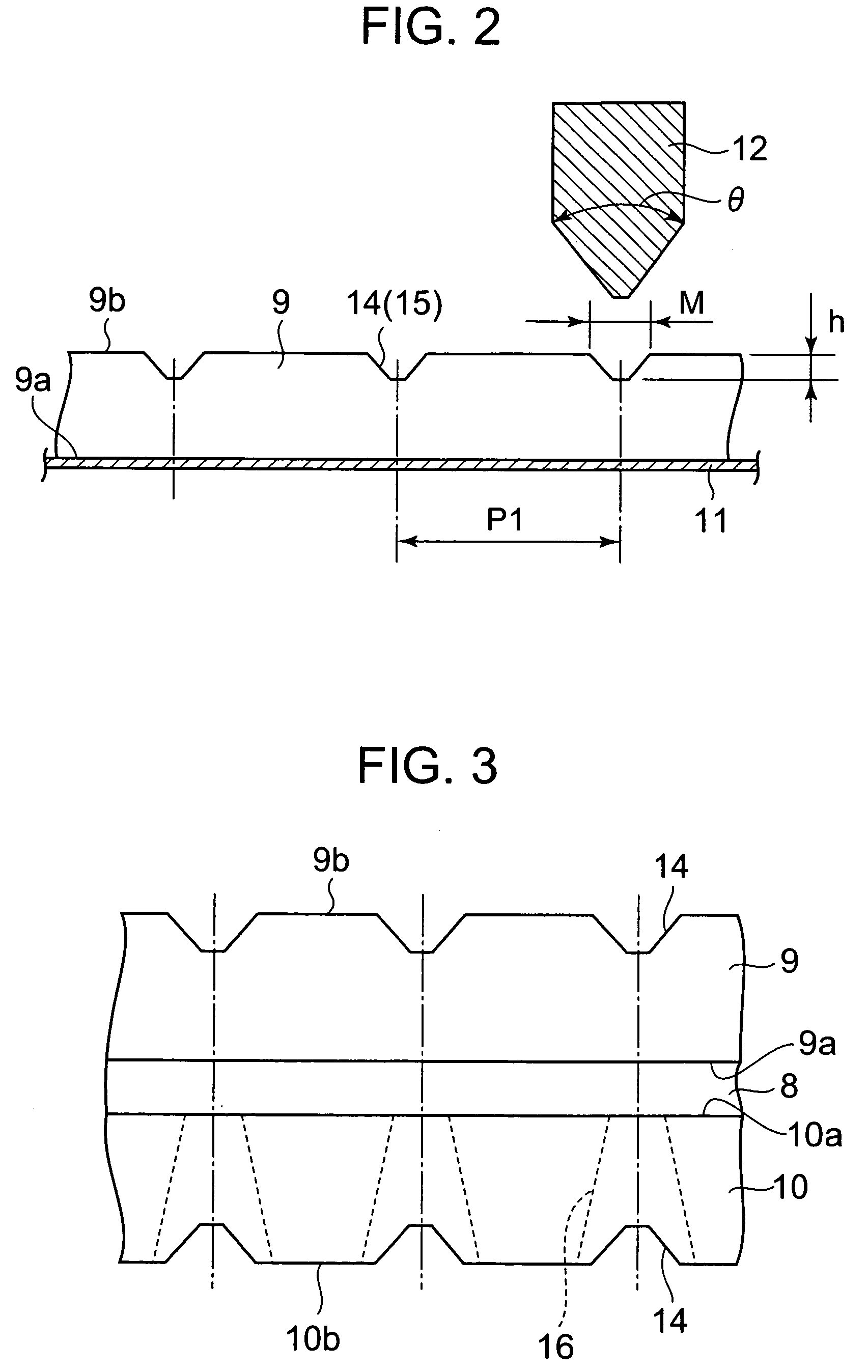

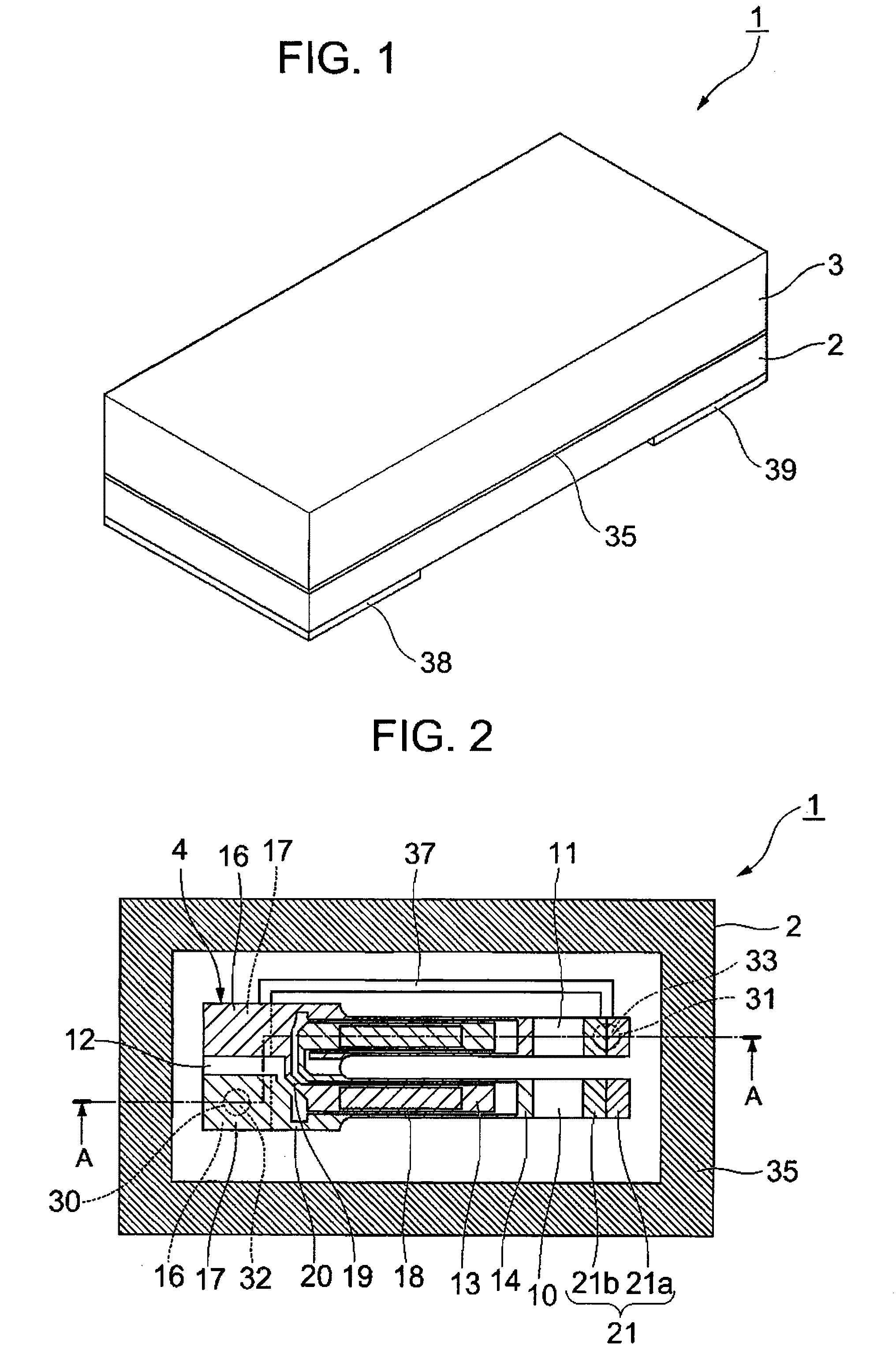

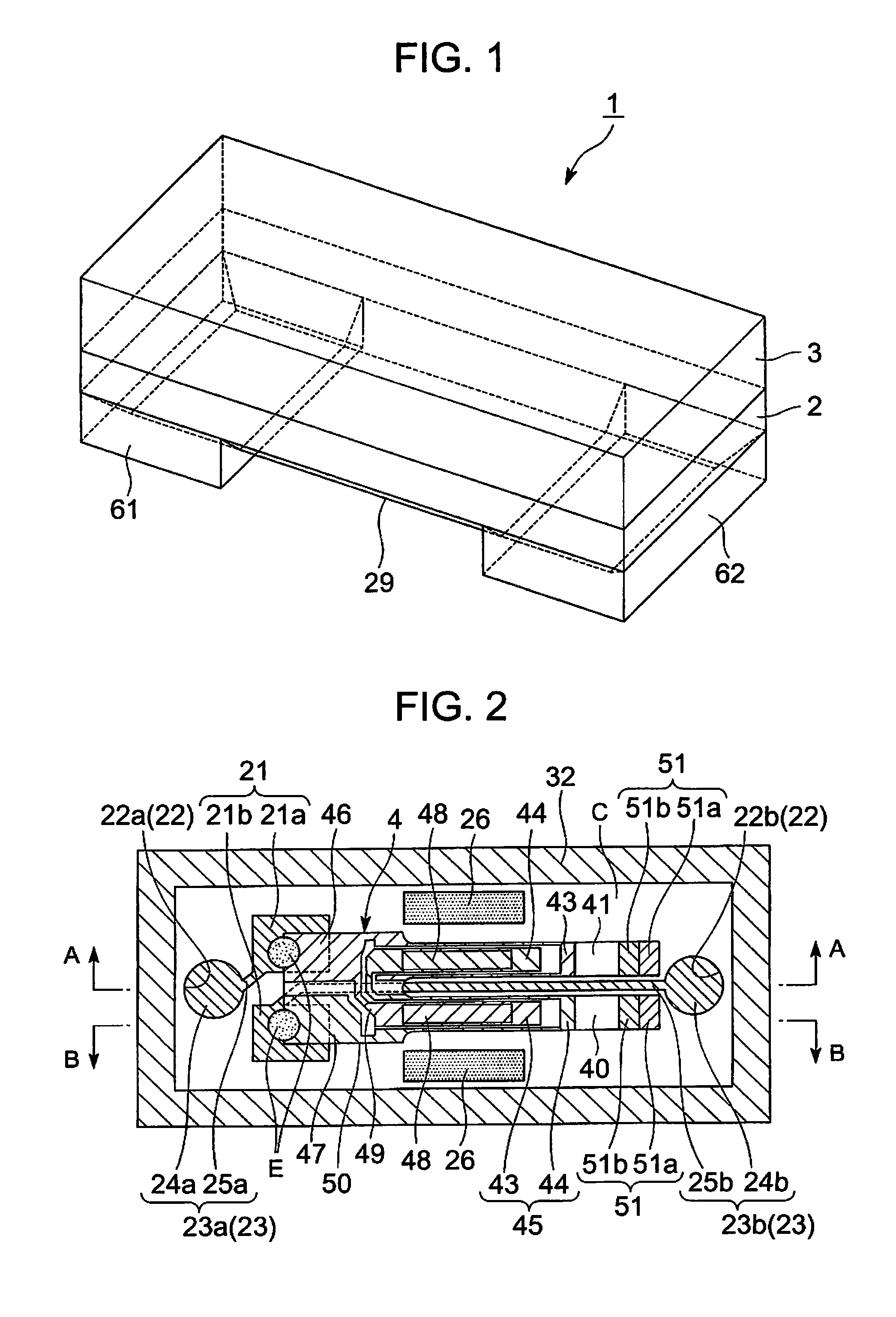

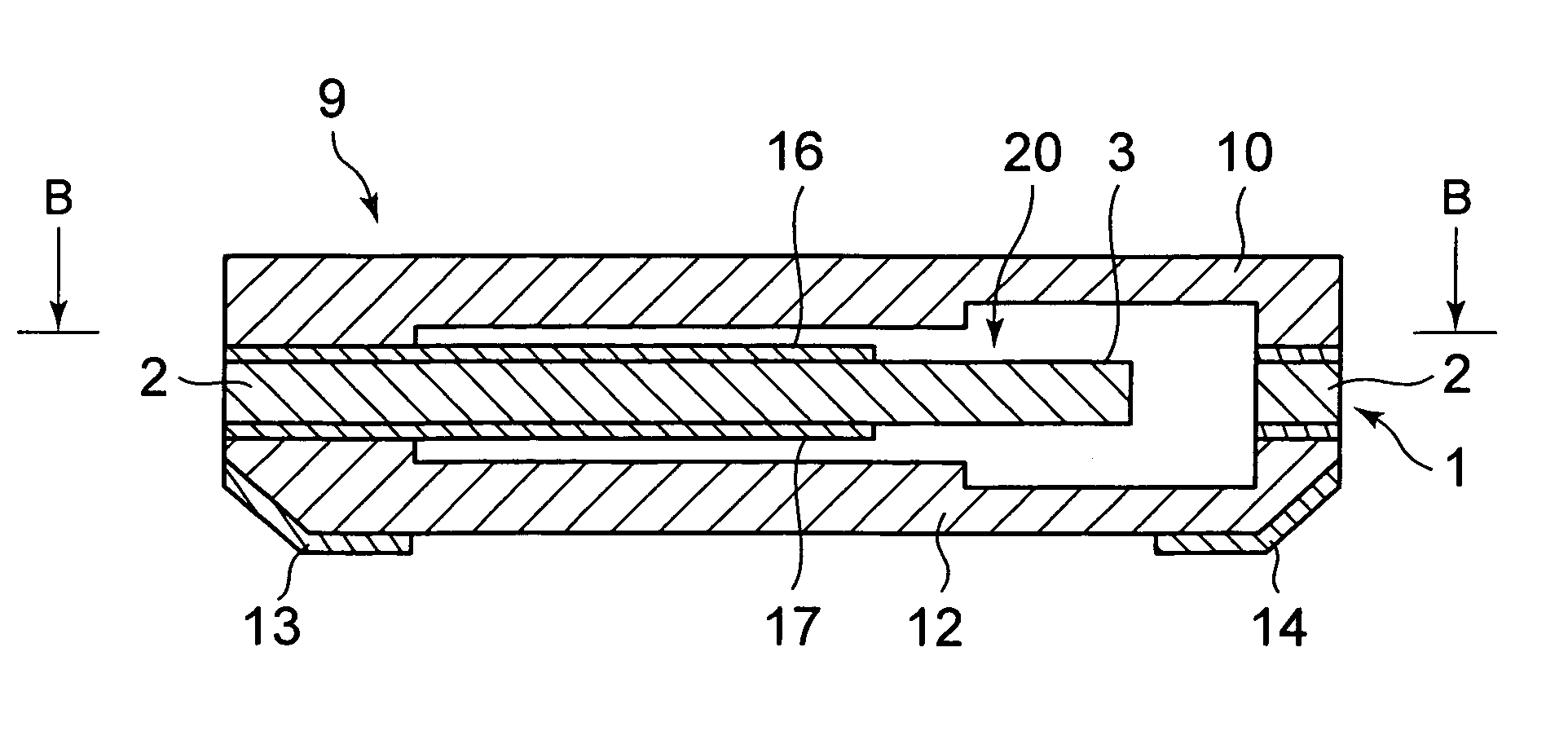

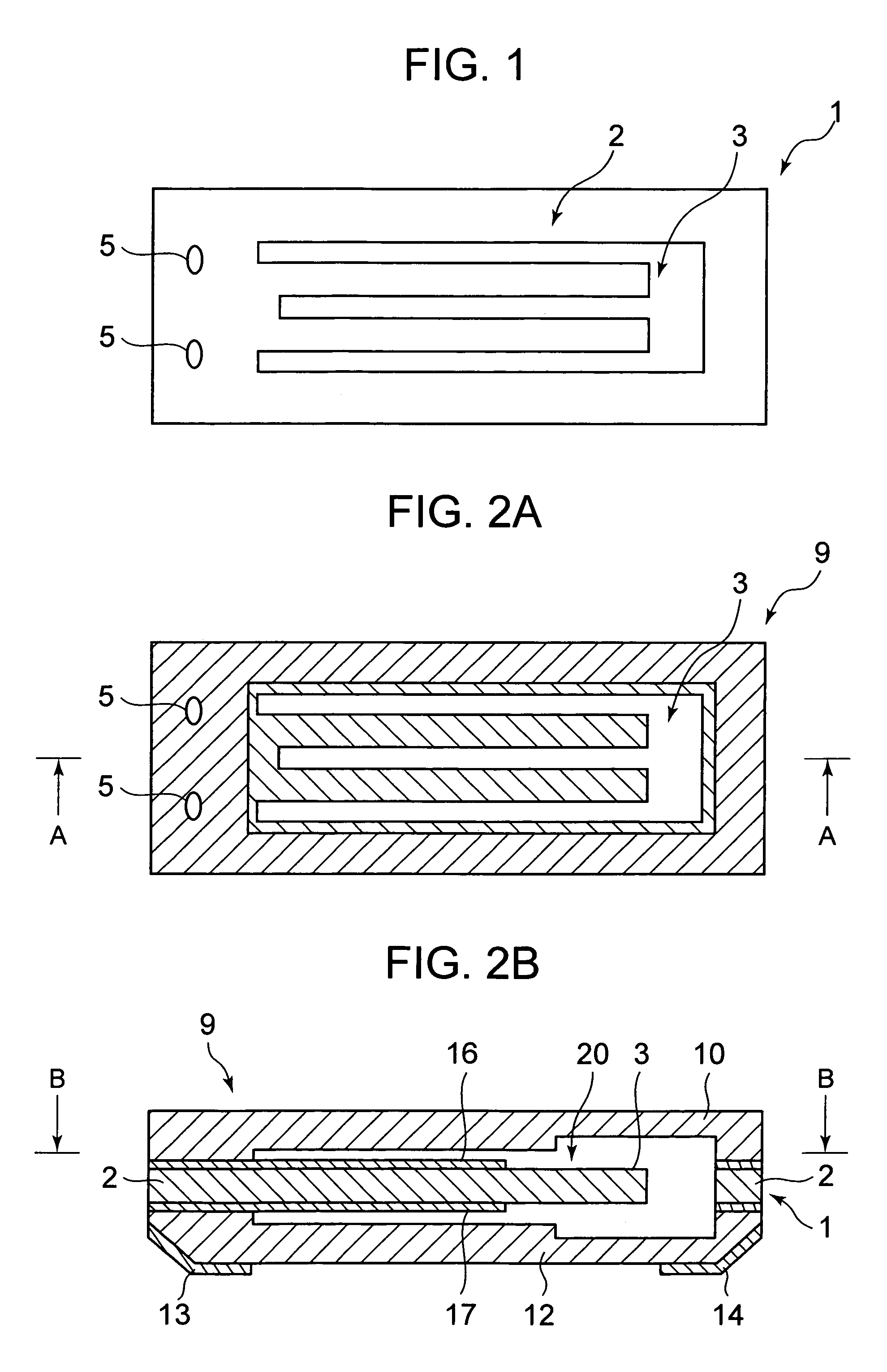

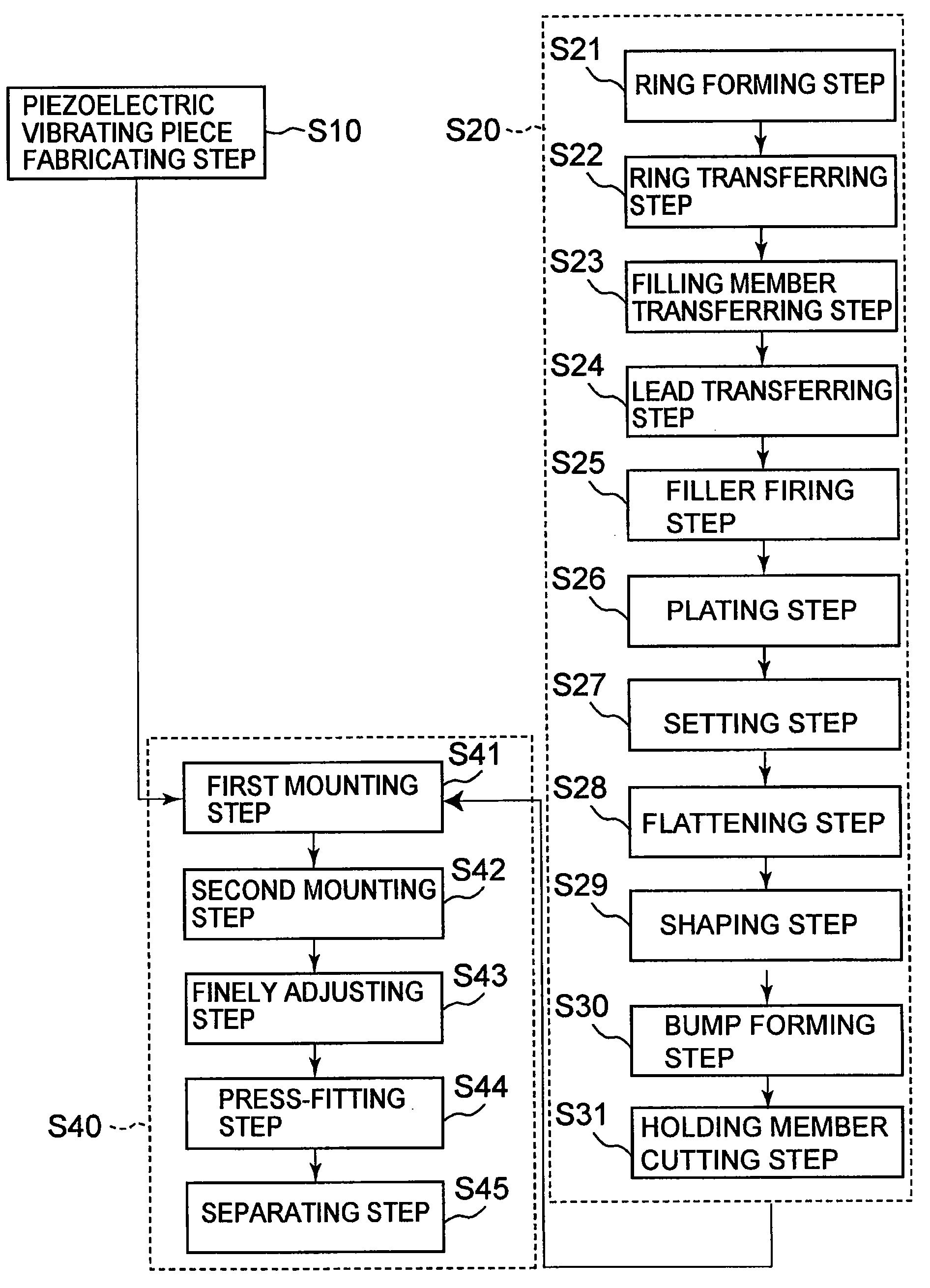

Method of manufacturing piezoelectric vibrator, piezoelectric vibrator, oscillator, electronic device, and radio clock

InactiveUS20100308697A1Thinner and more compactEfficient preparationPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesRadio clockEngineering

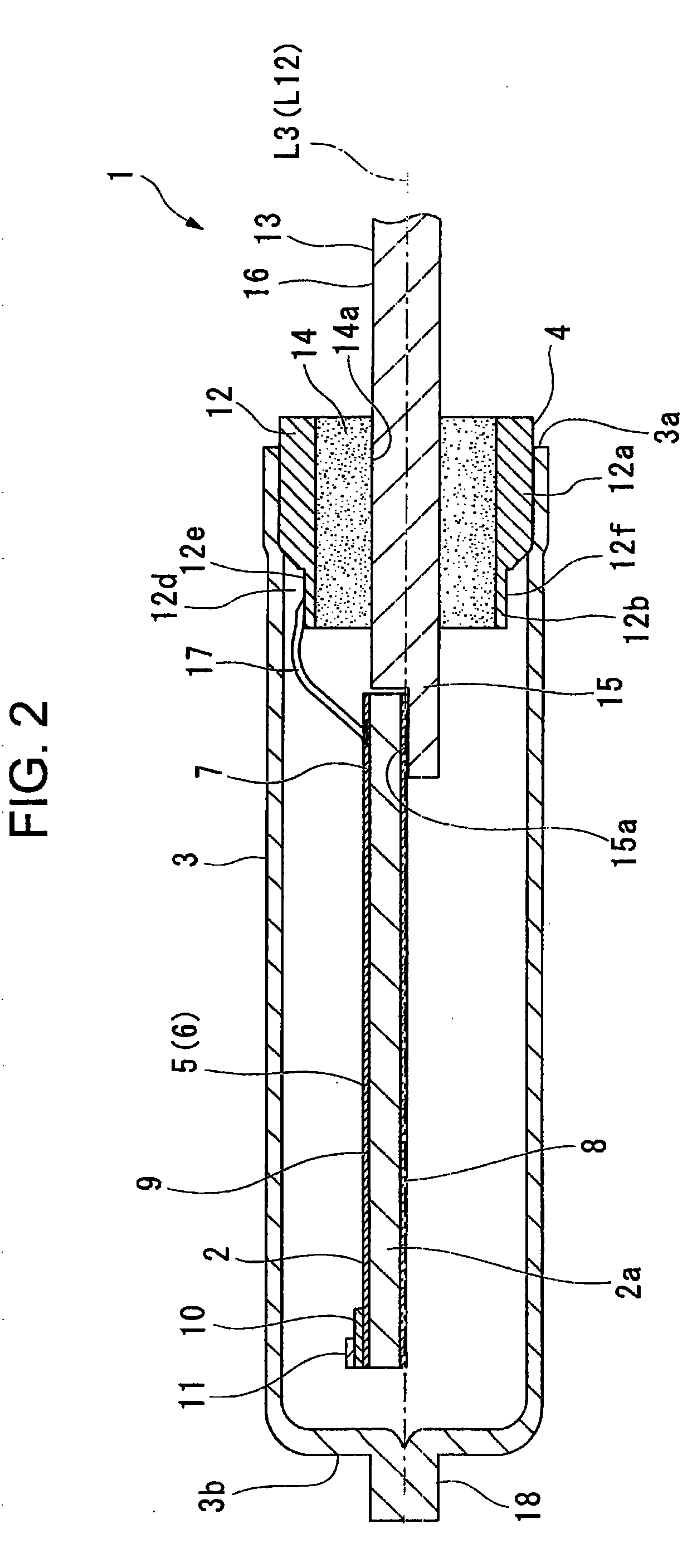

A piezoelectric vibrator includes a base substrate, a lid substrate, a piezoelectric vibrating reed, a pair of external electrodes, a pair of through electrodes, and routing electrodes. The base substrate is made of a glass material and a bonding film is formed on the upper surface of the base substrate. The lid substrate is made of a glass material, includes a recess for a cavity, and is bonded to the base substrate with the bonding film interposed therebetween so that the recess faces the base substrate. The piezoelectric vibrating reed is bonded to the upper surface of the base substrate so as to be received in a cavity that is formed between the base substrate and the lid substrate by the recess. The pair of external electrodes is formed on the lower surface of the base substrate. The pair of through electrodes is formed so as to pass through the base substrate, maintains airtightness in the cavity, and is electrically connected to the pair of external electrodes, respectively. The routing electrodes are formed on the upper surface of the base substrate, and are electrically connected to the piezoelectric vibrating reed bonded to the pair of through electrodes.

