Operation method for reducing loss and improving operation rate of equipment

An operation method and a technology of equipment loss, which are applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as abnormal operation of equipment and difficult removal of ore deposits at the bottom of the ceramic filter tank, and achieve significant removal of ore deposits. , reduce friction, reduce the effect of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

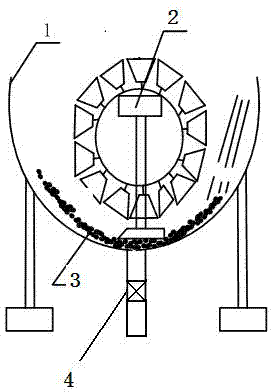

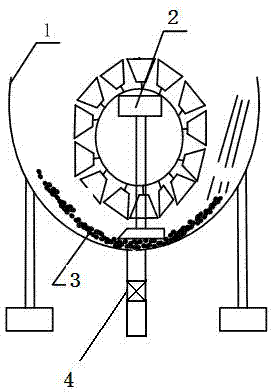

[0022] Combine below figure 1 , the present invention is further described:

[0023] An operation method for reducing equipment loss and improving its operation rate is characterized in that it comprises the following steps:

[0024] Step 1: tank cleaning

[0025] Open the discharge valve 4 arranged at the bottom of the filter tank 1, inject clear water into the filter tank 1 through an external clean water pipe, clean the filter tank 1, and close the clean water pipe after cleaning;

[0026] Step 2: Residual pulp treatment

[0027] After the tank body is cleaned, start the agitator 2 arranged in the filter tank body 1, adjust the number of revolutions, the number of revolutions is 12 revs / min-20 revs / min, and the time for the agitator 2 to rotate is 2min- Stir for 10 minutes until the residual pulp 3 is suspended, and the residual pulp 3 moves with the rotation of the agitator 2. At this time, the bottom discharge valve 4 of the filter tank 1 is opened to discharge the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com