Stock guides and automatic waste discharge system comprising same

A material guide plate, automatic technology, applied in the direction of pushing out equipment, etc., can solve the problem of material leakage of the material guide plate, etc., to achieve the effect of solving material leakage, convenient manufacturing, and eliminating the cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

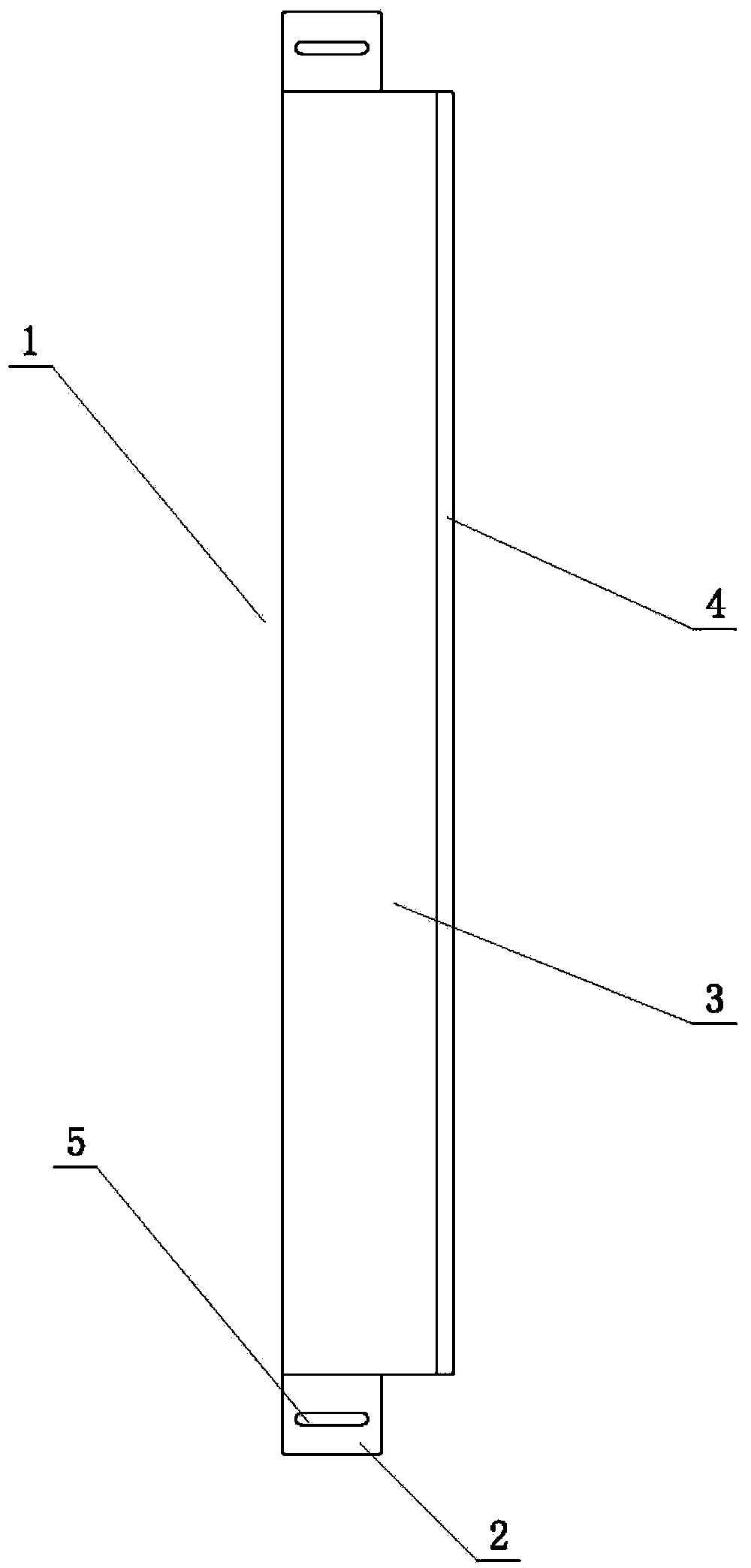

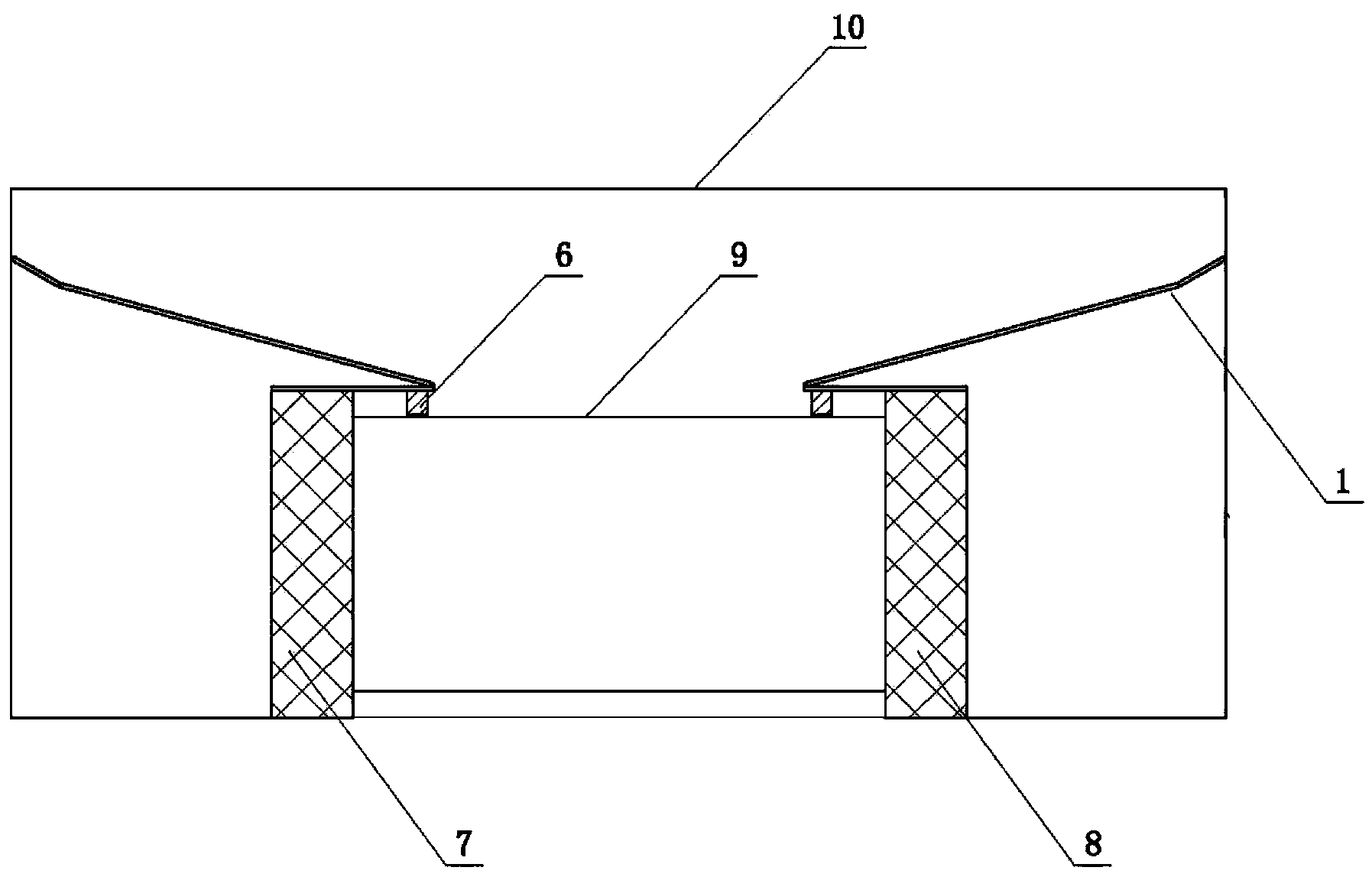

[0032] see Figure 1~Figure 3 , as a possible implementation mode, a material guide plate 1 for an automatic waste material export system, the waste material automatic export system includes a left bracket 7, a right bracket 8 and a material guide belt 9, and the material guide plate includes a guide plate installation frame 2, middle guide 3 and edge guide 4;

