Patents

Literature

71results about How to "Meet the requirements of energy saving and consumption reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

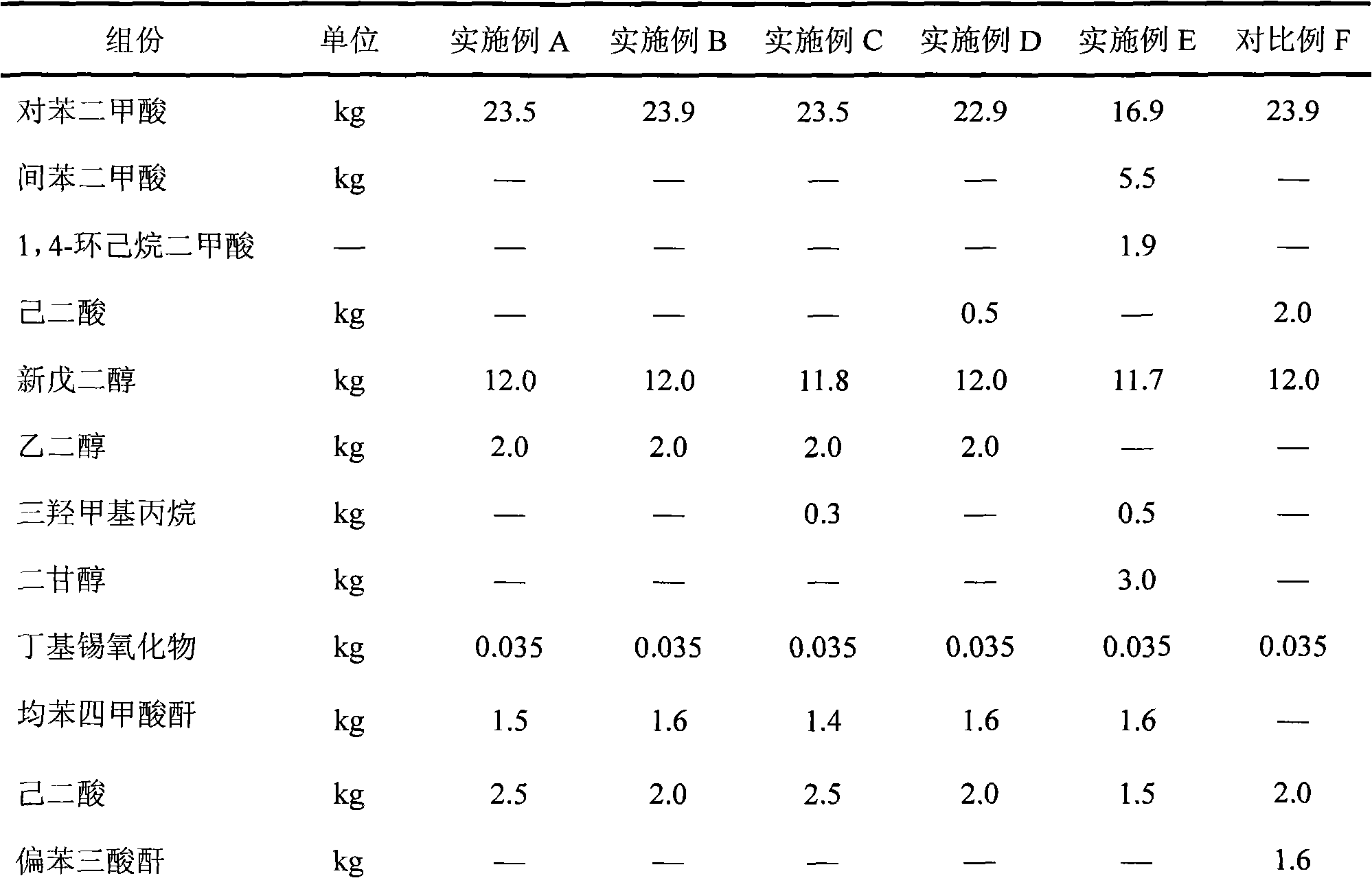

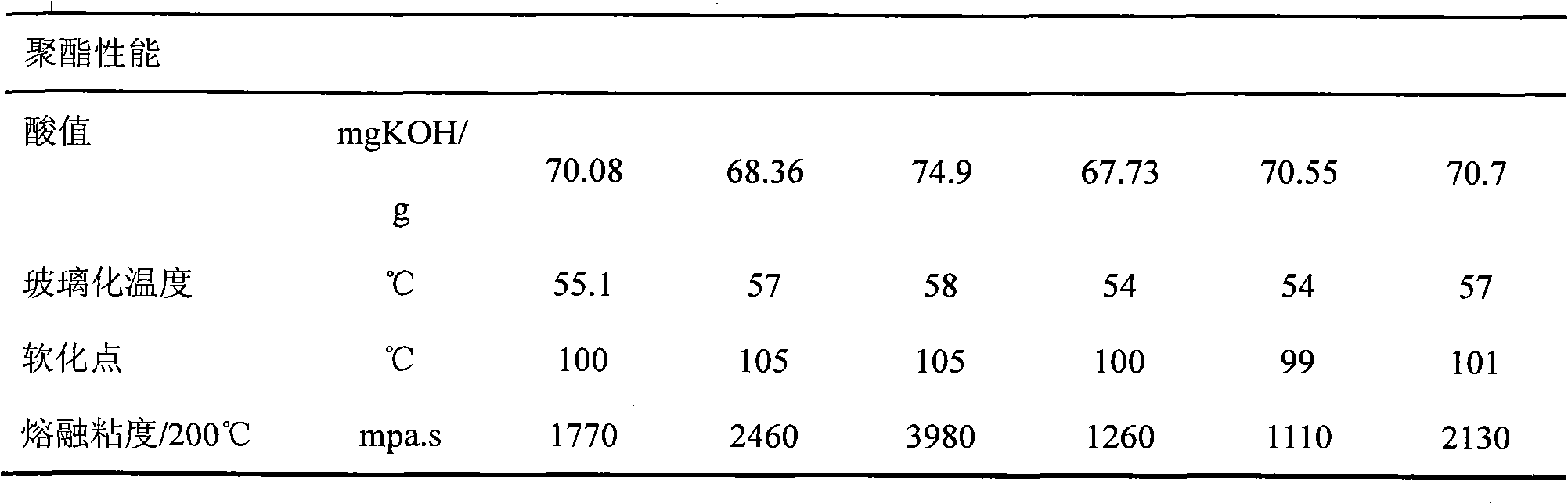

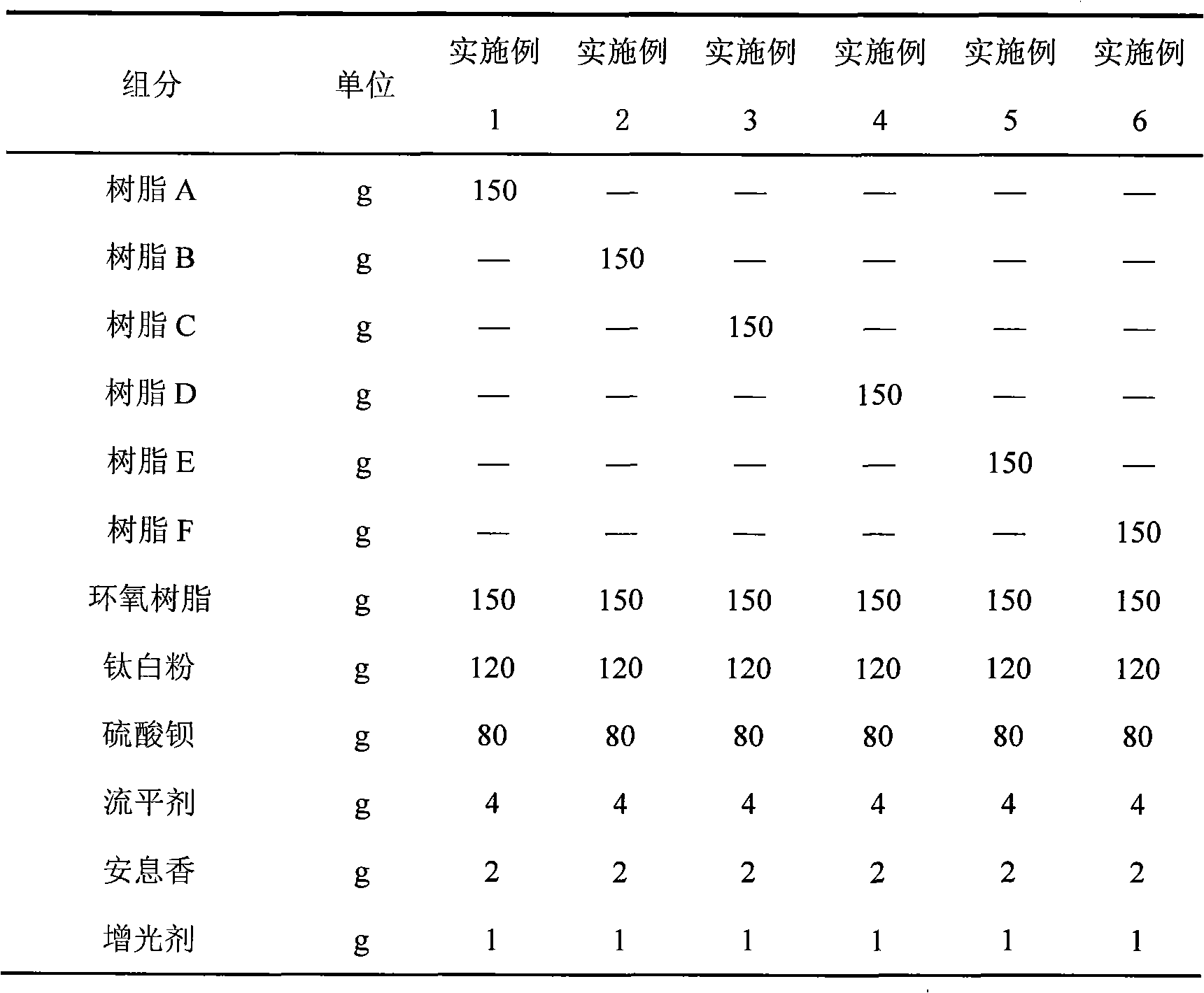

Low-temperature cured terminal carboxyl polyester resin for mixed powder coating and preparation method thereof

ActiveCN101735432ASuitable glass transition temperatureGood storage stabilityPowdery paintsEpoxy resin coatingsHybrid typeEpoxy

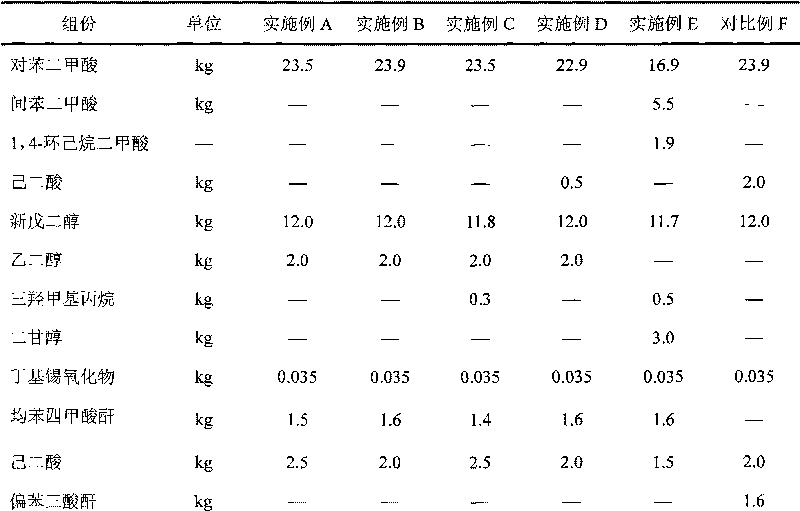

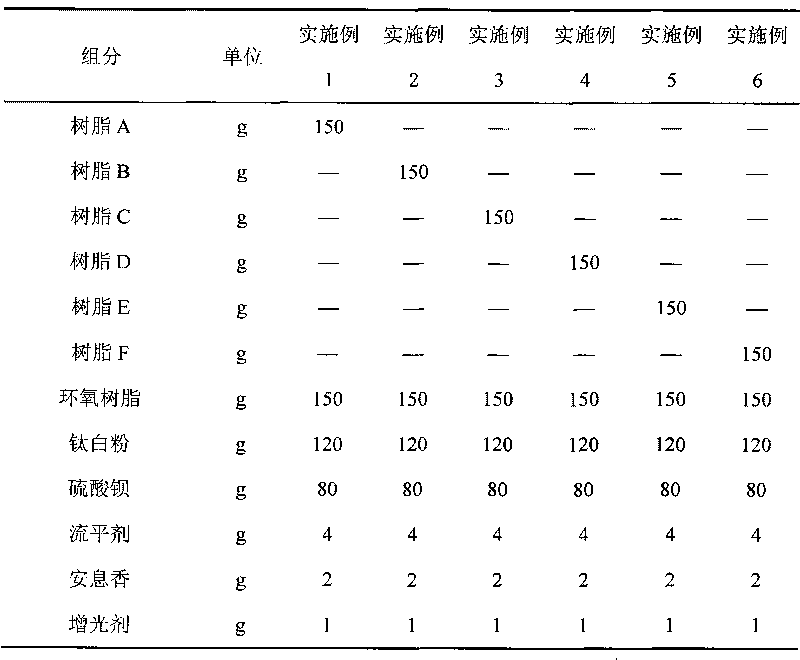

The invention discloses a low-temperature cured terminal carboxyl polyester resin for mixed powder coating. The polyester resin is prepared by performing melt polycondensation reaction on the following components in percentage by weight: 25 to 45 percent of polyalcohol, 35 to 65 percent of aromatic polyatomic acid, 0 to 10 percent of fat polyatomic acid, 0 to 2 percent of branching agent, 6 to 15 percent of acid hydrolysis agent, and 0.01 to 0.15 percent of esterification catalyst. The invention also discloses a method for preparing the low-temperature cured terminal carboxyl polyester resin. The prepared polyester resin has the characteristics of proper glass-transition temperature, softening point, good storage stability, and the like; the polyester resin, epoxy resin, filler and assistant in a certain proportion are mixed, and the mixture is prepared into powder through melt extrusion mixing, cooling, crushing and sieving; and the prepared powder can be cured at the temperature of 160 DEG C, and has the advantages of excellent leveling performance, good impact performance, and the like.

Owner:GUANGZHOU KINTE IND

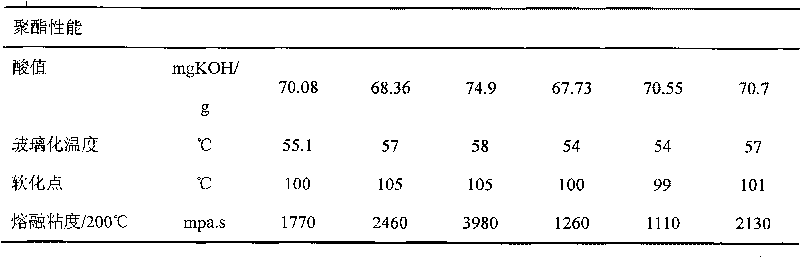

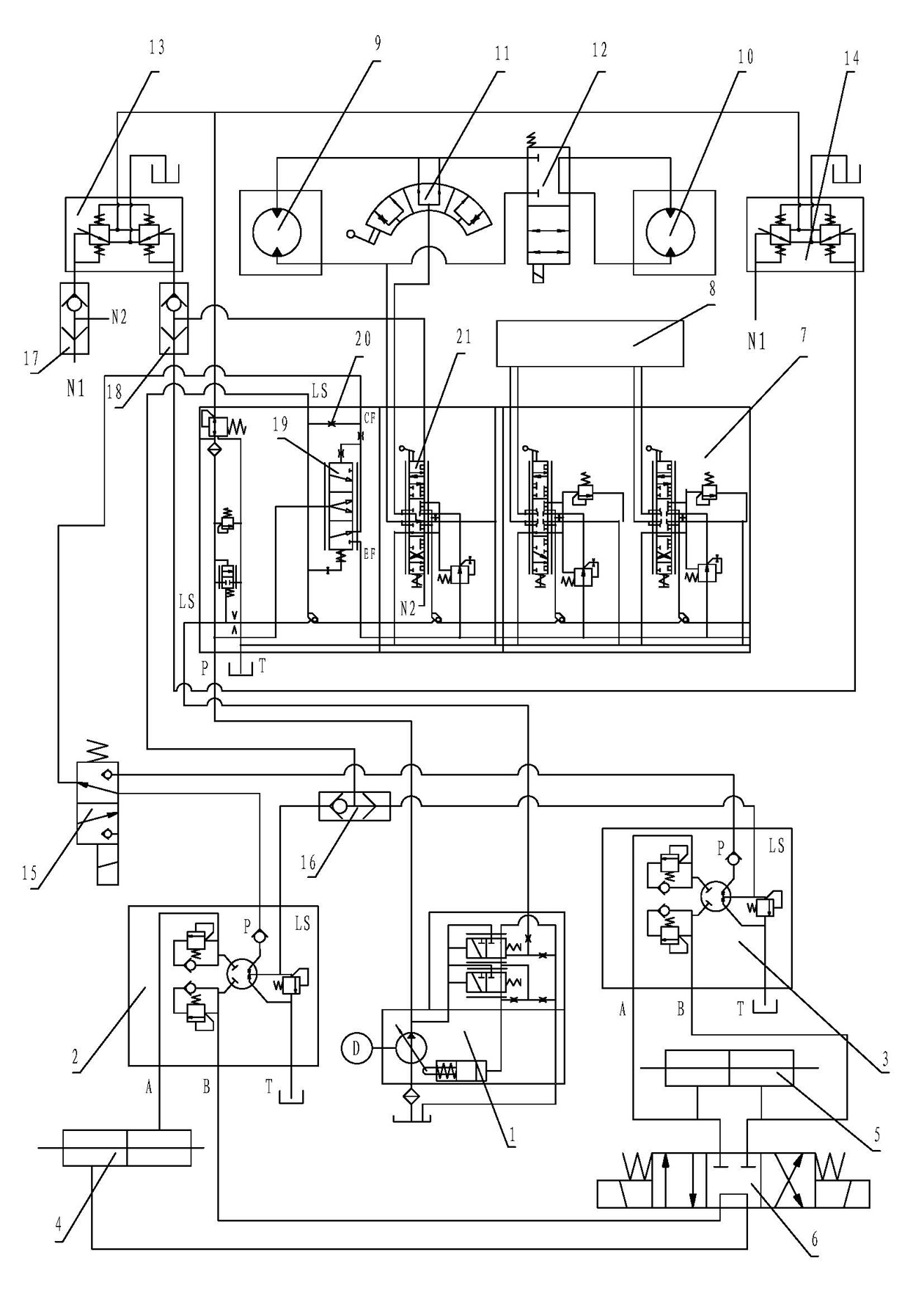

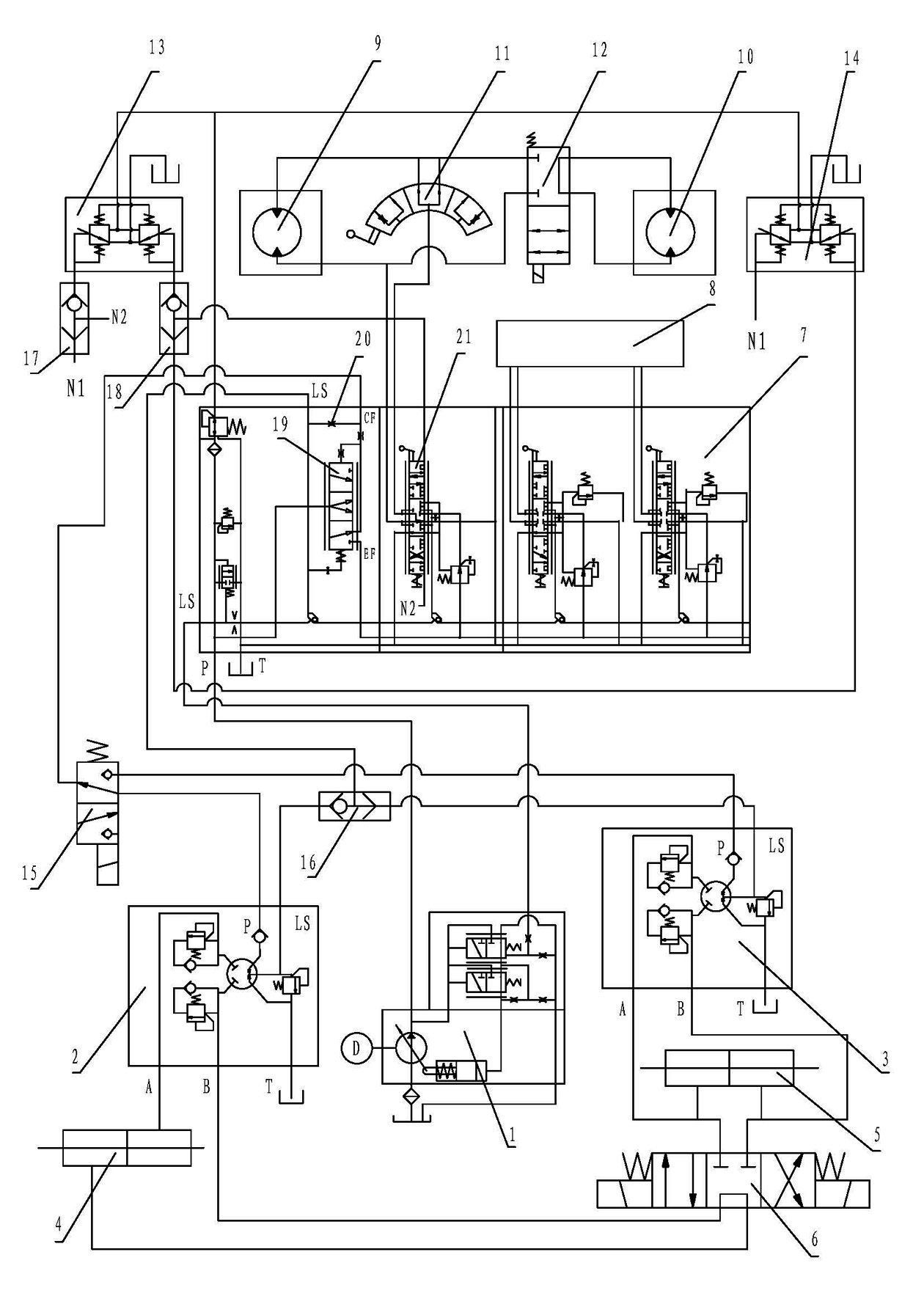

Multi-load hydraulic sensing system for single-power source and multi-system working

InactiveCN101954927AAchieve interlockRealize functionLifting devicesFluid steeringHydraulic motorLoad sensing

The invention relates to a multi-load hydraulic sensing system for single-power source and multi-system working, comprising a main liquid-control handle, an assistant liquid-control handle a load-sensitive variable pump, a load-sensing main steerer, a load-sensing assistant steerer, a front wheel steering oil cylinder, a back wheel steering oil cylinder, a front wheel hydraulic motor, a back wheel hydraulic motor and an operation actuating mechanism, wherein the load-sensitive variable pump is connected with a PVG multipath integrated valve, and the PVG multipath integrated valve is respectively connected with the main liquid-control handle and the assistant liquid-control handle, the front wheel steering oil cylinder and the rear wheel steering oil cylinder, and the operation actuating mechanism and also respectively connected with the load-sensing main steerer and the load-sensing assistant steerer through an anti-explosion two-position three-way electromagnetic valve; the load-sensing main steerer is connected with the front wheel steering oil cylinder, the load-sensing assistant steerer is connected with the back wheel steering oil cylinder, and the front wheel steering oil cylinder and the back wheel steering oil cylinder are connected through a three-position four-way electromagnetic valve; and a posture-adjusting valve and an anti-explosion two-position four-way electrohydraulic valve are arranged between the front wheel hydraulic motor and the back wheel hydraulic motor. The multi-load hydraulic sensing system can realize single-pump oil supply of a running system, a steering system and an operation actuating mechanism, and can also realize electric explosion prevention, two-way driving and all-around steering of the hydraulic system.

