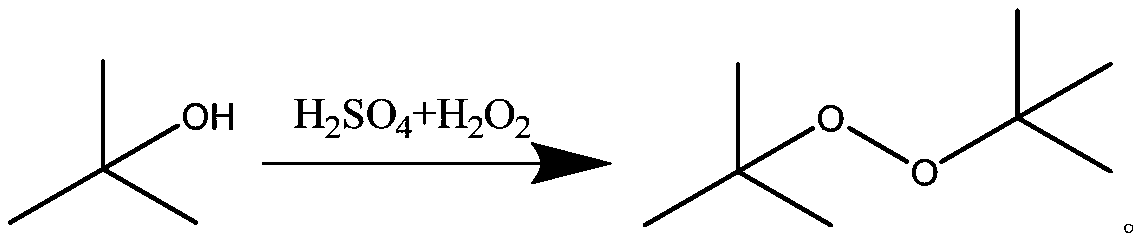

Di-tert-butyl peroxide synthesis method

A technology of di-tert-butyl peroxide and synthesis method, which is applied to the preparation of peroxide compounds, chemical instruments and methods, and the preparation of organic compounds, which can solve the problems of increased side reactions, etc., to solve the problem of temperature out of control and reduce the risk of reaction performance, to achieve the effect of segmented temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of synthetic method of di-tert-butyl peroxide, comprises the following steps:

[0034] (1) tert-butanol and concentration are 98% vitriol oil mixed in the first microchannel continuous flow reactor, the internal diameter size of the first microchannel continuous flow reactor is 1mm, and length is 5m, and temperature is 20 ℃, reaction time 1min;

[0035] (2) the material that step (1) obtains and concentration are the hydrogen peroxide mixed reaction of 50% in the second microchannel continuous flow reactor, and the time of mixed reaction is 4min; Tertiary butanol, the vitriol oil, hydrogen peroxide The molar ratio is: 1:1.05:0.55, the inner diameter of the second microchannel continuous flow reactor is 1mm, and it is composed of 10 microchannel mixer substrates connected, and the length of each microchannel mixer substrate is 4m , where the temperature of the first three pieces is controlled at 50°C, the temperature of the last one is controlled at 55°C, and the...

Embodiment 2

[0038] A kind of synthetic method of di-tert-butyl peroxide, comprises the following steps:

[0039] (1) the vitriol oil that tert-butanol and concentration are 98% is mixed in the first microchannel continuous flow reactor, and the internal diameter size of the first microchannel continuous flow reactor is 2mm, and length is 3m, and temperature is 15 ℃, reaction time 1min;

[0040] (2) the material that step (1) obtains and concentration are the hydrogen peroxide mixed reaction of 40% in the second microchannel continuous flow reactor, and the time of mixed reaction is 3min; Tertiary butanol, the vitriol oil, hydrogen peroxide The molar ratio is: 1:1.1:0.57, the inner diameter of the second microchannel continuous flow reactor is 2mm, and it is composed of 8 microchannel mixer substrates connected, and the length of each microchannel mixer substrate is 5m , where the temperature of the first two pieces is controlled at 48°C, the temperature of the last one is controlled at 5...

Embodiment 3

[0043] A kind of synthetic method of di-tert-butyl peroxide, comprises the following steps:

[0044] (1) the vitriol oil that tert-butanol and concentration are 90% is mixed in the first microchannel continuous flow reactor, and the internal diameter size of the first microchannel continuous flow reactor is 0.5mm, and length is 5m, and temperature is 25 ℃, reacts The time is 0.8min;

[0045] (2) the material that step (1) obtains and concentration are the hydrogen peroxide mixed reaction of 60% in the second microchannel continuous flow reactor, and the time of mixed reaction is 5min; Tertiary butanol, the vitriol oil, hydrogen peroxide The molar ratio is: 1:0.95:0.48, the inner diameter of the second microchannel continuous flow reactor is 0.5mm, and is composed of 12 microchannel mixer substrates connected, and the length of each microchannel mixer substrate is 3m, where the temperature of the first two pieces is controlled at 48°C, the temperature of the last one is contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com