Acid dipping device used for nuclear rod jacketing tube and having function of preventing acid wash from leaking

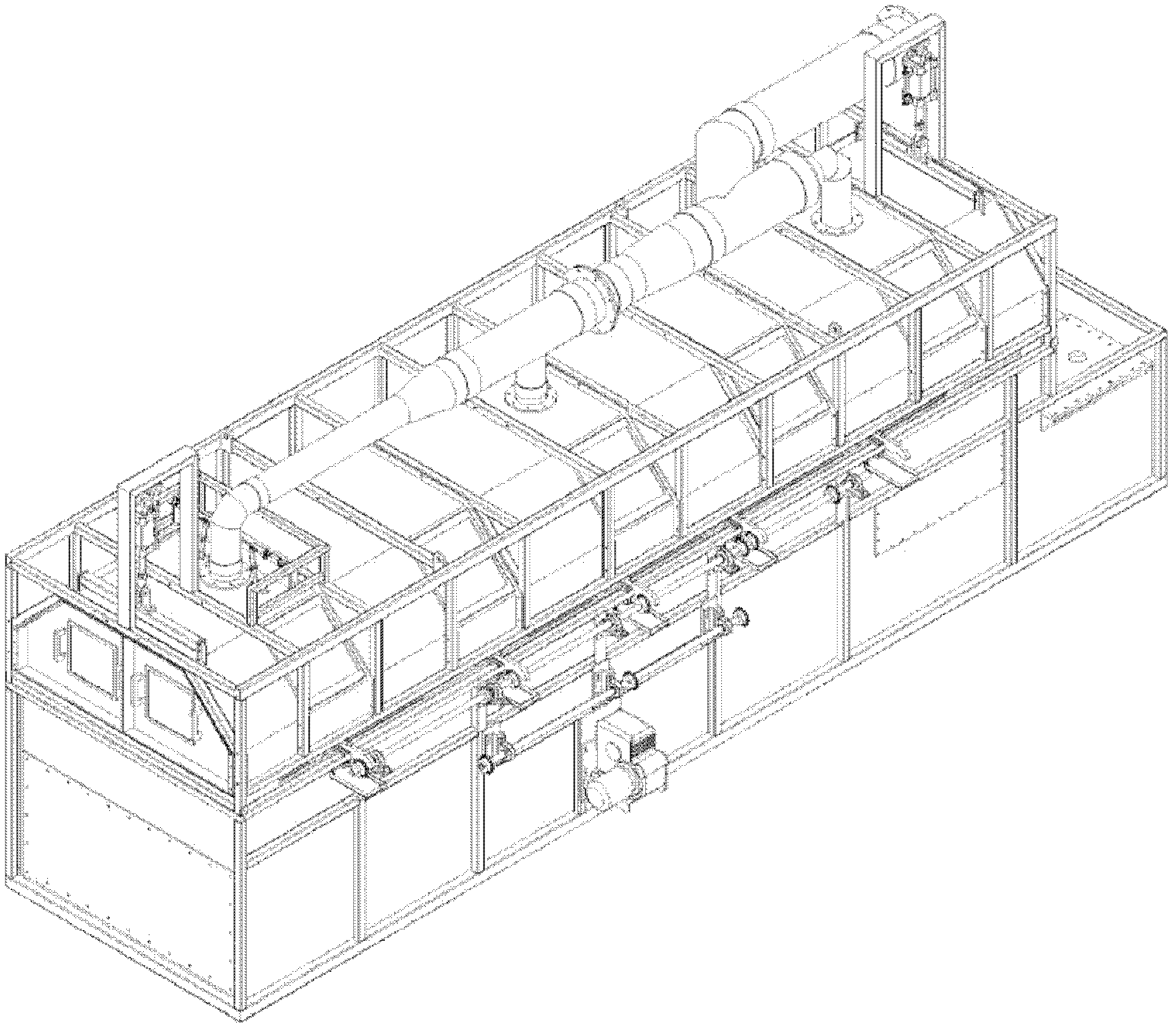

A rod cladding tube and processing device technology, applied in nuclear engineering, nuclear power generation, climate sustainability, etc., can solve problems such as operation delay, corrosion, pickling solution leakage, etc., and achieve quality reduction and economical pickling treatment , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