Owner:ORDNANCE TECH RES INST OF THE GENERAL ARMAMENT DEPT PLA

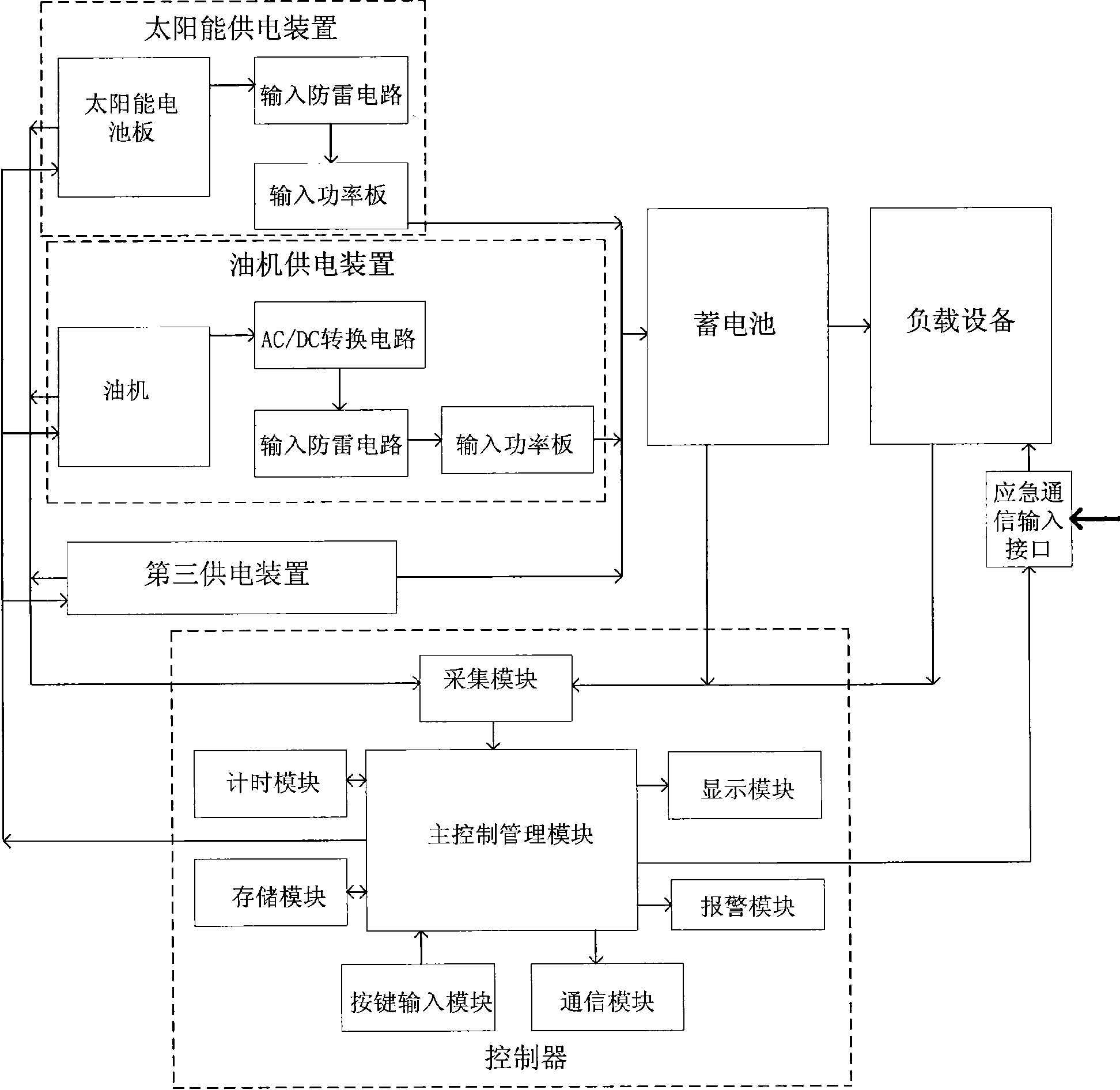

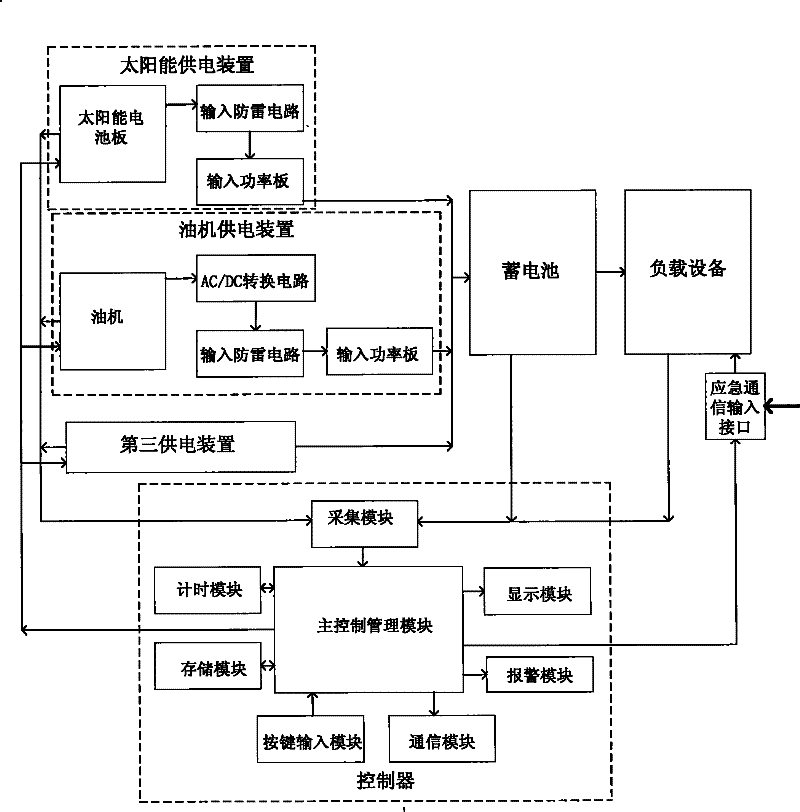

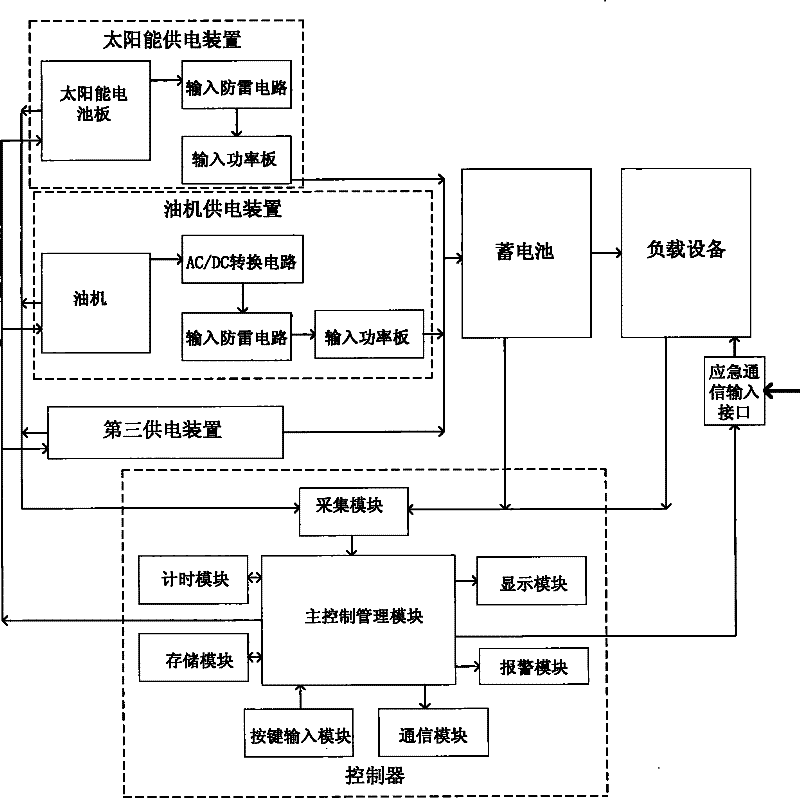

Method for controlling power supply system featuring complementation of solar energy and fuel energy

ActiveCN101572428AContinuous power supplyPrevent low battery powerBatteries circuit arrangementsSecondary cells charging/dischargingStart upEngine power

The invention relates to a method for controlling power supply system featuring complementation of solar energy and fuel energy. In the method, a controller collects input electric current of a solar energy power supply device, charge-discharge electric current of storage batteries and load current of a loading equipment; when the input electric current is less than 1.5 times of load current, the system enters an oil engine auxiliary power supply mode; in the oil engine auxiliary power supply mode, the controller reads the current status of the storage batteries and the current status of the oil engine power supply device and starts up or closes the oil engine power supply device according to certain logic; in the technical proposal of the invention, solar energy power supply mode serves as the main power supply mode, as a result, the solar energy can be fully utilized, requirements for environmental protection are met, the input electric current of a solar panel and the load current of the load device can be monitored in real time; in addition, the oil engine can be started up to supply power when the solar energy power supply device can not supply enough power, thus entering the oil engine auxiliary power supply mode and realizing continuous power supply, improving utilization efficiency of the oil engine and lengthening service life of the storage batteries, strengthening reliability of the power supply system while meeting the requirements on energy conservation and reduction of consumption.

Owner:EMERSON NETWORK POWER CO LTD

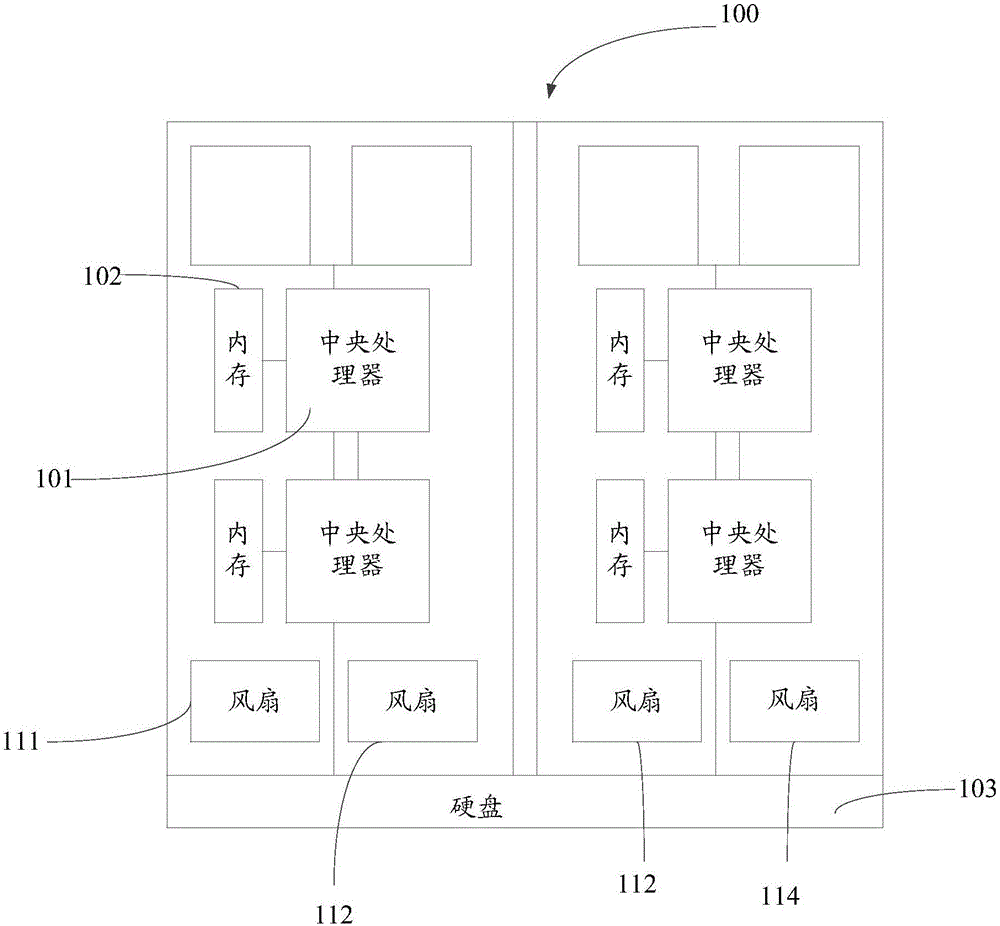

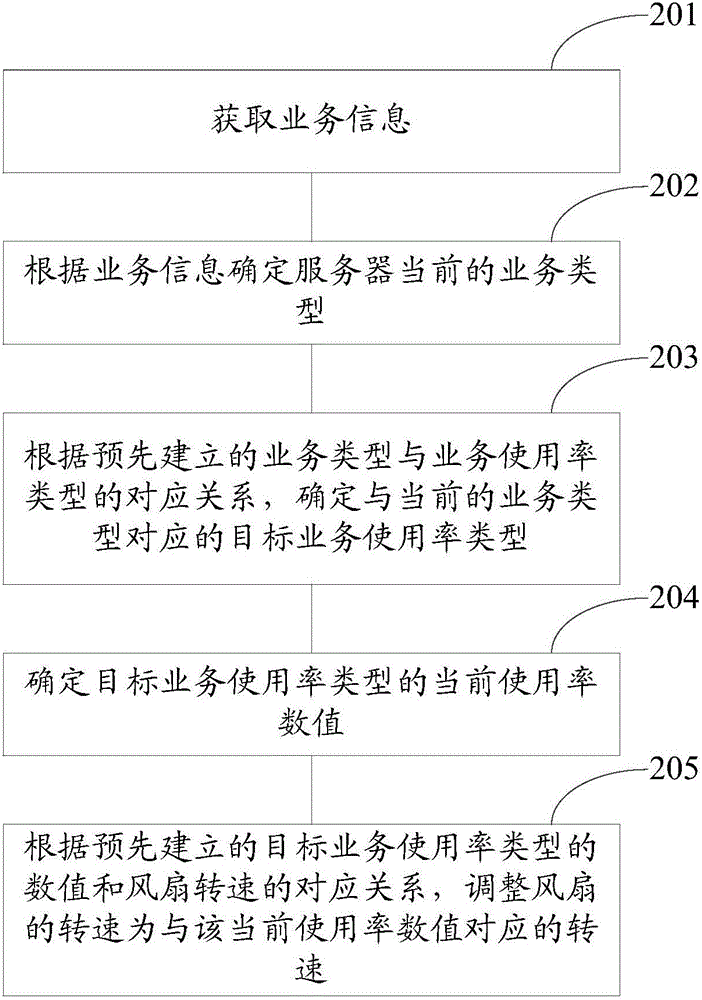

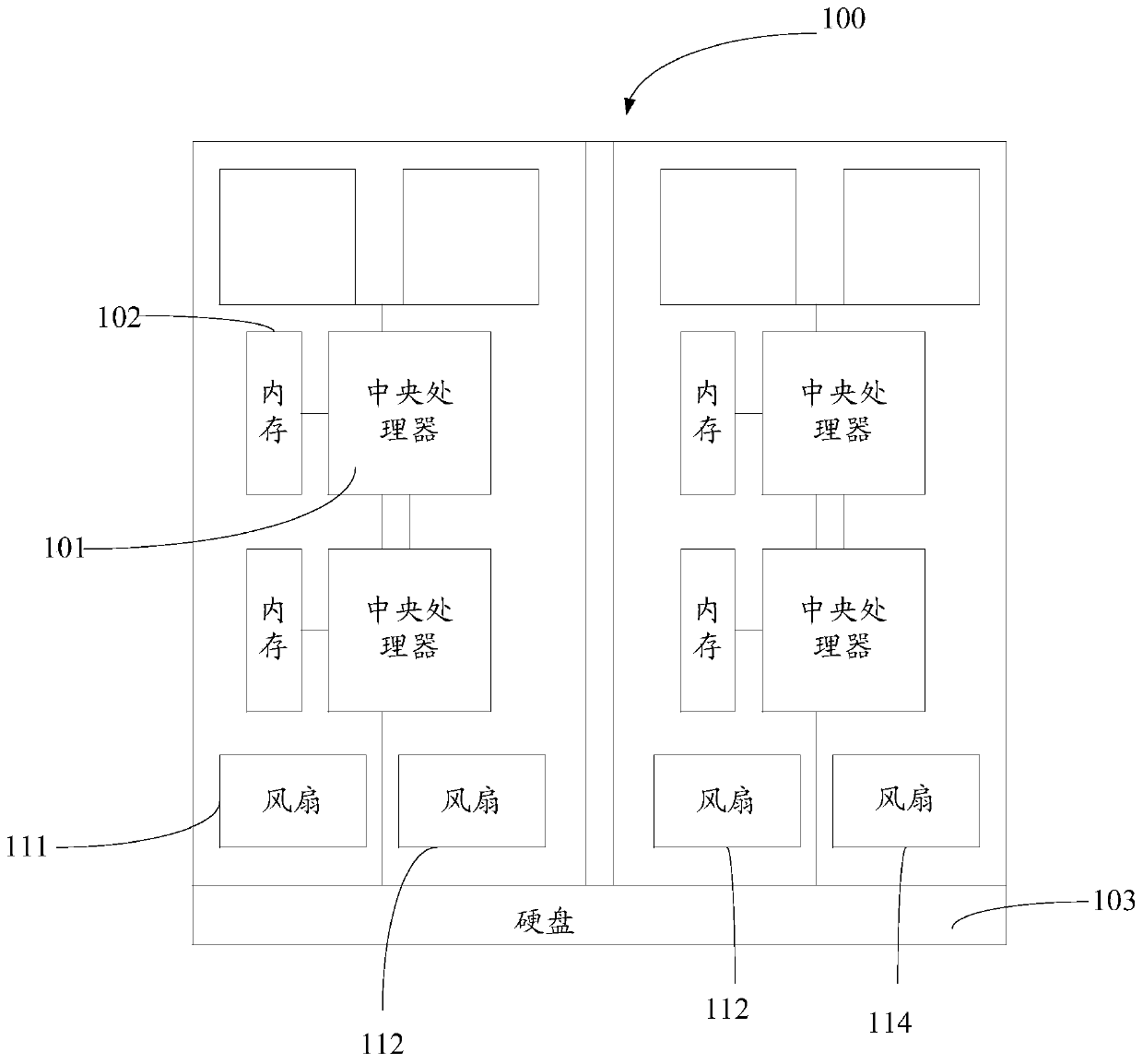

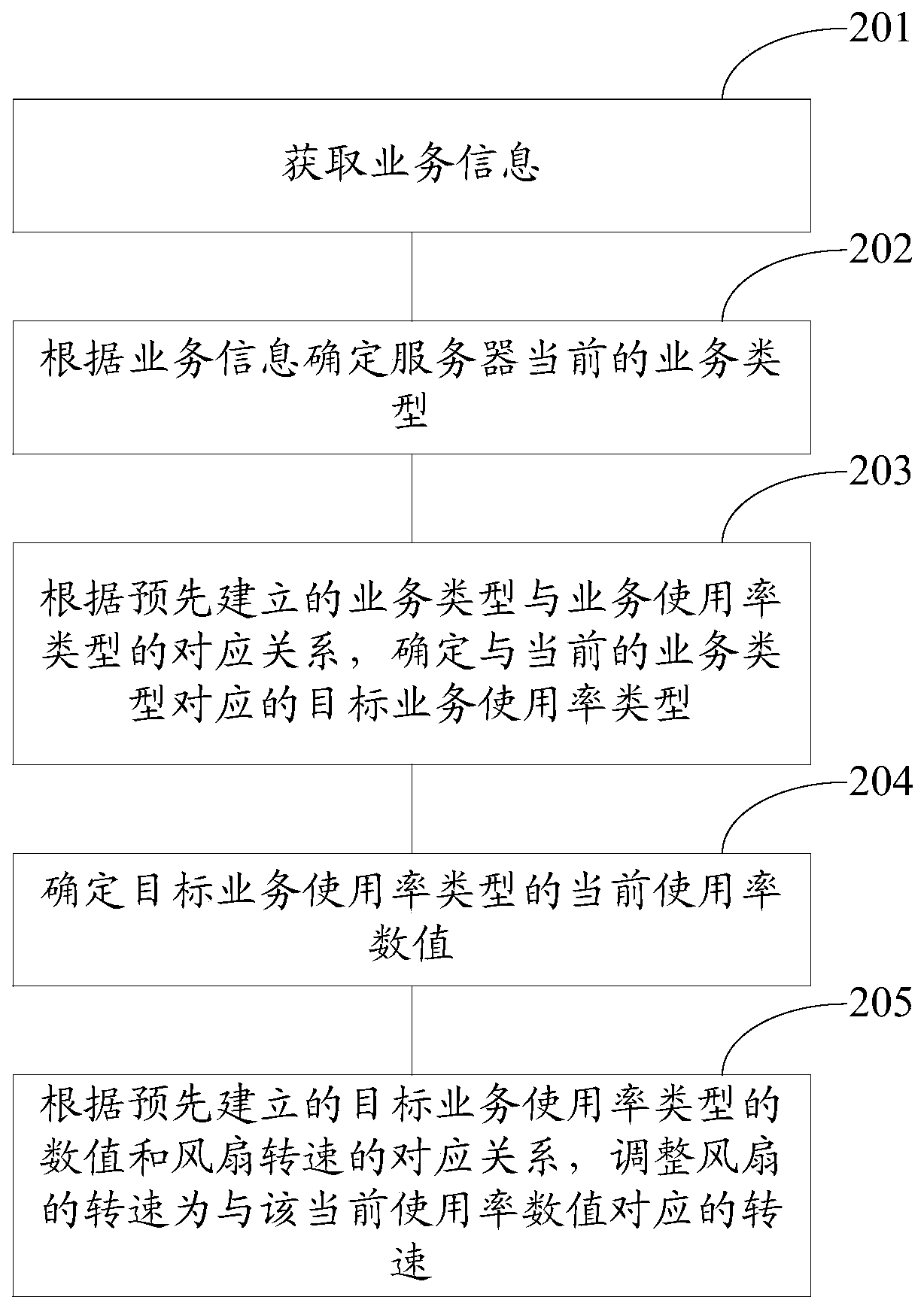

Method and equipment for adjusting rotation speed of fan

ActiveCN106325464AControl speedReduce power consumptionPower supply for data processingEngineeringPower consumption

The embodiment of the invention discloses a method and equipment for adjusting rotation speed of a fan. The method and the equipment are used for decreasing the power consumption of the fan on the equipment. The method is applied to the equipment with the fan, and comprises the following steps of obtaining business information; according to the business information, determining the current business type of the equipment; according to the current business type, adjusting the rotation speed of the fan. The method has the advantages that the rotation of the fan on the equipment can be adjusted according to the current business type of the equipment, so that the rotation speed of the fan can meet the requirement of heat radiation of the equipment under different business types; the rotation speed of the fan is correspondingly changed under the different business types; the rotation speed of the fan is flexibly controlled, the power consumption of the fan is decreased, and the requirements of energy saving and consumption decreasing are met.