[0033] The guide plate mounting frame 2 is used to respectively install the material guide plate on the left bracket 7 and the right bracket 8 of the waste automatic exporting system;

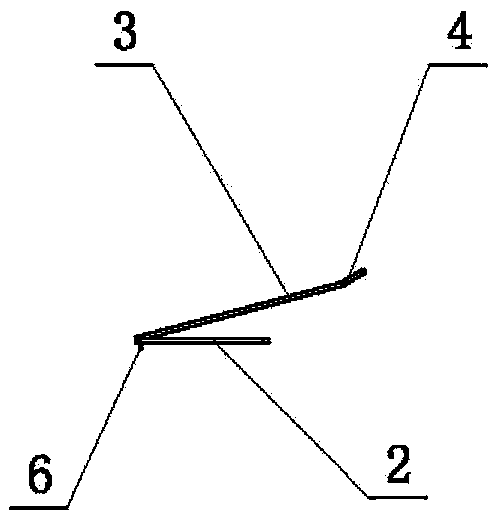

[0034] The middle guide plate 2 is arranged on the side of the guide plate mounting frame close to the center of the guide belt 9 of the waste automatic export system, and the middle guide plate is inclined upward and outward relative to the center of the guide belt;

[0035] The edge guide 3 is connected to the other side of the middle guide, and the edge guide is close to the side of the waste opening.

[0036] In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com