Heat-pump distillation technology for recycling dichloromethane solvent

A methylene chloride, heat recovery technology, applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry and other directions, can solve the problems of high production energy consumption, high harm, high toxicity, etc., to reduce operating costs and save consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

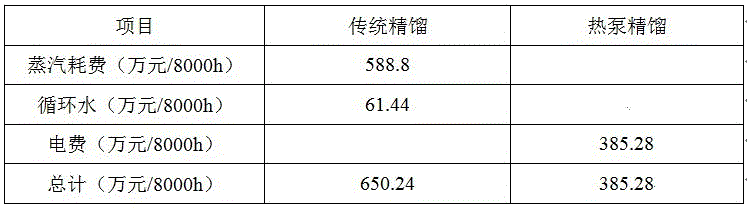

[0029] An enterprise uses dichloromethane as the extraction agent, and adopts rectification to recover the dichloromethane solvent. It requires the concentration of dichloromethane at the top of the tower to be higher than 95%, and the processing capacity is 10t / h, of which the dichloromethane content is 50%.

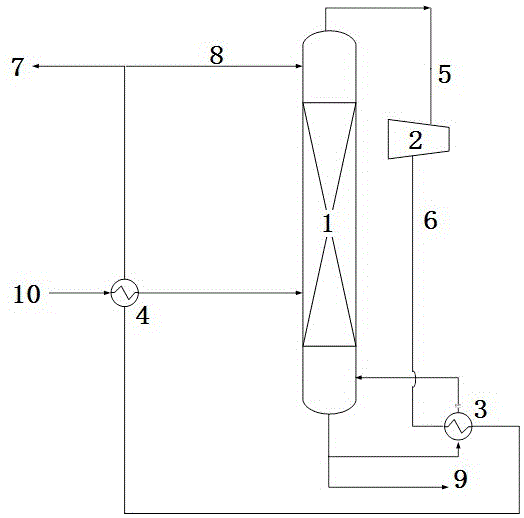

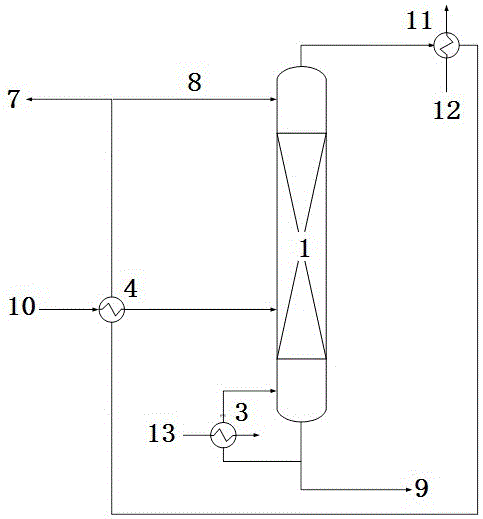

[0030] A dichloromethane solvent recovery heat pump rectification process is mainly composed of a rectification tower 1, a compressor 2, a reboiler 3 and a preheater 4. The rectification tower 1 adopts a packed tower, and the main separation task is completed in the tower, and the dichloromethane vapor 5 with a concentration of 95% is extracted from the top of the tower, and the dichloromethane vapor is boosted and heated through a steam compressor 2, and the compressed dichloromethane Methylene chloride vapor 6 is used as the heat source of reboiler 3. After heat exchange in reboiler, methylene chloride vapor is condensed into methylene chloride solution. After the liqu...

Embodiment 3

[0037] A factory uses dichloromethane as a solvent to produce a certain product, and needs to recover dichloromethane. The processing capacity is 2t / h, of which the content of dichloromethane is 40%, and the concentration of dichloromethane at the top of the tower is required to be greater than 80%.

[0038] A dichloromethane solvent recovery heat pump rectification process is mainly composed of a rectification tower 1, a compressor 2, a reboiler 3 and a preheater 4. The rectifying tower 1 adopts a packed tower, and the main separation task is completed in the tower, and the dichloromethane vapor 5 with 85% concentration is produced at the top of the tower, and the dichloromethane vapor is boosted and heated through a steam compressor 2, and the compressed dichloromethane Methylene chloride vapor 6 is used as the heat source of reboiler 3. After heat exchange in reboiler, methylene chloride vapor is condensed into methylene chloride solution. After the liquid phase is preheated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com