Spraying equipment

An equipment and integrated technology, applied in the direction of spray device, liquid spray device, etc., can solve the problems of essential oil leakage, essential oil waste, no anti-volatile or anti-spill, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

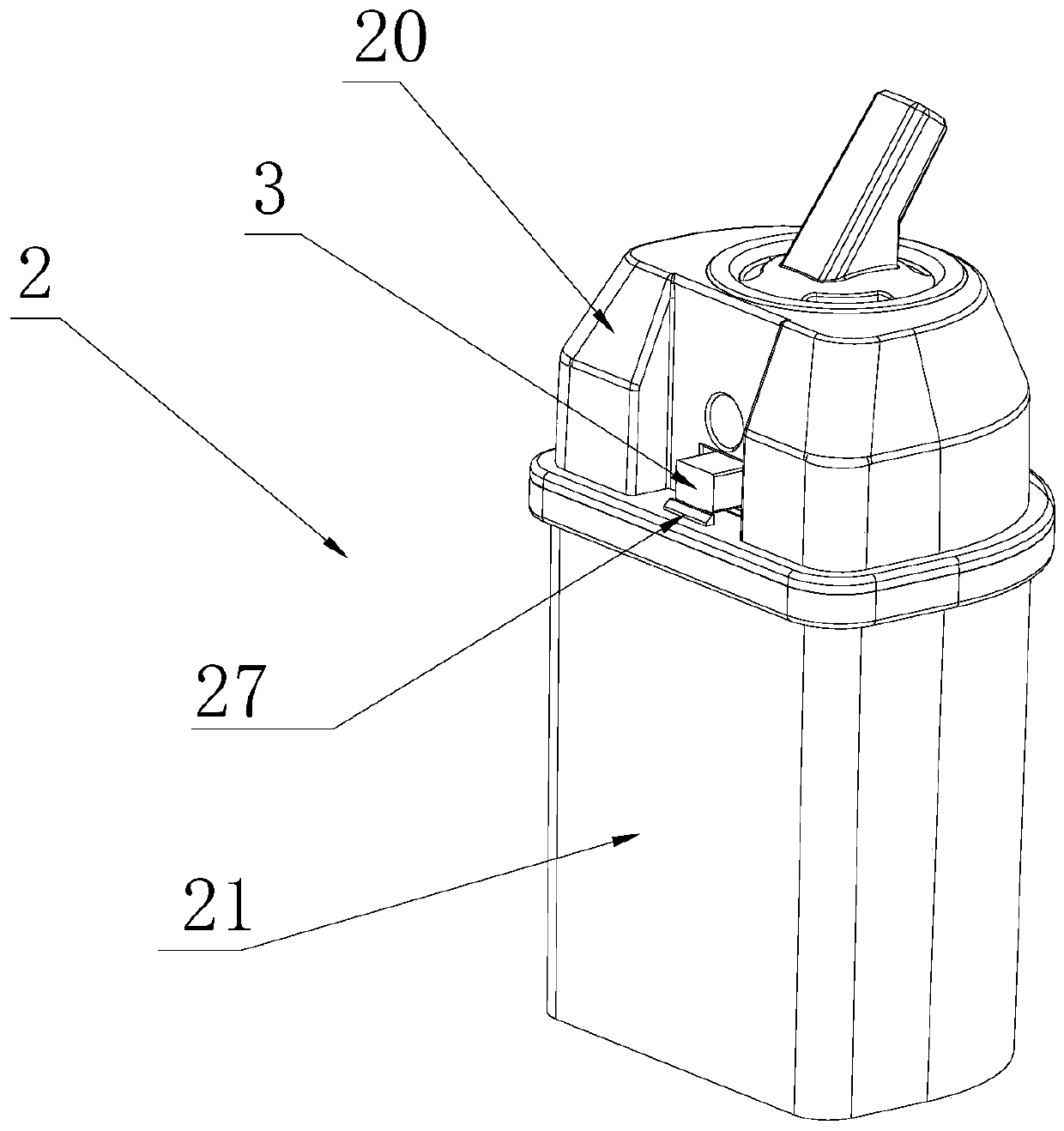

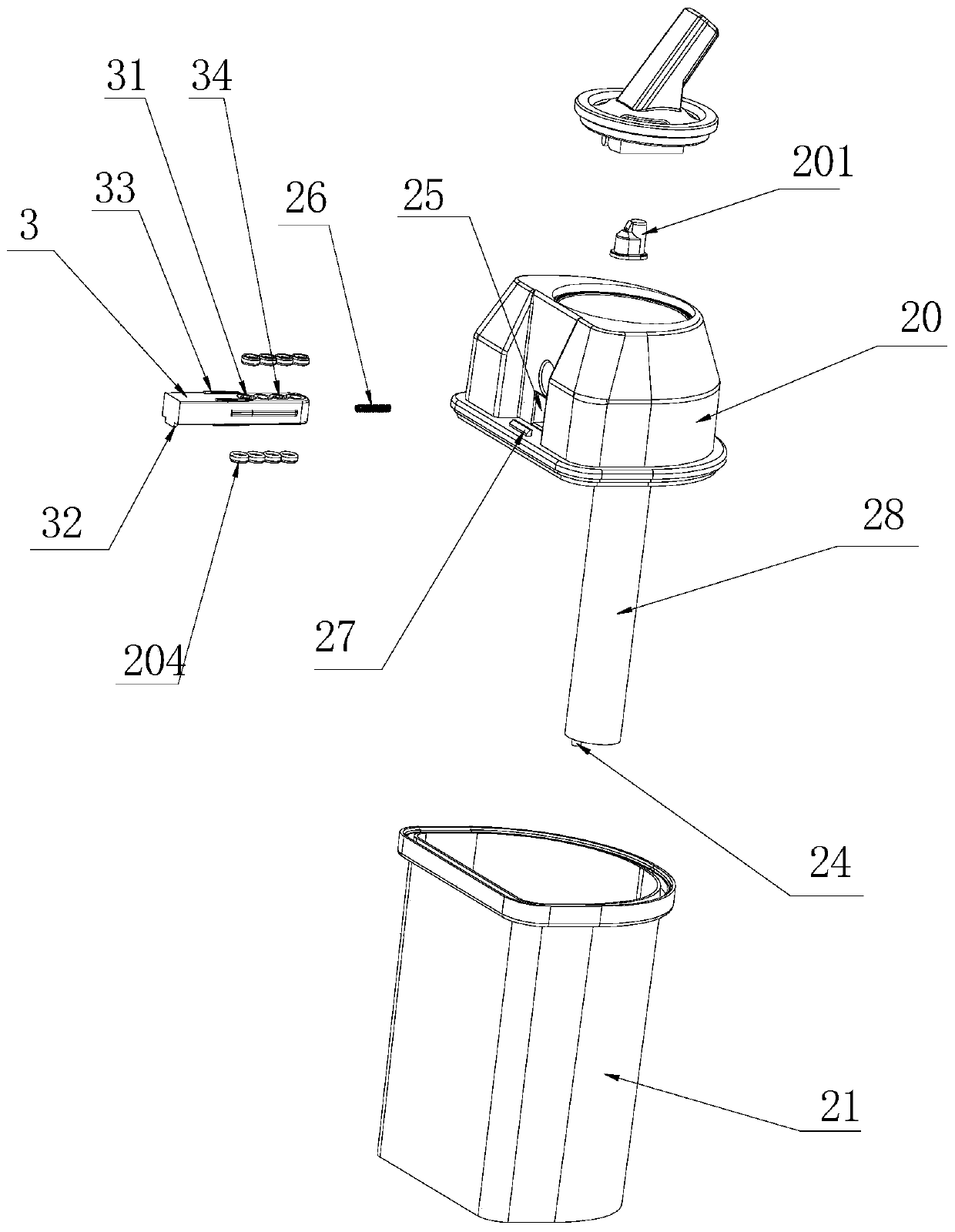

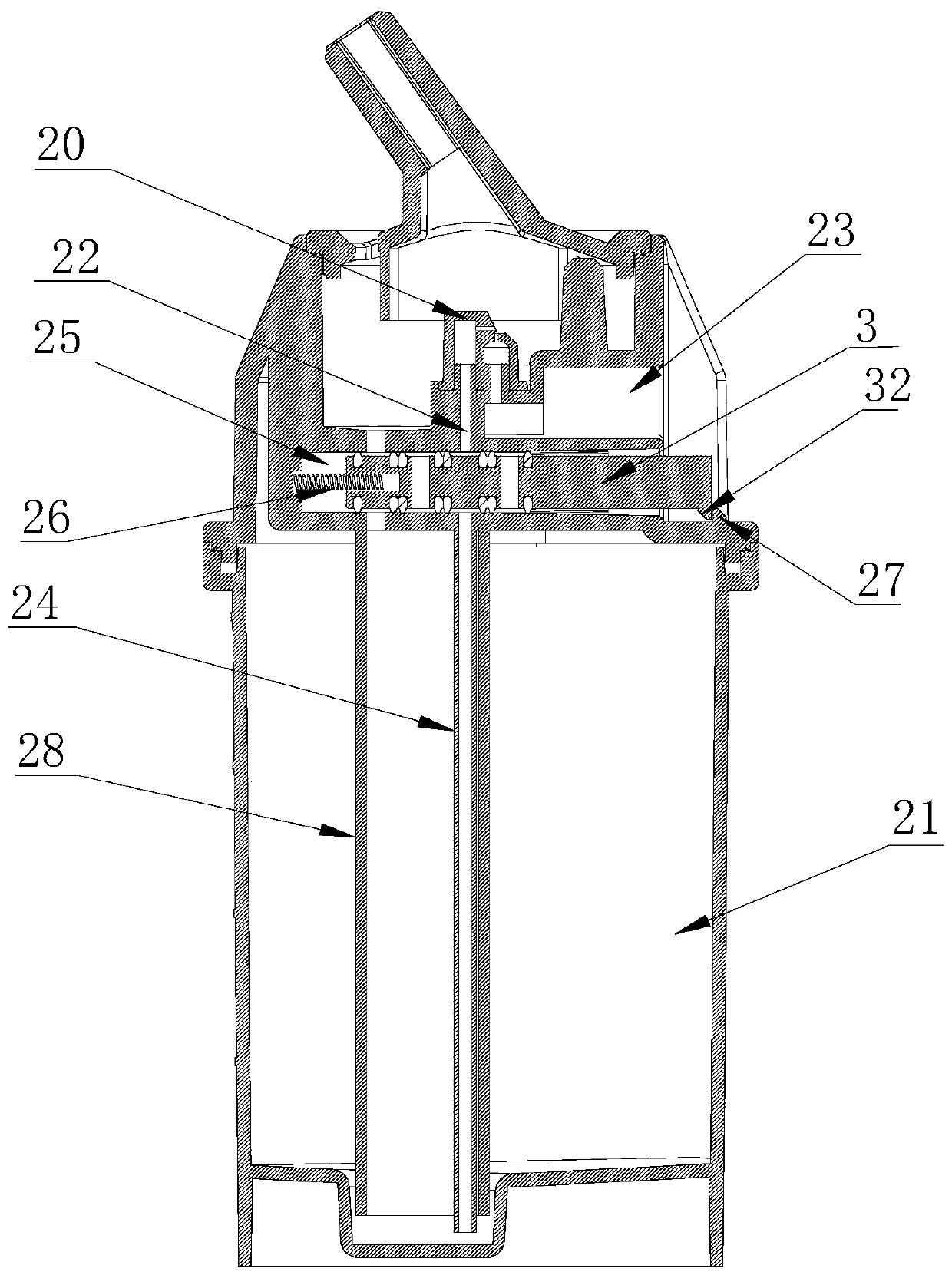

[0030] refer to Figure 1-6 , a spraying device, comprising a body 1 and an integrated bottle 2 mounted on the body 1 for containing liquid, the integrated bottle 2 includes an atomizing head and a liquid containing chamber 21 connected with the atomizing head, the atomizing A liquid flow path 22 and an air path 23 are provided in the head, and a liquid flow path conduction block 3 that can move relative to the liquid flow path 22 of the atomization head is provided in the atomization head, and the liquid flow path conduction block 3 There is a liquid flow path conducting hole 31; the body 1 is provided with an air source interface 11, and the air source interface 11 is connected to the air path 23; the body 1 is provided with a block for conducting the liquid flow path 3 locate the positioning block 12 at the preset position;

[0031] When the integrated bottle 2 is installed on the body 1, the positioning block 12 and the liquid flow path conduction block 3 are in tight con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com