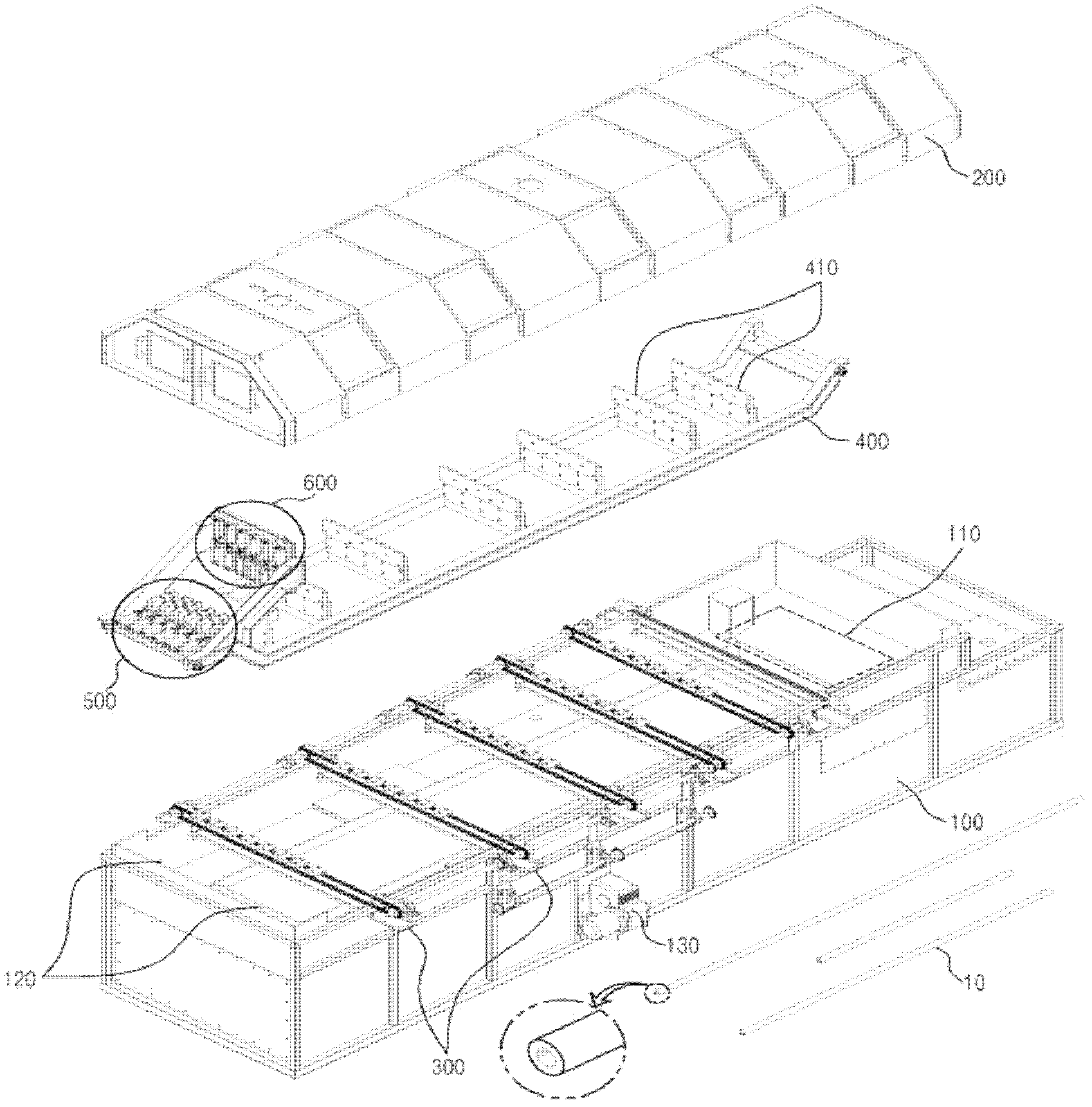

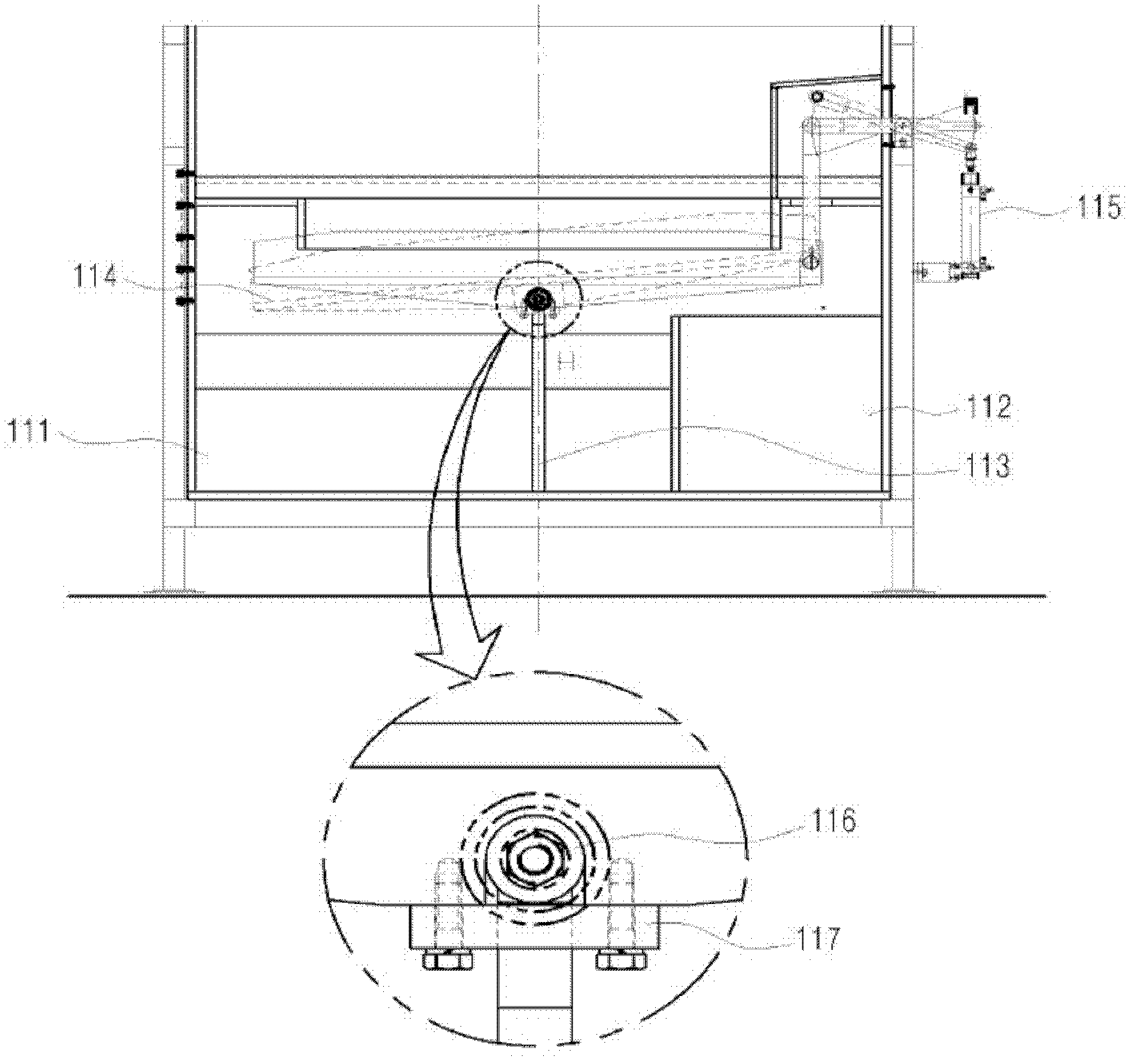

[0043] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. First, when adding reference numerals to constituent elements in each drawing, the same numerals are used as much as possible even if the same constituent elements are shown in different drawings. In addition, when describing the present invention below, when it is considered that a detailed description of a related known function or structure will unnecessarily obscure the gist of the present invention, the detailed description thereof will be omitted.

[0044] The nuclear fuel rod cladding tube 10 pickled by the nuclear fuel rod cladding tube pickling treatment device 1 of the present invention becomes the metal cladding tube of the nuclear fuel rod in the final step, and the acid pickling process of the nuclear fuel rod cladding tube according to the present invention The washing treatment device 1 is particularly preferably subjected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com