Owner:XFUSION DIGITAL TECH CO LTD

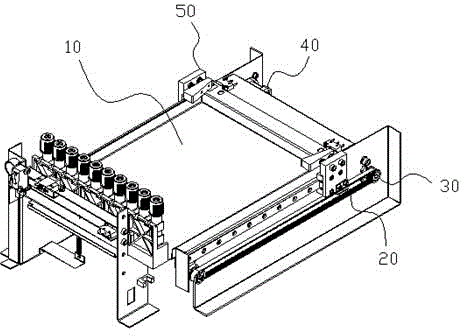

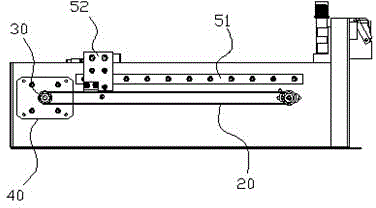

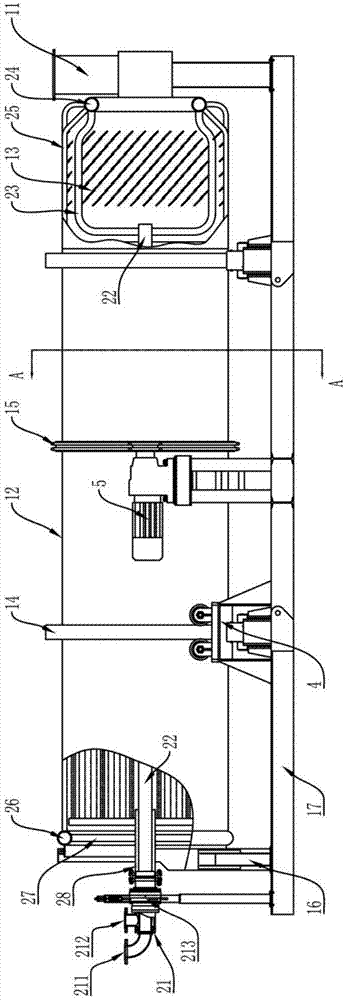

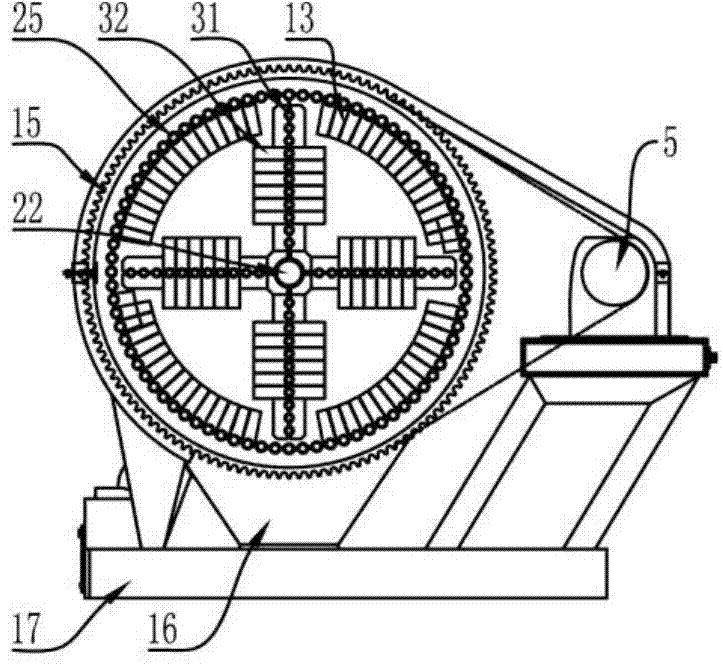

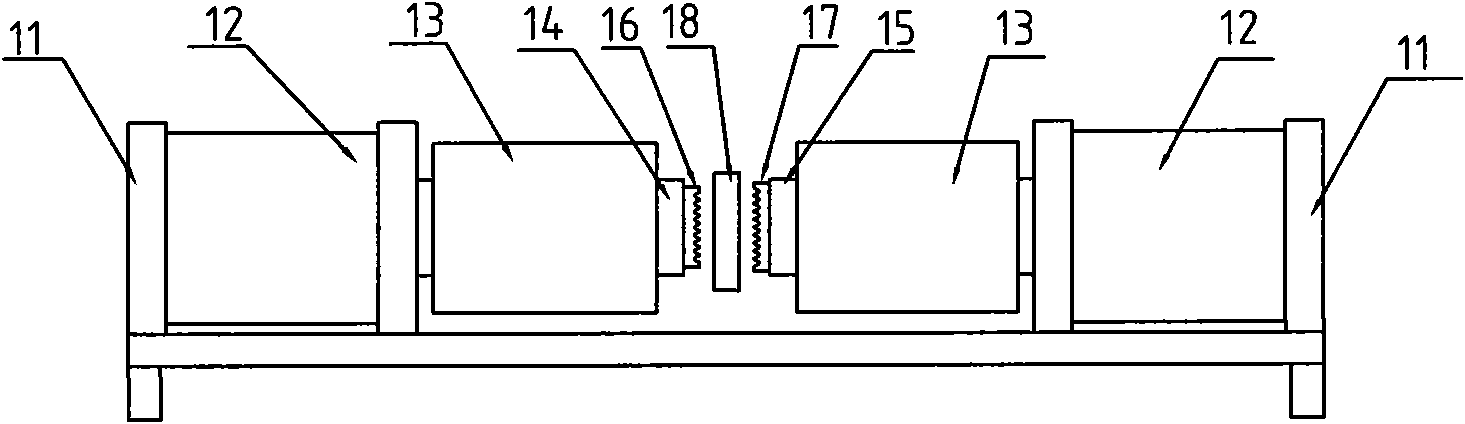

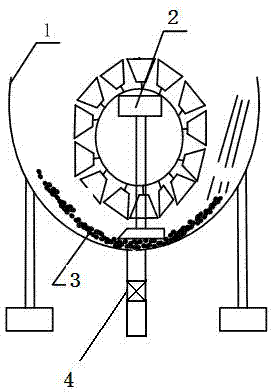

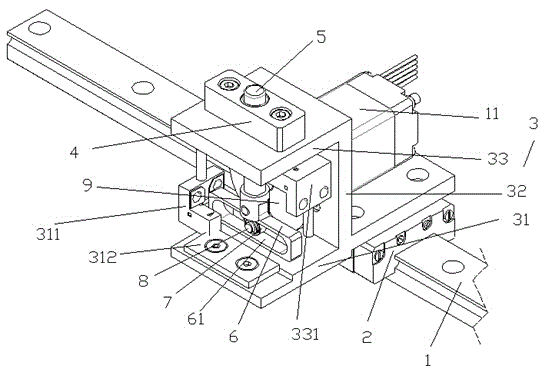

Sample introduction device of blood cell analyzer

ActiveCN104991080AHigh precisionEasy loadingMaterial analysisReciprocating motionBlood cell analysis

The invention relates to the technical field of medical and health apparatuses, particularly to a sample introduction device of a blood cell analyzer. The sample introduction device includes a test tube sample holder loading disc, a synchronous belt, synchronous pulleys driving the synchronous belt to do reciprocating motion, a motor driving the synchronous pulleys to rotate and a guide mechanism. The guide mechanism includes linear slide rails parallel to the synchronous belt and a sliding block able to slide on the linear slide rails. The sliding block is in fixed connection with the synchronous belt and is driven by the motor to move. The sample introduction device also includes a push block that is fixed on the sliding block and does reciprocating motion along with the synchronous belt. Under the driving of the push block, the test tube loaded test tube sample holder is conveyed to a specific location along the guide mechanism. The device provided by the invention employs the linear guide rails to replace existing linear bearings to serve as the guide transmission mechanism, the load is large, the stability is stronger, and the rigidity is enough.

Owner:ZHONGSHAN CHUANGYI BIOCHEM ENG

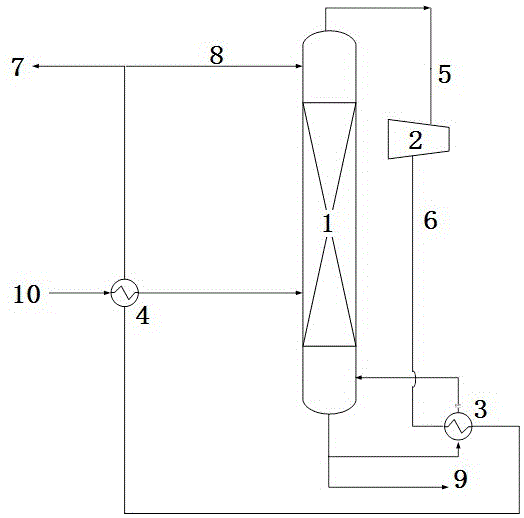

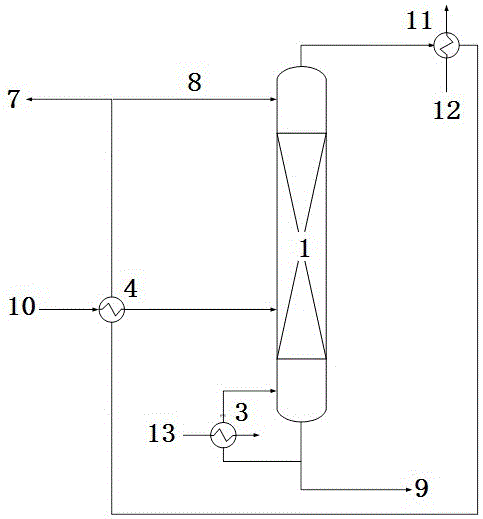

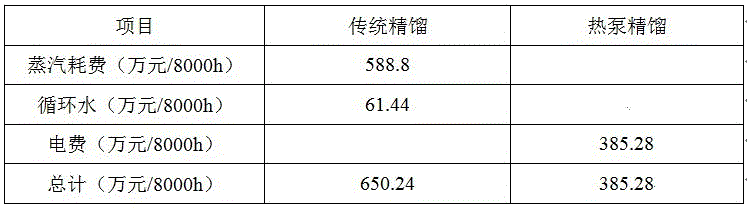

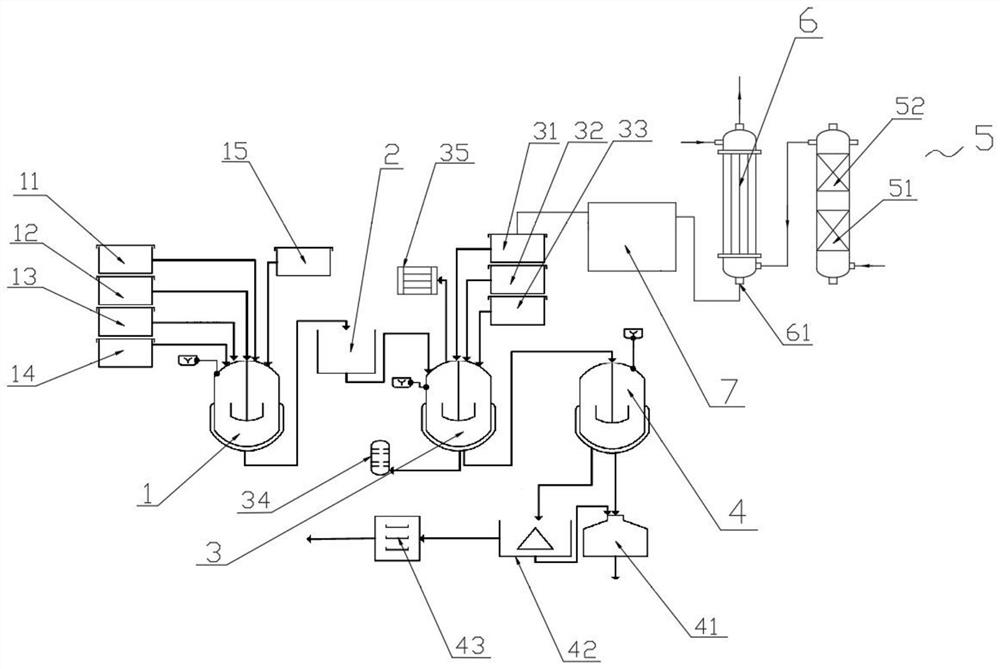

Heat-pump distillation technology for recycling dichloromethane solvent

InactiveCN105693460AReduce consumptionMeet the requirements of energy saving and consumption reductionHalogenated hydrocarbon preparationRefluxGas phase

The invention provides a heat-pump distillation technology for recycling a dichloromethane solvent and belongs to the field of heat-pump distillation. A feedstock (10) heated by a preheater enters a distillation tower (1), a main separation task is completed in the distillation tower, dichloromethane steam (5) with the concentration of 80%-99.99% is produced from a tower top and is subjected to boosting and heating by a steam compressor, compressed dichloromethane steam (6) enters the hot side of a reboiler (3), after the steam exchanges heat of a liquid phase at the bottom of the tower, condensate is the liquid phase, and the liquid phase passes through the hot side of the preheater (4); after the feedstock (10) is preheated, a part of the feedstock is taken as a tower top discharging material (7), and the other part is taken as tower top reflux (8); a tower bottom outlet is divided into two ways, one way is evaporated into a gas phase through the cold side of the reboiler (3) and enters the tower bottom, and the other way is taken as a tower bottom heavy-component discharging material (9); the operating pressure of the distillation tower is 100 kPa-400kPa, and the reflux ratio is 0.5-6; the compression ratio of the steam compressor is 1.5-6. According to the heat-pump distillation technology for recycling the dichloromethane solvent, the energy consumption in traditional production is reduced.

Owner:JIANGSU LEKE ENERGY SAVING TECH CO LTD

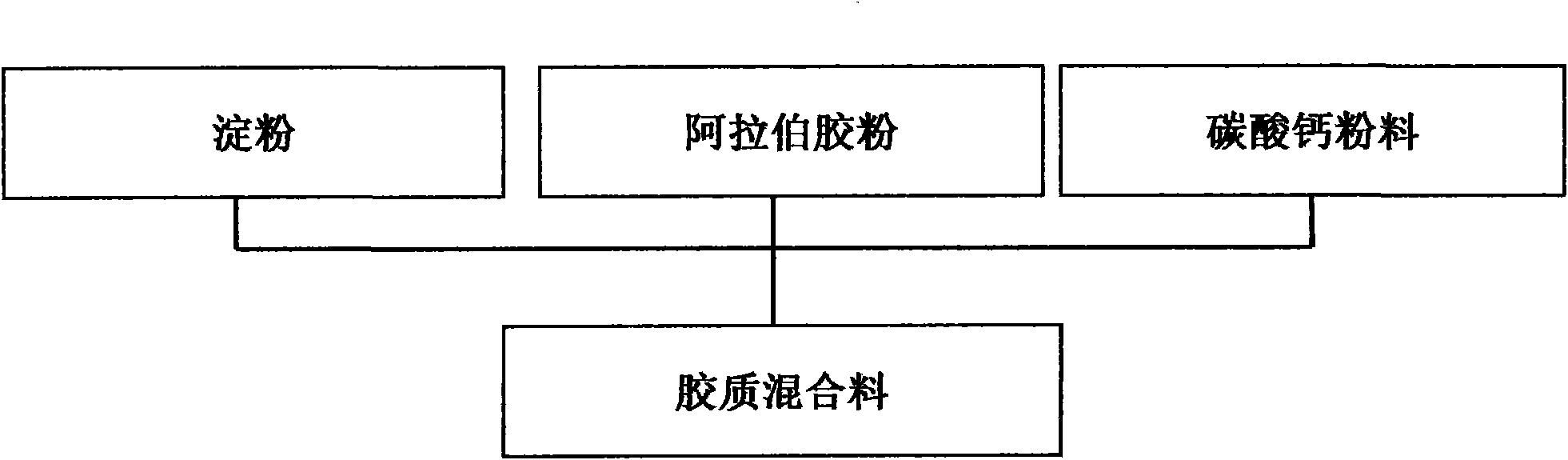

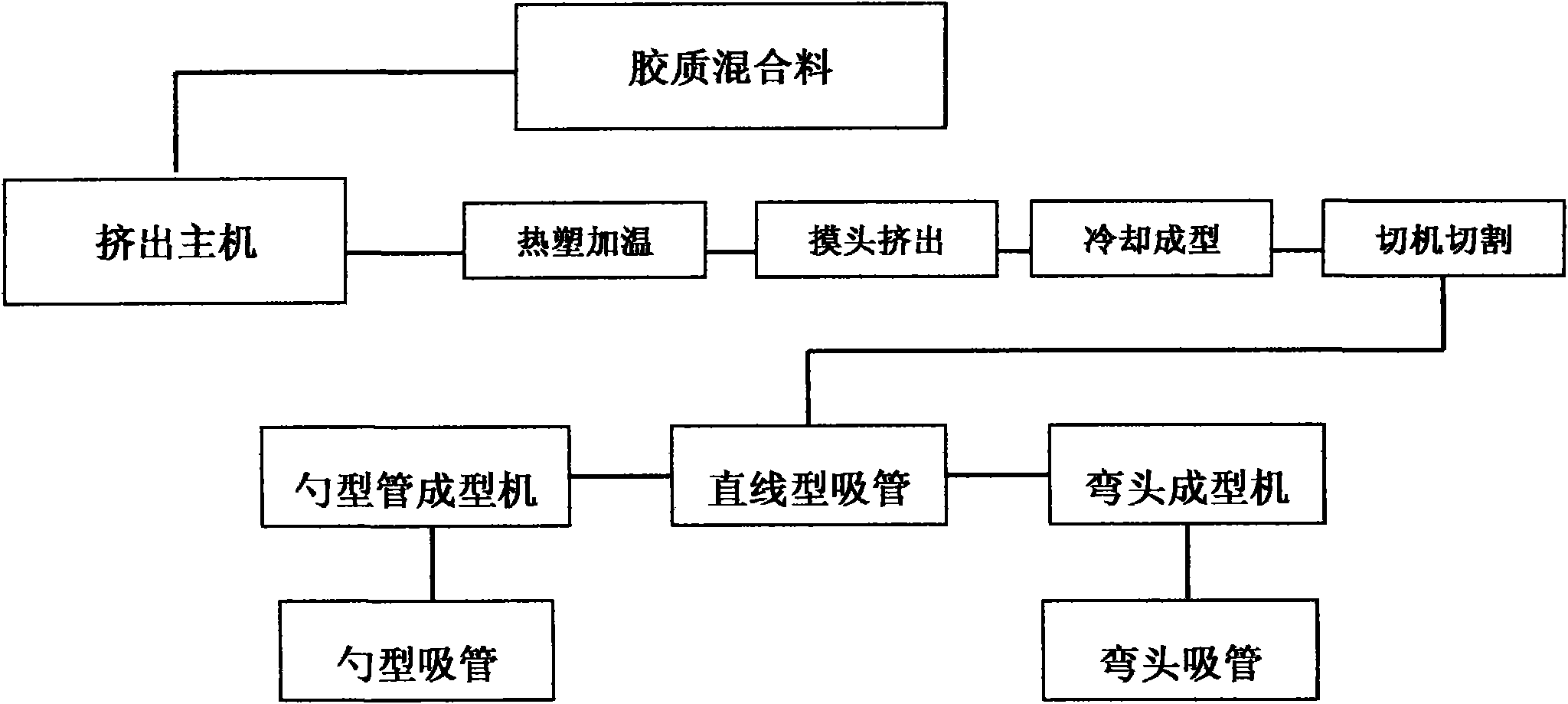

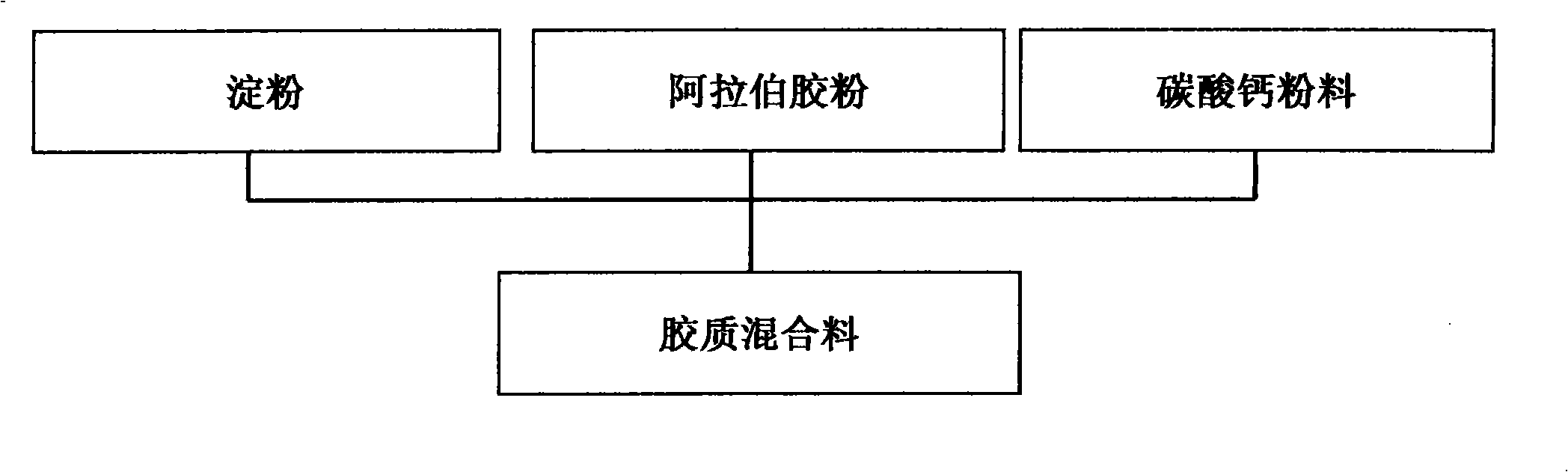

Method for preparing degradable biomass material and straw

InactiveCN102167845AWide variety of sourcesLow priceTubular articlesTablewaresRational methodGum arabic

The invention provides a method for preparing a degradable biomass material. The method is characterized by comprising the following steps of: (1) preparing raw materials, namely weighing the following raw material components in percentage by weight: 79 to 99 percent of starch serving as a main material, 0.5 to 1 percent of arabic gum serving as a modified material and 0.1 to 20 percent of calcium carbonate serving as a filler; (2) mixing the components to form a gummy mixture; and (3) and standing the gummy mixture at a low temperature for later use. The invention also discloses a method for preparing a straw by using the material; and the method comprises the following steps of: (4) preparing a straw extrusion main machine and a circular die head which is matched with the main machine for use; (5) feeding the gummy mixture into the extrusion main machine to prepare a continuous circular hollow straw; and (7) cutting the prepared continuous straight straw into straw sections. The invention also provides the straw prepared by the method. The material provided by the invention has the advantages of complete degradation, scientific and rational method, high product performance and low cost.

Owner:楼仲平

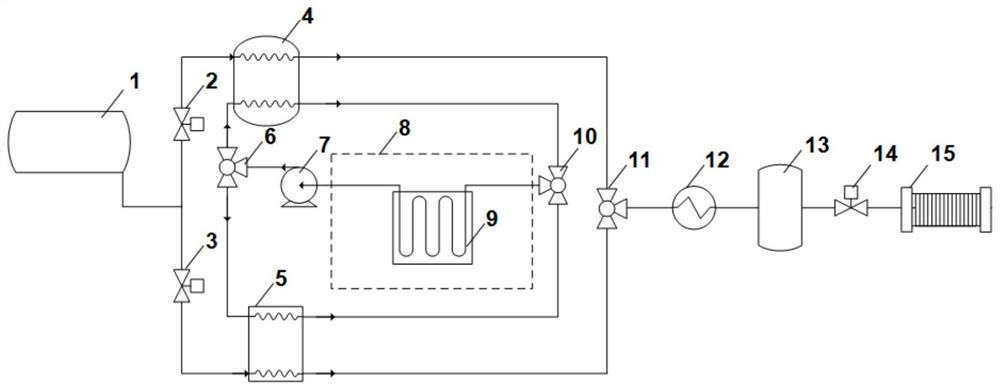

Liquid hydrogen refrigerating system for fuel cell cold-chain logistics vehicle

InactiveCN112009349AAchieving zero emissionsMeet the needs of developing clean energyAir-treating devicesDomestic cooling apparatusCold chainLogistics management

The invention discloses a liquid hydrogen refrigerating system for a fuel cell cold-chain logistics vehicle. A liquid hydrogen storage tank discharges liquid hydrogen outwards, and the liquid hydrogenenters a heat exchanger and a regenerator through an on-off controllable pipeline. Liquid hydrogen releases cold energy in the heat exchanger and the regenerator, and the cold energy is heated and converted into low-temperature hydrogen. Low-temperature hydrogen can enter a fuel cell using channel to be used by a fuel cell. And a secondary refrigerant flows out of a cold plate and is led to the heat exchanger or the regenerator. The secondary refrigerant completing cold transfer in the heat exchanger and the regenerator returns to the cold plate through the on-off controllable pipe, and the cold is transferred to a refrigerated truck carriage. On the basis that conversion from liquid hydrogen to hydrogen is completed and the hydrogen supply requirement of the fuel cell is met, liquid hydrogen cold energy utilization is achieved, the energy utilization efficiency is improved, the energy-saving and environment-friendly development requirement is met, and wide development prospects are achieved.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

