Integrated apparatus and method integrated in anaerobic digester to implement high-fiber material slurrying and scum shell breaking

An anaerobic digestion and reactor technology, applied in the direction of fiber raw materials, fiber raw material treatment, biochemical equipment and methods, etc., can solve the problems of long biochemical pretreatment, bursting of discharge pipe reactor, poor fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is a further description of the present invention, rather than a limitation of the present invention.

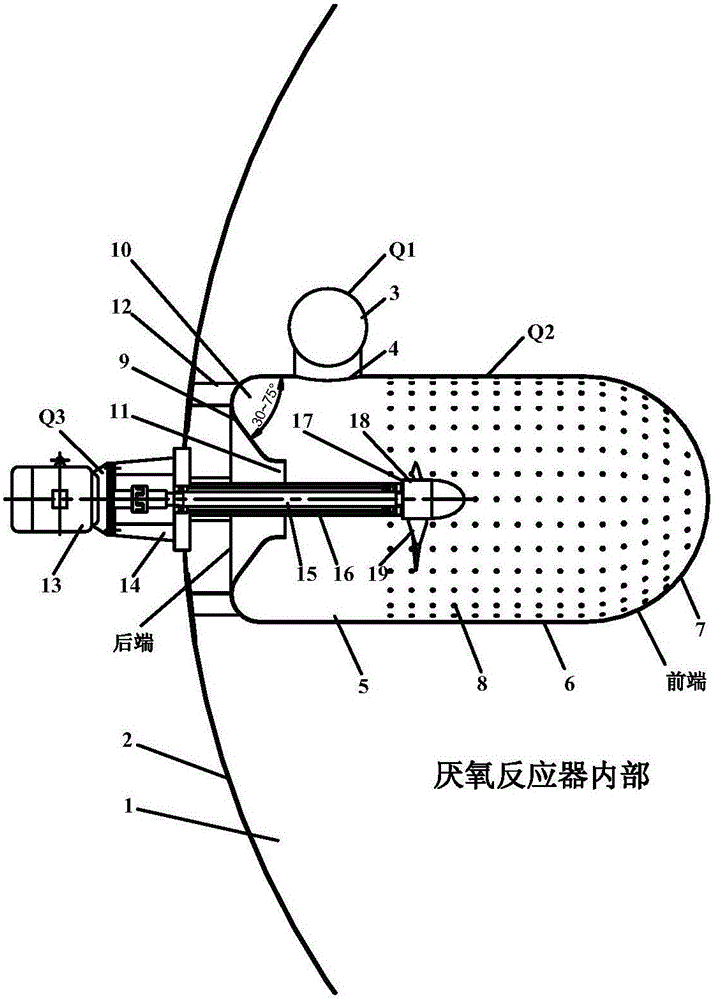

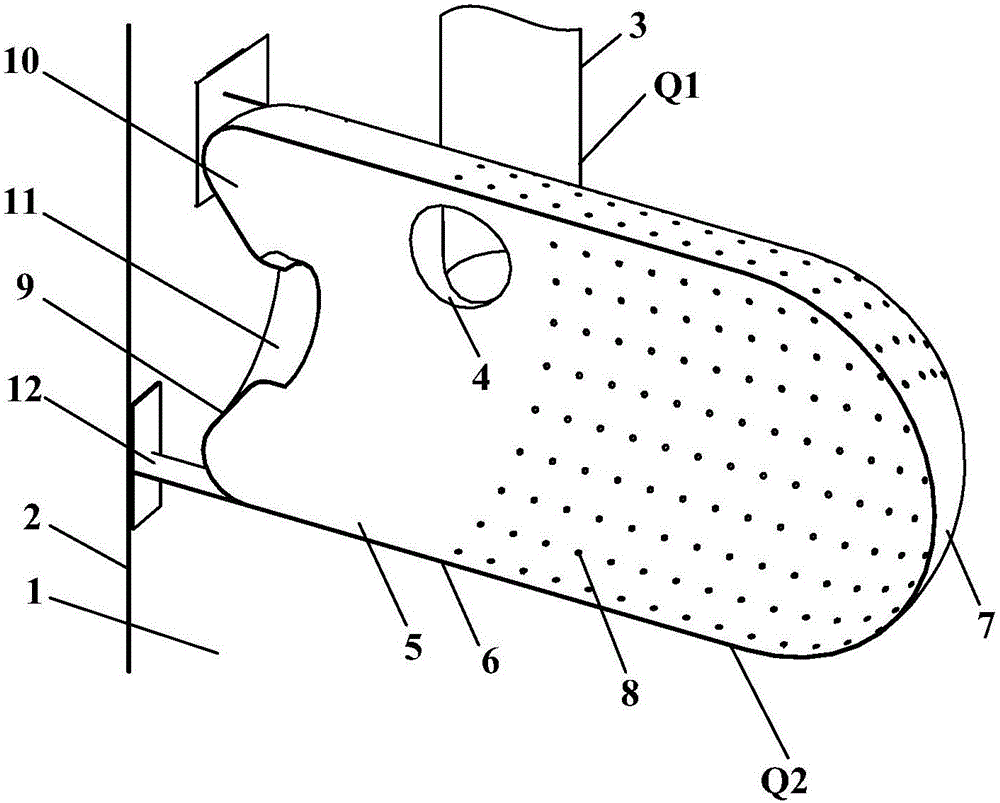

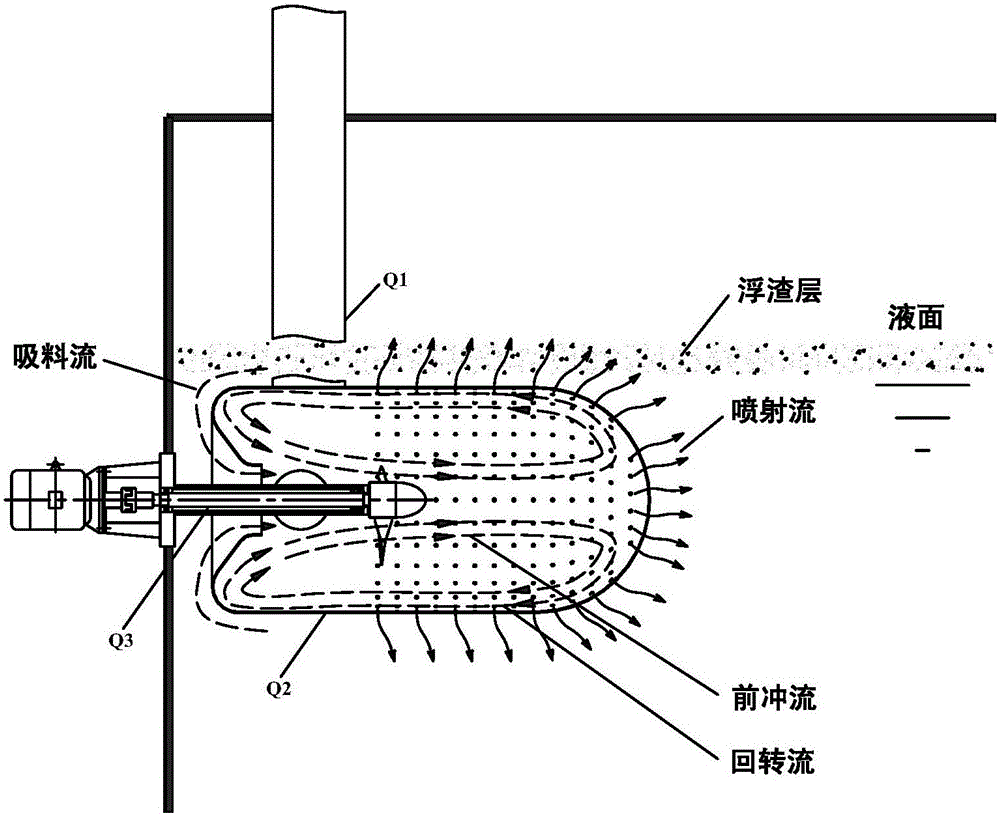

[0030] This embodiment is integrated in the anaerobic digestion reactor to realize the integrated device for pulping high-fiber raw materials and removing scum crusts, such as figure 1 , 2 As shown, the device is composed of three parts: a raw material delivery unit Q1 communicated with the outside world, a chamber unit Q2 connected to the raw material delivery unit Q1 installed in the anaerobic digestion reactor 1, and a pulping unit Q3;

[0031] The raw material conveying unit Q1 includes a feeder 3;

[0032] The chamber unit Q2 includes a raw material pulping chamber 5 in the shape of a cannonball that provides an operating space for the pulping of input raw materials. Enclosed by the head 7 and the arc-shaped baffle plate 9, the raw material pulping chamber 5 is fixed on the anaerobic digestion reactor wall 2 near the liquid surface at the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com