Owner:SII CRYSTAL TECH

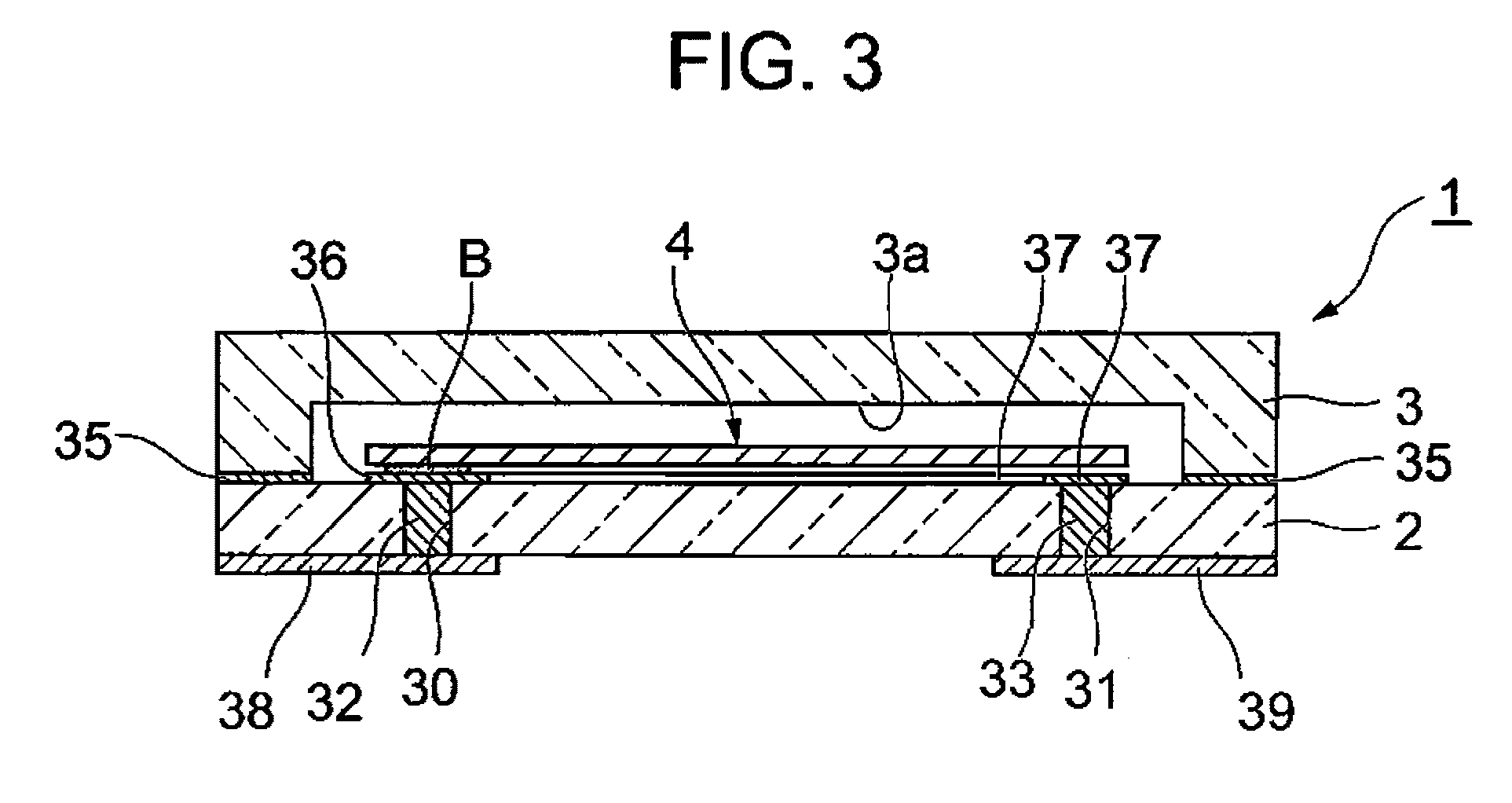

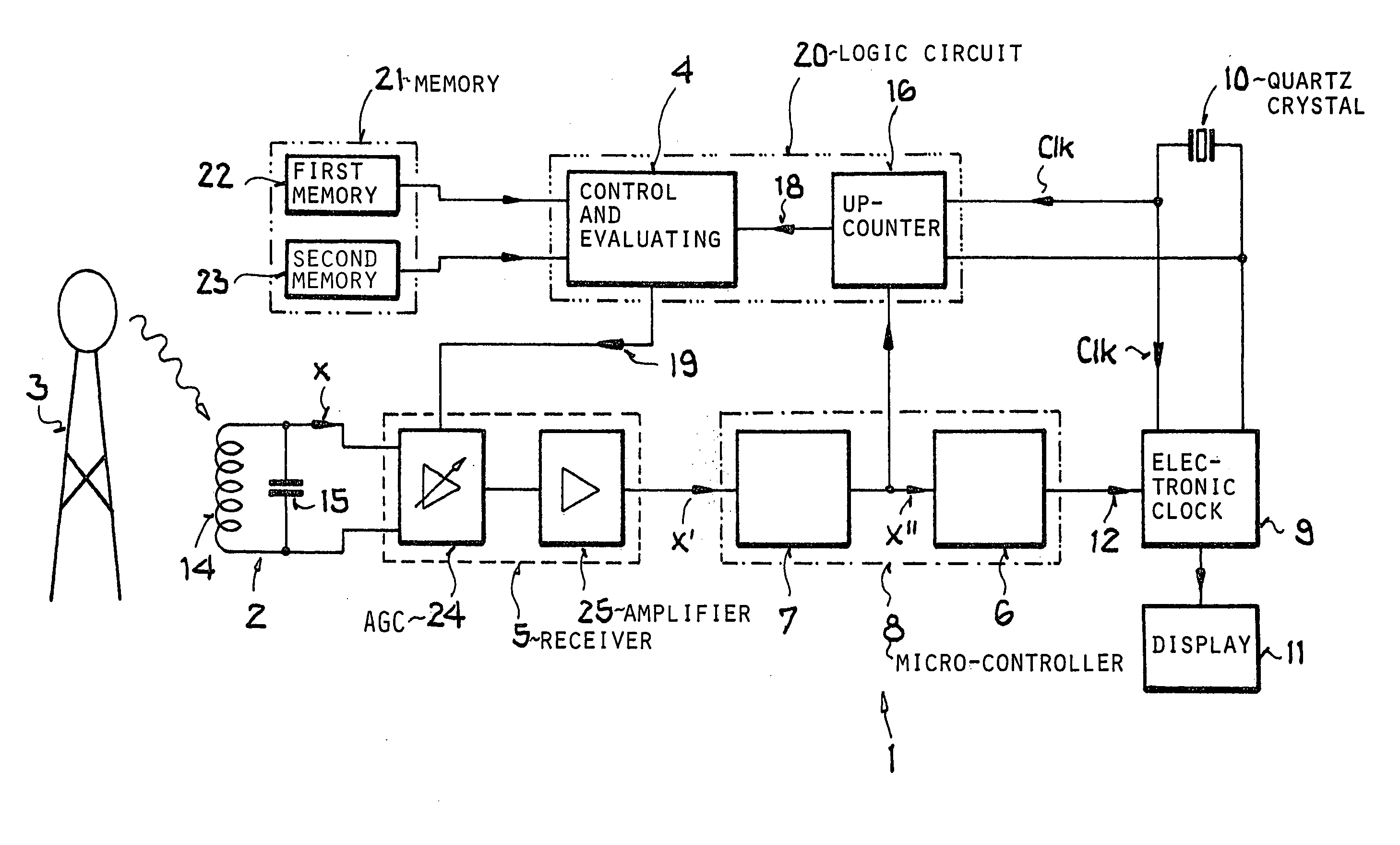

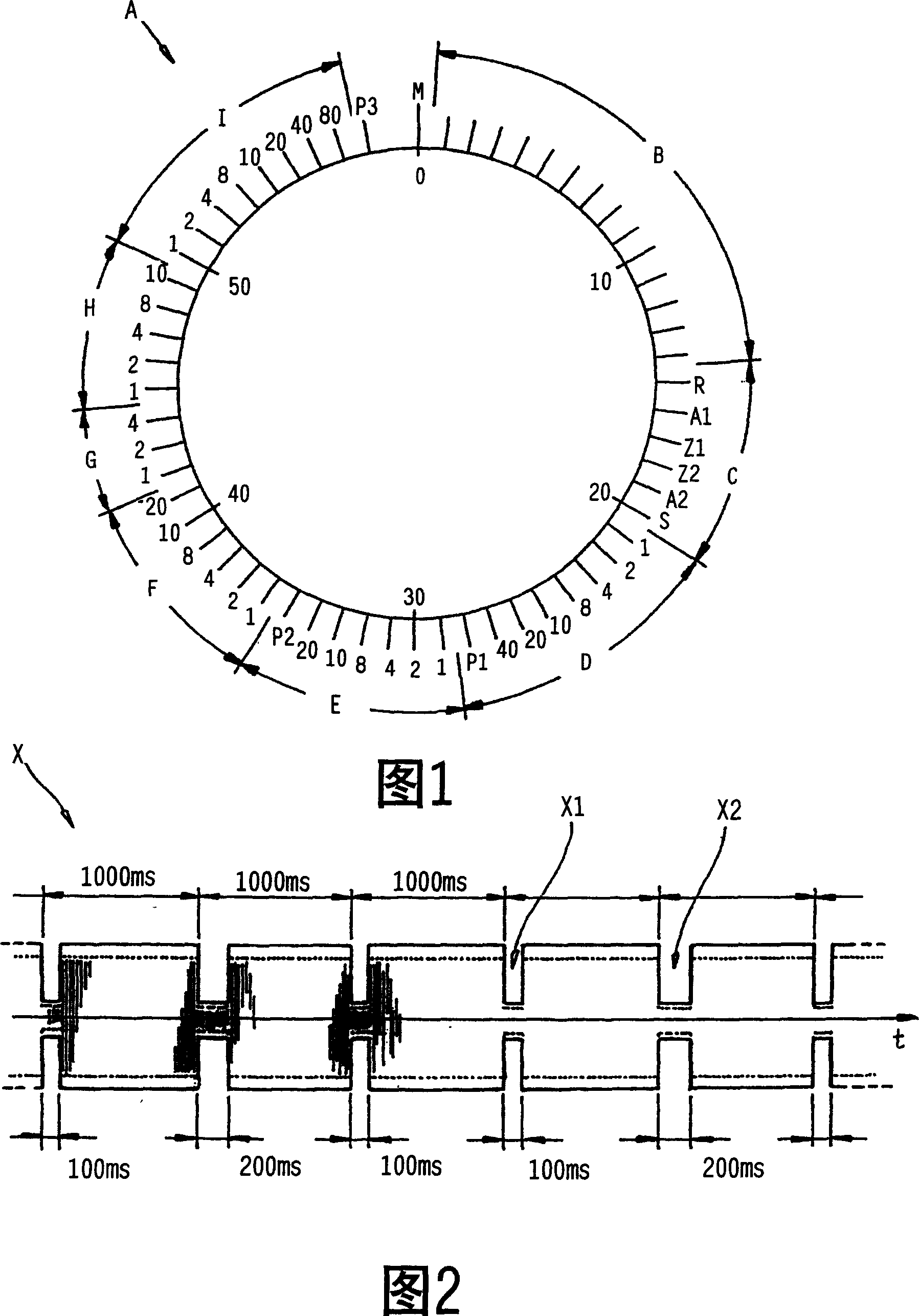

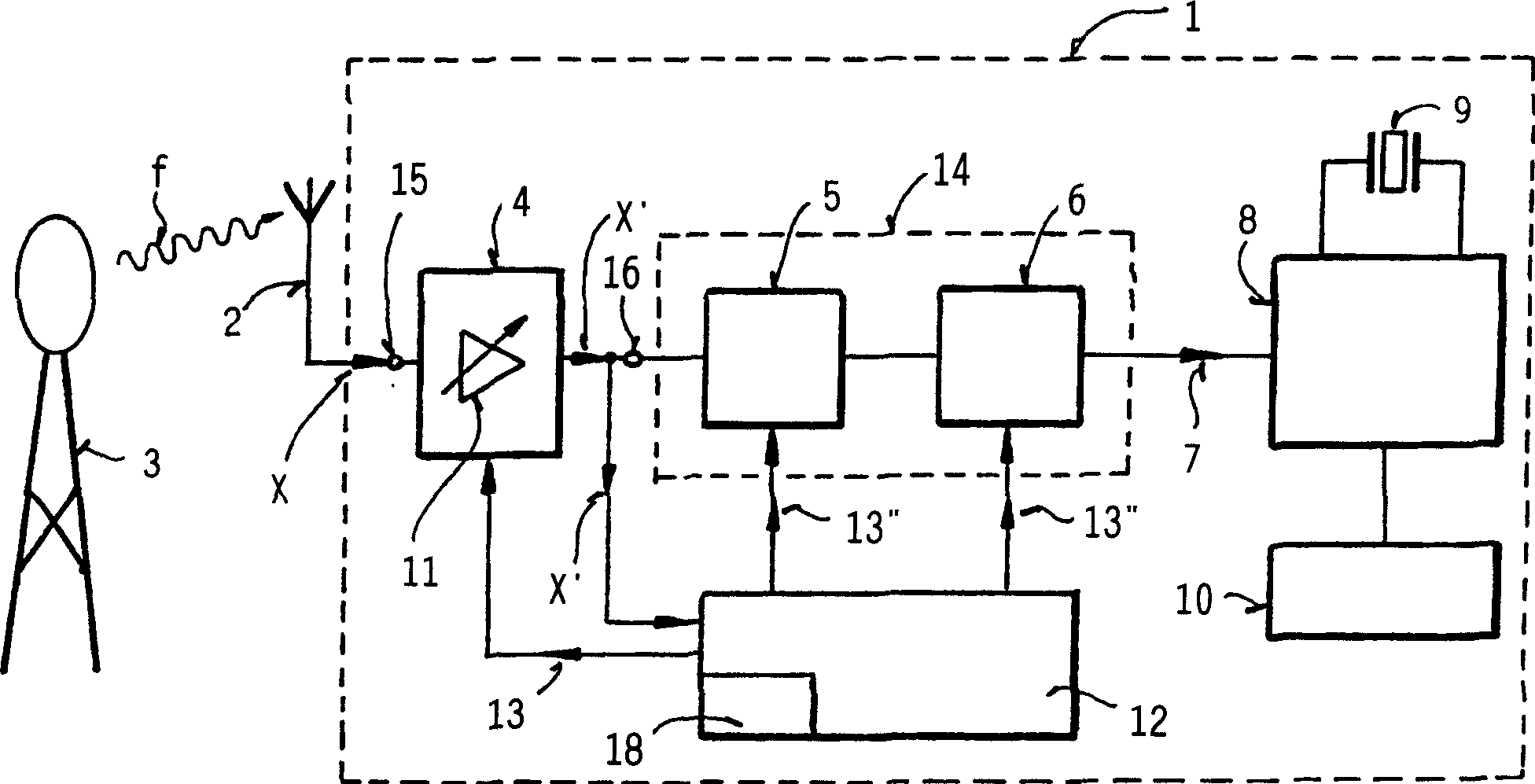

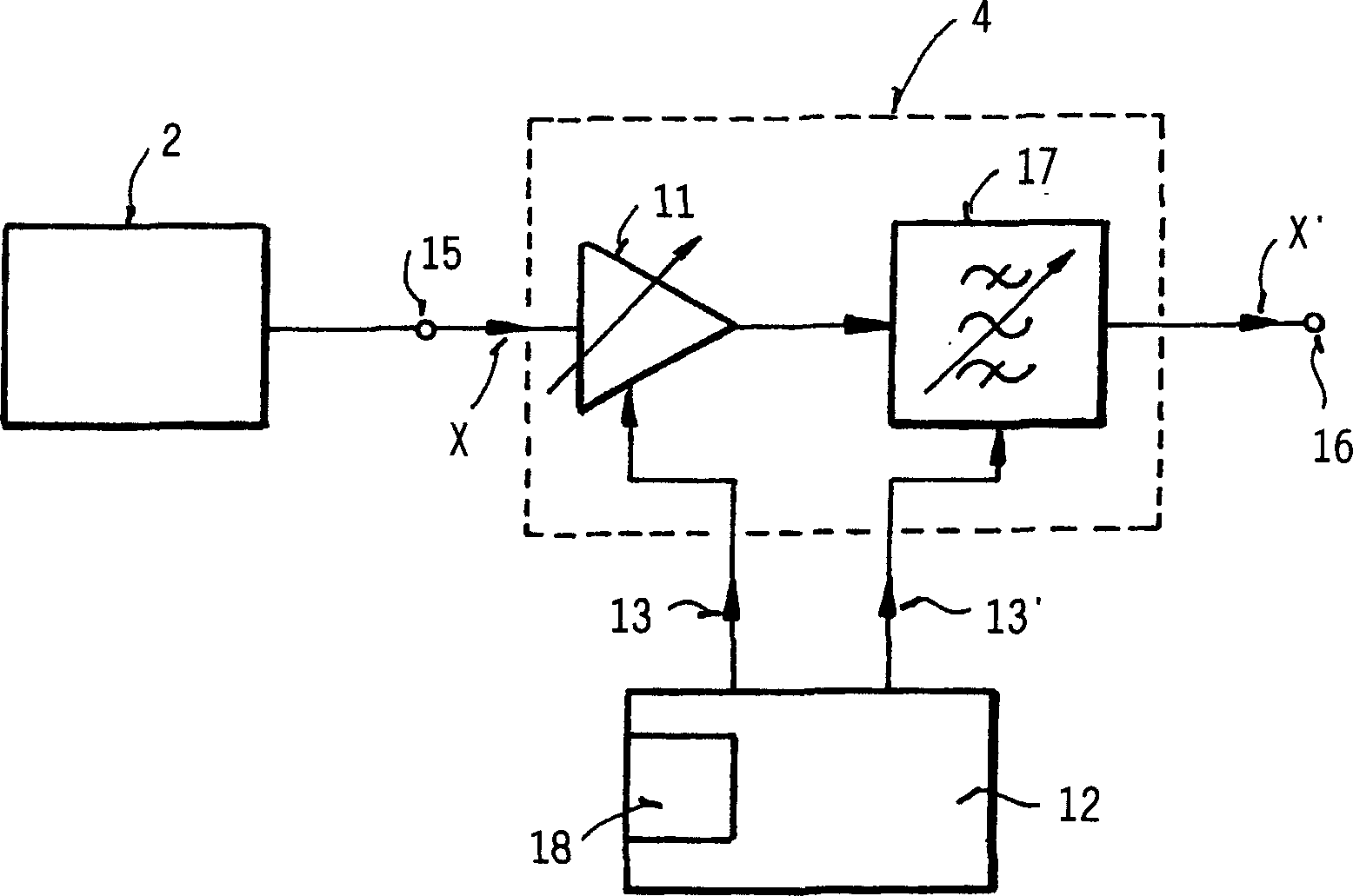

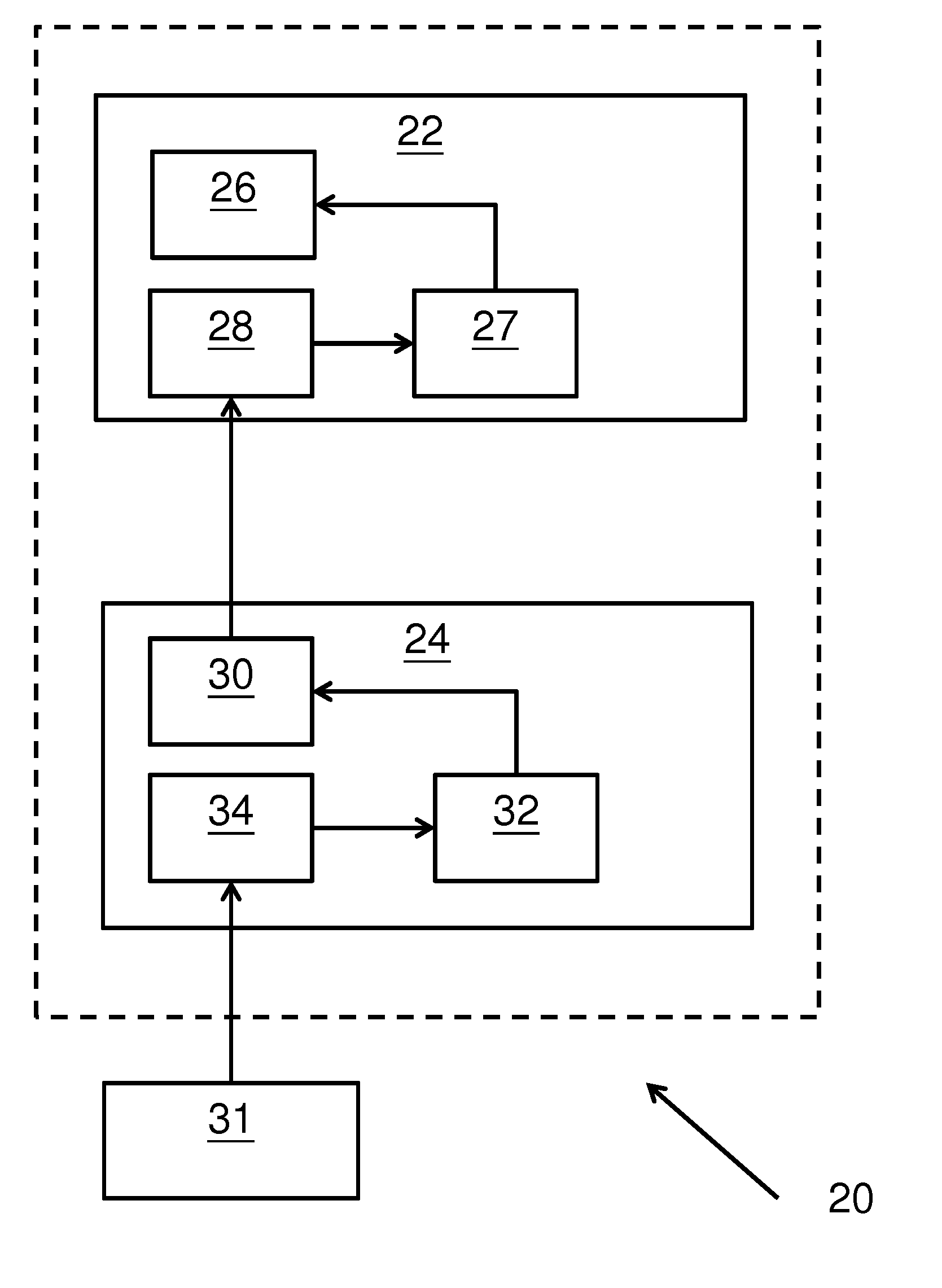

Radio-controlled clock and method for gaining time information

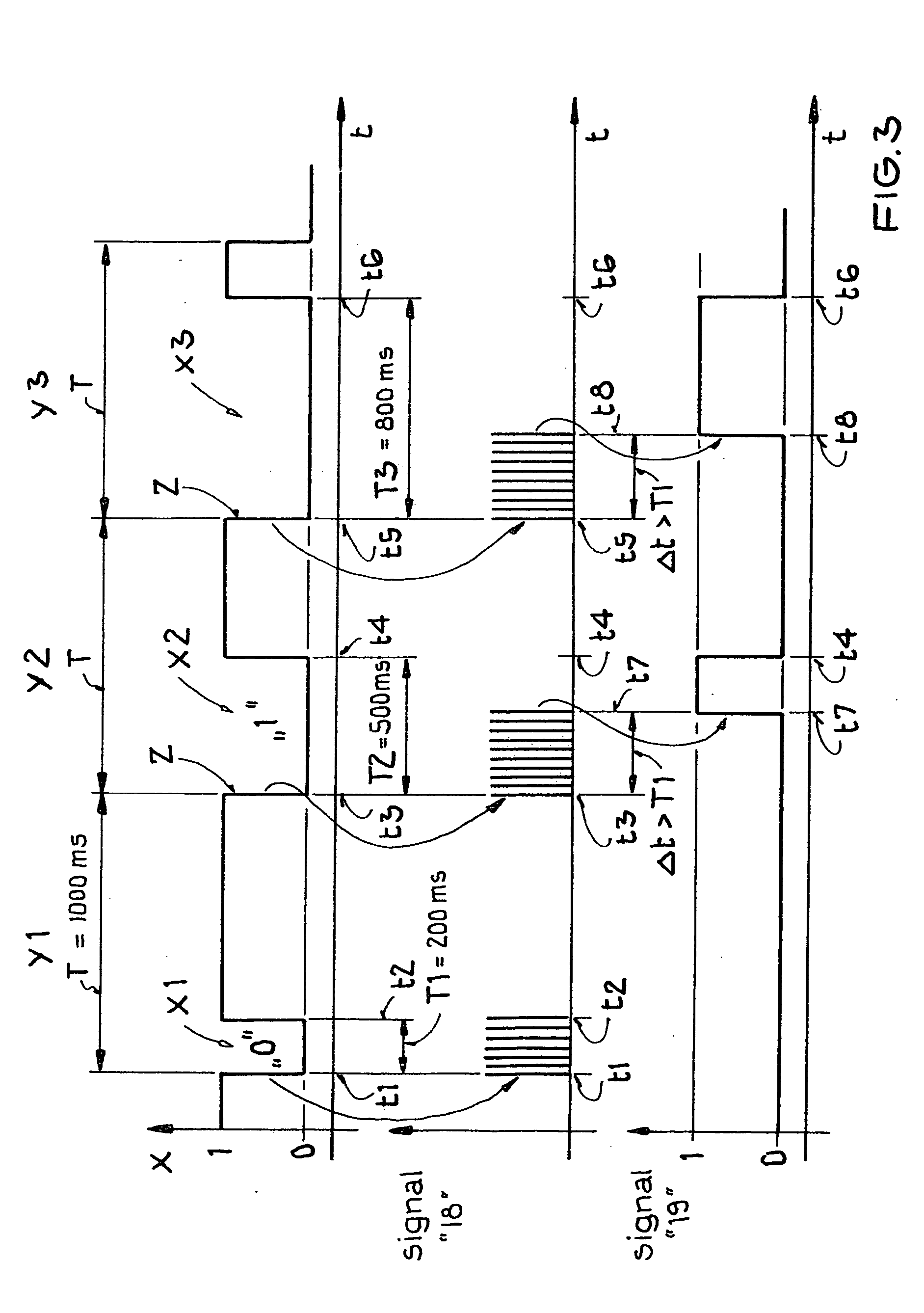

InactiveUS20050202796A1Synchronous motors for clocksSetting time indicationTime informationRadio clock

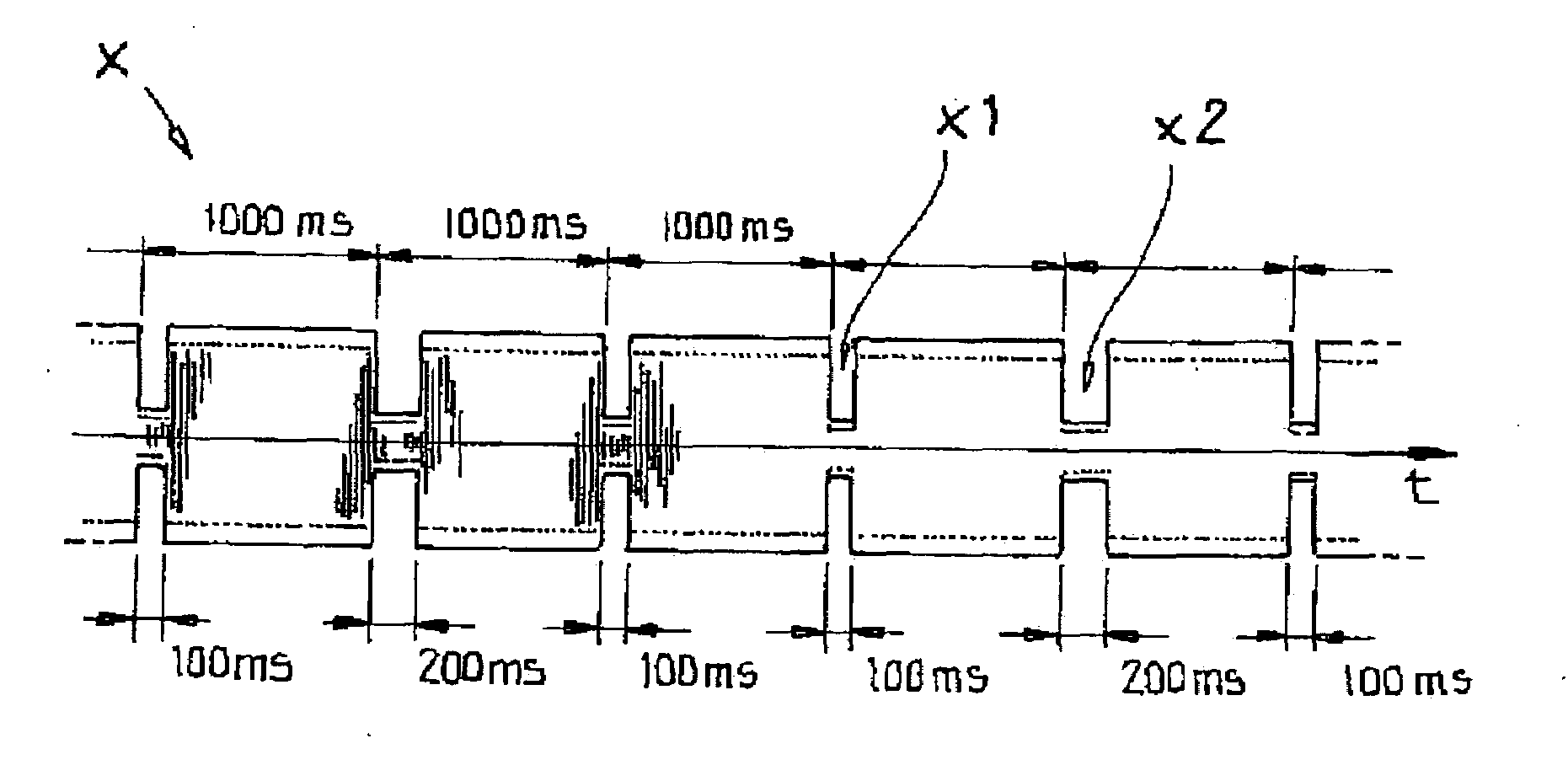

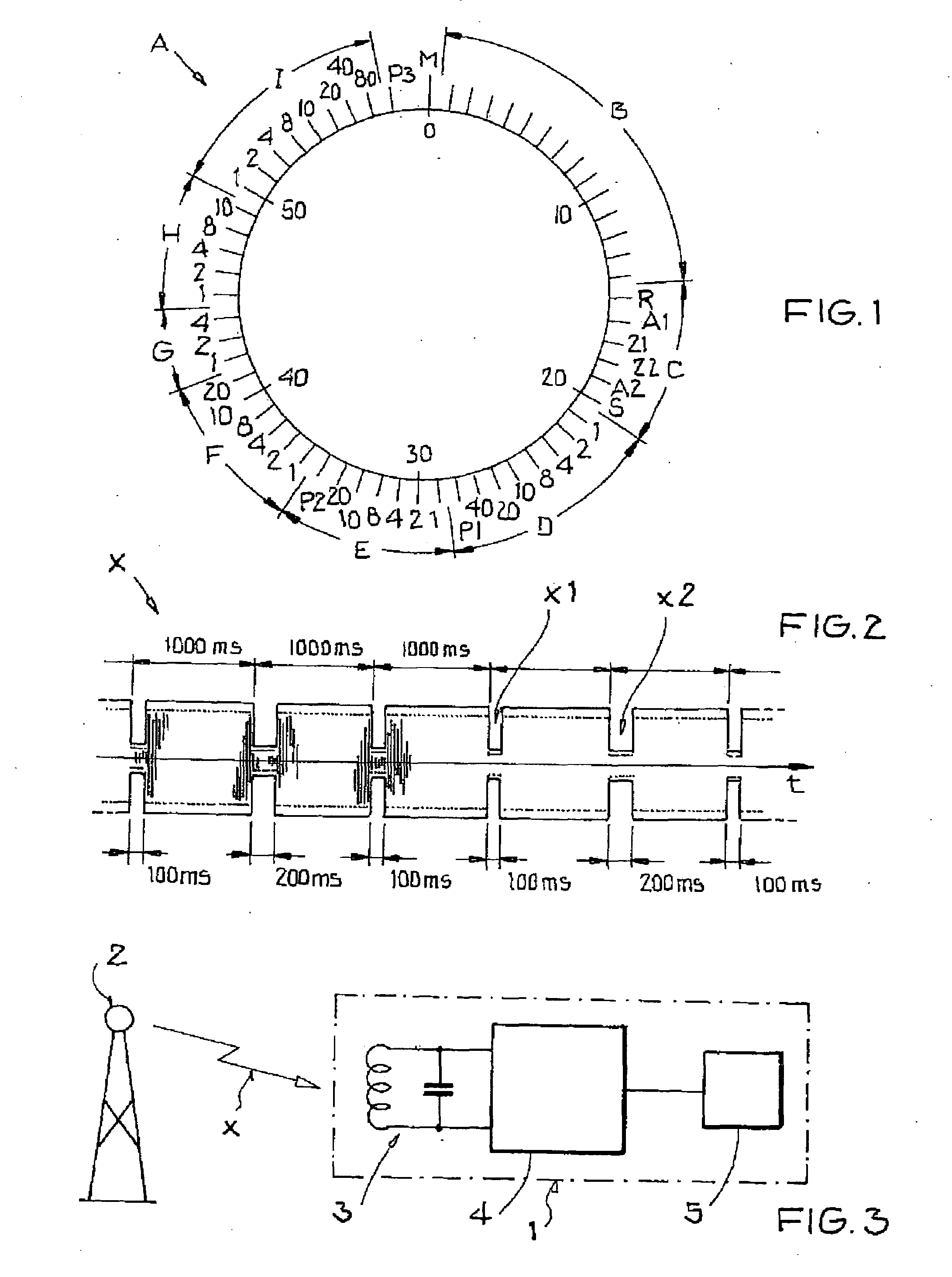

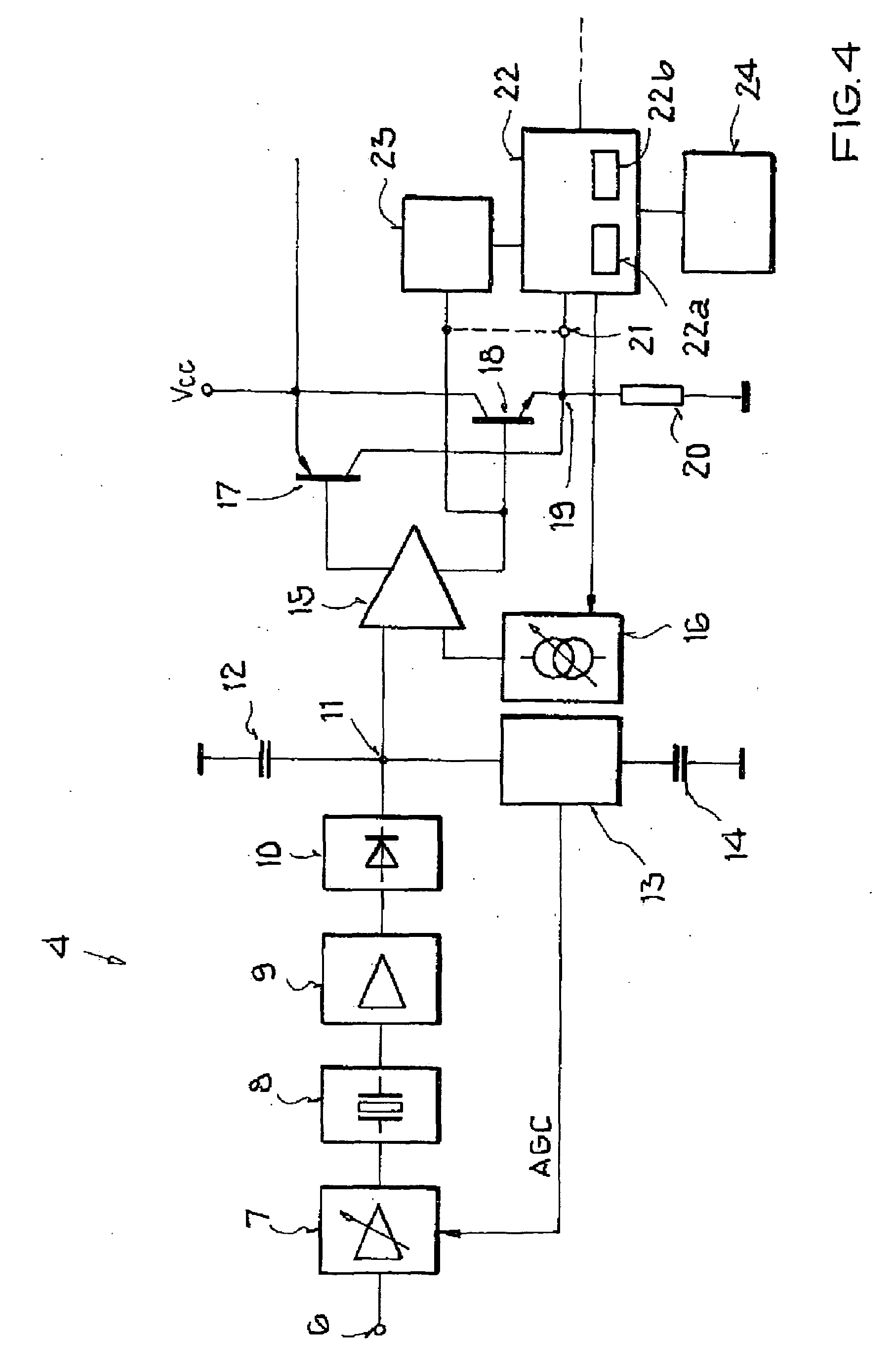

Time signals for controlling a radio clock are transmitted by a transmitter and received by a receiver as amplitude modulated time signals, formed of a multitude of time frames. Each time frame has a constant duration. These time signals are first automatically amplified. A so-called telegram of at least one received time signal is stored in a memory. At least one change of an amplitude of a time signal is determined in advance or predetermined and such amplitude change has a duration that is longer than a given or determined duration (Δt). When a predetermined amplitude change begins the automatic amplification is locked-in. The present circuit arrangement for operating a radio-controlled clock is equipped with components for performing the foregoing operations.

Owner:ATMEL GERMANY +2

Piezoelectric transducer, piezoelectric transducer manufacturing method, oscillator, electronic device, and radio clock

InactiveUS20100301954A1Reduce frequencyIncrease productionPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksTransducerRadio clock

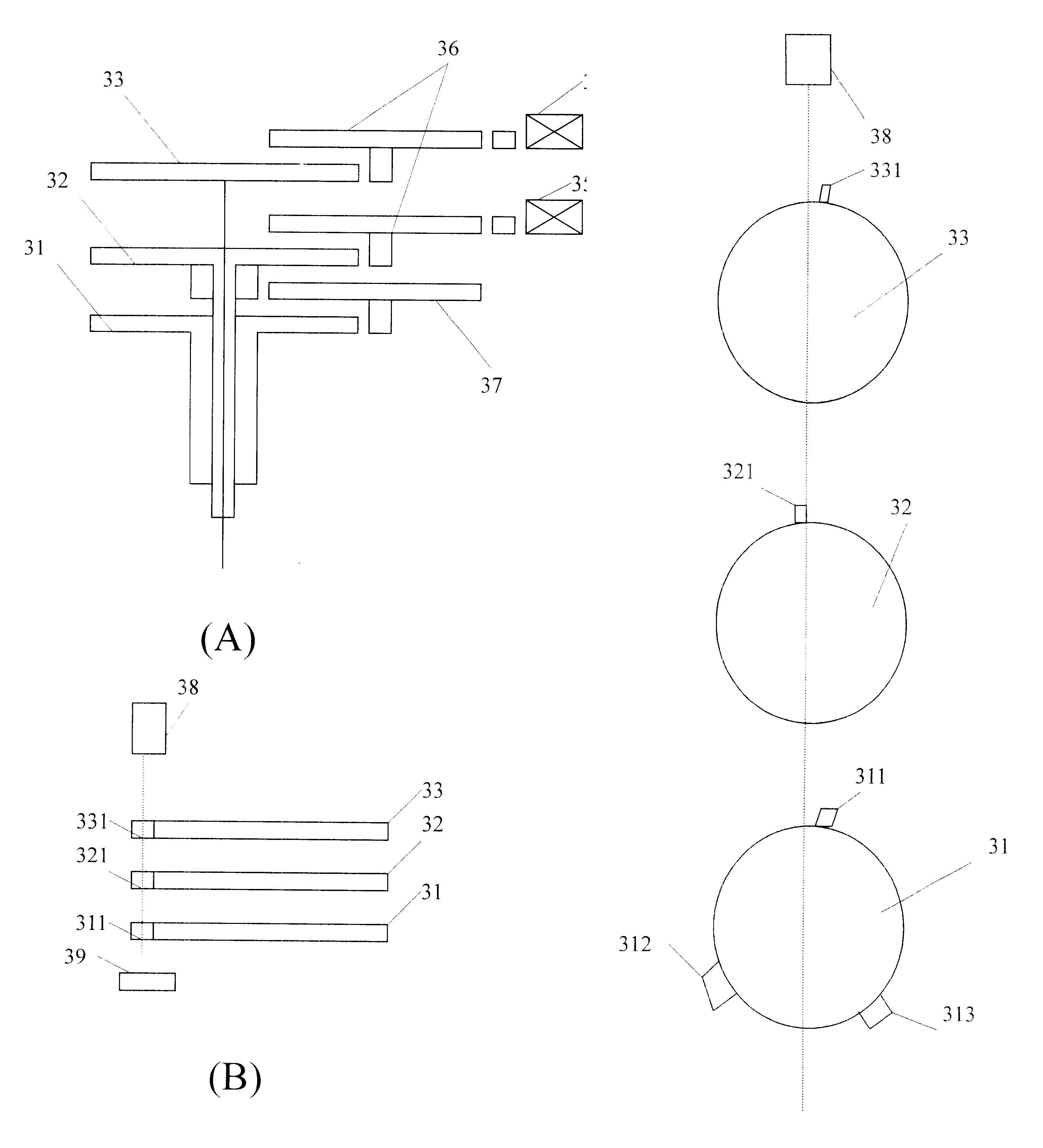

Provided are: a piezoelectric oscillation piece which has a pair of oscillation arms disposed in parallel with each other with base ends of the oscillation arms fixed to a base of the piezoelectric oscillation piece and with weight metal films formed at the tips of the oscillation arms; a base substrate on the upper surface of which the piezoelectric oscillation piece is mounted; a lid substrate joined with the base substrate such that the mounted piezoelectric oscillation piece can be accommodated in a cavity; and a control film disposed in the vicinity of the pair of the oscillation arms as viewed in the plan view and formed at least on either of the substrates in such a manner as to extend from the base end side to the tip side in the longitudinal direction of the oscillation arms for increasing the degree of vacuum inside the cavity by heating. The control film is locally deposited on the side surfaces of the oscillation arms in the vicinity of the control film by heating.

Owner:SII CRYSTAL TECH

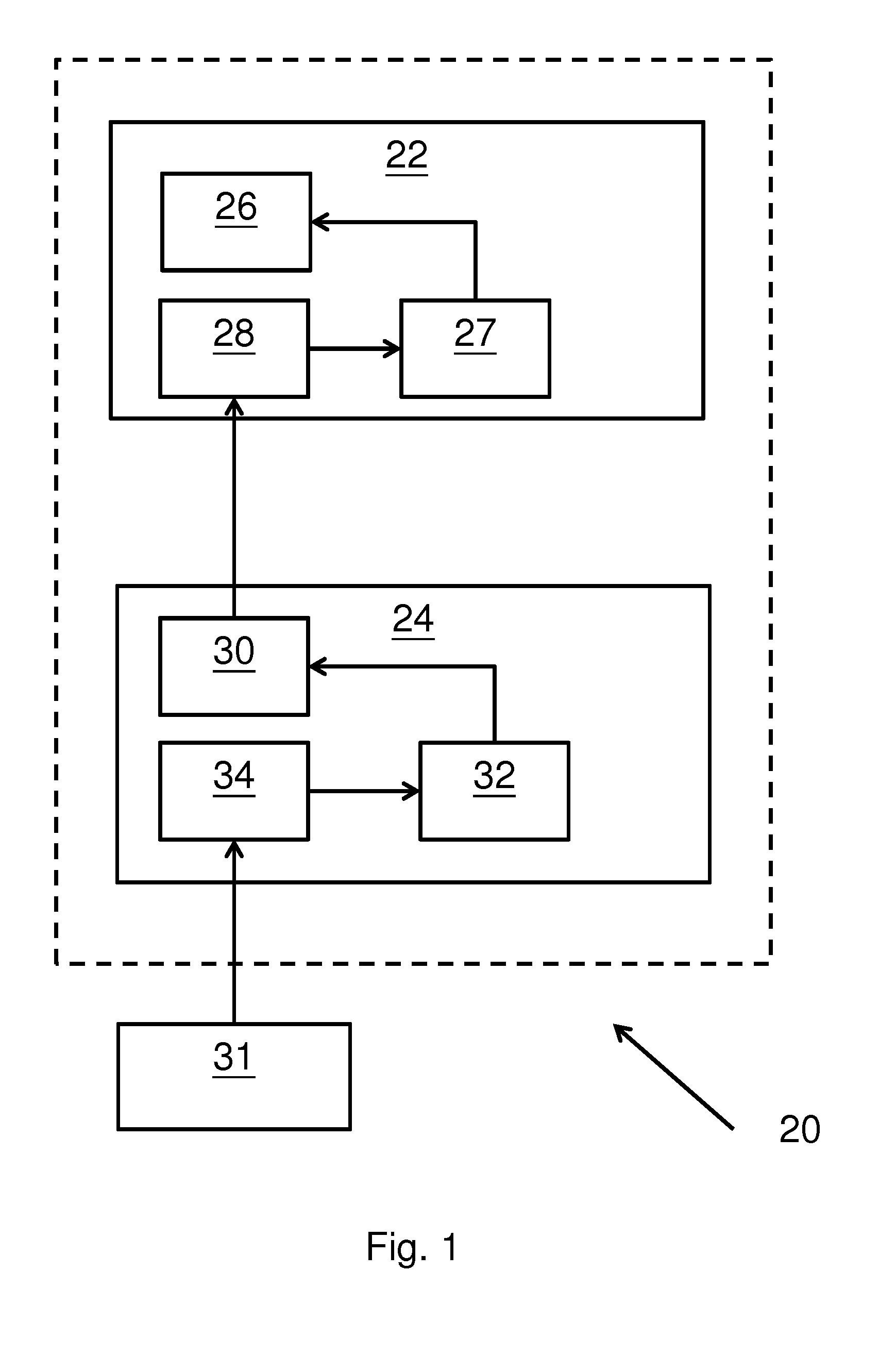

Radio clock and method for extracting time information

ActiveUS20080107210A1Improve system sensitivitySimple adaptationAnalogue/digital conversionAmplitude demodulation by homodyne/synchrodyne circuitsTime informationRadio clock

A method for extracting time information from a received, amplitude-modulated time signal is provided. The method provides that the time signal is demodulated, the analog signal thus obtained is digitized by a comparator, and the digital signal thus obtained is analyzed to extract the time information. In addition, a characteristic value of the time duration of at least one signal phase of a specific signal level of the digital signal is compared to a target value, and a comparator threshold of the comparator is altered as a function of a result of the comparison such that the time duration of at least the applicable signal phase of the digital signal approaches the target value. In this way, an improved system sensitivity is achieved according to the invention in a receiver for receiving time signals. In particular, the frequency of occurrence of errors due to misreading of pulse lengths is reduced here, and distorted received signals are better detected as being distorted on account of their temporal deviation from the applicable target value. In addition, compensation of manufacturing tolerances of the various components in the described circuit arrangement is possible.

Owner:ATMEL CORP

Piezoelectric vibrator manufacturing method, and piezoelectric vibrator, oscillator, electronic apparatus, and radio clock

InactiveUS20100237739A1Quality improvementLow costPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesResonanceRadio clock

A piezoelectric vibrator manufacturing method includes a cavity forming step for forming depressions for a cavities on at least one of two wafers; a bonding electrode film forming step for forming bonding electrode films on bonded surfaces of the both wafers; a mount pattern forming step for forming a pair of mount patterns in the cavity; a through hole forming step for forming a pair of through holes in the cavity; a through electrode forming step for forming a pair of through electrodes electrically connected with the pattern in the cavity; a mount step for electrically connecting the pattern and a piezoelectric vibrating strip, a superimposing step for superimposing the both wafers and storing getter materials; a bonding step for anodically bonding the both wafers to fabricating a wafer member; a gettering step for adjusting the degree of vacuum in the interior of the cavity while measuring a series resonance resistance value; and a cutting step for cutting the wafer member into individual pieces.

