Device for introducing reaction gases into a reaction chamber and epitaxial reactor which uses said device

A technology of epitaxial reactor and reaction gas, applied in the direction of chemical reactive gas, chemical/physical/physicochemical nozzle reactor, chemical method of reacting gas medium with gas medium, etc., can solve the species that hinder chemicals , reduce efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

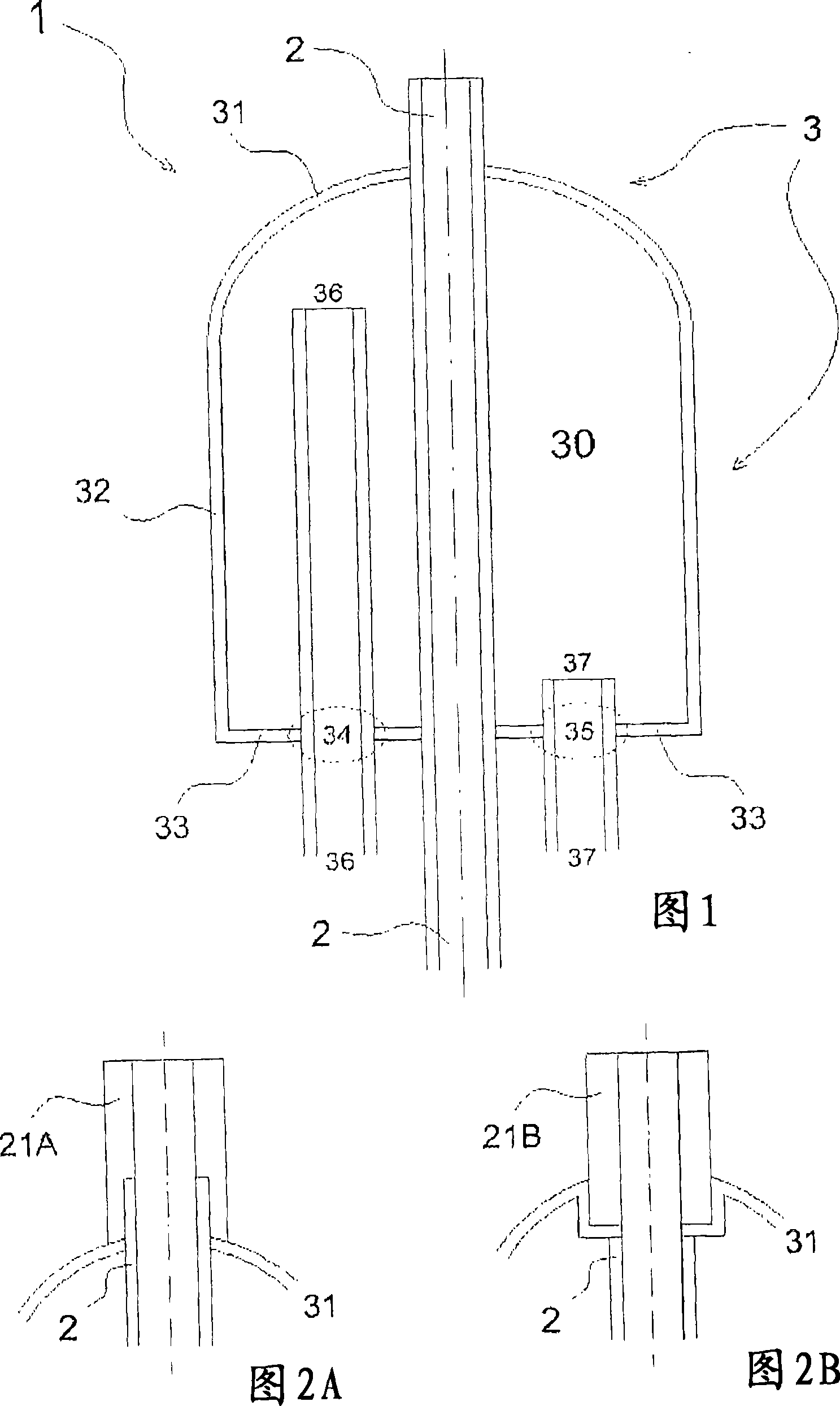

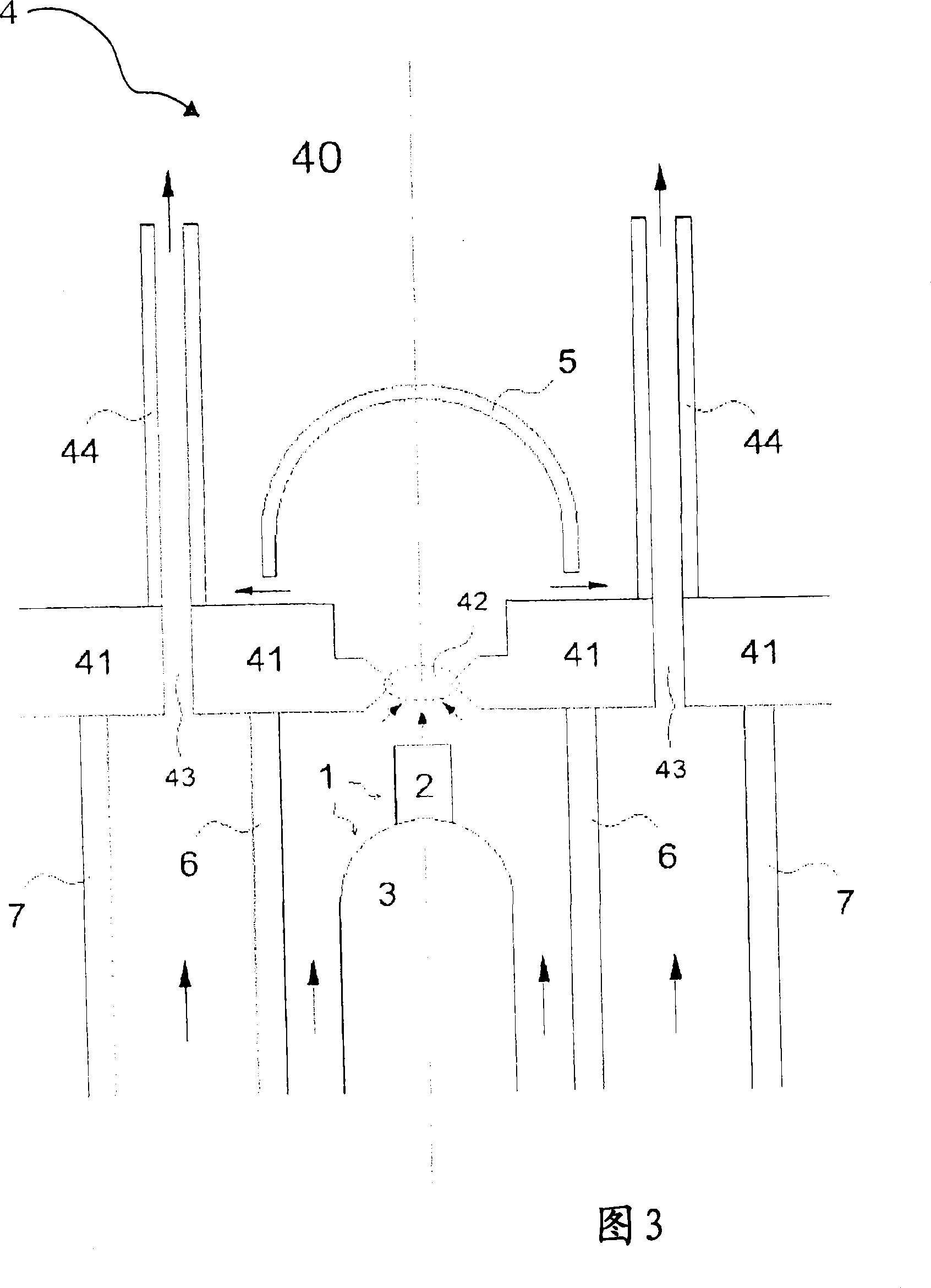

[0024] Fig. 1 shows an example of an embodiment of the device, the whole device being denoted by reference numeral 1 . The shown device 1 is also partially shown in FIG. 3, wherein the device 1 in FIG. 4 ) into the reaction chamber 40.

[0025] The apparatus 1 envisages a supply duct for conveying a reaction gas indicated by reference numeral 2 and a cooling member generally indicated by reference numeral 3 .

[0026] In the embodiment of FIG. 1 , the member 3 comprises a housing delimiting a chamber 30 by a cylindrical portion 32 terminating in a cover 31 on a first side and a circle on a second side. Disk 33.

[0027] The duct 2 runs inside and outside the housing 3 , through the cover 31 , in particular through a hole in the cover 31 , through the disc 33 , in particular through a hole in it. The cover 31 and the disk 33 are sealed on the pipe 2; since these parts are generally made of metal, the sealing is usually done by welding, so there is no problem in ensuring the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com