a drying machine

A technology for drying the grains and grains, applied in the preparation of alcoholic beverages, etc., can solve the problems of easy agglomeration and hardening, leakage of materials, inability to ventilate holes, etc., and achieves sufficient air blowing and heat exchange, uniform discharge temperature, and convenient and thorough cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

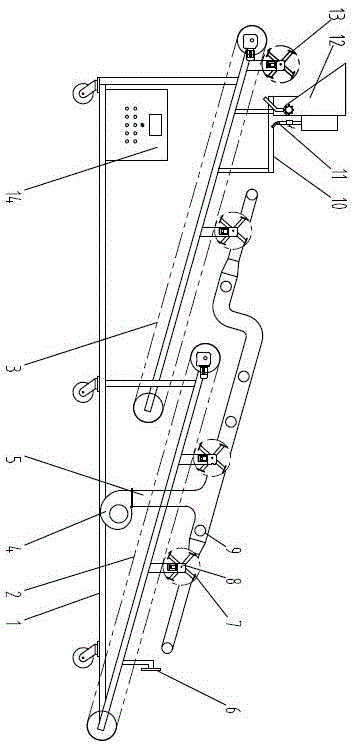

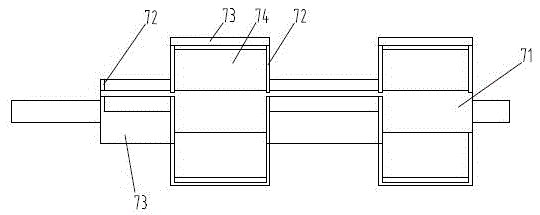

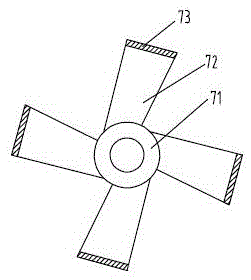

[0033] Figure 1 to Figure 6 Shows the dross airing machine provided by the present invention, including a conveying device and an air supply device, the air outlet of the air supply device is located above the conveying device; the conveying device is provided with a dregs turning shovel mechanism 7, which includes The rotating shaft 71 and the turning shovel wings 72 distributed along the circumferential direction on the rotating shaft 71 , the ends of the turning shovel wings 72 are provided with a shovel plate 73 .

[0034] The conveying device is a chain conveyor, and the chain conveyor includes a conveyor chain and a driving device connected to it. There are two chain conveyors, which are respectively the first stage chain conveyor 2 and the The secondary chain plate conveyor 3, the feed end of the second st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com