Owner:SII CRYSTAL TECH

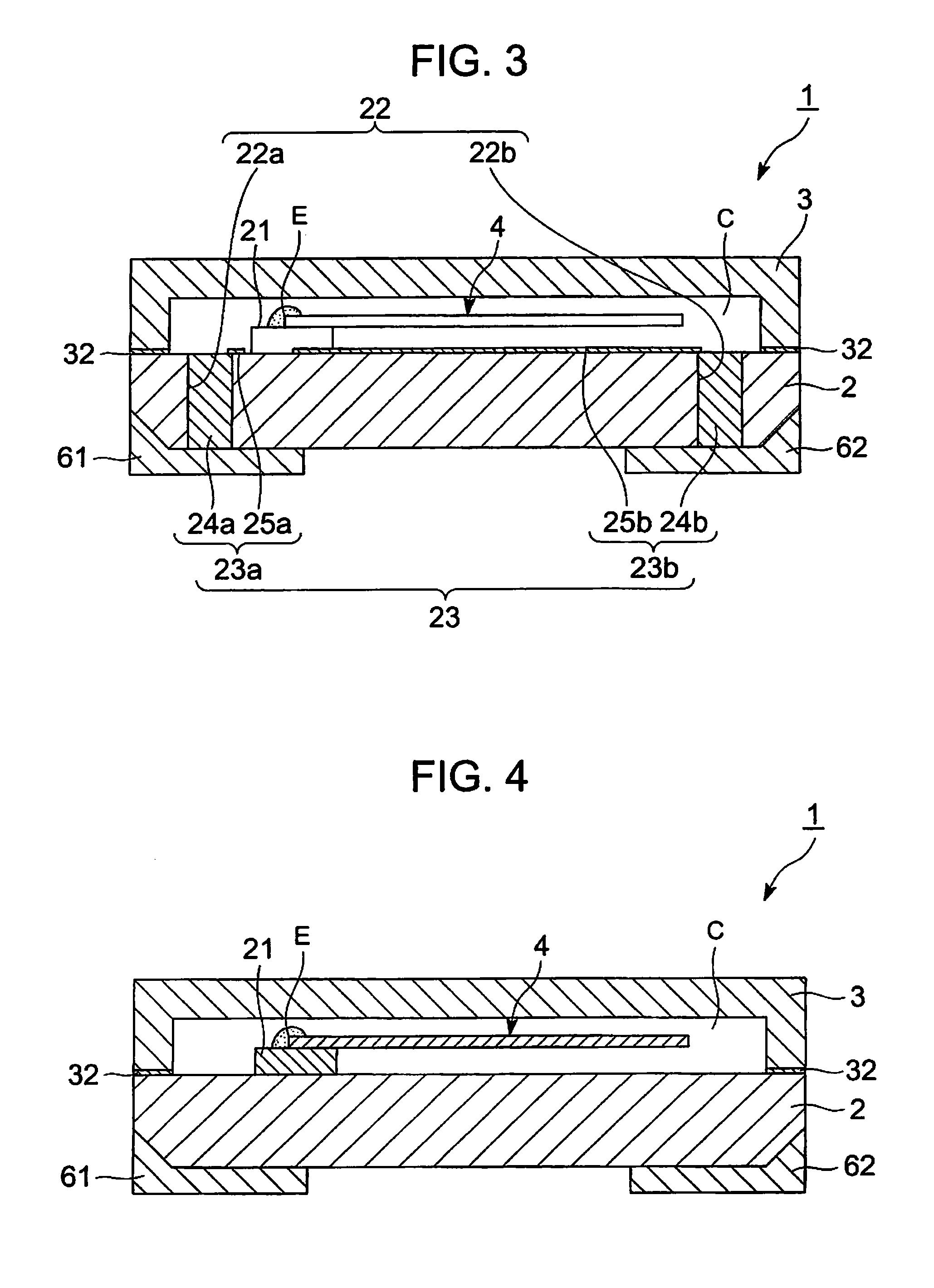

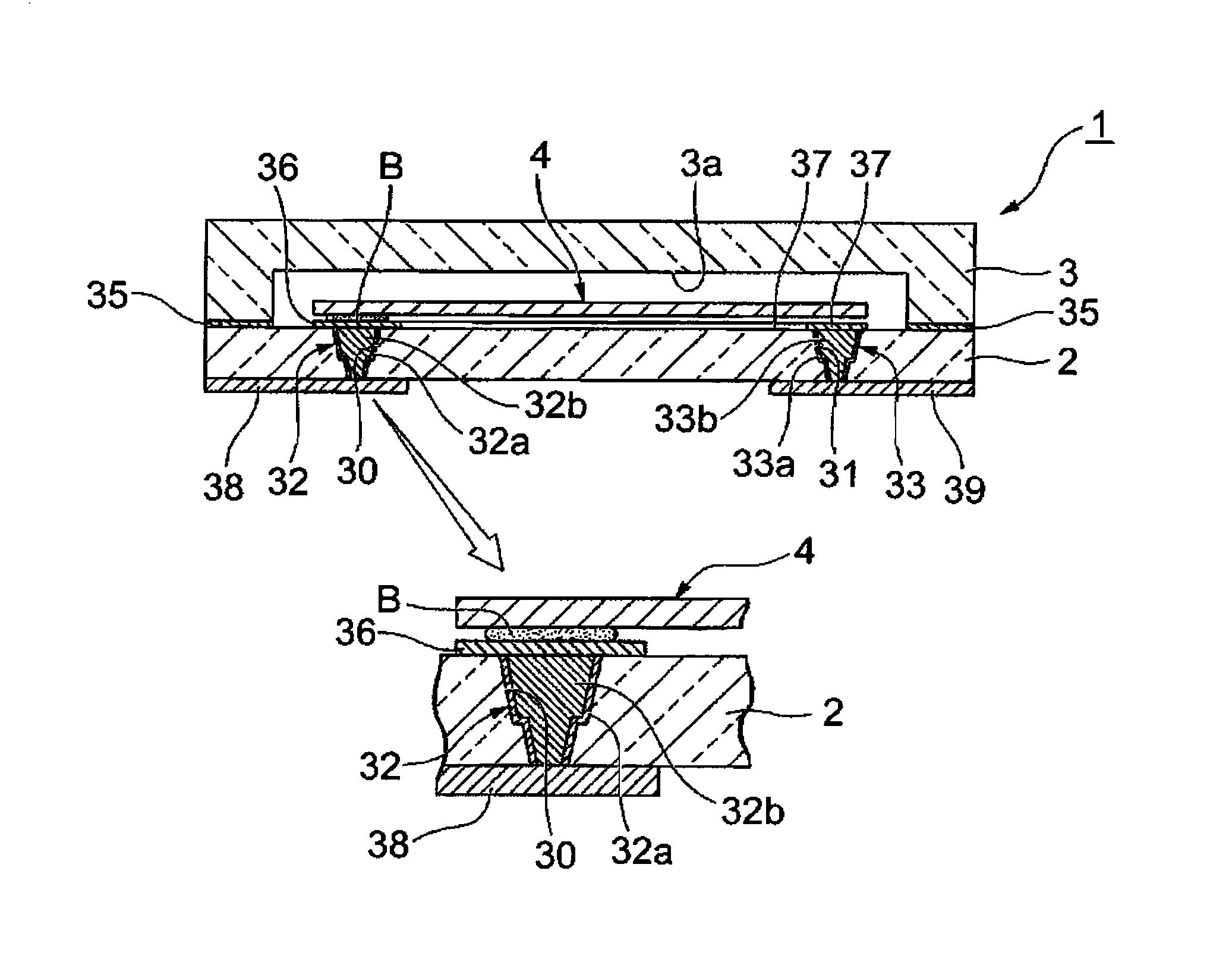

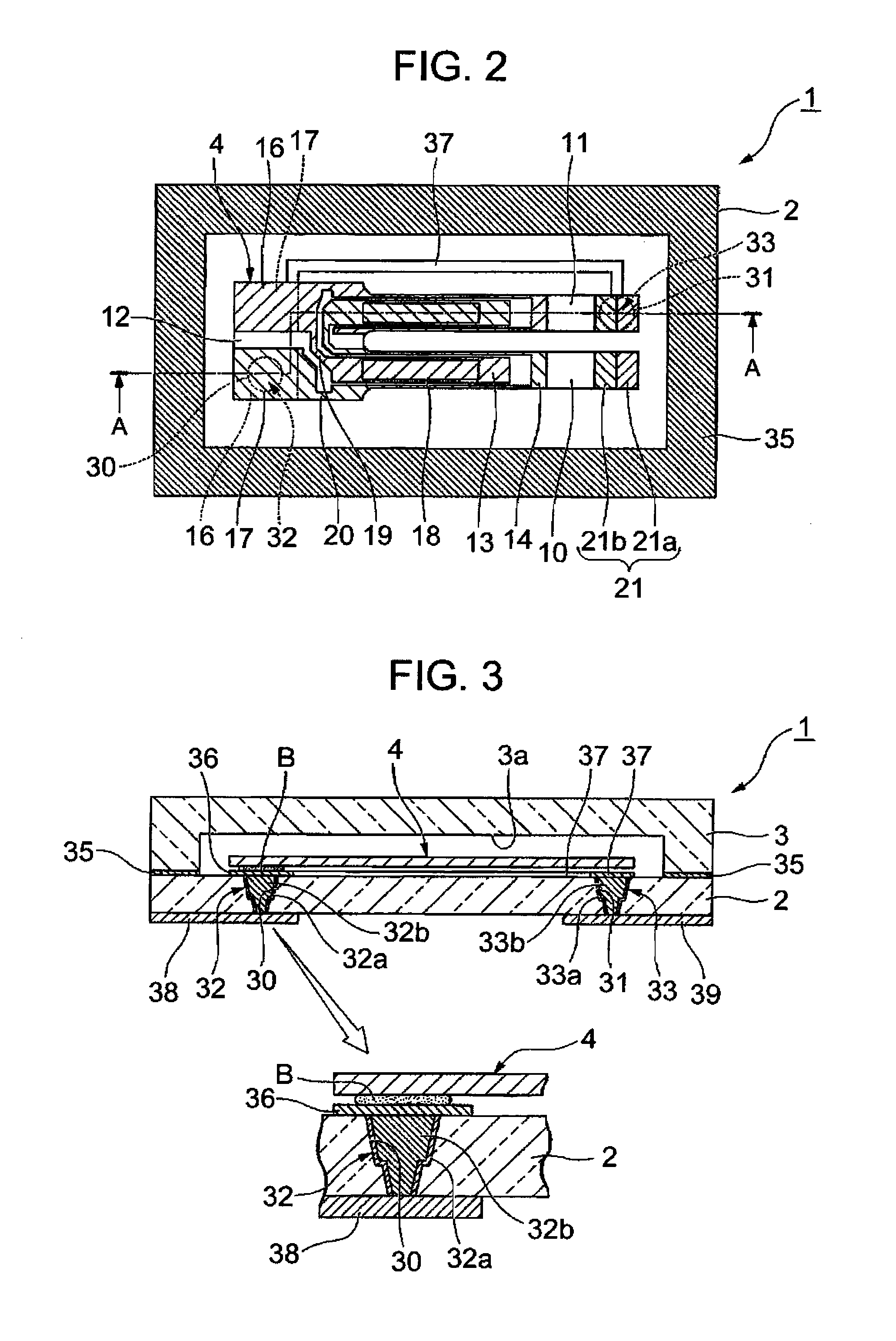

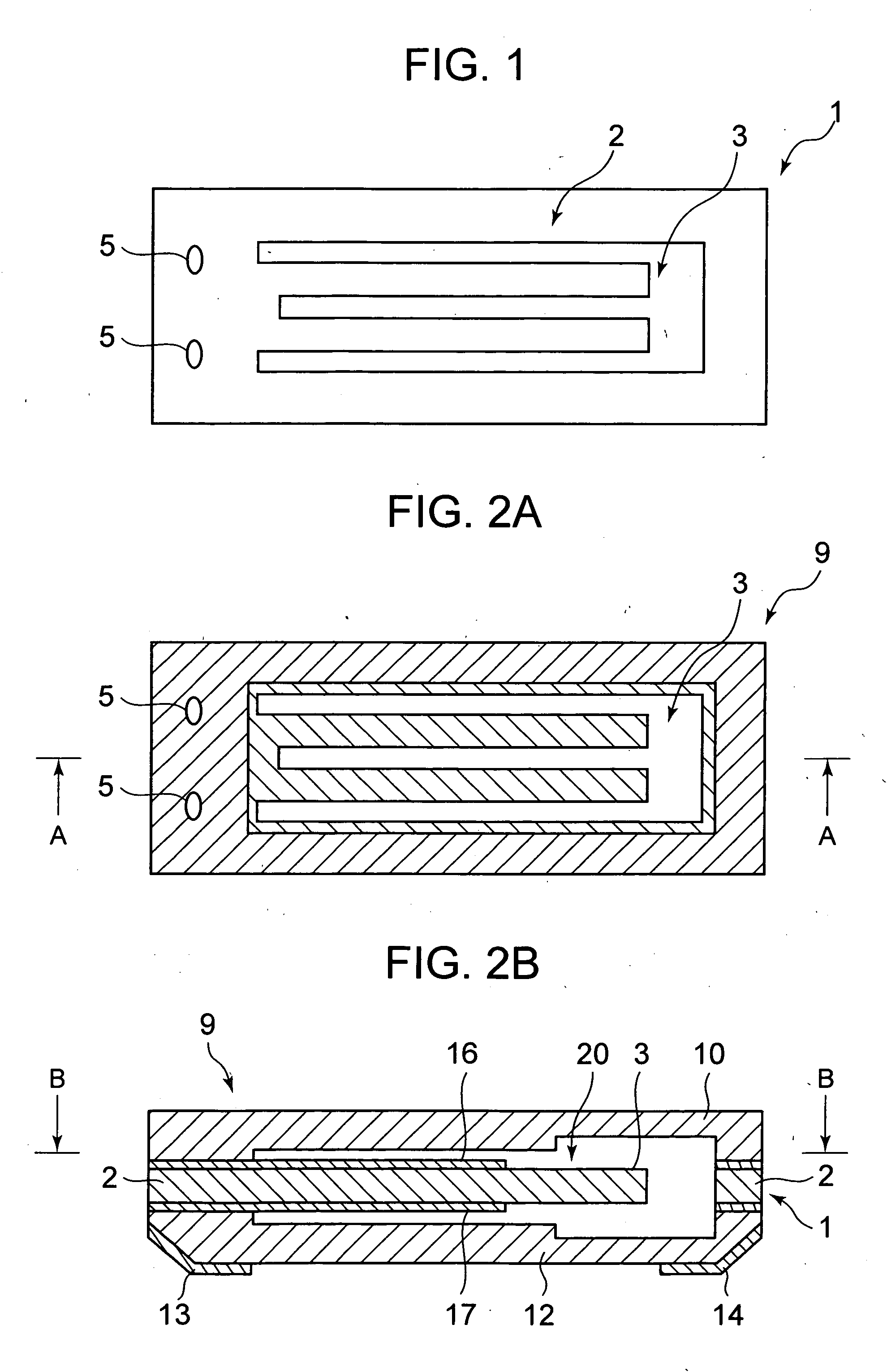

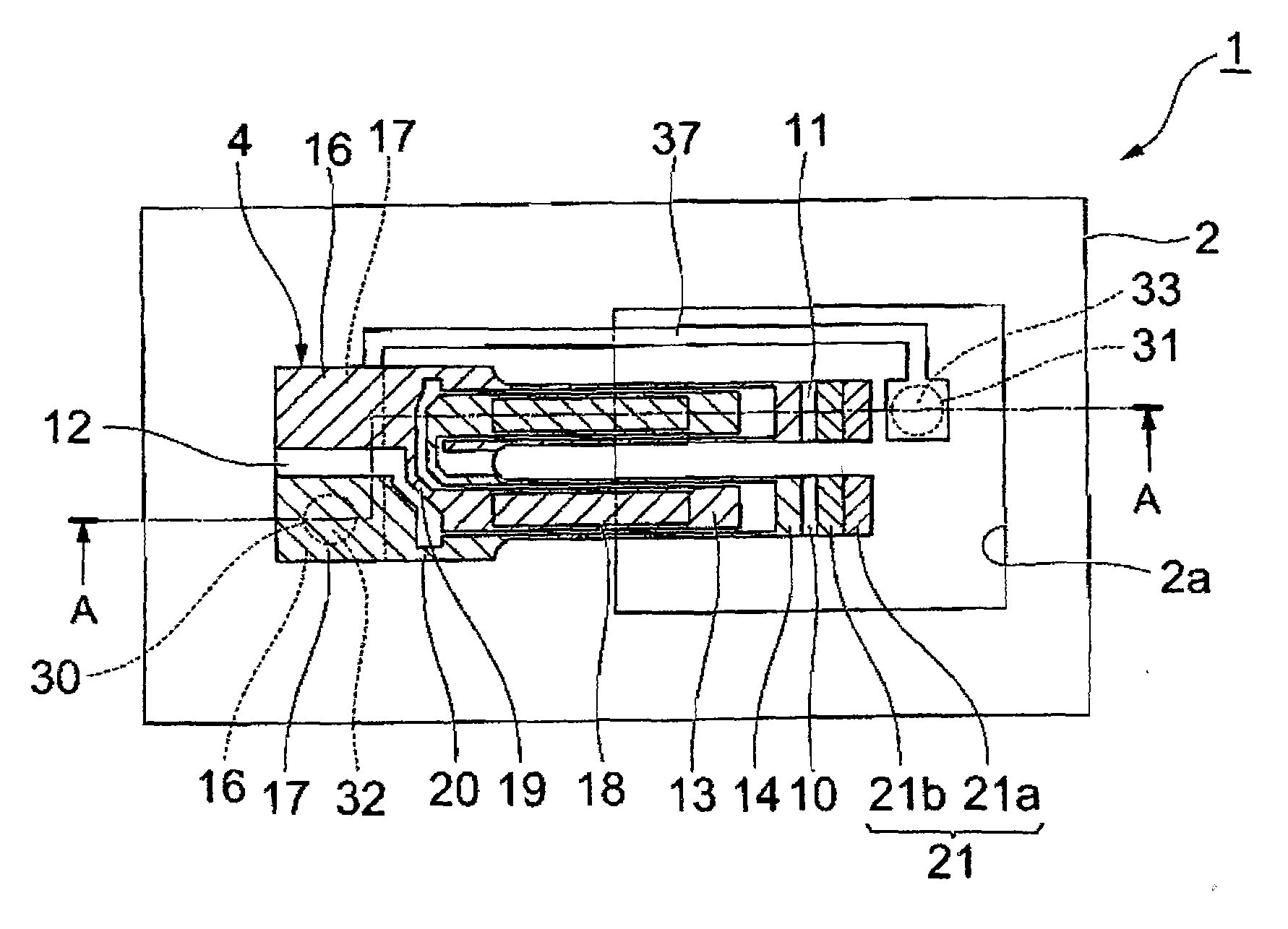

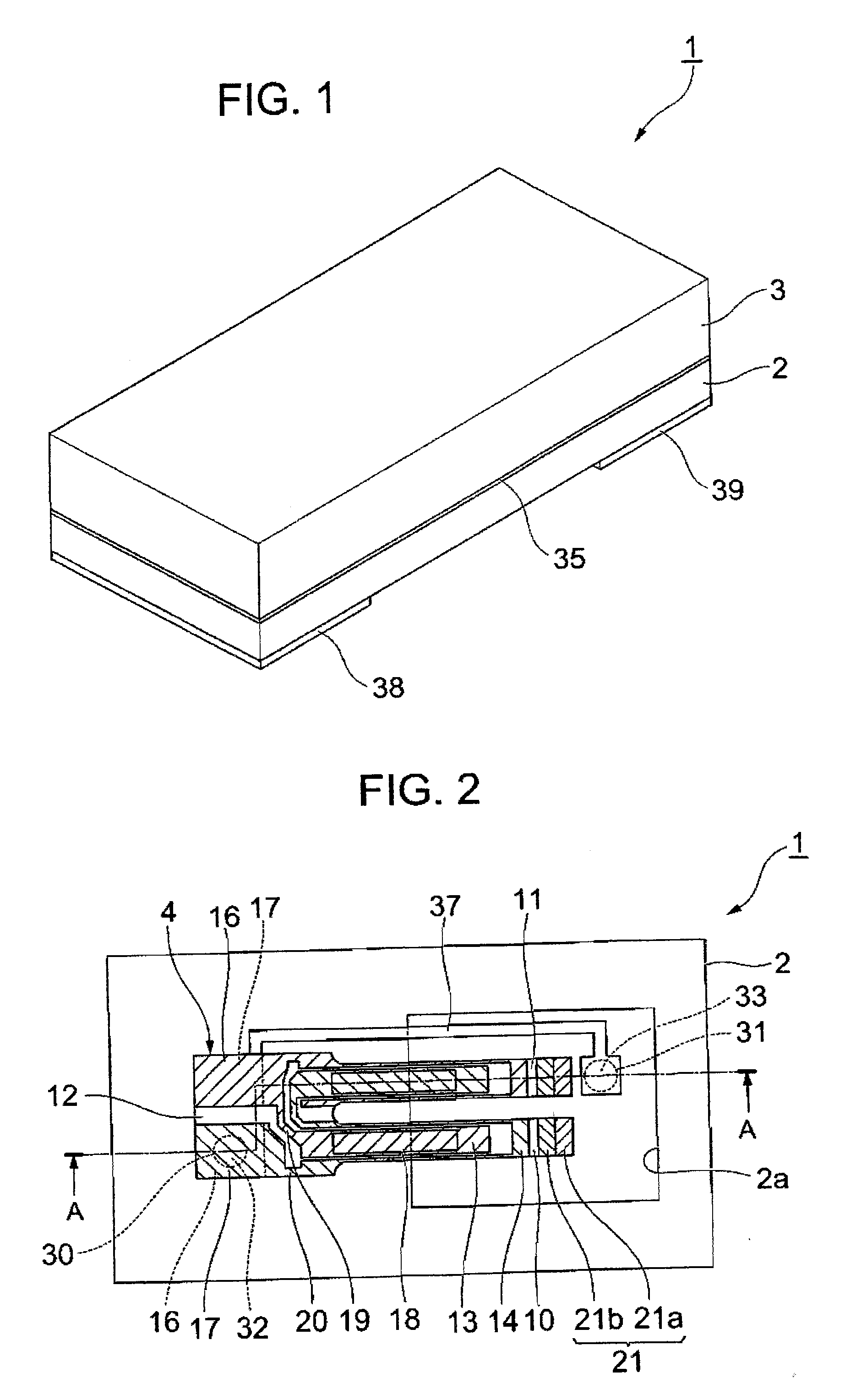

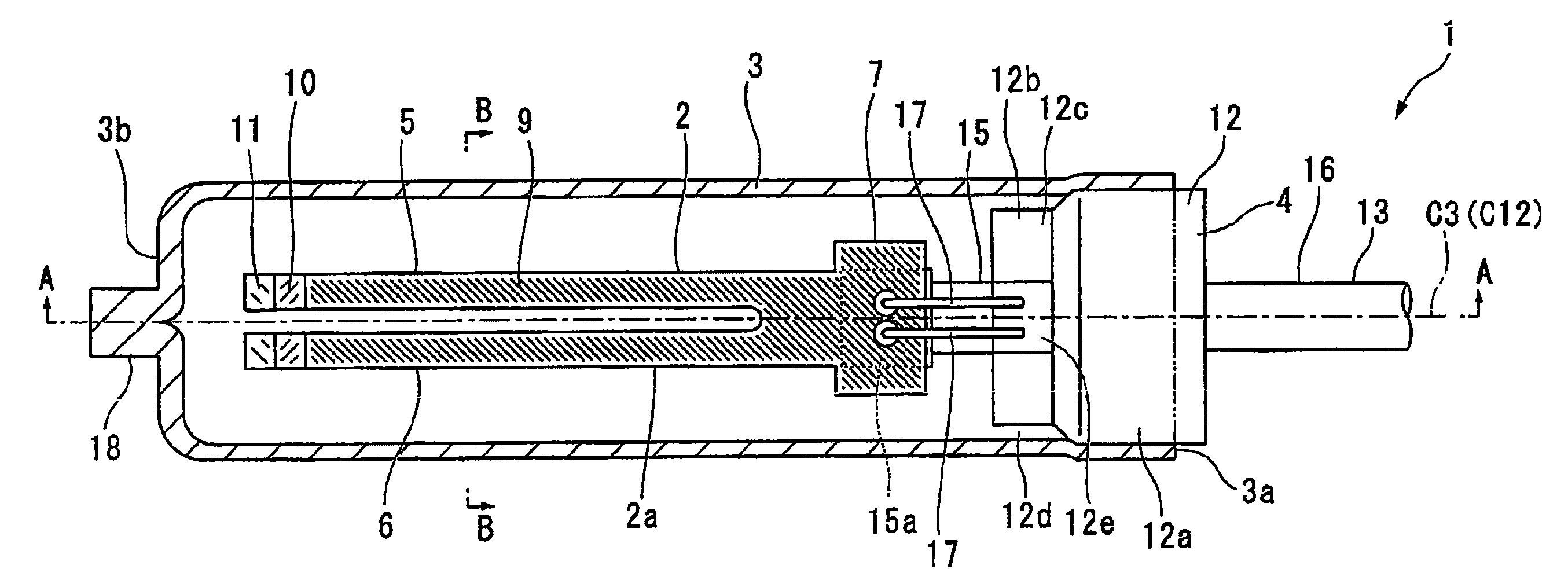

Method of manufacturing piezoelectric vibrator, piezoelectric vibrator, oscillator, electronic device, and radio-clock

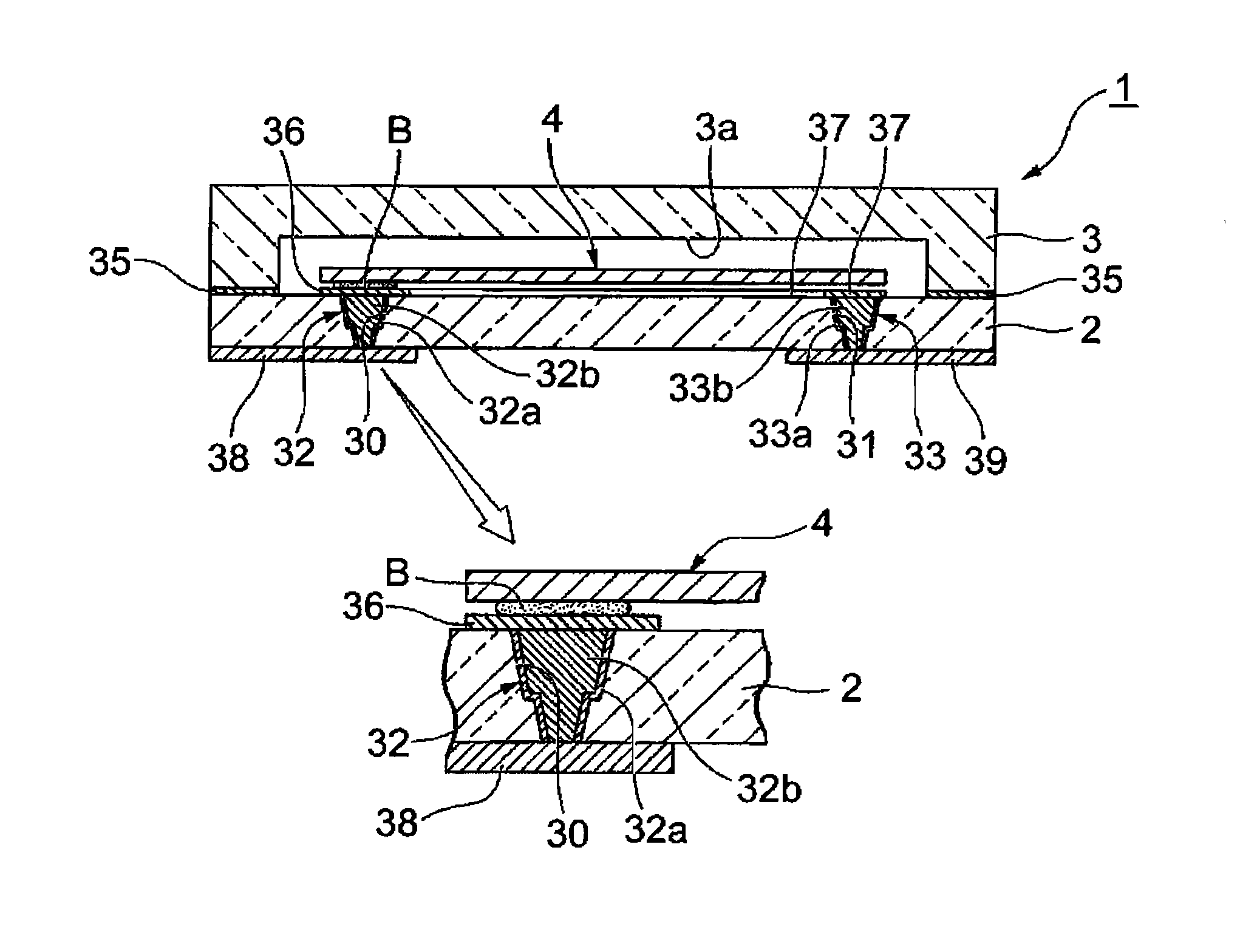

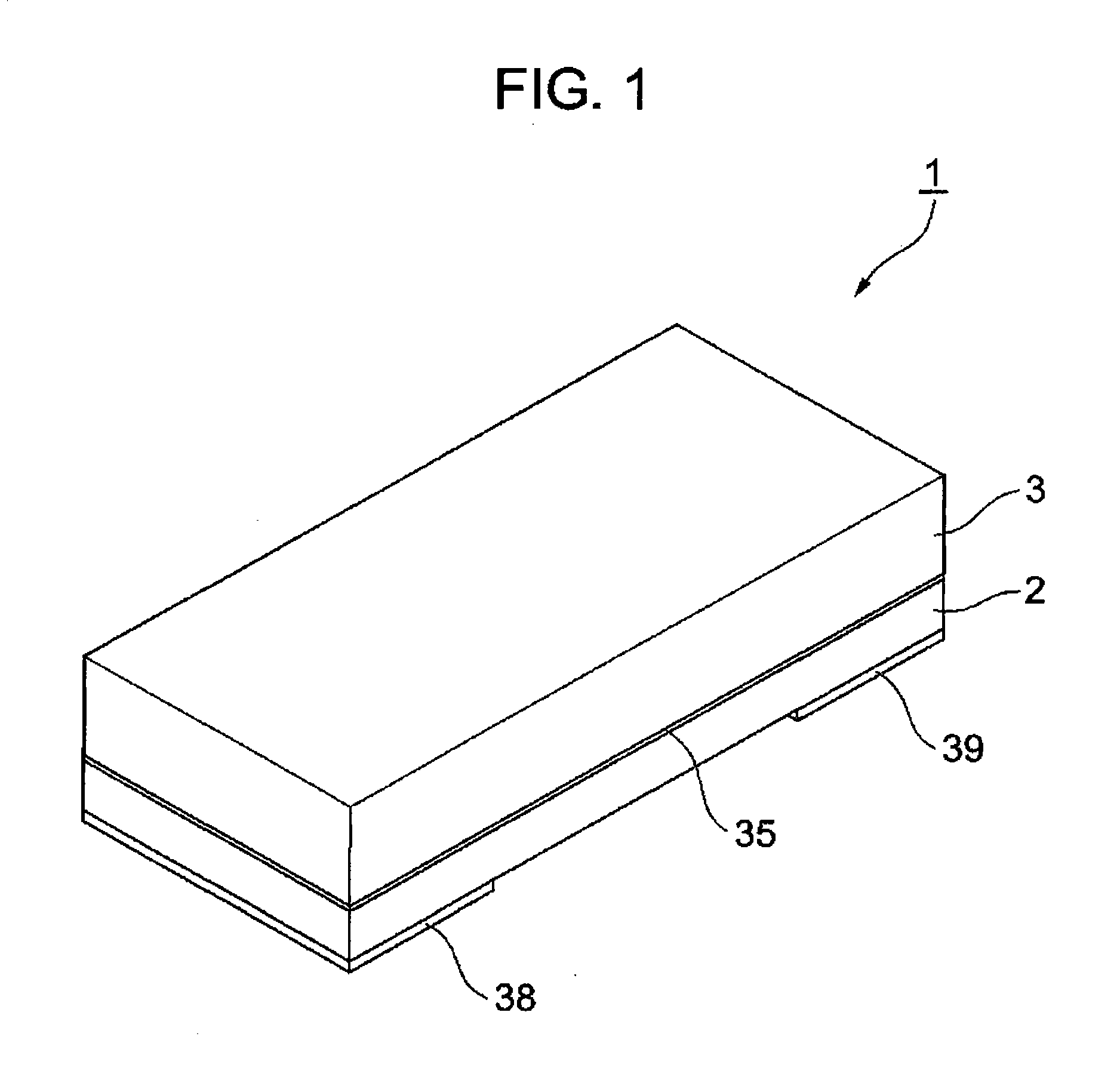

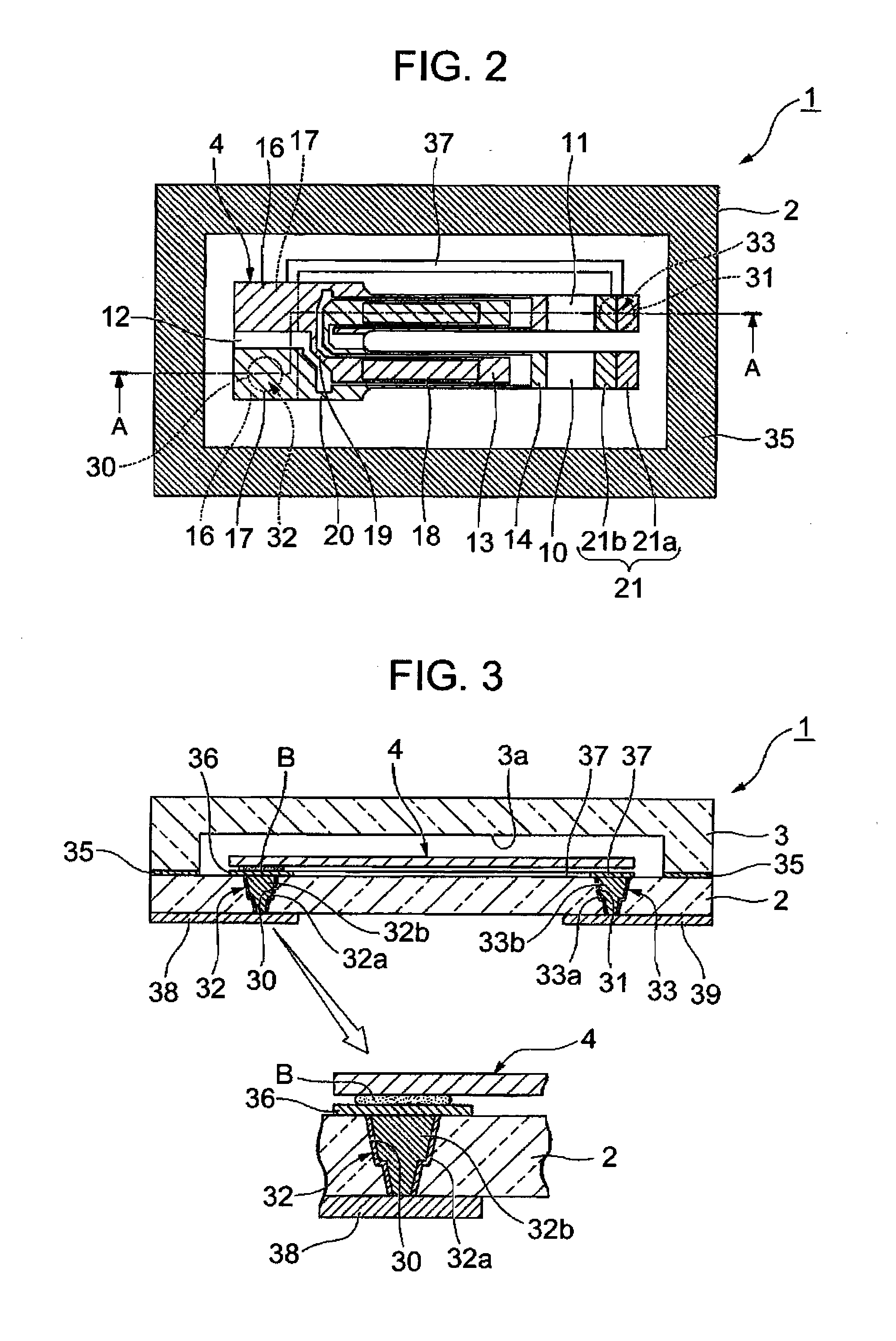

InactiveUS8058778B2Efficient preparationImprove air tightnessPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksRadio clockEngineering