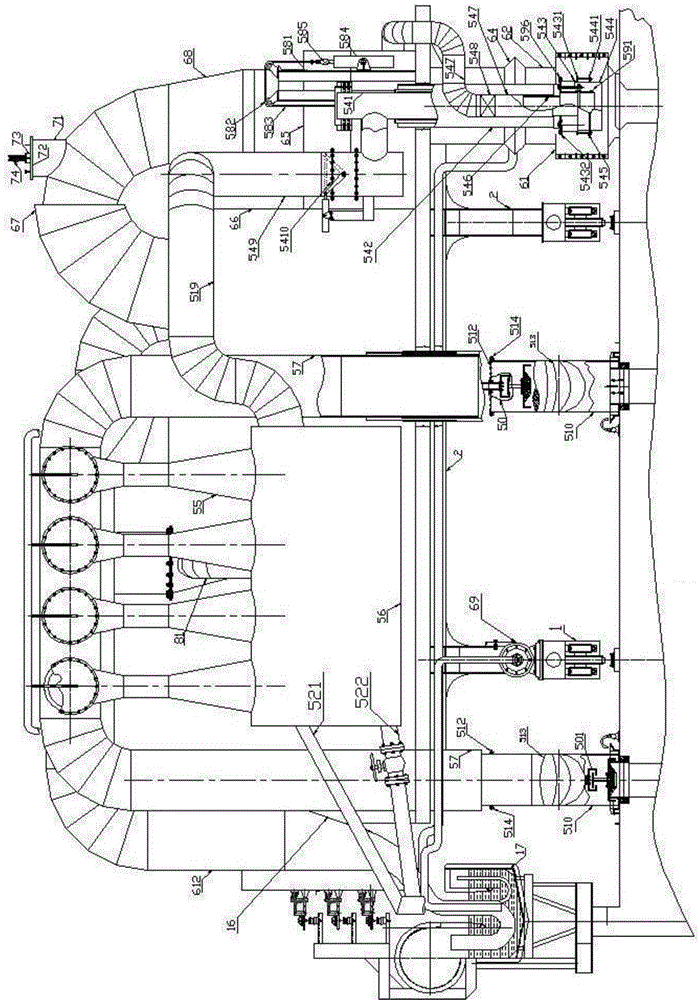

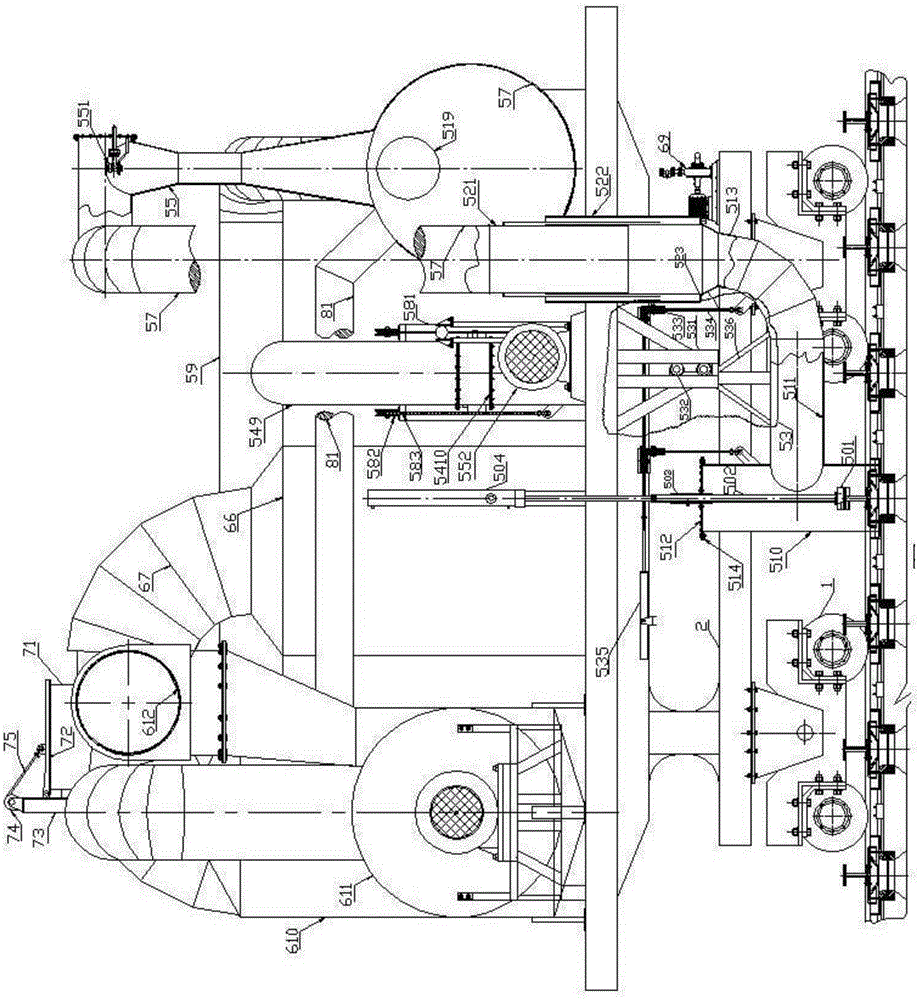

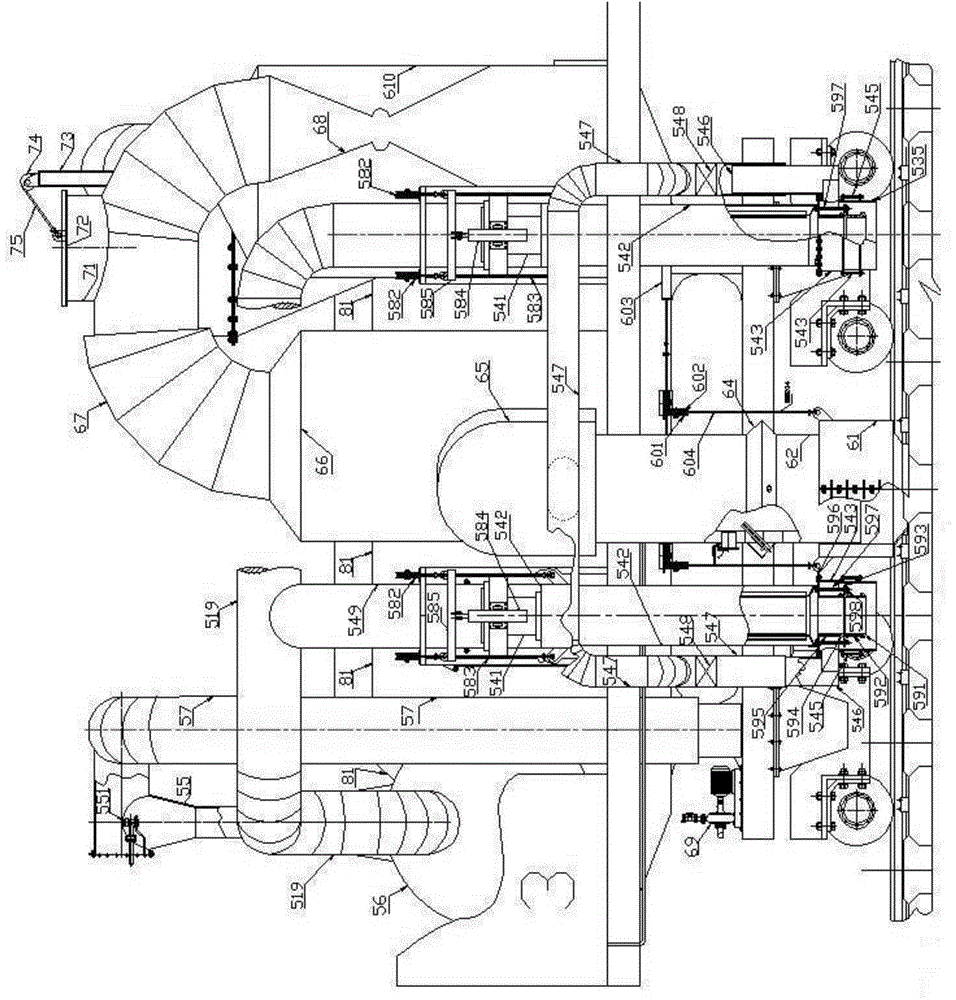

Internal-suction type multifunctional car capable of guiding smoke, recovering coal gas and eliminating smoke and dust via combustion

ActiveCN104610986AHigh efficiency of recycling smoke guideReduce the energy consumption of smoke guide and dust removalOven incrustations prevention/removalCharging devicesCombustionCarbonization

The invention particularly relates to an internal-suction type multifunctional car capable of guiding smoke, recovering coal gas and eliminating smoke and dust via combustion, which belongs to the technical field of coking with a coke oven. The multifunctional car inherits the advantages of smoke guiding via combustion and smoke guiding via high-pressure ammonia water ejection N-1 and N+2 pipes, and has the advantages of capacity of deep-processing and recycling of energy, energy conservation, low manufacturing cost and operation cost and good economic benefits and environmental protection effects. According to a technical scheme in the invention, a running gear is arranged at the bottom of a frame body; a movable adsorption conduit and a fixed adsorption conduit are both arranged on the frame body; the movable adsorption conduit is inserted and mounted in the fixed adsorption conduit; a jet pump is communicated with the fixed adsorption conduit and a gas-collecting and water-storing tank; the coal gas outlet of the gas-collecting and water-storing tank is communicated with the smoke inlet of a carbonization chamber through a fixed smoke guide pipe; and the coal gas inlet of a combustion smoke-and-dust elimination system is communicated with a second smoke outlet located at the top of the coal loading carbonization chamber. The multifunctional car provided by invention can be widely used in the field of coke.

Owner:刘瑞军

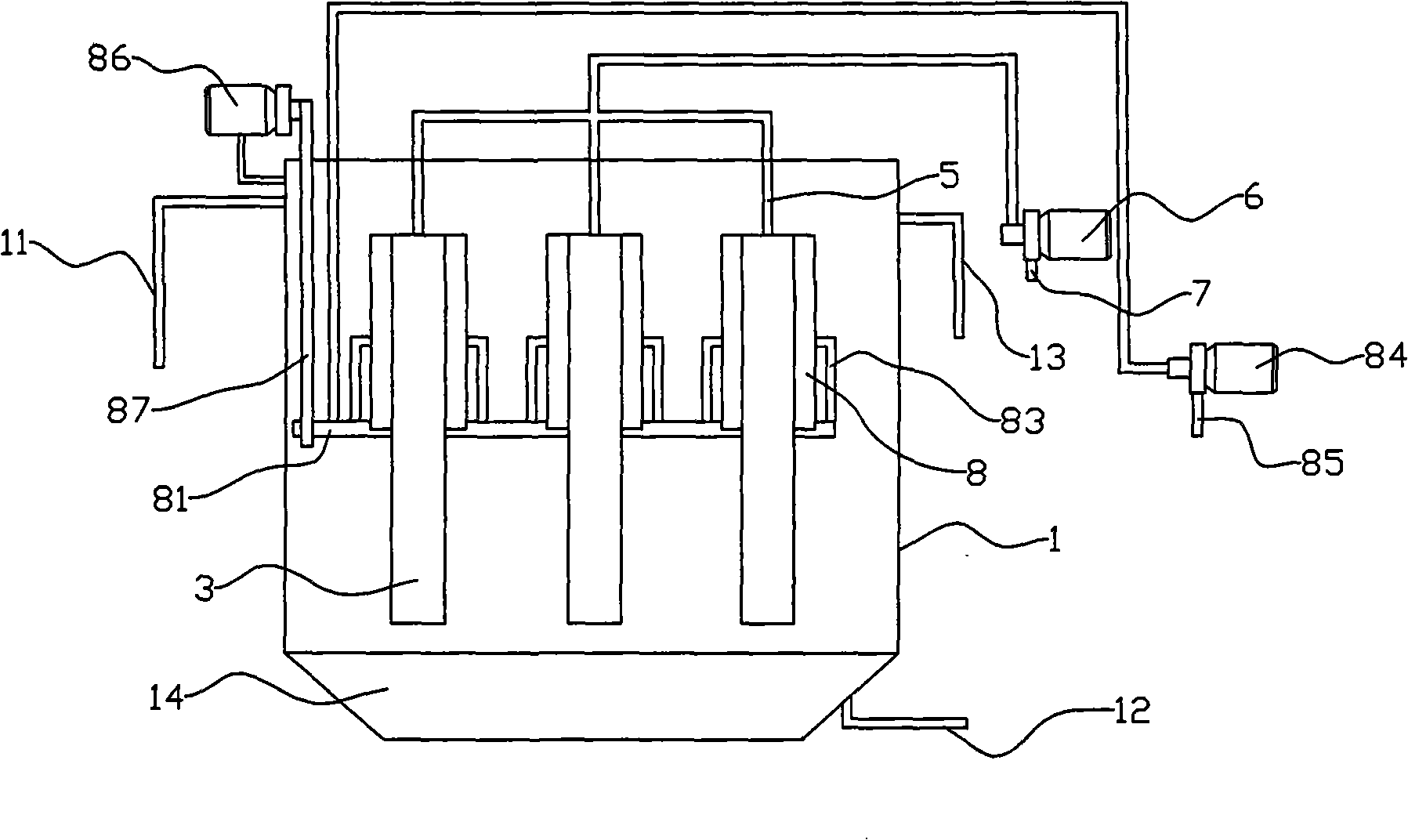

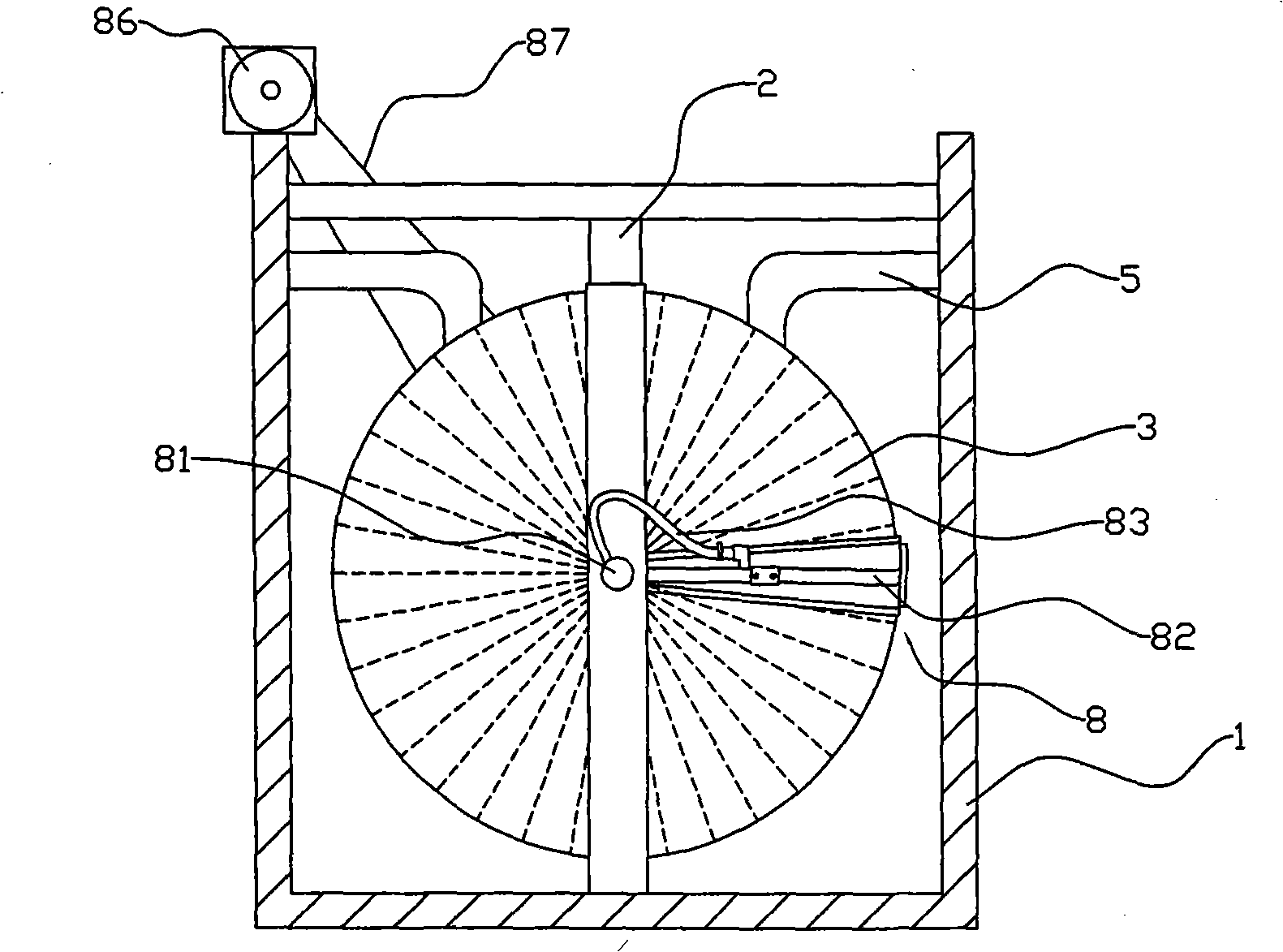

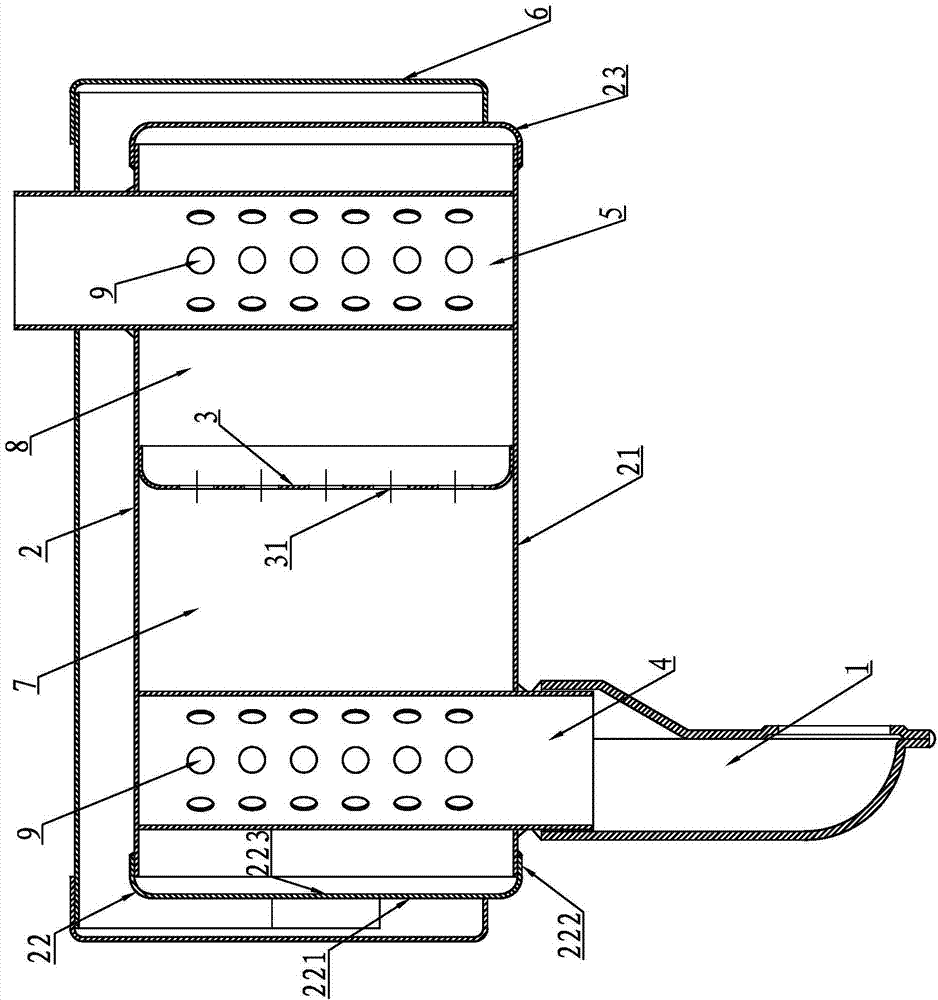

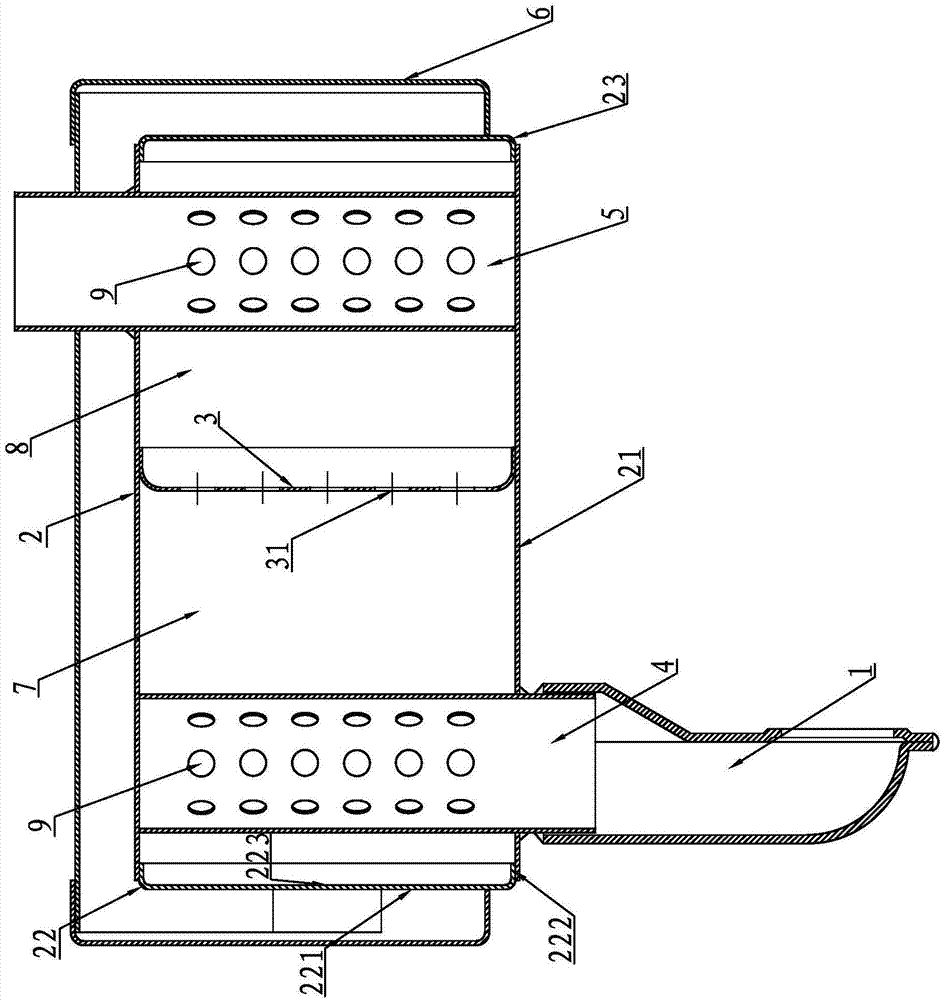

Immersed filter

ActiveCN101357276ASmall footprintLow running costStationary filtering element filtersWater storage tankFilter media

The invention discloses a submerged filter, comprising a water storage tank, a supporting rack arranged inside the water storage tank, one or more filter discs fixedly arranged on the supporting rack, a filter medium arranged on the surface of the filter discs, and an inner cavity of the filter discs which is communicated with a discharge hole by an outlet tube and a water pump. The submerged filter has the advantages of small area occupancy, low operation cost, low water consumption for backwash which only accounts for 0.5%-2.0% of the total filtered water, lower energy consumption which only accounts for 20%-25% of the energy consumption of a conventional pressure filter or a vacuum filter, and meeting the requirements of saving energy and reducing energy consumption.

