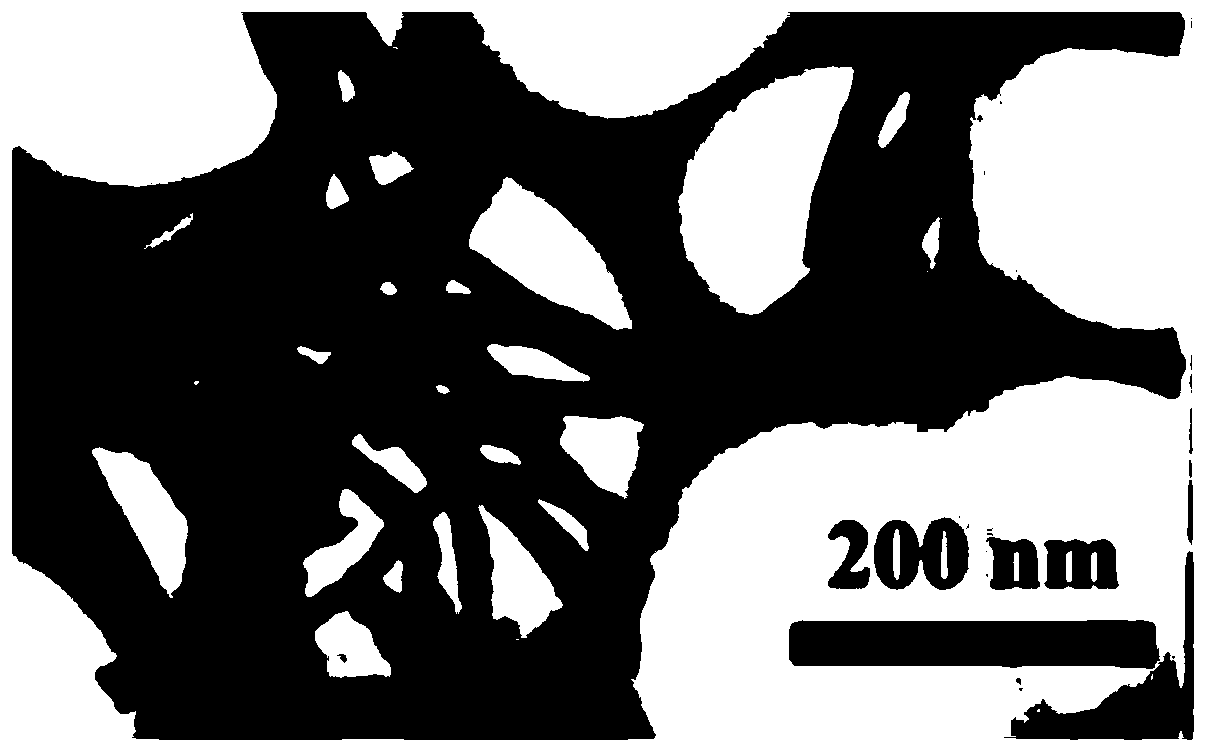

Hollow nanofiber Co3O4/S composite material as well as preparation method and application thereof

A technology of composite materials and nanofibers, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low specific capacity and poor positive electrode conductivity, etc., and achieve high specific capacity and good rate performance , good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) 1.2g Co(CH 3 COO) 2 4H 2 O (cobalt acetate tetrahydrate), 0.5g PAN (polyacrylonitrile) and 0.1g PVP (polyvinylpyrrolidone) were dissolved in 15ml DMF (N,N-dimethylformamide), and stirred under electromagnetic stirring at room temperature for 15-18h , standing for 12 to 15 hours to obtain electrospinning solution;

[0037] (2) Use a syringe (needle inner diameter 1.2mm) to extract the electrospinning liquid prepared in step (1), fix it on a high-voltage electrospinning machine for electrospinning, and use carbon paper as a receiving device to collect, the voltage is 15kV, and the needle and carbon The paper spacing is 12-15 cm, the injection flow rate is 60 μL / min, the temperature is 21-25 °C, and the relative humidity is 80%, to prepare nanofibers;

[0038] (3) oxidizing the nanofibers prepared in step (2) in air at 300°C for 2 hours, thereby preparing the HCON material;

[0039] (4) After mixing sulfur and the HCON material prepared in step (3), place it at 155...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com