High-toughness and highly heat-resistant polylactic acid (PLA) alloy material and preparation method thereof

An alloy material, polylactic acid technology, applied in the field of polymer materials and their preparation, can solve problems such as less modification research, and achieve the effects of low cost, improved toughness and heat resistance, and high melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

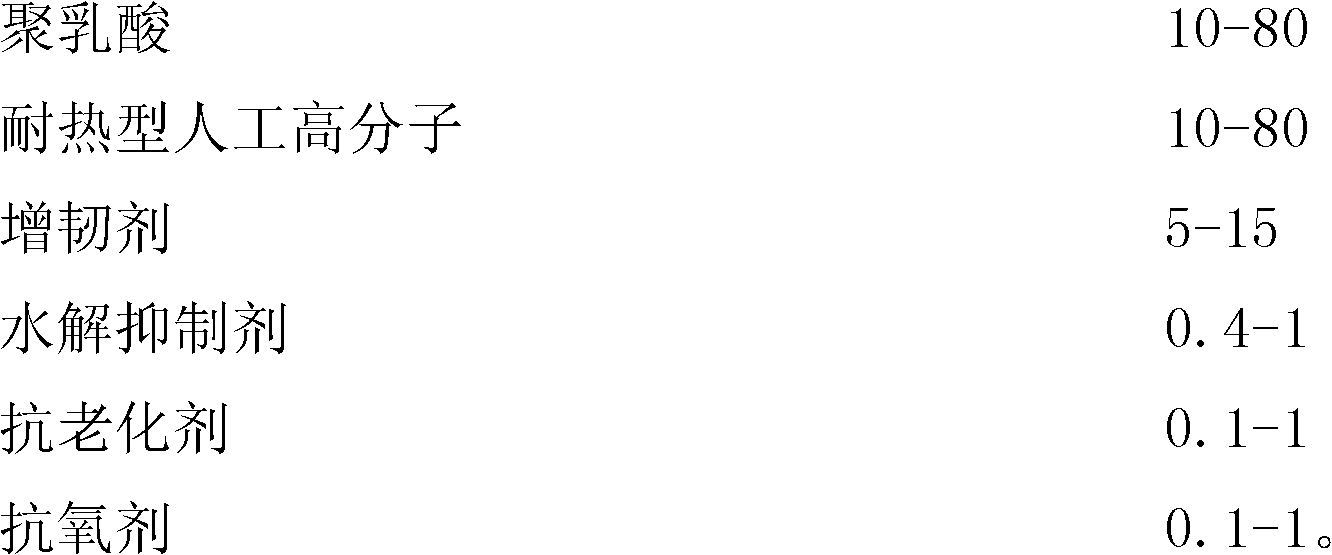

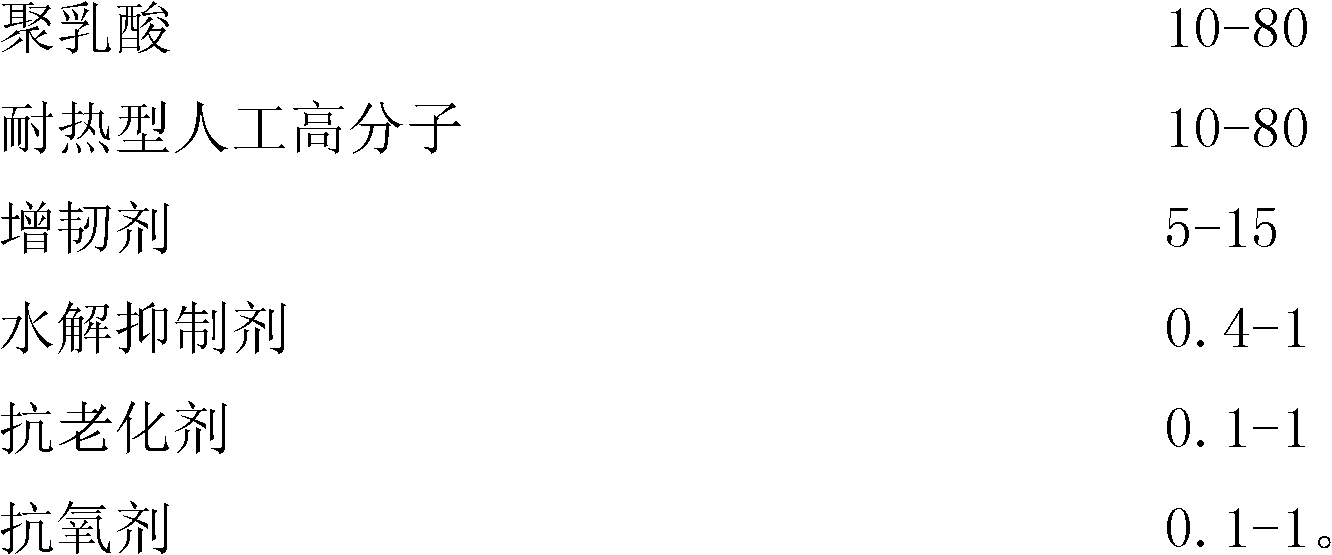

Method used

Image

Examples

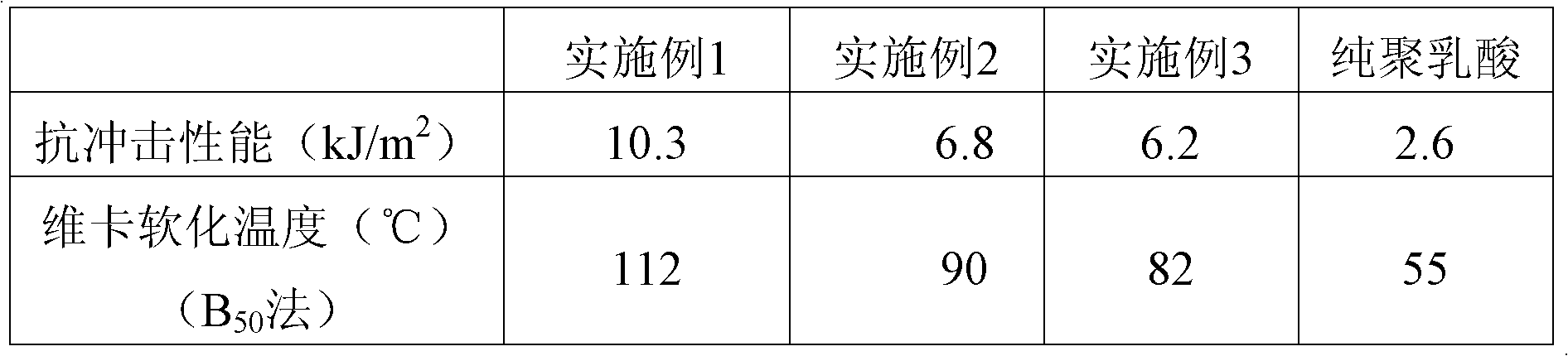

Embodiment 1

[0021] (1) Vacuum dry polylactic acid, polycarbonate, polymethyl methacrylate, and ABS at 50°C for 8 hours to remove moisture;

[0022] (2) the above-mentioned polycarbonate after drying, polymethyl methacrylate and ABS and hydrolysis inhibitor carbodiimide, antiaging agent hindered amine antioxidant, antioxidant four (β-(3, 5 di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester was stirred in a dry high-speed mixer according to the proportioning to make it evenly mixed, and then reacted in a twin-screw extruder, the screw speed was 180rpm, extruded The output temperature is 270°C; the polylactic acid is blended and extruded with other materials by side forced feeding, and the product is air-cooled, pelletized, and vacuum-dried to obtain a toughened and heat-resistant polylactic acid masterbatch.

[0023] Wherein, weight percent: polylactic acid content is 35%, heat-resistant type artificial polymer polycarbonate content is 44%, polymethyl methacrylate content is 1...

Embodiment 2

[0025] (1) Vacuum dry polylactic acid, polyoxymethylene, and ACR at 70°C for 5 hours to remove moisture;

