Method for preparing 2-amino-5-thiol-1, 3, 4-thiadiazole copper controlled-release microcapsule and prepared microcapsule

A slow-release, microcapsule technology, applied in the field of pesticides, can solve the problems of difficult transportation, easy stratification, single dosage form of thiophanate copper, and achieve the effect of reducing tedious work and stable storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

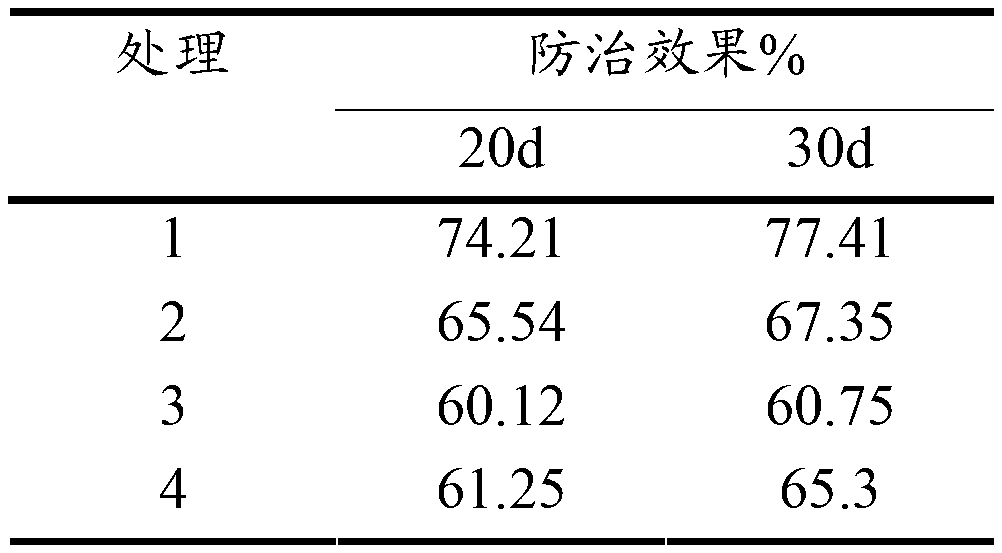

Image

Examples

preparation example Construction

[0038] The present invention also provides a preparation method of the above-mentioned thiazolyl copper sustained-release microcapsules, which comprises the following steps:

[0039] The first step is the preparation of the prepolymer, dissolving the isocyanate derivatives in cyclohexanone, adding a chain extender, heating and reacting to obtain the prepolymer;

[0040] In the second step, the preparation of the emulsion, the prepolymer prepared in the first step is dissolved in water, and stirred until the prepolymer is completely dissolved to form a mixed solution, and the mixed solution of the capsule core is added and emulsified to prepare an emulsion. The mixed solution of the capsule core is It is obtained by stirring and mixing thiabyl copper, capsule core solvent and co-solvent;

[0041] The third step is to polymerize the capsule wall, mix the urea-formaldehyde resin prepared by polycondensation of urea and formaldehyde solution with the emulsion prepared in the secon...

Embodiment 1

[0056] In a 500mL container, dissolve 20g of hexamethyl diisocyanate in 60g of cyclohexanone, place the container in an oil bath, and stir magnetically at a speed of 400r / min. 18 g of 1,4-butanediol was added to the reaction vessel, and the reaction was continued for 20 hours. Afterwards, the reaction mixture was distilled at 100° C. for 6 hours to distill off excess cyclohexanone, water, and hexamethyl diisocyanate, leaving a light yellow, viscous prepolymer.

[0057] Take another 500mL container, dissolve 40g of prepolymer in 250mL of water, stir magnetically until the prepolymer is completely dissolved, add 5g of Thiobacterium copper, 20g of methyl soyate and 4g of geminipyrrolidone, and mix evenly, and emulsify at high speed The machine emulsifies at a speed of 10000r / min for 20 minutes to form an O / W emulsion.

[0058] Add 20g of urea and 25g of formaldehyde solution with a mass percent concentration of 37% to the emulsion to form a mixed solution. The temperature is slo...

Embodiment 2

[0060] In a 500ml container, dissolve 30 g of hexamethyl diisocyanate in 50 g of cyclohexanone, place the container in an oil bath, and stir magnetically at a speed of 1200 r / min. After reacting for 0.5 hours, 5 g of ethylene glycol was added to the reaction vessel at a rate of 5 mg / s, and the reaction continued for 40 hours. Afterwards, the reaction mixture was distilled at 100° C. for 5 hours to distill off excess cyclohexanone, water, and hexamethyl diisocyanate, leaving a light yellow, viscous prepolymer.

[0061] Take another 500ml container, dissolve 60g of prepolymer in 250mL of water, stir until the prepolymer is completely dissolved, add 10g of capsule core mixed liquid Thiobacterium copper, 20g of coco fatty acid methyl ester and 1g of lauryl alcohol ester into the capsule core The mixture is mixed evenly, emulsified by a high-speed emulsifier at a speed of 30000r / min for 10 minutes to form an O / W emulsion.

[0062] Add 30g of urea and 35g of formaldehyde solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com