Inflating beam-grate type cooler for dry slag system of electric power boiler

A cooling machine and boiler technology, which is used in the cooling of instruments, removal of solid residues, and parts of instruments, etc., can solve the problems of uncontrollable cooling air volume of boilers, influence of boiler combustion, and large cooling water consumption, etc., to achieve the equipment structure. Simple and compact, the effect of improving the operation rate and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

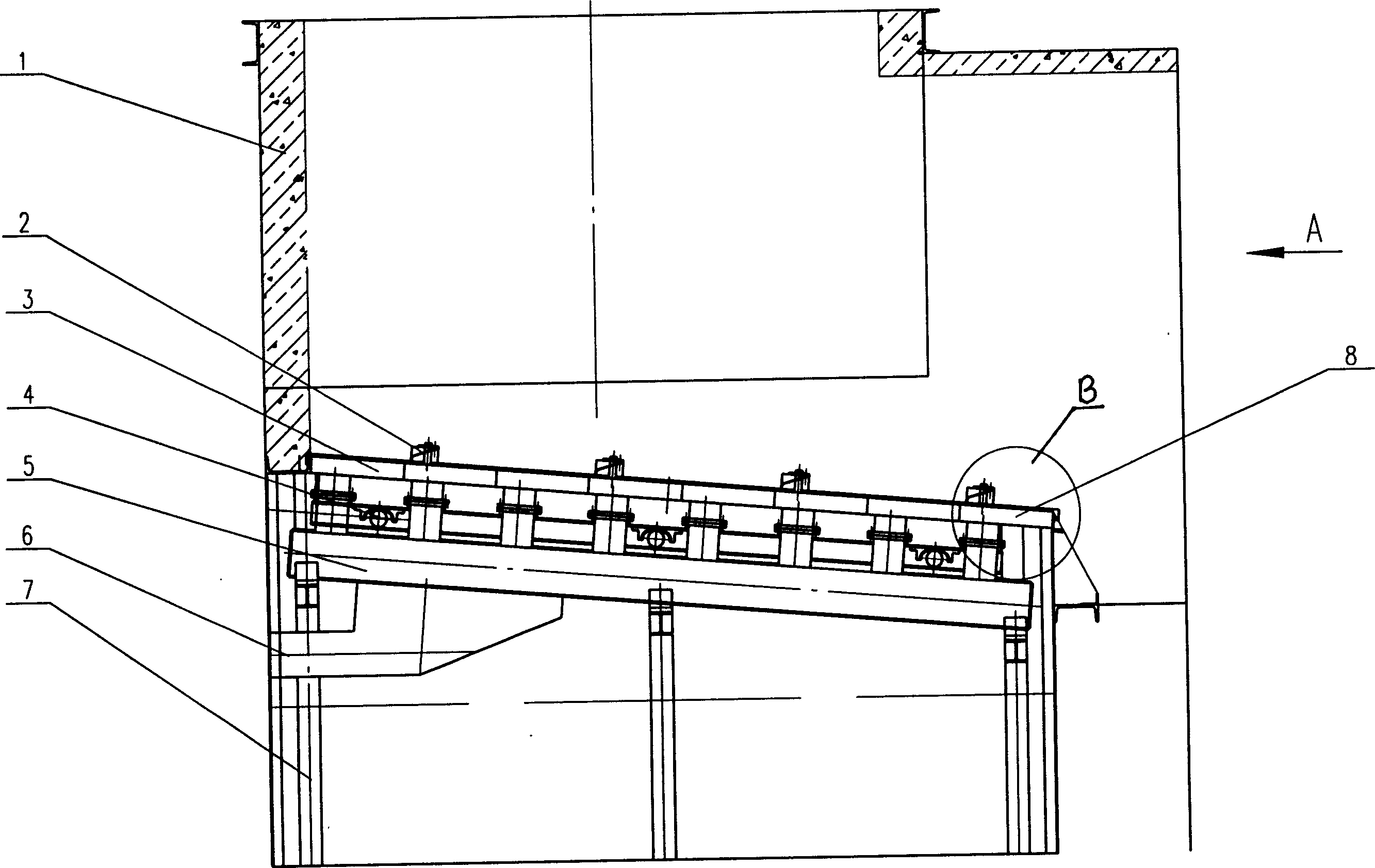

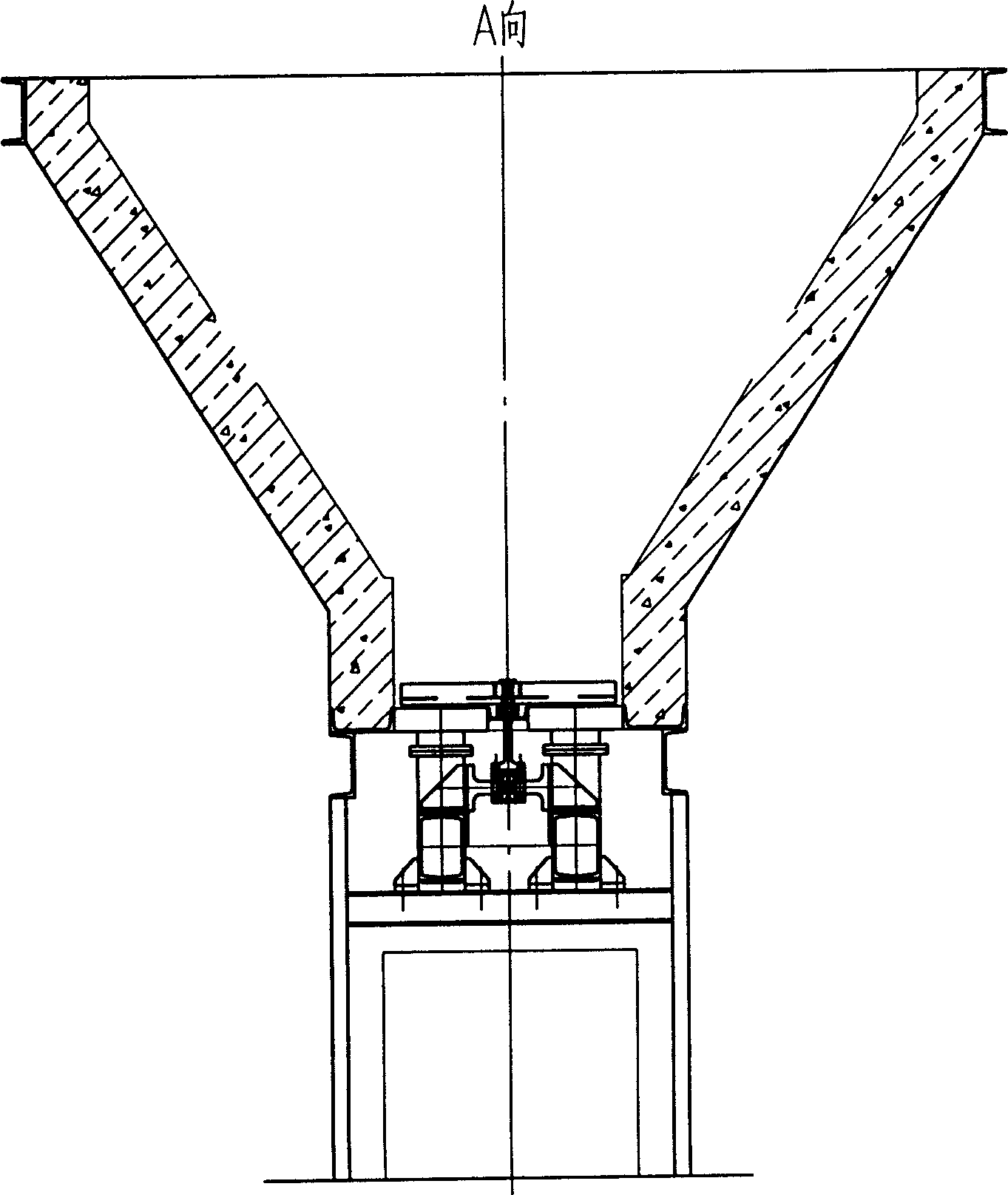

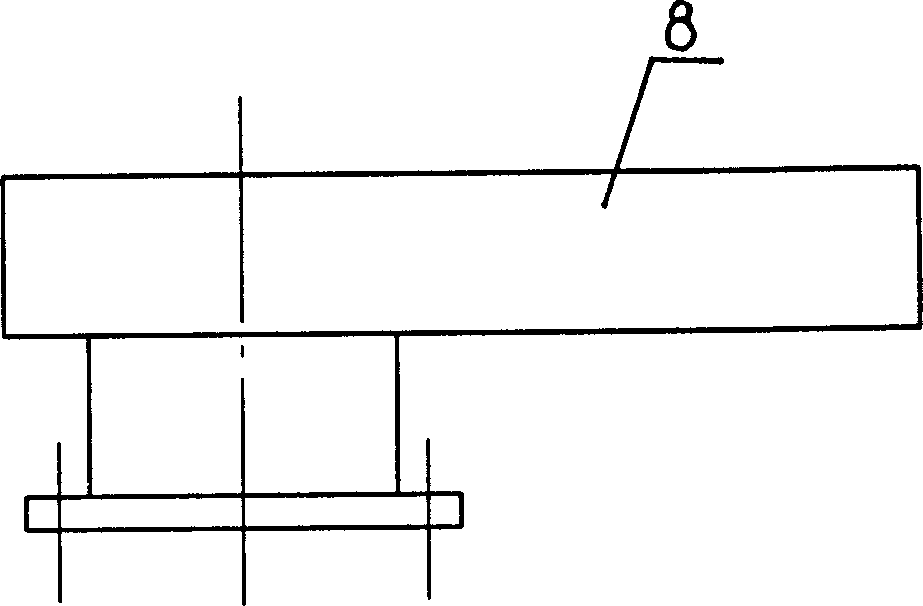

[0018] see figure 1 , figure 2 and image 3 , an inflatable beam grate cooler for dry slag removal system of an electric boiler, comprising an upper shell 1, a material pushing device 2, a grate bed 3, a transmission and support device 4, a grate bed support device 5, and an air-filled air duct 6 , Lower shell and supporting device 7 and inflatable grate plate 8. The upper shell 1 is connected with the lower shell and the support device 7 through bolts, and the upper shell 1 is built with refractory materials for heat insulation to reduce the surface heat dissipation of the equipment and improve the heat recovery efficiency; the grate bed support device 5 The bolts are connected with the lower shell and the support device 7, and the grate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com