Owner:JIANGMEN CHUANYUAN ENVIRONMENT TECH CO LTD

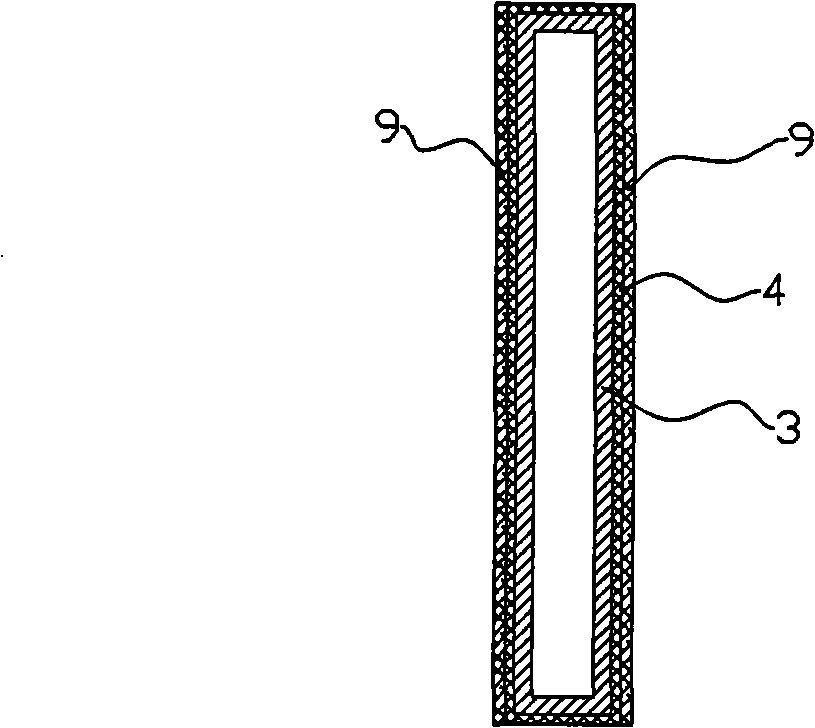

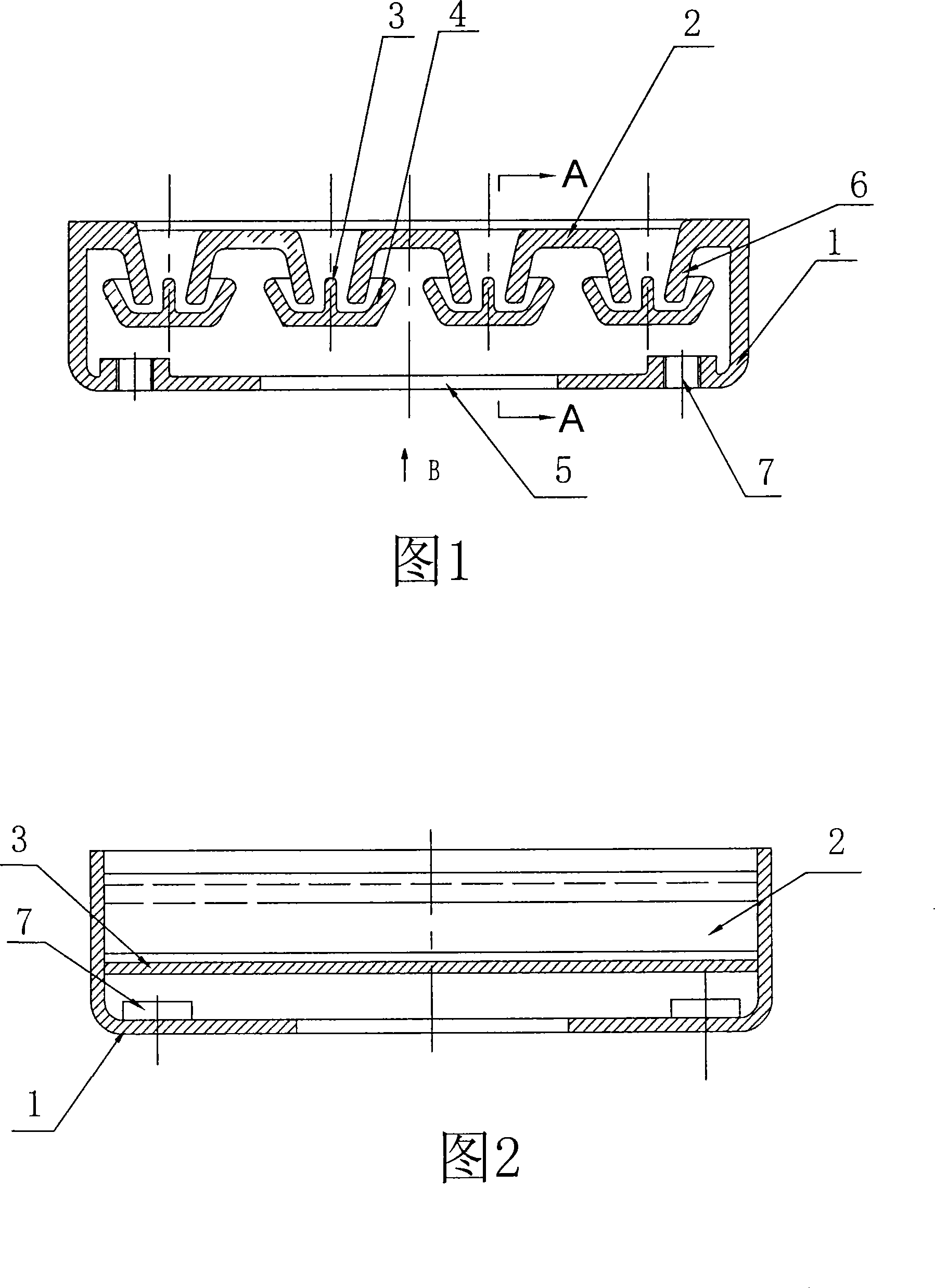

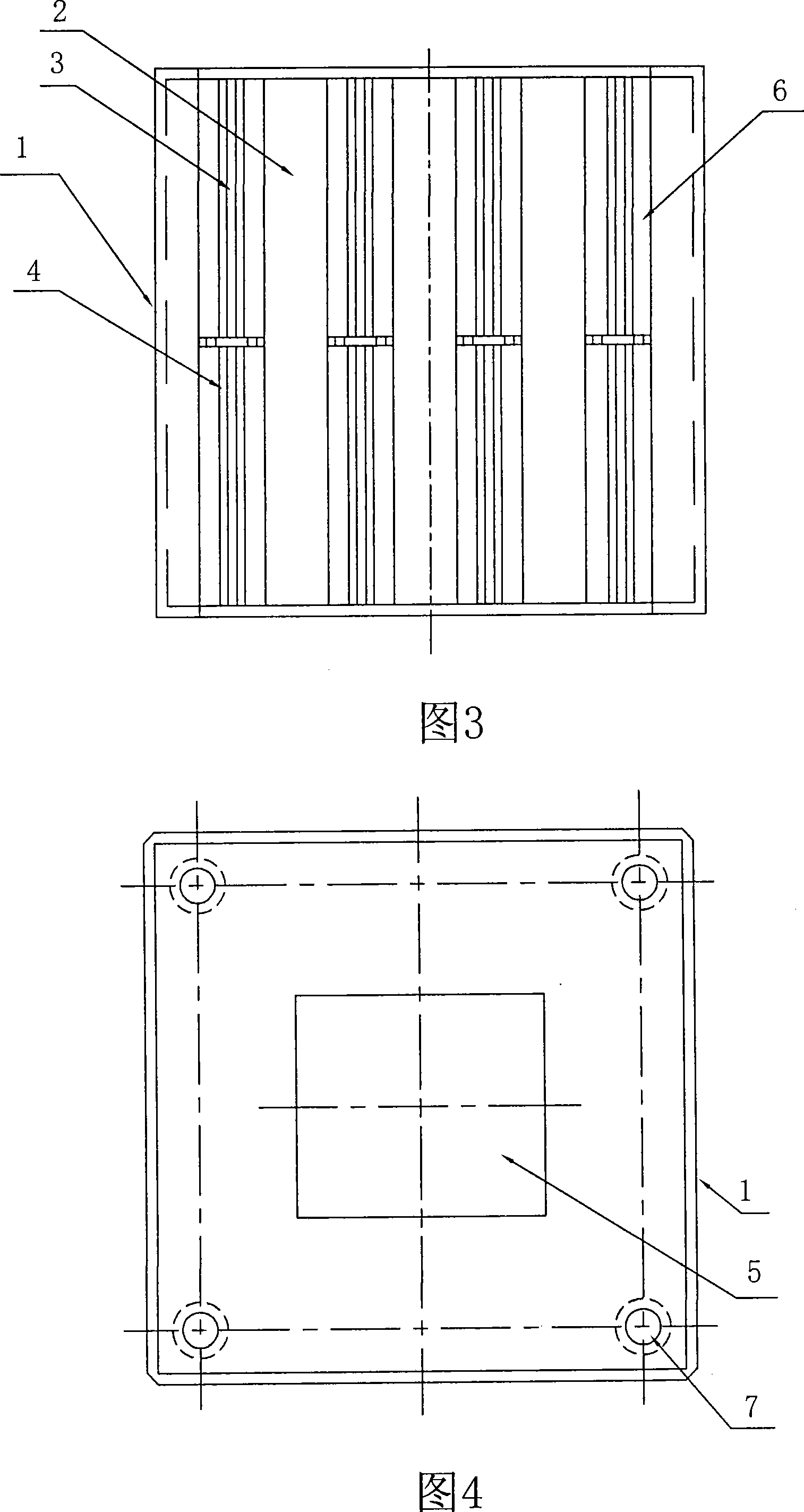

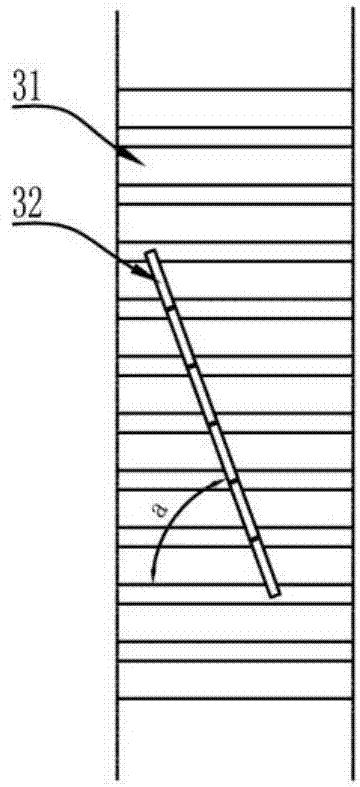

Grid plate of energy-saving grid cold machine

InactiveCN101231146AThere will be no material leakageReduce manufacturing costHandling discharged materialEngineeringStraddle

The invention relates to an energy-saving type grate plate of a grate cooler, which belongs to a part of a cement kiln and furnace and comprises a chassis 1, the bottom of which is provided with a wind inlet 5. The invention is characterized in that two side edges opposite to the chassis 1 are connected with hems 6, inverse U-shaped trough plates 2 and positive U-shaped trays 4 are respectively arranged in the chassis 1, wherein, two downward side edges of each inverse U-shaped trough plate 2 are respectively arranged in adjacent positive U-shaped trays 4 in an interval straddle way , the hems 6 are inserted in adjacent positive U-shaped trays 4 in an interval way, wind outlets 7 are formed between adjacent inverse U-shaped trough plates 2 as well as between the inverse U-shaped trough plates 2 on both sides and the hems 6 on corresponding side edges, and a main body of a section of each wind outlet 7 forms an inverse trapezoid. A strip-shaped wind stopping convex bar 3 is arranged on a central position of each positive U-shaped tray 4, and the upper end surface of the wind stopping convex bar 3 is higher than the lower edge of the inserted side edge of each inverse U-shaped trough plate 2. The invention has the advantages of simple structure, good effects of burning loss prevention and return blow prevention and high permeability of cooling wind, and increases the cooling efficiency of the grate cooler with a big extent.