[0026] (2) Combine the above-mentioned dried polyoxymethylene and ACR with hydrolysis inhibitor DCC, anti-aging agent hindered phenolic antioxidant, antioxidant (3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid The octadecyl ester is stirred in a dry high-speed mixer according to the proportion to make it evenly mixed, and then reacted in a twin-screw extruder, the screw speed is 100rpm, the extrusion temperature is 180°C, and the polylactic acid is forced to feed from the side It is blended and extruded with other materials, and the product is air-cooled, pelletized, and vacuum-dried to obtain a toughened and heat-resistant polylactic acid masterbatch.

[0027] Wherein, weight percentage: wherein polylactic acid content is 48%, heat-resistant type artificial polymer POM content is 42%, toughening agent ACR content is 8%, hydrolysis inhibitor DCC content is 0.8%, hindere...

Embodiment 3

[0029] (1) Vacuum dry polylactic acid, nylon 6, and SEBS at 80°C for 3 hours to remove moisture;

[0030] (2) Combine the above-mentioned dried nylon 6 and SEBS with hydrolysis inhibitor TIC, anti-aging agent benzotriazole light stabilizer, antioxidant β-(3,5-di-tert-butyl-4-hydroxybenzene Base) Cyclohexyl propionate was stirred in a dry high-speed mixer according to the ratio to make it evenly mixed, and then reacted in a twin-screw extruder with a screw speed of 25rpm and an extrusion temperature of 250°C. Polylactic acid was taken from the side Compulsory feeding and other materials are blended and extruded, and the product is water-cooled, pelletized, and vacuum-dried to obtain toughened and heat-resistant polylactic acid masterbatches.

[0031] Percentage by weight: the content of polylactic acid is 70%, the content of heat-resistant artificial polymer PA6 is 21%, the content of toughening agent SEBS is 6%, the content of anti-aging agent benzotriazole light stabilizer is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com