3MW-grade full-cycle air inlet axial flow impulse type supercritical carbon dioxide turbine

A full-cycle air intake and carbon dioxide technology, applied in the field of steam turbines, can solve the problems of increasing the construction cost of supercritical carbon dioxide cycle, not having the ability of high-power model expansion, and weakening the verification ability of the test bench, so as to reduce the air leakage at the tip of the blade. Loss, reduce axial thrust, improve the effect of rotor stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

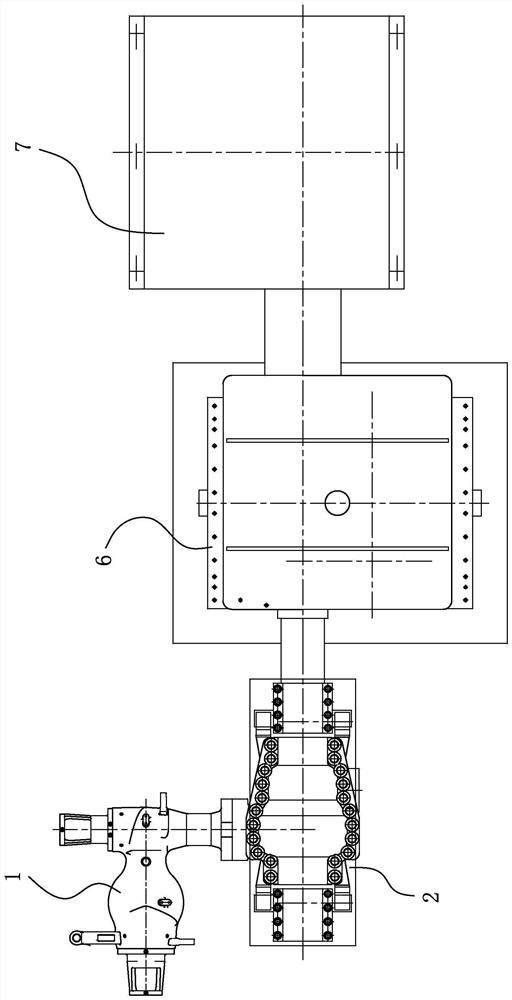

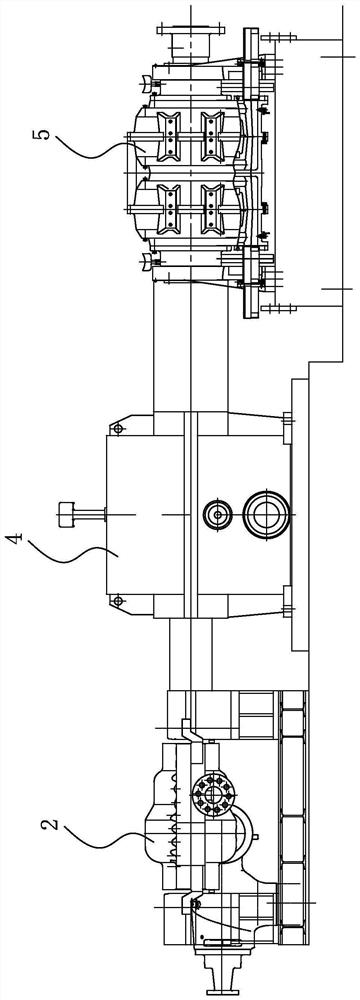

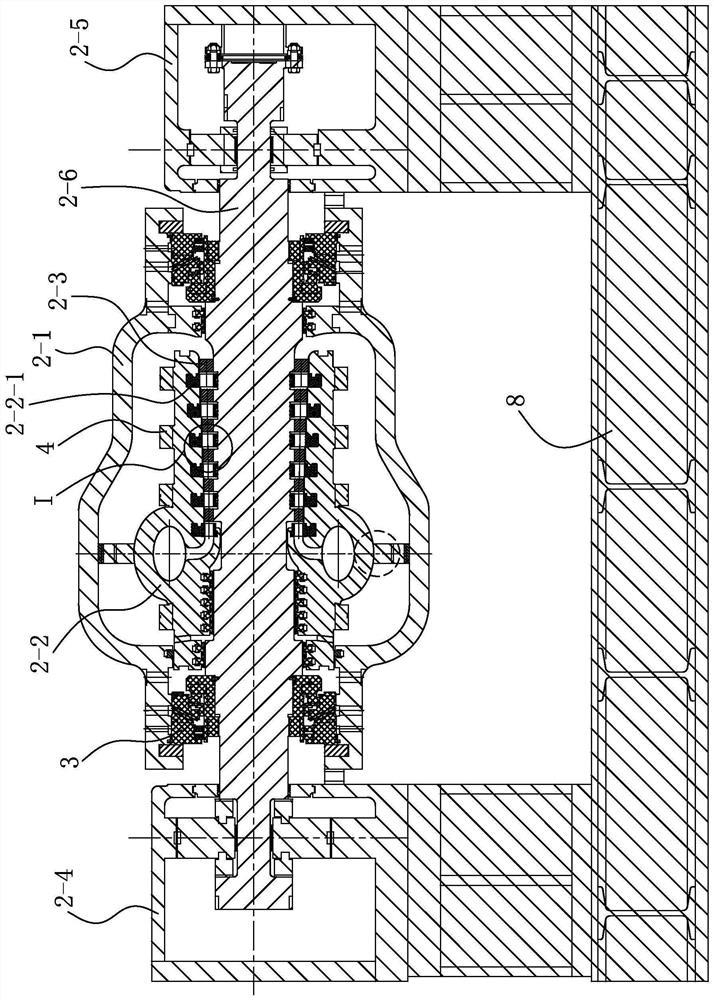

[0014] combine Figure 1-Figure 4 To illustrate, a 3MW level full-circumference axial-flow impulsive supercritical carbon dioxide turbine of this embodiment includes a main gas regulating valve 1 and a turbine body 2, and the turbine body 2 includes an outer cylinder 2-1, an inner cylinder 2-2, moving blade 2-3, front bearing housing 2-4 and rear bearing housing 2-5; the inner cylinder 2-2 is arranged in the outer cylinder 2-1, and the outer cylinder 2-2 is sealed with the shaft 2-6, The two ends of the shaft 2-6 are rotatably supported on the front bearing box 2-4 and the rear bearing box 2-5, and the main gas regulating joint valve 1 is installed on the turbine body 2 and communicated with the inner cylinder 2-2; The turbine body 2 is a unidirectional flow impulsive turbine, the rotor includes integral moving blades 2-3 and shaft 2-6, the inner cylinder 2-2 is a cylindrical inner cylinder, and the air intake of the inner cylinder 2-2 The structure is a tangential volute str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com