Owner:万大龙

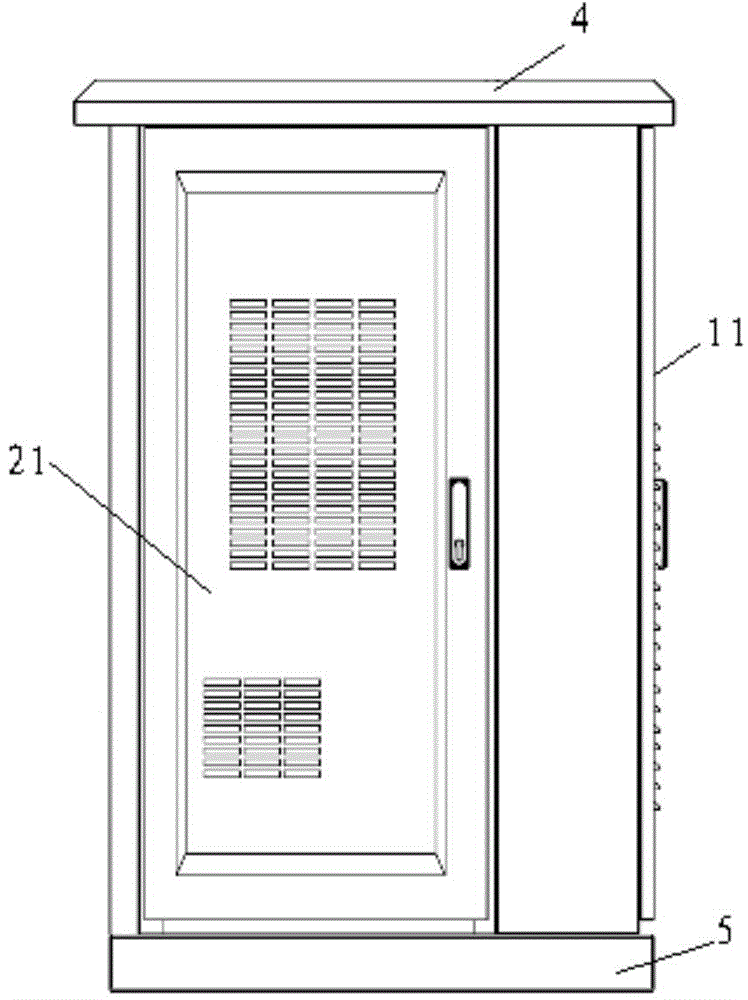

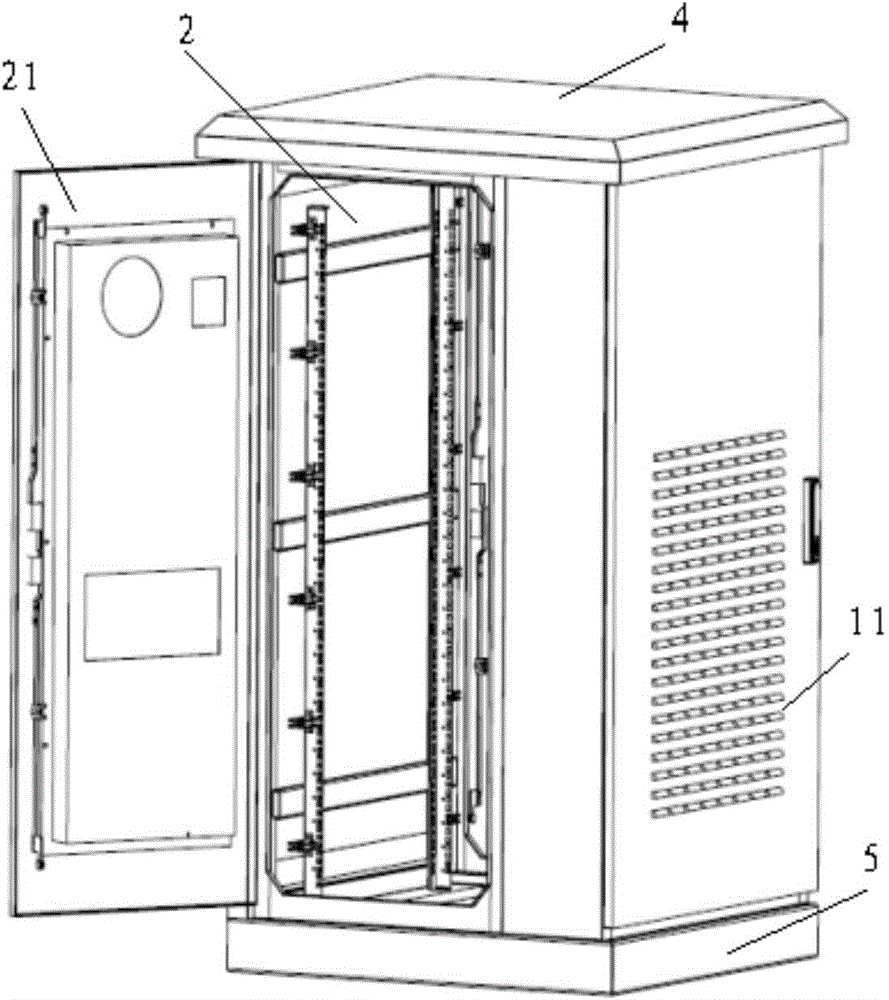

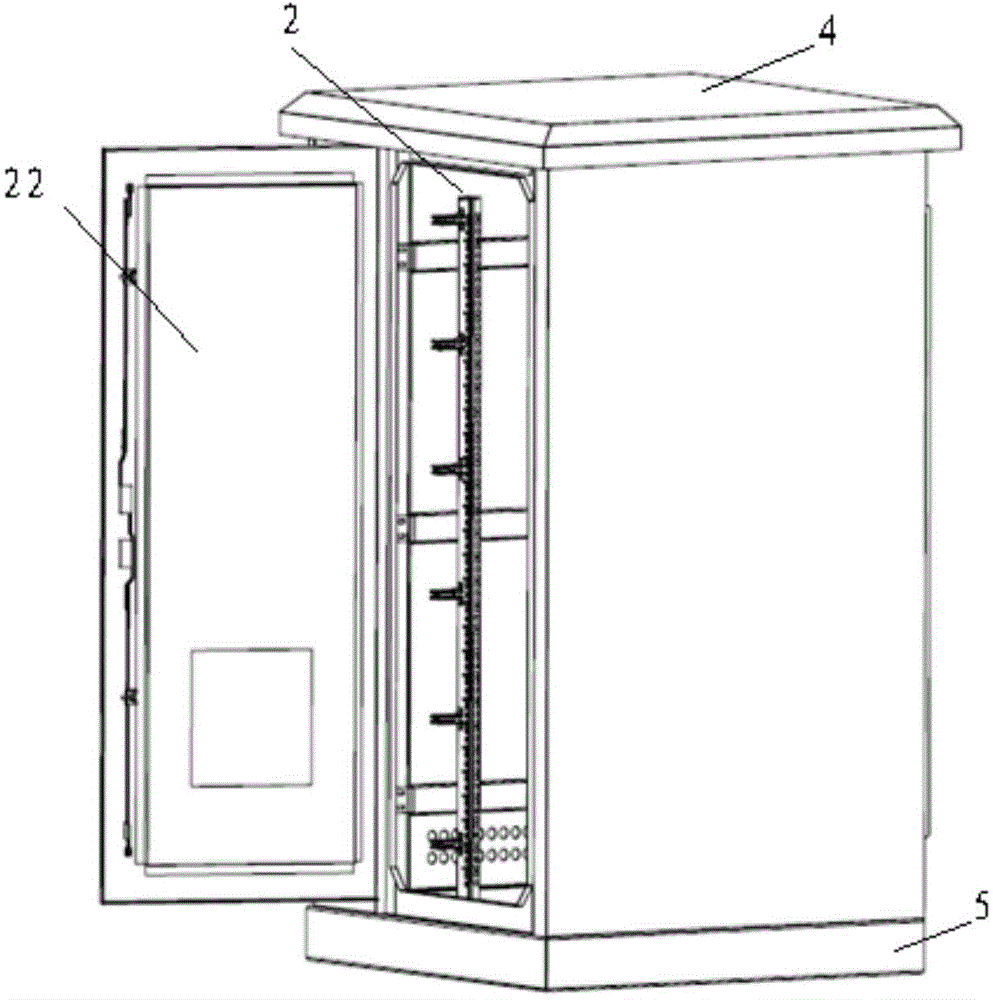

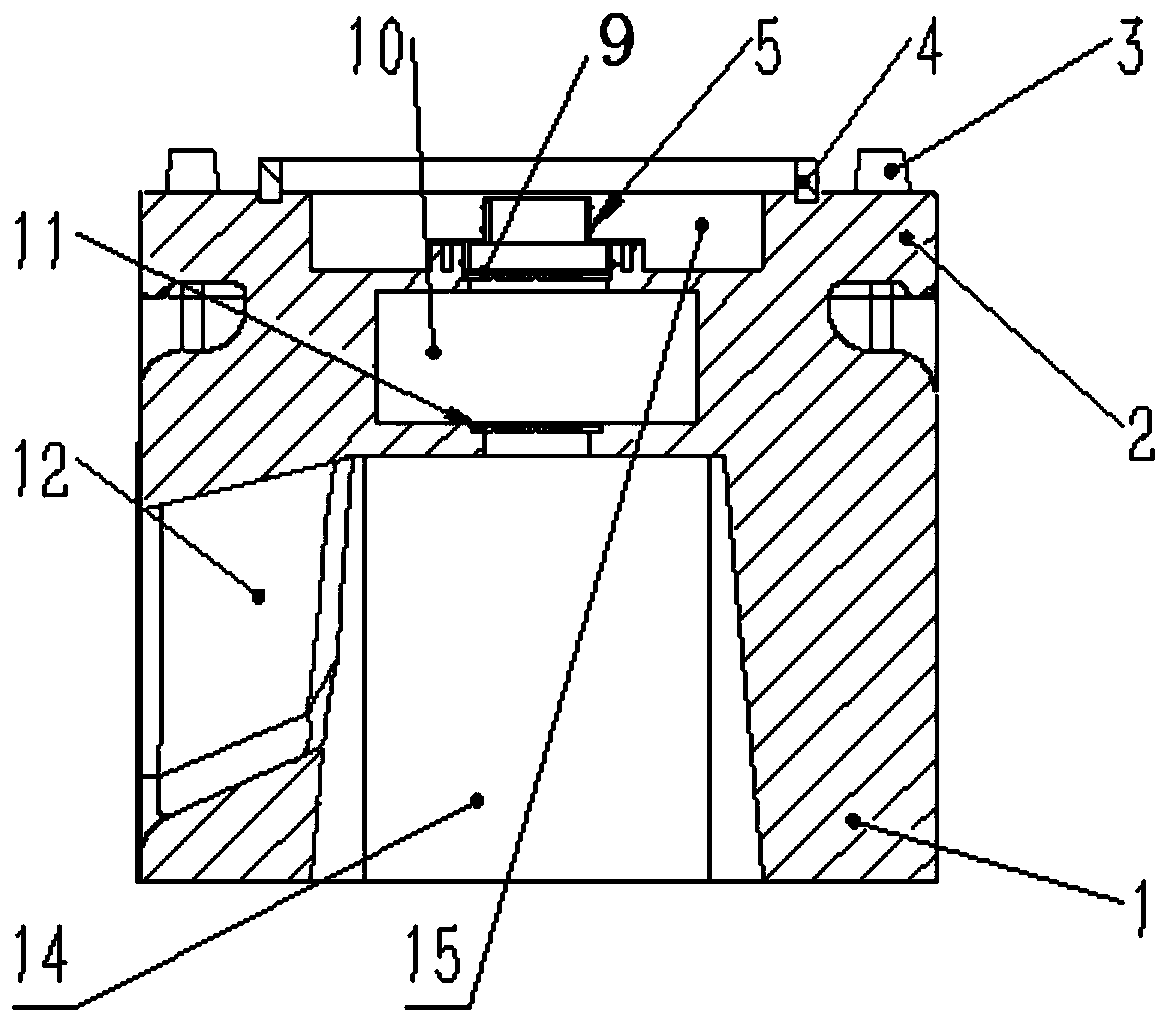

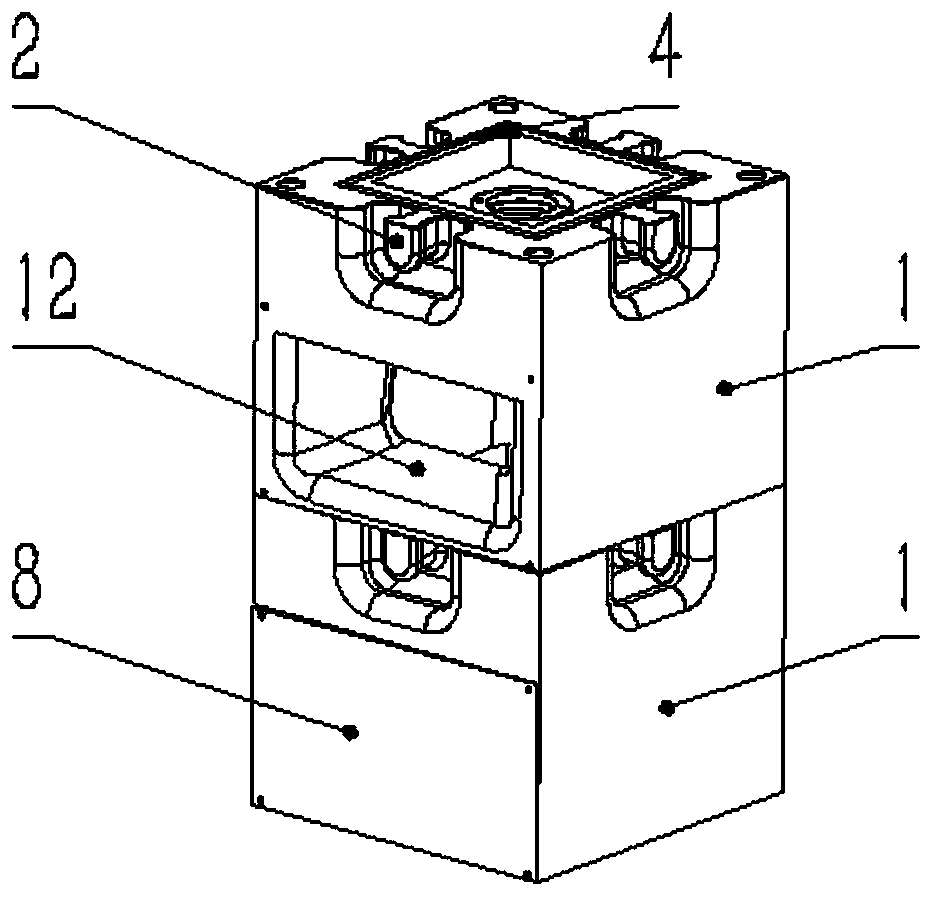

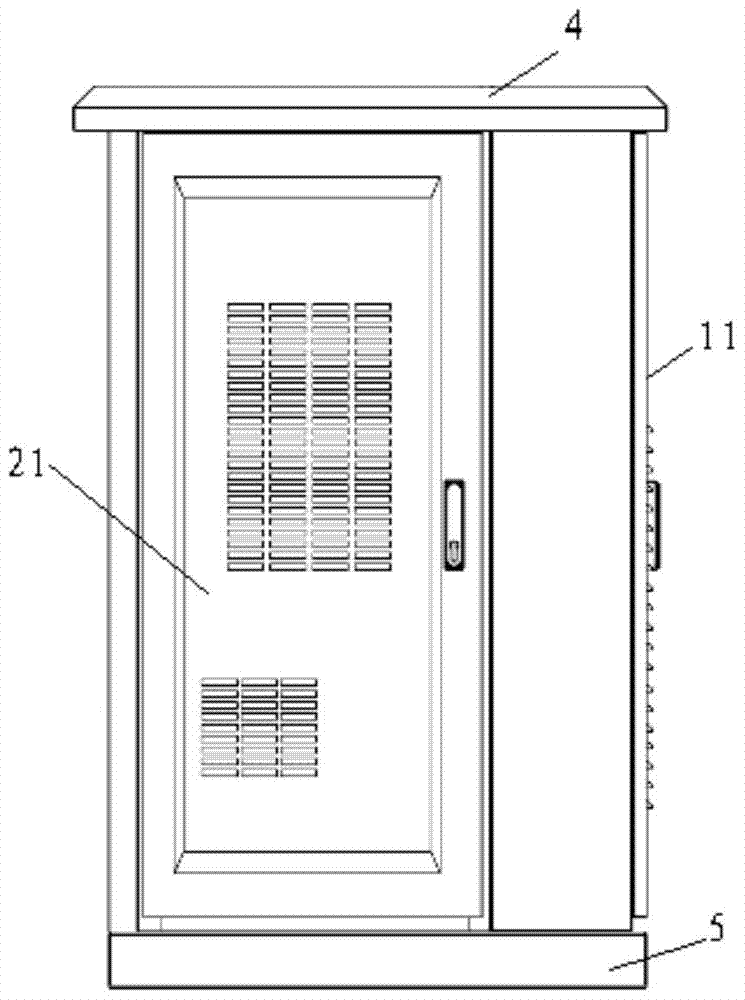

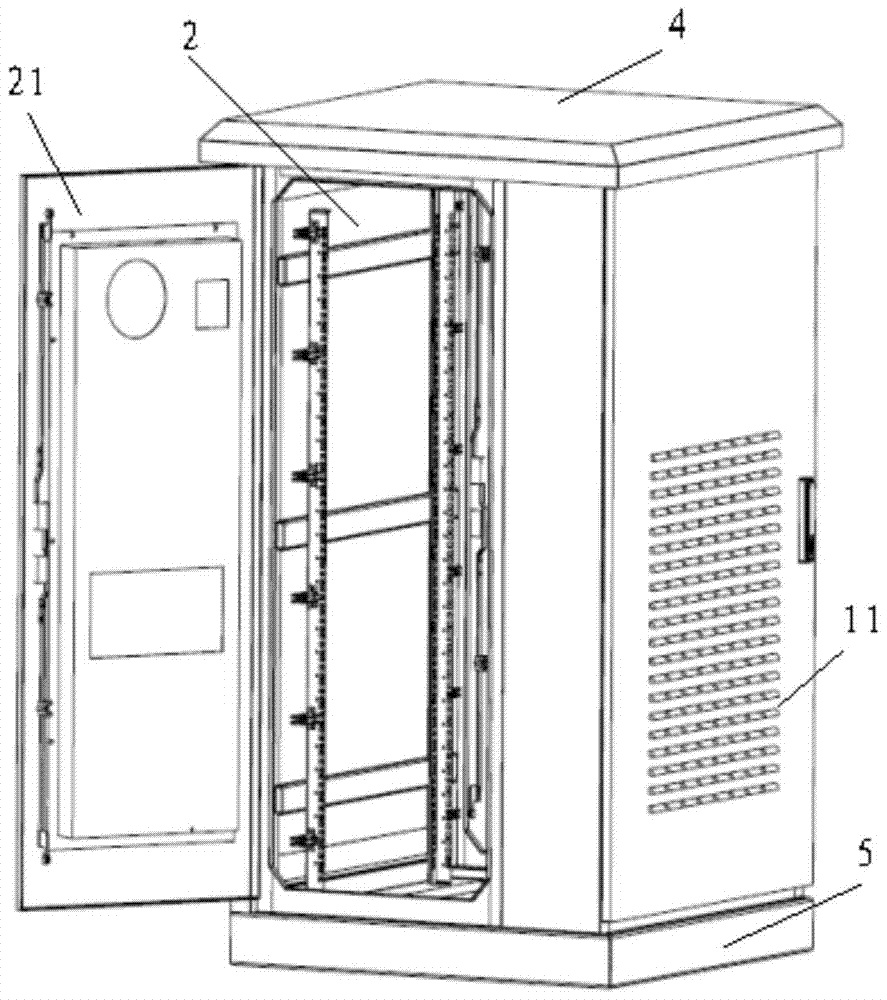

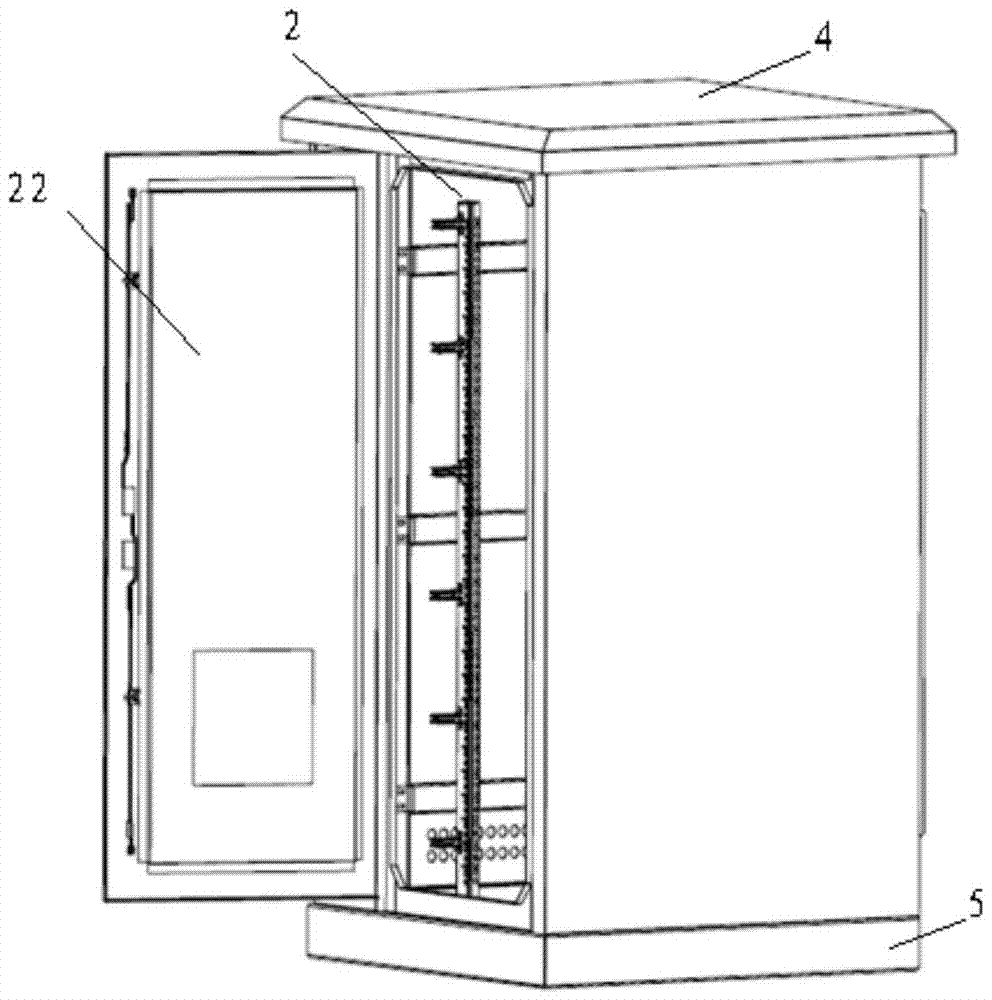

Cabinet

InactiveCN104582338AReduce thermostat energy consumptionRun maskElectrical apparatus casings/cabinets/drawersEngineeringSelf adaptive

The invention discloses a cabinet which is characterized by comprising a cabinet body, wherein a first bin and a second bin are formed inside the cabinet body; the first bin comprises a structure for placing a first type of equipment; the second bin comprises a structure for placing a second type of equipment; a working operation temperature of the first type of equipment is higher than that of the second type of equipment; the first bin and the second bin are separated by a partition. According to the invention, the cabinet is divided into the first bin and the second bin, so that the influence of high-temperature operation equipment with high self-adaptive temperature capacity, such as a RRU (Remote Radio Unit), in the first bin on the temperature of the second bin is reduced, the temperature regulation energy consumption of the cabinet is reduced, while the operation of other equipment is also prevented from being influenced by high heat generated by the high-temperature operation equipment, so that classified and independent-bin thermal management of high and low temperature equipment is realized and the cabinet meets the requirements for saving energy and reducing consumption.

Owner:POTEVIO INFORMATION TECH CO LTD

Fault coal upgrading material cooler

ActiveCN103776286AImprove heat transfer coefficientAchieve reuseOther heat production devicesMoving conduit heat exchangersSlagWater pipe

The invention discloses a fault coal upgrading material cooler which comprises a rotating barrel, a slag feeding box is arranged at the front end of the rotating barrel, a slag discharging box is arranged at the rear end, the rotating barrel is of a film wall structure, and a plurality of material pushing plates are arranged on the film wall in a spiral mode. The front end and the rear end of a film wall fin water pipe on the film wall are connected with a front annual collecting box and a rear annual collecting box respectively. A water inlet main pipe and a water outlet main pipe are arranged on the axis of the rotating barrel. The water inlet main pipe sleeves the water outlet main pipe, and the water inlet main pipe and the water outlet main pipe are connected with a water feeding and discharging device. The water outlet main pipe is communicated with the front portion of the rotating barrel and connected with the front annual collecting box through a water outlet elbow. The rear annual collecting box is connected with the water inlet main pipe through a water distributing pipe. By means of exchange of radiation heat and conduction heat between materials and the rotating barrel, heat exchanging coefficient is high. The cooler reduces the material temperature, waste heat is fully absorbed through cooling water, recycling of the waste heat is achieved, and the requirement of saving energy and reducing consumption is met.

Owner:SICHUAN LONGLINKECHUANG ENERGY SAVING & ENVIRONMENT PROTECTING CO LTD

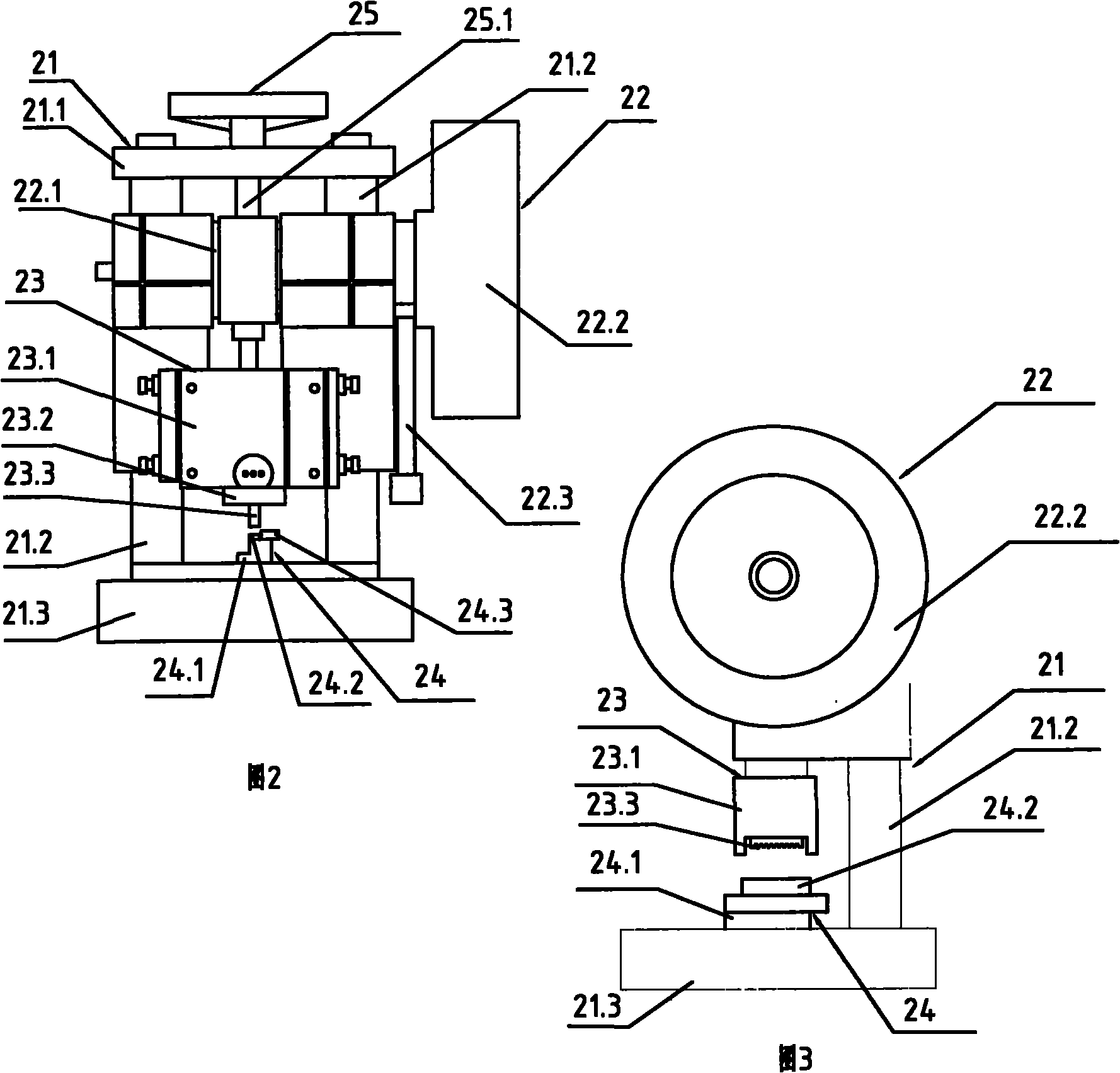

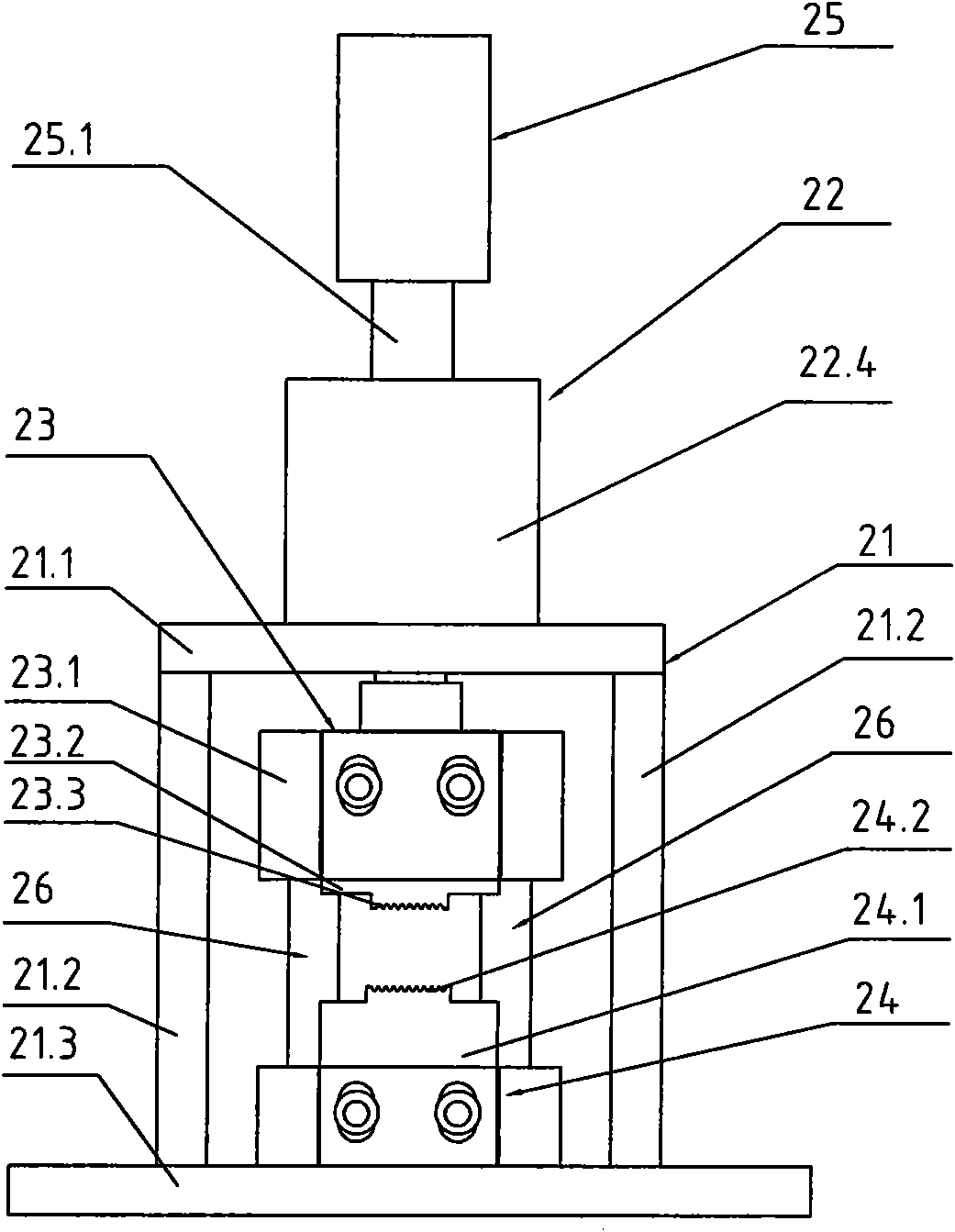

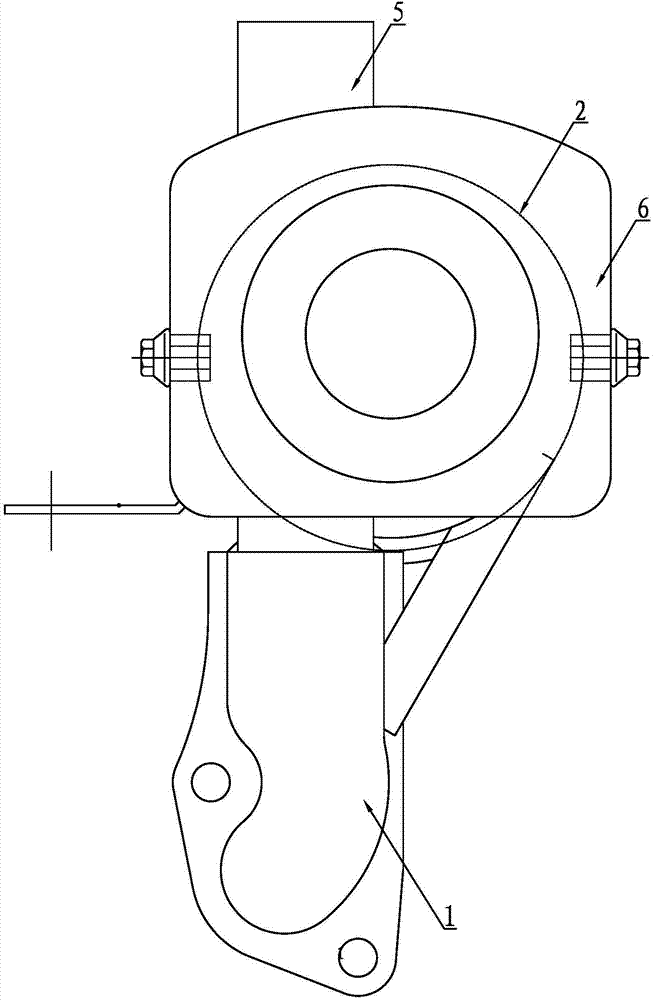

Double-face riveting press of HDMI (High-Definition Multimedia Interface) terminal

ActiveCN101916956AFew componentsCompact structureLine/current collector detailsElectric energyEngineering

The invention discloses a double-face riveting press of a HDMI (High-Definition Multimedia Interface) terminal, mainly comprising a frame 21, a transmission device 22, a sliding assembly 23 and a fixed assembly 24; wherein the transmission device 22 is arranged on the frame 21 and comprises a transmission shaft 22.1; the sliding assembly 23 is mainly composed of a sliding block, an upper die holder and an upper die; the sliding block is arranged at the lower part of the transmission device 22 and connected with the transmission shaft of the transmission device; the sliding block is connected with left and right upright columns in sliding fit manner; the upper die holder is fixed on the lower end face of the sliding block; the upper die is arranged on the lower end face of the upper die holder; the fixed assembly 24 is mainly composed of a lower die holder, a lower die and a terminal positioning clamp; the lower die holder is arranged on the upper end face of a base of the frame 21; and the lower die and the terminal positioning clamp are arranged on the upper end face of the lower die holder. The invention has the advantages of compact structure, electric energy saving and high work efficiency.

