Grid plate of energy-saving grid cold machine

A grate cooler and energy-saving technology, applied in the field of grate cooler components, can solve the problems of easy burning and loss of cooling effect, simple structure, etc., and achieve the effects of reducing maintenance costs, stabilizing the air supply system, and preventing return air leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

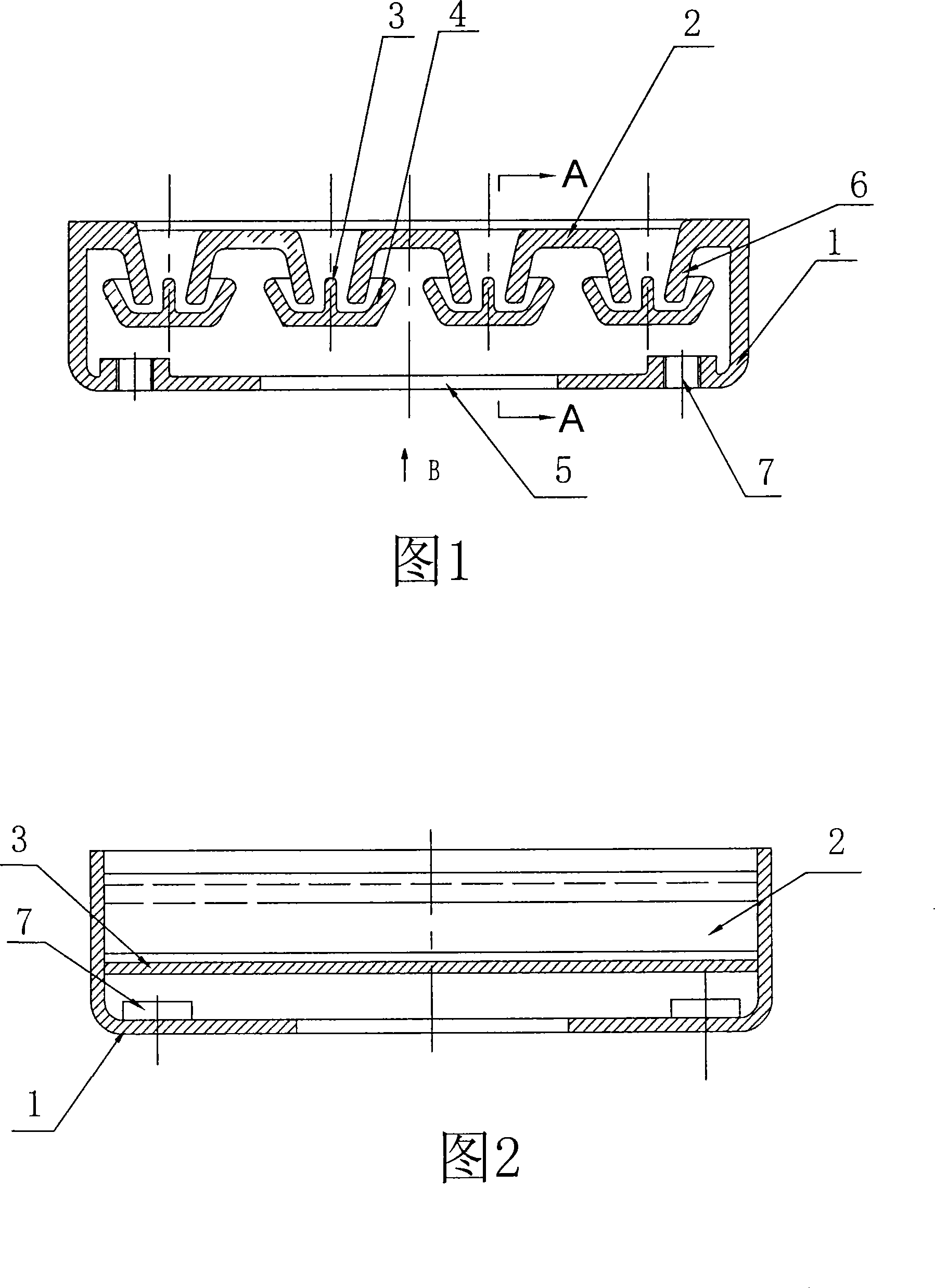

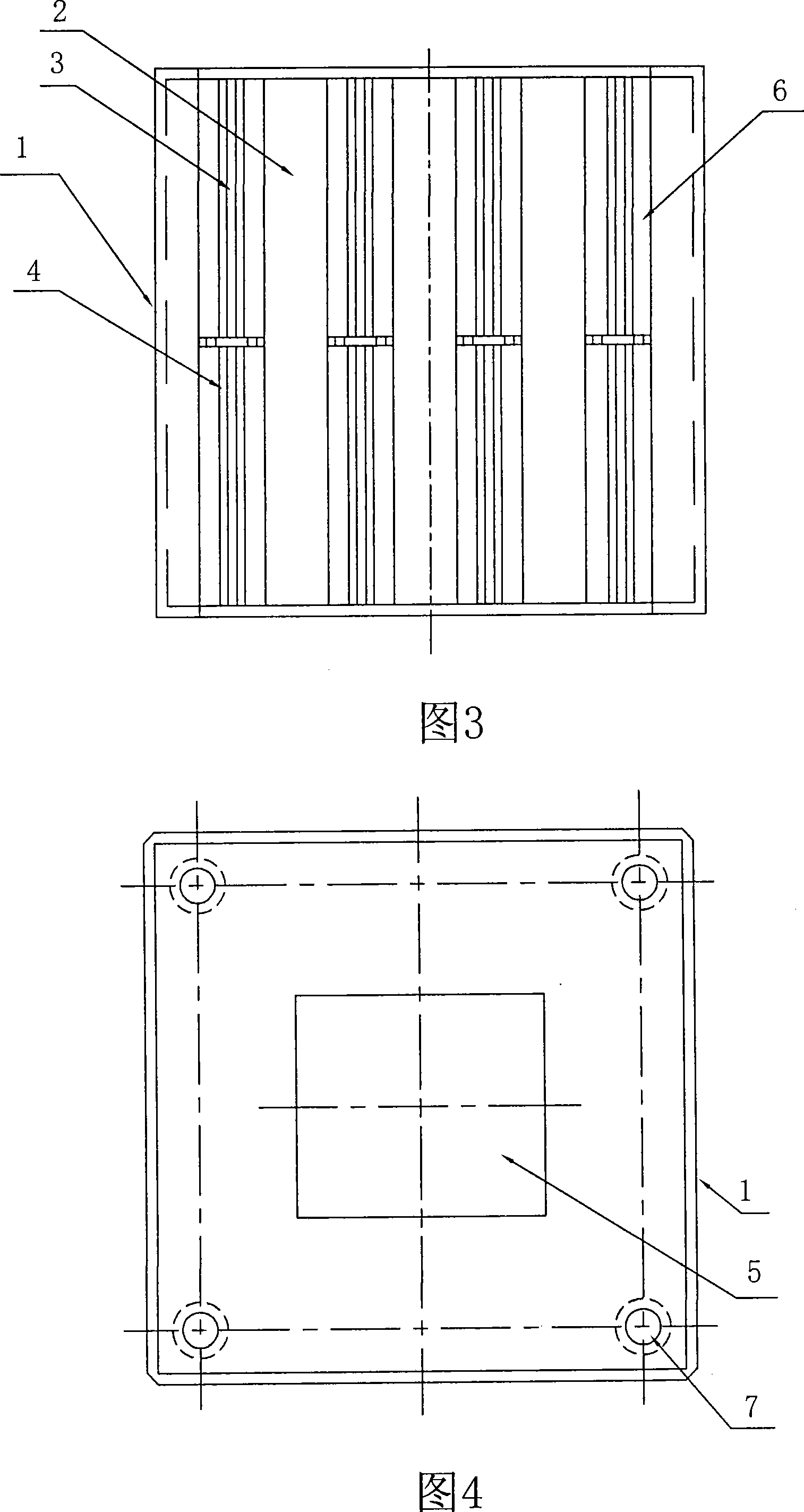

[0018] As shown in Figure 1-4.

[0019] An energy-saving grate cooler grate plate, which includes a chassis 1, an inverted U-shaped groove plate 2, an elongated windshield rib 3 and a positive U-shaped tray 4, as shown in Figure 1, the bottom of the chassis 1 is provided with an air inlet 5 ( As shown in Figure 4), its four corners are provided with mounting holes 7, and the opposite sides of the chassis 1 are connected with folded edges 6 that are first folded flat inwards and then folded downwards inwards. 1 is respectively provided with an inverted U-shaped groove plate 2 and a positive U-shaped tray 4, and the two ends of the inverted U-shaped groove plate 2 and the positive U-shaped tray 4 are respectively fixed on the front and rear end walls of the chassis 1 (as shown in Figure 3). The two downward sides of the U-shaped groove plate 2 are stradd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com