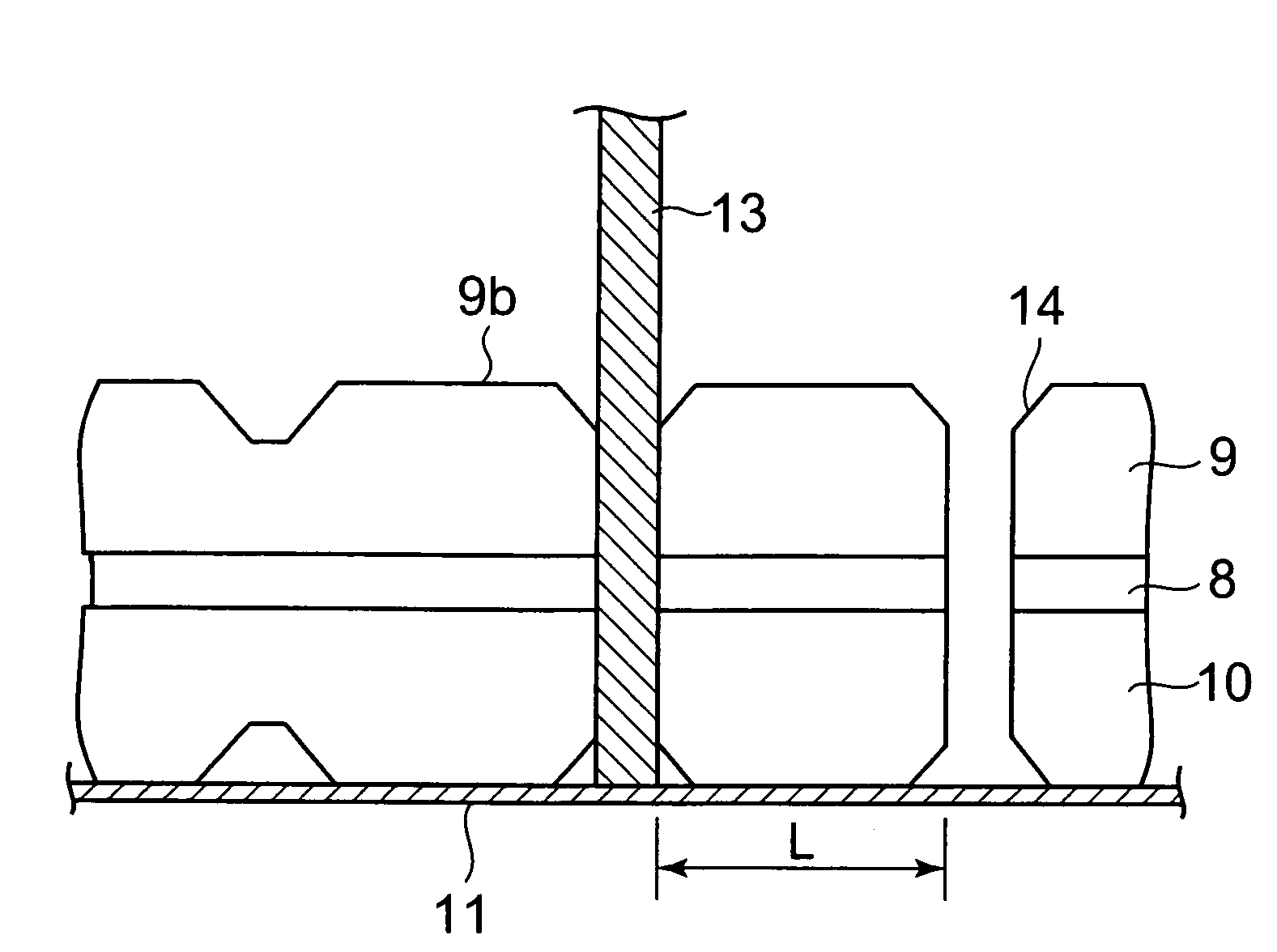

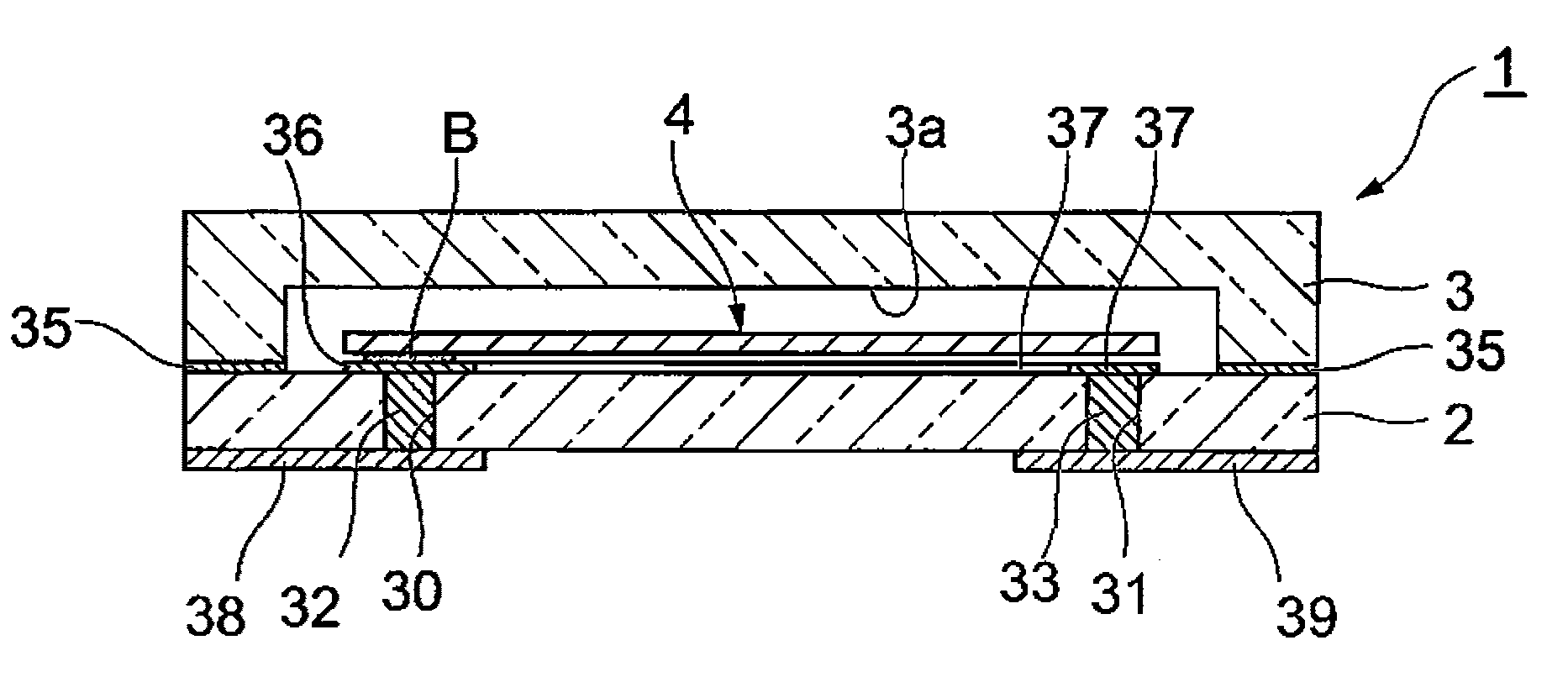

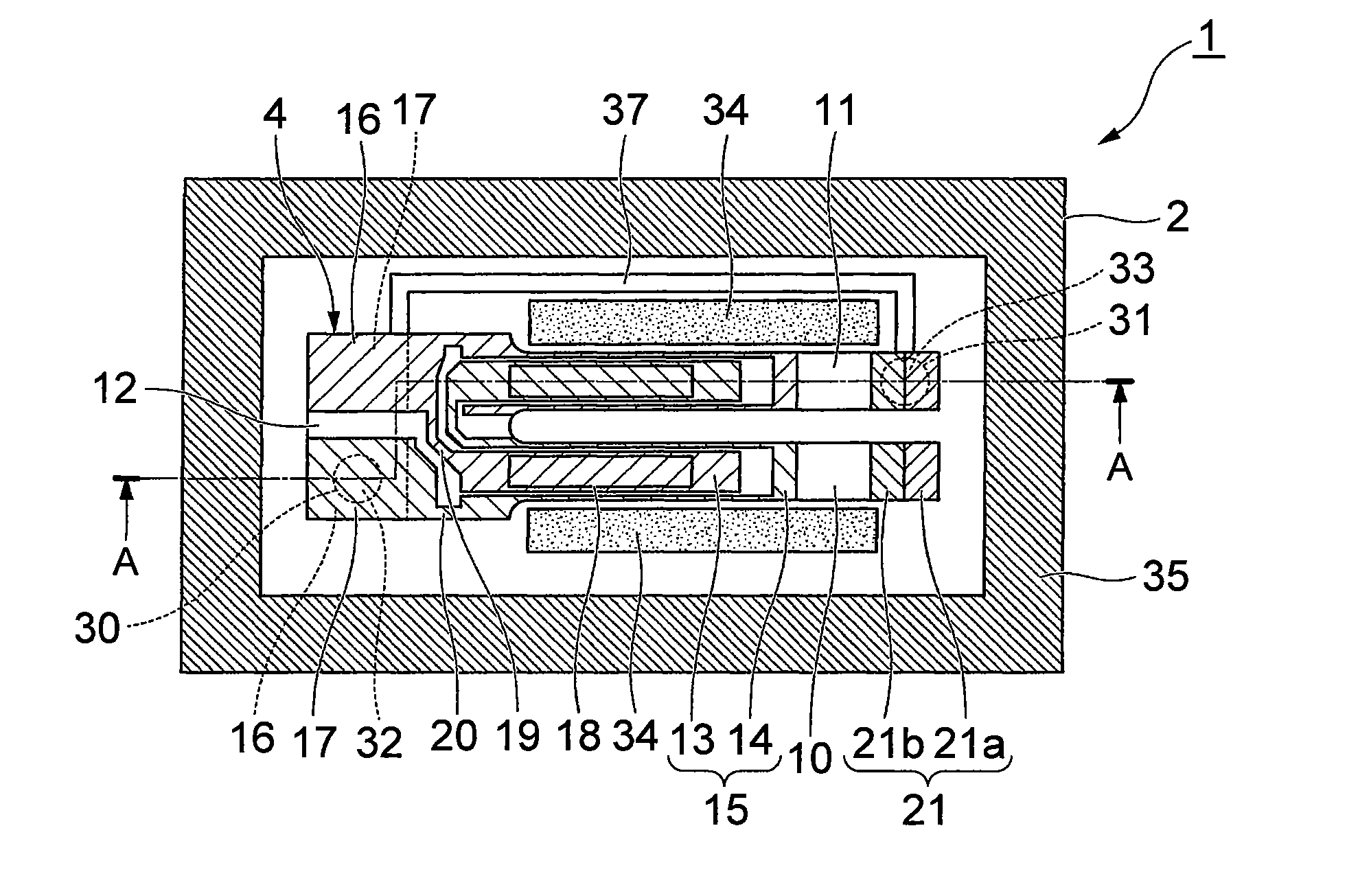

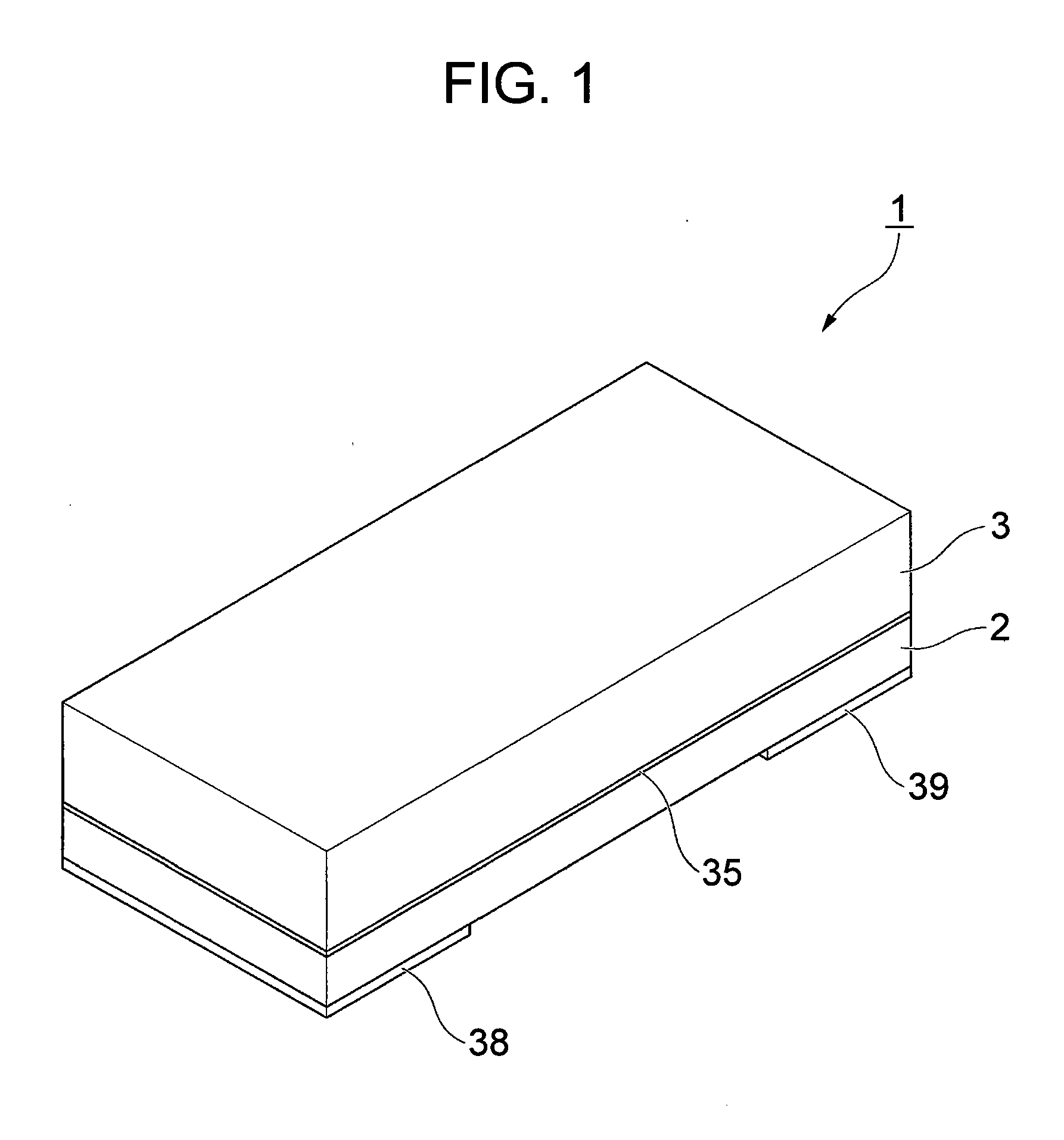

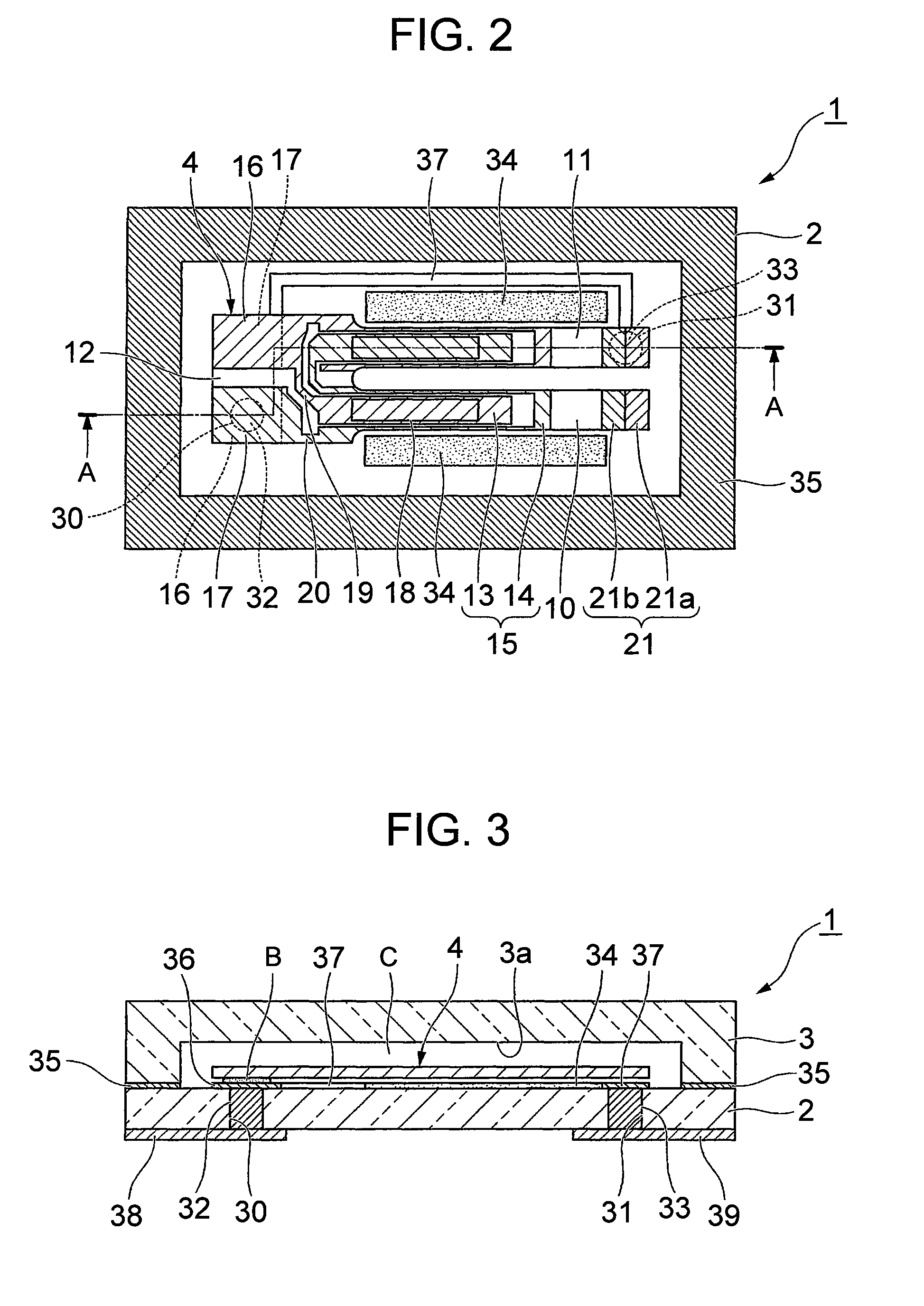

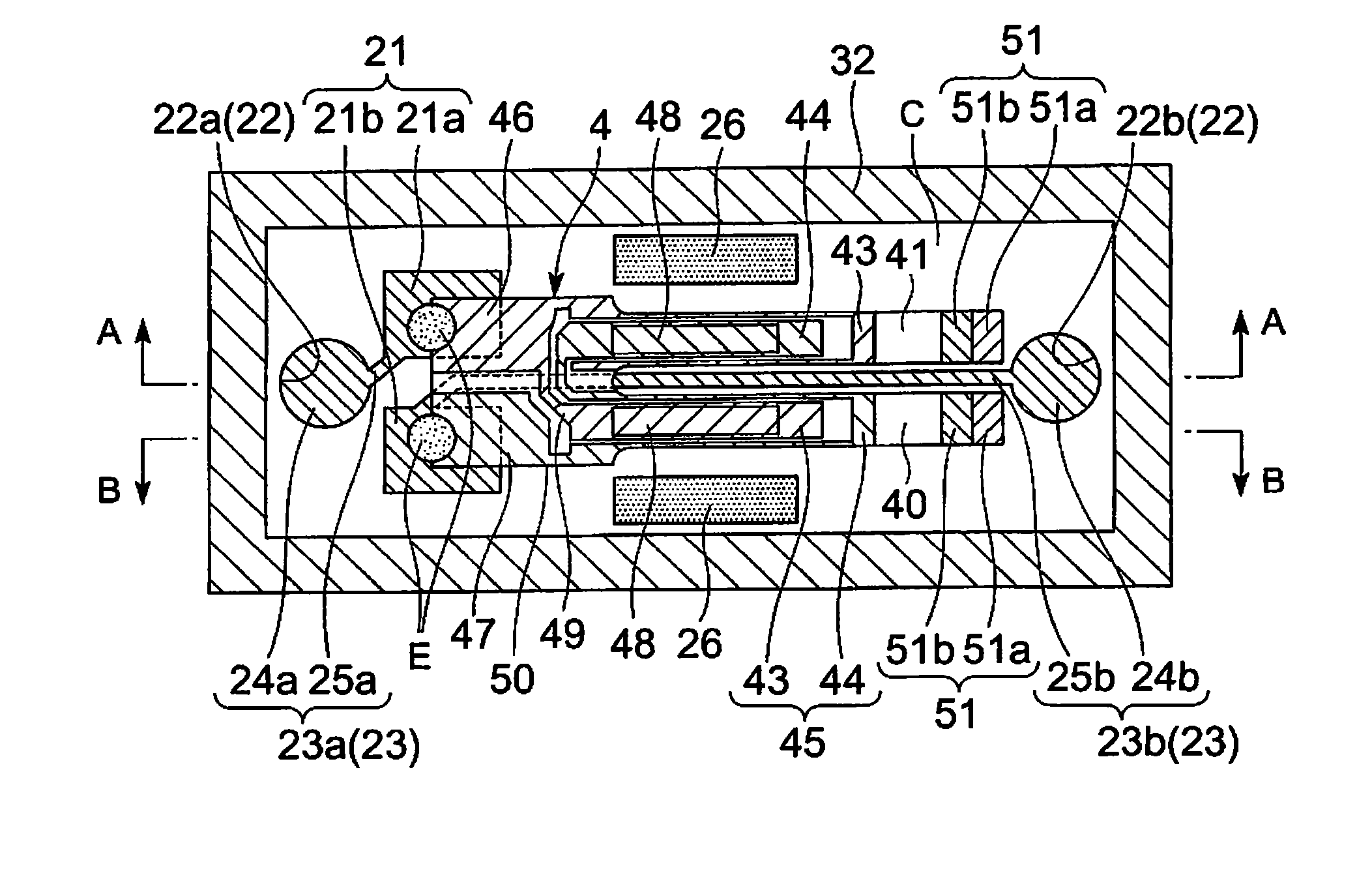

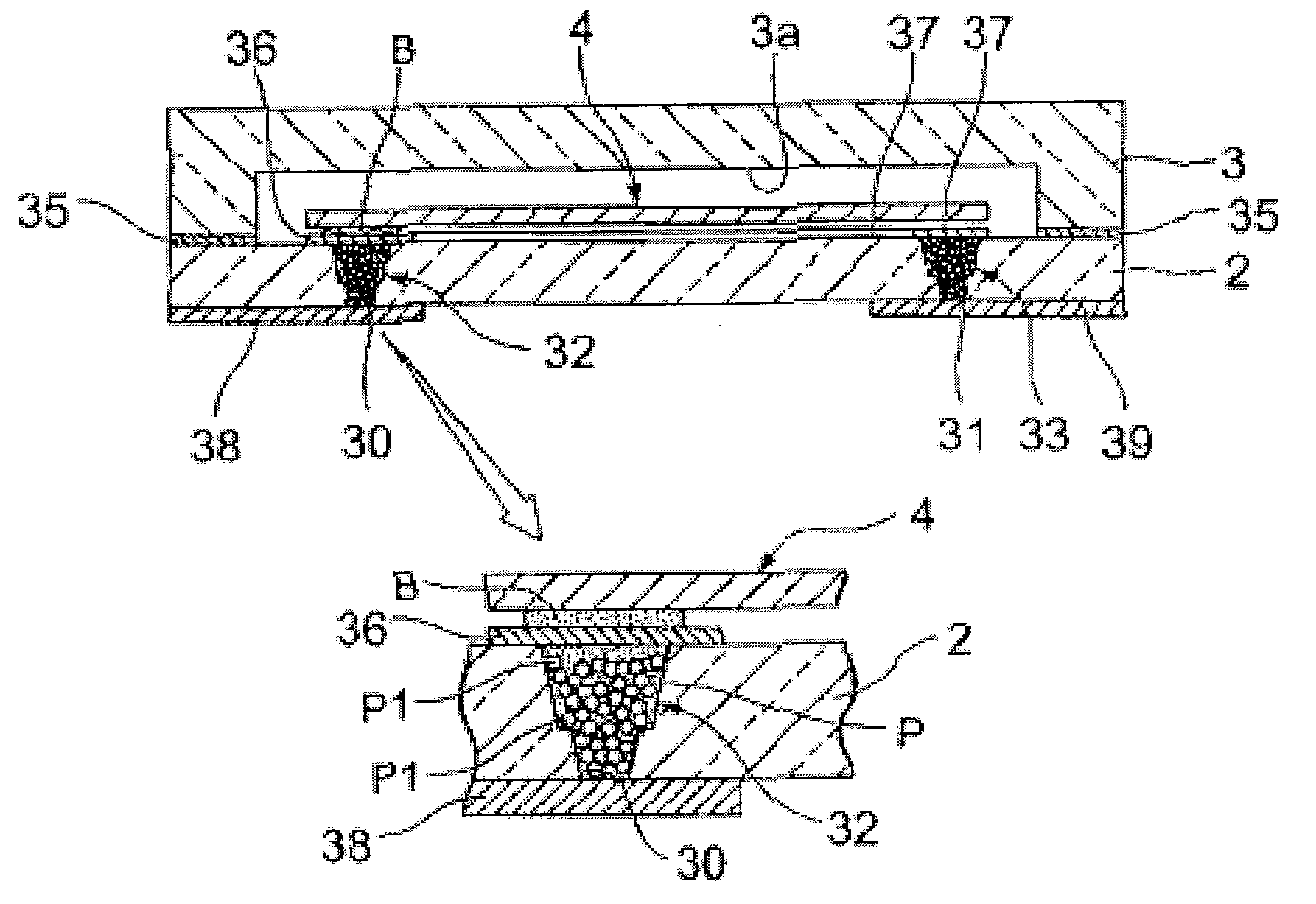

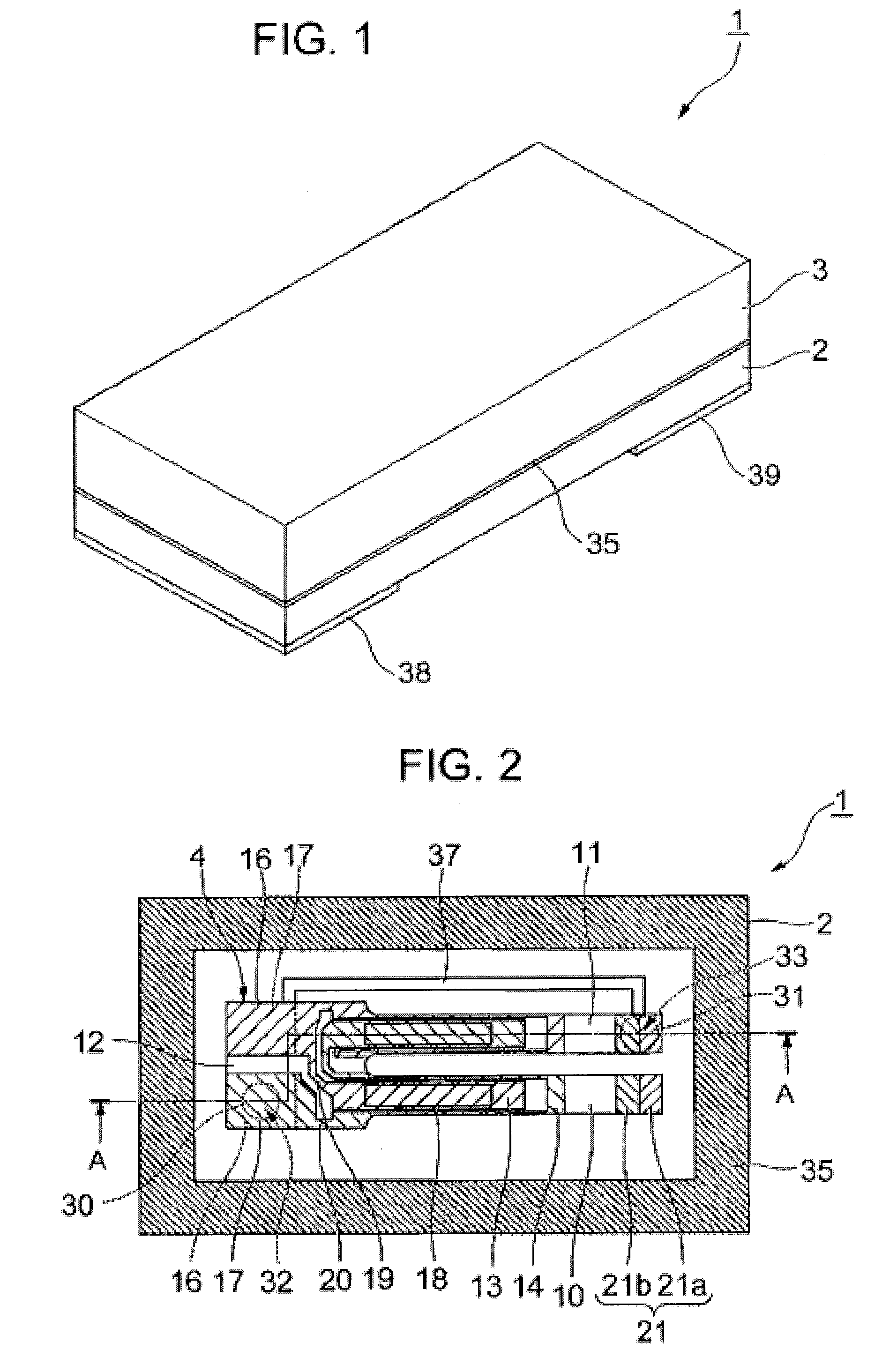

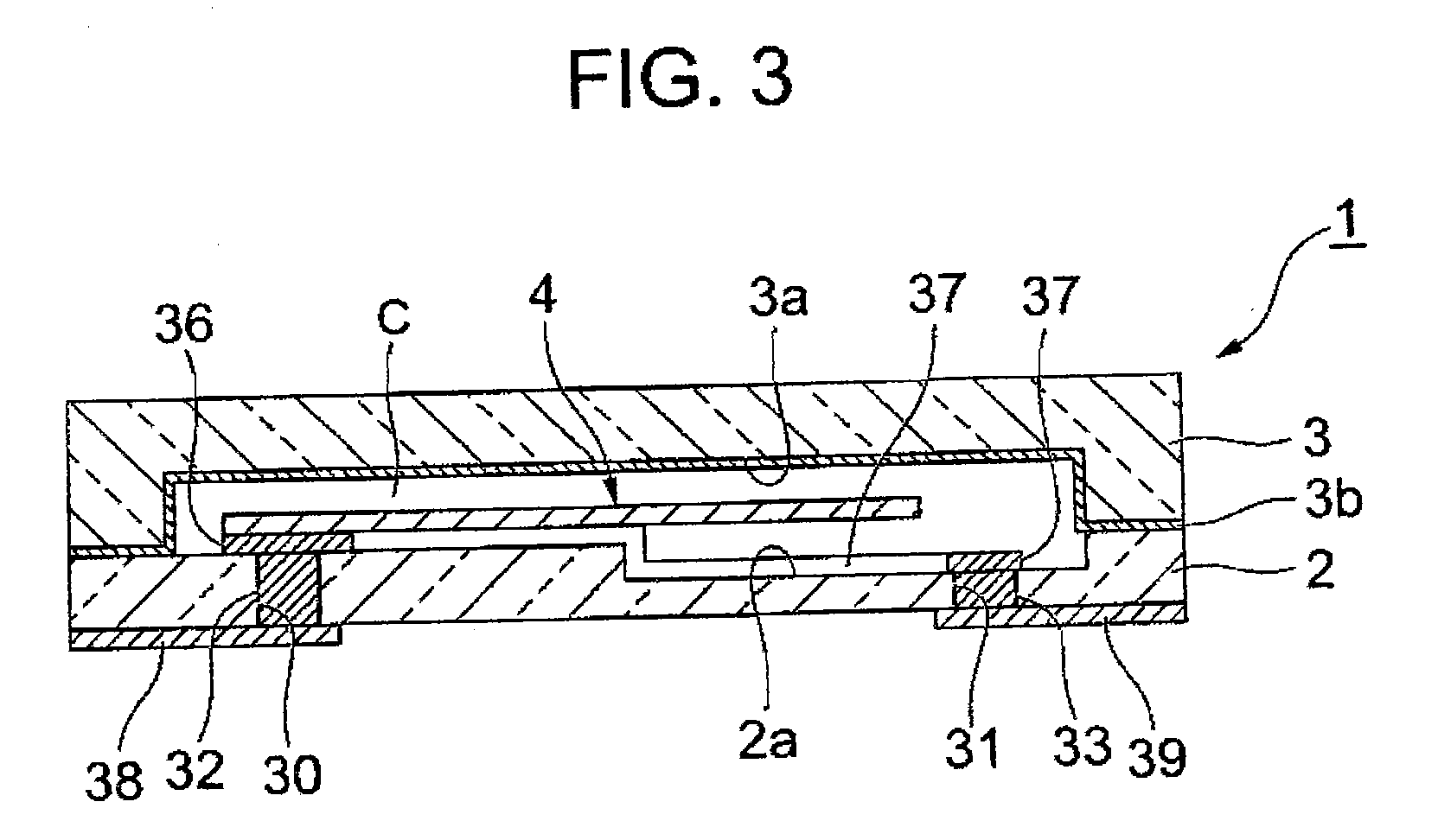

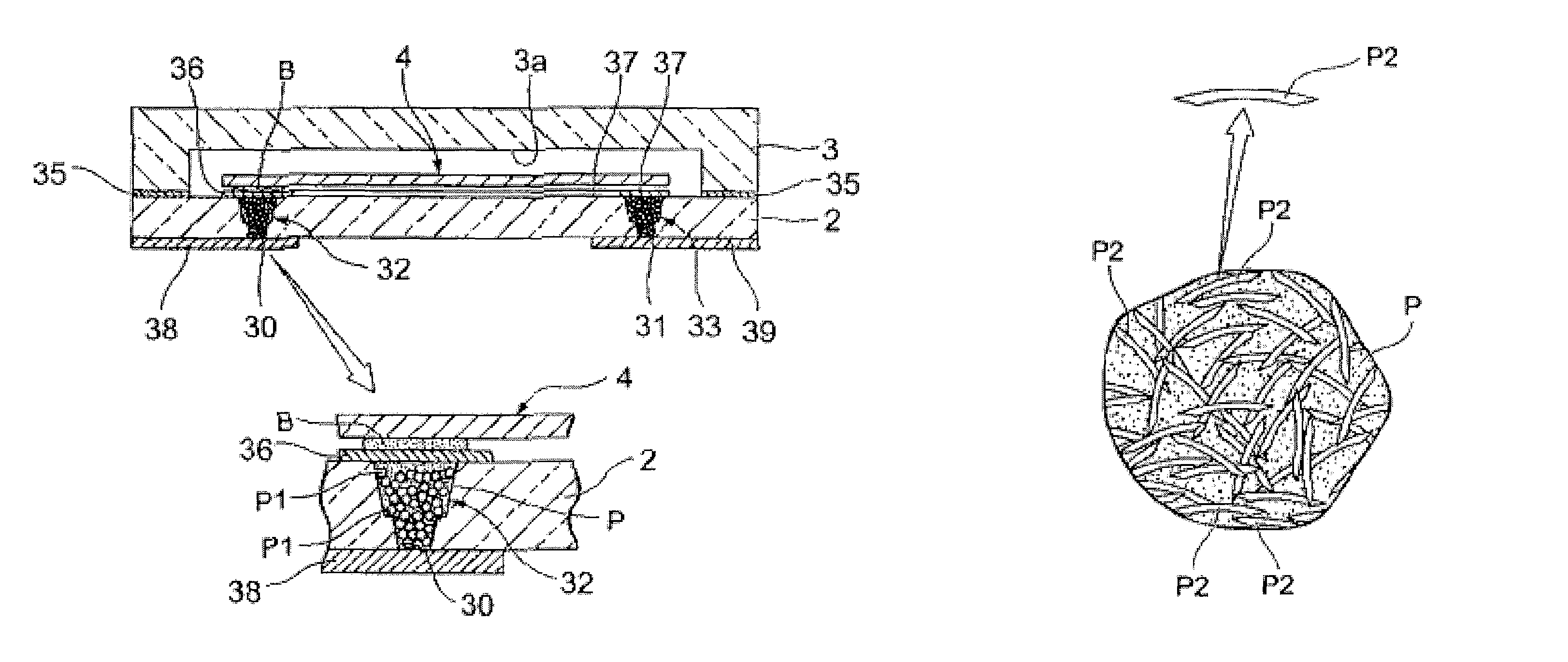

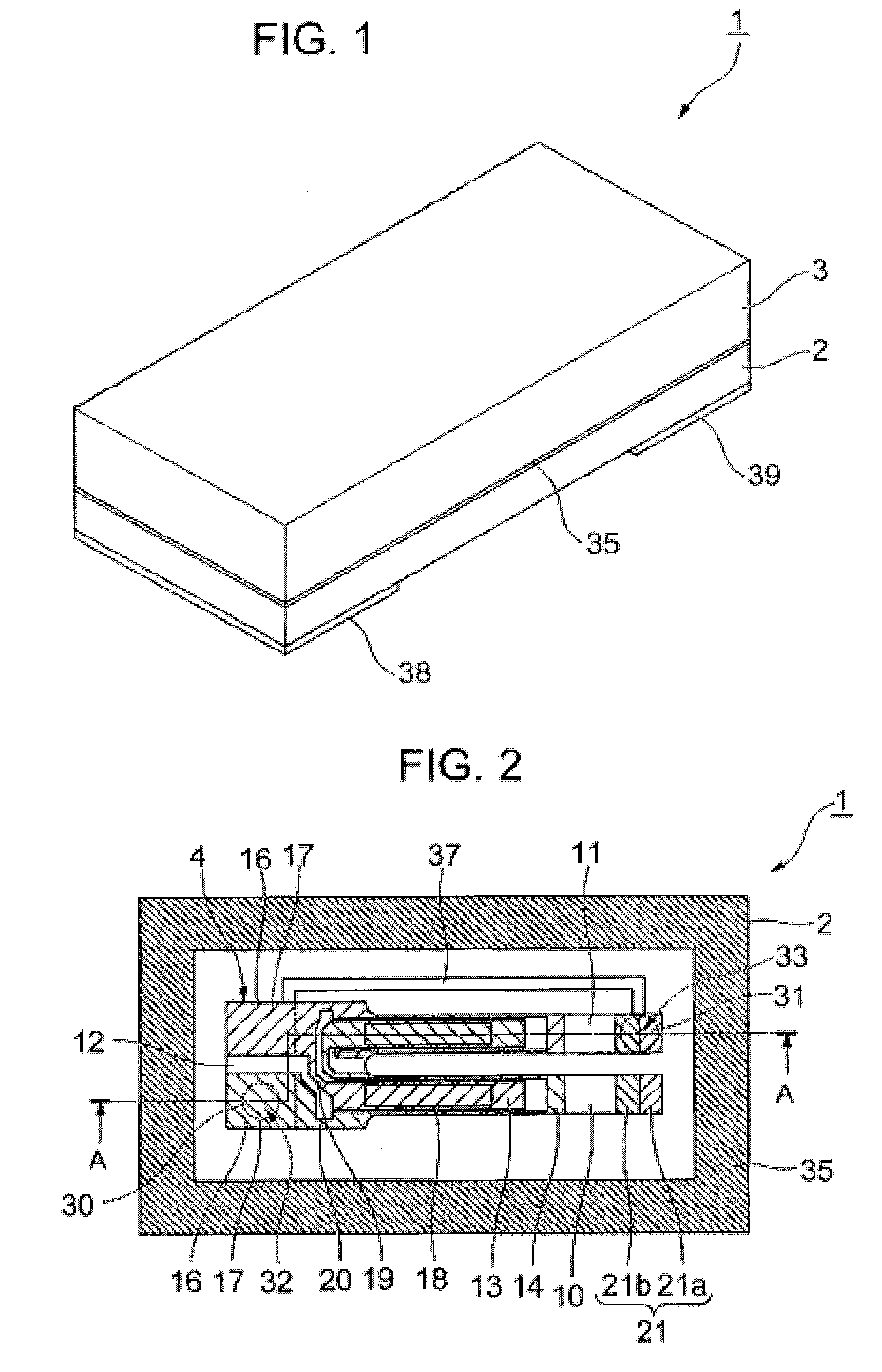

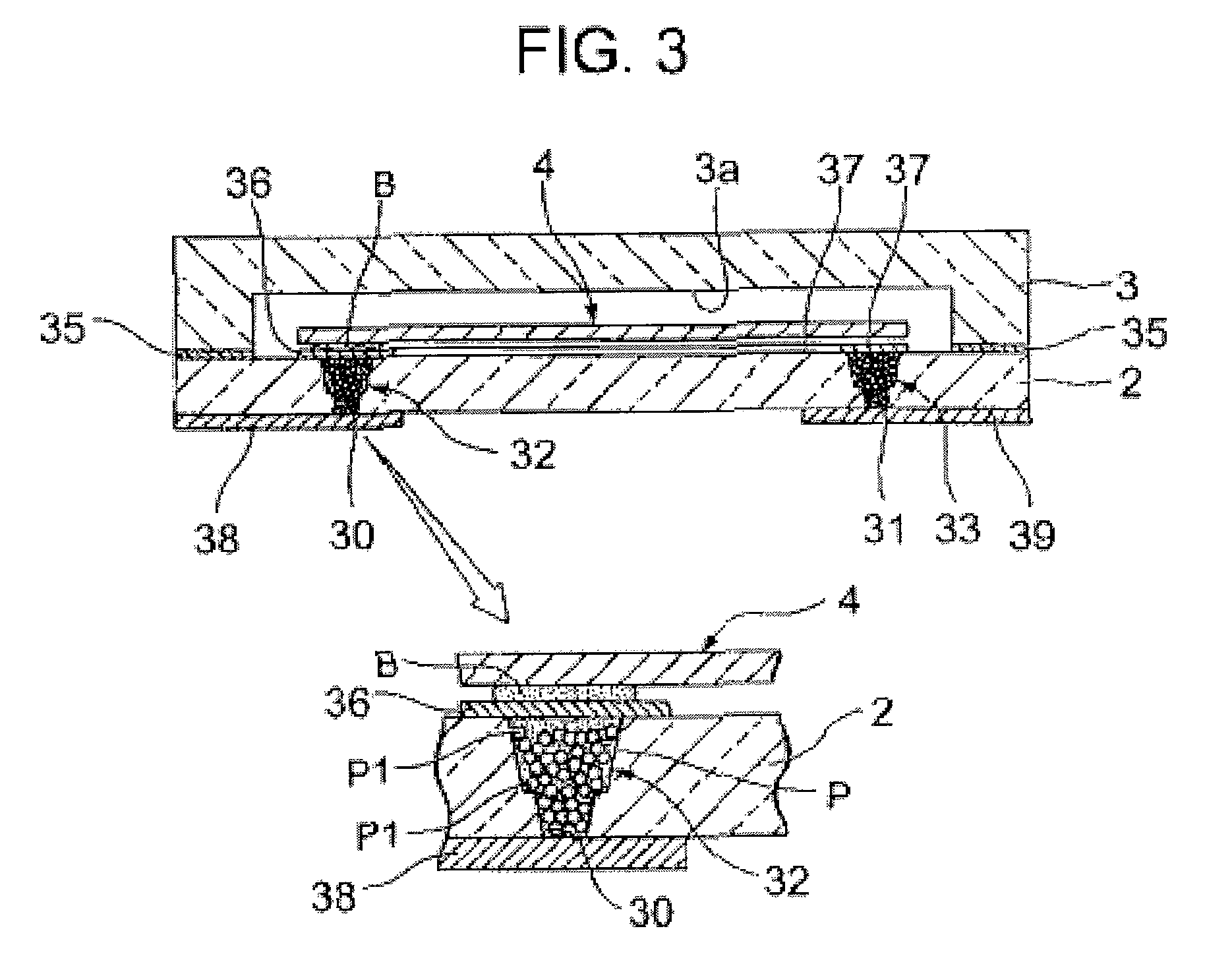

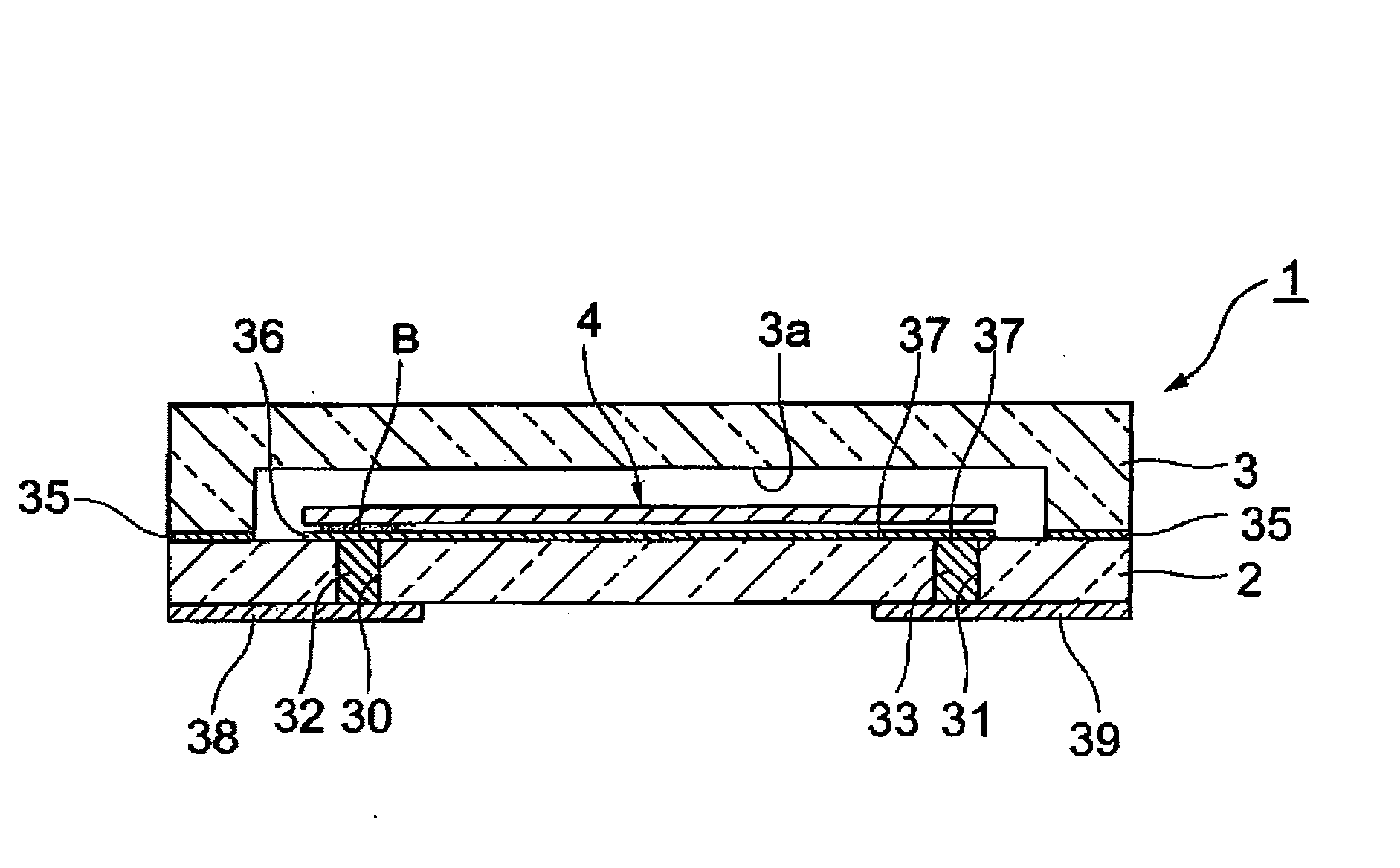

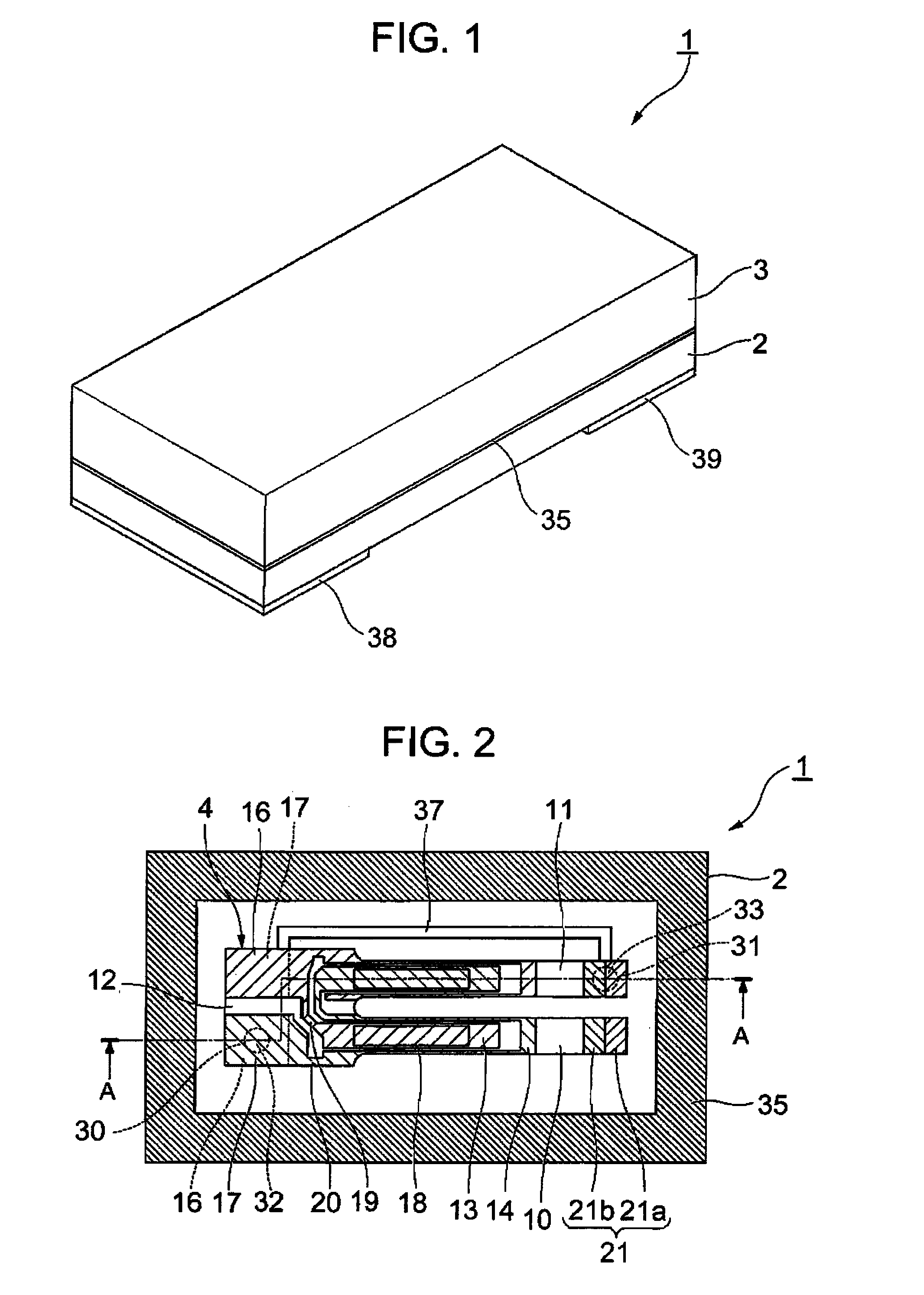

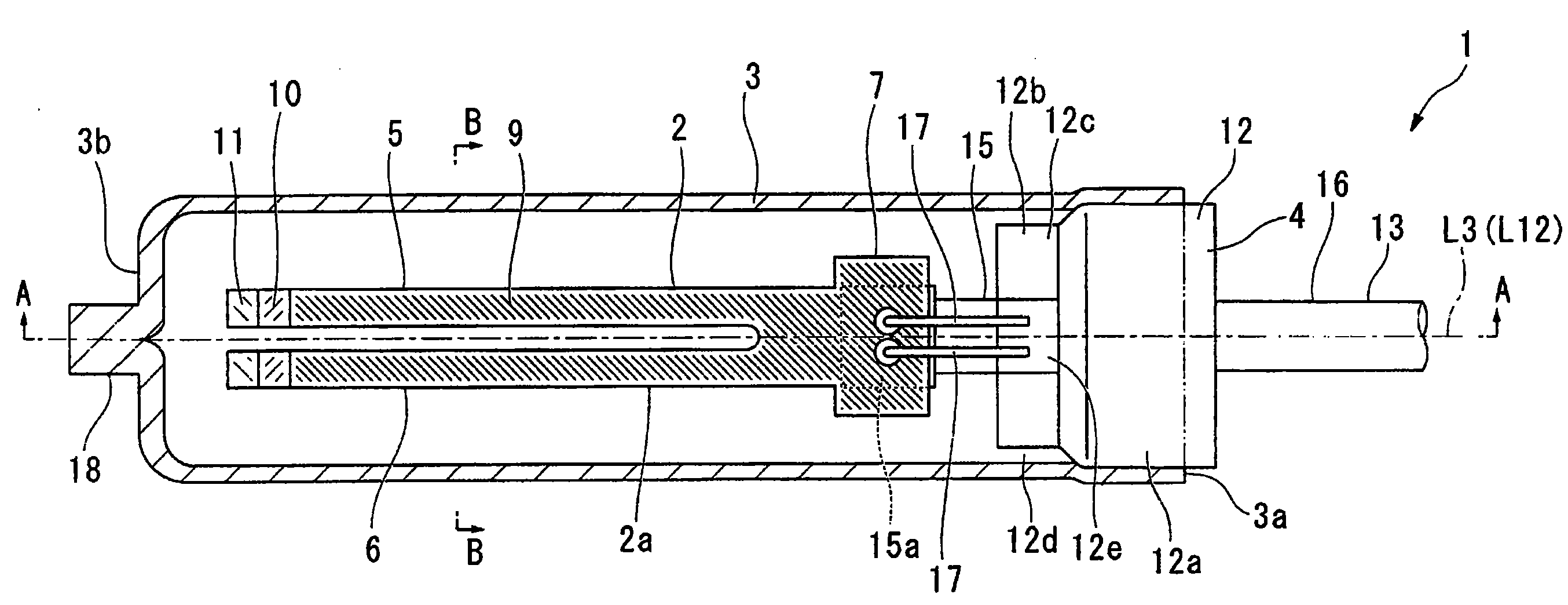

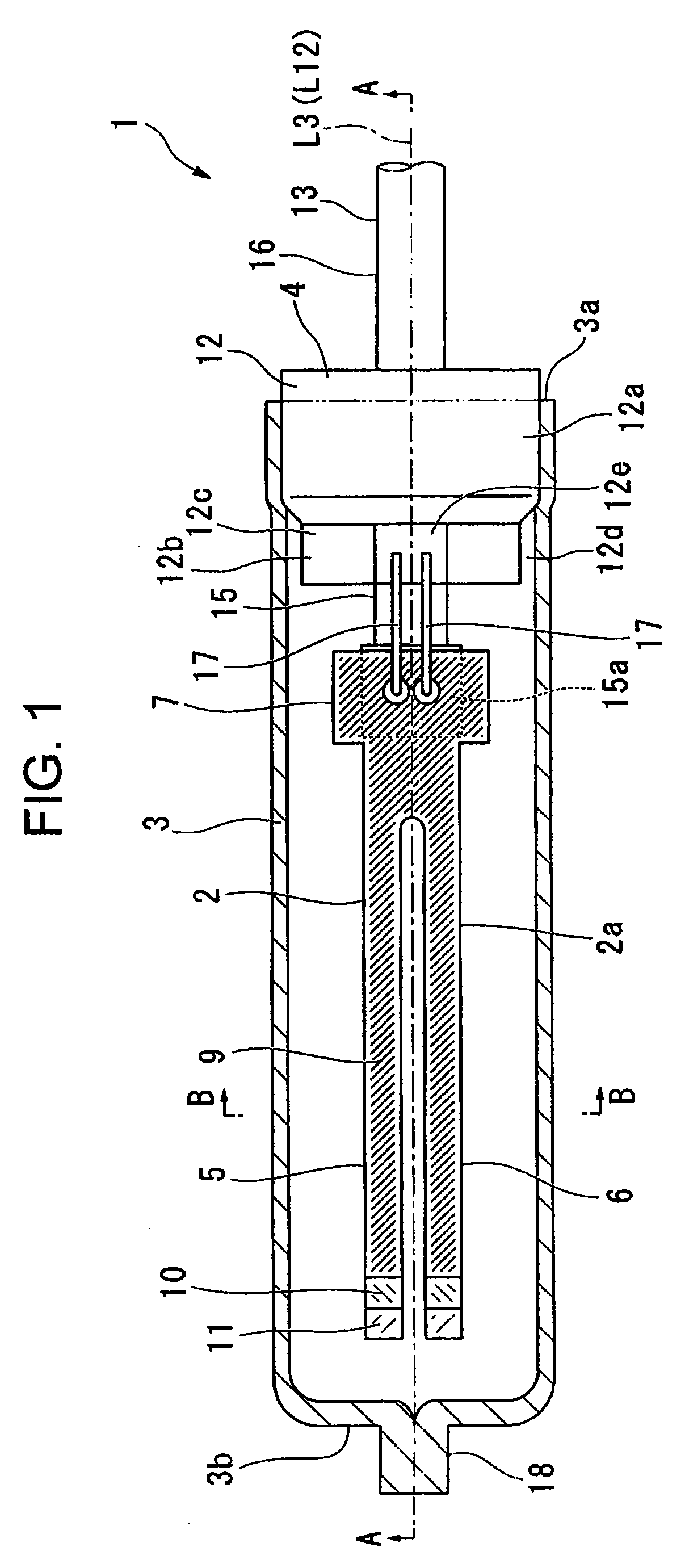

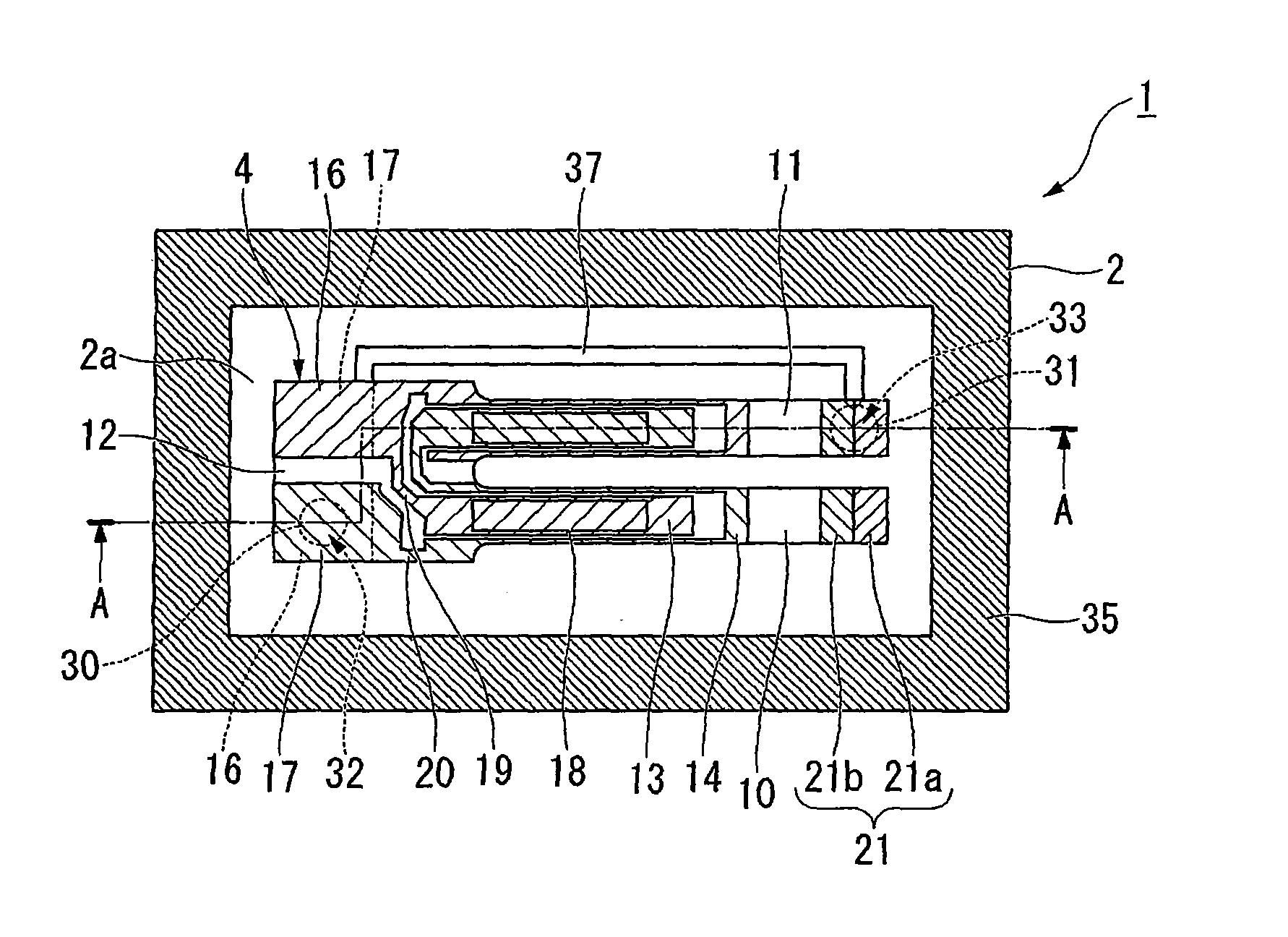

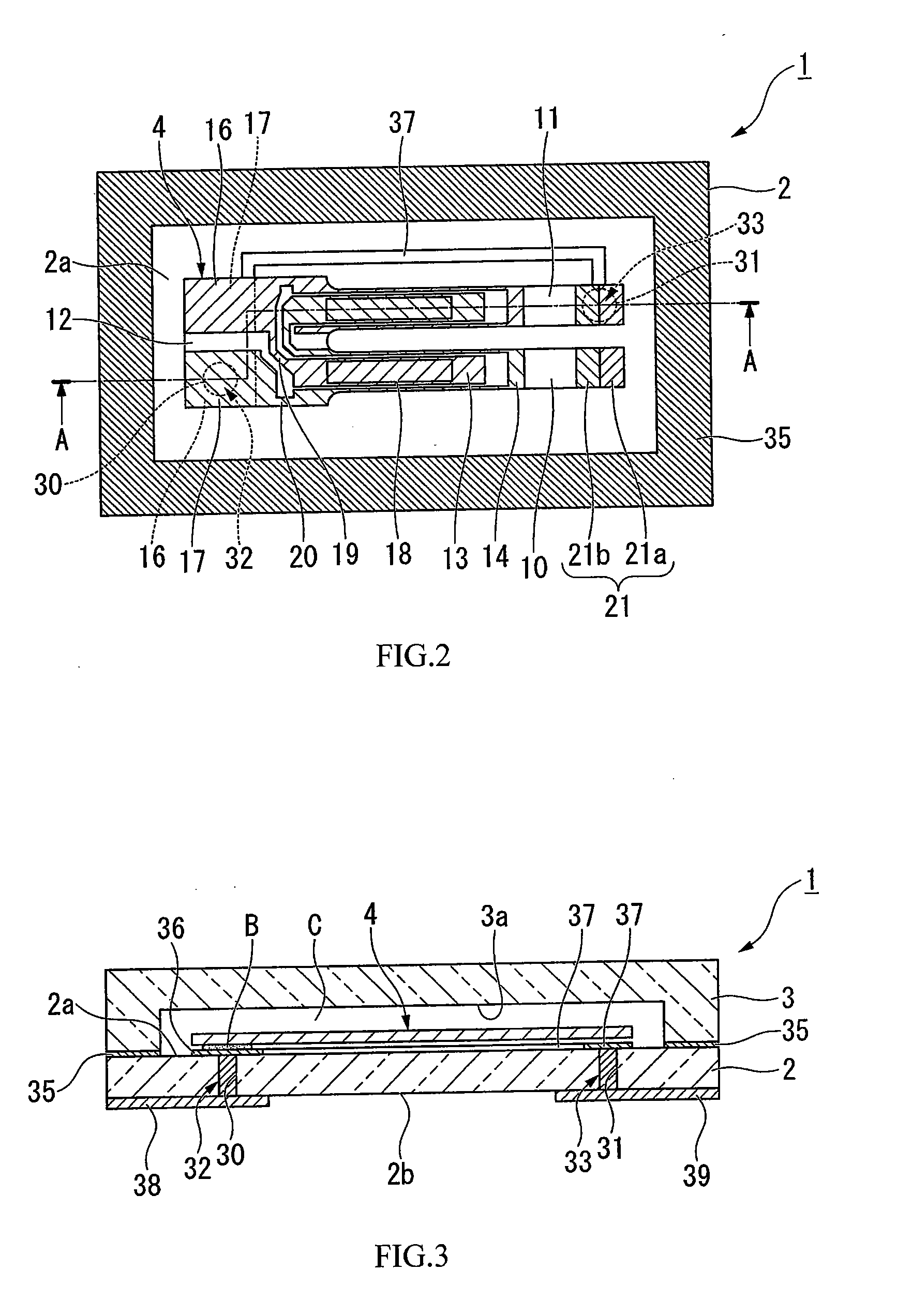

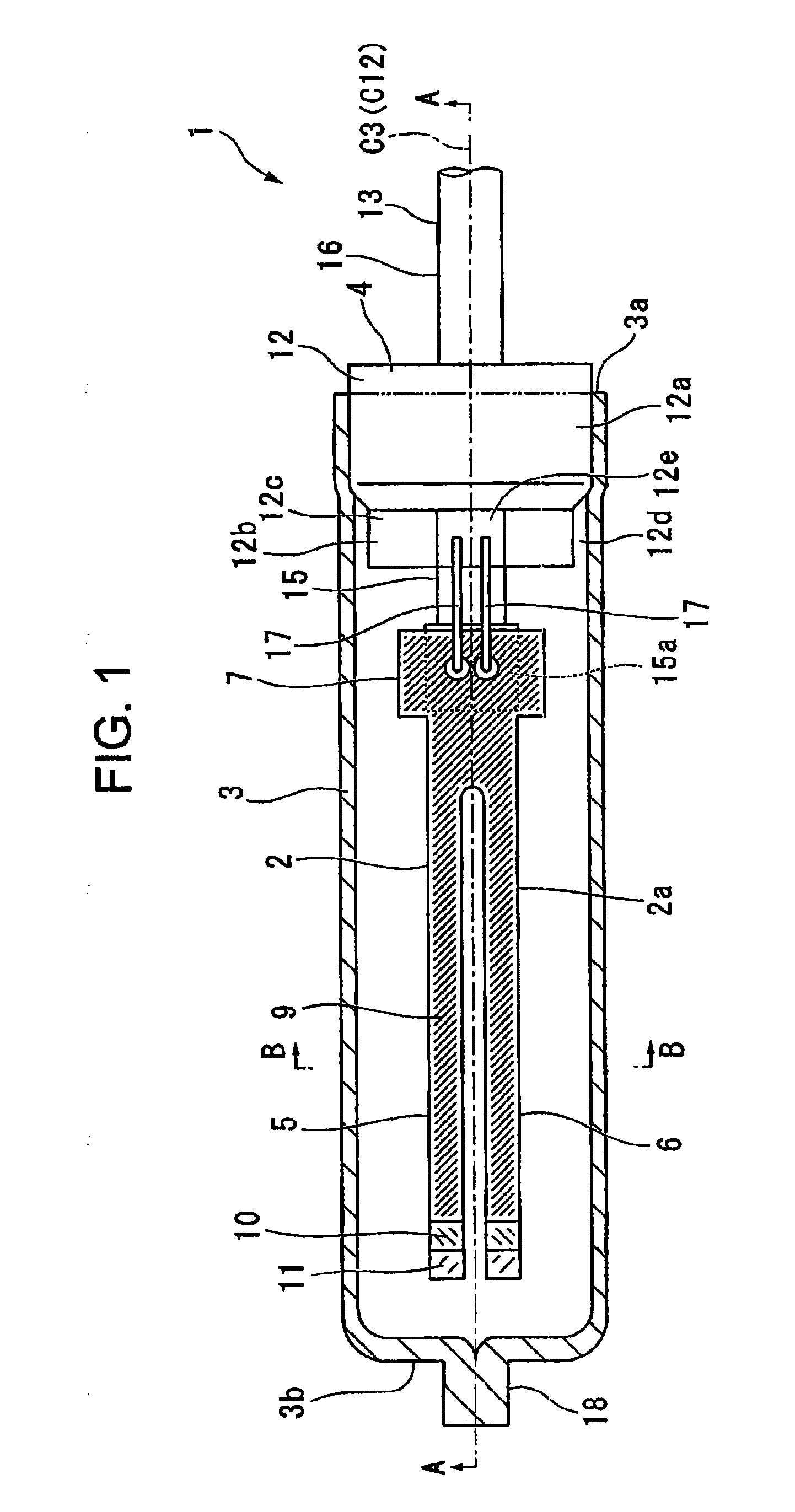

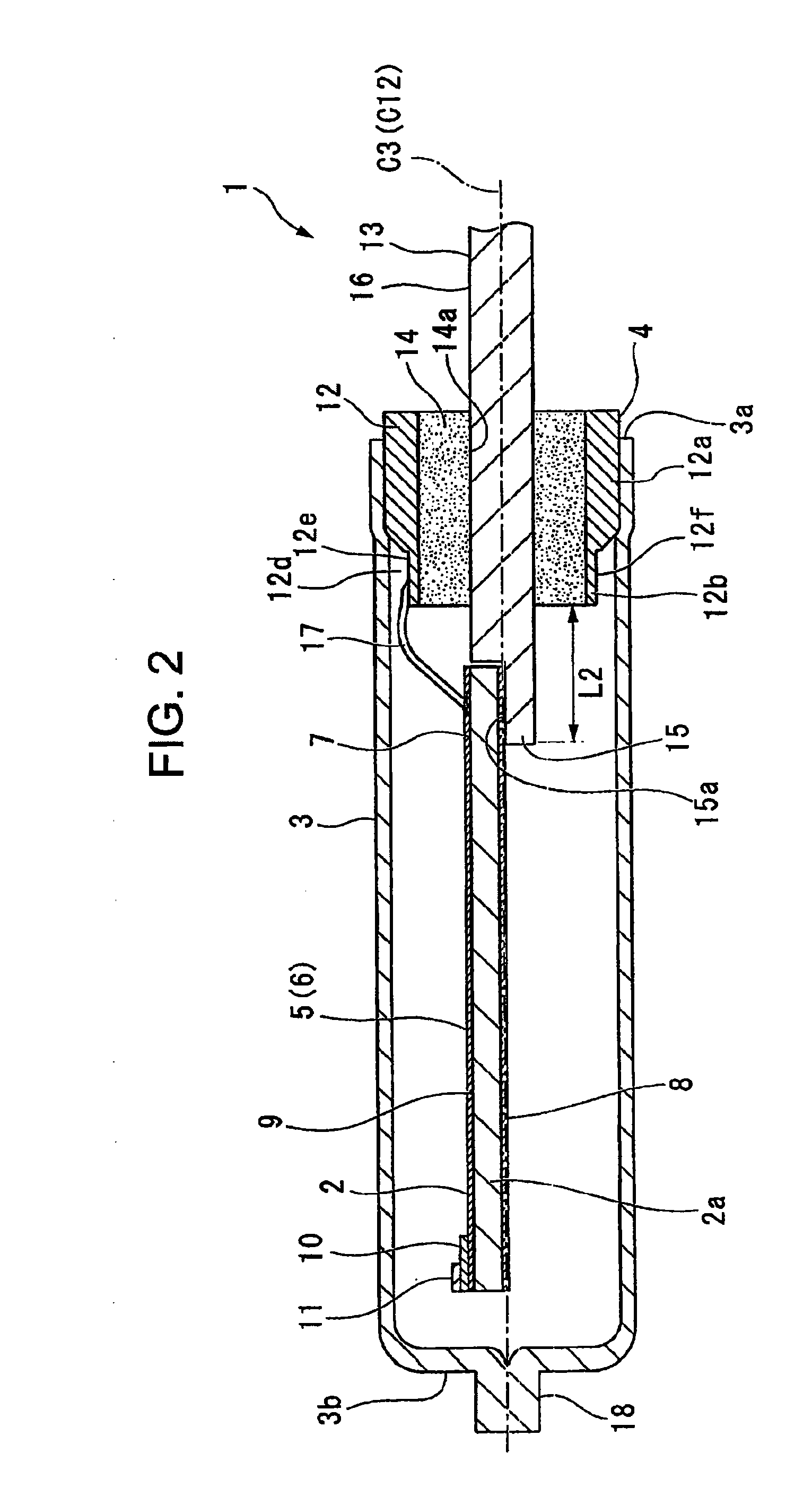

There is provided a piezoelectric vibrator 1 that includes a base substrate 2, a lid substrate 3, a piezoelectric vibrating reed 4, a pair of external electrodes 38 and 39, a pair of through electrodes 32 and 33, and routing electrodes 36 and 37. The lid substrate 3 includes a recess 3a for a cavity and is bonded to the base substrate so that the recess faces the base substrate. The piezoelectric vibrating reed 4 is bonded to the upper surface of the base substrate in a cavity that is formed between both the substrates. The pair of external electrodes 38 and 39 is formed on the lower surface of the base substrate. The pair of through electrodes 32 and 33 is formed so as to pass through the base substrate and is electrically connected to the pair of external electrodes, respectively. The routing electrodes 36 and 37 are formed on the upper surface of the base substrate and electrically connect the pair of through electrodes to the piezoelectric vibrating reed. The through electrodes include electrode films 32a and 33a that are formed on the inner surfaces of the through holes 30 and 31, and glass bodies 32b and 33b that are fixed to the inner surfaces of the through holes with the electrode films interposed therebetween so as to close the through holes.

Owner:SEIKO INSTR INC

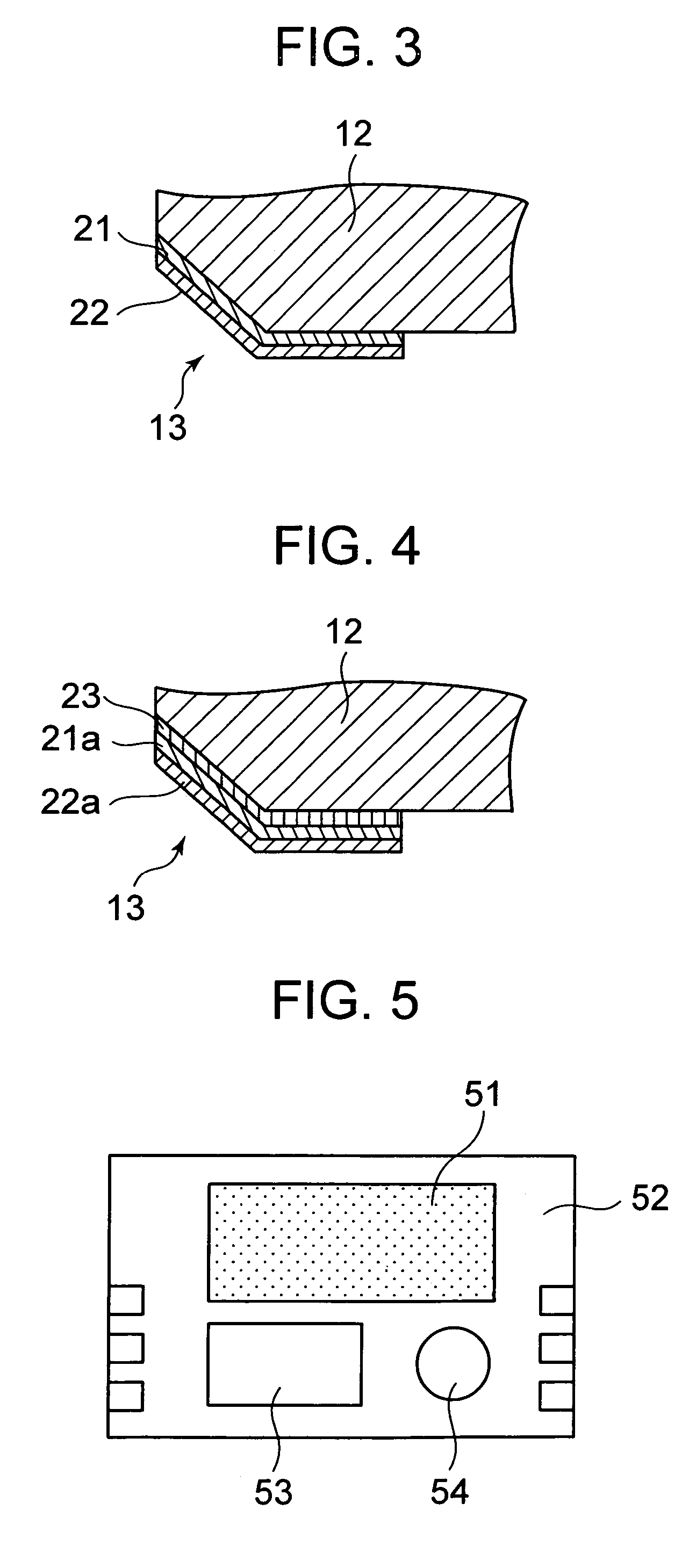

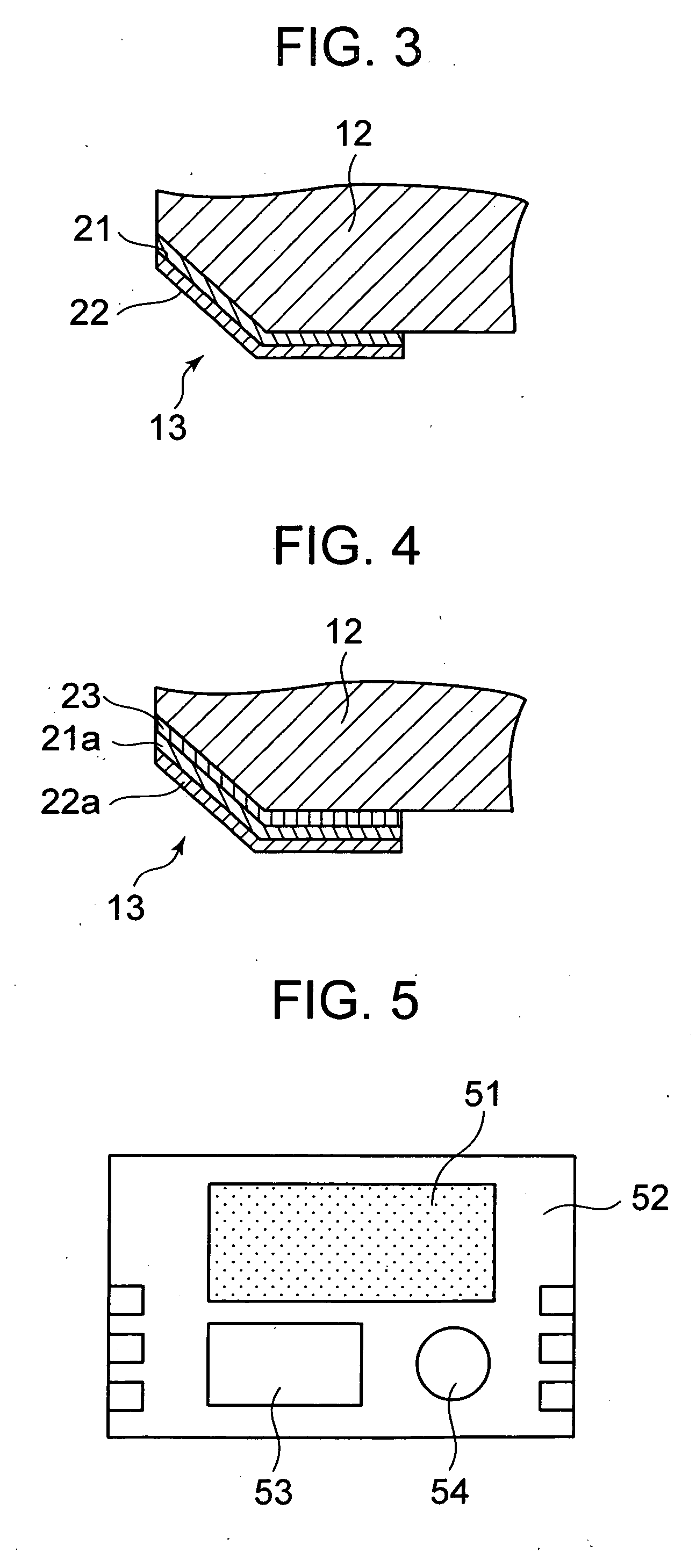

Surface mount type piezoelectric vibrator, oscillator, electronic device, and radio clock

