High-pressure-difference-resisting multi-grade adjusting device for pipeline

A technology of resisting high pressure difference and regulating device, which is applied in valve device, valve device for absorbing fluid energy, valve details, etc. Unsatisfactory sealing and other problems, to achieve the effect of improving vibration and flow characteristics, highlighting substantive characteristics, and reducing impact and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

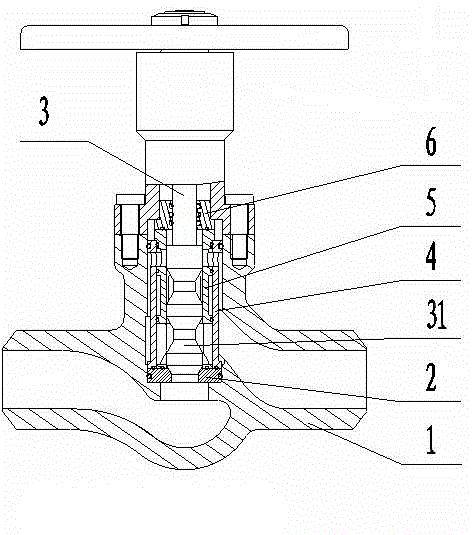

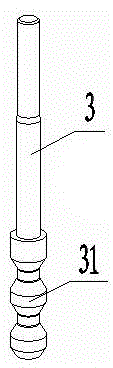

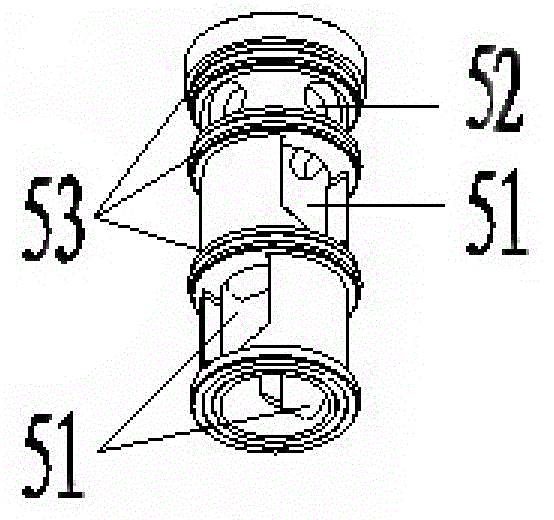

[0020] A multi-stage anti-high pressure difference adjustment device for pipelines, including a valve stem 3 and a valve body 1, the valve body 1 is provided with a valve seat 2, the valve stem is sleeved in the valve body, and the lower end of the valve stem is provided with the The shaft plug 31 that is sealingly matched with the valve seat is at least two-stage shaft plug. The shaft plug 31 is covered with a sleeve 5 that matches the shaft plug. Sleeve 4, the sleeve is provided with throttling hole 51 and through hole 52, is provided with outlet hole 41 on the decompression sleeve, is provided with compression sleeve 6 on the valve stem, and described each stage axle plug is circular truncated shape.

[0021] The valve stem moves axially in the sleeve. When the medium fluid flows into the valve seat through the improved pipeline with a multi-stage anti-high pressure difference adjustment device, the medium is evenly dispersed to the surrounding by the conical surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com