Fault coal upgrading material cooler

A technology of upgrading coal and cooler, applied in the direction of heat exchanger type, indirect heat exchanger, mobile duct heat exchanger, etc., can solve the problem of affecting the indoor temperature of material stacking workshop, inconvenient for direct transportation and storage, and loss of a large amount of waste heat. and other problems, to achieve the effect of high reliability, low maintenance cost and large equipment safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will be described in conjunction with the accompanying drawings and a specific embodiment.

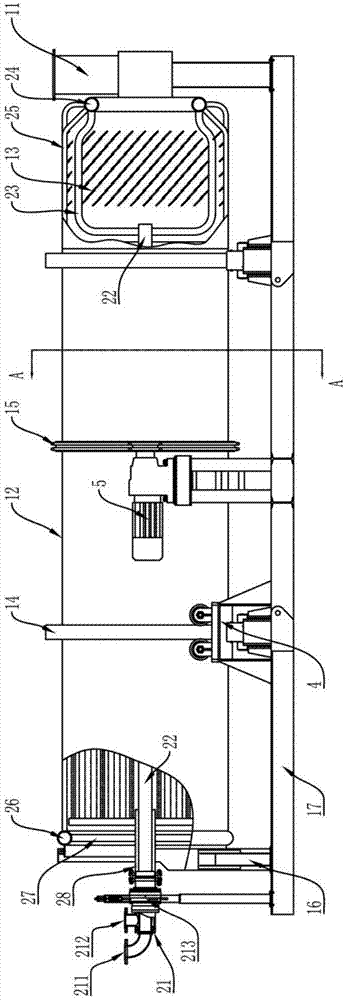

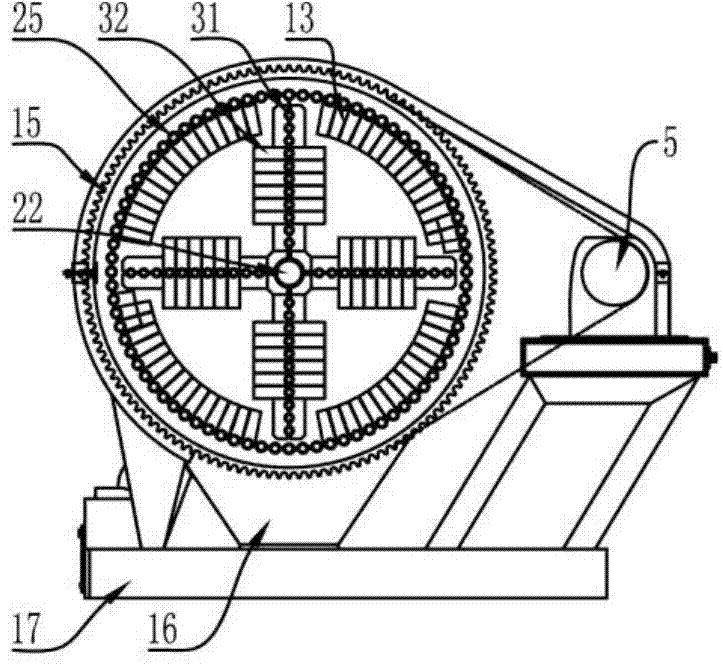

[0025] see Figure 1 to Figure 4 . The low-quality and upgraded coal material cooler described in this embodiment includes a rotating cylinder 12, on which a support retaining ring 14 is arranged, and the cylinder 12 is placed on the supporting wheel set 4 through the supporting retaining ring, and the supporting wheel Group 4 is mounted on base 17 . A driven wheel 15 is arranged on the rotating cylinder 12 , and the driven wheel 15 is in transmission connection with the driving wheel of the driving device 5 . Driving wheel and driven wheel can select sprocket wheel or gear for use. Driving device 5 belongs to existing equipment, as electric motor, diesel engine.

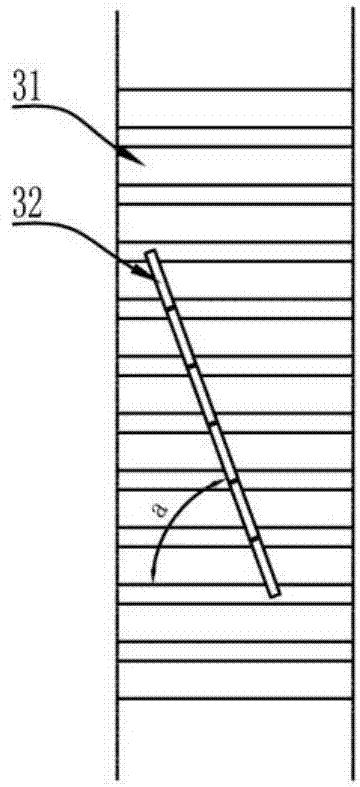

[0026] A slag inlet box 11 is installed at the front end of the rotating cylinder 12, and a slag outlet box 16 is installed at the rear end. The rotating cylinder 12 has a membrane wall structure, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com