A shaftless gas turbine

A technology for gas turbines and main shafts, applied in the direction of blade support elements, machines/engines, stators, etc., can solve problems such as inability to better meet performance requirements, difficulties in vibration and noise control, high construction and maintenance costs, and achieve energy utilization High efficiency, compact structure, and the effect of reducing air leakage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiments and drawings, but not limited to the following embodiments.

[0032] The present invention provides a new type of turbine equipment with high efficiency, high power, good stability and high integration formed by the rotation of a stator assembly and a rotatable hubless rotor assembly with blades, that is, the so-called spindleless gas turbine.

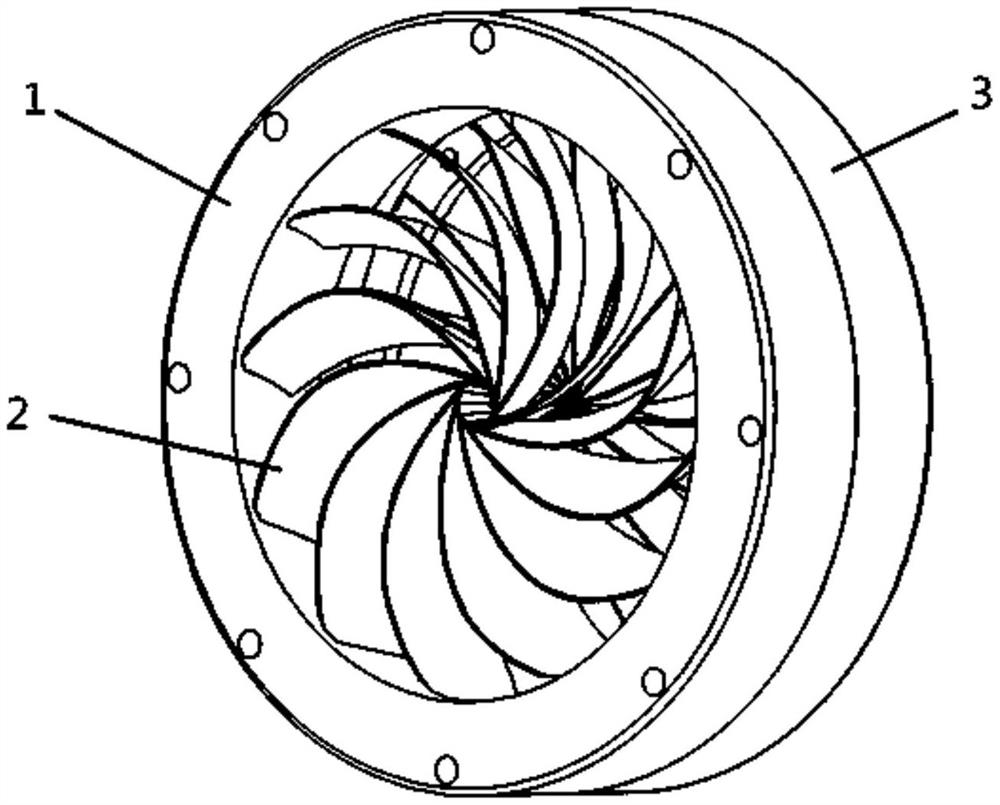

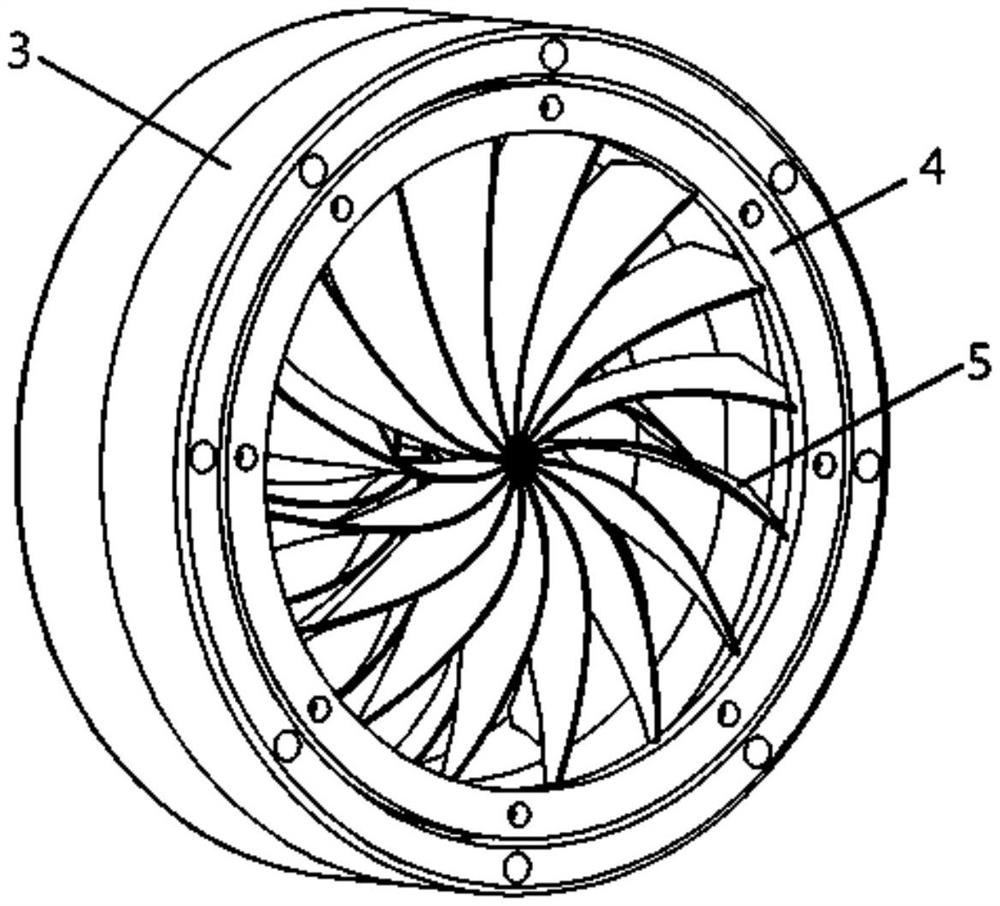

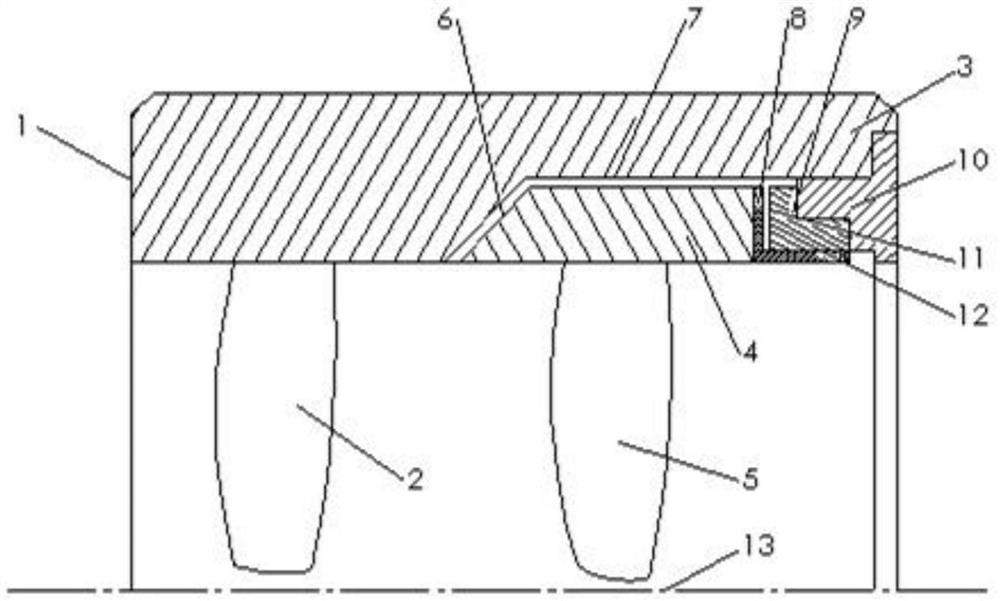

[0033] The shaftless gas turbine provided by the present invention has a structure such as figure 1 and figure 2 As shown, it consists of three parts: rotor assembly, stator assembly and bearing assembly, wherein: the rotor assembly is installed in the inner cavity of the housing 3 and is supported by the bearing assembly installed in the housing 3; the stator assembly is directly connected to the housing 3 connected.

[0034] The rotor assembly includes a rotor ring 4 and a plurality of rotor blades 5 , the plurality of rotor blades 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com