InactiveUS7358652B2Easy to implementPiezoelectric/electrostriction/magnetostriction machinesImpedence networksSurface mountingMetal alloy

A surface mount type piezoelectric vibrator comprises a piezoelectric vibrator piece having an electrode, an airtight container made of glass or a ceramic material for encapsulating the piezoelectric vibrator piece, and an external terminal formed on an exterior surface of the airtight container and connected to the electrode of the piezoelectric vibrator piece. The external terminal comprises a metal alloy of Ni and Cr. A film of Au is formed on a surface of the metal alloy of Ni and Cr.

Owner:SII CRYSTAL TECH

Method of manufacturing piezoelectric vibrator, piezoelectric vibrator, oscillator, electronic device, and radio clock

InactiveUS20100308696A1Improve air tightnessImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesSemiconductor/solid-state device detailsPiezoelectric actuatorsRadio clock

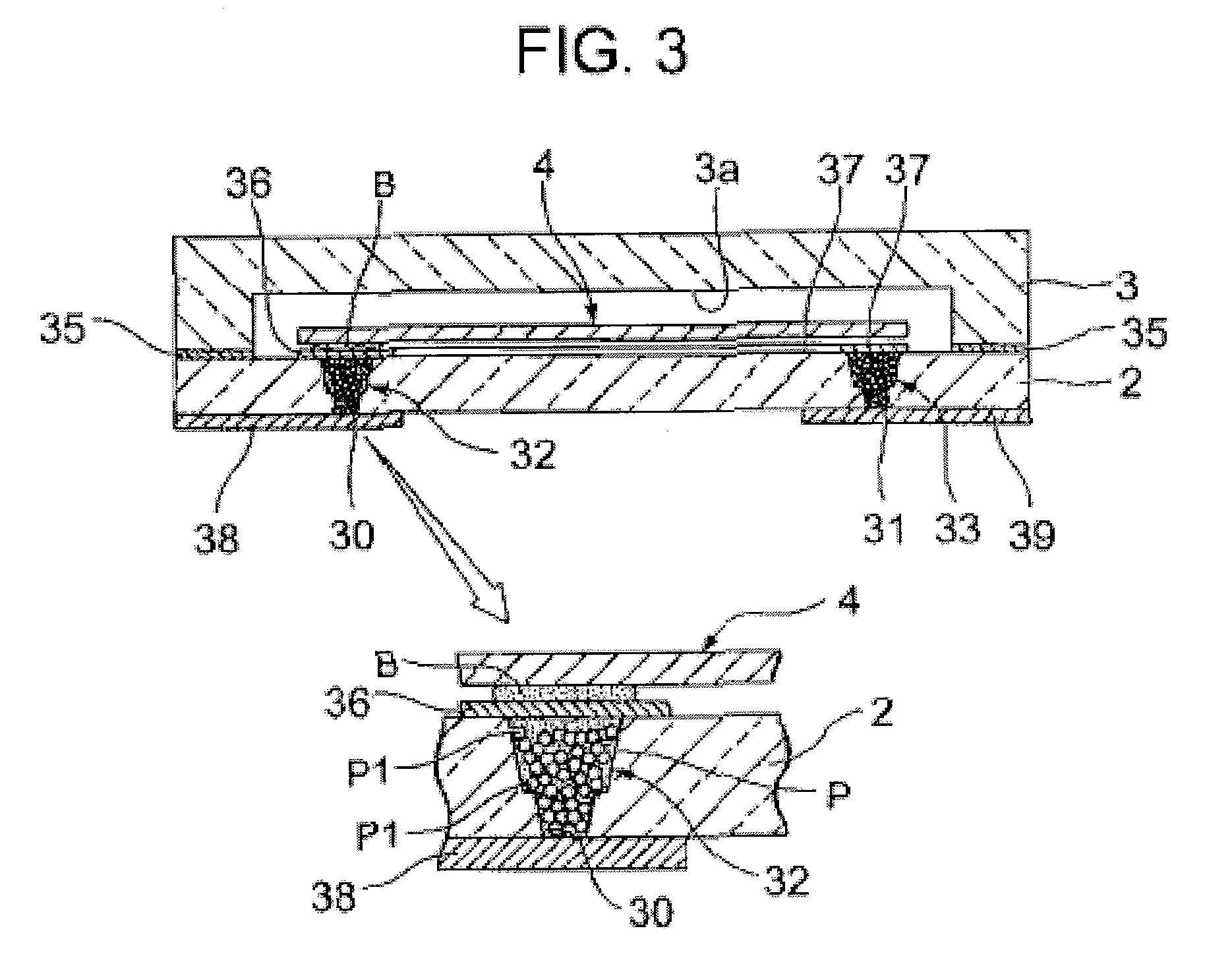

There is provided a piezoelectric vibrator 1 that includes a base substrate 2, a lid substrate 3, a piezoelectric vibrating reed 4, a pair of external electrodes 38 and 39, a pair of through electrodes 32 and 33, and routing electrodes 36 and 37. The lid substrate 3 includes a recess 3a for a cavity and is bonded to the base substrate so that the recess faces the base substrate. The piezoelectric vibrating reed 4 is bonded to the upper surface of the base substrate so as to be received in a cavity that is formed between both the substrates. The pair of external electrodes 38 and 39 is formed on the lower surface of the base substrate. The pair of through electrodes 32 and 33 is formed by hardening paste P, which contains a plurality of metal fine particles and a plurality of metal beads P1, so as to pass through the base substrate, maintains airtightness in the cavity, and is electrically connected to the pair of external electrodes, respectively. The routing electrodes 36 and 37 are formed on the upper surface of the base substrate and electrically connect the pair of through electrodes to the piezoelectric vibrating reed. The melting point of the metal bead is higher than the firing temperature of the paste.