Owner:NINGBO KANGDA ELECTRONICS

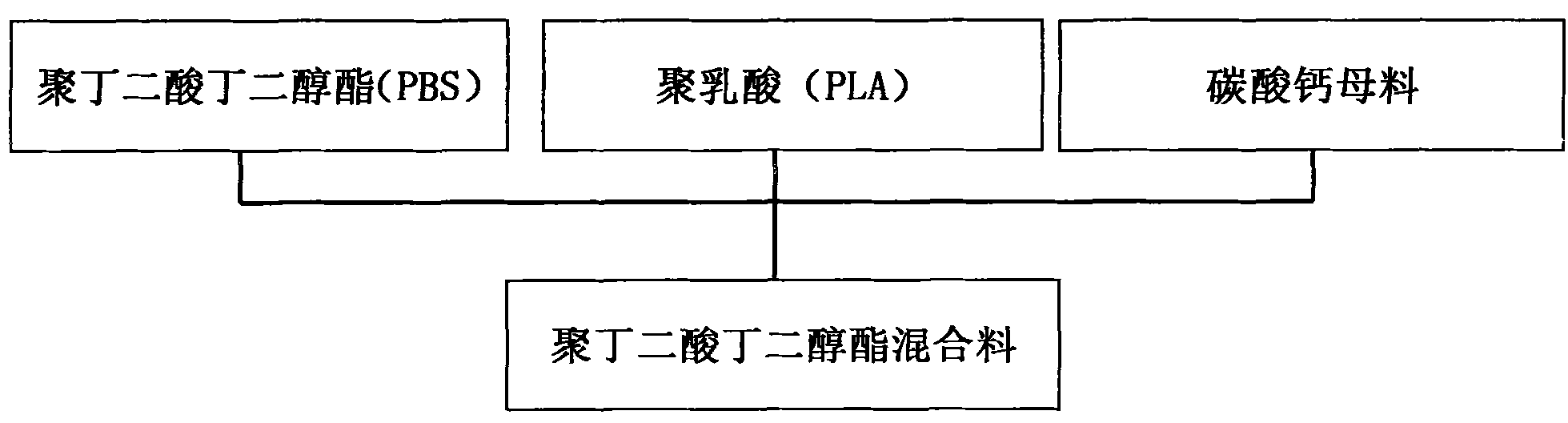

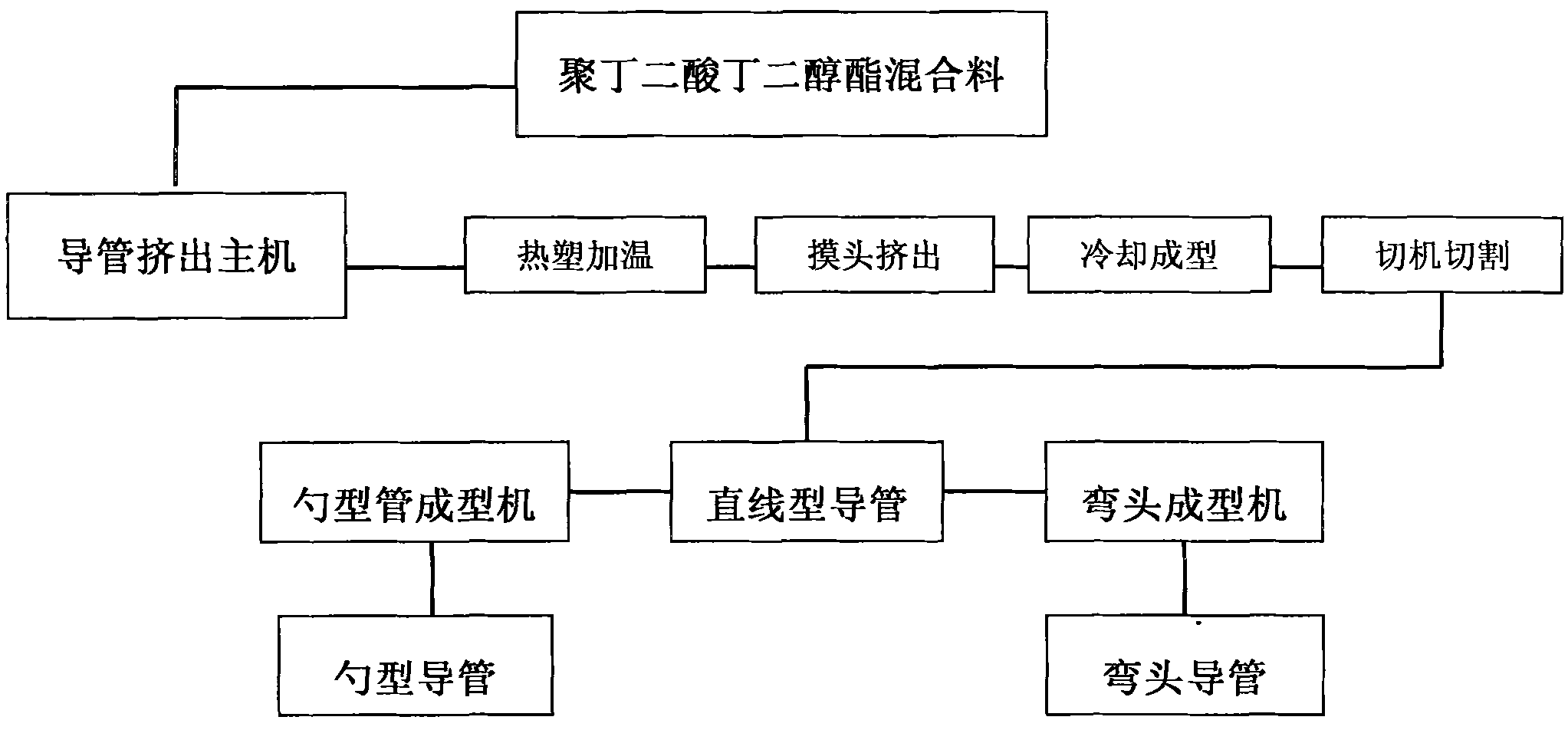

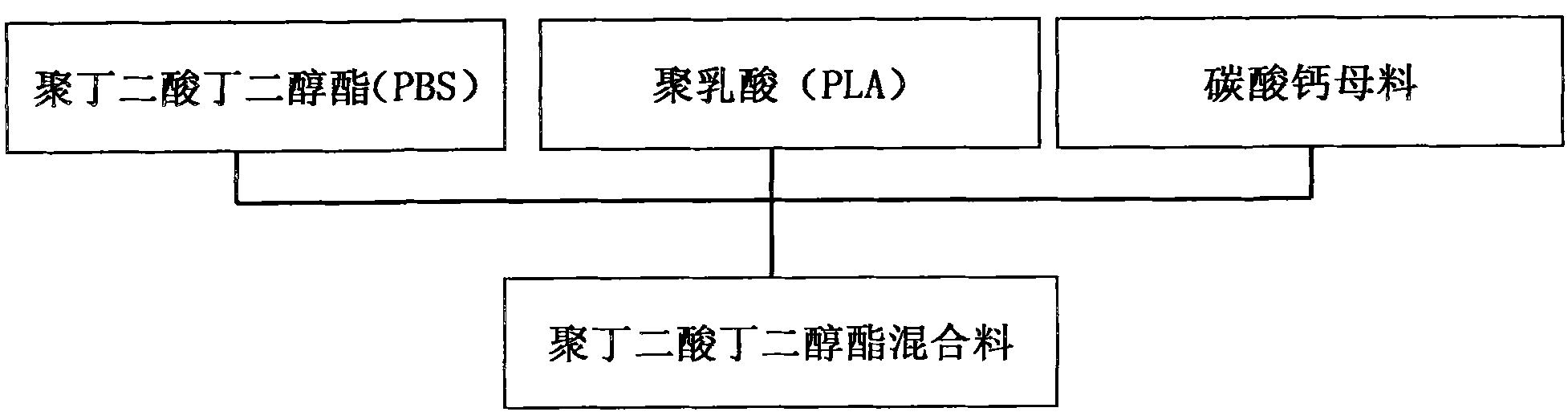

Preparation method for biomass degradation material and magnetic powder catheter

InactiveCN102140234AImprove impact resistanceGood flexibilityRigid pipesBiomass degradationFiller Excipient

The invention provides a preparation method for biomass degradation material, which comprises the following steps: (1) preparing raw materials: weighing the following compositions of raw materials by weight percentage: 40 to 60 of major ingredient poly( butylene succinate), 40 to 60 of modified material polylactic acid and 0.1 to 20 of filler calcium carbonate master batch; (2) mixing the compositions to form modified poly( butylene succinate) mixture; and (3) statically placing the modified mixture at low temperature for standby application. The invention also discloses a method for manufacturing a magnetic powder catheter by adopting the raw materials, which comprises the following steps: (4) preparing a magnetic powder catheter extrusion main machine and a round die head matched with the main machine for use; (5) feeding the modified poly( butylene succinate) mixture into the extrusion main machine so as to manufacture a continuous round hollow magnetic powder catheter; and (7) cutting the continuous round hollow magnetic powder catheter into magnetic powder catheter sections. The invention also provides the magnetic powder catheter prepared by the method. The materials provided by the invention can completely degrade. The method is scientific and reasonable; the production efficiency is high; the product performance is good; and the cost is low.

Owner:广州高馨能生物科技有限公司

Low-temperature cured terminal carboxyl polyester resin for mixed powder coating and preparation method thereof

ActiveCN101735432BSuitable glass transition temperatureGood storage stabilityPowdery paintsEpoxy resin coatingsEpoxyPolymer science

The invention discloses a low-temperature cured terminal carboxyl polyester resin for mixed powder coating. The polyester resin is prepared by performing melt polycondensation reaction on the following components in percentage by weight: 25 to 45 percent of polyalcohol, 35 to 65 percent of aromatic polyatomic acid, 0 to 10 percent of fat polyatomic acid, 0 to 2 percent of branching agent, 6 to 15 percent of acid hydrolysis agent, and 0.01 to 0.15 percent of esterification catalyst. The invention also discloses a method for preparing the low-temperature cured terminal carboxyl polyester resin. The prepared polyester resin has the characteristics of proper glass-transition temperature, softening point, good storage stability, and the like; the polyester resin, epoxy resin, filler and assistant in a certain proportion are mixed, and the mixture is prepared into powder through melt extrusion mixing, cooling, crushing and sieving; and the prepared powder can be cured at the temperature of 160 DEG C, and has the advantages of excellent leveling performance, good impact performance, and the like.

Owner:GUANGZHOU KINTE IND

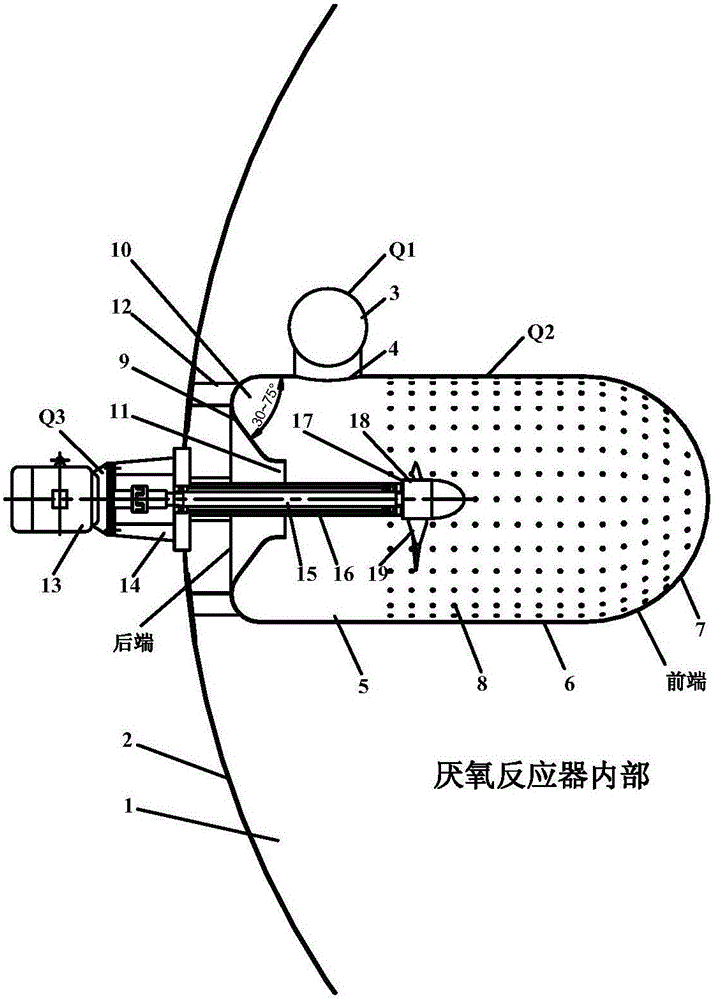

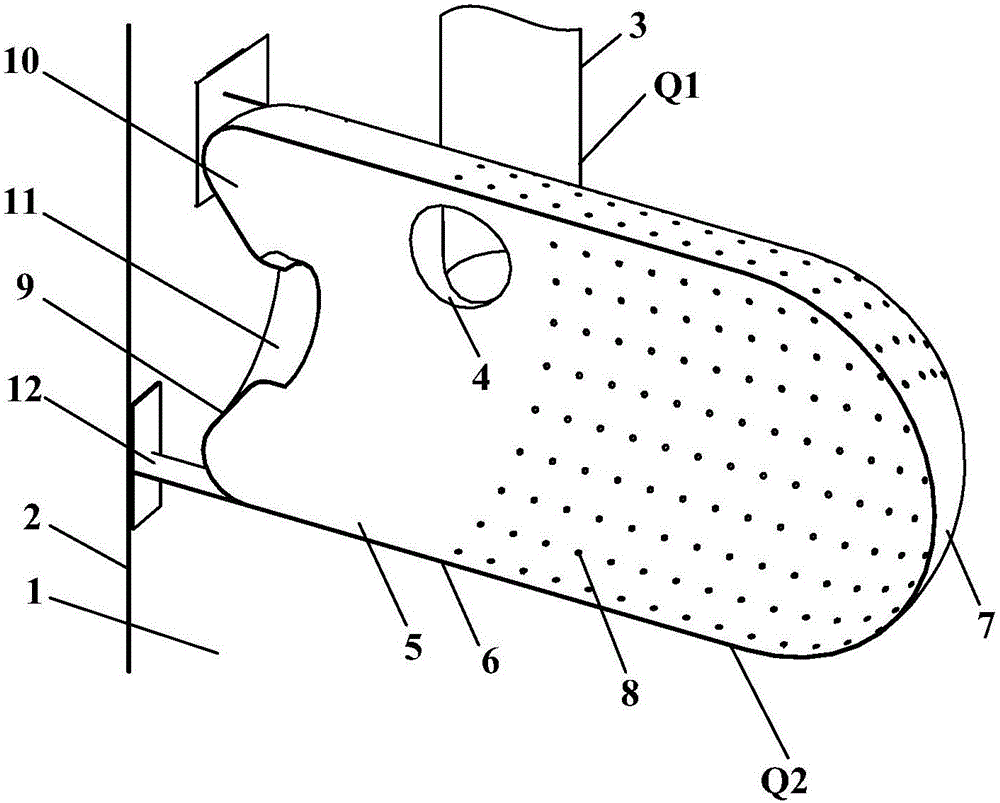

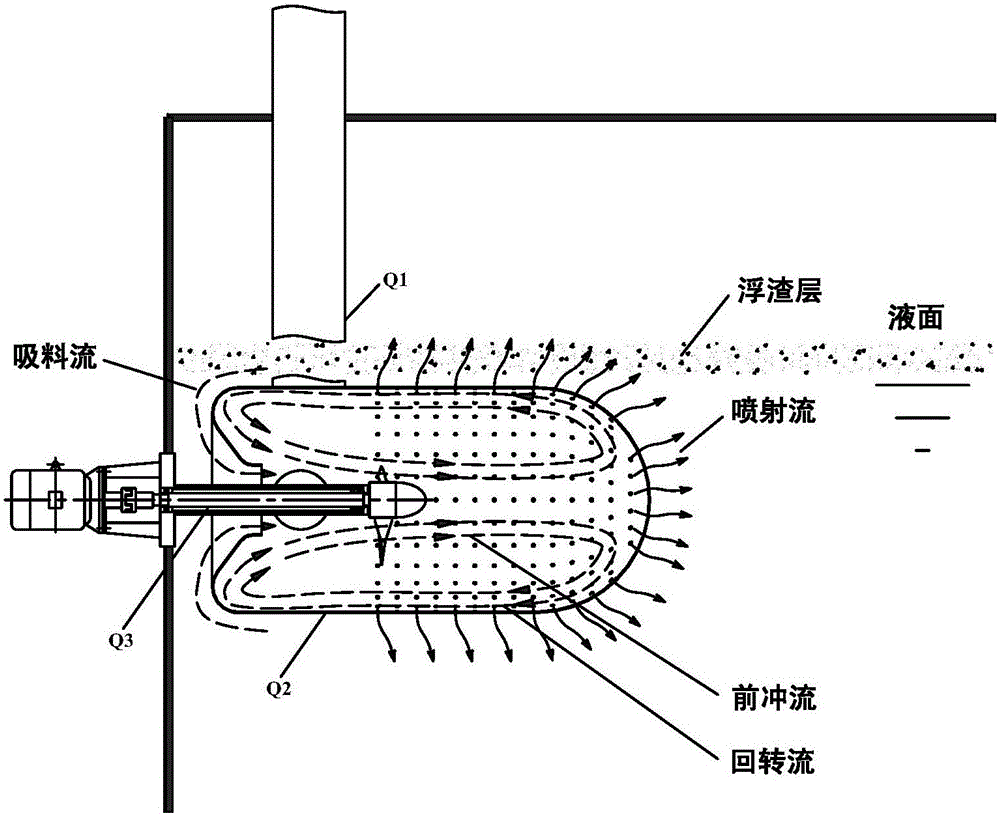

Integrated apparatus and method integrated in anaerobic digester to implement high-fiber material slurrying and scum shell breaking

ActiveCN106085831ACrust cannot lastImprove impact performanceBioreactor/fermenter combinationsBiological substance pretreatmentsFiberSlurry

The invention discloses an integrated apparatus and method integrated in an anaerobic digester to implement high-fiber material slurrying and scum shell breaking, the apparatus is composed of a material conveying unit, a chamber unit mounted in the anaerobic digester and a slurry breaking unit, the slurry breaking unit is combined with the chamber unit that has special structural design, inner slurry is circulated during operation, multiple breaking treatments are carried out on high-fiber material, the size of the material discharged out of a material breaking chamber is limited through slurry breaking outlets distributed on the outer wall of the chamber, larger specific surface area for the material is provided, better contact of anaerobic microorganisms with the material is provided, and gas producing efficiency is improved; the integrated treatment implementing high-fiber material slurrying and scum shell breaking in the anaerobic digester enables reduced investment cost, simplified operation steps, lower energy consumption and promising market prospect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

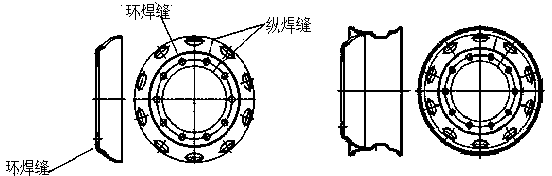

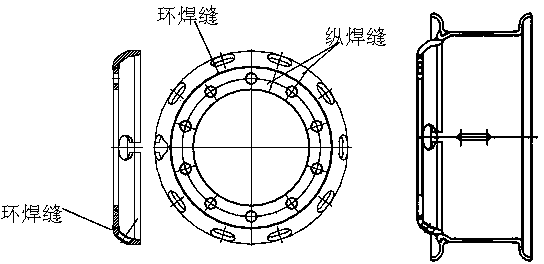

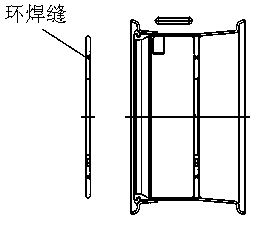

Method for designing and processing wheel spoke structure

The invention discloses a design and a process of mechanical parts, and particularly relates to a process for designing and processing a wheel spoke structure on various wheels. The process for designing and processing the wheel spoke structure comprises the steps of carrying out cold machining on two or more strips into a circular ring, installing and welding the circular ring into a cake material, forming, assembling the cake material on a rim, and welding into a wheel. The process has the characteristic that at least one ring weld and more than two longitudinal welds are arranged on the wheel spoke, and the wheel spoke structure can be seen in attached drawings. The process has the advantages that the material utilization rate is increased to about 95 percent from below 65 percent in comparison with that of a process for directly producing a cake material by a super-wide wheel spoke; a cold machining process is always adopted, an incircle does not wrinkle up, and the heat consumption is not increased, thus the process is very environmental-friendly.

Owner:周永红

Diesel engine silencer of tension-free silencing chamber structure

InactiveCN103790677AReduce manufacturing costReduce consumptionSilencing apparatusMachines/enginesManufacturing technologyAtmospheric air

The invention relates to a diesel engine silencer of a tension-free silencing chamber structure. The diesel engine silencer comprises a gas intake pipe, a tension-free silencing shell, a silencing partition plate, a primary noise reducing pipe, a terminal noise reducing pipe and a scalding-proof shield. The tension-free silencing shell comprises a sectional material pipe body, a left end cover and a right end cover. The left end cover and the right end cover are fixed at the two ends of the sectional material pipe in a sealed mode respectively. The silencing partition plate is arranged in the tension-free silencing shell. A silencing hole is formed in the silencing partition plate. The tension-free silencing shell is divided by the silencing partition plate into a primary noise reducing cavity and a silencing cavity of a terminal noise reducing cavity. The primary noise reducing cavity is communicated with the primary noise reducing pipe. The terminal noise reducing cavity is communicated with the terminal noise reducing pipe. The outlet of the terminal noise reducing pipe is communicated with the air. The gas intake pipe is communicated with the primary noise reducing cavity through the primary noise reducing pipe. The scalding-proof shield is fixed to the outer end of the tension-free silencing shell. The diesel engine silencer of the tension-free silencing chamber structure is simple in structure, good in manufacturing technology, low in production cost, good in anti-vibration anti-fracture performance and reliable in use and the noise reducing performance of the diesel engine silencer is equal to that of an existing product.

Owner:常州金坛佳越机械有限公司

Operation method for reducing loss and improving operation rate of equipment

InactiveCN102302872AReduce lossImprove work rateMoving filtering element filtersFailure rateProcess engineering

The invention relates to an operation method for reducing the loss and improving the operation rate of equipment, which comprises the following three steps of: washing a tank body, treating residual accumulated ore, and performing secondary cleaning. The operation method for reducing the loss and improving the operation rate of the equipment is scientific in design, easy to operate and obvious in accumulated ore removing effect; meanwhile, by the operation method for reducing the loss and improving the operation rate of the equipment, friction between a stirrer and the tank body can be effectively reduced, and the failure rate of the equipment is reduced.

Owner:YUNNAN DAHONGSHAN PIPELINE

Method for controlling power supply system featuring complementation of solar energy and fuel energy

ActiveCN101572428BTake advantage ofReal-time monitoring of input currentBatteries circuit arrangementsSecondary cells charging/dischargingEnvironmental resistancePower flow

The invention relates to a method for controlling power supply system featuring complementation of solar energy and fuel energy. In the method, a controller collects input electric current of a solar energy power supply device, charge-discharge electric current of storage batteries and load current of a loading equipment; when the input electric current is less than 1.5 times of load current, thesystem enters an oil engine auxiliary power supply mode; in the oil engine auxiliary power supply mode, the controller reads the current status of the storage batteries and the current status of the oil engine power supply device and starts up or closes the oil engine power supply device according to certain logic; in the technical proposal of the invention, solar energy power supply mode serves as the main power supply mode, as a result, the solar energy can be fully utilized, requirements for environmental protection are met, the input electric current of a solar panel and the load current of the load device can be monitored in real time; in addition, the oil engine can be started up to supply power when the solar energy power supply device can not supply enough power, thus entering theoil engine auxiliary power supply mode and realizing continuous power supply, improving utilization efficiency of the oil engine and lengthening service life of the storage batteries, strengthening reliability of the power supply system while meeting the requirements on energy conservation and reduction of consumption.

Owner:EMERSON NETWORK POWER CO LTD

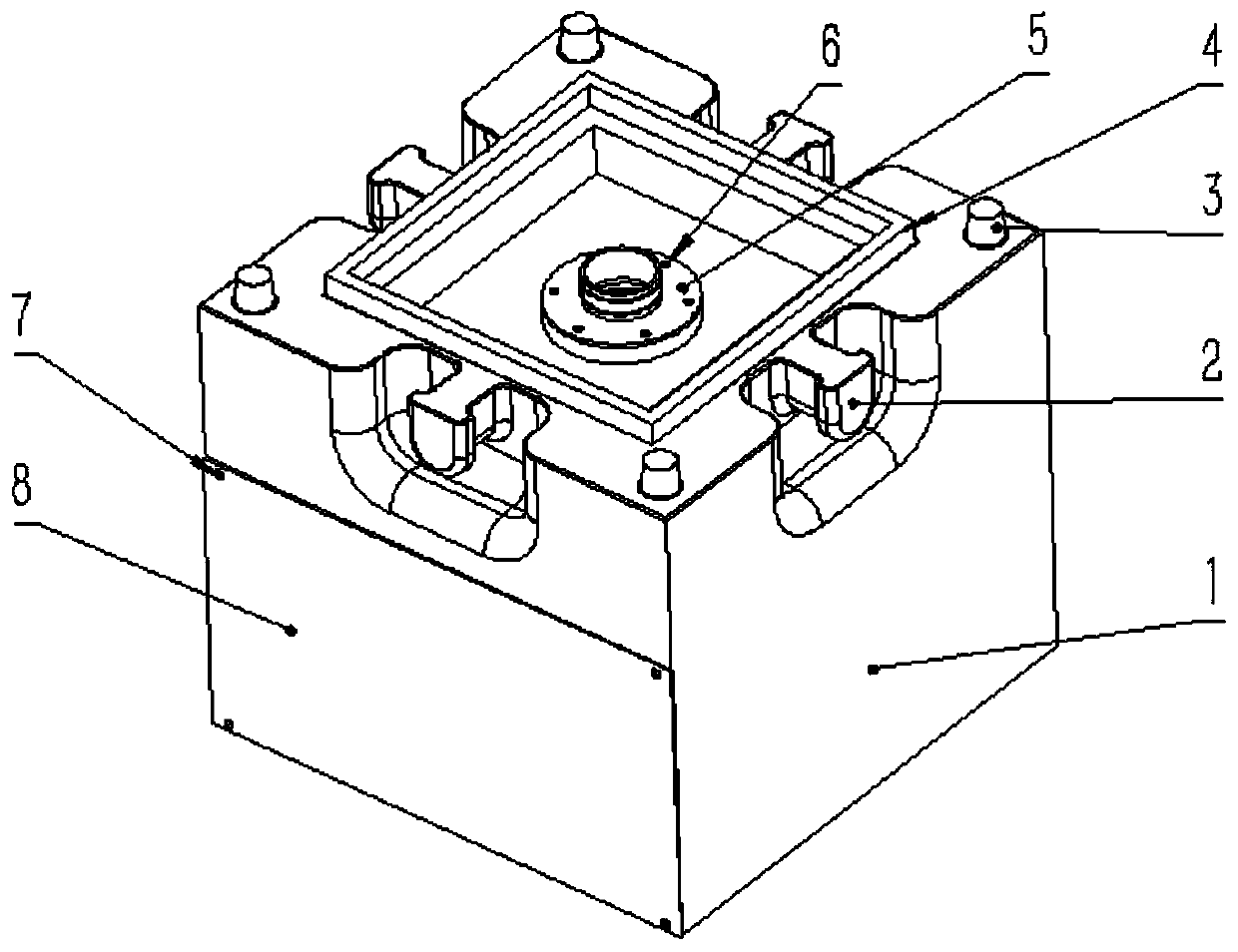

Casting site flue gas recovery method and multifunctional casting weight capable of achieving dust collection and recovery

PendingCN110586907AReduce maintenance costsImprove performanceGas treatmentDispersed particle filtrationRecovery methodFlue gas

The invention relates to a multifunctional casting weight capable of achieving dust collection and recovery. The multifunctional casting weight includes a weight body, and a through flue gas channel is formed in the weight body; the side face of the flue gas channel is connected with a side suction channel, and the bottom surface of the flue gas channel is connected to a top suction channel; a gasprocessing chamber is connected to the top of the flue gas channel, and the gas processing chamber is filled with a gas processing medium; a gas collection port is formed in the top of a gas outlet of the gas processing chamber; an air inlet of the top suction channel is formed in the bottom surface of the weight body; and an air inlet of the side suction channel is formed in the side face of theweight body. A casting site flue gas recovery method based on the casting weight is further included and comprises the steps that firstly, the flue gas channel is formed in the weight body; then theweight body is placed on a sand mold sand box in a casting mould closing state, and the air inlet of the flue gas channel corresponds to a pouring cup, a sand mold air hole and a casting riser in position; recovered flue gas is connected to an air inlet of flue gas centralized recovery processing equipment through a pipeline; and the centralized recovery processing equipment is provided with an air extraction device to form negative pressure in the flue gas channel.

