Gas turbine cooling blade with crown

A technology for gas turbines and cooling blades, which is applied to the supporting elements of blades, engine elements, machines/engines, etc., can solve the problem of low cooling efficiency of cold air, achieve good processability and engineering application prospects, improve cooling effect, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

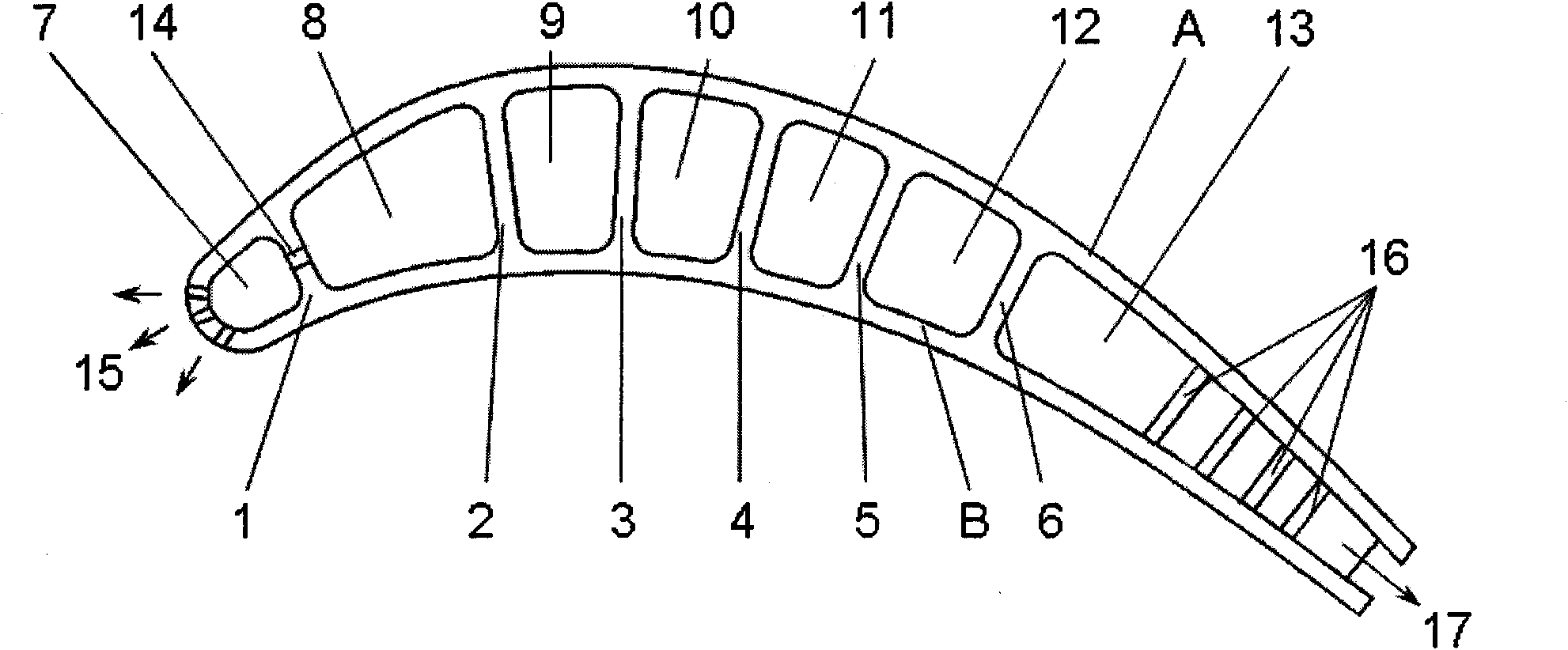

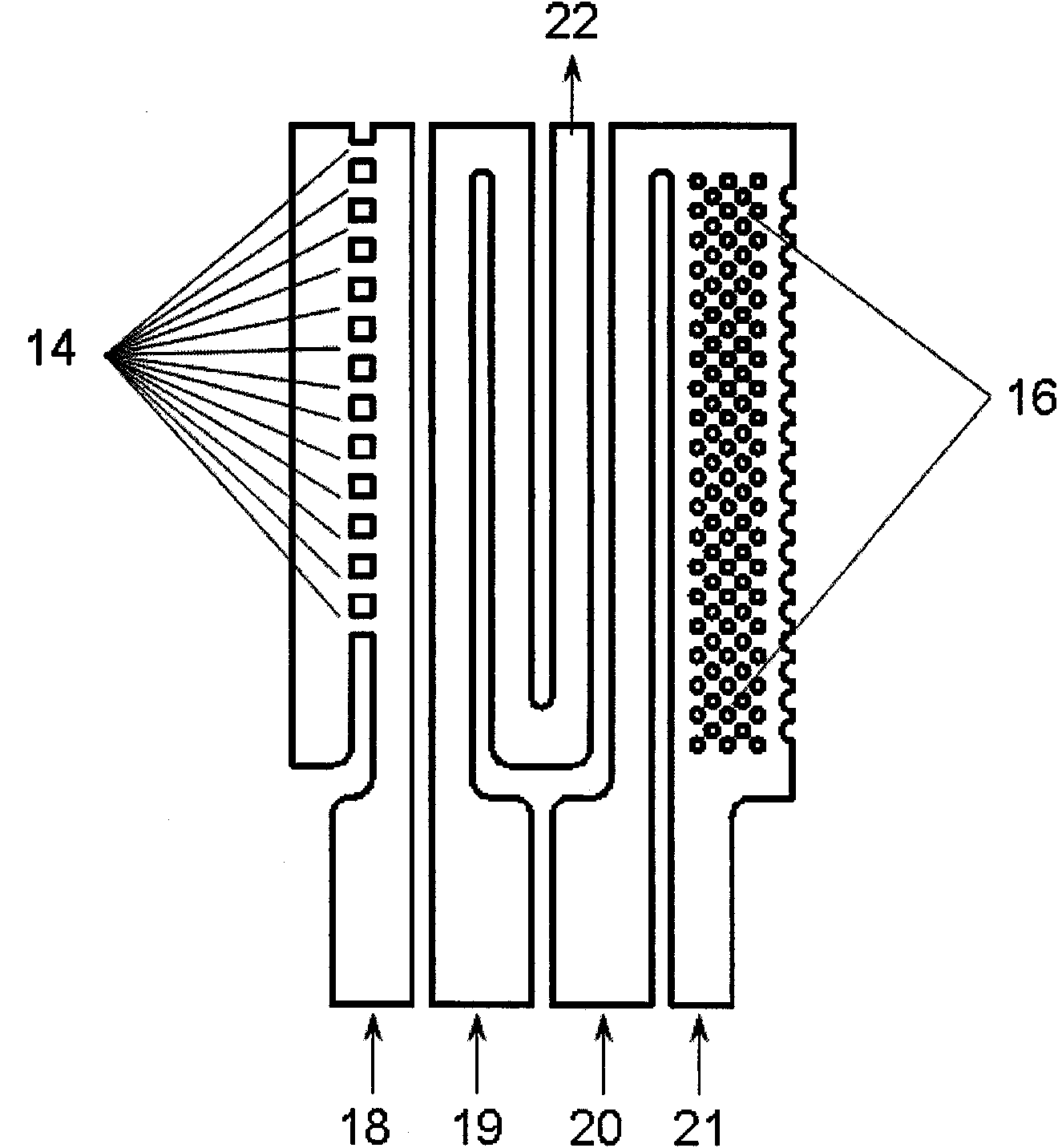

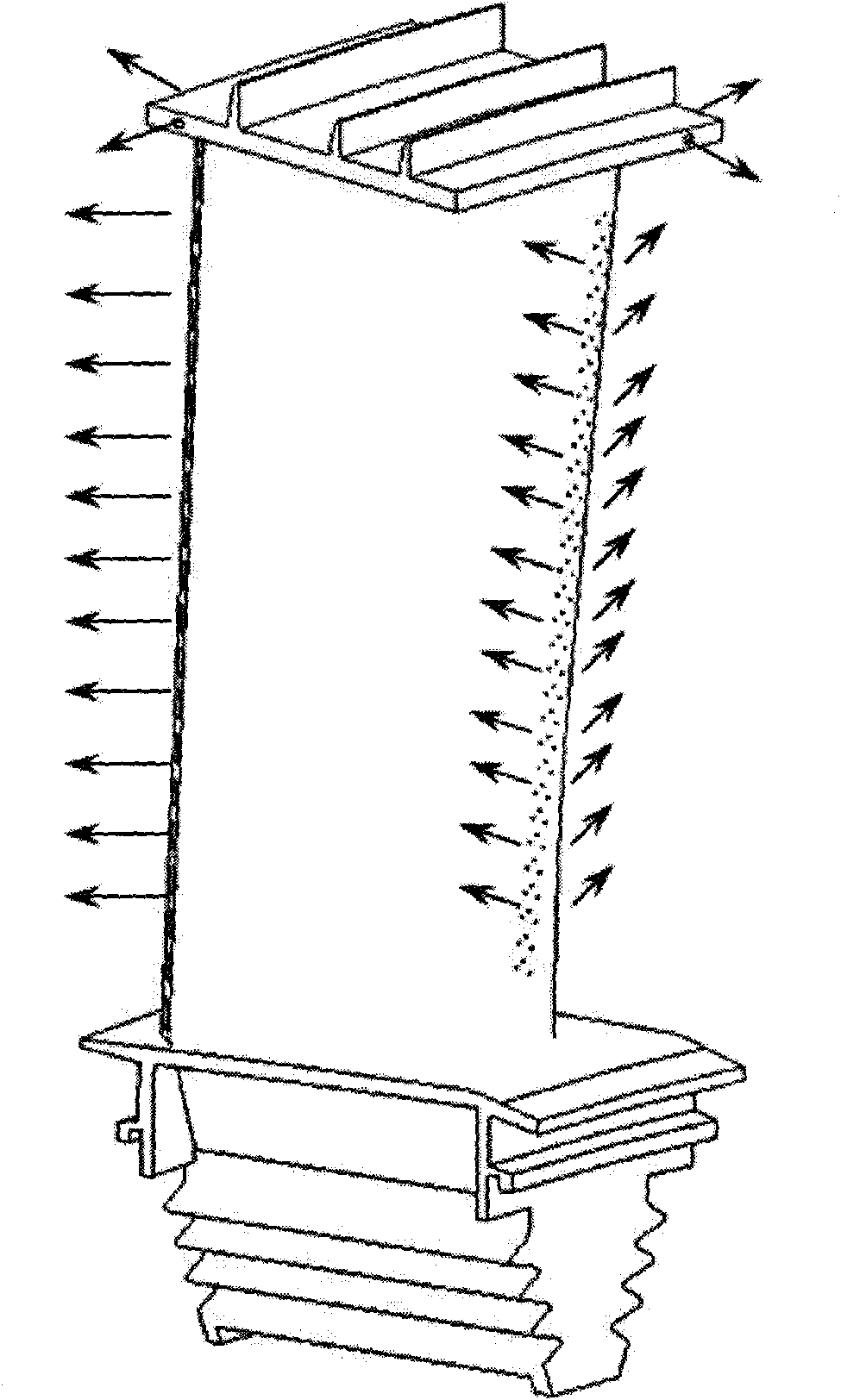

[0017] Such as figure 1 and figure 2 As shown, the airfoil of the crowned cooling blade includes an outer wall A and an inner wall B, and the partitions 1, 2, 2, 3, 4, and 5 are arranged in sequence from the leading edge to the trailing edge of the blade. 5. Partition plate six 6 divides the inner cavity of the blade into cooling chamber one 7, cooling chamber two 8, cooling chamber three 9, cooling chamber four 10, cooling chamber five 11, cooling chamber six 12 and cooling chamber seven 13, among which Plate two 2 and clapboard five 5 divide the cooling channel of the cooling blade airfoil into two independent parts: front, middle and rear; clapboard one 1 is equidistantly arranged with 12 impingement cooling holes 14, and the cooling air flows in the airfoil cooling cavity. When 28 is flowing, the cooling air is sprayed out through the impact cooling hole to blow the cooling air to the front edge of the inner wall B of the airfoil for cooling. There are air film holes 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com