Owner:SEIKO INSTR INC

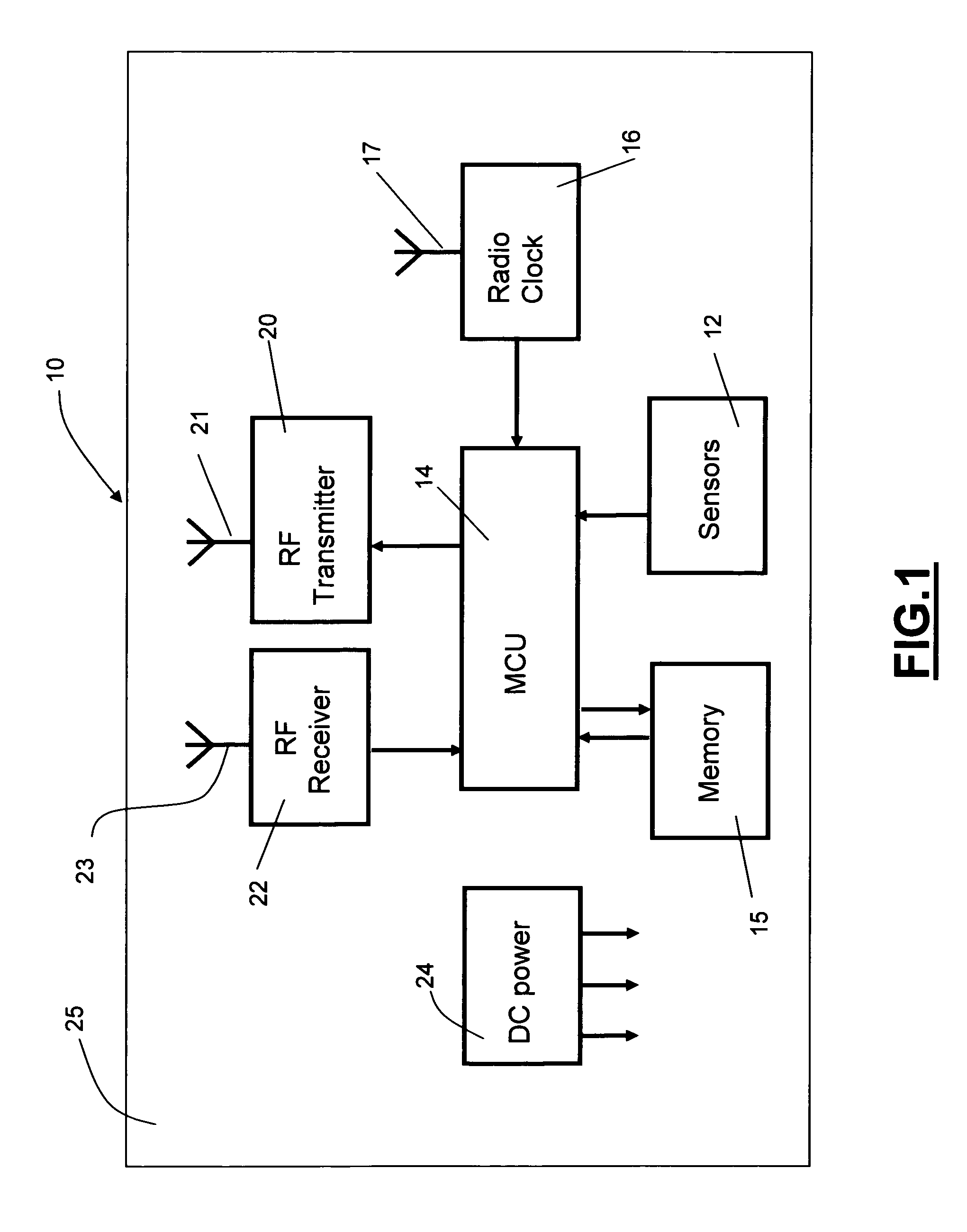

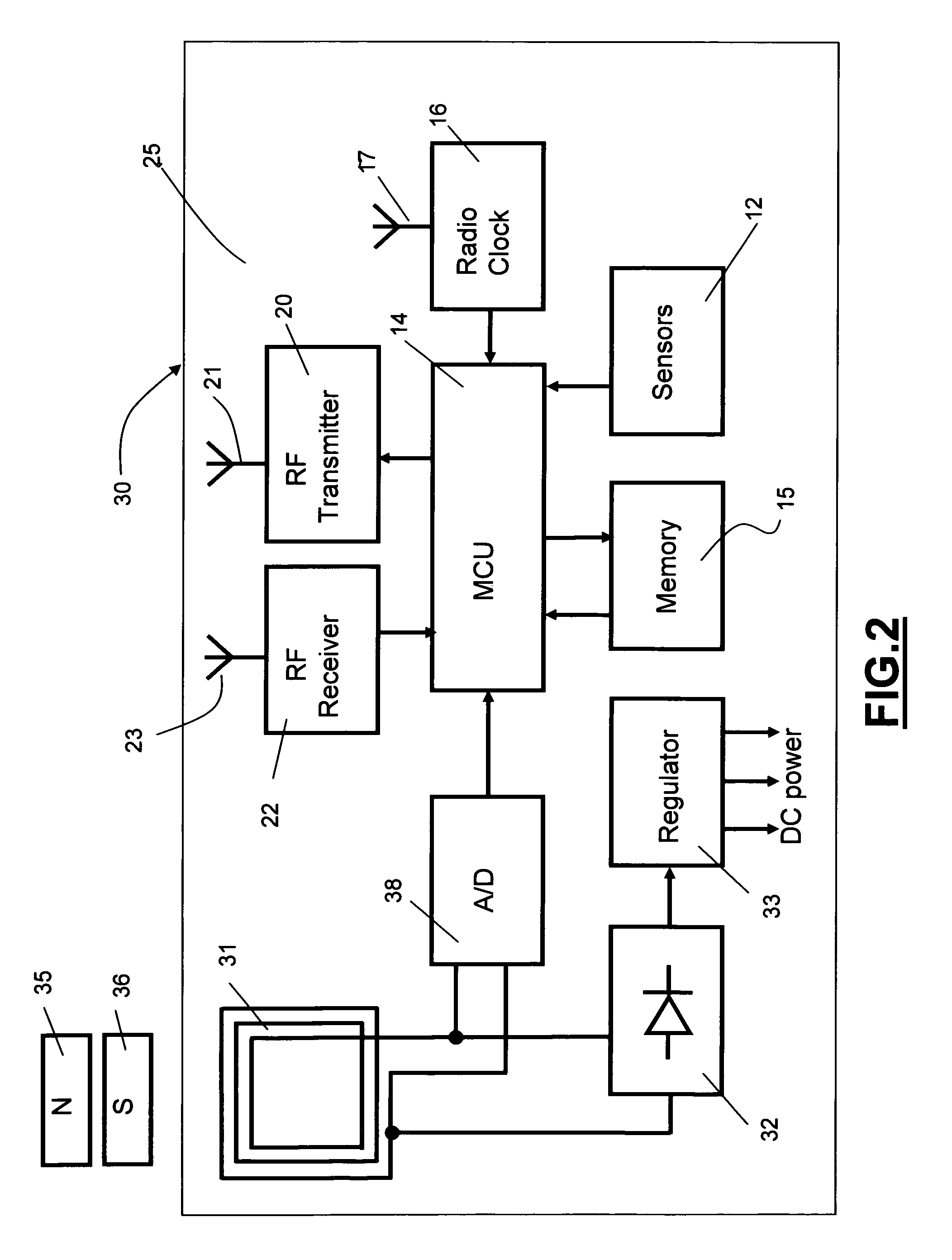

Tire parameter sensor unit with real time data storage

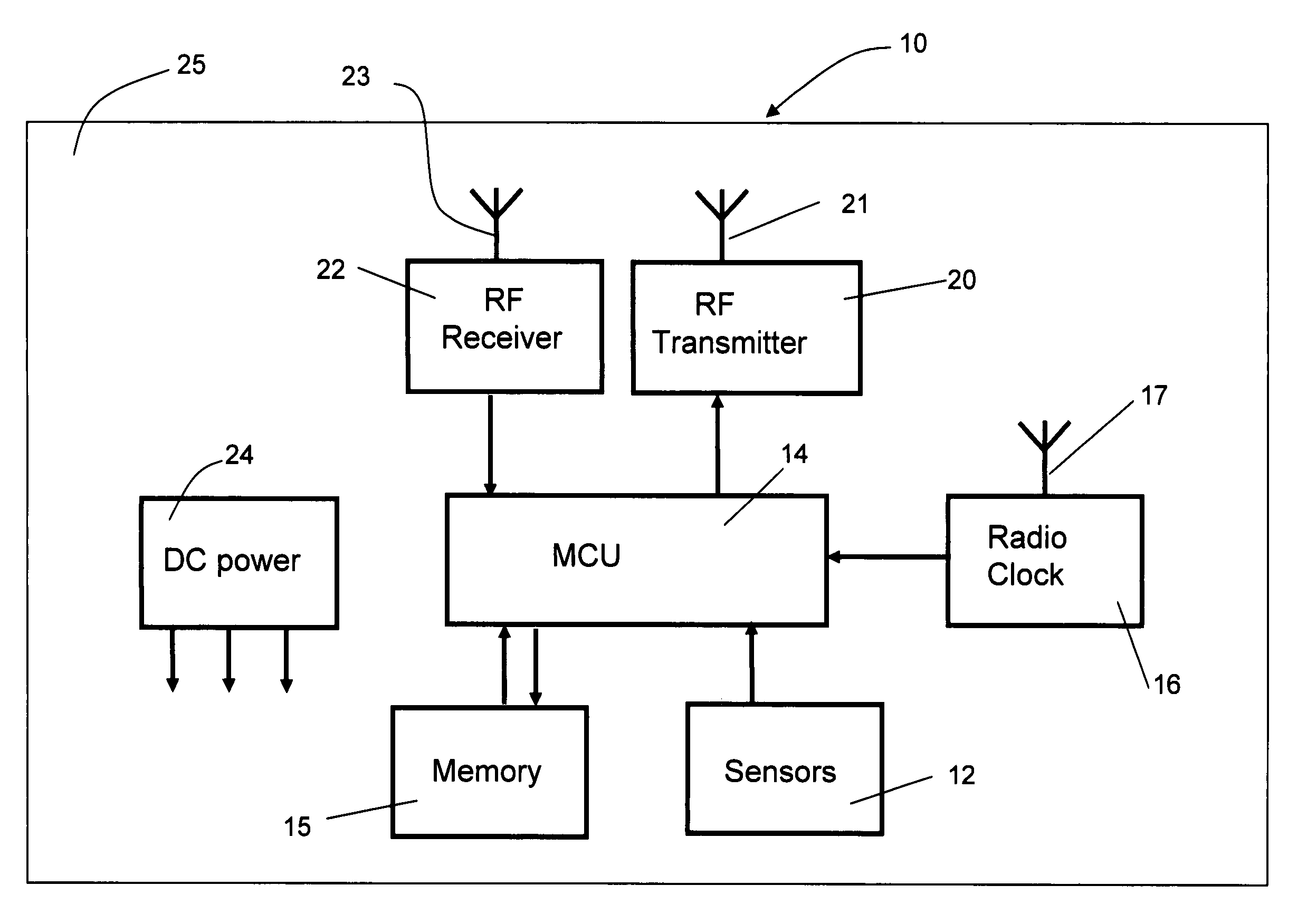

InactiveUS7562568B2Registering/indicating working of vehiclesTyre measurementsInternal pressureReal-time data

A tire parameter sensor unit for monitoring one or more vehicle tire parameters such as internal tire pressure and temperature and developing a permanent log of the operational history of the tire. The sensor unit has a power system, a processor / transmitter, a radio time clock, one or more sensors, and a memory mounted on a substrate. This assembly is permanently attached to the tire in the side wall or tread wall. Initial tire identification information is stored in the memory upon tire fabrication. During the lifetime of the tire, operational information specifying the tire operating conditions (pressure, temperature, etc.) is permanently stored in the memory along with real time data. The operational information and real time data can be read out from memory to provide the history log.

Owner:SILICON VALLEY MICRO C

Surface mount type piezoelectric vibrator, oscillator, electronic device, and radio clock

InactiveUS20060158067A1Easy to implementImpedence networksPiezoelectric/electrostriction/magnetostriction machinesSurface mountingRadio clock

The present invention is enabling to easily solder again in soldering of a surface mount type piezoelectric vibrator. An external electrode is formed by an alloy metal of Cr and Ni, namely, NiCr. Further, on the surface of NiCr, an oxidation resistant film for oxidation resistance is formed by a film of Au. Therefore, in the structure of an external electrode, the layer of NiCr is formed on the surface of glass, and further, the layer of Au is formed thereon. In the meantime, NiCr and Au are deposited by spattering (a spatter method) as a film with a low stress. In the external electrode of such a structure, the layer of Au is dispersed in the solder by soldering, however, since Cr in NiCr reduces the diffusion speed of Ni into the solder, Ni is remained in the external terminal. Since Ni is a metal to make the alloy metal with the solder, it is possible to perform soldering again by removing this quartz crystal vibrator.

Owner:SII CRYSTAL TECH

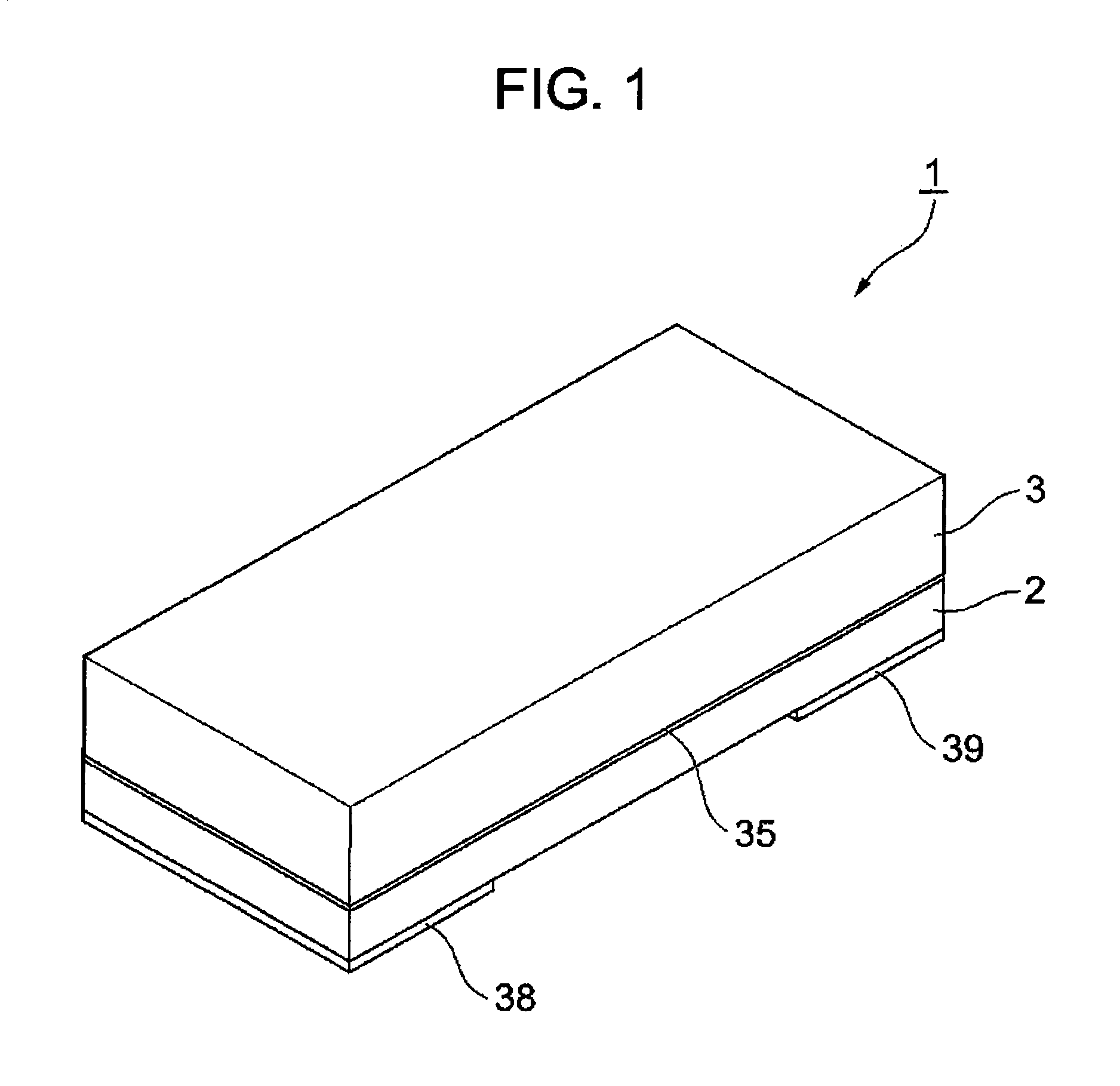

Method of manufacturing piezoelectric vibrator, piezoelectric vibrator, oscillator, electronic device, and radio-clock

InactiveUS20100308695A1Efficient preparationImprove air tightnessPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksPiezoelectric actuatorsRadio clock

There is provided a piezoelectric vibrator 1 that includes a base substrate 2, a lid substrate 3, a piezoelectric vibrating reed 4, a pair of external electrodes 38 and 39, a pair of through electrodes 32 and 33, and routing electrodes 36 and 37. The lid substrate 3 includes a recess 3a for a cavity and is bonded to the base substrate so that the recess faces the base substrate. The piezoelectric vibrating reed 4 is bonded to the upper surface of the base substrate in a cavity that is formed between both the substrates. The pair of external electrodes 38 and 39 is formed on the lower surface of the base substrate. The pair of through electrodes 32 and 33 is formed so as to pass through the base substrate and is electrically connected to the pair of external electrodes, respectively. The routing electrodes 36 and 37 are formed on the upper surface of the base substrate and electrically connect the pair of through electrodes to the piezoelectric vibrating reed. The through electrodes include electrode films 32a and 33a that are formed on the inner surfaces of the through holes 30 and 31, and glass bodies 32b and 33b that are fixed to the inner surfaces of the through holes with the electrode films interposed therebetween so as to close the through holes.

Owner:SEIKO INSTR INC

Method for timing a clock

A method for timing a radio clock includes the steps of initiating the photoelectric element to sense the references on the hour hand, the minute hand and the second hand, determining whether a reference that stands for the second hand is detected, stopping the second hand at a zero position when the reference that stands for the second hand is detected, initiating the motors of the hour and the minute hands, revolving the hour and minute hand wheels until a reference mark on the hour hand wheel is detected, stopping the hour hand wheel and the minute hand wheel when the reference mark of the minute hand wheel is detected by the photoelectric element; and synchronizing the hour hand, the minute hand and the second hand with readings of the hour, the minute and the second of a time signal sent from a time station.

Owner:PENG KOUNG CHUNG

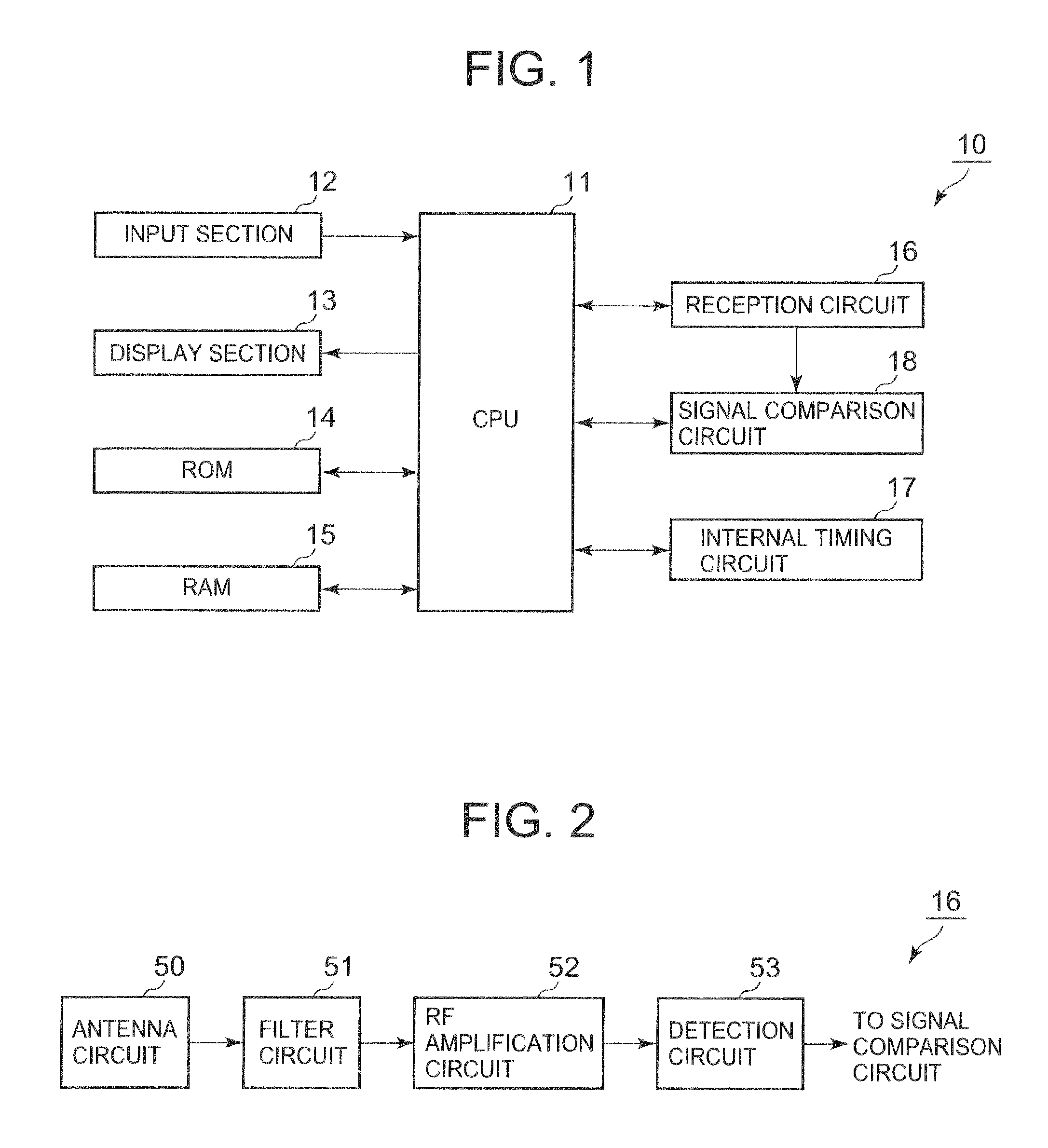

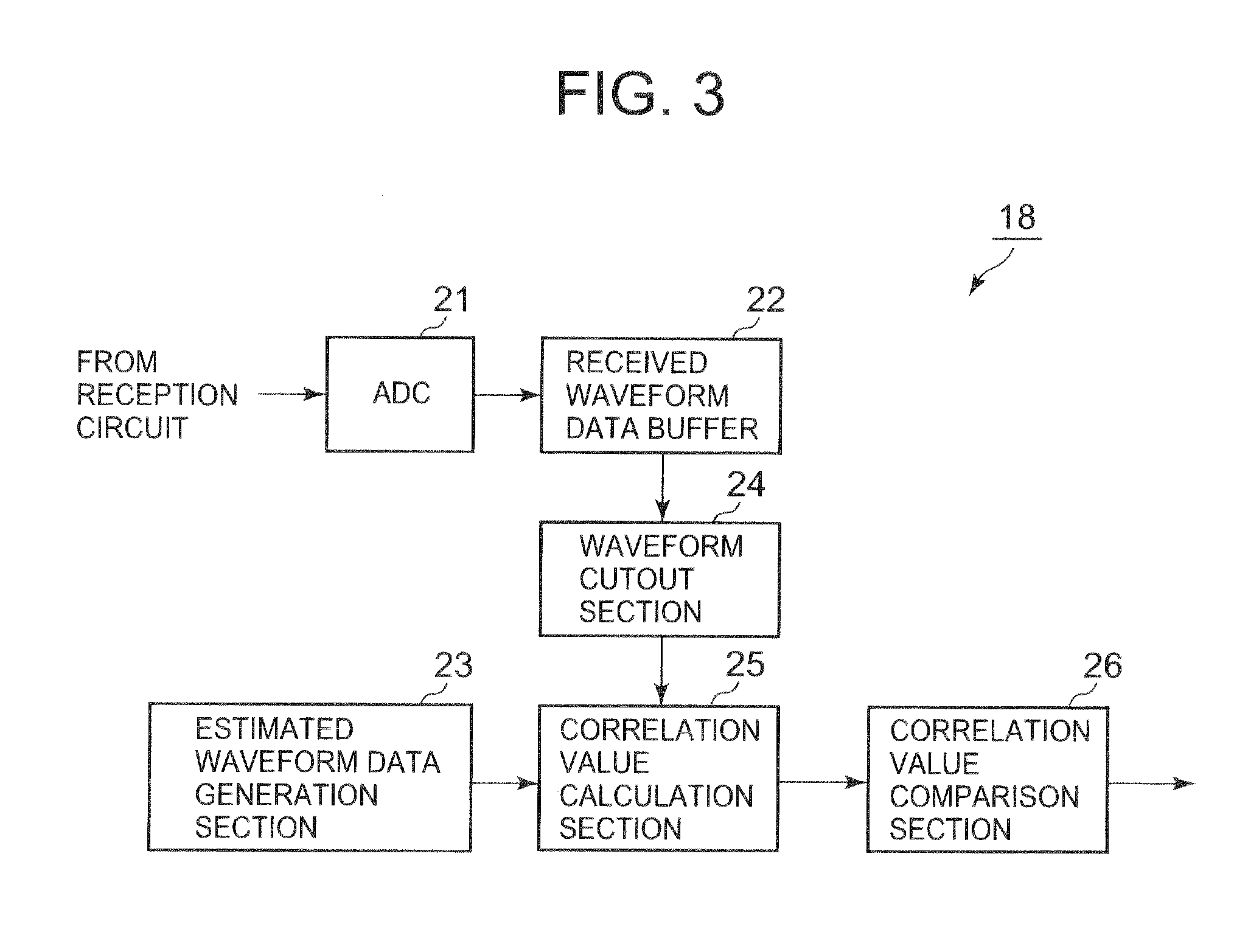

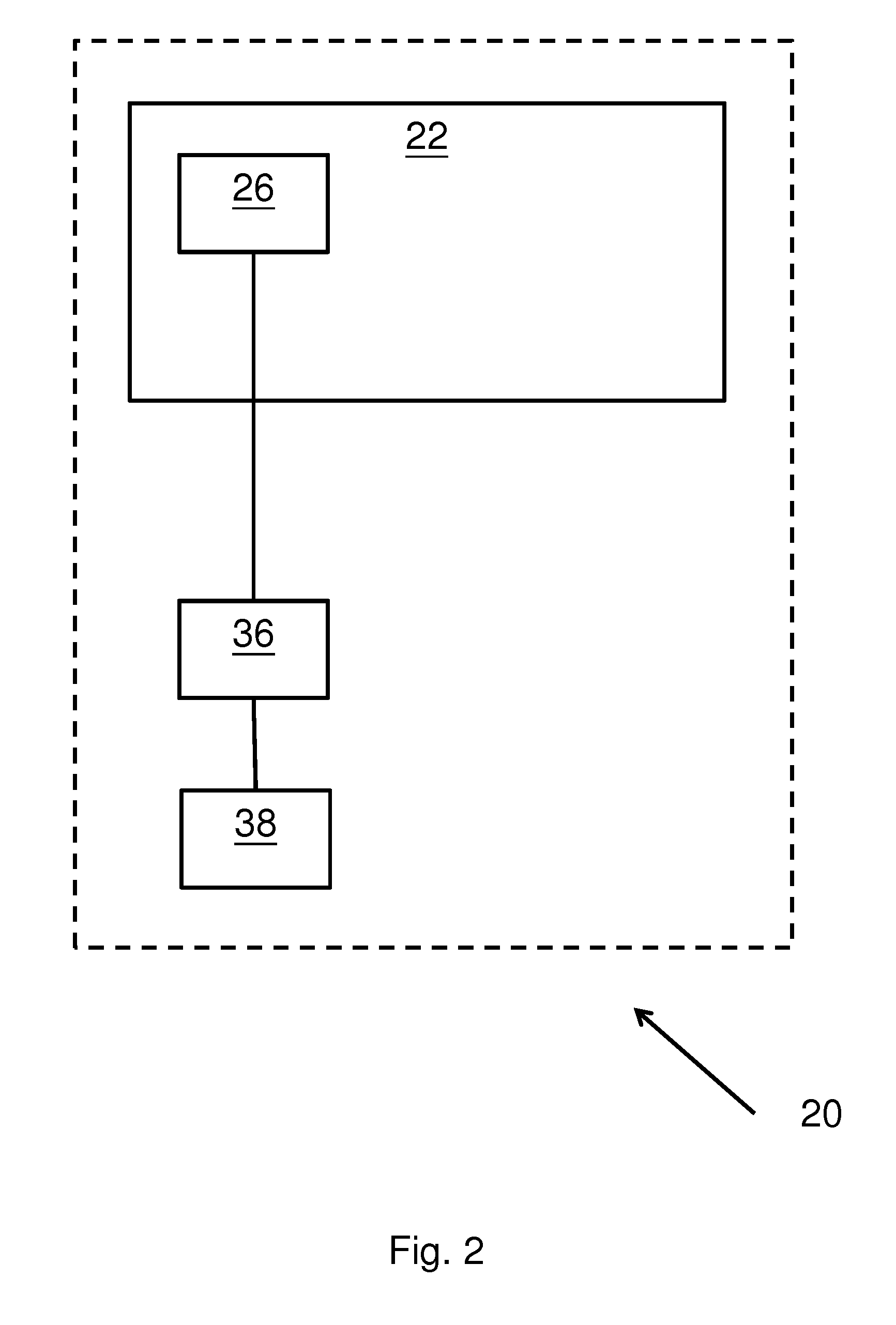

Time information obtaining device and radio clock

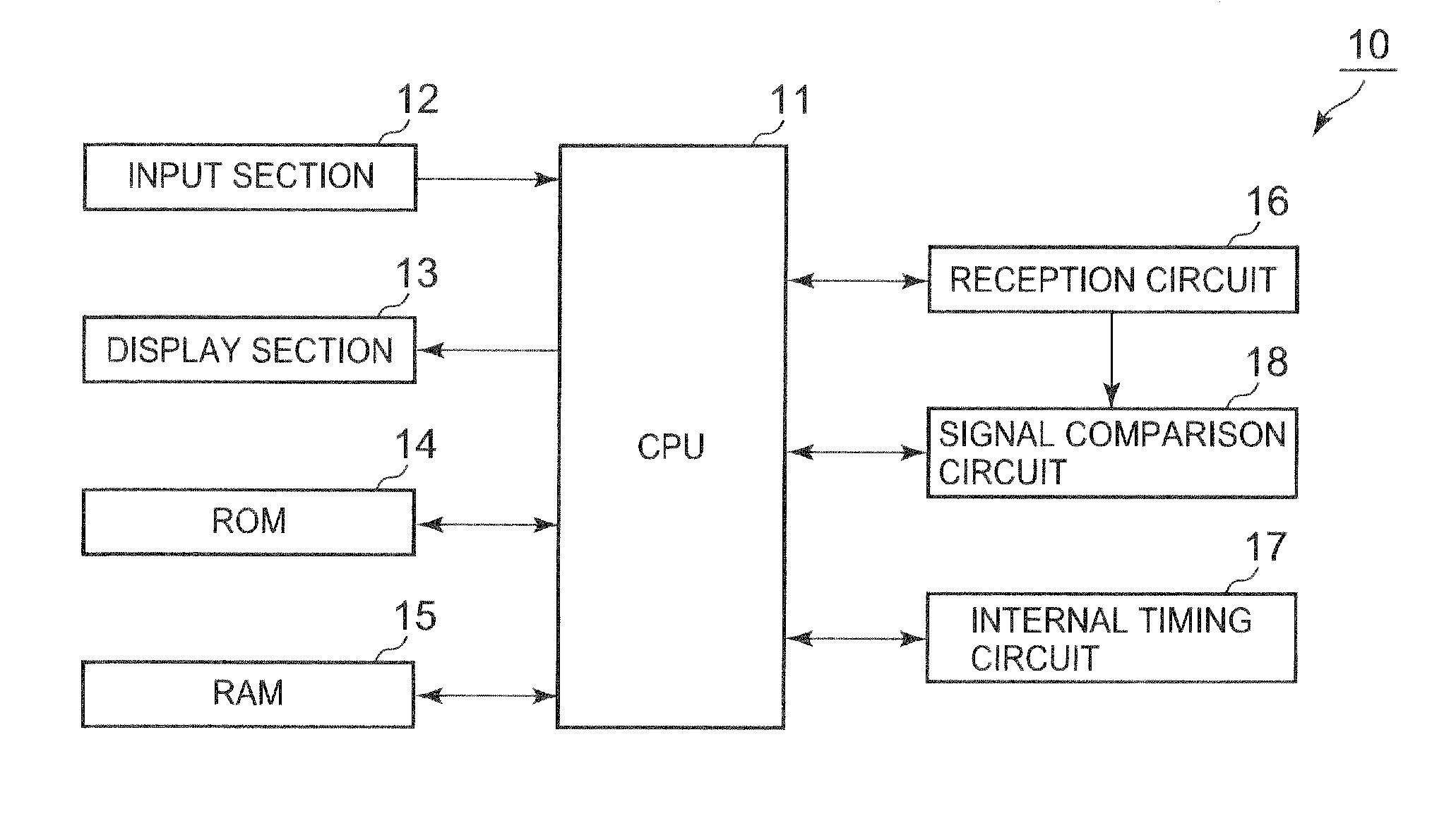

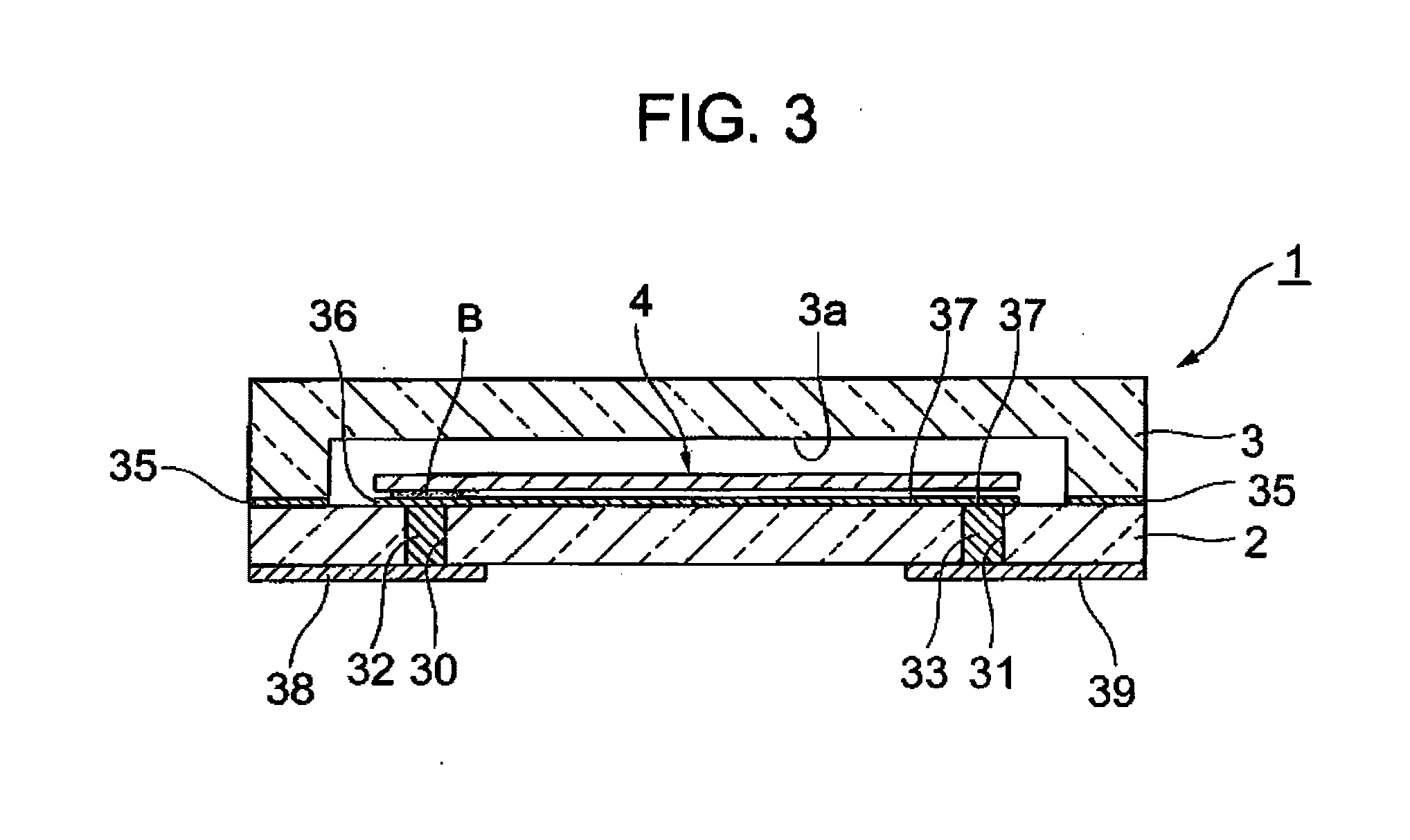

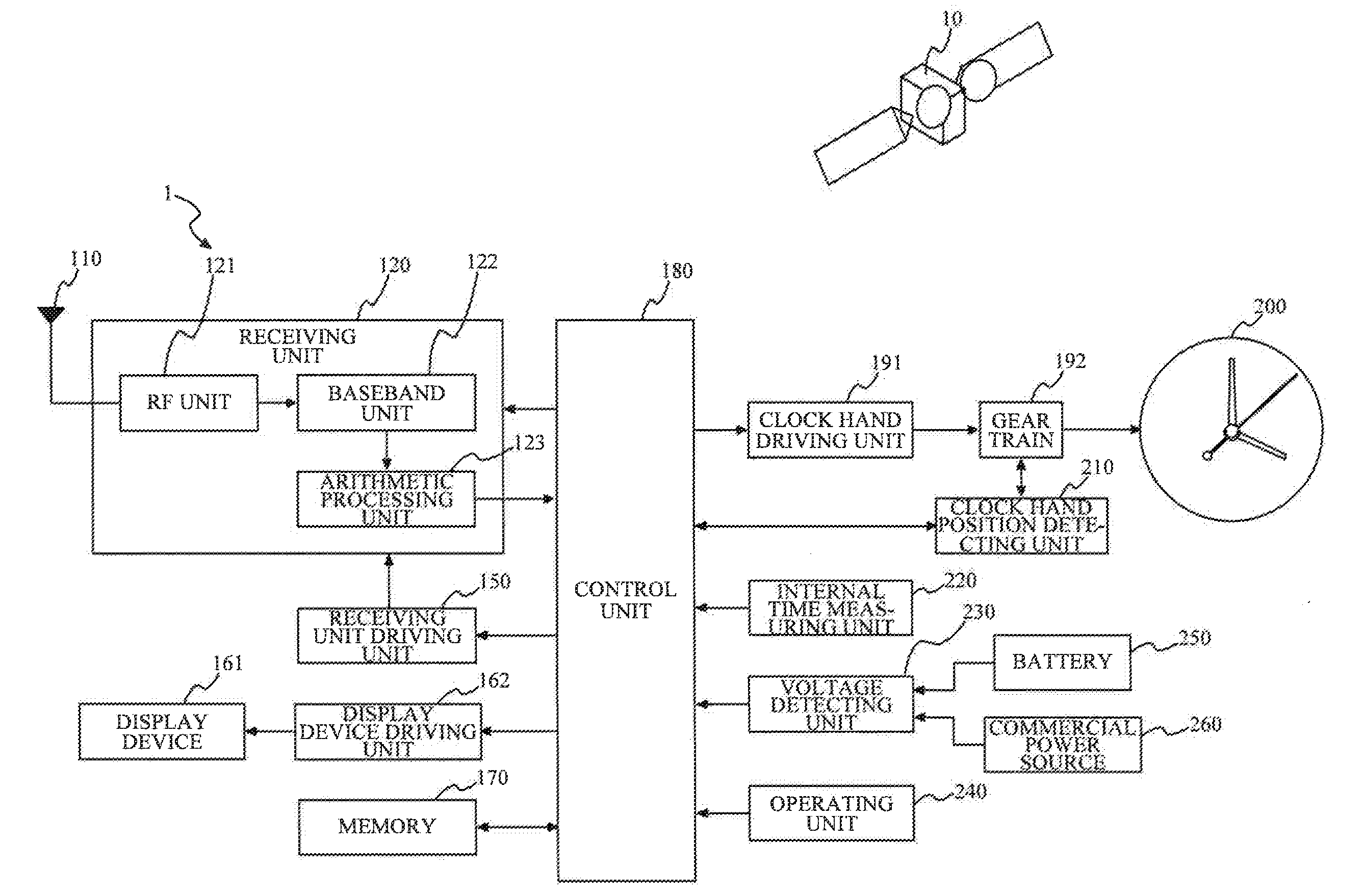

ActiveUS20100014388A1Synchronous motors for clocksTime-pieces with integrated devicesTime informationUnit of time

Disclosed is a time information obtaining device comprising: a reception section to receive a standard time radio wave; an input waveform data generation section to generate input waveform data, based on data having the unit of time length; an estimated waveform data generation section to generate estimated waveform data, wherein the estimated waveform data comprises the value in which each sample point is described by the plurality of bits, and has the same time length as the input waveform data, and comprises at least one code which configures the time code, and a waveform of the estimated waveform data is sequentially shifted by a predetermined sample; a correlation value calculation section to calculate a correlation value; a correlation value comparison section to compare the correlation value to calculate an optimal value; and a control section to specify a beginning position of a second in the time code.