Owner:江苏钢锐精密机械有限公司

cabinet

InactiveCN104582338BReduce thermostat energy consumptionRun maskElectrical apparatus casings/cabinets/drawersEngineeringEnergy analysis

The invention discloses a cabinet, which is characterized in that the cabinet includes a cabinet, and the inside of the cabinet includes a first warehouse and a second warehouse; the first warehouse includes a structure for placing the first type of equipment; the second warehouse includes a The structure for placing the second type of equipment; the operating temperature of the first type of equipment is higher than that of the second type of equipment; the first warehouse and the second warehouse are separated by a partition. The invention divides the cabinet into the first warehouse and the second warehouse, which reduces the influence of the high temperature operating equipment in the first warehouse, such as RRU, on the temperature of the second warehouse, reduces the temperature adjustment energy consumption of the cabinet, and at the same time It also avoids the high heat generated by high-temperature operating equipment from affecting the operation of other equipment, so as to realize the thermal management of high-temperature and low-temperature equipment in different bins, which meets the requirements of energy saving and consumption reduction.

Owner:POTEVIO INFORMATION TECH CO LTD

Method and device for adjusting fan speed

ActiveCN106325464BControl speedReduce power consumptionDigital data processing detailsEngineeringRadiation

The embodiment of the invention discloses a method and equipment for adjusting rotation speed of a fan. The method and the equipment are used for decreasing the power consumption of the fan on the equipment. The method is applied to the equipment with the fan, and comprises the following steps of obtaining business information; according to the business information, determining the current business type of the equipment; according to the current business type, adjusting the rotation speed of the fan. The method has the advantages that the rotation of the fan on the equipment can be adjusted according to the current business type of the equipment, so that the rotation speed of the fan can meet the requirement of heat radiation of the equipment under different business types; the rotation speed of the fan is correspondingly changed under the different business types; the rotation speed of the fan is flexibly controlled, the power consumption of the fan is decreased, and the requirements of energy saving and consumption decreasing are met.

Owner:XFUSION DIGITAL TECH CO LTD

Magnesium-calcium material and preparation method thereof

The invention relates to a magnesium-calcium material and a preparation method thereof. The preparation method comprises the following steps: mixing 60-70 wt% of magnesia-calcia particles, 20-30 wt% of magnesia-calcia fine powder, 2-5 wt% of cerium phosphate and 3-6 wt% of phosphotitanate, uniformly stirring, carrying out compression molding, and naturally drying for 20-30 h; and drying for 8-16 hat the temperature of 110 DEG C, firing for 2-5 h at the temperature of 1500-1700 DEG C, and cooling to obtain the magnesium-calcium material, wherein the MgO content of the magnesia-calcia is greater than or equal to 40 wt%, the particle size of magnesia-calcia particles is 0.2-11 mm, and the particle size of the magnesia-calcia fine powder is 3-200 [mu]m; the particle size of the cerium phosphate is 3-200 [mu]m; and the content of P2O5 in the phosphotitanateis greater than or equal to 1wt%, and the content of TiO2 in the phosphotitanate is greater than or equal to 1 wt%. The method is simple in process, low in cost and environmentally friendly, and the prepared magnesium-calcium material is excellent in hydration resistance, remarkable in metal melt purification effect and suitable forpurifying refractory materials for smelting.

Owner:WUHAN UNIV OF SCI & TECH

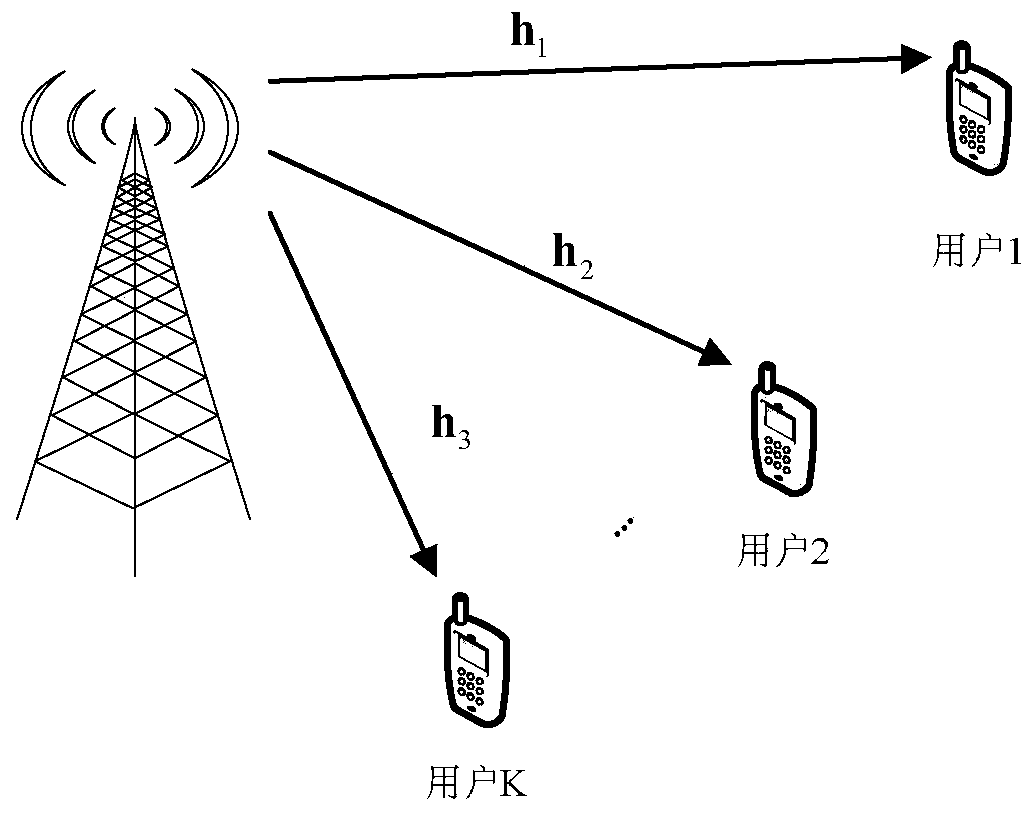

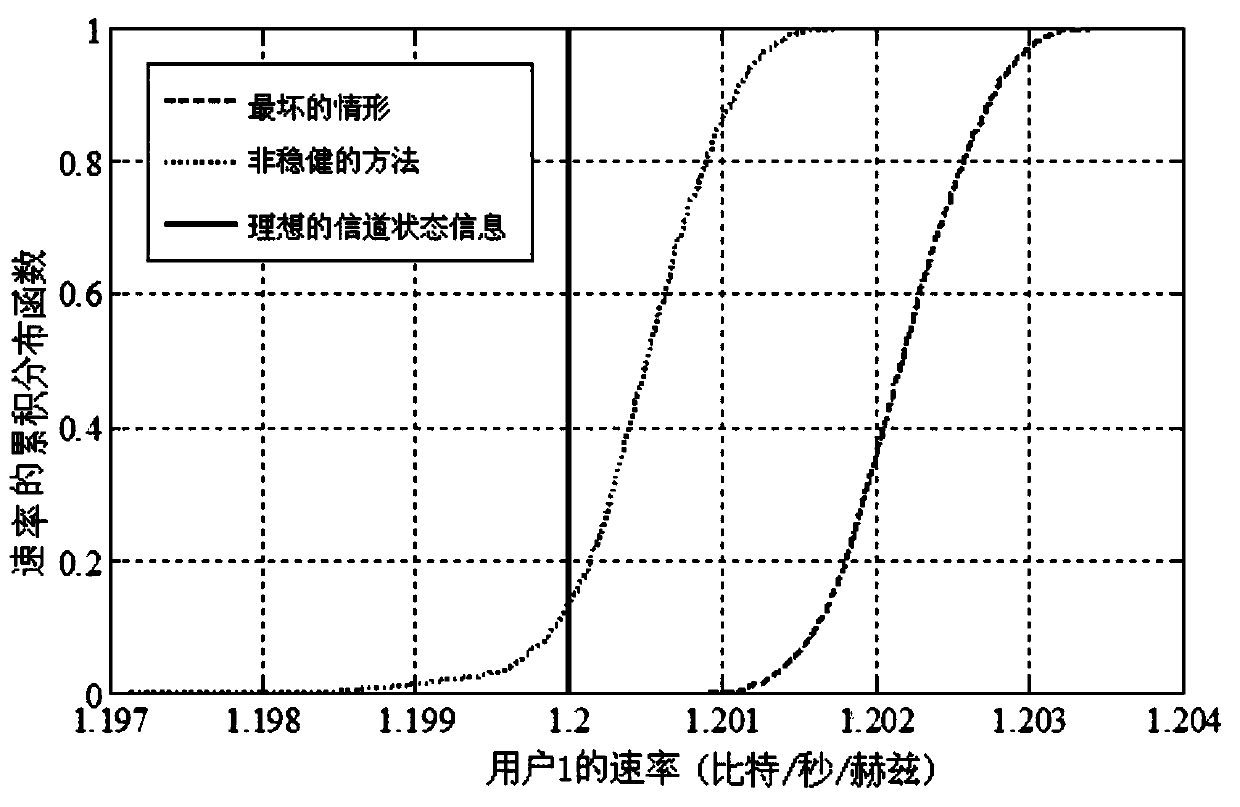

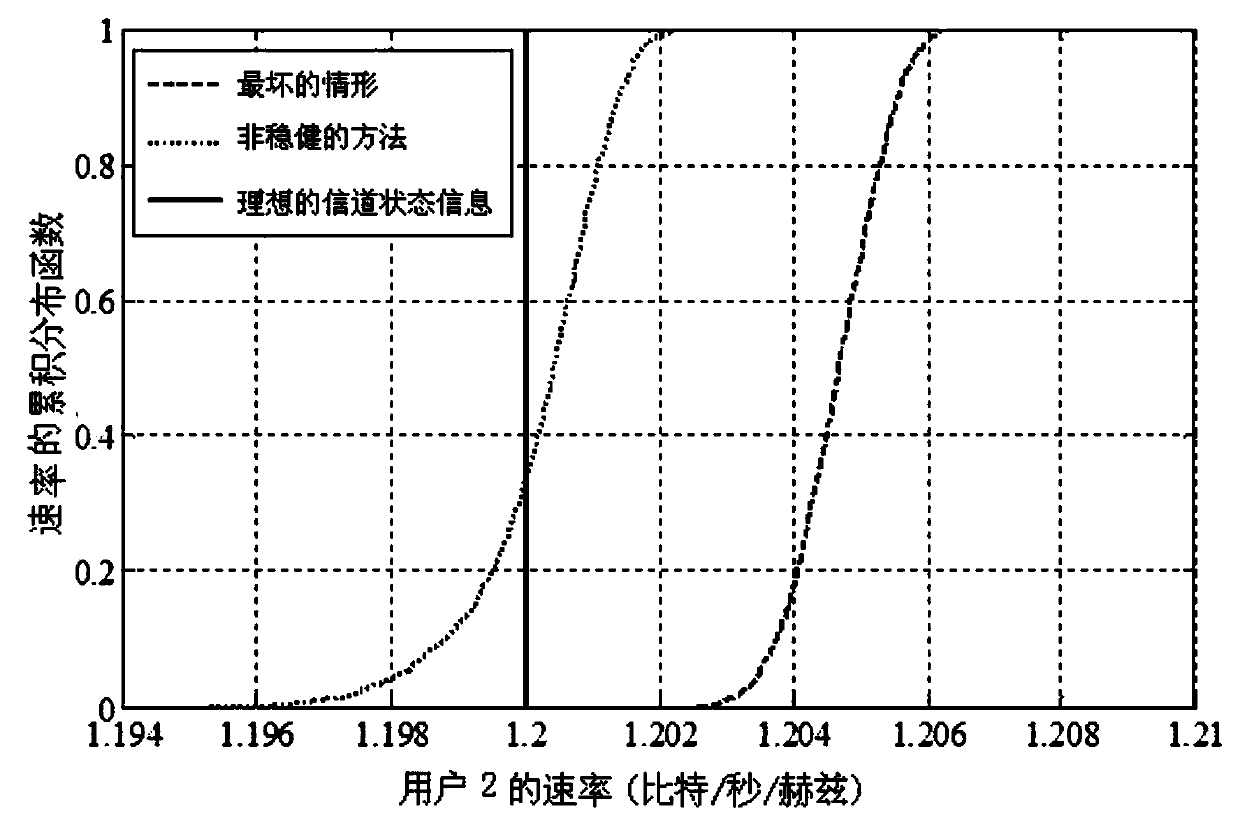

Optimization method for robust beamforming in non-orthogonal multiple access technology for visible light communication

InactiveCN107332614BSatisfy quality of serviceMeet the requirements of energy saving and consumption reductionSpatial transmit diversityClose-range type systemsQuality of serviceInterior point method

The invention discloses an optimization method of visible light communication non-orthogonal multiple access technology robust beam-forming. The specific steps are as follows: establishing a system model of the NOMA to minimize the transmitting power while satisfying the user service quality, thereby satisfying the energy conservation and consumption reduction requirement in the future mobile communication technology. By using the convex optimization method, the relax transformation is performed on the established non-convex system function, and then the solution is performed by using the interior point method. Compared with the existing modeling and processing method, the method disclosed by the invention can satisfy the quality of service requirement and reduce the outage probability under the existence of the estimation error.

Owner:CHINA UNIV OF MINING & TECH

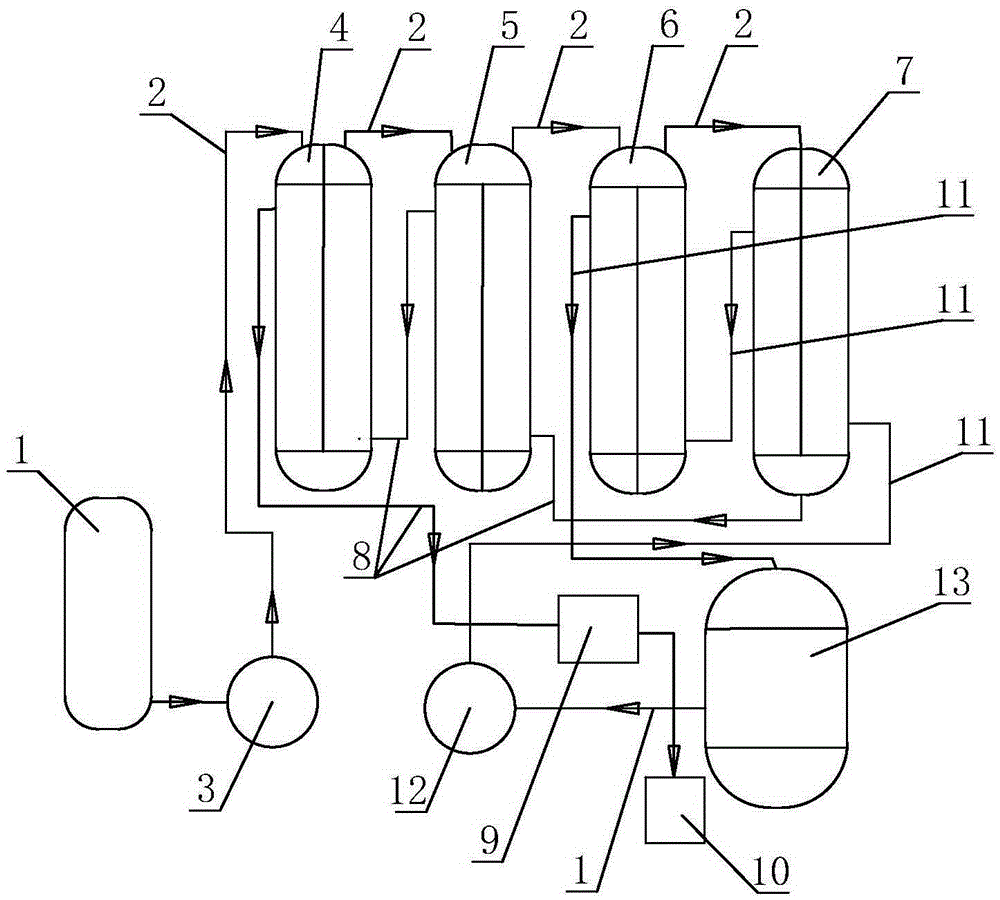

Combustible gas generator

ActiveCN105347301AMeet the requirements of energy saving and consumption reductionSimple structureHydrogenHydrogen/synthetic gas productionHydrogenCombustible gas

A combustible gas generator comprises a stock tank, wherein the stock tank is connected with a feedstock inlet of a primary heat exchanger via a feedstock pump through a feedstock input pipeline, a feedstock outlet of the primary heat exchanger is connected with a feedstock inlet of a secondary heat exchanger through a feedstock input pipeline, a feedstock outlet of the secondary heat exchanger is connected with a feedstock inlet of a reformer through a feedstock input pipeline, a feedstock outlet of the reformer is connected with a feedstock inlet of a methanol reactor through a feedstock input pipeline, a combustible gas outlet of the methanol reactor is connected with the bottom of the secondary heat exchanger through a combustible gas transmission pipeline, and the top of the secondary heat exchanger is connected with the bottom of the primary heat exchanger through a combustible gas transmission pipeline. The combustible gas generator is simple in structure, low in manufacturing cost, low in running energy consumption, and capable of heating a mixed liquor containing 50-85 percent of water and 15-50 percent of methanol to produce mixed combustible gases such as hydrogen (the content being over 75 percent), oxygen, carbon monoxide and methane which can replace existing natural gas, a great amount of energy sources are saved, and the use cost is greatly lowered.

Owner:刘建安 +1

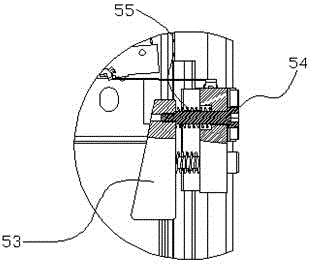

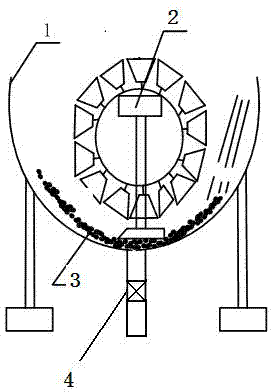

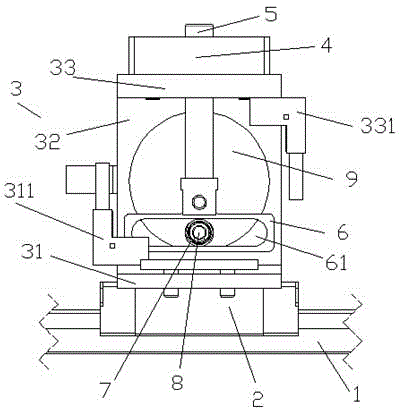

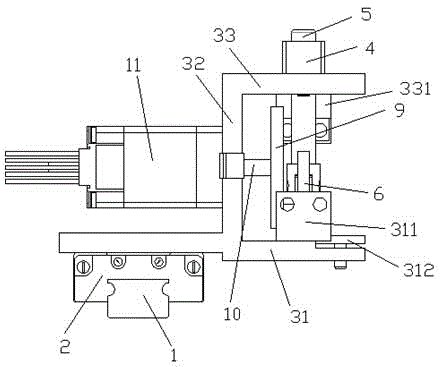

Grabbing device used for blood cell analyzer

ActiveCN104913946ASimple structureGuaranteed uptimeWithdrawing sample devicesControl using feedbackCircular discBiochemical engineering

The invention belongs to the technical field of medical apparatus and instruments, and especially relates to a grabbing device used for a blood cell analyzer. The grabbing device comprises a guide rail, an installation pedestal, and a fixing pedestal; the installation pedestal is arranged on the guide rail; the fixing pedestal is arranged on the installation pedestal; the fixing pedestal comprises a bottom plate, a side plate, and a top plate; the base plate and the top plate are arranged on the two ends of the side plate respectively; the top plate is provided with a bushing; the bushing is penetrated through by a grabbing guide rod; one end of the grabbing guide rod is connected with a lead rod; a bearing is arranged in the lead rod; an eccentric pin is arranged in the bearing; the eccentric pin is arranged at the eccentric part of a circular disc; the center of the circular disc is provided with a rotating shaft; and one end of the rotating shaft is connected with a motor. The grabbing device is simple in structure; operation is stable and reliable; assembling complexity is reduced; it is convenient for assembling and maintenance; moving and positioning accuracy is high; operation is smooth; the grabbing device is durable; service life is long; processing is convenient; and cost is low.

Owner:ZHONGSHAN CHUANGYI BIOCHEM ENG

MgO-CePO4 material and preparation method thereof

ActiveCN110436957APromote sinteringImprove mechanical propertiesCeramicwareThermal conductivityMagnesite

The invention relates to a MgO-CePO4 material and a preparation method thereof. The technical solution is that the method comprises the following steps: firstly mixing 50-70 wt% of sintered magnesite,20-40 wt% of magnesium hydroxide, 5-10 wt% of cerous phosphate and 1-10 wt% of aluminate, performing uniform stirring, and performing compression moulding; and performing natural drying for 20-24 h,performing drying at 110-200 DEG C for 8-24 h, performing firing at 1300-1600 DEG C, performing heat preservation for 3-6 h, and performing cooling to obtain the MgO-CePO4 material. According to the method provided by the invention, the MgO-CePO4 material prepared by the method has thermal-insulating properties, mechanical properties and erosion resistance, has the characteristics of good thermalresistance performance, a moderate bulk density, moderate strength, low thermal conductivity and strong anti-erosion ability, and can meet the requirements of saving energy and reducing consumption ofindustrial equipment.

Owner:WUHAN UNIV OF SCI & TECH

Novel process and synthesis device for preparing glyphosate by hydrolyzing by-product acid instead of hydrochloric acid

PendingCN112194677AIncrease production capacityHigh purityGroup 5/15 element organic compoundsPhosphorous acidPtru catalyst

The invention discloses a novel process and a synthesis device for preparing glyphosate by hydrolyzing by-product acid instead of hydrochloric acid. The novel process comprises the steps of (1) preparing a synthetic liquid L1 by taking glycine, dimethyl phosphite and paraformaldehyde as raw materials, methanol as a solvent and triethylamine as a catalyst; (2) adding post-treatment hydrochloric acid into the synthetic liquid L1 for hydrolysis and desolvation, and adding alkali to adjust the pH after hydrolysis and desolvation; and (3) adding deionized water, cooling, stirring and crystallizingto obtain a crystallization solution L2, washing and drying to obtain a glyphosate finished product. According to the invention, improvement is carried out on the basis of glyphosate production by a glycine alkyl ester method, a by-product hydrochloric acid for preparing phosphorus trichloride is adopted to replace hydrochloric acid to hydrolyze a synthetic liquid after post-treatment, and meanwhile, each key process index parameter is optimized, so that the utilization rate of the by-product acid in a chemical industrial park is increased, and the yield and the purity of the glyphosate raw powder are greatly improved. Meanwhile, because a large amount of water carried by the introduction of hydrochloric acid is avoided, the recovery energy consumption of by-products such as methanol and the like and the discharge amount of wastewater are also reduced.

Owner:ZHENJIANG JIANGNAN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com