Preparation method for biomass degradation material and magnetic powder catheter

A technology of biomass degradation and magnetic powder, applied in the field of biodegradable materials and their products, can solve the problems of non-degradation, large market demand and consumption, saving energy and resource consumption, saving direct costs, and reducing raw material consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

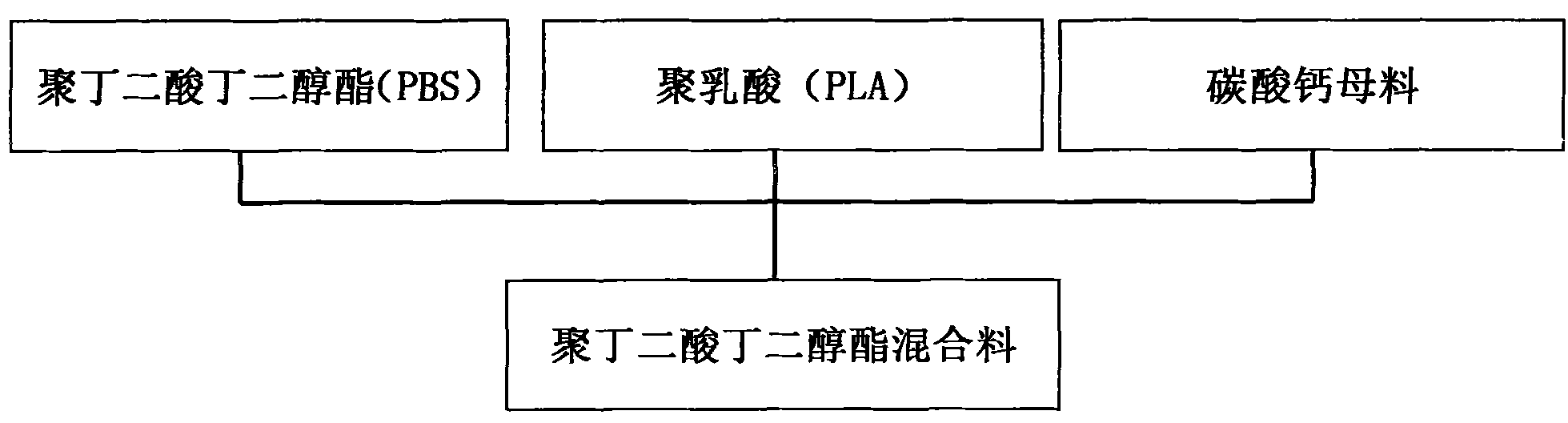

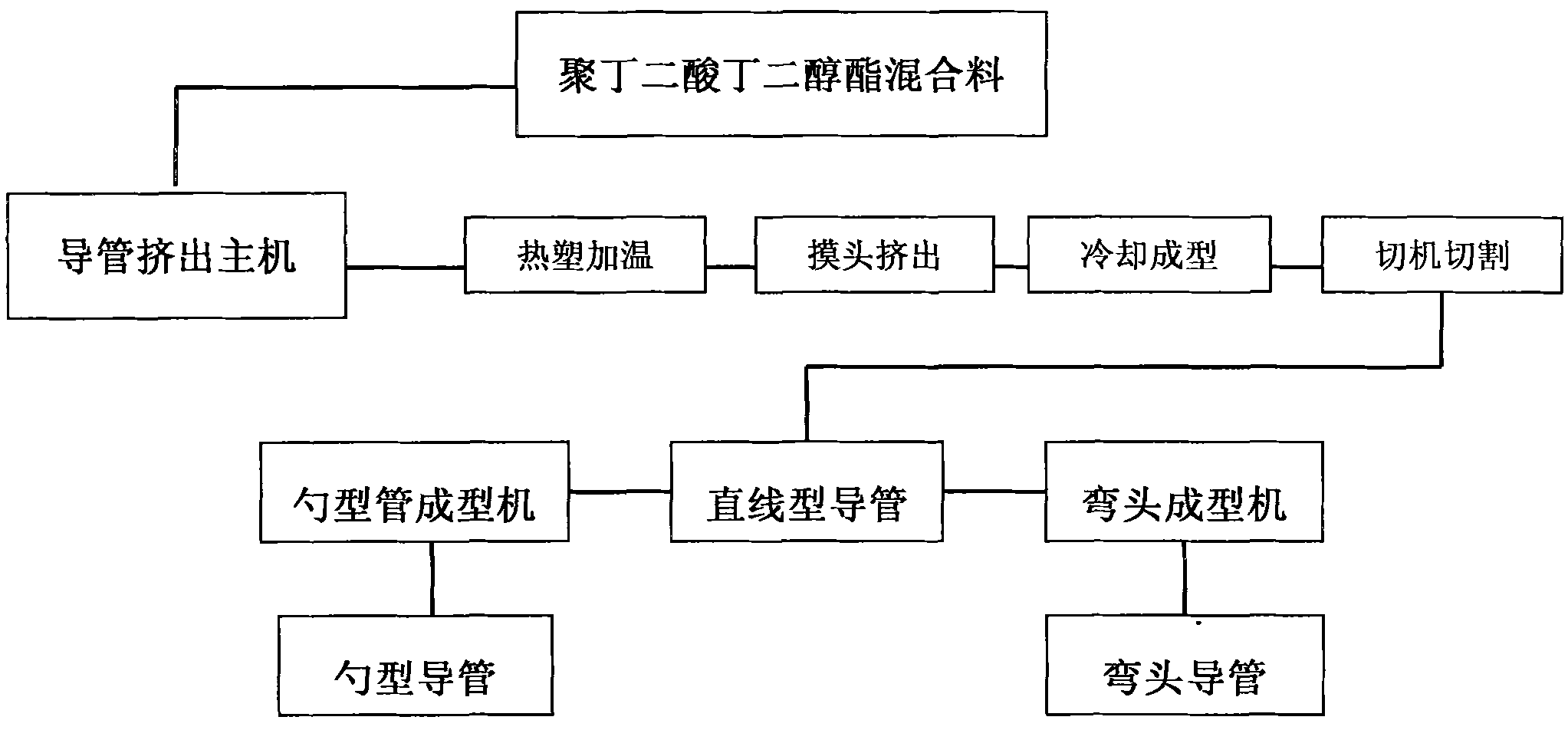

[0061] see figure 1 , a kind of preparation method of biomass degradable material provided by the embodiment of the present invention, it comprises the following steps:

[0062] 1) Preparation of raw materials: According to weight percentage, take the following raw material components:

[0063] Main material polybutylene succinate 40-60, modified polylactic acid 40-60, filler calcium carbonate masterbatch 0.1-20;

[0064] 2) Component mixing:

[0065] Firstly, the above components are prepared into 100-300 mesh powder, and dried;

[0066] Weigh the polybutylene succinate of 1 / 3 of the total amount, add all the polylactic acid, stir and mix;

[0067] Then add the remaining polybutylene succinate and all the calcium carbonate masterbatch gradually and stir and mix until it is completely added, so that the powder components are evenly mixed to form a modified polybutylene succinate mixed material;

[0068] 3) Vacuumize the modified polybutylene succinate mixture under low te...

Embodiment 2

[0080] The preparation method of the biomass degradable material provided by this embodiment is basically the same as that of Example 1, the difference is that:

[0081] The weight percentage of each component in the step 1) is: 40-50% polybutylene succinate as main material, 40-50% polylactic acid as modified material, and 1-10% calcium carbonate masterbatch as filler.

[0082] The preparation method of a magnetic powder catheter using the biomass degradable material provided in this embodiment is basically the same as that in Embodiment 1, except that it also includes the following steps:

[0083] 6) An elbow forming machine is prepared, and the pipe body of the continuous magnetic powder conduit is subjected to an elbow indentation process to obtain a bendable magnetic powder conduit in the middle;

[0084] The magnetic powder conduit prepared by the above method provided in this embodiment is basically the same as that in Embodiment 1, except that the magnetic powder condu...

Embodiment 3

[0086] The preparation method of the biomass degradable material provided by this embodiment is basically the same as that of Example 1, the difference is that:

[0087] The weight percent of each component in the step 1) is:

[0088] The main material is polybutylene succinate 40, the modified polylactic acid, and the filler calcium carbonate masterbatch 20.

[0089] The preparation method of a magnetic powder catheter using the biomass degradable material provided in this embodiment is basically the same as that in Embodiment 1, except that it also includes the following steps:

[0090] 9) A scoop forming machine is prepared, and the cutting part of the tube body of the continuous magnetic powder catheter is subjected to a scoop-shaped indentation process to obtain a scoop-shaped magnetic powder catheter at one or both ends.

[0091] The magnetic powder conduit prepared by the above method provided in this embodiment is basically the same as that in Embodiment 1, the differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com