Owner:CASIO COMPUTER CO LTD

Method of manufacturing piezoelectric vibrator, piezoelectric vibrator, oscillator, electronic device, and radio clock

InactiveUS20100313399A1InhibitionQuality improvementPiezoelectric/electrostrictive device manufacture/assemblyLamination ancillary operationsRadio clockEngineering

When a base substrate where through electrodes are formed is anodically bonded to a lid substrate that includes a bonding film formed on the entire lower surface thereof, a method of manufacturing a piezoelectric vibrator includes a superimposing process for superimposing the lid substrate on the base substrate so that a piezoelectric vibrating reed is received in a cavity, after bonding the piezoelectric vibrating reed to the upper surface of the base substrate; a setting process for placing a dummy member, which is made of a material in which ions can be transferred at a bonding temperature, on an electrode plate, and placing the superimposed substrates on the dummy member so that the base substrate faces the dummy member; and an applying process for applying a bonding voltage between the electrode plate and the bonding film after heating the dummy member and the substrates up to the bonding temperature.

Owner:SII CRYSTAL TECH

Method of manufacturing piezoelectric vibrator, piezoelectric vibrator, oscillator, electronic device, and radio clock

InactiveUS8069543B2Efficient preparationImprove air tightnessPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive resonant transducersRadio clockElectrical and Electronics engineering

There is provided a piezoelectric vibrator 1 that includes a base substrate 2, a lid substrate 3, a piezoelectric vibrating reed 4, a pair of external electrodes 38 and 39, a pair of through electrodes 32 and 33, and routing electrodes 36 and 37. The lid substrate 3 includes a recess 3a for a cavity and is bonded to the base substrate so that the recess faces the base substrate. The piezoelectric vibrating reed 4 is bonded to the upper surface of the base substrate so as to be received in a cavity that is formed between both the substrates. The pair of external electrodes 38 and 39 is formed on the lower surface of the base substrate. The pair of through electrodes 32 and 33 is formed by hardening paste P, which contains a plurality of metal fine particles and a plurality of metal beads P1, so as to pass through the base substrate, maintains airtightness in the cavity, and is electrically connected to the pair of external electrodes, respectively. The routing electrodes 36 and 37 are formed on the upper surface of the base substrate and electrically connect the pair of through electrodes to the piezoelectric vibrating reed. The melting point of the metal bead is higher than the firing temperature of the paste.

Owner:SEIKO INSTR INC

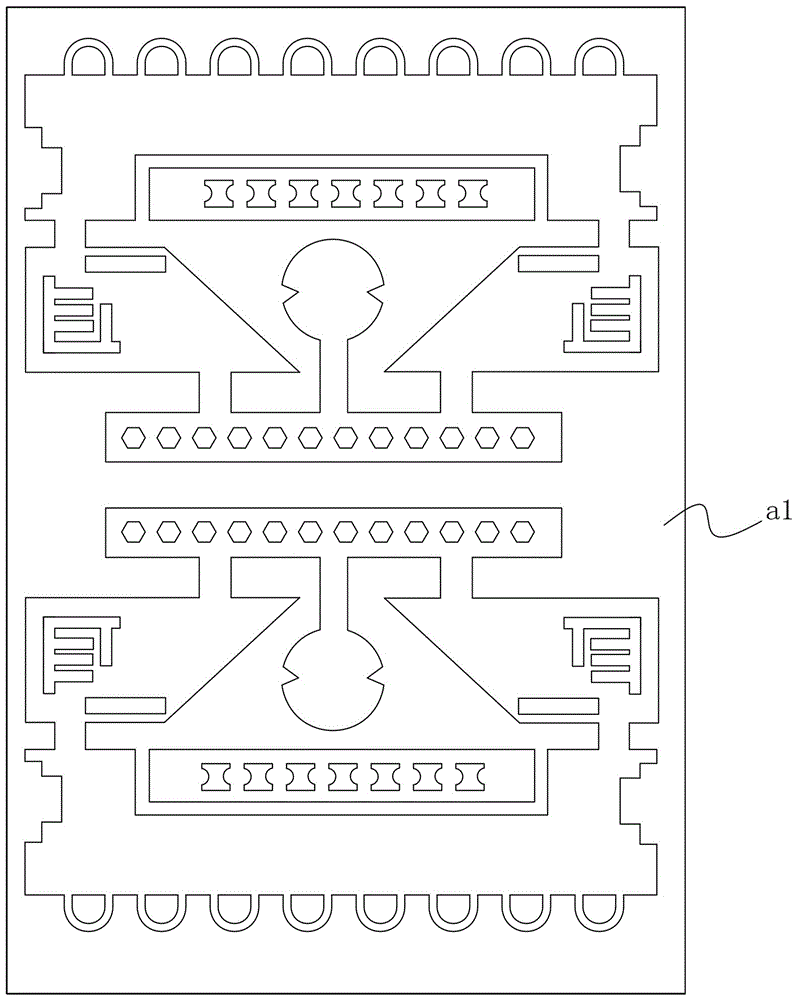

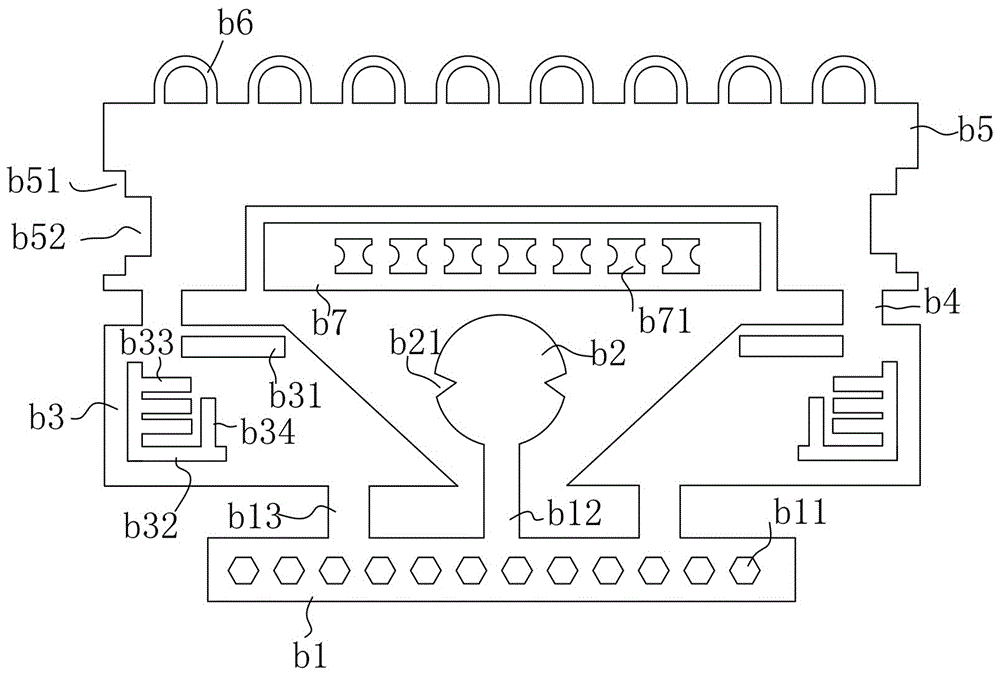

Method of manufacturing a package, and package, electronic device, piezoelectric vibrator, oscillator, electronic apparatus, and radio clock

InactiveUS20100236038A1Quality improvementLow costPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksScreen printingPiezoelectric actuators

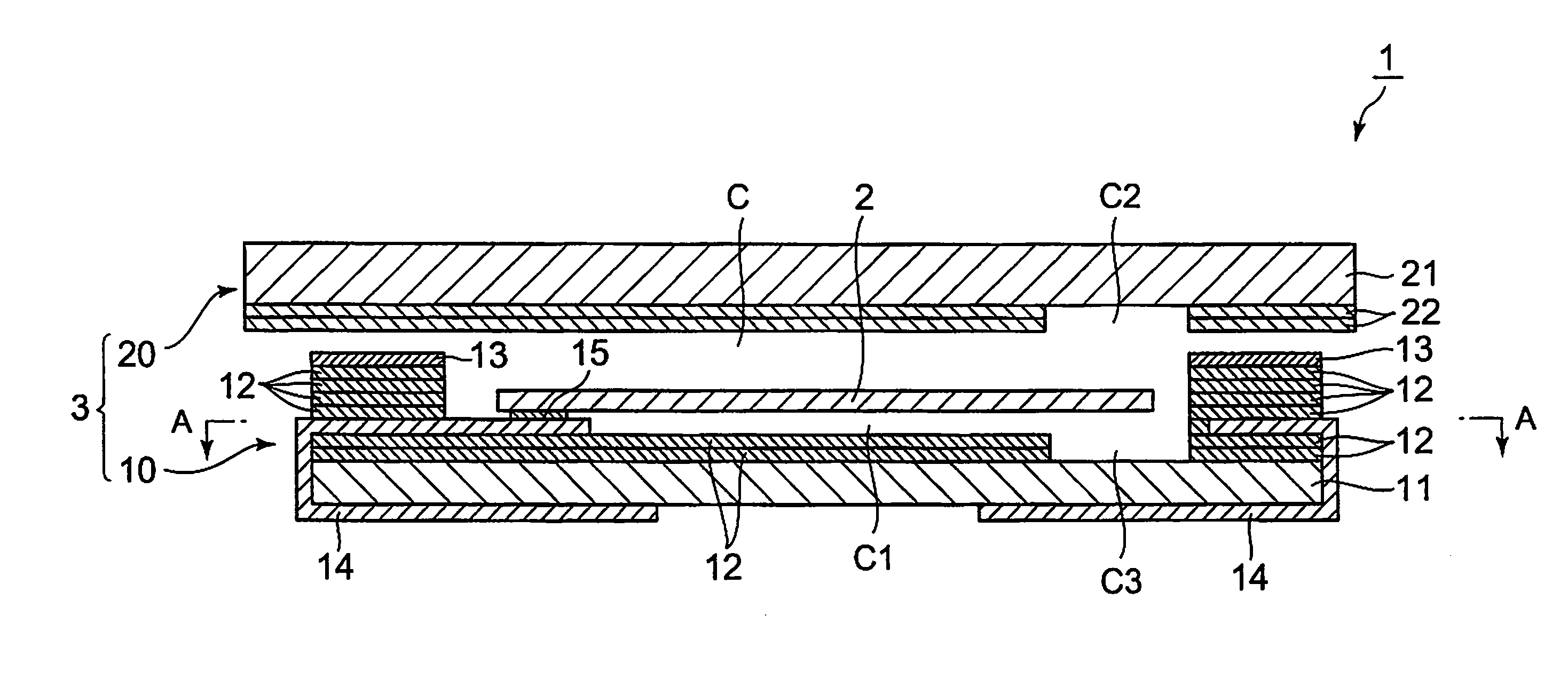

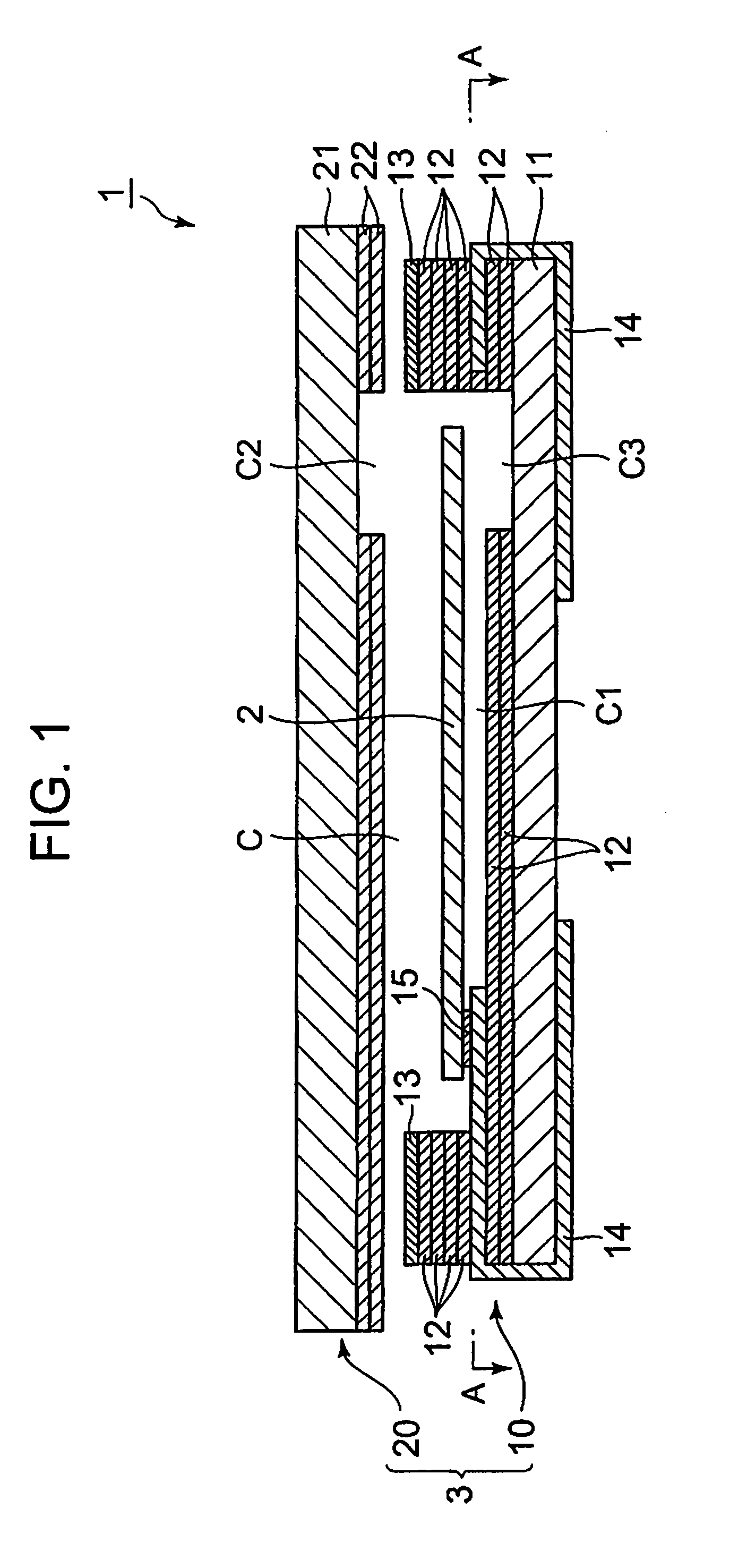

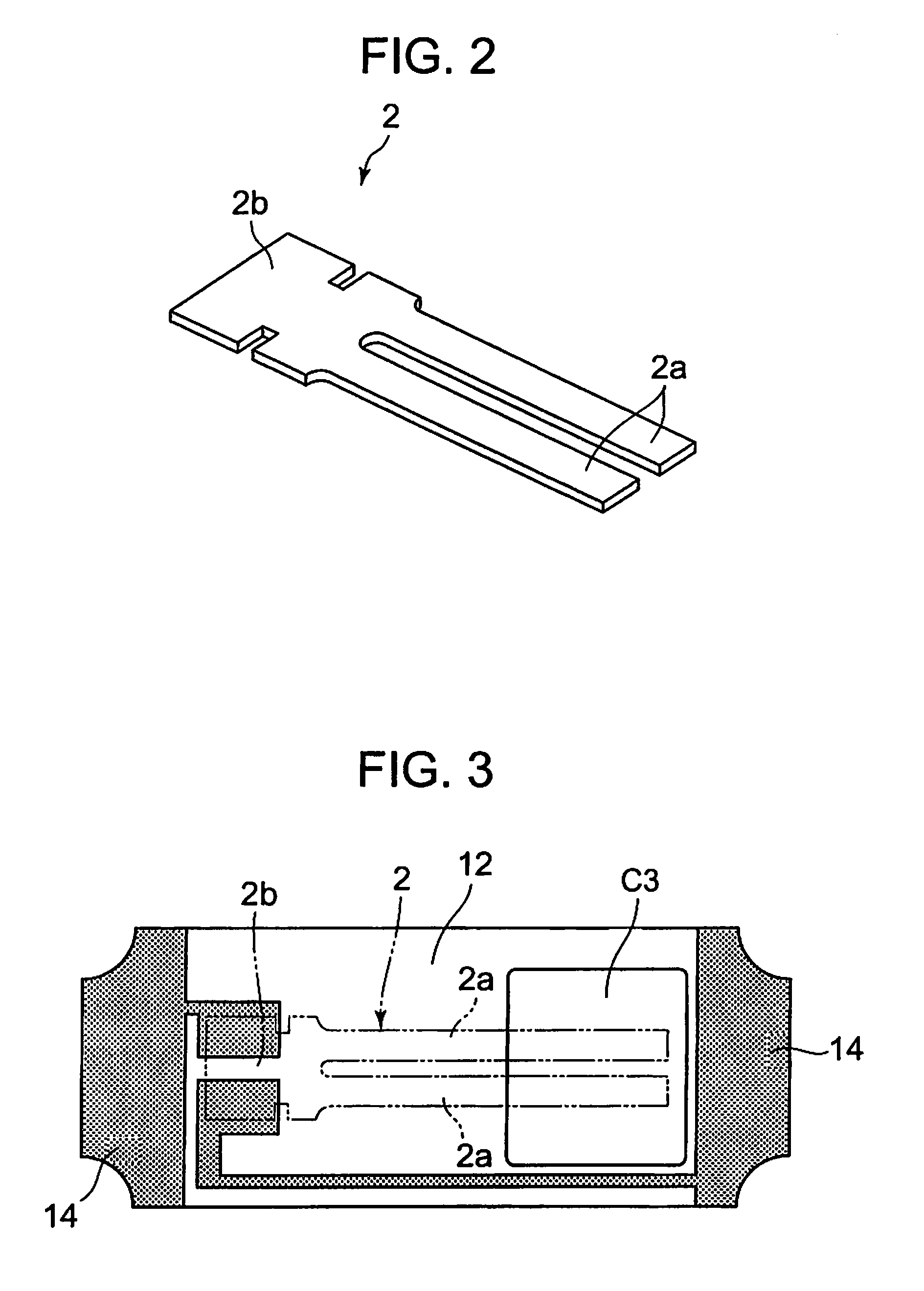

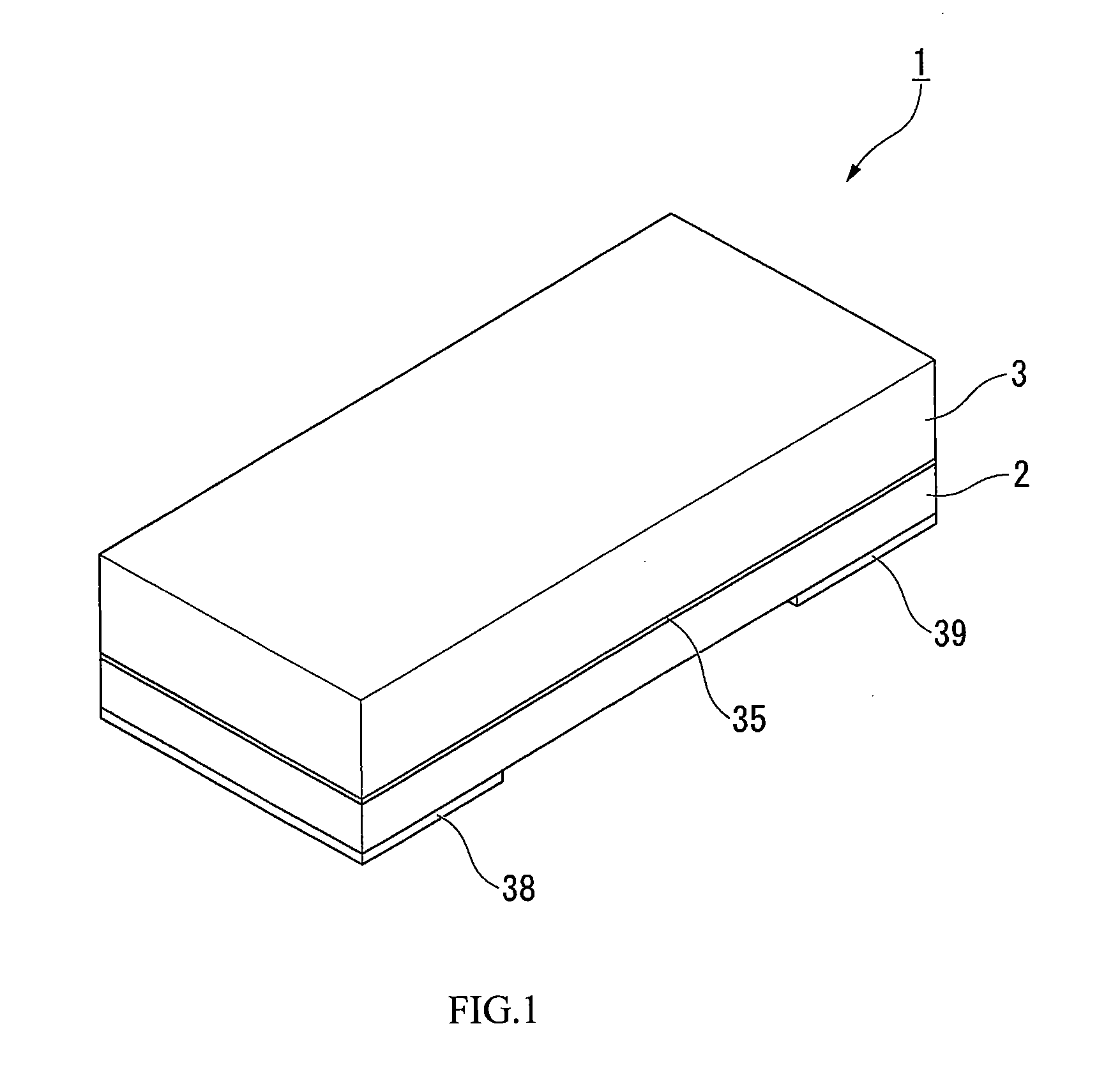

There is There is provided a method of manufacturing a package 1 having a base substrate 10 and a lid substrate 20 bonded to each other and both formed of a glass base material; and a cavity C formed between the both substrates for storing an encapsulated object 2 in a state of being hermetically encapsulated, including: a depression forming step for forming a depression C1 for a cavity which defines the cavity when the both substrates are superimposed to each other on at least one of the both substrates; and a bonding step for superimposing the both substrates so as to store the encapsulated object in the depression and then bonding the both substrates to encapsulate the encapsulated object in the cavity, characterized in that in the depression forming step, printed layers 12 are laminated on an upper surface of a flat plate-shaped glass base material 11 in a frame shape in plan view by screen printing, and then the printed layers and the glass base material are baked at the same time to form the depression.

Owner:SII CRYSTAL TECH

Method of manufacturing piezoelectric vibrator, piezoelectric vibrator, oscillator, electronic device, and radio clock

InactiveUS20100301709A1Improve air tightnessImprove reliabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsRadio clock

There is provided a piezoelectric vibrator 1 that includes a base substrate 2, a lid substrate 3, a piezoelectric vibrating reed 4, a pair of external electrodes 38 and 39, a pair of through electrodes 32 and 33, and routing electrodes 36 and 37. Both surfaces of the base substrate 2 are polished. The lid substrate 3 includes a recess 3a for a cavity C and is bonded to the base substrate. The piezoelectric vibrating reed 4 is bonded to the upper surface of the base substrate so as to be received in a cavity that is formed between the base substrate and the lid substrate. The pair of external electrodes 38 and 39 is formed on the lower surface of the base substrate. The pair of through electrodes 32 and 33 is formed so as to pass through the base substrate, maintains airtightness in the cavity, and is electrically connected to the pair of external electrodes, respectively. The routing electrodes 36 and 37 are formed on the upper surface of the base substrate and electrically connect the pair of through electrodes to the bonded piezoelectric vibrating reed. The through electrodes are formed by the hardening of paste that contains a plurality of nonspherical metal fine particles.

Owner:SII CRYSTAL TECH

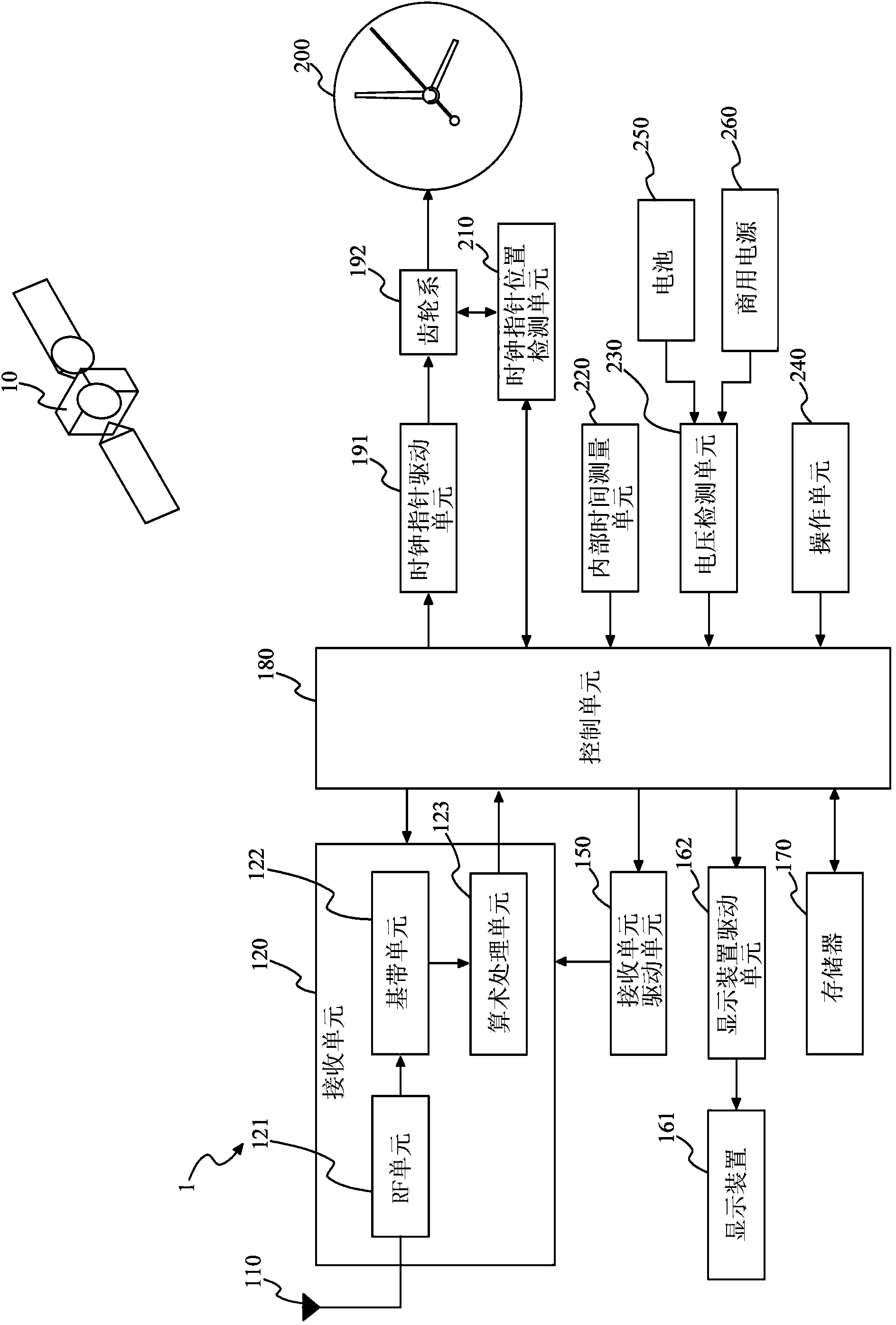

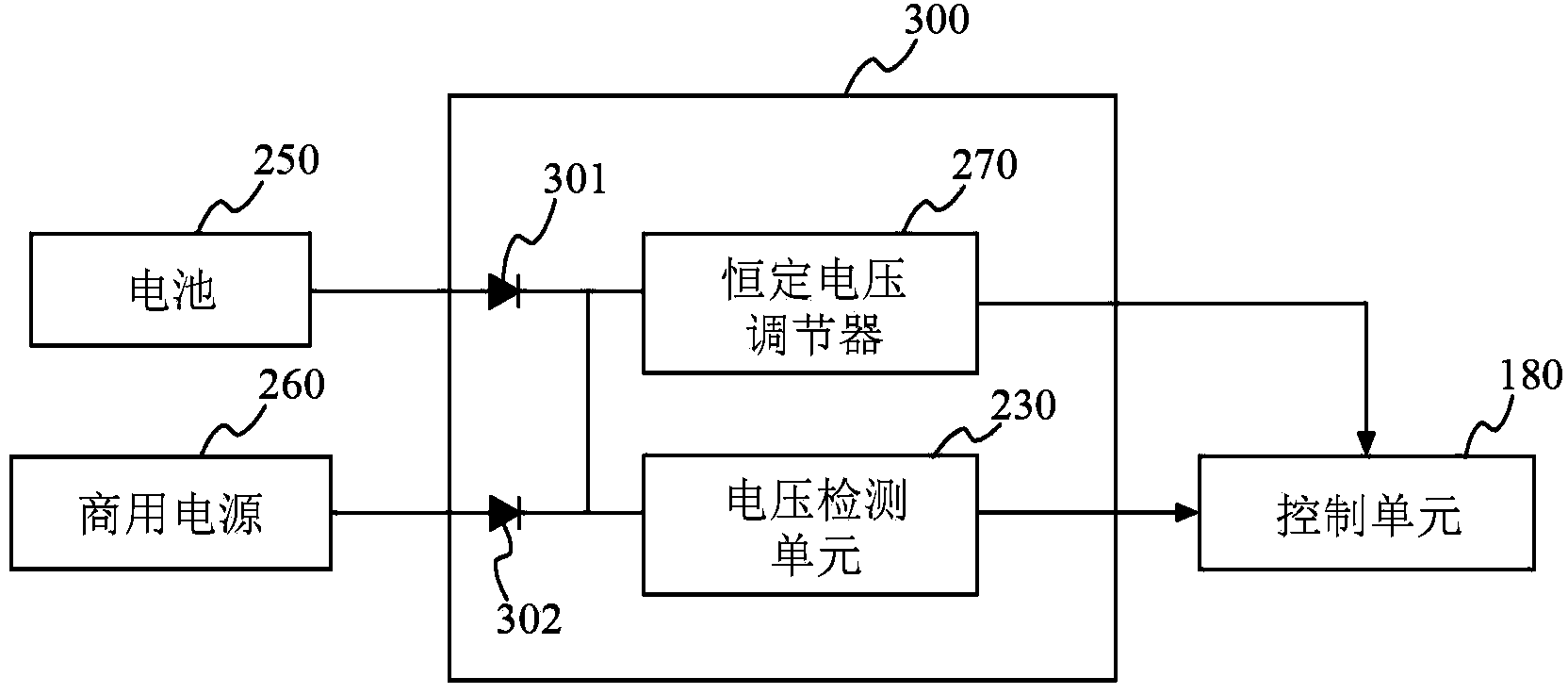

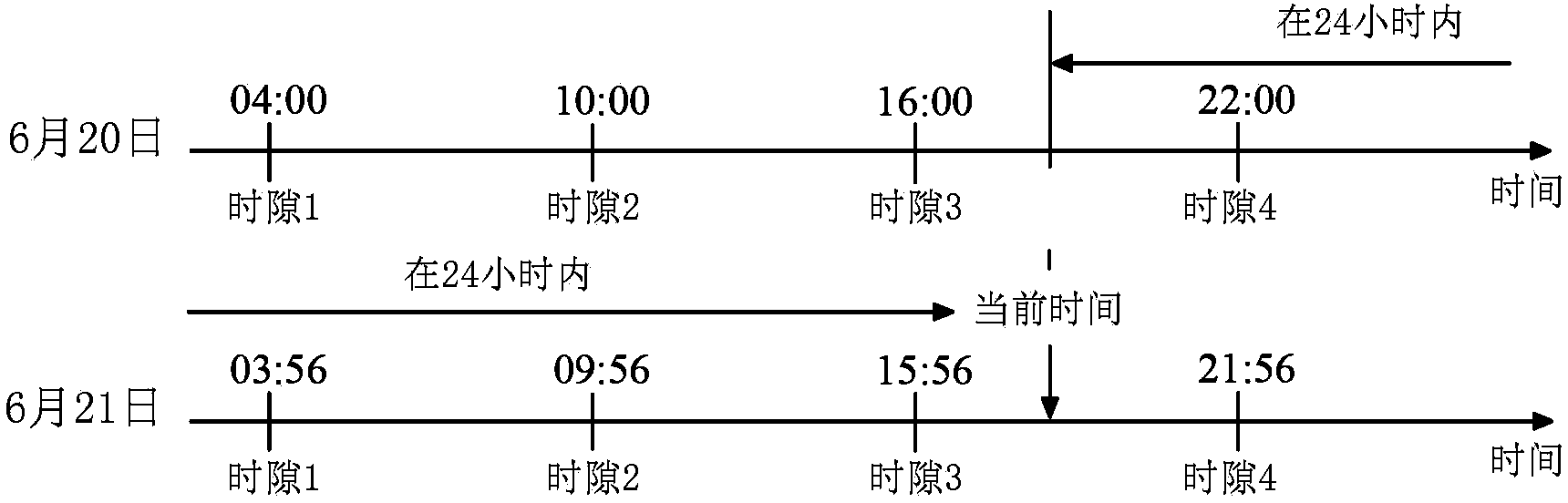

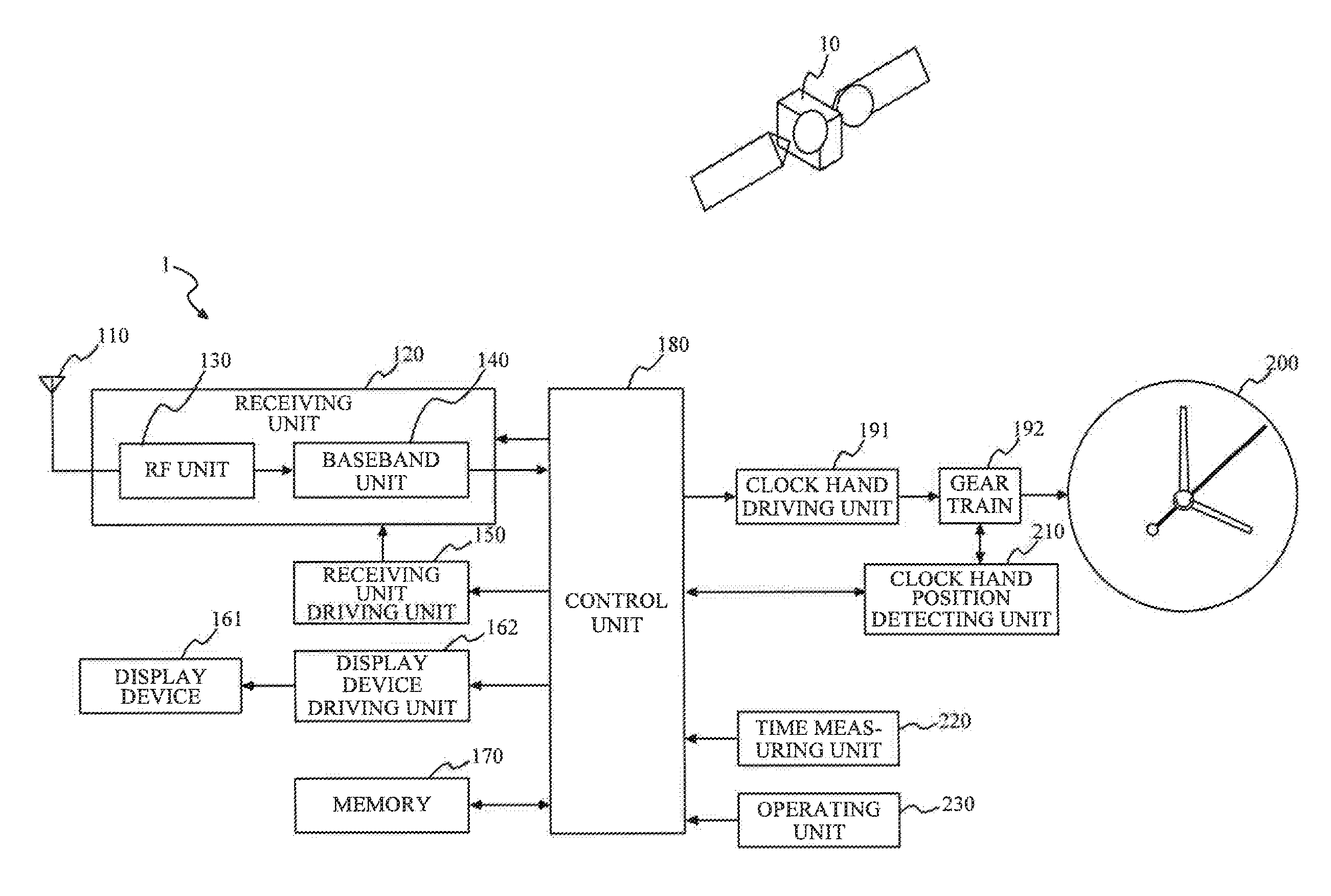

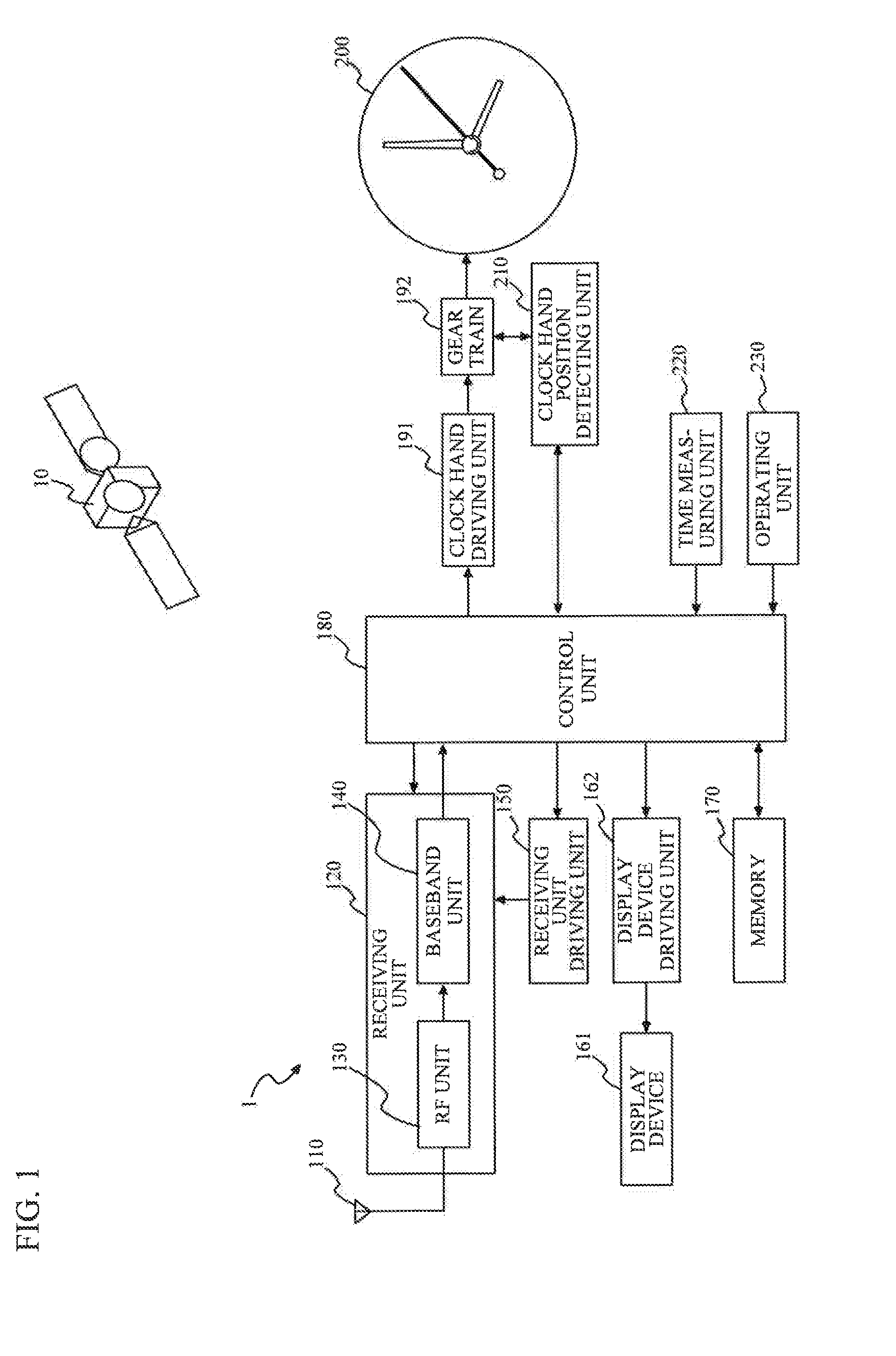

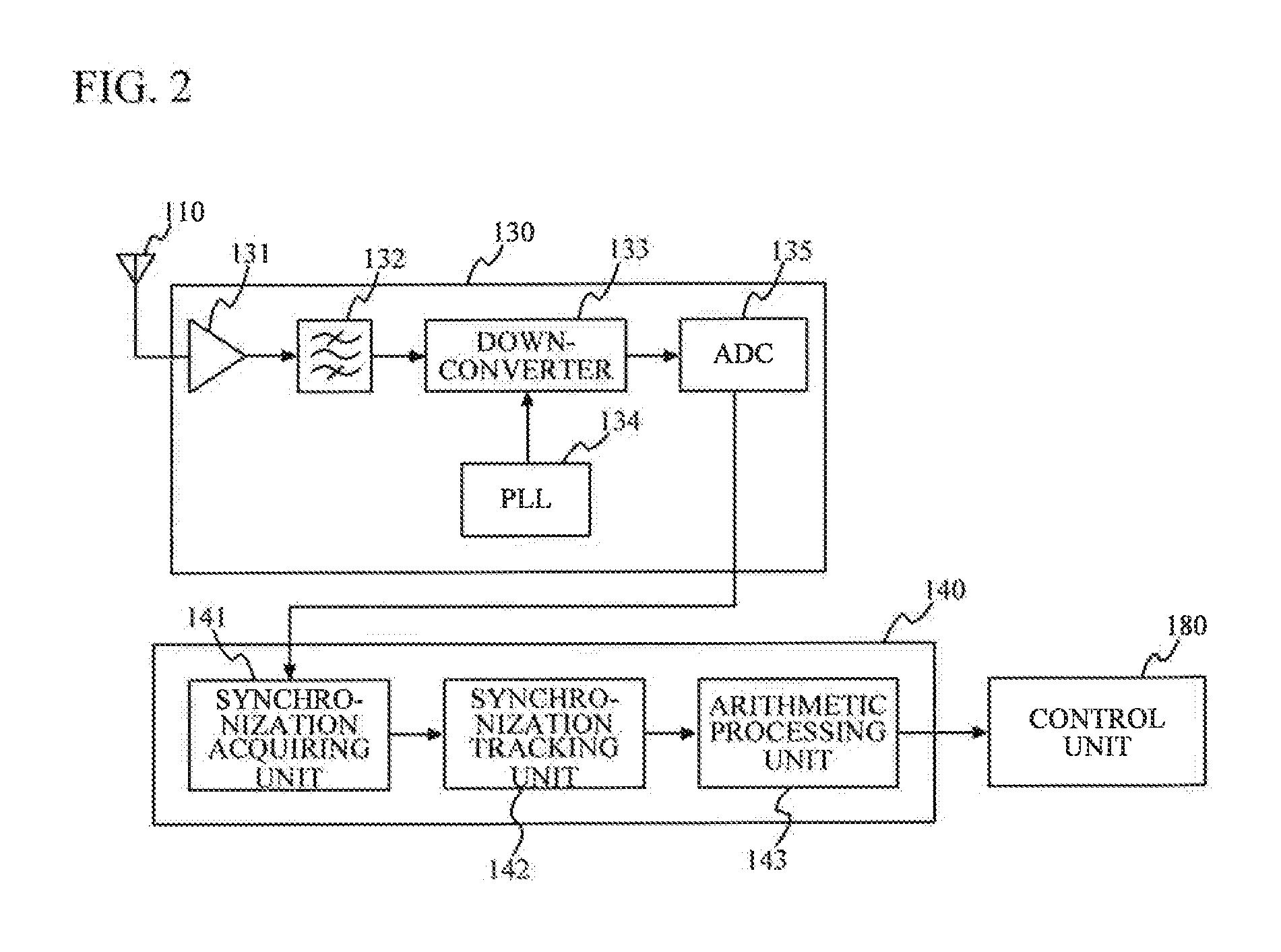

Radio clock

A radio clock including: an antenna configured to receive a satellite signal transmitted from GPS satellite; a receiving unit configured to perform a receiving process to acquire information contained in the satellite signal received by the antenna within a predetermine upper limit period; and a control unit configured to change the number of receiving processes to be performed in a predetermined period and change the upper limit period in accordance with a total sum of durations of the receiving processes performed in the predetermined period.

Owner:SEIKO TIME CREATION INC

Method of fabricating case, piezoelectric oscillator, oscillator, electronic appliance, and radio clock

InactiveUS20090039737A1Small sizeEasy to manufactureAcoustic indicationPiezoelectric/electrostriction/magnetostriction machinesRadio clockDeep drawing

Owner:SII CRYSTAL TECH

Radio clock

A radio clock including: an antenna configured to receive a satellite signal transmitted from GPS satellite; a receiving unit configured to perform a receiving process to acquire information contained in the satellite signal received by the antenna within a predetermine upper limit period; and a control unit configured to change the number of receiving processes to be performed in a predetermined period and change the upper limit period in accordance with a total sum of durations of the receiving processes performed in the predetermined period.

Owner:SEIKO TIME CREATION INC

Radio clock

A radio clock including: an antenna configured to receive a satellite signals transmitted from a plurality of GPS satellites; a receiving unit configured to perform a receiving process to acquire information tram a satellite signal received by the antenna, the information being contained in the satellite signal; and a control unit configured to control the receiving unit to keep synchronized with the GPS satellite that has transmitted the satellite signal and control the receiving unit to receive a satellite signal containing date information for date correction when the information acquired by the receiving unit does not contain the date information.

Owner:SEIKO TIME CREATION INC

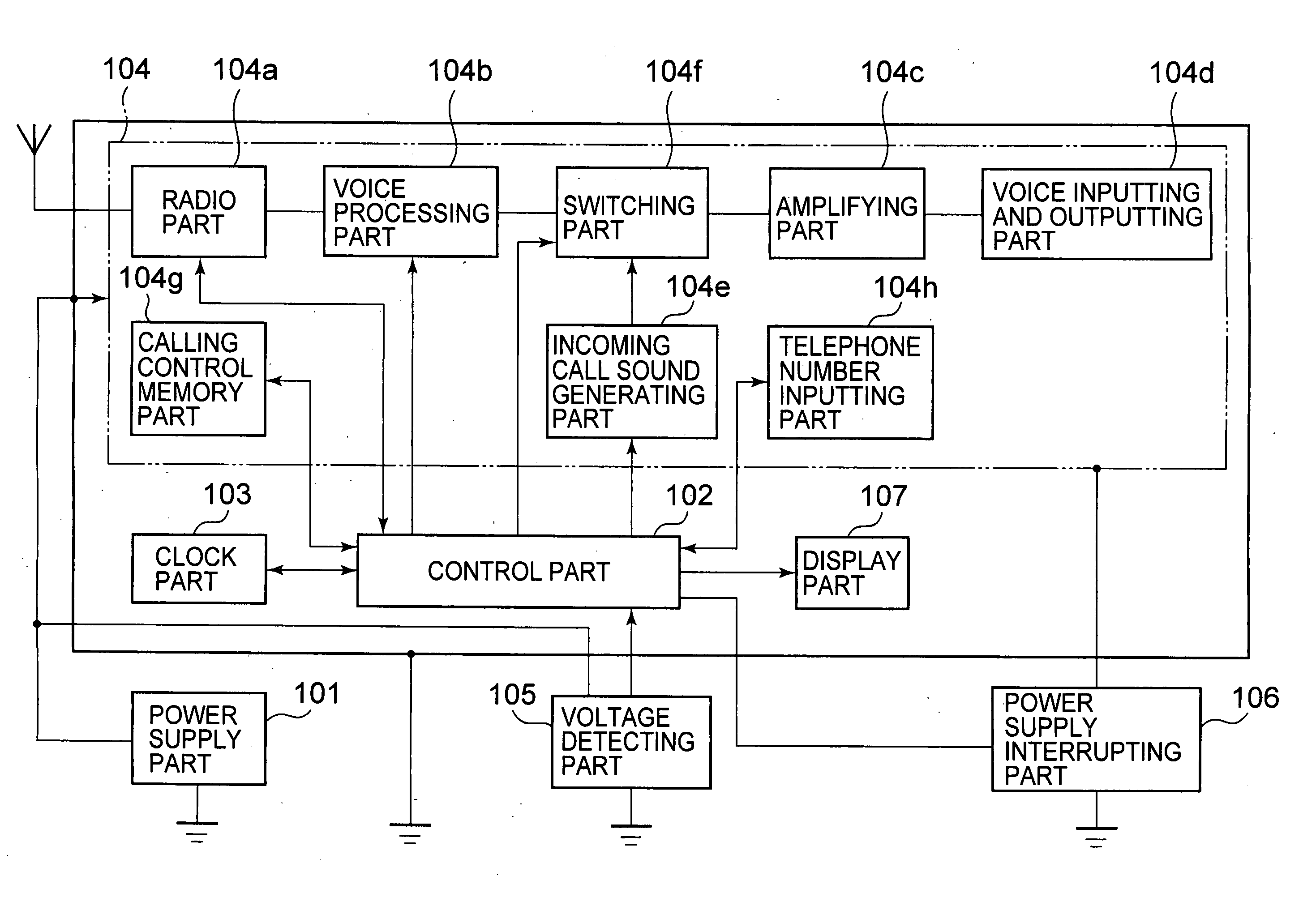

Receiver circuit for radio clock and method for operating receiving circuit

ActiveCN1684010AEasy to decodeEasy to evaluateSynchronous motors for clocksElectric windingTime informationBandpass filtering

The circuit (4) has a reception input to receive a time signal carrying encoded time information. An amplifier circuit amplifies the signal to produce an amplified time signal, and includes an adjustable amplifier with a variable amplification factor that is adjusted depending on frequency of the received time signal. An adjustable bandpass filter filters the amplified time signal to produce a filtered amplified time signal. Independent claims are also included for the following: (A) a radio-controlled clock including a receiver circuit (B) a method of acquiring time information.

Owner:ATMEL GERMANY +1

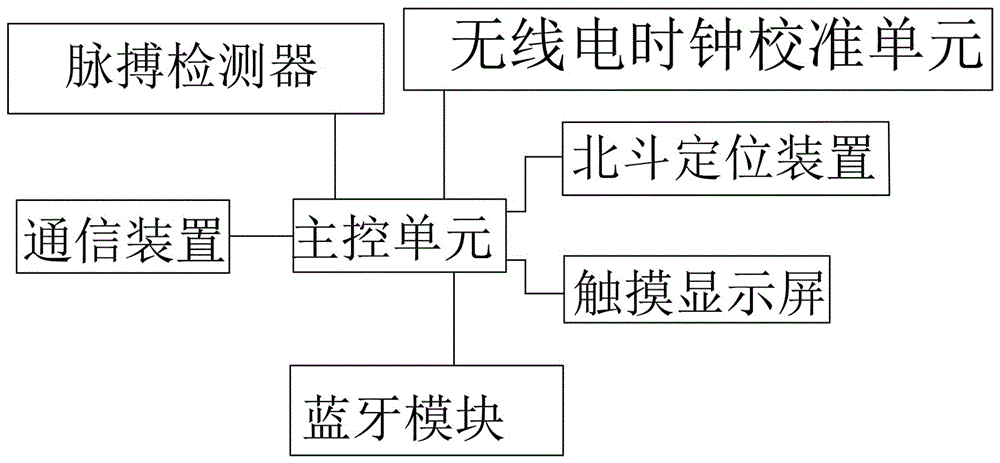

Intelligent watch with pulse monitoring function

The invention discloses an intelligent watch with a pulse monitoring function. The intelligent watch comprises a master control unit, a touch display screen, a communication device, a button cell and a radio clock calibration unit. The touch display screen and the communication device are in signal connection with the master control unit respectively, the communication device comprises a communication chip and a communication antenna, the button cell supplies power to the master control unit, the touch display screen and the communication device, and the radio clock calibration unit is in signal connection with the master control unit. By arrangement of the radio clock calibration unit, clock calibration can be performed at any time, and convenience in tuning is achieved.

Owner:沈磊

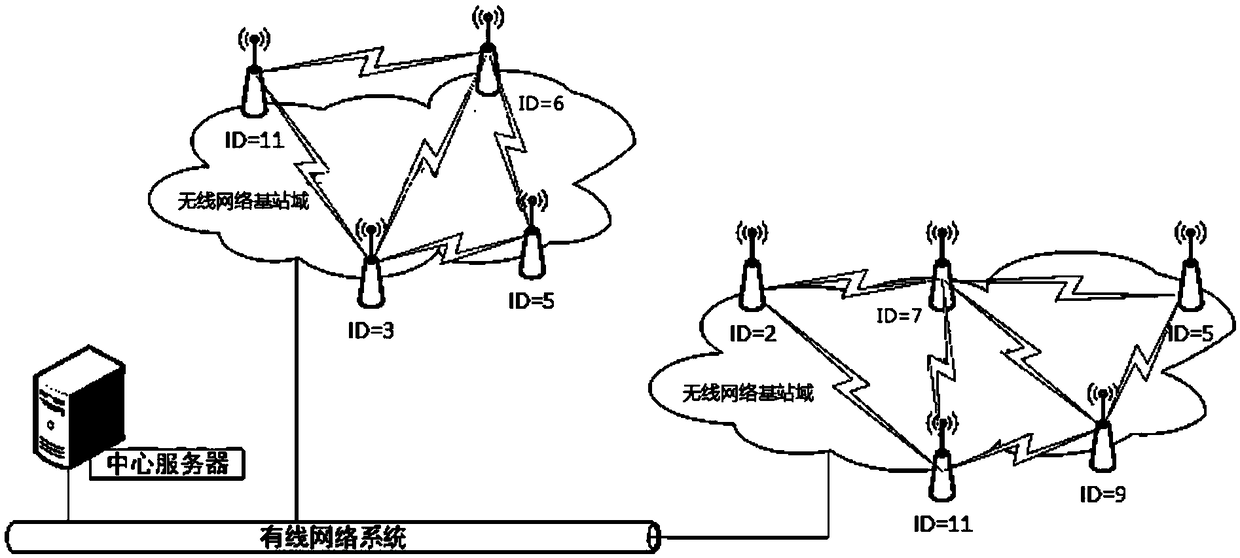

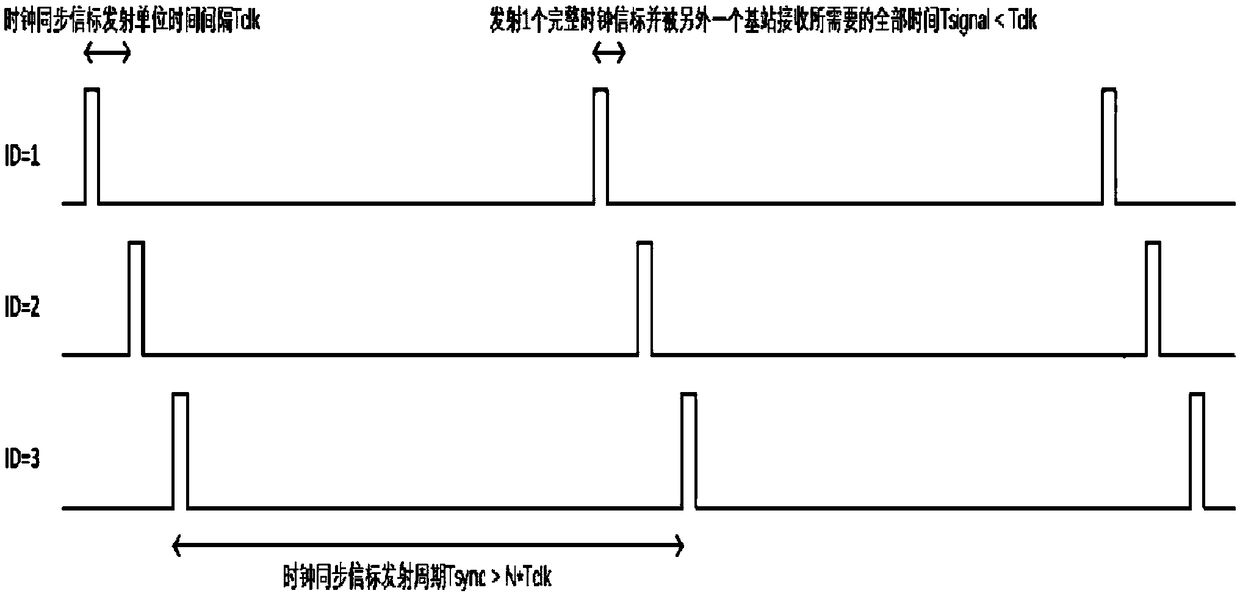

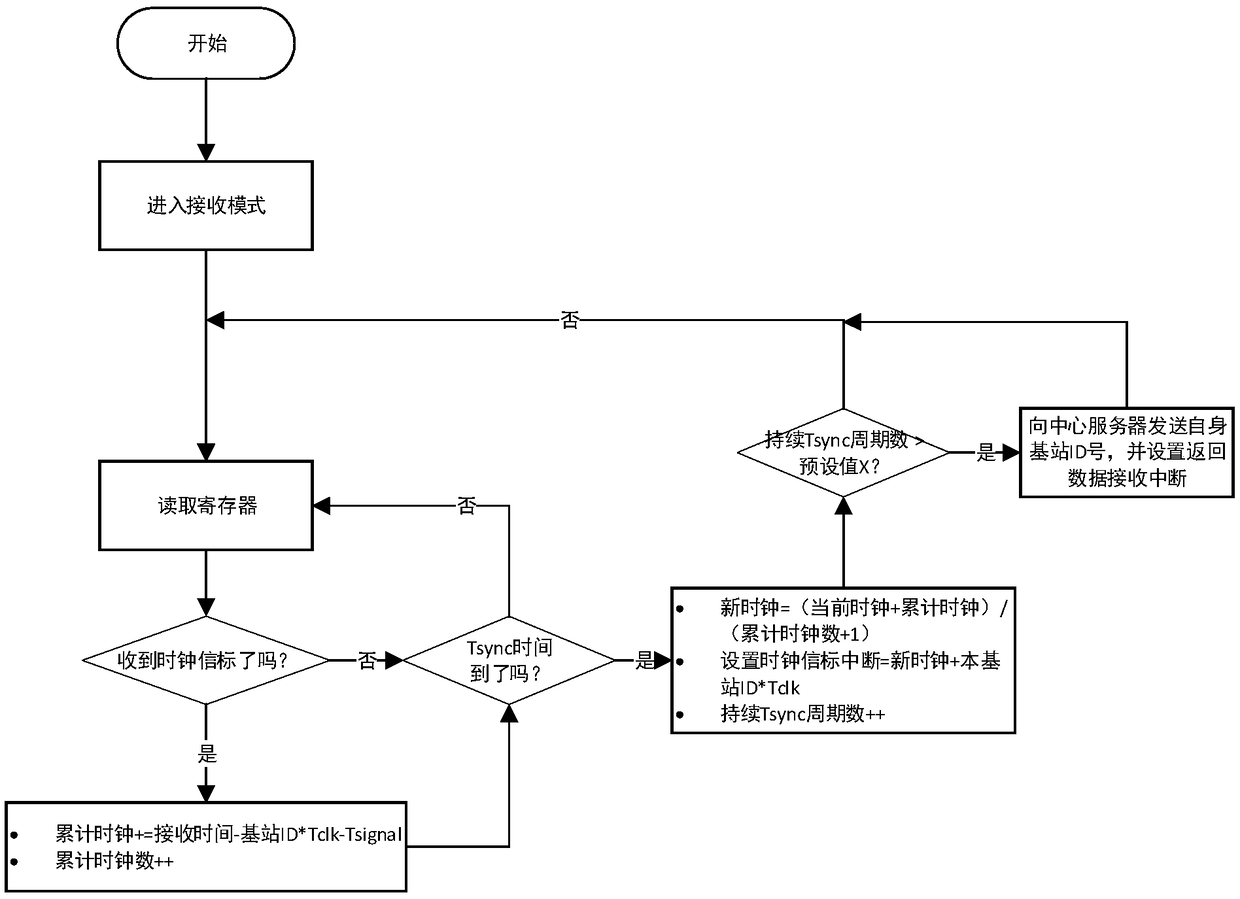

Radio clock synchronization method, system and medium without central base station

ActiveCN109067496AAchieve precise synchronizationSolve the accuracy problemSynchronisation arrangementTime-division multiplexRadio clockClock synchronization

The invention provides a wireless clock synchronization method without a central base station, a system and a medium, comprising the following steps: a base station domain dividing step: dividing eachbase station to obtain a divided base station domain; base station domain clock synchronization step: according to the divided base station domain, clock synchronization parameters corresponding to each base station in the base station domain are allocated to synchronize clock information of each base station in the base station domain. The invention can realize precise synchronization of clocksbetween base stations in a Tsync time period. The invention can solve the problems of low synchronization precision and clock out-of-step after synchronization and the like existing in the prior art.The invention can realize the dynamic division of the base station domain, and solve the problems of dynamic discrimination, decomposition and combination of the smallest base station domain when thebase station is dynamically increased, decreased or moved.

Owner:昂科信息技术(上海)股份有限公司

Method of fabricating hermetic terminal and hermetic terminal, method of fabricating piezoelectric oscillator and piezoelectric oscillator, oscillator, electronic appliance, and radio clock

InactiveUS7719171B2Easy to flattenImprove reliabilityPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyRadio clockElectroplating

Owner:SII CRYSTAL TECH

Anodic wafer bonding method, method of manufacturing packages, method of manufacturing piezoelectric vibrators, oscillator, electronic apparatus, and radio clock

InactiveUS20110285245A1Quality improvementGuaranteed uptimeLamination ancillary operationsPiezoelectric/electrostriction/magnetostriction machinesRadio clockConductive materials

An anodic wafer bonding method according to the present invention is an anodic wafer bonding method for bonding a first substrate formed of an insulating material or a dielectric material and a second substrate which can be anodically bonded by applying a voltage to a bonding film formed of a conductive material formed between the substrates in a state in which the first substrate and the second substrate are laminated, in which the voltage is applied to the bonding film from a plurality of points at the time of anodic wafer bonding.

Owner:SEIKO INSTR INC

Receiving device, radio clock, and receiving method

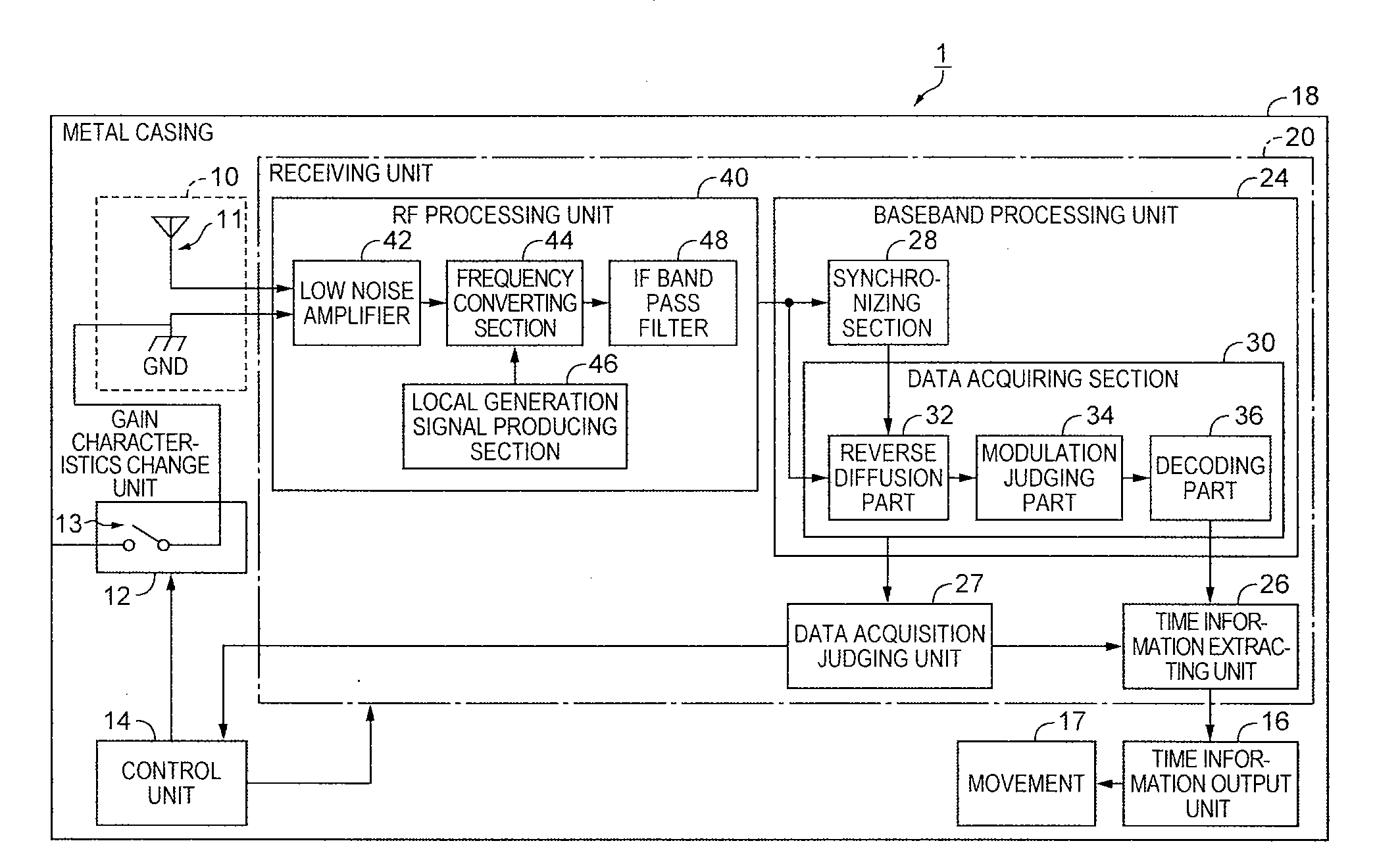

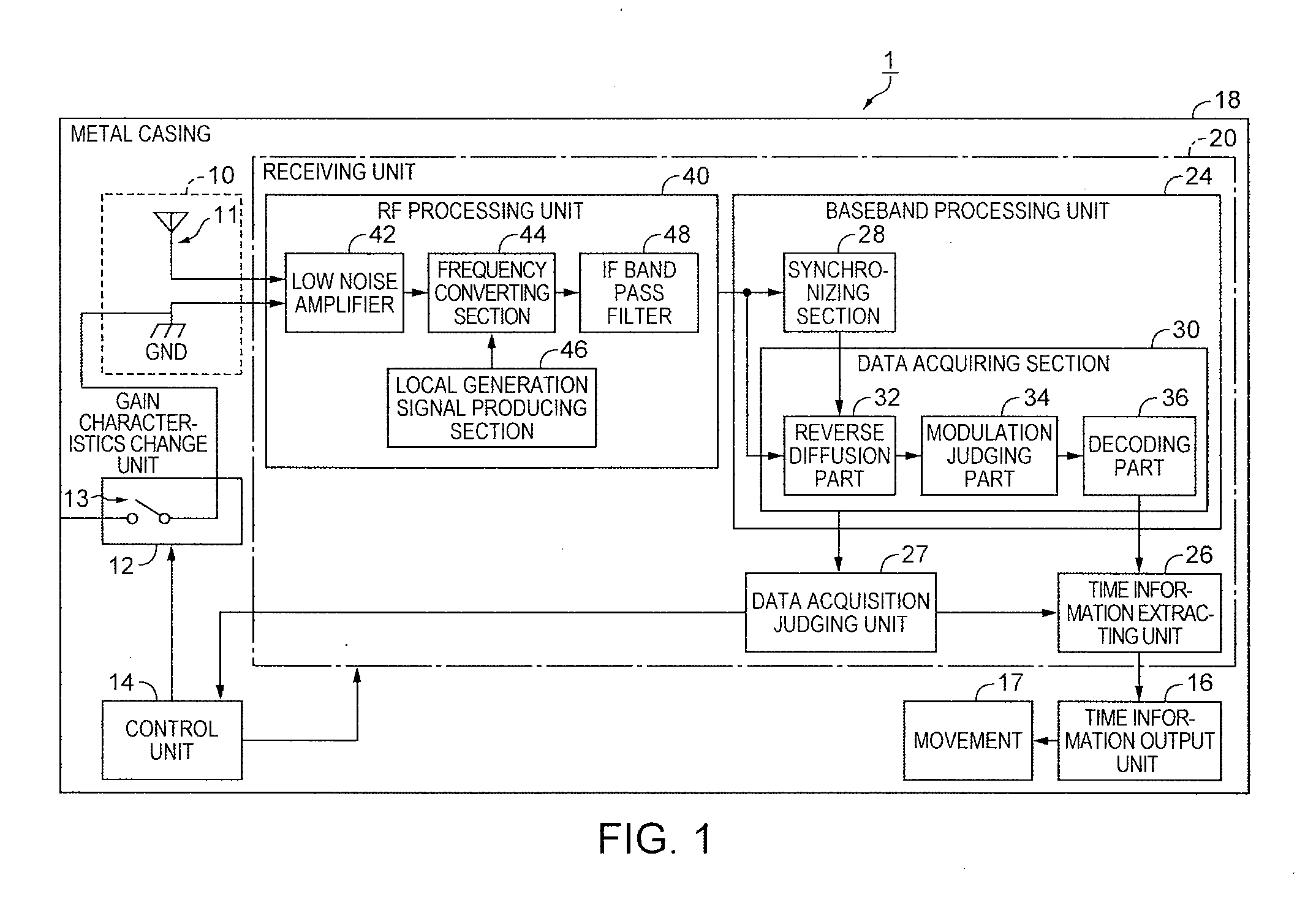

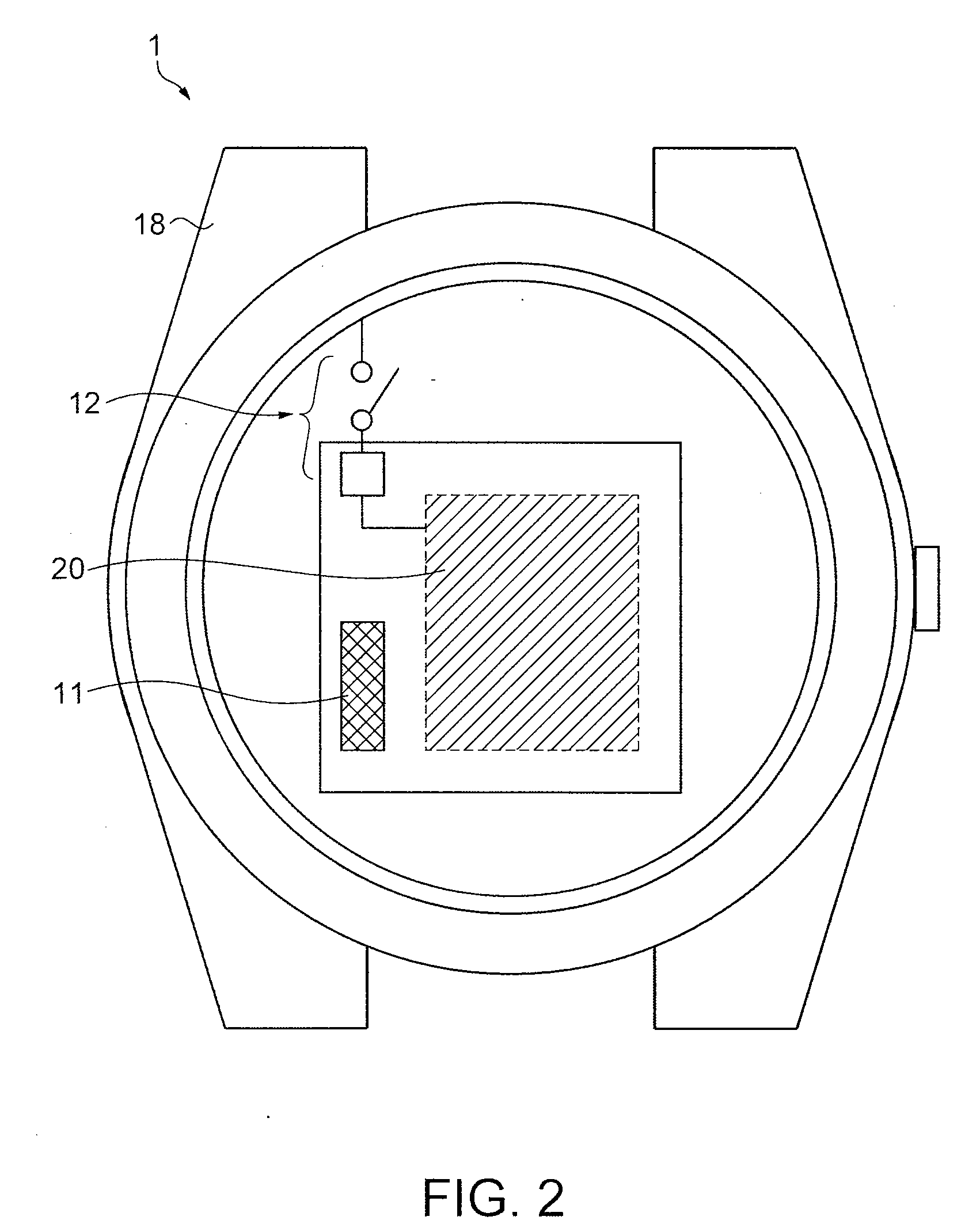

InactiveUS20090040876A1Solve the real problemDecrease in impedance matchingAntenna supports/mountingsSynchronous motors for clocksTime informationRadio clock

A receiving device includes: an antenna to which a communication signal containing time information is inputted; a ground allowing the antenna to function; a conductive part; a gain characteristics change unit which interrupts continuity between the ground and the conductive part to change the gain characteristics of the antenna; a receiving unit which obtains the time information from the communication signal inputted to the antenna; and a control unit which commands the gain characteristics change unit to interrupt the continuity and commands the receiving unit to obtain the time information. When the time information cannot be obtained from the communication signal inputted to the antenna having a certain type of gain characteristics, the control unit commands the gain characteristics change unit to interrupt the continuity and commands the receiving unit to obtain the time information from the communication signal inputted to the antenna whose gain characteristics have been changed.

Owner:SEIKO EPSON CORP

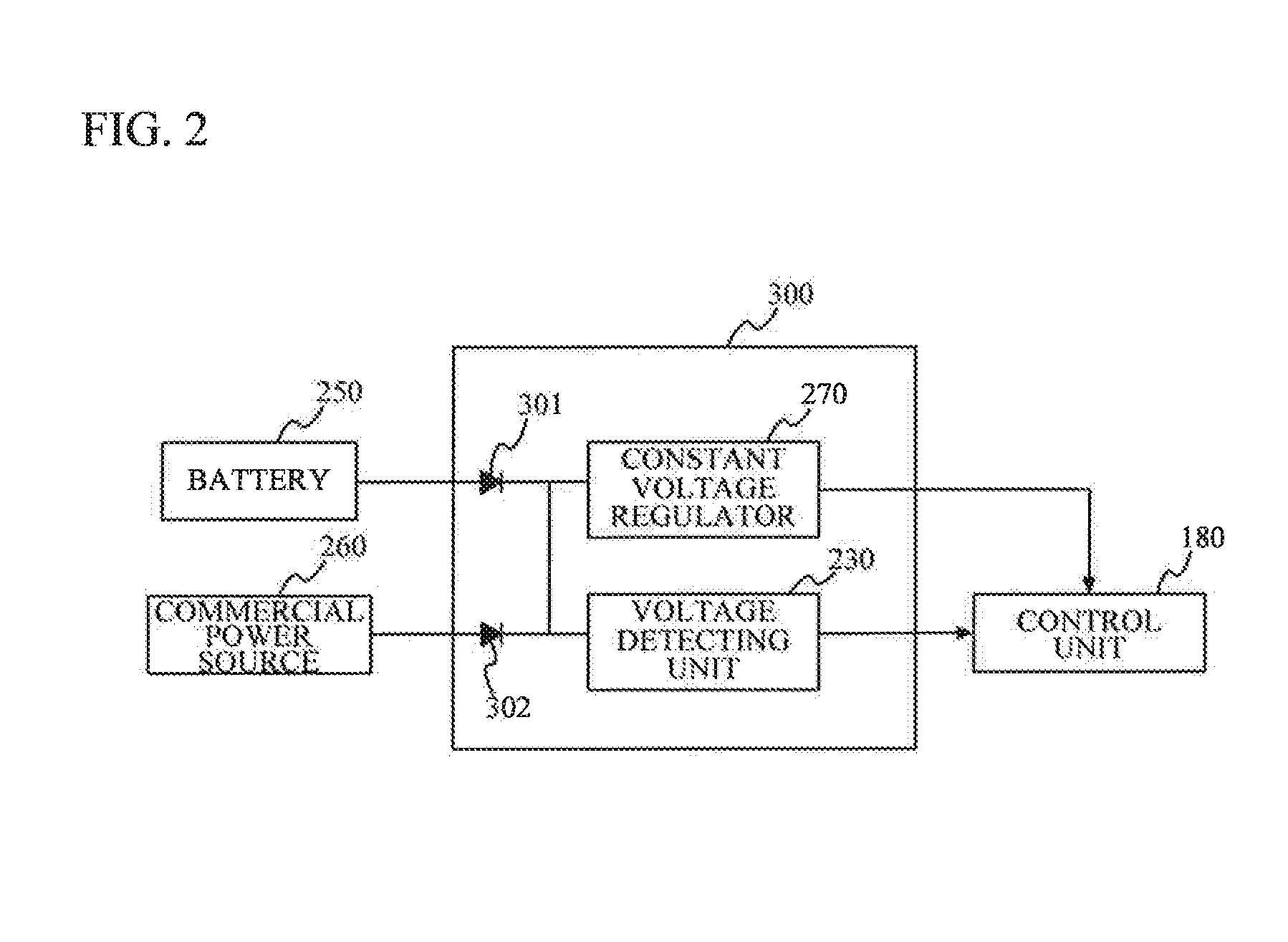

Wireless charger system with radio controlled clock

InactiveUS20130076305A1Minimizing effect of heatMinimize impactNear-field transmissionBatteries circuit arrangementsWireless connectivityBattery charger

A wireless charger system comprising a wireless charger and a remote device wireless connected to the wireless charger is disclosed. The wireless charger emits a charging signal at a first frequency range. The remote device receives a radio-controlled clock signal at a second frequency range, and modulates the radio-controlled clock signal via a carrier frequency to a modulated radio-controlled clock signal at a third frequency range. The modulated radio-controlled clock signal does not interfere with the charging signal, allowing the remote device to send the modulated radio-controlled clock signal to the wireless charger for display. An alternate wireless charger system comprising a wireless charger and an indoor temperature sensor is also disclosed.

Owner:OREGON SCI GLOBAL DISTRIBUTION

Method of fabricating hermetic terminal and hermetic terminal, method of fabricating piezoelectric oscillator and piezoelectric oscillator, oscillator, electronic appliance, and radio clock

InactiveUS20090039971A1Improve reliabilityEnsure reliabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesRadio clockEngineering

A method of fabricating a hermetic terminal includes: joining and firing wherein a bar-shaped member to be a lead is inserted into a ring, and they are fired to form a hermetic terminal intermediate having the bar-shaped member fixed in the ring; flattening wherein an end part of the bar-shaped member to be the inner lead portion of the lead is flattened to form a stair portion; and shaping wherein an end part of the stair portion is cut to shape the stair portion into a predetermined shape, wherein in the joining and firing step, a solid round bar longer than the lead is used as the bar-shaped member, and one end side of the bar-shaped member to be the inner lead portion is inserted into the ring so that the one end side is longer than the inner lead portion in the hermetic terminal as a completed product.

Owner:SII CRYSTAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com